#machining parts machinery parts made in china

Explore tagged Tumblr posts

Text

Shortly before noon on Aug. 19, 2023, a Russian cruise missile sliced past the golden onion domes and squat apartment blocks of the Chernihiv skyline in northern Ukraine. The Iskander-K missile slammed into its target: the city’s drama theater, which was hosting a meeting of drone manufacturers at the time of the attack. More than 140 people were injured and seven killed. The youngest, 6-year-old Sofia Golynska, had been playing in a nearby park.

Fragments of the missile recovered by the Ukrainian armed forces and analyzed by Ukrainian researchers found numerous components made by U.S. manufacturers in the missile’s onboard navigation system, which enabled it to reach its target with devastating precision. In December, Ukraine’s state anti-corruption agency released an online database of the thousands of foreign-made components recovered from Russian weapons so far.

Russia’s struggle to produce the advanced semiconductors, electrical components, and machine tools needed to fuel its defense industrial base predates the current war and has left it reliant on imports even amid its estrangement from the West. So when Moscow launched its full-scale invasion of Ukraine in February 2022, major manufacturing countries from North America, Europe, and East Asia swiftly imposed export controls on a broad swath of items deemed critical for the Russian arms industry.

Russia quickly became the world’s most sanctioned country: Some 16,000 people and companies were subject to a patchwork of international sanctions and export control orders imposed by a coalition of 39 countries. Export restrictions were painted with such a broad brush that sunglasses, contact lenses, and false teeth were also swept up in the prohibitions. Even items manufactured overseas by foreign companies are prohibited from being sold to Russia if they are made with U.S. tools or software, under a regulation known as the foreign direct product rule.

But as the war reaches its two-year anniversary, export controls have failed to stem the flow of advanced electronics and machinery making their way into Russia as new and convoluted supply chains have been forged through third countries such as Kazakhstan, Turkey, and the United Arab Emirates, which are not party to the export control efforts. An investigation by Nikkei Asia found a tenfold increase in the export of semiconductors from China and Hong Kong to Russia in the immediate aftermath of the war—the majority of them from U.S. manufacturers.

“Life finds a way,” said a senior U.S. intelligence official, quoting the movie Jurassic Park. The official spoke on background to discuss Russia’s evasion of export controls.

Some of the weapons and components analyzed by investigators were likely stockpiled before the war. But widely available Russian trade data reveals a brisk business in imports. More than $1 billion worth of advanced semiconductors from U.S. and European manufacturers made their way into the country last year, according to classified Russian customs service data obtained by Bloomberg. A recent report by the Kyiv School of Economics found that imports of components considered critical for the battlefield had dipped by just 10 percent during the first 10 months of 2023, compared with prewar levels.

This has created a Kafkaesque scenario, the report notes, in which the Ukrainian army is doing battle with Western weapons against a Russian arsenal that also runs on Western components.

It is an obvious problem, well documented by numerous think tank and media reports, but one without an easy solution. Tracking illicit trade in items such as semiconductors is an exponentially greater challenge than monitoring shipments of conventional weapons. Around 1 trillion chips are produced every year. Found in credit cards, toasters, tanks, missile systems, and much, much more, they power the global economy as well as the Russian military. Cutting Russia out of the global supply chain for semiconductors is easier said than done.

“Both Russia and China, and basically all militaries, are using a large number of consumer electronic components in their systems,” said Chris Miller, the author of Chip War: The Fight for the World’s Most Critical Technology. “All of the world’s militaries rely on the same supply chain, which is the supply chain that primarily services consumer electronics.”

Export controls were once neatly tailored to keep specific items, such as nuclear technology, out of the hands of rogue states and terrorist groups. But as Washington vies for technological supremacy with Beijing while also seeking to contain Russia and Iran, it has increasingly used these trade restrictions to advance broader U.S. strategic objectives. For instance, the Biden administration has placed wide-ranging prohibitions on the export of advanced chips to China.

“At no point in history have export controls been more central to our collective security than right now,” Matthew Axelrod, the assistant secretary for export enforcement at the U.S. Commerce Department, said in a speech last September. U.S. National Security Advisor Jake Sullivan has described export controls as “a new strategic asset in the U.S. and allied toolkit.”

Russia’s ability to defy these restrictions doesn’t just have implications for the war in Ukraine. It also raises significant questions about the challenge ahead vis-à-vis China.

“The technological question becomes a key part of this story and whether or not we can restrict it from our adversaries,” said James Byrne, the director of open-source intelligence and analysis at the Royal United Services Institute, a British think tank.

In the Russian city of Izhevsk, home to the factory that manufactures Kalashnikov rifles, shopping malls are being converted into drone factories amid a surge in defense spending that has helped the country’s economy weather its Western estrangement. Arms manufacturers have been urged to work around the clock to feed the Russian war machine, while defense is set to account for one-third of the state budget this year.

“We have developed a concept to convert shopping centers—which, before the start of the SMO [special military operation], sold mainly the products of Western brands—to factories for assembly lines of types of domestic drones,” Alexander Zakharov, the chief designer of the Zala Aero drone company, said at a closed event in August 2022, according to the Russian business newspaper Vedomosti. “Special military operation” is what the Russian government calls its war on Ukraine. Zala Aero is a subsidiary of the Kalashnikov Concern that, along with Zakharov, was sanctioned by the United States last November.

Defense companies have bought at least three shopping malls in Izhevsk to be repurposed for the manufacture of drones, according to local media, including Lancet attack drones, which the British defense ministry described as one of the most effective new weapons that Russia introduced to the battlefield last year. Lancets, which cost about $35,000 to produce, wreaked havoc during Ukraine’s offensive last year and have been captured on video striking valuable Ukrainian tanks and parked MiG fighter jets.

Like a lot of Russia’s weapons systems, Lancets are filled with Western components. An analysis of images of the drones published in December by the Washington-based Institute for Science and International Security found that they contained several parts from U.S., Swiss, and Czech manufacturers, including image processing and analytical components that play a pivotal role in enabling the drones to reach their targets on the battlefield.

“The recurring appearance of these Western products in Russian drone systems shows a keen dependence on them for key capabilities in the drone systems,” the report notes. Lancets are not the only drones found to contain Western components. Almost all of the electronic components in the Iranian Shahed-136 drones, which Russia is now manufacturing with Iranian help to use in Ukraine, are of Western origin, a separate analysis published in November concluded.

Early in the war, the Royal United Services Institute analyzed 27 Russian military systems, including cruise missiles, electronic warfare complexes, and communications systems, and found that they contained at least 450 foreign-made components, revealing Russia’s dependence on imports.

One of the principal ways that Russia has evaded Western export controls has been through transshipment via third countries such as Turkey, the UAE, and neighboring states once part of the Soviet Union. Bloomberg reported last November that amid mounting Western pressure, the UAE had agreed to restrict the export of sensitive goods to Russia and that Turkey was considering a similar move. Kazakh officials announced a ban on the export of certain battlefield goods to Russia in October.

Suspected transshipment is often revealed by striking changes in trade patterns before and after the invasion. The Maldives, an island chain in the Indian Ocean that has no domestic semiconductor industry, shipped almost $54 million worth of U.S.-made semiconductors to Russia in the year after the invasion of Ukraine, Nikkei Asia reported last July.

Semiconductor supply chains often span several countries, with chips designed in one country and manufactured in another before being sold to a series of downstream distributors around the world. That makes it difficult for companies to know the ultimate end user of their products. This may seem odd—until you realize that this is the case for many everyday products that are sold around the world. “When Coca-Cola sells Coca-Cola, it doesn’t know where every bottle goes, and they don’t have systems to track where every bottle goes,” said Kevin Wolf, a former assistant secretary for export administration at the U.S. Commerce Department.

While a coalition of 39 countries, including the world’s major manufacturers of advanced electronics, imposed export restrictions on Russia, much of the rest of the world continues to trade freely with Moscow. Components manufactured in coalition countries will often begin their journey to Moscow’s weapons factories through a series of entirely legal transactions before ending up with a final distributor that takes them across the border into Russia. “It starts off as licit trade and ends up as illicit trade,” said a second senior U.S. intelligence official, who spoke on condition of anonymity.

The further items move down the supply chain, the less insight governments and companies have into their ultimate destination, although sudden changes in behavior of importers can offer a red flag. In his speech last September, Axelrod, the assistant secretary, used the example of a beauty salon that suddenly starts to import electronic components.

But the Grand Canyon of loopholes is China, which has stood by Moscow since the invasion. In the first days of the war, U.S. Commerce Secretary Gina Raimondo warned that Washington could shut down Chinese companies that ignored semiconductor export controls placed on Russia. Last October, 42 Chinese companies were added to export control lists—severely undercutting their ability to do business with U.S. companies—for supplying Russian defense manufacturers with U.S. chips.

But as the Biden administration carefully calibrates its China policy in a bid to keep a lid on escalating tensions, it has held off from taking Beijing to task. “I think the biggest issue is that we—the West—have been unwilling to put pressure on China that would get China to start enforcing some of these rules itself,” said Miller, the author of Chip Wars.

A spokesperson for the U.S. Commerce Department’s Bureau of Industry and Security (BIS) said: “Due to the restrictions imposed by the United States and key allies and partners, Russia has been left with no choice but to spend more, lower its ambitions for high-tech weaponry, build alliances with other international pariah states, and develop nefarious trade networks to covertly obtain the technologies it needs.

“We are deeply concerned regarding [Chinese] support for Russia’s defense industrial base. BIS has acted to add over 100 [China]-based entities to the Entity List for supporting Russia’s military industrial base and related activities.”

Export controls have typically focused on keeping specific U.S.-made goods out of the hands of adversaries, while economic and financial sanctions have served broader foreign-policy objectives of isolating rogue states and cauterizing the financing of terrorist groups and drug cartels. The use of sanctions as a national security tool grew in wake of the 9/11 attacks; in the intervening decades, companies, government agencies, and financial institutions have built up a wealth of experience in sanctions compliance. By contrast, the use of export controls for strategic ends is relatively novel, and compliance expertise is still in its infancy.

“It used to be that people like me could keep export controls and sanctions in one person’s head. The level of complexity for each area of law is so intense. I don’t know anyone who is truly an export control and sanctions expert,” Wolf said.

Export controls, experts say, are at best speed bumps designed to make it harder for Russia’s defense industrial base to procure Western components. They create “extra friction and pressure on the Russian economy,” said Daniel Fried, who as the State Department coordinator for sanctions policy helped craft U.S. sanctions on Russia after its annexation of Crimea in 2014. Russia is now paying 80 percent more to import semiconductors than it did before the war, according to forthcoming research by Miller, and the components it is able to acquire are often of dubious quality.

But although it may be more cumbersome and expensive, it’s a cost that Moscow has been willing to bear in its war on Ukraine.

Western components—and lots of them—will continue to be found in the weapons Russia uses on Ukraine’s battlefields for the duration of the war. “This problem is as old as export controls are,” said Jasper Helder, an expert on export controls and sanctions with the law firm Akin Gump. But there are ways to further plug the gaps.

Steeper penalties could incentivize U.S. companies to take a more proactive role in ensuring their products don’t wind up in the hands of the Russian military, said Elina Ribakova, a nonresident senior fellow at the Peterson Institute for International Economics. “At the moment, they’re not truly motivated,” she said.

Companies that run afoul of sanctions and the Foreign Corrupt Practices Act, a U.S. federal law that prohibits the payment of bribes, have been fined billions of dollars. Settlements of export control violations are often an order of magnitude smaller, according to recently published research.

In a speech last month, Axelrod said the United States would begin issuing steeper penalties for export control violations. “Build one case against one of the companies extremely well, put out a multibillion-dollar fine negotiation, and watch everybody else fall in line,” Ribakova said.

And then there’s the question of resources. BIS has an annual budget of just $200 million. “That’s like the cost of a few fighter jets. Come on,” said Raimondo, speaking at the Reagan National Defense Forum last December.

The agency’s core budget for export control has, adjusted for inflation, remained flat since 2010, while its workload has surged. Between 2014 and 2022, the volume of U.S. exports subject to licensing scrutiny increased by 126 percent, according to an agency spokesperson. A 2022 study of export control enforcement by the Center for Strategic and International Studies recommended a budget increase of $45 million annually, describing it as “one of the best opportunities available anywhere in U.S. national security.”

When it comes to enforcement, the bureau has about 150 officers across the country who work with law enforcement and conduct outreach to companies. The Commerce Department has also established a task force with the Justice Department to keep advanced technologies out of the hands of Russia, China, and Iran. “The U.S. has the most robust export enforcement on the planet,” Wolf said.

But compared with other law enforcement and national security agencies, the bureau’s budgets have not kept pace with its expanding mission. The Department of Homeland Security has more investigators in the city of Tampa, Florida, than BIS does across the entire country, Axelrod noted in his January speech.

On the other side, you have Russia, which is extremely motivated to acquire the critical technologies it needs to continue to prosecute its war. The Kremlin has tasked its intelligence agencies with finding ways around sanctions and export controls, U.S. Treasury Undersecretary Brian Nelson said in a speech last year. “We are not talking about a profit-seeking firm looking for efficiencies,” the second senior U.S. intelligence official said. “There will be supply if there is sufficient demand.”

18 notes

·

View notes

Text

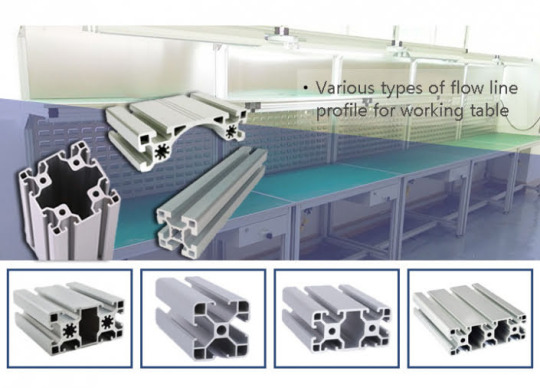

Discovering the Aluminum Profiles Versatility

Aluminum billets are heated and forced through a die's curved aperture to create an Aluminum profile, often referred to as aluminum extrusions, which have consistent cross-sectional geometries. It is possible to create complex designs with exact proportions using this approach. These profiles are appropriate for a variety of applications as they may be made in an extensive array of sizes, forms, and finishes.

Utilization of Aluminum Profiles

Building: A lot of aluminum profiles are utilized in buildings for curtain walls, windows, doors, frame systems, and structural elements. They are perfect for architectural projects because of their lightweight design, resistance to corrosion, and tolerance to extreme weather conditions.

Automobile: Aluminum profiles are used in engine components, heat exchangers, body frames, and chassis constructions in the automobile sector. Their excellent strength-to-weight ratio contributes to improved performance, increased fuel economy, and weight reduction of the vehicle.

Electronics: Aluminum profile China dissipates heat produced by electronic components by acting as heat sinks in electronic equipment. Because of its superior thermal conductivity, heat is dissipated effectively, minimizing overheating and prolonging the life of electronic equipment.

Aluminum profiles are used in aerospace applications for fuselage panels, interior parts, and aircraft structures. Aluminum is a desirable material in aircraft manufacture because of its lightweight characteristics, which also allow for increased cargo capacity and fuel savings.

Industrial Machinery: Conveyor systems, assembly lines, robotic equipment, and other pieces of machinery are made using aluminum profiles. Their adaptability enables machine frames and structural supports to be tailored to individual needs.

Aluminum Profile Benefits

Lightweight: Compared to steel or other metals, aluminum profiles are lighter due to their excellent strength-to-weight ratio. This feature lowers total costs by streamlining the handling, installation, and shipping procedures.

Corrosion Resistance: Due to its inherent corrosion resistance, aluminum can endure exposure to air, moisture, and chemicals. This characteristic guarantees resilience and endurance in many settings.

Formability: Aluminum profiles are easily extruded into intricate combinations and forms, enabling accurate measurements and bespoke designs. This formability makes applications across several sectors more versatile.

Aesthetic Appeal: Anodizing, powder coating, painting, and other surface treatments by Aluminum profile Manufacturer can be applied to aluminum profiles to improve their look and offer more resistance to wear and corrosion.

#Aluminum profile Manufacturer#Aluminum profile Company China#Aluminum profile Company#Aluminum profile Process#Aluminum profile China#Aluminum profile

2 notes

·

View notes

Text

LETTERS FROM AN AMERICAN

November 16, 2023

HEATHER COX RICHARDSON

NOV 17, 2023

The summit of the leaders of the Asia-Pacific Economic Cooperation (APEC) economies continued today in San Francisco, California.

Formed in 1989, APEC is made up of the economies of 21 nations around the Pacific Rim: Australia, Brunei, Canada, Indonesia, Japan, South Korea, Malaysia, New Zealand, Philippines, Singapore, Thailand, Taiwan, Hong Kong, China, Mexico, Papua New Guinea, Chile, Peru, Russia, Vietnam, and the United States. Together, these economies make up about 62% of global gross domestic product and almost half of global trade.

David Sanger of the New York Times today noted an apparent shift in the power dynamic between President Joe Biden and Chinese president Xi Jinping, who met yesterday for a four-hour conversation. Earlier in his presidency, Xi was riding on a strong economy that overshadowed that of the U.S. and looked as if it would continue to do so. Then, Xi favored what was known as “wolf warrior” diplomacy: the aggressive defense of China’s national interests against what Chinese envoys portrayed as foreign hostility, especially that of the U.S.

Under that diplomatic regime, Xi emphasized that liberal democracy was too weak to face the twenty-first century. The speed and momentous questions of the new era called for strong leaders, he said. In early February 2022, Russia and China held a summit after which they pledged that the “[f]riendship between the two States has no limits.”

Things have changed.

The U.S. has emerged from the coronavirus pandemic with a historically strong economy, while China’s economy is reeling from a real estate bubble and deflation at the same time that government crackdowns have made foreign capital flee. This summer, Xi quietly sidelined Qin Gang, the foreign minister associated with wolf warrior diplomacy, and in October, he replaced Defense Minister General Li Shangfu, who is under U.S. sanctions for overseeing weapon purchases from Russia.

Indeed, China has also been quietly pushing back from its close embrace of Russia. Just weeks after their February 2022 declaration, Russia invaded Ukraine in an operation that Russian president Vladimir Putin almost certainly expected would be quick and successful, permitting Russia to seize key Ukrainian ports and land. Such a victory would have strengthened both Russia and China at the same time it weakened Europe, the United States, and their allies and partners.

Instead, Ukraine stood firm, and the North Atlantic Treaty Organization (NATO) and allies and partners have stood behind the embattled country. As the war has stretched on, sanctions have cut into the Russian economy and Putin has had to cede power to Xi, accepting the Chinese yuan in exchange for Russian commodities, for example. This week, Alberto Nardelli of Bloomberg reported that the European Union is considering another round of sanctions, including a ban on the export of machine tools and machinery parts that enable Russia to make ammunition.

In a piece at the Center for European Policy Analysis today, Julia Davis, who monitors Russian media, noted that Russia lost an extraordinary 997,000 people between October 2020 and September 2021, even before the war began. Now it is so desperate to increase its population that its leadership claims to have stolen as many as 700,000 Ukrainian children and is urging women to have as many children as possible.

Holly Ellyatt of CNBC noted that to the degree they even mentioned it, Russian media sniped at the Biden-Xi summit, but it was hard to miss that although Russian president Putin was not welcome to attend, Xi came and engaged in several high-level meetings, assuring potential investors that China wants to be friends with the U.S. Also hard to miss was Xi’s pointed comment that the China-U.S. relationship “is the most important bilateral relationship in the world.”

Going into this summit, then, the U.S. had the leverage to get agreements from China to crack down on the precursor chemicals that Chinese producers have been shipping to Latin America to make illegal fentanyl, restore military communications between the two countries now that Li has been replaced, and make promises about addressing climate change. Other large issues of trade and the independence of Taiwan will not be resolved so easily.

Still, it was a high point for President Biden, whose economic policies and careful investment in diplomatic alliances have helped to shift the power dynamic between the U.S. and two countries that were key geopolitical rivals when he took office. Now, both the U.S. and China appear to be making an effort to move forward on better terms. Indeed, Chinese media has shifted its tone about the U.S. and the APEC summit so quickly readers have expressed surprise.

Today, Biden emphasized “the unlimited potential of our partnerships…to realize a future that will benefit people not only in the Asia-Pacific region but the whole world,… [a] future where our prosperity is shared and is inclusive, where workers are empowered and their rights are respected, where our economies are sustainable and resilient.”

Biden and administration officials noted that companies from across the Asia-Pacific world have invested nearly $200 billion in the U.S. since Biden took office, creating tens of thousands of good jobs, while the U.S. has elevated its engagement with the region, holding bilateral talks, creating new initiatives and deepening economic partnerships.

Today, Biden and Commerce Secretary Gina Raimondo announced that the Indo-Pacific Economic Framework, an economic forum established last year as a nonbinding replacement for the Trans-Pacific Partnership former president Trump abruptly pulled out of, had agreed on terms to set up an early warning system for disruptions to supply chains, cooperation on clean energy, and fighting corruption and tax evasion.

In a very different event in San Francisco today, a federal jury convicted David DePape, 43, of attempted kidnapping and assault on account of a federal official’s performance of official duties for his attack on former House Speaker Nancy Pelosi’s husband Paul with a hammer on October 28 of last year, fracturing his skull.

DePape’s lawyers did not contest the extensive evidence against him but tried to convince the jury that DePape did not commit a federal crime because he did not attack Pelosi on account of Representative Pelosi’s official position. Instead, they said, DePape had embraced the language of right-wing lawmakers and pundits and believed in a conspiracy theory that pedophile elites had taken over the country and were spreading lies about former president Donald Trump.

DePape told jurors he had come to conspiracy theories through Gamergate, a 2014–2015 misogynistic online campaign of harassment against women in the video game industry, which turned into attacks on feminism, diversity, and progressive ideas. Trump ally Steve Bannon talked of pulling together the Gamergate participants behind Trump and his politics.

Also today, a subcommittee of the House Ethics Committee set up to investigate allegations against Representative George Santos (R-NY) issued its report. The Republican-dominated committee found that Santos had lied about his background during his campaign and, furthermore, that he appears to be a serial liar. Those lies also “include numerous misrepresentations to the government and the public about his and his campaign’s financial activities.”

That is, the committee found, Santos defrauded his campaign donors, falsified his financial records, and used campaign money on beauty products, rent, luxury items from Hermes and Ferragamo, and purchases at the website Only Fans. The subcommittee recommended the Ethics Committee refer Santos to the Department of Justice, and “publicly condemn Representative Santos, whose conduct [is] beneath the dignity of the office” and who has “brought severe discredit upon the House.”

Santos says he will not run for reelection.

—

LETTERS FROM AN AMERICAN

HEATHER COX RICHARDSON

#Letters From An American#Heather Cox Richardson#Ethics#Santos#Xi#China US relations#Asia-Pacific Economic Cooperation (APEC)#gamergate#Pelosi

5 notes

·

View notes

Text

Automatic Cigarette Making Machines: A Complete Guide

Introduction

According to Peter Drucker, efficiency outperforms what is currently being done. This quote perfectly captures the essence of automatic cigarette making machines in china, a revolutionary advancement in cigarette manufacturing. Whether for personal use or large-scale production, these machines have changed how cigarettes are produced, offering convenience, speed, and cost efficiency. With the rising demand for custom-made cigarettes, cigarette making machines for sale have become a hot commodity in the industry. This guide will walk you through how these machines work, their benefits, and what to consider when choosing one.

How Automatic Cigarette Making Machines Work

1. Understanding the Basic Mechanism

Automatic cigarette making machines streamline the process of cigarette production by automating the rolling, filling, and packaging process. Unlike manual rolling, these machines ensure cigarette size, weight, and quality consistency.

The primary components of a high-speed cigarette making machine include:

Tobacco feeding system: Ensures a steady supply of tobacco.

Paper rolling unit: Wraps the tobacco in cigarette paper.

Filter attachment system: Places a filter at one end for a finished cigarette.

Cutting and packing module: Cuts the cigarette to the required length and packages them.

2. High-Speed Cigarette Making Equipment

For commercial use, high-speed cigarette making equipment like the m2500 cigarette making machines in uae can produce thousands of cigarettes per hour. These machines are ideal for large-scale manufacturing and ensure uniformity in production.

Advantages of Automatic Cigarette Rolling Machines

1. Cost-Effective Production

Purchasing cigarette rolling equipment can significantly reduce the cost per cigarette compared to store-bought alternatives. The initial investment pays off quickly due to reduced production costs.

2. Customization

With an automatic cigarette rolling machine in pakistan, users can select their preferred tobacco blend, rolling paper type, and filter size, providing a personalized smoking experience.

3. Efficiency and Speed

Machines like the M2500 cigarette making machines are designed for rapid production, making them ideal for businesses looking to produce high volumes in a short time.

4. Consistency and Quality Control

Unlike manual rolling, these machines ensure each cigarette maintains the same quality, preventing variations that can impact taste and burn rate.

Choosing the Right Cigarette Manufacturing Machinery

When looking for cigarette manufacturing machinery, consider the following:

Production Volume: Are you making cigarettes for personal use or commercial purposes?

Speed and Efficiency: High-speed models can increase productivity significantly.

Customization Features: Some machines offer advanced settings for filter length, paper thickness, and tobacco blend.

Durability and Maintenance: Opt for a machine with easy maintenance and durable parts to ensure longevity.

Budget: Compare prices and choose a machine that offers the best value for money.

Final Thoughts

We specialize in providing the best cigarette making machines for businesses and individuals worldwide. Our machines are known for their durability, high performance, and ease of use. We proudly export to countries including Iran, UAE, Pakistan, China, and Russia, ensuring global availability and top-tier service. If you are looking for a reliable and efficient machine, contact us today to find the perfect solution for your needs!

#best cigarette making machines#cigarette manufacturing machinery#M2500 cigarette making machines#automatic cigarette rolling machine in pakistan#cigarette rolling equipment#m2500 cigarette making machines in uae#high-speed cigarette making equipment#cigarette making machines for sale#automatic cigarette making machines in china

0 notes

Text

Industrial Gear Oils Market

Industrial Gear Oils Market Overview:

Industrial Gear Oils Market Size is forecast to reach $ 5820.0 Million by 2030, at a CAGR of 3.80% during forecast period 2024–2030.

Request PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

According to an IndustryArc report, the Industrial Gear Oils Market in 2030 was valued at $5820.0 million and is expected to grow rapidly considering the large industrialization and manufacturing activities especially in the BRICS (Brazil, Russia, India, China and South Africa) region. Industrial Gear oils are used across various industries namely the mining, construction, energy, oil and gas, chemicals, food and beverage industries as they involve heavy machinery and drive systems which need to be heavily lubricated, well oiled, under heavy pressures and high temperatures. This market is segmented based on its applications, end user industry and gearbox configuration. One application which is witnessing a large demand for Industrial Gear Oils is the renewable energy industry in the construction of wind turbines.

Industrial Gear Oils Market Outlook:

Industrial Gear oils are made of 2 major ingredients — the base oil and additives — that aim to suppress undesirable properties and enhance desirable ones so as to ease the functioning of automatic transmission. Wind energy, one of the popular renewable energy source has become a favorite worldwide, particularly in the European Union. The efficiency of the wind-turbines clearly depends on the reliability of the gear boxes that are an integral part of these machines. In addition, worm gear drives in industrial applications such as lifts, elevators, conveyor belts and torsen differentials are also witnessing a large demand. Thus, for the effective, reliable and long term running of these gear based machines, gear oils help to fulfill these requirements.

Industrial Gear Oils Market Growth drivers:

As the wind energy is rapidly evolving and a high growth industry, this large growth rate would directly boost the demand for high performance, excellent corrosion and oxidation resistance, enhanced bearing and long life operational performance industrial gear oil. Furthermore, as the developing countries in the APAC region such as India and China invest and build large manufacturing facilities and transportation technologies due to heavy urbanization and population growth, the reliable operation of machines in these sectors would be vital, which are impacted by gear oil performance. In addition, many responsible customers who are environment friendly and prefer sustainable alternatives to synthetic oil gears, would increasingly demand for bio-based alternatives.

Industrial Gear Oils Market Challenges:

The prime challenge faced by the Industrial Gear Oils market is the unstable crude oil market wherein the latter could directly impact the former, as crude oil is the prime raw material needed to manufacture gear oils for industries. Crude oil is the most volatile product in the world, and thus selling price of certain industrial gear oils would be dictated by the fluctuating prices of oil. Moreover, as concerns for environmental impact of industrial gear oils are rising among many industrial customers, key players would be forced to develop and market bio-based lubricants that are derived from vegetable oils that deliver an equivalent performance when compared to synthetic or mineral based gear oils.

For more details on this report — Request for Sample

Industrial Gear Oils Market Research Scope:

The base year of the study is 2023, with forecast done up to 2030. The study presents a thorough analysis of the competitive landscape, taking into account the market shares of the leading companies. It also provides information on unit shipments. These provide the key market participants with the necessary business intelligence and help them understand the future of the Industrial Gear Oils market. The assessment includes the forecast, an overview of the competitive structure, the market shares of the competitors, as well as the market trends, market demands, market drivers, market challenges, and product analysis. The market drivers and restraints have been assessed to fathom their impact over the forecast period. This report further identifies the key opportunities for growth while also detailing the key challenges and possible threats. The key areas of focus include the types of plastics in the Industrial Gear Oils market, and their specific applications in different types of vehicles.

Industrial Gear Oils Market Report: Industry Coverage

Industrial Gear Oils– By Gear Configuration: Worm Gears, Spur Gears, Helical Gears, Bevel Gears, Light Duty Gears and Others

Industrial Gear Oils– By Application: Wind Turbine Gearboxes, Shock loads, Mining Machinery, Extreme loads, Worm drives and others

Industrial Gear Oils– By Make-up: Synthetic, Mineral oil, Additives, Bio-based and others

Industrial Gear Oils– By End-User: Agriculture, Chemicals, Oil and gas, Mining, Energy and Power, Construction, Food and Beverage, Transportation and Fleet, Paper and Pulp and Others

The Industrial Gear Oils market report also analyzes the major geographic regions for the market as well as the major countries for the market in these regions. The regions and countries covered in the study include:

North America: The U.S., Canada, Mexico

South America: Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, Costa Rica

Europe: The U.K., Germany, Italy, France, The Netherlands, Belgium, Spain, Denmark

APAC: China, Japan, Australia, South Korea, India, Taiwan, Malaysia, Hong Kong

Middle East and Africa: Israel, South Africa, Saudi Arabia

Industrial Gear Oils Market Key Players Perspective:

Some of the Key players in this market that have been studied for this report include: Addinol Lube Oil GmbH, Advanced Lubrication Specialitis Inc., Amalie Oil Co., BP P.L.C., Bechem Lubrication Technology LLC, Chevron Corporation, Croda International PLC, ExxonMobil Corporation and others.

Market Research and Market Trends of Industrial Gear Oils Market

Researchers at the Nanotechnology & Catalysis Research Centre (NANOCAT), University of Malaya, Malaysia developed a potential antioxidant for Industrial Gear Oils. Esters of Thiolated Butylated Hydroxytoluene (BHT) derived from vegetable oils were discovered to have profound antioxidant properties, a vital property in industrial gear oils that prevent oxidation, rust and As the gear oils used in heavy duty industries are exposed to high temperatures and heavy pressures, the thermal stability, antioxidant behavior, structural integrity and performance are a cause of concern for many industrial customers. End user industries are aiming for gear oils with longer life cycles and which fulfill the above criteria. Bio-based lubricants available in the market have yet to compete on par with synthetic based gear oils and thus discoveries like this can push the green industrial gear oils to become a viable replacement to environmentally damaging synthetic and mineral based lubricants.

Get this Report on discount of $1000 on purchase of Credit Card

Researchers are actively seeking improvised nanomaterials for functioning as a lubricant additive due to their compact size and large surface area. A novel attempt to create an oil soluble Ni-promoted Molybdenum disulfide (MoS2) nanostructure has been successful by the Centre for NanoScience and Technology based in India. As industries aim to deliver gearboxes that are expected to operate heavy loads at high speeds and harsh conditions, without undergoing major surface failures and frictional damages. Thus, nanotechnology additive solutions as this can prove to improve the performance of traditionally used industrial gear oils thereby driving growth and increased demand for high performance gear oils.

#IndustrialGearOils#LubricantsMarket#IndustrialLubricants#GearOilSolutions#MachineryMaintenance#HeavyMachinery#IndustrialMachinery#EngineeringSolutions#ManufacturingIndustry#IndustrialInnovation#HighPerformanceLubricants#GearOilTechnology#SyntheticLubricants#OilAndLubricants#EcoFriendlyLubricants#SustainableOils#EnergyEfficiency#B2BMarketing#IndustryLeaders#MarketInsights

0 notes

Text

China best manual stretcher ship to one of our customers who always regarding quality as priority. We sold hundreds of these various sizes stretcher to various customers from small to big.

Improved type aluminum clamps CNC made with quality rubber, artistic and long lasting;

Tension Error margin is 0.6N/cm;

Mesh stretching size can be arbitrary adjusted;

Each part has its special features; the support frame is light and firm, easy to operate;

Strong clamping force is the main reason to decide the quality of mesh stretching and our product is right beyond all other products at this point;

Machinery before delivery all under tension tests of 48N/cm to make sure customers can use this machine for medium or high tension screen mesh stretching purpose.

‘’Be honest and trustworthy‘’ is always my motto throughout all these and future years. #stretchingmachine #screenstretcher #meshstretcher #screenframestretcher #screenstretchingmachine #meshstretchingmachine

0 notes

Text

TWO KINDS OF TECHNOLOGY

207. An argument likely to be raised against our proposed revolution is that it is bound to fail, because (it is claimed) throughout history technology has always progressed, never regressed, hence technological regression is impossible. But this claim is false.

208. We distinguish between two kinds of technology, which we will call small-scale technology and organization-dependent technology. Small-scale technology is technology that can be used by small-scale communities without outside assistance. Organization-dependent technology is technology that depends on large-scale social organization. We are aware of no significant cases of regression in small-scale technology. But organization-dependent technology DOES regress when the social organization on which it depends breaks down. Example: When the Roman Empire fell apart the Romans' small-scale technology survived because any clever village craftsman could build, for instance, a water wheel, any skilled smith could make steel by Roman methods, and so forth. But the Romans' organization-dependent technology DID regress. Their aqueducts fell into disrepair and were never rebuilt. Their techniques of road construction were lost. The Roman system of urban sanitation was forgotten, so that not until r ather recent times did the sanitation of European cities equal that of Ancient Rome.

209. The reason why technology has seemed always to progress is that, until perhaps a century or two before the Industrial Revolution, most technology was small-scale technology. But most of the technology developed since the Industrial Revolution is organization-dependent technology. Take the refrigerator for example. Without factory-made parts or the facilities of a post-industrial machine shop it would be virtually impossible for a handful of local craftsmen to build a refrigerator. If by some miracle they did succeed in building one it would be useless to them without a reliable source of electric power. So they would have to dam a stream and build a generator. Generators require large amounts of copper wire. Imagine trying to make that wire without modern machinery. And where would they get a gas suitable for refrigeration? It would be much easier to build an icehouse or preserve food by drying or picking, as was done before the invention of the refrigerator.

210. So it is clear that if the industrial system were once thoroughly broken down, refrigeration technology would quickly be lost. The same is true of other organization-dependent technology. And once this technology had been lost for a generation or so it would take centuries to rebuild it, just as it took centuries to build it the first time around. Surviving technical books would be few and scattered. An industrial society, if built from scratch without outside help, can only be built in a series of stages: You need tools to make tools to make tools to make tools ... . A long process of economic development and progress in social organization is required. And, even in the absence of an ideology opposed to technology, there is no reason to believe that anyone would be interested in rebuilding industrial society. The enthusiasm for "progress" is a phenomenon peculiar to the modern form of society, and it seems not to have existed prior to the 17th century or thereabouts.

211. In the late Middle Ages there were four main civilizations that were about equally "advanced": Europe, the Islamic world, India, and the Far East (China, Japan, Korea). Three of those civilizations remained more or less stable, and only Europe became dynamic. No one knows why Europe became dynamic at that time; historians have their theories but these are only speculation. At any rate, it is clear that rapid development toward a technological form of society occurs only under special conditions. So there is no reason to assume that a long-lasting technological regression cannot be brought about.

212. Would society EVENTUALLY develop again toward an industrial-technological form? Maybe, but there is no use in worrying about it, since we can't predict or control events 500 or 1,000 years in the future. Those problems must be dealt with by the people who will live at that time.

0 notes

Text

Automation and Smart Technologies: Transforming the Machine Tools Market

Market Overviews

In 2023, the machine tools industry generated income of USD 78.8 billion in 2023, which is projected to experience a CAGR of 4.4% over the forecast period, to attain USD 105.6 billion by the end of the decade. This is primarily attributable to the fact that the precision and proficiency in making are the key indicators for minimum wastage and alteration. Machine tool, which has a very high precision level, can help to avoid material wastages and cost reduction at the time of assembly of the part.

The major reason for the growth of automation and robotics in machining technologies can be identified in the weak workforce in the high-level manufacturing industry of the developed countries and greater use of these techniques in the aerospace, defense, medical device, marine and other sectors.

The progress of Industry 4.0 has conversed multiple innovations like artificial intelligence, big data, robots and automation, allowing more efficacy, productivity and flexibility across major sectors. One of the factors, which increased the use of machine tools in the metal fabrication and industrial manufacturing industries, is the growth of the pressure on manufacturers for good quality products with efficiency, sustainability and acceptable lead time and no possible errors. An example is, automotive industry introduced visual inspection system in their production, this had a great impact in PPM defects.

Key Insights

The metal cutting category held a larger market share of around 70% in 2023 globally.

Metal cutting machine tools is an important part of the industry, which includes automotive, aerospace, defense, mechanical engineering, and medical devices industries for precise shaping of metal and alloys such as iron, steel aluminum, titanium, and copper.

This category contains a huge range of different machinery like crurshers, grinding machines, turning machines, milling machine, electrical discharge machine (EDM) and many other.

Of them, milling machine markets outshine because of their capability to generate accurate cuts of metal, making them primarily engineered by manufacturers.

In contrast, the metal forming machines are used for bending, shaping, and other processes that are associated with metalworking.

The CNC category held a larger market share of around 75% in the global machine tools market in 2023 and is the fastest-growing in the automation segment.

CNC machines reduce manufacturing time and error rates by using CAD and CAM software to receive design instructions from a computer.

They are able to accomplish more tasks in one line prompt then one would be able to give. Therefore, there is a reduction in level of guided instruction.

Numerous types of production equipment like milling, grinding, turning, lathing, drilling and electrical discharge machining can be also merged with CNC technology.

Standard tools like change-handing on the lathe machine or milling with a handheld machine necessitates a higher level of expertise and may not conform to the set shape.

CNC technology is preferred over conventional machine tools for higher precision and more efficient production.

APAC held the largest revenue share in the global machine tools market in 2023 due to increasing industrialization and population growth in countries like China and India.

Competition among emerging economies to become manufacturing powerhouses, coupled with government initiatives like Make in India, Made in China 2025, and Making Indonesia 4.0, has created a favourable investment environment.

Significant growth is also observed in the IT sector of North America.

Source: P&S Intelligence

#Machine Tools Market Share#Machine Tools Market Size#Machine Tools Market Growth#Machine Tools Market Applications#Machine Tools Market Trends

1 note

·

View note

Text

Concrete Mixer Machine Manufacturers In China

In the context of the rapid development of China’s manufacturing industry, concrete mixer, as an indispensable part of infrastructure construction, the strength and technical level of its manufacturer directly affects the efficiency and quality of the entire industrial chain. Haomei Machinery as one of the top concrete mixer machine manufacturers in china, after more than thirty years of development and expansion, it has grown into a comprehensive enterprise integrating research and development, design, production and sales. During this period, Haomei have experienced many technological innovations and market challenges, and has always maintained its leading position in the industry by virtue of its strong independent research and development capability and keen market insight.

– Selection of high quality raw materials

In terms of raw materials, Haomei Machinery insists on choosing high-strength steel as the main structural material to ensure that the concrete mixer has sufficient strength and durability. For key components such as mixing blades, special alloy steel is used to improve their wear resistance and service life. In addition, all steel materials are subject to strict quality inspection to ensure that each component meets the high standard requirements.

– Advanced manufacturing process

In order to enhance the performance and aesthetics of the products, the company has introduced the international leading robot welding technology and shot blasting treatment equipment. Robot welding not only improves the welding precision, but also ensures the consistency of the welded parts and reduces the production cost. The shot blasting treatment can remove the oxidized skin and rust on the metal surface, improve the surface roughness, and lay a good foundation for the subsequent surface coating. The surface coating is made of corrosion-resistant epoxy resin paint or polyurethane paint, which is uniformly applied through the automated spraying system to enhance the concrete mixer’s ability to protect itself from harsh environments.

– Diversified Product Line

The company provides a wide range of concrete mixers, including single-shaft, double-shaft forced type and other types, which can be adapted to the construction needs in different scenarios. Among them, the stationary concrete batching plant is suitable for large-scale and long-term projects, while the mobile concrete batching plant is suitable for shorter construction periods and frequent site transfers. According to different customer needs, the concrete mixer output ranges widely, from tens of cubic meters to hundreds of cubic meters per hour. In terms of models, there are both compact concrete mixers for small projects and heavy duty mixing plants for large projects. Each model is meticulously designed to meet output requirements while taking into account ease of operation and ease of maintenance.

Haomei Machinery’s core competence lies in its innovative R&D capability and strict quality management system. Whether it is the selection of raw materials or every detail in the manufacturing process, it reflects the relentless pursuit of high quality. In addition, the perfect after-sales service network is also one of the key factors to win customers’ trust.

All in all, as a well-known concrete mixer machine manufacturer in China and even globally, Haomei Machinery has won wide recognition in the market for its excellent technical strength and reliable product quality. In the future, it will continue to devote itself to technological innovation and service upgrading to contribute to the development of the industry.

This resource is from https://www.concretebatchplant24.com/concrete-mixer-machine-manufacturers-in-china.html Should you be interested in, please contact us at: Haomei Machinery Equipment Co.,ltd Whatsapp/Wechat: 0086 181 3788 9531 Email: [email protected]

#concrete mixer machine manufacturers in china#concrete mixer machine manufacturers#concrete mixer machine#concrete mixer

0 notes

Text

Ceramic Guide Market Dynamics and Long-Term Growth Forecasts 2024 - 2032

The ceramic guide market is gaining momentum due to its diverse applications in various industries, including automotive, aerospace, and manufacturing. This article provides an in-depth analysis of the ceramic guide market, exploring its current landscape, key trends, challenges, and future opportunities.

Overview of Ceramic Guides

The ceramic guide market is set for significant growth, driven by rising demand across automotive, aerospace, and manufacturing sectors. With ongoing advancements in ceramic materials and a strong focus on sustainability.

What Are Ceramic Guides?

Ceramic guides are components made from advanced ceramic materials designed to provide precise guidance and support for moving parts in machinery. Their unique properties, such as high wear resistance and low friction, make them ideal for various applications, particularly in environments that demand durability and precision.

Applications of Ceramic Guides

Automotive Industry: Used in engine components, transmission systems, and braking systems to reduce friction and wear.

Aerospace Sector: Employed in aircraft engines and landing gear systems, where lightweight and high-strength materials are essential.

Manufacturing and Robotics: Utilized in CNC machines and robotic arms to ensure smooth movement and accuracy.

Market Dynamics

Current Market Landscape

The ceramic guide market is experiencing steady growth, fueled by advancements in manufacturing technologies and increasing demand for high-performance components across multiple sectors. The global market is expected to expand significantly in the coming years.

Key Drivers of Market Growth

Growing Industrial Automation: The rise of automation in manufacturing processes is increasing the demand for precision components, including ceramic guides.

High Demand in Automotive and Aerospace Industries: The push for lightweight, durable, and high-performance materials in these sectors is driving the adoption of ceramic guides.

Technological Advancements: Innovations in ceramic materials and processing techniques are enhancing the performance and applicability of ceramic guides.

Trends Influencing the Market

Shift Towards Lightweight Materials

The demand for lightweight materials in various industries is prompting a shift towards ceramic guides. These materials provide significant weight savings without compromising strength or durability, making them attractive for aerospace and automotive applications.

Increasing Focus on Sustainability

Sustainability is becoming a key consideration for manufacturers. The use of ceramic materials, which are often more environmentally friendly than traditional metals, aligns with the growing emphasis on sustainable production practices.

Regional Market Insights

North America

North America is a prominent market for ceramic guides, driven by the presence of major automotive and aerospace manufacturers. The region’s focus on innovation and technology advancements further supports market growth.

Europe

Europe is a key player in the ceramic guide market, with countries like Germany and the UK leading in industrial automation and advanced manufacturing. The region’s stringent regulations on performance and safety are also driving the adoption of high-quality ceramic components.

Asia-Pacific

The Asia-Pacific region is witnessing rapid industrial growth, particularly in countries like China and India. The increasing demand for automotive components and the rise of manufacturing sectors in these countries are significant drivers of the ceramic guide market.

Competitive Landscape

Major Players in the Market

CeramTec GmbH

Kyocera Corporation

NGK Insulators, Ltd.

Saint-Gobain

3M Company

These companies are focusing on research and development, strategic collaborations, and expansions to enhance their market presence and product offerings.

Future Outlook

Market Projections

The ceramic guide market is anticipated to grow at a compound annual growth rate (CAGR) of approximately 5-7% over the next five years. Factors such as increasing industrial automation, technological advancements, and a focus on lightweight materials will contribute to this growth.

Challenges Ahead

While the market outlook is positive, several challenges must be addressed:

High Production Costs: The initial investment for ceramic materials and manufacturing processes can be substantial.

Market Competition: The ceramic guide market is becoming increasingly competitive, necessitating continuous innovation and differentiation.

Conclusion

The market presents numerous opportunities for stakeholders. Understanding the key trends and dynamics within this sector will be essential for companies looking to thrive in the ceramic guide market.

0 notes

Text

Injection Molding in China: A Comprehensive Guide to Manufacturing Excellence

China has long been recognized as a global manufacturing powerhouse, and injection molding is one of the key industries where the country excels. As businesses around the world seek cost-effective and high-quality manufacturing solutions, injection molding china industry has become a go-to option. This article explores the advantages, processes, and considerations involved in leveraging injection molding in China for your business.

Why Choose Injection Molding in China?

China's injection molding industry offers several benefits that make it an attractive choice for businesses:

Cost-Effectiveness: The primary reason companies opt for injection molding cost in China is the significant cost savings. Lower labor costs, coupled with advanced manufacturing infrastructure, allow Chinese manufacturers to produce high-quality molded parts at a fraction of the cost compared to Western countries.

Skilled Workforce: China boasts a large pool of skilled workers experienced in injection molding. This expertise ensures precision and consistency in the production of complex components, making China a reliable choice for both simple and intricate designs.

Advanced Technology: Chinese manufacturers have invested heavily in state-of-the-art machinery and technology. This allows them to offer a wide range of services, from rapid prototyping to large-scale production runs, while maintaining high standards of quality.

Scalability: Whether you need a small batch of prototypes or mass production of millions of units, Chinese injection molding companies have the capacity to scale production according to your needs. This flexibility is crucial for businesses of all sizes.

Global Supply Chain Integration: China's well-established logistics networks and proximity to major global markets enable efficient shipping and distribution. This ensures that your molded parts can be delivered to your doorstep or directly to your customers, reducing lead times and costs.

The Injection Molding Process in China

The injection molding process in China follows a standardized procedure, ensuring consistency and quality across all projects. The key steps include:

Design and Prototyping: The process begins with the design of the mold and the creation of a prototype. Chinese manufacturers often use advanced software and 3D printing technology to produce accurate prototypes that meet your specifications.

Mold Manufacturing: Once the prototype is approved, the mold is manufactured. This involves precision machining of the mold cavity, which will shape the final product. Chinese mold makers are known for their attention to detail, ensuring that the mold meets exacting standards.

Injection Molding: The actual molding process involves injecting molten material, typically plastic, into the mold cavity. The material cools and solidifies, taking the shape of the mold. This step is repeated to produce the required number of parts.

Quality Control: Chinese injection molding companies place a strong emphasis on quality control. Each part is inspected for defects, and any necessary adjustments are made to the mold or process to ensure consistent quality in the final product.

Finishing and Assembly: After molding, the parts may undergo additional finishing processes, such as trimming, painting, or assembly. Chinese manufacturers offer a full range of finishing services, allowing you to receive fully finished products ready for use or distribution.

Considerations When Choosing a Chinese Injection Molding Partner

While China offers numerous advantages for injection molding, it’s important to carefully select the right manufacturing partner. Here are some key considerations:

Reputation and Experience: Look for manufacturers with a proven track record in the industry. Experienced companies are more likely to deliver high-quality products and meet deadlines.

Communication: Clear and effective communication is crucial for successful collaboration. Ensure that your Chinese partner understands your requirements and can provide regular updates on the progress of your project.

Intellectual Property Protection: While China has made significant strides in protecting intellectual property, it's still important to take precautions. Work with manufacturers who have strong IP protection policies in place.

Compliance with Standards: Ensure that the manufacturer adheres to international quality and safety standards. This is especially important if your products will be sold in regulated markets.

Conclusion

Injection molding in China offers a compelling combination of cost-effectiveness, quality, and scalability. By choosing the right partner and taking the necessary precautions, businesses can leverage China's manufacturing expertise to produce high-quality molded parts that meet their specific needs. Whether you’re a startup looking to prototype a new product or a large corporation seeking mass production, China's injection molding industry has the capabilities to help you succeed.

0 notes

Text

The Introduction

Pig breeding is an important part of China's agriculture, but the problem of handling a large amount of pig manure has become increasingly prominent. If not handled properly, pig manure not only causes environmental pollution, but may also pose a health threat to farm staff. Fortunately, through scientific treatment methods, pig manure can be converted into valuable organic fertilizer, which not only solves the pollution problem, but also realizes the recycling of resources. This article will describe in detail how pig manure is converted into organic fertilizer and the machinery and equipment required.

Feasibility of converting pig manure into organic fertilizer

Pig manure is a waste rich in organic matter, which can be converted into high-quality organic fertilizers after proper treatment. Pig manure contains a large amount of nitrogen, phosphorus, potassium and other nutrients, which are essential for plant growth. In addition, pig manure also contains a rich microbial community, which can decompose organic matter and produce heat and carbon dioxide during fermentation, achieving the effect of disinfection and sterilization. Therefore, it is completely feasible to convert pig manure into organic fertilizer.

Method of converting pig manure into organic fertilizer

Composting Method:

The pig manure was mixed evenly with organic materials such as straw and rice husk in a certain proportion.

Stacked in a ventilated, dry place for aerobic fermentation.

Turn the pile regularly to facilitate oxygen entry and heat release, speeding up the fermentation process.

After a period of time (usually a few months), pig manure will be converted into decomposed organic fertilizer.

Digester method:

Pig manure was mixed with water and put into a digester for anaerobic fermentation. In this process, microorganisms decompose organic matter to produce biogas and biogas residue.

Biogas can be used for electricity generation or domestic gas, while biogas residue can be used as organic fertilizer.

Biological fermentation method:

Use professional microbial agents to accelerate the fermentation process of pig manure.

After the bacteria agent and pig manure were mixed evenly, sealed fermentation was carried out. This method can shorten the fermentation time and improve the quality of organic fertilizer.

Required machinery and equipment

In order to efficiently convert pig manure into organic fertilizer, a series of professional machinery and equipment need to be used. Here are some of the main equipment introductions:

Fermentation and stacking machine:

It is used to turn the pile regularly to ensure sufficient oxygen inside the pig manure pile and promote the fermentation process.

There are trough type and crawler type (Windrow Compost Turning Machine) and other types, can be selected according to the site and demand.

Organic Fertilizer Crusher:

The large debris and stones in the fermented organic fertilizer are crushed to improve the quality of the fertilizer.

Rotary Screening Machine:

The crushed organic fertilizer was screened to remove impurities and ensure the purity of the fertilizer.

Double Shafts Paddles Mixer:

The organic fertilizer after screening and crushing is stirred and mixed to ensure stable product quality.

At the same time, it can be used to add other fertilizers and trace elements, and produce special fertilizer or compound fertilizer.

Disc Granulator:

The evenly mixed materials were pelleted to make granular organic fertilizer.

Rotary Dryer Machine:

The finished particles are dried to remove excess water and increase the strength of the particles for easy storage and transportation.

Rotary Cooler Machine:

The dried particles were cooled to prevent clumping.

Rotary Screening Machine:

The cooled particles were graded and screened to select qualified finished products.

Enveloping machine:

The qualified particles were coated to increase their brightness and roundness.

Packing machine:

The encapsulated organic fertilizer particles are bagged for easy storage and sale.

Conveying machine:

It is used for conveying materials between different processes to improve production efficiency.

Conclusion

The conversion of pig manure from pig farms into organic fertilizer not only solves the problem of environmental pollution, but also realizes the recycling of resources. By using scientific treatment methods and professional machinery and equipment, high quality organic fertilizer can be produced efficiently. This will not only help improve soil quality and plant growth, but also bring additional economic benefits to the farm. Therefore, pig farms should actively promote the production and application of pig manure organic fertilizer.

1 note

·

View note

Video

youtube

In 2010, Sharp Technocast Industries made a significant impact by founding their aluminium die casting plant under the name Italscale. This strategic move combined the production and machining of aluminium die-cast parts, allowing the company to cater to the increasing demands of Italian and European customers. Aluminium Die Casting SRL, known for its high level of technology, innovation, and extensive experience, excels in project planning and realization of tooling for die-casting production and machining.

Our mission is to provide high-precision aluminium die-cast parts "just in time" to meet customer needs. We prioritize good cooperation with each customer to support their quality goals and lean activities, ensuring their competitiveness. We deliver complete solutions from a single source, strictly complying with environmental, work, and safety regulations, as well as energy-efficient production processes.

Continuous improvement is a core principle for us, and our employees receive ongoing training to enhance customer satisfaction. The application of lean principles yields excellent results, implemented systematically and with full employee commitment. Our advanced machinery, including 26 fully equipped 80 Frame Moter Body No Back Type, 80 Frame Flange, and 80 Frame Endseal Cover, allows us to produce aluminium alloy castings ranging from a few grams to 16 kg in weight.

In 2010, Italscale was acquired by Altra Industrial Motion Corp., a leading global manufacturer of standard and custom geared motor solutions with production facilities in Germany, China, the USA, Slovakia, and Italy. Join us on this transformative journey as we explore the advancements in aluminium die casting and our unwavering dedication to quality and sustainability.

0 notes

Text

Metal nut copper

Stainless steel is a kind of hardware parts specially customized and high-precision machining. It is made of stainless steel and has the excellent characteristics of stainless steel, such as strong corrosion resistance, good oxidation resistance, strong and durable. Unlike standard nuts, non-standard nuts are custom machined according to specific needs and design requirements to meet the precise fit and fastening requirements of various special application scenarios. In the precision machining process, advanced manufacturing technology and strict process control ensure that the nut has extremely high dimensional accuracy and shape accuracy. The nut can reliably function in a variety of complex and demanding environments, whether in high-load, high-vibration mechanical equipment, or in areas such as instruments with high precision requirements. It has a very wide range of applications, covering many industries such as machinery manufacturing, aerospace, electronic technology, and the automotive industry, providing a key guarantee for the stable connection of various equipment and structures. In short, non-standard precision machining stainless steel with its unique customization, excellent performance and precision processing, has become an indispensable important hardware parts in many fields.

1 note

·

View note

Text

China made COIL FOR SOLENOID VALVE CCP115D for power station

"China made COIL FOR SOLENOID VALVE CCP115D for power station The company has a large flow, high discharge pressure, good performance, high efficiency, long life, high reliability, special for the technical valve products. Our company's main products: hydraulic machinery and components, hydroelectric generating units; coal-fired generating units; generating units; electrical and electronic products processing; mechanical parts processing. Mainly engaged in the power industry host (steam turbine, water machine, boiler, turbine) accessories, spare parts, spare parts, auxiliary equipment and environmental protection equipment.

Yoyik can offer many spare parts for power plants as below:

DF-COIL FOR SOLENOID VALVE CCP115D-DF

vacuum pump price A10VSO100DFR1/32R EH oil Re-Circulating pump F3-V10-IS6S-1C-20 axial piston pump PV29 2RID CO2 vertical centrifugal pump LK45/CZ65-250-4 centrifugal pump DFB125-80-260-01 centrifugal pump parts CZ50-250C vertical centrifugal pump DFB-80-80-240 screw pump stainless HSNS210-42 centrifugal water pump 65-250A Valve Spring 8-YT668Y64150 Two position four way valve 4WE10C-20/AW220NZ5L roots vacuum pump WS-30 trip globe valve SHV20 ball valve MHARKH-18L-16-4465-EGPN350/DN16 electric oil transfer pump DLZB820-R64A vacuum pump parts KZ100-WS tee joint Rotary valve HH6424DF32 mannual bellows globe valve WJ15F1.6P LP accumulator bladder YZ326641-B/2.5GAL twin screw pump ACG045N6IVBP vacuum cleaner P-1433 BALL BEARING SINGLE ROW RADIAL DEEP GROOVE NO.6205 mechanical shaft seal 108-45 centrifugal pump working DFB80-50-220 solenoid valve HR3W6DG220NV high pressure piston pump PVH098R01AD30A rotary piston pump PVH74QIC-RSM-IS-10-C25-31 screw pump diagram 3GR25X4 vacuum pump compressor P-1258 pressure hose SMS-20-915mm-C vane pump diagram F320V5A1C22R sealing ring HB4-56J8-118 rubber coupling 80LY-45-3 vacuum pump 269v P-2811 axial piston pump MOOG0514 7005 37 manual vacuum pump P-1945 COIL FOR SOLENOID VALVE CCP115D

pressure hose SMS-10/12-305mm-B centrifugal pump parts DFB100-80-250-14 mechanical face seal 104G-40 vane pumps F3 V10 1S6S 1C20 multistage centrifugal pumps DFB80-520-240 600MW turbine DC Emergency pump (EOP)coupling 125LY-32 globe throttle check valve LJC100C-2.5P mechanical seal 39 mm 80AY50*10 centrifugal pump types YCZ50-250 Spare parts package G054 Accumulator for Heavy Railway Wagon Scheduling Unit NXQ63/31.5MPa fluid transfer pump YW-32-160 solenoid valve RV5-10-0-35 Suction valve W204856-TFE, W207782-PVC , W207783-PVC piston hydraulic pump PVM098 GR55KSP55.65-31.75K vane pumps F3V10-1S6S-1C20 HYDRAULIC SERVO PROPORTIONAL VALVE D664-4798-L05HABW6NEX2-G solenoid valve C9206015 vacuum oil pump P-1836 solenoid valve D1VW20BVZP92XB510 sealing oil water-ring vacuum pump mechanical seal 2S-185 EH oil pump PVHD74R01AA10A250000001ABO1OA dc screw pump HSNH860-46 mechanical seal 65 mm QG400/300-CW COMPLETE O-RING KIT FOR TURNING GEAR 0-0281-0005-00 electric oil transfer pump DLZB820-R64A-8 hydraulic pumps 80SDZL-26 globe throttle check valve LJC80C-1.6P vacuum pump compressor 30-WS-32 EH accumulator bladder NXQ-25/31.5-L-Y Steel pipe flange metal gasket HG/T20612-2009 radial piston pump hydraulic PVH74QIC-RF-1S-10-C25-31 057 globe throttle check valve LJC100C-4.0P metering piston pump A10VS045DR/31R-PPA12N00 vacuum pump oil P-1609-1 hydraulic jack pump 50SDZLJ-40Ax1.3 COIL FOR SOLENOID VALVE CCP115D

DFYLSYC-2024-7-15-A

"

0 notes

Text

Our paper straw single packaging machine is designed for environmental protection. Using advanced automation technology, each paper straw can be individually packaged quickly and accurately to ensure its hygiene and safety. Whether it's a restaurant, cafe or fast food restaurant, it can easily handle heavy use needs. Choose our pindividual straw packing machine to make every use full of environmental awareness and let us protect our earth together.

How Does Our Individual Straw Ping Machine Work?

Adopted with PLC controller; the main motor is equipped with variable frequency speed regulation; touch screen man-machine interface. Easy for parameters setting & operating.

The cutting section of our straw manufacturing machine adopted with numerical multi-blades cutting system. Servo synchronous tracking cutting system makes it higher precision and multi-blades cutting makes it higher efficient.

The single straw packing machine's body and main spare parts are made of stainless steel instead of painting. Ensure the hygiene and environmental protection of the products.

What to Expect from Our Paper Straw-Making Machines?

Embrace eco-friendliness with confidence by choosing our advanced individual straw packing machine from Chuangfeng. Here's what you can expect:

Cutting-Edge Technology: Our single straw packing machines incorporate state-of-the-art technology, ensuring the production of top-quality paper straws that are sturdy and durable.

Environmentally Conscious Production: Start your journey towards environmental conservation with small, yet impactful steps. Our paper straw packing machine craft paper straws, providing a sustainable alternative to traditional plastic straws.

High-Quality Output: Experience the excellence of Chuangfeng's machinery through the production of high-quality, reliable paper straws. Enjoy your drinks guilt-free, knowing you're contributing to a greener planet.

Expertise in Manufacturing: As one of the most professional paper straw and paper tube machines suppliers in China, Chuangfeng brings years of experience and expertise to the table, ensuring reliable and efficient equipment.

Unique Advantages: Benefit from Chuangfeng's distinctive advantages in paper straw and tube equipment manufacturing, setting us apart from others in the industry.

Make a conscious choice for the environment—choose Chuangfeng's Paper Straw Making Machines and make sustainability a way of life.

0 notes