#Linear Gauge Sensor

Explore tagged Tumblr posts

Text

Harnessing Ono Sokki's Linear Gauge Sensor for Accurate Data

Precision and reliability are crucial factors in the measurement of displacement, particularly in today's dynamic industrial environment. Our Linear Gauge Sensor are recognized as leading-edge tools for obtaining precise data across diverse applications. Let's explore the exceptional features of these sensors and their effective utilization.

Our device is meticulously engineered to deliver unparalleled accuracy in displacement measurement. The sensor utilize cutting-edge technology to ensure precise readings, making them indispensable in industries where even the slightest deviation can have significant repercussions.

Features of the sensor

High Precision: It's boast high precision, allowing for precise measurement of displacement with minimal margin for error.

Reliability: Built to withstand demanding industrial environments, these sensor offer consistent and reliable performance under various conditions.

Versatility: With a range of models available, Ono Sokki caters to diverse applications, ensuring that there's a sensor suitable for every need.

Digital Interface: The GS series Digital Linear Gauges feature advanced digital interfaces, enabling seamless integration with modern measurement systems.

Applications of the Device

The versatility of the sensor makes it ideal for a wide array of applications across industries. Here are some key areas where these sensor excel:

Manufacturing and Quality Control

In manufacturing processes where precision is paramount, our sensor play a crucial role in ensuring product quality. From automotive to aerospace industries, these sensor help maintain tight tolerances and uphold stringent quality standards.

Automotive Testing

In automotive testing applications, such as chassis testing and suspension analysis, linear variable differential transducer provide precise displacement measurement, enabling engineers to fine-tune vehicle performance and safety parameters.

Research and Development

In research and development environments where innovation thrives on accurate data, further facilitate groundbreaking discoveries by providing researchers with reliable displacement measurements.

Harnessing The Power

To harness the full potential, it's essential to employ best practices in sensor installation, calibration, and data interpretation. Here are some tips for maximizing the effectiveness of these sensor:

Proper Installation

Ensure that the sensor is installed securely and aligned correctly with the target object to obtain accurate measurements consistently.

Calibration

Regular calibration is crucial to maintaining the accuracy of the sensor over time. Follow the manufacturer's guidelines for calibration procedures and frequency.

Data Analysis

Invest in software tools or systems that allow for a thorough analysis of the data collected by the sensor. Extract valuable insights to optimize processes and improve overall efficiency.

Quality Assurance

Ono Sokki's sensor represents the pinnacle of precision and reliability in displacement measurement technology. With their advanced features and versatile applications, these sensor empower industries to achieve new heights of accuracy and efficiency. By harnessing the capabilities of LVDT sensors and implementing best practices, businesses can unlock a world of possibilities and stay ahead in today's competitive landscape.

For any clarifications or queries, please feel free to contact us:

Mobile: +91–92055–92194 or +91–92055–92195

Email ID: [email protected]

Website: www.onosokki.co.in

#Linear Gauge Sensor#LVDT#Linear Variable Differential Transducer#sound level meter#noise level meter#class 2 sound level meter#class 1 sound level meter#db meter#ono sokki india

0 notes

Text

I'm extracting out (and updating) my current hypothesis about what happened with the Titan submersible from my extremely large commentary post (link to its current iteration: https://www.tumblr.com/jackalgirl/762730158416379904/only-one-1-day-behind-now-just-got-done-with?source=share -- I'm very much behind on watching and probably won't catch up until the weekend.

I've attached images, above, which I've taken from Dr. Kramer's presentation on behalf of the NTSB (link to original presentation here: https://media.defense.gov/2024/Sep/25/2003553505/-1/-1/0/CG-107%20NTSB%20TITAN%20MATERIAL%20ANALYSIS.PDF_REDACTED.PDF). Please note that the red circle and "Group 4" annotation on the slide labelled "Strain Gage Response" are from me (they're not in the original presentation).

If I'm reading this correctly (and I might not be), it looks like that at the time of the loud bang, there was a marked increase in strain at the sensor point in the axial (longitudinal, or along the forward/aft axis of the vehicle) direction, and a slightly smaller (but still marked) decrease in strain in the radial (around the right/left, or "starboard/port" as we would say in sailing, circumference of the vehicle).

The other two slides are Dr. Kramer's own visualizations: instead of plotting depth/strain over time as OceanGate had done, he simply focused on depth vs. strain. You can see the difference pre-"loud bang" (which happened on Dive 80) and post-. Instead of being a straight linear increase and decrease, now the gauge is slow to pick up the increase in strain during descent and quick to let it off on ascent.

So I suspect that in Dive 80, the "loud bang" was the sound of the hull delaminating into the three shells Dr. Kramer mentioned in his presentation (layer 1 into shell 1, layers 2/3 into shell 2, layers 4/5 into shell 3), with the most distinct and complete delamination between shell 1 and 2. at least two shells (layer 1 and layers 2-5), or possibly the three layers found in the debris (layer 1 as shell 1, layers 2/3 as shell 2, layers 3/4 as shell 3). I'm thinking that it could have been two shells at the point of the "loud bang" (layer 1 as shell 1, layers 2-5 as shell 2), and that the implosion itself caused layers 2-5 to separate into two distinct shells. But I believe that layer 1 definitely delaminated from the rest and the sound of this happening was the "loud bang".

This seems to make sense with respect to the strain gauge response: suddenly layer 1 is not being compressed by the other layers in the radial direction (less strain), and it's not being supported by the other layers in the axial direction as much, a direction in which the hull is acting like a bridge (it was only supported by the titanium rings at the end, so there would have been considerable stress in the middle since it was a straight line and not an arch, so more strain). I hypothesize that this delamination was most pronounced on the forward end of the hull.

What this tells me is that the strain gauges on layer 1, now separated from the rest of the hull's layers (at least in the forward area of the hull), would not have shown the same strain until the increased pressure (due to depth) had compressed the outer shell(s) enough to start affecting layer 1/shell 1.

I believe that the rubbing noted on shell 1 occurred because the outer two shells (possibly still laminated, so really just two shells at this point maybe) had more freedom to move and were, in fact, moving. This also weakened the epoxy bond between the shells and the forward ring.

On the final dive, the epoxy gave way. This allowed explosive saltwater intrusion into the interstices between the shells, popping them apart, Because the delamination was most pronounced in the forward part of the shell, the carbon fiber there for the most part simply shattered. Larger pieces remained intact in the aft direction. Parts of shell 3 did not delaminate at the adhesive part, but were simply cracked off by the forces being applied from the forward direction.

I'll come back and reassess this hypothesis when the hearings are over (or have reached a point where they have settled on a determination of what happened), and see how closely this allies with the conclusion they reach.

I would be curious to see if there would be any attempt to make a new hull (or at least a section, or "coupon") in the same way as Titan's hull, then put it under pressure and seeing if the layers would pop apart and if they do, what sounds it makes.

13 notes

·

View notes

Text

Dropship Essentials: Power Supplies, Gauges & Pumps

In the rapidly evolving world of industrial automation, having the right foundational components is vital to maintaining operational continuity and optimizing system performance. At Dropship Automation Solutions, we equip industries with critical technologies that ensure precision, reliability, and efficiency.

This blog explores three indispensable elements of modern automation—power supplies, pressure gauges, and pumps—each playing a key role in powering and protecting today’s smart manufacturing systems.

1. Power Supplies: Fueling Automation Reliability

Understanding Power Supplies in Automation

Power supplies convert and regulate electrical energy to ensure that machines and control systems receive consistent and safe power. They are the unseen force keeping automated environments running smoothly.

Types and Applications:

Types: Linear power supplies, switched-mode power supplies (SMPS), uninterruptible power supplies (UPS)

Applications: Control panels, PLC systems, industrial sensors, robotic systems

Advantages: Voltage stability, energy efficiency, circuit protection

Why Power Supplies Matter:

Without a reliable power supply, even the most advanced automation systems can fail. Power supplies prevent system disruptions, reduce equipment damage, and ensure safe, consistent operation.

2. Pressure Gauges: Precision in Process Control

Role of Pressure Gauges in Automation

Pressure gauges are critical for monitoring and maintaining optimal pressure levels in pneumatic and hydraulic systems—helping prevent leaks, system failures, and dangerous over-pressurization.

Key Types and Use Cases:

Types: Analog gauges, digital pressure gauges, differential pressure gauges

Applications: Boilers, HVAC systems, chemical plants, hydraulic equipment

Advantages: Accurate pressure monitoring, real-time alerts, enhanced safety

Why Pressure Gauges Matter:

By providing real-time pressure feedback, these gauges help protect sensitive components, maintain system efficiency, and ensure compliance with safety standards.

3. Pumps: The Flow Enablers of Automation

Pumps in Industrial Automation

Pumps are used to move fluids—whether liquids, gases, or slurries—through systems with precise control. From cooling machinery to transferring chemicals, pumps support countless automation processes.

Types and Industrial Use:

Types: Centrifugal pumps, diaphragm pumps, gear pumps, peristaltic pumps

Applications: Water treatment, lubrication systems, chemical dosing, cooling circuits

Advantages: Reliable fluid transfer, low maintenance, adaptable to diverse industrial environments

Why Pumps Matter:

Pumps ensure that materials are transported efficiently within automation systems. A reliable pump minimizes downtime, enhances productivity, and protects process quality.

Seamless Integration for Maximum Efficiency

Consider the possibilities in a well-orchestrated automation setup where:

Power supplies deliver clean and stable energy,

Pressure gauges continuously monitor and regulate system conditions,

Pumps keep vital fluids flowing without interruption.

This integrated approach enables industries to achieve higher system uptime, safer operations, and measurable cost savings.

Conclusion

As automation continues to shape the future of manufacturing, it's the core components—like power supplies, pressure gauges, and pumps—that provide the foundation for innovation. At Dropship Automation Solutions, we offer a wide range of top-tier components designed for maximum performance and reliability in industrial environments.

Ready to automate smarter? Explore our full product lineup or connect with our experts to design your ideal automation ecosystem.

Contact: +1 (234) 288-1755 Email: [email protected] Location: 1440 W. Taylor St #2555, Chicago, IL 60607

0 notes

Text

Efficient Trapezoidal Screw Production Solutions: Techniques & Technologies

Trapezoidal screws, often used in linear motion systems and mechanical actuators, are critical components in a wide range of industries—from automotive to aerospace and industrial machinery. Known for their robust design and efficiency in converting rotary motion into linear motion, the demand for high-quality trapezoidal screws has significantly grown. As a result, manufacturers are constantly seeking optimized and scalable trapezoidal screw production solutions.

This article covers everything you need to know about producing trapezoidal screws, including materials, machining technologies, threading techniques, quality assurance, and automation trends in 2025.

1. What is a Trapezoidal Screw?

A trapezoidal screw is a type of lead screw with a trapezoid-shaped thread profile, typically conforming to standards like ISO or DIN. Unlike square threads, trapezoidal threads offer better load distribution and are easier to machine, making them ideal for high-load, low-speed applications.

Common Applications:

CNC machine beds

Linear actuators

Presses and lifting devices

Industrial automation systems

2. Choosing the Right Materials

Material selection is crucial for durability, precision, and resistance to wear. Common materials include:

Carbon Steel: Cost-effective and strong, often used with surface hardening.

Stainless Steel: Excellent corrosion resistance, preferred for medical and food-grade applications.

Bronze or Brass: Common for nuts paired with steel screws to reduce friction and galling.

Plastic or Polymer Composites: For low-load, high-speed applications, especially where lubrication is a concern.

Key Considerations:

Operating temperature

Load requirements

Corrosive environments

Maintenance cycles

3. Production Methods and Machining Solutions

a. Turning and Thread Cutting

Traditional lathes and modern CNC turning centers are used for cutting the trapezoidal thread profile.

Single-point threading on CNC lathes ensures precision but is time-intensive.

Thread rolling is a faster, deformation-based process ideal for high-volume production.

b. Thread Milling

Thread milling offers flexibility, especially for internal threads or difficult-to-machine materials. It reduces tool wear and produces cleaner finishes.

c. Grinding and Finishing

Post-threading, precision grinding improves surface quality and dimensional tolerance. Centerless and cylindrical grinding methods are popular for finishing the screw shaft.

4. Thread Standards and Tolerances

Global standards such as ISO 2904, DIN 103, and ANSI/ASME B1.5 define dimensions, tolerances, and profiles for trapezoidal screws. Precision is key, especially in applications where backlash or misalignment can impact performance.

Pitch accuracy and lead deviation must be tightly controlled.

Use of coordinate measuring machines (CMMs) and thread gauges ensures compliance.

5. Heat Treatment and Surface Coatings

To enhance durability and wear resistance, manufacturers often apply:

Case hardening or nitriding

Black oxide coating for mild corrosion resistance

Zinc or nickel plating

Teflon or PTFE coating for smooth motion

Each treatment is selected based on environmental conditions and expected wear cycles.

6. Quality Control and Inspection

Precision is everything. Key quality assurance practices include:

Microscopic inspection of threads

Surface roughness measurement

Load and torque testing

Dimensional accuracy checks with optical comparators

Modern facilities integrate inline sensors and AI-driven quality monitoring systems to flag defects in real-time.

7. Automation in Trapezoidal Screw Production

In 2025, smart manufacturing is transforming screw production. Here’s how:

a. CNC Automation

Automated lathes and thread milling machines minimize human error and increase consistency.

b. Robotic Handling

Collaborative robots (cobots) are used for part loading/unloading, inspection, and material movement.

c. MES Integration

Manufacturing Execution Systems (MES) streamline production planning, track progress, and optimize workflows.

d. Digital Twin Technology

Simulations of production lines and tool paths reduce setup time and improve first-pass yield.

8. Custom Screw Design Capabilities

Many industries require non-standard trapezoidal screws with customized:

Lengths

Thread profiles

Shaft features (flats, keyways, undercuts)

Nut assemblies (anti-backlash, split nuts)

Modern CAD/CAM software enables rapid prototyping and seamless CNC code generation, allowing quick design-to-production cycles.

9. Cost-Saving Strategies

To stay competitive, manufacturers implement the following strategies:

Batch production for economies of scale

Tool wear monitoring to avoid defects

Lean manufacturing principles to reduce waste

Local sourcing of raw materials to minimize delays and cost

10. Sustainability and Environmental Practices

Eco-conscious manufacturing is gaining ground. Companies are:

Using recyclable materials

Recycling cutting fluids and coolants

Installing energy-efficient CNC machines

Adopting green certifications like ISO 14001

Conclusion

The production of trapezoidal screws involves a blend of precision engineering, material science, and modern manufacturing technology. As industries demand more efficient, customizable, and high-performance lead screws, manufacturers must adopt advanced production methods and digital tools to stay ahead.

Whether you’re an established manufacturer or entering the lead screw industry, investing in optimized trapezoidal screw production solutions is key to meeting market expectations in 2025 and beyond.

0 notes

Text

The Essential Guide to Data Acquisition and Signal Conditioning

In today’s data-driven world, industries rely on accurate and reliable data to make informed decisions. Whether in manufacturing, healthcare, or research, data acquisition (DAQ) systems play a crucial role in collecting, analyzing, and interpreting signals from various sources. However, raw signals are often noisy or distorted, necessitating signal conditioning to improve accuracy and reliability. This guide delves into the fundamentals of Data Acquisition and Signal Conditioning, their importance, and how they enhance overall system performance.

What is Data Acquisition (DAQ)?

Data acquisition (DAQ) is the process of collecting and measuring physical or electrical signals from real-world sources such as temperature sensors, pressure transducers, and strain gauges. The primary components of a DAQ system include:

Sensors and Transducers – Convert physical parameters into electrical signals.

Signal Conditioning Units – Process signals to make them suitable for digitization.

Analog-to-Digital Converters (ADC) – Convert analog signals into digital data.

Data Processing and Storage – Processed data is stored or transmitted for analysis.

The Importance of Signal Conditioning

Raw signals from sensors often contain noise, interference, and unwanted fluctuations. Signal conditioning is the process of modifying these signals to improve their quality and accuracy before digital conversion. Key functions of signal conditioning include:

Amplification – Boosts weak signals for better detection.

Filtering – Removes unwanted noise and interference.

Isolation – Protects DAQ systems from high voltage spikes and electrical interference.

Linearization – Corrects non-linear responses from certain sensors.

Multiplexing – Enables multiple signals to be processed through a single channel.

Types of Signal Conditioning Techniques

Different applications require different signal conditioning techniques to ensure high-quality data collection. Some of the most common techniques include:

1. Amplification

Amplifiers enhance low-voltage signals from sensors, making them easier to process. This is particularly useful in applications where signals are weak, such as thermocouple readings or biomedical sensors.

2. Filtering

Filters remove unwanted frequencies and noise from signals. Common filter types include:

Low-pass filters – Remove high-frequency noise while preserving useful low-frequency components.

High-pass filters – Eliminate low-frequency disturbances such as DC offsets.

Band-pass filters – Allow only a specific range of frequencies to pass through.

3. Isolation

Isolation prevents interference and protects sensitive components from high voltage or ground loops. Optical isolation and transformer isolation are commonly used to enhance safety and performance.

4. Linearization

Some sensors, like thermocouples, produce non-linear outputs. Linearization techniques correct these deviations to ensure accurate measurements.

Choosing the Right DAQ System

Selecting the right data acquisition system depends on factors such as:

Type of Sensors – Ensure compatibility with input signals.

Sampling Rate – Determines the speed at which data is collected.

Resolution – Higher resolution leads to more precise data representation.

Connectivity Options – USB, Ethernet, or wireless connectivity for seamless data transfer.

Environmental Conditions – Consider factors such as temperature, humidity, and vibration resistance.

Applications of DAQ and Signal Conditioning

These technologies are used across various industries, including:

Manufacturing – Monitoring equipment performance and process control.

Automotive – Testing vehicle components and performance analysis.

Medical and Healthcare – Biomedical signal monitoring and diagnostics.

Aerospace – Aircraft testing and environmental monitoring.

Research and Development – Experimentation and data analysis.

Conclusion

Data acquisition and signal conditioning are fundamental in ensuring accurate, high-quality data collection for industrial, scientific, and research applications. By understanding the principles and best practices behind DAQ systems, businesses and researchers can make more informed decisions, improve operational efficiency, and enhance system reliability. Investing in a well-optimized DAQ system with proper signal conditioning ensures precise and actionable insights for any application.

0 notes

Text

RTD PT-100: Precision in Temperature Measurement

Temperature measurement is a cornerstone of countless industrial, scientific, and environmental applications. Among the many tools available for accurate temperature sensing, the RTD PT-100 stands out for its precision, reliability, and versatility. This sensor type has become a trusted choice for industries ranging from manufacturing to healthcare, where precise thermal readings are critical.

What is an RTD PT-100?

RTD stands for Resistance Temperature Detector, a device that measures temperature by correlating the resistance of the sensor element with temperature. The PT-100 & Test plug for pressure gauge is a specific type of RTD that uses platinum as its sensing element and has a resistance of 100 ohms at 0°C. Platinum is chosen for its stability, high melting point, and predictable resistance-temperature relationship, making it ideal for accurate temperature measurements.

How Does the RTD PT-100 Work?

The PT-100 operates on the principle that the electrical resistance of a material changes with temperature. As the temperature increases, the resistance of the platinum element in the PT-100 increases in a linear and predictable manner. This relationship is described by the equation:

Rt=R0(1+α⋅T)R_t = R_0 (1 + \alpha \cdot T)Rt=R0(1+α⋅T)

Where:

RtR_tRt is the resistance at temperature TTT.

R0R_0R0 is the resistance at 0°C (100 ohms for PT-100).

α\alphaα is the temperature coefficient of resistance (approximately 0.00385 for platinum).

By measuring the resistance of the sensor, the corresponding temperature can be calculated with high precision.

Key Features of the RTD PT-100

High Accuracy The PT-100 provides exceptional accuracy, often within ±0.1°C, depending on the class of the sensor. This level of precision makes it suitable for critical applications where even minor temperature variations matter.

Wide Temperature Range The PT-100 can measure temperatures from as low as -200°C to as high as 600°C, making it versatile for use in both cryogenic and high-temperature environments.

Stability and Repeatability Platinum’s inherent stability ensures that the PT-100 maintains consistent performance over time. Its repeatability guarantees that measurements remain reliable across multiple uses.

Linear Response The nearly linear relationship between resistance and temperature simplifies calibration and data interpretation, ensuring straightforward integration into monitoring systems.

Durability The PT-100 is designed to withstand harsh environments. With proper housing and protection, it can endure mechanical stress, vibration, and exposure to chemicals or moisture.

Applications of the RTD PT-100

The RTD PT-100 & Glass Tube Thermometer is used in a wide range of industries and applications due to its versatility and reliability.

Industrial Processes In manufacturing, precise temperature control is vital for processes such as metalworking, chemical production, and food processing. The PT-100 ensures accurate monitoring, improving product quality and safety.

HVAC Systems Heating, ventilation, and air conditioning systems rely on PT-100 sensors to maintain optimal temperature conditions, enhancing energy efficiency and comfort.

Medical and Laboratory Equipment In medical devices and laboratory settings, temperature accuracy is crucial for patient care and experimental integrity. PT-100 sensors are used in incubators, sterilizers, and research equipment.

Energy Sector Power plants, especially those using steam turbines, require precise temperature measurements to optimize efficiency and safety. The PT-100 is commonly used in these applications.

Environmental Monitoring For climate studies and environmental monitoring, the PT-100 provides accurate data on temperature variations, contributing to research and policy-making.

Advantages of the RTD PT-100

Precision and Reliability Few temperature sensors can match the accuracy and reliability of the PT-100. Its consistent performance under varying conditions makes it a dependable choice.

Ease of Calibration The linear response of the PT-100 simplifies calibration processes, reducing downtime and maintenance costs.

Compatibility The PT-100 can be integrated with various monitoring and control systems, including programmable logic controllers (PLCs) and digital displays.

Customizable Designs Depending on the application, PT-100 sensors can be customized with different housings, lead wire configurations, and protective coatings.

Limitations of the RTD PT-100

While the PT-100 offers numerous benefits, it is essential to consider its limitations:

Cost Compared to other temperature sensors like thermocouples or thermistors, the PT-100 is relatively expensive. However, its accuracy and longevity often justify the higher initial investment.

Slower Response Time The PT-100 has a slower response time compared to thermocouples, which may be a disadvantage in applications requiring instant temperature changes.

Susceptibility to Lead Wire Resistance Variations in lead wire resistance can affect accuracy, especially in two-wire configurations. This issue can be mitigated by using three-wire or four-wire configurations.

Installation and Maintenance Tips

To ensure optimal performance, proper installation and maintenance are crucial:

Correct Placement Install the PT-100 sensor in a location that represents the actual temperature of the process or environment. Avoid areas with high vibration or mechanical stress unless the sensor is specifically designed for such conditions.

Use Protective Housings In harsh environments, protective housings or thermowells can shield the sensor from physical damage and chemical exposure.

Regular Calibration Periodically calibrate the PT-100 to account for any drift in accuracy over time. This ensures consistent and reliable readings.

Inspect Connections Check the sensor’s connections for wear or corrosion, which can impact performance. Use high-quality connectors and cables for durability.

Conclusion

The RTD PT-100 is a benchmark in temperature measurement technology, offering unparalleled precision, stability, and reliability. Its wide range of applications and adaptability to various conditions make it an indispensable tool across industries. While it may have some limitations, the benefits far outweigh the drawbacks, making it a worthwhile investment for anyone requiring accurate temperature monitoring.

By understanding its working principles, features, and applications, users can harness the full potential of the RTD PT-100 to optimize processes, ensure safety, and achieve superior outcomes in temperature-sensitive operations.

0 notes

Text

How to Maintain and Calibrate a Coordinate Measuring Machine for Optimal Performance

A Coordinate Measuring Machine (CMM) is a vital tool in precision measurement, widely used across industries like aerospace, automotive, and manufacturing to ensure component quality and accuracy. However, to get the most accurate results from a CMM, it’s essential to keep it well-maintained and properly calibrated. Routine maintenance and calibration not only extend the machine’s lifespan but also ensure reliable measurements, enhancing overall production quality. Here’s a guide to maintaining and calibrating your CMM to achieve optimal performance.

1. Understand the Importance of Regular Maintenance

Routine maintenance is crucial for preventing breakdowns and ensuring your CMM remains reliable and accurate. Over time, factors like dust accumulation, wear on moving parts, and fluctuations in temperature can impact the machine's performance. A well-maintained CMM not only improves measurement consistency but also helps avoid costly repairs and downtime.

Common maintenance tasks include cleaning, inspecting key components, and ensuring optimal environmental conditions. By adhering to a regular maintenance schedule, you can keep your CMM in peak condition and avoid measurement inaccuracies.

2. Keep the Machine and Its Surroundings Clean

Keeping the CMM and its surrounding environment clean is one of the simplest yet most effective maintenance steps. Dust, dirt, and debris can accumulate on sensitive parts, such as probes and sensors, leading to measurement errors and damaging the machine over time.

Here are some best practices for maintaining a clean environment:

Dusting and Wiping: Regularly dust the machine’s frame and base and use lint-free wipes to clean sensitive components.

Clean Probes and Styli: Clean probes and styli with approved cleaning solutions, taking care not to scratch or damage them.

Maintain a Controlled Environment: CMMs are highly sensitive to environmental changes. Place the machine in a temperature- and humidity-controlled room to avoid issues caused by fluctuations that can affect accuracy.

3. Inspect and Lubricate Moving Parts

Regularly inspecting and lubricating moving parts, such as guideways, bearings, and linear scales, helps to prevent wear and ensures smooth operation. Most manufacturers recommend specific types of lubricants to use for CMMs, so it’s important to follow these guidelines precisely to avoid damaging the machine.

Inspecting for signs of wear or damage in critical areas, such as the probe head and bearings, is also essential. If any parts show signs of excessive wear, it’s best to replace them promptly to prevent further damage or inaccuracies.

4. Check and Calibrate Probes

Probes are the core measurement tools of a CMM, and their accuracy is paramount. Over time, probes can drift due to mechanical wear or external impact. Regularly checking and recalibrating probes ensures they provide accurate readings.

Here’s how to maintain and calibrate your CMM probes:

Run a Probe Qualification: Run a probe qualification program to confirm that it is functioning within acceptable tolerances.

Replace Worn Styli: Inspect the stylus tip for wear or damage and replace it as needed, as even small imperfections can affect measurement accuracy.

Regularly Calibrate Probes: Calibrate the probe regularly, especially after any impact or when changing probe configurations. This helps reset the reference points and maintains measurement accuracy.

5. Calibrate Your CMM Regularly

Calibration is essential for ensuring that the CMM consistently produces accurate measurements. Calibration involves verifying and adjusting the machine's accuracy against a known standard. Most manufacturers recommend calibrating your CMM at least once a year, though high-precision applications may require more frequent calibration.

Calibration can be performed by:

Using Certified Calibration Tools: Certified artifacts, such as gauge blocks or ball bars, are used to check and adjust the CMM’s accuracy against standardized dimensions.

Engaging Professional Calibration Services: Many companies prefer professional calibration services, as certified technicians use specialized equipment to ensure the machine meets industry standards and compliance requirements.

6. Monitor Environmental Conditions

Environmental factors, such as temperature, humidity, and vibrations, can significantly affect the performance of a CMM. Ensuring a stable environment is essential for maintaining calibration accuracy and reducing measurement drift.

Here are some tips to maintain a controlled environment for your CMM:

Temperature Control: Keep the room at a consistent temperature, ideally between 20-22°C (68-72°F), as recommended by most manufacturers. Sudden temperature changes can cause material expansion or contraction, impacting measurement results.

Vibration Reduction: Avoid placing the CMM near heavy machinery or other sources of vibration. Excessive vibrations can disrupt the machine’s sensitive components, leading to inaccurate readings.

Humidity Control: High humidity can lead to condensation, which can affect sensitive electronic components. Maintaining moderate humidity levels (typically 45-55%) helps prevent moisture buildup.

Conclusion

Proper maintenance and regular calibration are essential for keeping a Coordinate Measuring Machine in peak condition. By implementing regular cleaning, inspection, probe maintenance, and environmental monitoring, you can ensure the longevity and accuracy of your CMM. Whether you’re using it for quality control, product development, or precision manufacturing, a well-maintained CMM supports reliable and accurate measurements, which are crucial for maintaining high-quality standards in any industry.

0 notes

Text

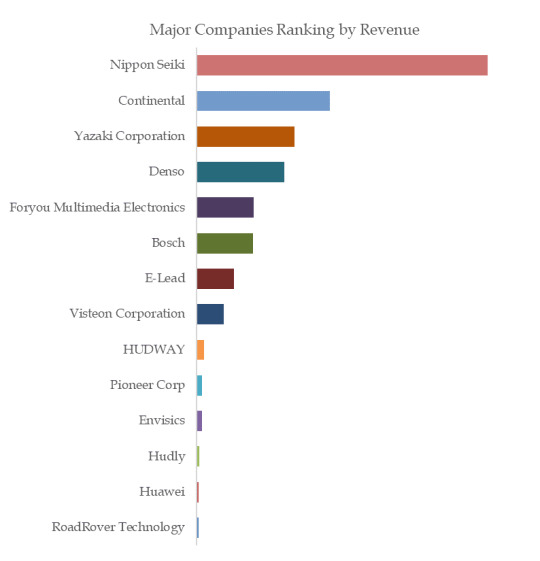

Global Top 14 Companies Accounted for 67% of total Head-Up Display market (QYResearch, 2021)

Head-up Display (HUD) is a digital transparent image that displaying the same information you would get from the dashboard. This can include everything from your current speed to the revs on your engine, and even various temperature gauges.

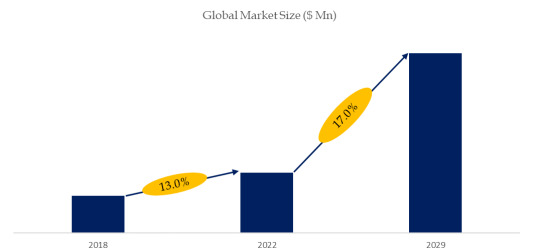

According to the new market research report “Global Head-Up Display Market Report 2023-2029”, published by QYResearch, the global Head-Up Display market size is projected to reach USD 4.04 billion by 2029, at a CAGR of 17.0% during the forecast period.

Figure. Global Head-Up Display Market Size (US$ Million), 2018-2029

Figure. Global Head-Up Display Top 14 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Head-Up Display include Nippon Seiki, Continental, Yazaki Corporation, Denso, Bosch, Visteon Corporation, E-Lead, Foryou Multimedia Electronics, Huawei, HUDWAY, etc.

In 2022, the global top five players had a share approximately 67.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

China supplier MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B power plant spare parts

China supplier MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B power plant spare parts Sold by YOYIK. Deyang YOYIK is a professional production, development, sale of power plant dedicated spare parts and accessories processing company. Through more than 20 years of efforts, the majority of customers have been fully recognized. Limited space, and look forward to your calls for consultation, we will sincerely for your service, your satisfaction is our greatest comfort! Yoyik can offer many spare parts for power plants as below: #DF-MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B-DF Signal Converter ADAM4520 Magnetic Proximity Sensors DF2018 Analog Linear Displacement Sensor ZDET-20B Shaft Speed Sensors CS-1-G-100-05-00 Digital display AC ammeter PA194I-3X1 rpm sensor indicator G-065-05-01 Magnetic Pick-up Speed Sensor DF2012 angular displacement sensor B151.36.09G09 displacement sensor FRD.WJA2.301H lvdt linear position sensor TDZ-1E-31 temperature measurement sensor pt100 WZP2-014s PT100 2M lvdt transducer displacement LVDT-400-6 rtd cable WZPK-646 displacement transducer TDZ-1E-32 rotation sensor D-100-02-01 lvdt transducer displacement HL-3-100-15 LVDT Displacement Transducer Sensors B151.36.09.04.15 thermocouple machine WRN-332NM rtd probe WZPM2 lvdt full form B151.36.09G32 Platinum Thermocouple Wire WRN2-630 LX1=225*76 rpm speed meter DF9011-B dc speed control sensor G-090-02-01 replace thermocouple WRN2-239 0-600℃ linear variable displacement transducer B151.36.09G08 full form of lvdt ZDET1000B pressure switch black 396725-LKTS16 speed meter sensor HZSP-475-50-10-HL celsius thermometer WSS-461 0~350℃ non-contact displacement sensor ZD-7000TDB oil pressure sensor SPB424BXCC RPM Sensor magnetic GSH5 RPM Sensor magnetic CS-1 L=100 Thermocouple Type-K TE-109 tachometer price DF9011-B Type K Thermocouple Cartridge WRNKB-446S/TG MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B rtd cable WZP-201 LVDT Position Sensors K156.36.06.004 vacuum pressure gauge 1201901 lvdt 20mm sensor LVDT-35-3 furnace thermocouple TE-305 Rotary Torque Sensor ZS-02 L=65 element cartridge heaters ZJ-14.5-180 rpm sensor generator DF2018 Surface Thermocouple TC03A2-KY-2B/S13 lvdt-sensor ZDET-25B thermocouples extension lead wires TE-303 linear displacement sensor FRD.WJA2.308 LVDT Position Sensors A191.36.09.03 lvdt 0-300 TDZ-1G-32 pt100 rtd probe thermowell WRNK2 pt100 rtd WZP-221 rotational speed sensor CS-1-G-100-02-01 lvdt displacement transducer B151.36.06(1)G02 thermal resistance tester WZP2M-201 thermocouple k-type WRNK2-294 non-contact displacement sensor TDZ-1E-12 lvdt working principle 400TD non-contact displacement sensor TDZ-1E-22 BENTLY Cable 330130-040-12-00 Tacho RPM sensor CS-3 M16-L60 cartridge heater electric heating heater DJ-22-2/ZBK54019-88 liquid level gauge UTG2005C Displacement sensor 5000TDG 0-250mm LVDT Position Sensors TDZ-1-21 lvdt full form TDZ-1-33 pt100 thermocouple machine WRNK2-292 lvdt displacement sensor inductive sensor HL-6-20-15 thermowell flange TC03A2-KY-2B/S3 Gear speed sensor CS-3-M16-L120 Shaft Rotation Speed Sensors DF6202-005-050-04-00-10-000 lvdt 20mm sensor B151.36.09G42 MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B DFYLSYC-2024-6-17-A

0 notes

Text

Pressure Transmitter: Purpose and Types

The term "pressure transmitter" refers to a pressure sensor instrument that is widely used in industrial and automotive applications that helps detect pressure in fluids, gases, and liquids. They use various techniques to assess the pressure in the equipment to warn about potential disaster circumstances in advance.

A spherical gauge with several colored stripes displays the various pressure levels. These monitor heights, depth, pressure loss, and water flow in conjunction with other equipment to stop leaks in the industrial system.

Purpose of Pressure Transmitter

Numerous industrial applications frequently employ pressure transmitters. Pressure transducers are commonly used in oil exploration and offshore drilling to monitor the differences in numbers between the outside and inside of pressure-sensitive equipment.

Certain metrics must be maintained to guarantee that the gathering and drilling procedure is carried out to ethical and effective standards. The same holds true for onshore petrochemical, gas, and chemical plants. They thereby drastically lower maintenance expenses.

Pressure transmitters can be coupled to other systems, including electrical circuits, making them useful for a variety of applications. Thus, the pressure transmitter market will generate revenue of $4,168.7 million by 2030.

In order to preserve the best possible product condition, many industries utilize pressure-sensitive storage and transport equipment. This equipment must be precisely monitored to ensure safe delivery and ultimate application. Pressure transducers are also used in laboratories to gauge the pressure of the atmosphere in a vacuum chamber, facilitating a wide variety of new research.

Types of Pressure Transmitters

There are four basic categories for pressure transmitters:

Gauge Pressure Transmitter

As the name implies, they gauge pressure and compare it to air pressure. Due to the utilization of liquid and gas, these transmitters are frequently utilized in process industries. Gauge pressure transmitters are an essential part of the business since they need to maintain their pressure under control.

Absolute Transmitters

The pressure in relation to a complete vacuum is measured using these transmitters. In essence, a sealed chamber is used to house the measured medium to generate a reference to an absolute vacuum. Such absolute pressure transmitters are often used in applications requiring a very high degree of precision.

Accuracy of Pressure Transmitters

Pressure transmitters now have a significantly higher degree of precision. A device's accuracy depends on a number of factors, including hysteresis, linearity, and repeatability. Regardless of the kind of equipment and application, these are the top three characteristics of every pressure transmitter. The makers frequently group all of these factors together and display them as a single number.

Differential-Pressure Transmitter

These transmitters are often used to compare various pressure kinds. Both level applications and flow applications are applicable to them. Due to their benefits over competing devices, such transmitters have been employed to monitor flow rates.

Multivariable Pressure Transmitters

When there are several variables involved, these transmitters are employed. Among other things, these factors may include temperature and volumetric flow. These transmitters are frequently employed in businesses that measure steam and gas flow.

Source: P&S Intelligence

#Pressure Transmitter Market Share#Pressure Transmitter Market Size#Pressure Transmitter Market Growth#Pressure Transmitter Market Applications#Pressure Transmitter Market Trends

1 note

·

View note

Text

What Are Solar Power Inverters?

A solar power inverter is one of the key parts of your photovoltaic solar energy system. It turns the direct current (DC) power produced by your solar panels into alternating current (AC) power that you can use in your home or feed back into the grid.

Peak efficiency is an excellent metric to look at, but keep in mind that your inverter won’t always be operating under optimal conditions. Weighted efficiency ratings are a more accurate gauge.

Maximum Power Point Tracking (MPPT)

MPPT, also known as power point tracking or PPT, is a technology that helps solar power inverters panels extract maximum energy from their cells. Essentially it works like a car’s transmission – it automatically adjusts the ratio of speed and torque.

The IV curves (voltage-current) of a PV cell have multiple peaks which move around with varying irradiation, panel temperature and other conditions. An MPPT controller sweeps through these points to find the exact voltage and current that maximizes output.

The key ingredient to an MPPT solar charge controller is the current sensor, which measures the actual amount of current flowing from the PV panel to the battery. This real-time information enables the controller to optimize voltage and current for maximum power. Hall-effect sensors and Rogowski coils are commonly used as they are less expensive than digital microprocessors. There are a few non-digital linear MPPT charge controllers out there but they tend to lose efficiency and aren’t as reliable as digital models.

Efficiency Curves

Inverter efficiency curves provide a good gauge of inverter performance throughout the solar day. They’re a more accurate measure than peak efficiency figures, which don’t take into account the variability of sunshine and environmental factors.

The shape of the efficiency curve will have a significant impact on the optimum inverter size for a PV system, particularly for those with time-of-use electricity pricing plans. For example, an inverter whose efficiency curve drops abruptly at low power levels may need to be oversized, which will result in a significant loss of energy production.

Inverter manufacturers estimate the power conversion efficiency of their devices using a linear model fitted to sensor data. This information is cross-validated against real-time data from the inverters themselves. The resulting reference level of inverter efficiency can be compared to weighted efficiency values, such as those provided by the California Energy Commission. This will help PV system designers identify any inverters that are oversized, potentially saving them money by avoiding the cost of an unnecessary inverter upgrade.

Battery Chargers

The battery charger is a device that charges your solar power storage system's batteries. The charger controls how much current is drawn from the battery and regulates the charge voltage. It is important to make sure the battery charger is rated for your solar energy system's max load and that it is not overloaded.

A string inverter connects groups of solar panels into a single circuit, known as a "string," and converts the DC power produced by the entire string into AC electricity for your home. This is a mature and proven technology and is generally affordable for residential systems. However, a primary drawback is that if one panel is shaded or damaged, it will reduce the performance of the entire string.

A microinverter installed on each individual solar panel allows the solar power inverter to monitor each panel's performance. This is also called MPPT at the panel level. Manufacturers claim this can improve array performance by as much as 5%, especially when shading is present.

Safety

When photons strike solar cells on a panel, they knock electrons loose from the semiconductor wafer, creating an electric current. This current is DC electricity, which won’t work with most home appliances. Solar inverters transform this DC energy into AC electricity that can run your equipment.

Inverters monitor the status of the system and provide information about the efficiency and health of your solar panels. They can also integrate with battery storage solutions to deliver backup power in the event of a grid outage or at night.

As with any electrical component, a solar inverter may pose a risk of shock if improperly used. This is why it’s important to work with certified solar professionals and follow all installation and maintenance guidelines. Fortunately, solar inverters are designed with a variety of safety mechanisms to reduce the risk of injury. This includes insulated enclosures and other protective measures that ensure safe operation. For example, SolarEdge’s Sense Connect and SafeDC technologies have been tested and validated by TNO to meet or exceed global safety standards.

0 notes

Text

Applications of OP07 in Electronics

In the realm of electronics, precision and dependability reign supreme. Engineers and enthusiasts are perpetually in search of components that can elevate the performance of their circuits. Among these, the OP07 operational amplifier has garnered widespread acclaim for its precision and versatility. This article is a journey into the fascinating world of the OP07, unveiling its manifold applications in the realm of electronics.

Unveiling the OP07 Operational Amplifier

Before we embark on exploring the OP07's applications, it's essential to grasp what sets this operational amplifier apart.

What is the OP07?

The OP07 stands as a high-performance operational amplifier celebrated for its remarkable precision and minimal offset voltage. It is a versatile integrated circuit (IC) that finds its utility across a broad spectrum of electronic circuits.

Key Features of the OP07

High Precision: The OP07 boasts an ultra-low offset voltage and minimal input bias currents, rendering it ideal for applications that demand precision.

Wide Operating Voltage Range: This operational amplifier can function within a broad voltage range, making it suitable for both single and dual power supply setups.

Low Noise: With minimal input voltage and current noise, the OP07 ensures pristine and precise signal processing.

High Open-Loop Gain: Its elevated open-loop gain facilitates excellent linearity and stability in amplification tasks.

Now, let's embark on an exploration of the captivating applications of the OP07 operational amplifier in the realm of electronics.

Applications of the OP07

Signal Conditioning: The OP07 is the favored choice for signal conditioning tasks. Its precision and low noise characteristics render it ideal for amplifying and conditioning sensor signals, finding utility in applications like temperature measurement and strain gauge amplification.

Active Filters: In electronic filter design, active filters are pivotal in shaping a circuit's frequency response. The OP07's exceptional performance parameters make it the go-to component for active filter designs, ensuring precise filtering in audio and instrumentation applications.

Voltage References: Precision voltage references hold immense importance in numerous electronic systems. The OP07's stability and minimal offset voltage designate it as an excellent option for crafting accurate voltage references, assuring consistent performance in analog circuits.

Data Acquisition Systems: Data acquisition systems hinge on precise signal processing. The OP07 proves invaluable in data acquisition applications, delivering high precision in amplifying and conditioning analog signals from various sensors.

Instrumentation Amplifiers: Instrumentation amplifiers are indispensable in scenarios where precise measurements are paramount. The OP07, with its low offset voltage and minimal noise, frequently finds its place in instrumentation amplifier configurations for tasks encompassing medical instrumentation and industrial automation.

Active Rectifiers: In the domain of power electronics, active rectifiers come into play for converting alternating current (AC) to direct current (DC). The OP07's rapid response and precision earmark it for designing active rectifiers that offer enhanced efficiency and control.

Audio Applications: Audiophiles cherish the OP07's low noise and fidelity, making it a favored choice for audio amplification and equalization circuits within high-end audio equipment.

Conclusion

The OP07 operational amplifier stands as a versatile and precision-oriented component that has entrenched itself in diverse electronic applications. Its capacity to deliver accuracy and dependability renders it indispensable for both engineers and enthusiasts. Whether your pursuit involves instrumentation, data acquisition, or audio equipment, the OP07 can serve as your steadfast ally, ushering in exceptional outcomes.

So, the next time you embark on an electronics venture demanding precision and reliability, consider the OP07 operational amplifier—you'll find it to be an unwavering companion.

For a deeper dive into technical information and an array of resources on the OP07, access now.

0 notes

Text

A diaphragm formed on a silicon substrate

The specific advantages of using the piezoresistive sensors are high sensitivity, good linearity (at a constant temperature) and ability to track the pressure changes (without any kind of signal hysteresis).Automotive Industry or Applications: One can find the use of piezoresistive sensors in automotive industrial applications like air pressure selection, checking gas level and oil level.. These types of pressure sensors are manufactured with semiconductor technology, which helps them to operate on the resistive principle.

Manufactured with monocrystalline silicon (in a water format) the piezoresistive sensor provides very high mechanical strength and elastic behavior (up to the point of mechanical breakdown).Biomedical Application: Most often one can find the use of piezoresistive sensors in the blood pressure measurement equipment Advantages of Using Piezoresistive Pressure Sensors: The first advantage of using piezoresistive sensor- these are a low-cost yet effective sensor that offers fabrication opportunity.

A diaphragm formed on a silicon substrate in a piezoresistive sensor is believed to be, the sensing material that blends with applied pressure and causes a deformation (occurs in the crystal lattice of the diaphragm). No doubt, a competent pressure sensor manufacturer or supplier will provide you the best quality piezoresistive sensor devices at an affordable price. These types of pressure sensors are manufactured Submersible level transmitters with semiconductor technology that normally operates on the resistive principle.

One can experience that the piezoresistive pressure sensors have enabled automatic, precise and low-cost electric compensation of the standard error parameters, as its semiconductor components use the new signal processing techniques. This helps the pressure sensors to exhibit an only minor response to hysteresis and mechanical aging. It is believed that to know the optimal application of these types of pressure sensors, as a user, you need to understand their structure, manufacturing details and properties. Some Specific Application Areas: Advanced Household Appliances: In our daily life, we use many household appliances in which the piezoresistive sensors are sued, such as dishwashers, vacuum cleaners, and washing machines. It is important to get well-designed and durable piezoresistive pressure sensors for your specific application or industry to enjoy the best results by relying on a reliable manufacturer.

One should know that piezoresistive sensors are usable only after undergoing corrections that have been made to offset and for other certain effects, which are induced by their sensitivity to temperature variations and the manufacturing process. This type of resistance change caused in a monocrystalline semiconductor is known as a piezoelectric effect that is believed to be substantially higher than that in the standard strain gauges. This type of deformation leads to a change in the band structure of the piezoresistive sensors to change the resistivity of the material (which normally increases or decreases as per the orientation of the resistors). About Piezoresistive Sensors: In the piezoresistive sensors, we can see the pressure changes the resistance by mechanically deforming the sensor and enables the resistors in a bridge circuit.Has a mature processing technology that helps in suitably adjusting different pressure levels (achieved according to the application).

These days, the piezoresistive pressure sensors are widely used because of their strength and resistance properties. Manufacturing: Manufactured with MEMS technology, the piezoresistive sensors are used for various applications like the automotive industry, biomedical applications, and household appliances. This helps in making things easy for us and ensures the appliances deliver a top quality service.

1 note

·

View note

Text

Unlocking the Potential of Ono Sokki's Linear Variable Differential Transducer (LVDT)

Ono Sokki's Linear Variable Differential Transducer (LVDT) is a versatile sensor used for measuring linear displacement or position. Familiarize yourself with the working principles of LVDT. It consists of a primary coil and two secondary coils. As the core inside the coil moves, the voltage induced in the secondary coils changes proportionally, providing precise position measurements. Proper installation and calibration are crucial for accurate measurements. Follow the manufacturer's guidelines to mount the object securely and align it correctly with the measured object. Ensure that the LVDT is calibrated and zeroed appropriately before use. outputs an AC voltage that needs to be conditioned for further processing. Use a suitable signal conditioning circuit provided by Ono Sokki to amplify and filter the signal, eliminating noise and interference. Process and analyze the data to extract meaningful insights. Depending on your application, you may need to apply filtering techniques, signal averaging, or advanced algorithms to enhance the accuracy and quality of the measurements. Python libraries like NumPy and SciPy can be helpful for signal processing tasks. Process and analyze the data to extract meaningful insights. Depending on your application, you may need to apply filtering techniques, signal averaging, or advanced algorithms to enhance the accuracy and quality of the measurements.

What is an LVDT used for?

Industrial Automation: are used in industrial automation systems for precise positioning and control of machinery and equipment. They provide feedback on linear movements, allowing for accurate monitoring and adjustment of processes.

Quality Control and Metrology: It plays a crucial role in quality control and metrology applications. They are used for measuring dimensions, tolerances, and surface profiles in manufacturing processes, ensuring compliance with specifications, and maintaining product quality.

Material Testing: LVDTs are employed in material testing equipment to measure mechanical properties like strain, compression, or tensile strength. They provide accurate displacement measurements during mechanical testing and analysis.

Geotechnical Engineering: They are used in geotechnical applications to monitor ground movement and deformations. They help in measuring the settlement of structures, analysing soil behaviour, and providing early warnings for potential hazards.

Aerospace and Automotive: they are utilized in the aerospace and automotive industries for various applications, including flight control systems, suspension systems, fuel and hydraulic systems, and position feedback for movable components.

Research and Development: It finds applications in research and development projects across various scientific disciplines. They are used for precise measurements in areas such as material science, robotics, biomechanics, and more.

How does LVDT optimize measurement accuracy and precision for linear gauge sensors?

This is designed with high linearity, ensuring that the relationship between the measured linear displacement and the output voltage is consistent. Linear Gauge Sensor helps minimize measurement errors and deviations, enabling accurate and precise readings.

Excellent Signal-to-Noise Ratio: Provide a high signal-to-noise ratio, reducing the impact of external noise and interference on the measurement signal. This results in cleaner, more reliable data and enhances measurement accuracy.

Temperature Compensation: incorporate temperature compensation techniques. These compensate for temperature variations that can affect the performance of the sensor, ensuring accurate measurements even in changing environmental conditions.

Signal Conditioning: It offers dedicated signal conditioning circuits, or LVDT signal conditioners, to amplify and condition the LVDT output signal. These circuits help to minimize noise, enhance signal quality, and improve measurement accuracy.

Calibration and Linearity Correction: Ono Sokki provides calibration standards and techniques for their LVDTs, allowing users to perform regular calibration procedures. This ensures that it is accurately calibrated and enables correction for any non-linearities in the measurement output, further enhancing accuracy.

Mechanical Stability: They are designed to offer mechanical stability, minimizing mechanical vibrations or instabilities that could introduce measurement errors. Proper mounting and alignment techniques are employed to ensure reliable and repeatable measurements.

Data Acquisition: It can be easily integrated with various data acquisition systems, such as digital mustimeters or dedicated measurement instruments. These instruments offer high-resolution data acquisition capabilities, allowing precise capture of the LVDT output for accurate measurement analysis.

Where is LVDT applicable?

1. Manufacturing and industrial automation

2. Aerospace and defence

3. Automotive Industry

4. Civil Engineering and Structural Monitoring

5. Research and development

6. Medical Devices

7. Geotechnical Engineering

8. Quality Control and Metrology

9. Energy and power generation

Why is LVDT linear?

LVDTs are inherently linear due to their design and operating principles. The linear characteristic of an LVDT refers to its ability to provide a linear relationship between the physical displacement of its core and the output voltage it produces. They are constructed with a symmetrical arrangement of coils and a movable ferromagnetic core. This geometric symmetry ensures that the magnetic field generated by the primary coil is evenly distributed around the core. As a result, the induced voltages in the secondary coils are proportional to the core's position along the axis of motion. It uses a differential output configuration where two secondary coils are wound in opposite directions around the central primary coil. The voltages induced in the secondary coils are out of phase with each other. By taking the difference between these two outputs, a net voltage is obtained that is directly proportional to the core's displacement, resulting in a linear relationship.

Key to Reliable Linear Positioning

Ono Sokki's LVDT offers great potential for unlocking accurate and precise linear measurement capabilities. By understanding the principles of operation, properly installing and calibrating the sensor, implementing effective signal conditioning, and utilizing advanced techniques such as temperature compensation and linearity correction, users can optimize measurement accuracy and precision. It provides dedicated signal conditioning circuits, calibration standards, and expert support to ensure the optimal performance of their LVDTs. Additionally, maintaining mechanical stability, choosing appropriate data acquisition systems, and following quality assurance and maintenance practices contribute to unlocking the full potential. By leveraging the potential, users can obtain reliable and high-quality linear displacement measurements in various applications. Whether it's in manufacturing, automotive, aerospace, or research, the accuracy and precision offered empower users to make informed decisions, monitor critical processes, and achieve desired outcomes. Unlocking the potential involves continuous learning, staying updated with advancements in the field, and seeking support when needed. With proper implementation and utilization, LVDTs can be valuable tools for precise linear measurement and contribute to the success of diverse industries and applications.

For any clarifications or queries, please feel free to contact us:

Mobile: +91-92055-92194 or +91-92055-92195

Email ID: [email protected]

Website: www.onosokki.co.in

0 notes

Photo

LittleDog by Boston Dynamics (2009). This DARPA funded dog was developed specifically as a platform for research on legged locomotion and learning by Universities. LittleDog has four legs, each with three actuated degrees of freedom, strong enough for walking and climbing. Each lower leg is passively compliant with 1.0 cm of travel and includes a linear potentiometer for measuring its length. It has position sensors on each degree of freedom, an inertial measurement unit, and foot-force sensors to sense body kinematics, inertial and gravitational forces. Strain gauges detect touchdown events and provide measurements of the interaction forces between the robot and the environment. Quadruped robots can be very stable on uneven terrain, as shown in this video, where a static gait keeps its centre of gravity inside a supporting triangle composed of three standing feet. Cute or creepy? The jury is still out.

2 notes

·

View notes

Text

RTD PT-100 and Syphon: Precision and Protection in Industry

RTD PT-100 and Syphon: Essential Components in Industrial Temperature Measurement

In modern industrial environments, precise temperature measurement is critical for maintaining operational efficiency, ensuring product quality, and safeguarding equipment. Among the most commonly used devices for accurate temperature sensing are RTDs (Resistance Temperature Detectors), particularly the PT-100 type, which is known for its reliability and precision. Additionally, another key component used in temperature measurement systems is the syphon, which helps protect sensitive instruments from high temperatures and pressure surges. This article delves into the importance of RTD PT-100 sensors and syphons, highlighting their roles and applications in industrial temperature measurement.

What is an RTD PT-100?

An RTD PT-100 is a type of temperature sensor that operates on the principle of resistance change with temperature. Specifically, PT-100 refers to a platinum-based sensor that has a resistance of 100 ohms at 0°C. As the temperature increases, the resistance of the platinum element increases in a predictable manner. This property makes platinum an ideal material for precision temperature measurement due to its stable and linear resistance-to-temperature relationship over a wide range.

Key Features of PT-100 RTDs:

Accuracy: PT-100 sensors are highly accurate, with an accuracy typically ranging from ±0.1°C to ±0.5°C, depending on the class and design.

Temperature Range: These sensors can measure temperatures from -200°C to +850°C, making them versatile for various applications.

Stability: Platinum’s resistance properties are stable over time, ensuring long-term reliability and repeatability in measurements.

Linear Response: PT-100 sensors provide a nearly linear response to temperature changes, simplifying calibration and interpretation of results.

Durability: Platinum is a robust material that can withstand harsh environments, including extreme heat, cold, and corrosive conditions.

Applications of PT-100 RTDs:

RTD PT-100 sensors are widely used in industries such as chemical processing, oil and gas, food and beverage, pharmaceuticals, and HVAC (Heating, Ventilation, and Air Conditioning) systems. They are commonly installed in reactors, boilers, pipelines, and other critical equipment where temperature monitoring is essential for maintaining product quality, safety, and energy efficiency.

The Role of a Syphon in Temperature Measurement

A syphon is a protective device used in conjunction with pressure gauges, sensors, and other instruments to shield them from extreme temperatures and pressure fluctuations. In temperature and pressure measurement applications, syphons are often installed between the process line and the measurement instrument, acting as a barrier that prevents direct exposure to hot steam or fluids.

How a Syphon Works:

The syphon typically consists of a coiled or looped tube that traps a small amount of the process fluid (usually steam or gas) as it enters the system. This trapped fluid cools down in the tube, preventing the hot steam or gas from reaching the sensitive measuring instrument. By doing so, the syphon prolongs the lifespan of the instrument and ensures accurate readings even in high-temperature environments.

Key Benefits of Using a Syphon:

Instrument Protection: By isolating sensitive equipment from hot steam and pressure surges, syphons prevent damage to RTDs, thermometers, pressure gauges, and transmitters.

Improved Accuracy: Instruments that are protected from extreme conditions provide more reliable and consistent measurements.

Extended Lifespan: Syphons help reduce wear and tear on temperature sensors and pressure gauges, extending their operational life and reducing maintenance costs.

Versatility: Syphons can be used with a wide range of instruments, making them suitable for applications in industries such as power generation, oil refining, chemical production, and HVAC systems.

Combining RTD PT-100 and Syphon for Optimal Temperature Measurement

When used together, the RTD PT-100 and syphon offer a robust solution for accurate and reliable temperature measurement in demanding industrial environments. The PT-100 provides precise temperature readings, while the syphon protects the sensor from potential damage caused by high temperatures and pressure fluctuations. This combination is especially useful in steam applications, such as boilers and turbines, where both temperature and pressure can reach extreme levels.

Conclusion

In conclusion, the RTD PT-100 and syphon are indispensable components in industrial temperature measurement systems. While the PT-100 ensures accurate and stable temperature readings, the syphon provides crucial protection against high temperatures and pressure surges. Together, these components enable industries to maintain safe and efficient operations, reduce maintenance costs, and ensure the longevity of their equipment.

0 notes