#lithium ion Battery

Explore tagged Tumblr posts

Text

[In February, 2023], a small warehouse in the English city of Nottingham received the crucial final components for a project that leverages the power of used EV batteries to create a new kind of circular economy.

Inside, city authorities have installed 40 two-way electric vehicle chargers that are connected to solar panels and a pioneering battery energy storage system, which will together power a number of on-site facilities and a fleet of 200 municipal vehicles while simultaneously helping to decarbonize the UK’s electrical grid.

Each day Nottingham will send a combination of solar-generated energy — and whatever is left in the vehicles after the day’s use — from its storage devices into the national grid. The so-called “vehicle to grid” chargers deliver this energy just when it’s needed most, during peak evening demand, when people are home cooking, using hot water or watching TV. Later, the same chargers pull energy from the grid to recharge the vehicles in the wee hours of the night, when folks are sleeping and electricity is cheaper and plentiful.

“We are trying to create a virtual power station,” says Steve Cornes, Nottingham City Council’s Technical Lead. “The solar power and battery storage will help us operate independently and outside of peak times, making our system more resilient and reducing stress on the national grid. We could even make a profit.” ...

After around a decade, an EV battery no longer provides sufficient performance for car journeys. However, they still can retain up to 80 percent of their original capacity, and with this great remaining power comes great reusability.

“As the batteries degrade, they lose their usefulness for vehicles,” says Matthew Lumsden, chairman of Connected Energy. “But batteries can be used for so many other things, and to not do so results in waste and more mining of natural resources.”

The E-STOR hubs come in the form of 20-foot modular containers, each one packed with 24 repurposed EV batteries from Renault cars. Each hub can provide up to 300kW of power, enough to provide energy to dozens of homes. One study by Lancaster University, commissioned by Connected Energy, calculated that a second life battery system saved 450 tons of CO2 per MWh over its lifetime...

Battery repurposing and recycling is set to play a massive role over the coming years as the automobile industry attempts to decarbonize and the world more broadly attempts to fight waste. The production of EVs, which use lithium-ion batteries, is accelerating. Tesla, for example, is aiming to sell 20 million EVs per year by 2030 — more than 13 times the current level. In turn, 12 million tons of EV batteries could become available for reuse by 2030, according to one estimate.

“Over the next decade we are going to see this gigantic wave,” says Jessica Dunn, a senior analyst at the Union of Concerned Scientists. “Companies are recognizing this is a necessary industry. They need to ramp up infrastructure for recycling and reuse.”

-via Reasons to Be Cheerful, March 13, 2023

#ev#ev charger#electric vehicle#electric cars#batteries#battery recycling#lithium ion battery#auto industry#sustainability#circular economy#recycling#reuse#uk#nottingham#england#good news#hope

217 notes

·

View notes

Text

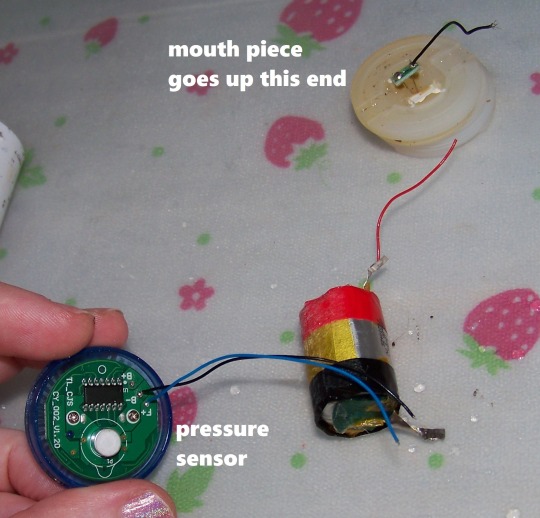

A few more photos to explain how badly designed a cheap vape pen is.

First off the pressure sensor that activates the heat for the vapour is very sensitive, it's at the opposite end to your mouth, once dropped and broken open - as this one was - just gentle pressure on the white button activates the heating element (and some LEDs).

Then you've got this hell battery.

A well-designed lithium-ion battery looks a lot like the Energizer one: a solid metal casing, caps at either end to stop electrical overload underneath the casing, if you sawed open the casing (basic wire cutters or a hand saw would take you at least 10-20 minutes to get into it) there'd be the densely wrapped "jelly roll" of graphite on thin plastic layers drenched in solvents like you can see in the next to last photo (I pried open the foil - don't do this).

This battery is not only barely covered with some tape and foil, it has metal bits going right into it, where the solvents can wick out or water can wick in. The solvents smell like nail polish remover (not quite like pure acetone, sweeter). They're toxic in high doses, in water or in an enclosed space but they're not the primary danger.

The stuff in the densely packed layers likes to ignite, violently, when in contact with the water in air. If you toss water on it or it gets waterlogged: the fire gets worse. Now imagine it gets crushed in the rubbish compactor and the firefighters get out the hose.

This uncased battery design will probably not stay legal for long but until legislation kicks in: if you see dropped or binned vape pens, bag them or put them in a pocket without other items (don't open them up like this idiot) and take them to any battery deposit place: your local supermarket should have special drop off bins.

7 notes

·

View notes

Text

youtube

How We Will Be Growing Batteries - Wood Battery Explained. With the ever-growing demand for electrifying everything, we need more sustainable and renewable batteries. Lithium ion batteries are cost-effective but rely on lithium, graphite, and other materials, whose sourcing has significant environmental and social impacts. One potential solution is being developed where wood is used to replace these materials with a bio-based, renewable alternative. So, would wood work or is it just… deadwood…?

Watch How Solar Panels Can Help Solve California’s Drought https://youtu.be/pCRX232VkBk?list=PLn...

Video script and citations:

https://undecidedmf.com/how-we-will-b...

Follow-up podcast:

Video version - https://www.youtube.com/channel/UC4-a...

Audio version - http://bit.ly/stilltbdfm

#undecided with matt ferrell#solarpunk#batteries#wood#plants#wood batteries#Lithium ion batteries#lithium ion battery#lithium battery#sustainability#Youtube

6 notes

·

View notes

Text

Can Lithium Ion Batteries Leak?

Lithium ion batteries are highly efficient energy storage devices, and they have revolutionized industry in many ways. It is important to understand the potential risks associated with these batteries, including their propensity for leaking.

Leaking of a battery can be caused by several factors, such as overcharging or prolonged use at high temperatures.

When lithium ions escape from the cells, they may cause damage to surrounding objects or people.

The good news is that modern lithium-ion batteries are designed with safety features that help reduce the chance of leakage occurring.

These include temperature sensors that cut off charging if it reaches an unsafe level and pressure valves that act as a release mechanism should too much gas build up inside the cell.

Additionally, manufacturers typically provide warning labels on products containing lithium-ion batteries informing users about proper usage and cautioning against overcharging or exposing them to excessive heat.

By following these guidelines, the risk of leaking can be greatly reduced.

2 notes

·

View notes

Video

youtube

Battery grid production

Click through to learn more about our products : https://orifeenergy.en.alibaba.com/productlist.html?spm=a2700.shop_index.88.14 As one of the biggest battery manufacturer in Guangdong province,we have 8 years experience in exporting business.The absolute advantage as follows

1. Multiple products for available: All kinds of type and capacity to meet different customer requirments.which lead acid type ups battery ,car battery ,motocycle ,traction battery,golf battery.Lithium type solar battery ,car battery ,motorcycle battery.

2. High performance:1)After 3 months storage,the remaining capacity still up to 94% .2)With 15 years designed floating life(20℃).3)Adaption with extreme temperature from -22℃-55℃.4)Stringing Walls Technology will let the transport more safer.No acid leakage.

3. Quality guarantee:3 years warranty for back up power,If there are any defective products,we will replace new one with next shipment.

4. Superior service:Support OEM/ODM.Free for designing the silk-printing and packing,MOQ 100PCS .(On and beyond 12V100AH) We sincerely hope to have an chance to be service you.

#youtube#battery#batteries#gel battery#lead acid battery#lithium ion battery#carbattery#motorcyclebattery#solar battery#agm battery#ups battery

2 notes

·

View notes

Text

Lethex Lithium-ion Batteries

Lithium-ion NMC

NMC batteries offer a combination of nickel, manganese, and cobalt. They are also called lithium manganese cobalt oxide batteries. Lethex manufacturers cutting-edge lithium ion batteries, that are superior in performance, robust and increases product lifecycle. Lithium ion batteries are far better in terms of usability, offers better capacity and performance, efficient and smaller in size as compared to conventional and traditional acid batteries.

These batteries are manufactured under controlled environment in state of the art manufacturing facility. Lithium ion batteries are used for diverse applications right from electric mobility to power tools.

Lithium-ion Phosphate

LFP batteries use phosphate as a cathode material. An important factor that makes LFP stand out is its long life cycle. Lethex offer LFP batteries with a life of 6 years. Often seen as a better choice for stationery applications, ranging from energy storage to mobile phones. The LFP is widely considered a better choice for solar cell storage.

These batteries are manufactured under environment in state of the art manufacturing facility.

#lethex#lithium#battery#lithium ion battery#lithium iron phosphate battery#lithium cobalt oxide battery#batteries

2 notes

·

View notes

Text

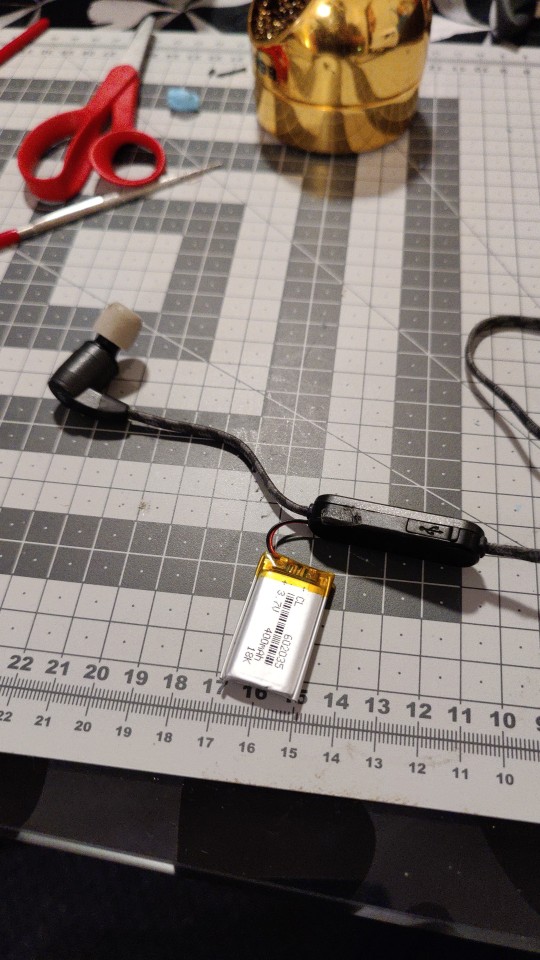

Swapping a large battery on one of those annoyingly wimpy 3 hour battery life earbuds, still many ways to critically blunder the operation

2 notes

·

View notes

Text

DO NOT USE A PYREX CONTAINER UNLESS THE 'PYREX' LOGO IS IN ALL CAPS.

If it says 'pyrex' in all lowercase, the glass is not tempered borosilicate, and WILL shatter when exposed to temperature differences!

youtube

Unless it says 'borosilicate' somewhere on the item, do not use glass cookware to contain a Li Ion battery! When this shatters, it will scatter burning chemicals and hydrogen all over the place and burn your house down!

114K notes

·

View notes

Text

Best Lithium Ion & E-cycle Lithium Battery Manufacturer | MaxVolt Energy

Best Lithium Battery in India: A Game-Changer in Energy Storage Solutions

In recent years, the demand for lithium batteries has skyrocketed in India, driven by the rapid adoption of electric vehicles (EVs), renewable energy systems, and portable electronic devices. Known for their efficiency, durability, and eco-friendliness, lithium batteries have emerged as a preferred choice for individuals and industries alike. Among the myriad of options available, choosing the best lithium battery in India requires careful consideration of quality, performance, and customization options offered by the manufacturer.

The Rise of Lithium Battery Manufacturers in India

India is witnessing a transformative shift in its energy landscape, with numerous lithium battery manufacturers stepping up to meet the growing demand. These manufacturers cater to diverse industries, providing solutions for electric vehicles, solar energy storage, industrial applications, and more. One of the key aspects that set the best manufacturers apart is their ability to deliver customized battery solutions tailored to specific needs.

Whether it’s a high-capacity battery for solar energy storage or a lightweight E-cycle lithium battery, customization ensures that the batteries perform optimally in their intended applications. This flexibility has been instrumental in boosting the adoption of lithium batteries across various sectors in India.

Why Choose Lithium-Ion Batteries?

Among the different types of lithium batteries available, lithium-ion batteries stand out for their superior performance. They offer a high energy density, longer lifespan, and faster charging capabilities compared to traditional lead-acid batteries. Moreover, they are lighter and require minimal maintenance, making them ideal for modern-day energy storage needs.

For electric cycles (E-cycles) and other EVs, lithium-ion batteries have become a go-to solution. These batteries provide the perfect balance of power and portability, ensuring a seamless riding experience. The best E-cycle lithium battery manufacturers prioritize safety and efficiency, offering batteries that are resistant to overcharging, overheating, and other common issues.

The Best Manufacturer of Lithium Batteries in India

Finding the best manufacturer of lithium batteries involves looking at a few critical factors:

-Quality Assurance: Top manufacturers adhere to stringent quality standards, ensuring that their products deliver reliable performance and safety.

- Innovation: Leading companies invest in research and development to stay ahead in the market, introducing innovative products like fast-charging and high-capacity batteries.

- Customization Options: Whether it’s for an electric vehicle, renewable energy setup, or portable device, customized battery solutions make a significant difference.

- Sustainability: With the global focus on reducing carbon footprints, eco-friendly manufacturing practices are a must.

Indian manufacturers are making significant strides in this field, offering world-class products that compete with international brands. They are also contributing to the government’s vision of an energy-independent and green India.

Why Customized Battery Solutions Matter

Not all energy requirements are the same, which is why customized battery solutions are crucial. For instance, the energy needs of an industrial setup differ vastly from those of an electric cycle. By understanding the specific demands of their clients, manufacturers can design batteries that deliver optimal performance while minimizing costs.

Conclusion

The best lithium battery in India is one that meets the user’s unique requirements, offering a perfect blend of performance, durability, and safety. With the growing number of lithium battery manufacturers in the country, businesses and consumers now have access to a range of cutting-edge solutions, from lithium-ion batteries to E-cycle lithium batteries. This marks a significant step towards a greener, more sustainable future.

Invest in high-quality, customized lithium battery solutions today to power your tomorrow.

#Best lithium battery in india#lithium battery manufacturer#customized battery solutions#lithium ion battery#E-cycle lithium battery#best manufacturer of lithium battery

0 notes

Text

"It seems like a new Silicon Valley startup could change the face of the battery industry forever by utilizing 3D printers to print solid-state batteries.

Solid-state batteries have advantages over lithium-ion because they aren’t flammable, they’re more easily recycled, work in extreme cold, and have greater energy density.

Solid-state batteries have traditionally been difficult to machine manufacture. But by using 3D printing arrays filled with powder, Sakuu systems can make these batteries not only using 40% less material, but in almost any shape the customer might want.

An electric bike could be powered by a battery that hugs a section of the central chassis, or a smartphone’s battery could run all the way around the frame of a circuit board. These unorthodox shapes are just one of the many advantages that Sakuu believe they can offer.

“Many people have built cells in the lab, but they have not been able to scale,” Sakuu CEO and founder Robert Bagheri told Fast Company. “Our vision started with that scalability in mind.”

The array, known as a Kavian, is much smaller than the traditional, “roll to roll” battery manufacturing methods, and because the powder loaded into the 3D printers can be extremely precise, there’s a 40% reduction in materials usage—a huge cost savings over competitors.

The batteries they print can be charged to 80% in just 15 minutes.

Because they can be printed in any shape, all kinds of clever innovations are possible, in all kinds of industries from e-mobility products to wearables and small devices. The company is even working with an aviation company that wants solid-state batteries for their aircraft with holes through the middle of it to help with heat management."

-via Good News Network, 2/27/23

#battery#batteries#tech industry#electricity#recycling#3d printing#lithium ion battery#good news#hope

170 notes

·

View notes

Text

#lithium ion battery#lithium batteries supplier#lithium battery price#lithium batteries india#lithium battery

0 notes

Text

youtube

137 Year Old Battery Tech May Be The Future of Energy Storage. As good as lithium ion batteries are, they have their limitations and challenges, but there’s also plenty of battery alternatives. Flow batteries alone have enough variations in chemistry to make your head spin. Zinc bromine batteries are one up-and-coming contender … and calling them up and coming sounds funny when you consider that they’ve existed for 137 years … but they might hold the future for energy storage. And for such an old idea, why now?

Watch Why Nuclear Fusion is Closer Than You Think https://youtu.be/yNP8by6V3RA?list=PLn...

Video script and citations:

https://undecidedmf.com/137-year-old-...

Follow-up podcast:

Video version - https://www.youtube.com/channel/UC4-a...

Audio version - http://bit.ly/stilltbdfm

#undecided with matt ferrell#solarpunk#battery#lithium ion battery#lithium battery#rechargeable batteries#Zinc bromine batteries#Flow batteries#sustainability#Youtube

6 notes

·

View notes

Text

youtube

Harveypower Lifepo4 Battery Pack Production Steps - Powerwall

Welcome to Harveypower's exclusive behind-the-scenes look at our Lifepo4 Battery Pack Production Steps for Powerwall. In this video, we invite you to witness the intricate process of how our expert technicians craft our top-of-the-line battery packs with the highest quality standards. From the precise battery cell stacking and bundling to the careful busbar connection, every step is executed with the utmost attention to detail.

Our advanced laser welding technology ensures the strongest bonds between each cell, ensuring maximum reliability and longevity. Once the battery pack is carefully fixed in its durable case, our technicians begin connecting the cables and performing a thorough voltage test to guarantee flawless performance.

Our wire harness assembly process is designed to deliver optimal power efficiency, while the port panel and BMS assembly ensure easy and convenient access to your battery pack.

At Harveypower, we take pride in producing high-quality products that our customers can rely on. We invite you to witness our battery production process firsthand and experience the excellence that goes into each and every one of our Lifepo4 Battery Packs.

#lifepo4 battery#lithium iron phosphate battery#lfp battery#lithium battery#solar battery#lithium manufacturer#lithium ion battery#lithium#solar battery storage#youtube#Youtube

2 notes

·

View notes

Text

Artek Energy offers high-performance lithium-ion 3.7V 4000mAh batteries for soundboxes, providing reliable power and long-lasting performance. Our batteries are designed for superior efficiency, ensuring your soundbox operates seamlessly for extended periods. Whether you're a manufacturer or a consumer, trust Artek Energy to supply top-quality lithium-ion batteries that meet your energy needs. Choose Artek Energy for safe, durable, and energy-efficient solutions that enhance the functionality of your sound systems

Visit: www.artekgroup.in For more info call us at +919354443010

1 note

·

View note

Text

Imagine an EV Battery With a Range of 3,000 Kilometres Between Charges. Korean researchers built a silicon anode Li-ion battery that could be a game changer.

https://www.21stcentech.com/imagine-ev-battery-range-3000-kilometres-charges/

0 notes