#lvdt sensors

Explore tagged Tumblr posts

Text

Harnessing Ono Sokki's Linear Gauge Sensor for Accurate Data

Precision and reliability are crucial factors in the measurement of displacement, particularly in today's dynamic industrial environment. Our Linear Gauge Sensor are recognized as leading-edge tools for obtaining precise data across diverse applications. Let's explore the exceptional features of these sensors and their effective utilization.

Our device is meticulously engineered to deliver unparalleled accuracy in displacement measurement. The sensor utilize cutting-edge technology to ensure precise readings, making them indispensable in industries where even the slightest deviation can have significant repercussions.

Features of the sensor

High Precision: It's boast high precision, allowing for precise measurement of displacement with minimal margin for error.

Reliability: Built to withstand demanding industrial environments, these sensor offer consistent and reliable performance under various conditions.

Versatility: With a range of models available, Ono Sokki caters to diverse applications, ensuring that there's a sensor suitable for every need.

Digital Interface: The GS series Digital Linear Gauges feature advanced digital interfaces, enabling seamless integration with modern measurement systems.

Applications of the Device

The versatility of the sensor makes it ideal for a wide array of applications across industries. Here are some key areas where these sensor excel:

Manufacturing and Quality Control

In manufacturing processes where precision is paramount, our sensor play a crucial role in ensuring product quality. From automotive to aerospace industries, these sensor help maintain tight tolerances and uphold stringent quality standards.

Automotive Testing

In automotive testing applications, such as chassis testing and suspension analysis, linear variable differential transducer provide precise displacement measurement, enabling engineers to fine-tune vehicle performance and safety parameters.

Research and Development

In research and development environments where innovation thrives on accurate data, further facilitate groundbreaking discoveries by providing researchers with reliable displacement measurements.

Harnessing The Power

To harness the full potential, it's essential to employ best practices in sensor installation, calibration, and data interpretation. Here are some tips for maximizing the effectiveness of these sensor:

Proper Installation

Ensure that the sensor is installed securely and aligned correctly with the target object to obtain accurate measurements consistently.

Calibration

Regular calibration is crucial to maintaining the accuracy of the sensor over time. Follow the manufacturer's guidelines for calibration procedures and frequency.

Data Analysis

Invest in software tools or systems that allow for a thorough analysis of the data collected by the sensor. Extract valuable insights to optimize processes and improve overall efficiency.

Quality Assurance

Ono Sokki's sensor represents the pinnacle of precision and reliability in displacement measurement technology. With their advanced features and versatile applications, these sensor empower industries to achieve new heights of accuracy and efficiency. By harnessing the capabilities of LVDT sensors and implementing best practices, businesses can unlock a world of possibilities and stay ahead in today's competitive landscape.

For any clarifications or queries, please feel free to contact us:

Mobile: +91–92055–92194 or +91–92055–92195

Email ID: [email protected]

Website: www.onosokki.co.in

#Linear Gauge Sensor#LVDT#Linear Variable Differential Transducer#sound level meter#noise level meter#class 2 sound level meter#class 1 sound level meter#db meter#ono sokki india

0 notes

Text

#Global LVDT Sensors Market Size#Share#Trends#Growth#Industry Analysis#Key Players#Revenue#Future Development & Forecast 2023-2032#global Global LVDT Sensors Market Size#global market report#industry analysis#global research market report

0 notes

Text

NewTek HAZLOC-Approved LVDTs for Hazardous and Explosive Environments

(NewTek: Pennsauken, NJ) — NewTek HazLoc-approved linear position sensors are certified for safe operation in hazardous locations with explosive gases, vapors, dust and other dangerous substances. Approved by Intertek Testing Laboratories and carrying the ETL mark, the NT-HL-750 LVDTs are intrinsically safe for use in Class I, Zone 0, and Zone 2 areas. These sensors meet stringent standards to…

0 notes

Text

LVDT Coil Winders: Precision and Innovation in Winding Technology

Coil winding is a critical process in manufacturing components for electrical and electromagnetic systems. Among the various winding equipment, LVDT (Linear Variable Differential Transformer) coil winders stand out for their precision and efficiency. These machines cater to industries requiring unparalleled accuracy, such as aerospace, medical devices, and automation. Let’s delve into the technical aspects of LVDT coil winders and their pivotal role in modern winding processes.

What Are LVDT Coil Winders?

LVDT coil winders are specialized machines designed to wind coils used in Linear Variable Differential Transformers. LVDTs are electromechanical sensors that measure linear displacement with high accuracy. To achieve optimal performance, these sensors rely on precisely wound coils, which are manufactured using advanced coil winder technology.

Key Features of LVDT Coil Winders

High Precision Winding: LVDT coil winders are equipped with programmable controls to ensure uniform tension and pitch throughout the winding process. This accuracy minimizes signal distortion and enhances the performance of the final product.

Automated Processes: Modern LVDT coil winders incorporate automation to handle complex winding patterns. These machines can wind fine wires with diameters as small as 10 microns, essential for high-sensitivity applications.

Customizable Configurations: From multi-spindle designs to versatile tooling, these machines can adapt to various coil specifications, ensuring compatibility with different LVDT models.

How LVDT Coil Winders Work

Core Components:

Tension Control System: Maintains consistent tension, preventing wire breakage or overlapping.

Rotational Mechanism: Allows precise control of spindle speed for even winding.

Guidance System: Directs the wire with sub-millimeter accuracy, critical for achieving the required winding density.

Process Overview:

Setup: The operator inputs specifications such as wire diameter, number of turns, and pitch into the machine’s control panel.

Tension Adjustment: The tension control system ensures the wire remains taut without snapping.

Winding: The machine executes the winding process, guided by pre-programmed instructions.

Quality Check: Advanced systems verify the coil’s dimensions and consistency before it moves to the next production stage.

Applications of LVDT Coil Winders

Aerospace Industry

In aerospace, LVDTs are integral to flight control systems. LVDT coil winders ensure these sensors meet stringent reliability and precision standards.

Medical Devices

LVDTs in medical imaging equipment demand ultra-fine coils. The high precision of these winders ensures optimal signal output, essential for accurate diagnostics.

Industrial Automation

Robust and accurate LVDTs are vital for industrial automation. Coil winders play a crucial role in manufacturing these sensors, ensuring they perform flawlessly in demanding environments.

Benefits of Using LVDT Coil Winders

Enhanced Efficiency: Automated features reduce production time while maintaining high quality.

Consistency: Uniform winding eliminates variability, ensuring each coil meets exacting standards.

Scalability: Adaptable to produce coils of various sizes and specifications for diverse applications.

The Role of LVDT Coil Winders in LV Winding Machines

While primarily focused on LVDT coil production, these winders share technological synergies with LV winding machines. Both rely on precision and automation to meet industry demands. For instance, a Coil Winder designed for LV applications benefits from advancements in LVDT winding technology, ensuring superior performance across electrical applications.

Conclusion

LVDT coil winders exemplify the fusion of engineering precision and technological innovation. Their ability to produce high-quality coils underpins the performance of critical systems in aerospace, medical, and industrial applications. As technology advances, these machines will continue to redefine standards in the coil winding industry.

What future advancements could further revolutionize winding equipment and their applications? Share your thoughts below!

0 notes

Text

Exploring the Different Types of Linear Position Sensors for Industrial Use

Linear position sensors play a vital role in modern industrial applications. Whether it's automation, manufacturing, or precision engineering, these sensors help measure and monitor the movement of machinery with remarkable accuracy. But with so many different types available, it can be overwhelming to choose the right one for your specific needs. Let’s break down the most common types of linear position sensors used in industrial environments.

1. Potentiometers: These are among the most basic and affordable types of linear position sensors. Potentiometers work by measuring changes in electrical resistance as the object moves. While they're cost-effective and straightforward to use, they might not be as durable as other options, especially in harsh industrial conditions.

2. LVDTs (Linear Variable Differential Transformers): Known for their high precision and durability, LVDTs are often used in environments that demand robustness, such as aerospace and automotive industries. These sensors work on the principle of electromagnetic induction and are great for applications where precision is critical. They can also withstand extreme conditions, making them ideal for heavy-duty industries.

3. Magnetostrictive Sensors: These sensors use a magnetic field to measure position, offering excellent accuracy and a long lifespan. They're widely used in hydraulic systems, automation, and other industrial applications where precision is key. Their non-contact measurement system means there's less wear and tear, enhancing their longevity.

4. Optical Encoders: Optical encoders measure position using light, making them incredibly precise. These sensors are commonly found in applications requiring high resolution, such as robotics and CNC machines. However, they may not perform well in environments with high levels of dust or moisture.

Choosing the right linear position sensor depends on factors like the environment, required precision, and budget. Whether you need durability, cost-efficiency, or high accuracy, there’s a sensor tailored for your specific industrial needs.

0 notes

Video

youtube

LVDT Displacement Sensor 4000TD-15-01: Critical Components for Steam Tur...

0 notes

Text

China supplier MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B power plant spare parts

China supplier MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B power plant spare parts Sold by YOYIK. Deyang YOYIK is a professional production, development, sale of power plant dedicated spare parts and accessories processing company. Through more than 20 years of efforts, the majority of customers have been fully recognized. Limited space, and look forward to your calls for consultation, we will sincerely for your service, your satisfaction is our greatest comfort! Yoyik can offer many spare parts for power plants as below: #DF-MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B-DF Signal Converter ADAM4520 Magnetic Proximity Sensors DF2018 Analog Linear Displacement Sensor ZDET-20B Shaft Speed Sensors CS-1-G-100-05-00 Digital display AC ammeter PA194I-3X1 rpm sensor indicator G-065-05-01 Magnetic Pick-up Speed Sensor DF2012 angular displacement sensor B151.36.09G09 displacement sensor FRD.WJA2.301H lvdt linear position sensor TDZ-1E-31 temperature measurement sensor pt100 WZP2-014s PT100 2M lvdt transducer displacement LVDT-400-6 rtd cable WZPK-646 displacement transducer TDZ-1E-32 rotation sensor D-100-02-01 lvdt transducer displacement HL-3-100-15 LVDT Displacement Transducer Sensors B151.36.09.04.15 thermocouple machine WRN-332NM rtd probe WZPM2 lvdt full form B151.36.09G32 Platinum Thermocouple Wire WRN2-630 LX1=225*76 rpm speed meter DF9011-B dc speed control sensor G-090-02-01 replace thermocouple WRN2-239 0-600℃ linear variable displacement transducer B151.36.09G08 full form of lvdt ZDET1000B pressure switch black 396725-LKTS16 speed meter sensor HZSP-475-50-10-HL celsius thermometer WSS-461 0~350℃ non-contact displacement sensor ZD-7000TDB oil pressure sensor SPB424BXCC RPM Sensor magnetic GSH5 RPM Sensor magnetic CS-1 L=100 Thermocouple Type-K TE-109 tachometer price DF9011-B Type K Thermocouple Cartridge WRNKB-446S/TG MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B rtd cable WZP-201 LVDT Position Sensors K156.36.06.004 vacuum pressure gauge 1201901 lvdt 20mm sensor LVDT-35-3 furnace thermocouple TE-305 Rotary Torque Sensor ZS-02 L=65 element cartridge heaters ZJ-14.5-180 rpm sensor generator DF2018 Surface Thermocouple TC03A2-KY-2B/S13 lvdt-sensor ZDET-25B thermocouples extension lead wires TE-303 linear displacement sensor FRD.WJA2.308 LVDT Position Sensors A191.36.09.03 lvdt 0-300 TDZ-1G-32 pt100 rtd probe thermowell WRNK2 pt100 rtd WZP-221 rotational speed sensor CS-1-G-100-02-01 lvdt displacement transducer B151.36.06(1)G02 thermal resistance tester WZP2M-201 thermocouple k-type WRNK2-294 non-contact displacement sensor TDZ-1E-12 lvdt working principle 400TD non-contact displacement sensor TDZ-1E-22 BENTLY Cable 330130-040-12-00 Tacho RPM sensor CS-3 M16-L60 cartridge heater electric heating heater DJ-22-2/ZBK54019-88 liquid level gauge UTG2005C Displacement sensor 5000TDG 0-250mm LVDT Position Sensors TDZ-1-21 lvdt full form TDZ-1-33 pt100 thermocouple machine WRNK2-292 lvdt displacement sensor inductive sensor HL-6-20-15 thermowell flange TC03A2-KY-2B/S3 Gear speed sensor CS-3-M16-L120 Shaft Rotation Speed Sensors DF6202-005-050-04-00-10-000 lvdt 20mm sensor B151.36.09G42 MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B DFYLSYC-2024-6-17-A

0 notes

Text

0 notes

Text

In-Depth Analysis of Market Share in the Aircraft Sensors Sector

Market Overview

The Aircraft Sensors Market was valued at USD 4.7 Billion in 2022 and is projected to grow from USD 5.17 Billion in 2023 to USD 7.0 Billion by 2027, at a Compound Annual Growth Rate (CAGR) of 8.3% during the forecast period. This significant growth is driven by the increasing need for advanced sensing solutions to ensure efficient operations and the safety of aircraft systems.

Market Size and Growth

Current Market Size

As of 2022, the global Aircraft Sensors Market stands at USD 4.7 billion. The market's size highlights its critical role in the aviation industry, which relies on sophisticated sensors to monitor various parameters essential for safe and efficient aircraft operations.

Projected Market Size

The market is anticipated to grow to USD 7.0 billion by 2027, with a robust CAGR of 8.3%. This growth trajectory underscores the expanding adoption of advanced sensor technologies in both commercial and military aviation sectors.

Market Drivers

Increased Usage of Sensors for Data Sensing and Measurement

Sensors play a crucial role in providing feedback on various flight conditions and the state of aircraft systems. For example, flow sensors detect the amount of lubricating oil, liquid coolant, and fluid movement in fuel transfer and bleed air systems. Liquid level sensors monitor oil, fuel, coolant, and fluid levels in hydraulic reservoirs and waste water tanks. Pressure sensors are essential in hydraulic systems used for braking, control surfaces, and landing gear operations. Position sensors, such as rotary variable differential transformers (RVDTs) and linear variable differential transformers (LVDTs), measure the displacement of aircraft parts like thrust reversers. Additionally, sensors monitor force, vibration, and temperature in critical systems.

Technological Advancements in Military Applications

The criticality of modern military airborne missions has led to the development of highly advanced navigational and surveillance systems. These systems enable long-range target detection in low-light conditions and include missile indication and deterrence systems capable of operating in radar-denied zones. The increasing number of sensors on military aircraft enhances situational awareness, driving demand in this sector.

Get a Deeper Understanding of the Industry by Visiting: https://www.marketsandmarkets.com/Market-Reports/aircraft-sensors-market-53630527.html

Market Restraints

Frequent Calibration and Maintenance Requirements

Aircraft sensors require regular calibration and maintenance to ensure accurate and reliable performance. For instance, airspeed sensors need frequent calibration to maintain proper auto-throttle modes and effective automatic landing operations. Pre-flight checks and periodic calibrations, often every 500 flight hours, are necessary. Sensors exposed to harsh environments, such as those on aerostructures and engines, are particularly susceptible to contamination and require more frequent calibration.

Market Opportunities

Increasing Adoption of Internet of Things (IoT) in Aviation

The rapid development of IoT and sensor networks presents significant opportunities for the Aircraft Sensors Market. IoT-enabled sensor networks are being widely adopted across various sectors, including aviation, to enhance operational efficiency and passenger experience. For example, temperature sensors in aircraft cabins facilitate automated temperature control systems, ensuring passenger comfort. IoT systems also monitor the condition of aircraft components, providing real-time data to pilots and ground crews, which improves maintenance efficiency and reduces runway downtime.

Enhancing Passenger Experience

IoT applications in aviation extend beyond operational efficiency to improving the passenger experience. Sensors that monitor cabin temperature, air quality, and lighting conditions contribute to a more comfortable journey. Additionally, sensors that track seat occupancy and in-flight entertainment preferences enable personalized services, enhancing overall passenger satisfaction.

Market Challenges

Cybersecurity Risks

The increasing digitalization and integration of systems in the aviation sector pose significant cybersecurity risks. The open and networked nature of modern aviation ecosystems makes them vulnerable to cyberattacks. For instance, the F-35's autonomic logistics information system (ALIS) uses sensors to detect aircraft performance and predict maintenance needs, communicating this data to ground crews. However, such systems are susceptible to cybersecurity threats, necessitating robust security measures to protect sensitive data and ensure the integrity of aircraft operations.

Market Segmentation

This Research Report Categorizes the Aircraft Sensors Market Into Sensor Type, Application, Aircraft Type, End Use, Connectivity, and Region:

By End Use:

OEM

Aftermarket

By Sensor Type:

Pressure Sensors

Temperature Sensors

Force Sensors

Torque Sensors

Speed Sensors

Position & Displacement Sensors

Level Sensors

Proximity Sensors

Flow Sensors

Optical Sensors

Motion Sensors

Radar Sensors

Smoke Detection Sensors

GPS Sensors

Others

By Aircraft Type:

Fixed-Wing

Rotary-Wing

Unmanned Aerial Vehicles

Advanced Air Mobility

By Application:

Fuel, Hydraulic, and Pneumatic Systems

Engine/Propulsion

Cabin & Cargo Environmental Controls

Aerostructures & Flight Control

Flight Decks

Landing Gear Systems

Weapon Systems

Others

By Connectivity:

Wired Sensors

Wireless Sensors

By Regions:

North America

Europe

Asia Pacific

Middle East

Latin America

Africa

By End Use

OEM Segment

The Original Equipment Manufacturer (OEM) segment is estimated to lead the Aircraft Sensors Market in 2022. The increasing demand for various aircraft types across different regions, driven by rising air traffic, is expected to boost the demand for aircraft sensors. OEMs play a crucial role in integrating advanced sensor technologies into new aircraft designs to meet stringent safety and performance standards.

By Sensor Type

Proximity Sensors

Proximity sensors are expected to hold the largest market share during the forecast period. These sensors detect the presence of objects without physical contact, making them essential for various aircraft applications. Proximity sensors emit electromagnetic radiation and detect changes in the return signals, converting the presence and movement of objects into electrical signals. Their widespread use and affordability make them a popular choice for object detection in aviation.

Download Sample PDF Copy to Understand More: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=53630527

By Region

North America

The North American region is expected to have the highest market share during the forecast period. Key companies such as Honeywell, General Electric, and TE Connectivity, which are headquartered in the U.S., lead the market in this region. North America is also a major hub for aircraft design and manufacturing, contributing to the region's dominant market position.

Competitive Landscape

The Aircraft Sensors Market is dominated by several globally established players, including:

Honeywell (US)

TE Connectivity (US)

Meggitt PLC (UK)

AMETEK Inc. (US)

Safran (France)

These key players offer a wide range of aircraft sensors and services to different stakeholders in the aviation industry. They focus on innovation and strategic partnerships to enhance their market positions.

Emerging Trends

Integration of Advanced Sensor Technologies

The integration of advanced sensor technologies, such as MEMS (Micro-Electro-Mechanical Systems) and fiber optic sensors, is a notable trend in the Aircraft Sensors Market. These technologies offer higher precision, reliability, and durability, making them suitable for critical applications in aviation.

Adoption of Wireless Sensor Networks

The adoption of wireless sensor networks in aircraft is gaining momentum. These networks enable seamless data transmission and real-time monitoring of aircraft systems, reducing the need for complex wiring and improving maintenance efficiency.

The Aircraft Sensors Market is poised for significant growth, driven by the increasing adoption of advanced sensing solutions, technological advancements in military applications, and the integration of IoT in aviation. Despite challenges such as frequent calibration requirements and cybersecurity risks, the market is expected to expand at a robust CAGR of 8.3%, reaching USD 7.0 billion by 2027.

The market's growth is supported by the demand for new aircraft, the need for enhanced situational awareness in military operations, and the adoption of IoT-enabled sensor networks. The North American region is projected to lead the market, followed by significant contributions from other regions with strong aerospace industries.

As the market continues to evolve, companies will focus on innovation, strategic partnerships, and the development of advanced sensor technologies to meet the growing demands of the aviation industry. The future of the Aircraft Sensors Market looks promising, with advancements in technology and increasing adoption of smart sensing solutions driving its expansion.

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America's best management consulting firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

Earlier this year, we formally transformed into one of America's best management consulting firms as per a survey conducted by Forbes.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines - TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we work with several Forbes Global 2000 B2B companies - helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, and facilitates analysis of interconnections through applications, helping clients look at the entire ecosystem and understand the revenue shifts in their industry.

To learn more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact: Mr. Aashish Mehra MarketsandMarkets™ INC.

630 Dundee Road Suite 430 Northbrook, IL 60062 USA: +1-888-600-6441

Email: [email protected] (Image Credit: Robotics and Automation News)

#Aircraft Sensors#Aircraft Sensors Market#Aircraft Sensors Industry#Global Aircraft Sensors Market#Aircraft Sensors Market Companies#Aircraft Sensors Market Size#Aircraft Sensors Market Share#Aircraft Sensors Market Growth#Aircraft Sensors Market Statistics

0 notes

Text

Calibration Services

covering disciplines as below:

Discipline

Parameters / Instruments taken up for Calibration

Electro-Technical

AC Voltage/AC Current/ DC voltage/ DC Current/ Resistance/Low Resistance/Temp. Simulation (Indicator/Controller)/Frequency/Timer/Stop Watch/ Active Power/Capacitance/AC Power Energy Single/Three Phase Active/Power Factor/Inductance/High Voltage(0-100KV)/Tan Delta

Thermal & Relative Humidity

Black Body Source/IR Thermal Imager / IR Thermometer/Infrared Temp. Sensor/ Contactless Temp. Sensor/Transmitter/Thermal Imaging/Camera/IR Gun/Radiation Pyrometer/IR Detector/Thermal Imager/Laser Pointed/IR Pyrometer/Temp. Indicator of Freezers/Oven/Environment Chamber/Incubator/Liquid Bath/ Dry Block Furnace/Metrology Well/Dry Block Calibrators/Muffle Furnace/BOD Incubator/Temp. Transmitter RTD’s Thermocouples /Glass Thermometer/Temp. Switch/Data Logger/Temp. Gauge/Thermal Mapping(Multiple Position)/Heating Chamber/Furnaces/Cold Room/Humidity Sensor with Indicator of Humidity Chamber/Climate Chamber/Temp. & Rh sensor with indicator/Thermo-Hygrometer/Data Logger with Internal-External Sensor

Mechanical

Tachometer/Digital Tachometer/Speed Sensor/ RPM Sensor with Indicator/

Centrifuge/Sound Level Meter/Bore Gauge/Coating Thickness Gauge/Dial Gauge/Plunger Dial Gauge/Dial Thickness Gauge/ External Micrometer/

Plunger Dial/Micrometer Head -L.C0.0001 mm/Inside Dial Caliper/Inside Pistol Caliper/Internal Micrometer/Magnetic V Block/Foils/Feeler Gauge/Height Gauge/Mould Cube/Snap Gauge/Test Sieves/Thread measuring pins/Ultrasonic Thickness Gauge/Vernier Caliper/Bevel Protractor/Combination set/Digital Angle Protractor/Cylindrical Measuring pins/ Comparator Stand/Depth Caliper/Depth Micrometer/ Elongation Index/Flakiness Index Apparatus/Plain Gauge/Steel Scale/Wheel Distance Gauge/Measuring Tape/Laser Distance Meter/Length Bar/Micrometer Setting Rod/Micrometer Extension Rod/Riser Rod/Height Setting Master/Outside Pistol Caliper/Outside Caliper Gauge/Caliper Checker/Step Gauge/Electronic Probe/Digimatic Indicator/LVDT-0.0001mm/Plunger Dial/Rubber Hardness Tester/Pressure Gauge/Vacuum Gauge/Pressure Transmitter/Pressure Transducer/Torque Wrench/Bench Centre/Surface Plate/Profile Projector/Surface Roughness Tester/ Weighing Balance

We prioritize customer satisfaction and strive to deliver exceptional service with fast turnaround times. Additionally, our competitive pricing ensures that you receive excellent value for your investment and offer onsite calibration services for your convenience.

We would like to invite you to review the attached documents containing our profile, certificates, scope, and additional details. Furthermore, we extend a warm invitation for you to visit our calibration facility. We are eager to collaborate with you and provide our esteemed services.

Please find enclosed the profile and other pertinent details of Quality Calibration Testing Solutions and same can be found on company’s website as below:

If you have any questions or would like to schedule calibration services, please don't hesitate to contact us. We would be delighted to discuss your requirements further and demonstrate how our calibration solutions can benefit your organization.

Thank you for considering our services. We look forward to the opportunity to work with you and deliver our exceptional services.

1 note

·

View note

Text

Unlocking the Potential of Ono Sokki's Linear Variable Differential Transducer (LVDT)

Ono Sokki's Linear Variable Differential Transducer (LVDT) is a versatile sensor used for measuring linear displacement or position. Familiarize yourself with the working principles of LVDT. It consists of a primary coil and two secondary coils. As the core inside the coil moves, the voltage induced in the secondary coils changes proportionally, providing precise position measurements. Proper installation and calibration are crucial for accurate measurements. Follow the manufacturer's guidelines to mount the object securely and align it correctly with the measured object. Ensure that the LVDT is calibrated and zeroed appropriately before use. outputs an AC voltage that needs to be conditioned for further processing. Use a suitable signal conditioning circuit provided by Ono Sokki to amplify and filter the signal, eliminating noise and interference. Process and analyze the data to extract meaningful insights. Depending on your application, you may need to apply filtering techniques, signal averaging, or advanced algorithms to enhance the accuracy and quality of the measurements. Python libraries like NumPy and SciPy can be helpful for signal processing tasks. Process and analyze the data to extract meaningful insights. Depending on your application, you may need to apply filtering techniques, signal averaging, or advanced algorithms to enhance the accuracy and quality of the measurements.

What is an LVDT used for?

Industrial Automation: are used in industrial automation systems for precise positioning and control of machinery and equipment. They provide feedback on linear movements, allowing for accurate monitoring and adjustment of processes.

Quality Control and Metrology: It plays a crucial role in quality control and metrology applications. They are used for measuring dimensions, tolerances, and surface profiles in manufacturing processes, ensuring compliance with specifications, and maintaining product quality.

Material Testing: LVDTs are employed in material testing equipment to measure mechanical properties like strain, compression, or tensile strength. They provide accurate displacement measurements during mechanical testing and analysis.

Geotechnical Engineering: They are used in geotechnical applications to monitor ground movement and deformations. They help in measuring the settlement of structures, analysing soil behaviour, and providing early warnings for potential hazards.

Aerospace and Automotive: they are utilized in the aerospace and automotive industries for various applications, including flight control systems, suspension systems, fuel and hydraulic systems, and position feedback for movable components.

Research and Development: It finds applications in research and development projects across various scientific disciplines. They are used for precise measurements in areas such as material science, robotics, biomechanics, and more.

How does LVDT optimize measurement accuracy and precision for linear gauge sensors?

This is designed with high linearity, ensuring that the relationship between the measured linear displacement and the output voltage is consistent. Linear Gauge Sensor helps minimize measurement errors and deviations, enabling accurate and precise readings.

Excellent Signal-to-Noise Ratio: Provide a high signal-to-noise ratio, reducing the impact of external noise and interference on the measurement signal. This results in cleaner, more reliable data and enhances measurement accuracy.

Temperature Compensation: incorporate temperature compensation techniques. These compensate for temperature variations that can affect the performance of the sensor, ensuring accurate measurements even in changing environmental conditions.

Signal Conditioning: It offers dedicated signal conditioning circuits, or LVDT signal conditioners, to amplify and condition the LVDT output signal. These circuits help to minimize noise, enhance signal quality, and improve measurement accuracy.

Calibration and Linearity Correction: Ono Sokki provides calibration standards and techniques for their LVDTs, allowing users to perform regular calibration procedures. This ensures that it is accurately calibrated and enables correction for any non-linearities in the measurement output, further enhancing accuracy.

Mechanical Stability: They are designed to offer mechanical stability, minimizing mechanical vibrations or instabilities that could introduce measurement errors. Proper mounting and alignment techniques are employed to ensure reliable and repeatable measurements.

Data Acquisition: It can be easily integrated with various data acquisition systems, such as digital mustimeters or dedicated measurement instruments. These instruments offer high-resolution data acquisition capabilities, allowing precise capture of the LVDT output for accurate measurement analysis.

Where is LVDT applicable?

1. Manufacturing and industrial automation

2. Aerospace and defence

3. Automotive Industry

4. Civil Engineering and Structural Monitoring

5. Research and development

6. Medical Devices

7. Geotechnical Engineering

8. Quality Control and Metrology

9. Energy and power generation

Why is LVDT linear?

LVDTs are inherently linear due to their design and operating principles. The linear characteristic of an LVDT refers to its ability to provide a linear relationship between the physical displacement of its core and the output voltage it produces. They are constructed with a symmetrical arrangement of coils and a movable ferromagnetic core. This geometric symmetry ensures that the magnetic field generated by the primary coil is evenly distributed around the core. As a result, the induced voltages in the secondary coils are proportional to the core's position along the axis of motion. It uses a differential output configuration where two secondary coils are wound in opposite directions around the central primary coil. The voltages induced in the secondary coils are out of phase with each other. By taking the difference between these two outputs, a net voltage is obtained that is directly proportional to the core's displacement, resulting in a linear relationship.

Key to Reliable Linear Positioning

Ono Sokki's LVDT offers great potential for unlocking accurate and precise linear measurement capabilities. By understanding the principles of operation, properly installing and calibrating the sensor, implementing effective signal conditioning, and utilizing advanced techniques such as temperature compensation and linearity correction, users can optimize measurement accuracy and precision. It provides dedicated signal conditioning circuits, calibration standards, and expert support to ensure the optimal performance of their LVDTs. Additionally, maintaining mechanical stability, choosing appropriate data acquisition systems, and following quality assurance and maintenance practices contribute to unlocking the full potential. By leveraging the potential, users can obtain reliable and high-quality linear displacement measurements in various applications. Whether it's in manufacturing, automotive, aerospace, or research, the accuracy and precision offered empower users to make informed decisions, monitor critical processes, and achieve desired outcomes. Unlocking the potential involves continuous learning, staying updated with advancements in the field, and seeking support when needed. With proper implementation and utilization, LVDTs can be valuable tools for precise linear measurement and contribute to the success of diverse industries and applications.

For any clarifications or queries, please feel free to contact us:

Mobile: +91-92055-92194 or +91-92055-92195

Email ID: [email protected]

Website: www.onosokki.co.in

0 notes

Text

0 notes

Text

NewTek HAZLOC-Approved LVDTs for Hazardous and Explosive Environments

(NewTek: Pennsauken, NJ) — NewTek HazLoc-approved linear position sensors are certified for safe operation in hazardous locations with explosive gases, vapors, dust and other dangerous substances. Approved by Intertek Testing Laboratories and carrying the ETL mark, the NT-HL-750 LVDTs are intrinsically safe for use in Class I, Zone 0, and Zone 2 areas. These sensors meet stringent standards to…

0 notes

Text

Global Position Transducers Market growth, trend, opportunity and forecast 2023-2030

Position Transducers Market

The Position Transducers Market is expected to grow from USD 1.70 Billion in 2022 to USD 2.60 Billion by 2030, at a CAGR of 5.30% during the forecast period.

Get the sample report: https://www.reliablebusinessinsights.com/global-position-transducers-market-r1297260

Position Transducers Market Size

Position transducers are devices used to measure linear or rotary positions of objects accurately. The global position transducers market research report categorizes the market based on type, including draw wire linear position transducers, incremental encoder, absolute position encoders, inductive proximity sensors, LVDT transducer, linear potentiometer, magnetostrictive transducer, and non-contact or laser linear position sensors. The report also segments the market by application, including metal processing industries, geotechnics, rubber and plastic injection presses, earth-moving and agricultural machines, blowing machines, renewable energies, machines in the automotive sector, pneumatic and hydraulic sensors, and the food industry, and by region, including North America, Asia Pacific, Middle East, Africa, Australia, and Europe. Leading market players include TE Connectivity, Honeywell, Gerfan, Rota Engineering, Novotechnik, Allergo Microsystems, Panasonic, and Qualcomm Technologies. Regulatory and legal factors specific to market conditions are also analyzed in the report.

Position Transducers Market Key Players

TE Connectivity

Honeywell

Gerfan

Rota Engineering

Novotechnik

Position Transducers Market Segment Analysis

One of the latest trends in the Position Transducers market is the integration of sensors with advanced technologies such as IoT and AI. The sensors are designed to capture position, acceleration, and temperature data, which is then analyzed using advanced data analytics tools to provide valuable insights to manufacturers and service providers. Moreover, the miniaturization of Position Transducers is also a major trend in the market, enabling its installation in small and confined spaces.

In conclusion, the Position Transducers market presents various growth opportunities with its wide target market and increasing demand for automation and motion control systems. However, challenges such as high costs and regular maintenance and calibration requirements need to be addressed to ensure a sustainable revenue growth path. By integrating advanced technologies, manufacturers can enhance their product offerings, which could lead to increased market adoption and revenue growth.

This report covers impact on COVID-19 and Russia-Ukraine wars in detail.

KEY PRODUCT APPLICATION COVERED

Metal Processing Industries

Geotechnics

Rubber and Plastic Injection Presses

Earth-Moving and Agricultural Machines

Blowing Machines

KEY PRODUCT TYPES COVERED

Draw Wire Linear Position Transducers

Incremental Encoder

Absolute Position Encoders

Inductive Proximity Sensors

Contact Info:

Krishna Sharma

US:- +1 507 500 7209Email:- [email protected]

0 notes

Text

Linear Variable Differential Transformer (LVDT) Sensors, Global Key Players Rank and Market Share, Top Twelve Companies Hold 39.18% (2022)

Linear Variable Differential Transformer (LVDT) Sensors Market Summary

LVDT is an acronym for Linear Variable Differential Transformer. It is a common type of electromechanical transducer that can convert the rectilinear motion of an object to which it is coupled mechanically into a corresponding electrical signal.

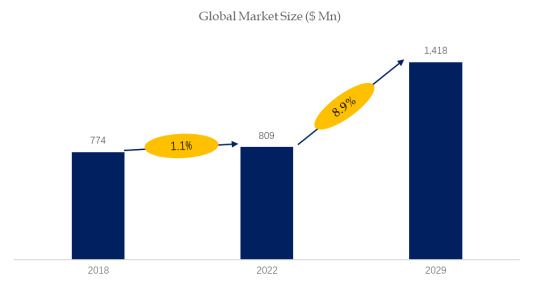

According to the new market research report “Global Linear Variable Differential Transformer (LVDT) Sensors Market Report 2023-2029”, published by QYResearch, the global Linear Variable Differential Transformer (LVDT) Sensors market size is projected to reach USD 1.42 billion by 2029, at a CAGR of 8.9% during the forecast period.

Figure. Global Linear Variable Differential Transformer (LVDT) Sensors Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Linear Variable Differential Transformer (LVDT) Sensors Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

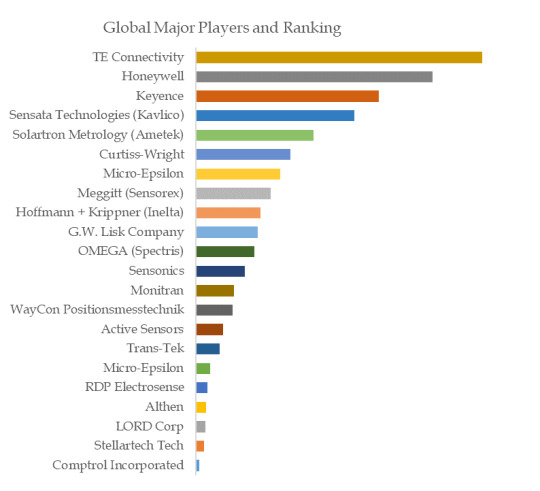

Figure. Global Linear Variable Differential Transformer (LVDT) Sensors Top Twelve Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Linear Variable Differential Transformer (LVDT) Sensors Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Linear Variable Differential Transformer (LVDT) Sensors include Comptrol Incorporated, Stellartech Tech, LORD Corp, Althen, RDP Electrosense, Micro-Epsilon, Trans-Tek, Active Sensors, WayCon Positionsmesstechnik, Monitran, etc.

In 2022, the global top 12 players had a share approximately 39.18% in terms of revenue.

Market Drivers:

1. The product has its own advantages: the LVDT sensor is a non-contact displacement sensor. There is no frictional contact between the coil and the iron core, and no wear will occur. Regardless of the level conversion and conditioning modules, the sensor body is a mechanical structure, which has the advantages of extremely high reliability, high precision, impact resistance and good dynamic performance, and is widely used in industrial and military fields.

2. Demand for industrial automation and smart manufacturing: With the advancement of Industry 4.0 and smart manufacturing, the demand for accurate, stable and reliable displacement measurement increases. LVDT sensors are widely used in automated production lines, due to their high accuracy, durability and wide operating temperature range. It is widely used in robotics, heavy machinery and precision manufacturing.

3. Aerospace and defense industry: In the aerospace and defense industry, precise displacement measurement of key parts of mechanical systems such as engines, flight control systems, missile guidance systems, etc. is crucial. LVDT sensors are used due to their high stability and harsh conditions. It is widely used due to its ability to adapt to the environment.

4. Technological innovation and product upgrades: With the continuous development of LVDT sensor technology, smaller, more efficient, and higher-precision products have emerged, meeting the market's demand for miniaturization and integration, and promoting further expansion of the market.

About The Authors

Analyst: Ran xinrong

Email: [email protected]

Website: www.qyresearch.com Hot Line:4006068865

QYResearch focus on Market Survey and Research

US: +1-888-365-4458(US) +1-202-499-1434(Int'L)

EU: +44-808-111-0143(UK) +44-203-734-8135(EU)

Asia: +86-10-8294-5717(CN) +852-30628839(HK)

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Linear Variable Displacement Transducers Market Consumption Analysis, Business Overview and Upcoming Trends|TE Commectivity, Honeywell, Sensata Technologies (Kavlico), AMETEK, etc

The linear variable displacement transducers (LVDT) market refers to the market for devices that are used to measure linear displacement or position changes. LVDTs are electromechanical devices that convert linear motion into an electrical signal for measurement and control purposes.

LVDTs are widely used in various industries and applications where precise and accurate measurements of linear displacement are required. They consist of a coil assembly and a core that moves within the coil. As the core moves, it induces changes in the output voltage of the coil, which can be measured and converted into a displacement value.

Free Download Link:-https://www.marketinforeports.com/Market-Reports/Request-Sample/342102

The LVDT market is driven by the increasing demand for high-precision measurement and control systems in industries such as automotive, aerospace, manufacturing, healthcare, and robotics. LVDTs offer several advantages over other displacement sensing technologies, including high resolution, excellent linearity, wide measurement range, and long-term stability.

The market for LVDTs is competitive, with several manufacturers offering a wide range of products tailored to different application requirements. LVDTs are available in various sizes, measurement ranges, and mounting options to accommodate different installation and integration needs. Major players in the market include sensor manufacturers, automation solution providers, and specialized LVDT manufacturers.

The LVDT market is influenced by factors such as technological advancements, industry regulations, and the need for accurate position feedback in critical applications. With advancements in LVDT design and manufacturing processes, newer models offer improved performance, higher accuracy, and increased durability.

The market is also driven by the growing trend towards automation and the need for precise positioning and motion control in various industries. LVDTs play a crucial role in automation systems, ensuring accurate feedback for positioning, leveling, and control applications.

Furthermore, the market is impacted by the integration of LVDTs with advanced technologies such as digital interfaces, wireless connectivity, and smart functionalities. This allows for easier integration with control systems, data logging, and remote monitoring, enhancing overall system efficiency and functionality.

As industries continue to demand higher accuracy and reliability in displacement measurement, the LVDT market is expected to witness further advancements. This may include the development of LVDTs with miniaturized form factors, improved resistance to harsh environmental conditions, and enhanced measurement capabilities in extreme temperature or pressure conditions.

In conclusion, the LVDT market caters to the demand for precise and accurate linear displacement measurement in various industries. With their high-resolution measurement capabilities and versatility, LVDTs play a critical role in applications requiring position sensing and control. The market is driven by industry demands for automation, accuracy, and reliability, leading to ongoing technological advancements in LVDT design and integration.

0 notes