#linear motor module

Explore tagged Tumblr posts

Text

youtube

0 notes

Text

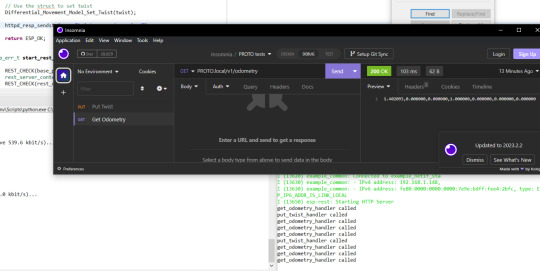

It works!*

So I (FINALLY) put the final touches on the software for my robot PROTO! (Listen, I am a software person, not a coming-up-with-names person)

Basically, it is a ESP32 running him. He takes HTTP messages. Either GET odometry, or PUT twist. Both just being a string containing comma separated numbers

Odometry is the robots best guess based on internal sensors where it is (Since PROTO uses stepper motors, which rotates in tiny tiny steps... it is basically counting the steps each motor takes)

Twist is speed, both in x,y and z directions, and speed in angular directions (pitch, roll and yaw). This is used to tell the robot how to move

Now, since PROTO is a robot on two wheels, with a third free-running ball ahead of him, he cannot slide to the side, or go straight up in the air. You can TRY telling him to do that, but he will not understand what you mean. Same with angular movement. PROTO can turn left or right, but he have no clue what you mean if you tell him to bend forward, or roll over.

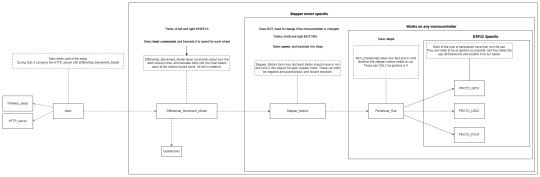

The software is layered (Which I use a BDD diagram to plan. I love diagrams!)

Basically PROTO gets a twist command and hands that over to the Differential_Movement_Model layer.

The Differential_Movement_Model layer translate that to linear momentum (how much to move forward and backwards) and angular momentum (how much to turn left or right). combines them, and orders each wheel to move so and so fast via the Stepper_Motors layer.

The Stepper_Motors turns the wanted speed, into how many steps each stepper motor will have to do per second, and makes sure that the wanted speed can be achieved by the motors. It also makes sure that the wheels turn the right way, no matter how they are mounted (In PROTO's case, if both wheels turn clockwise, the right wheel is going forward, and the left backwards.). It then sends this steps per second request down to the Peripheral_Hub layer.

The Peripheral_Hub layer is just a hub... as the name implies, it calls the needed driver functions to turn off/on pins, have timers count steps and run a PWM (Pulse-width modulation. It sends pulses of a particular size at a specific frequency) signal to the driver boards.

Layering it, also means it is a lot easer to test a layer. Basically, if I want to test, I change 1 variable in the build files and a mock layer is build underneath whatever layer I want to test.

So if I want to test the Stepper_Motors layer, I have a mock Peripheral_Hub layer, so if there are errors in the Peripheral_Hub layer, these do not show up when I am testing the stepper motor layer.

The HTTP server part is basically a standard ESP32 example server, where I have removed all the HTTP call handlers, and made my own 2 instead. Done done.

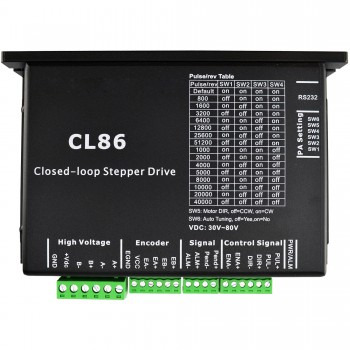

So since the software works... of course I am immediately having hardware problems. The stepper motors are not NEARLY as strong as they need to be... have to figure something out... maybe they are not getting the power they need... or I need smaller wheels... or I will have to buy a gearbox to make them slower but stronger... in which case I should proberbly also fix the freaking cannot-change-the-micro-stepping problem with the driver boards, since otherwise PROTO will go from a max speed of 0.3 meters per second, to most likely 0.06 meters per second which... is... a bit slow...

But software works! And PROTO can happily move his wheels and pretend he is driving somewhere when on his maintenance stand (Yes. it LOOKS like 2 empty cardboard boxes, but I am telling you it is a maintenance stand... since it sounds a lot better :p )

I have gone over everything really quickly in this post... if someone wants me to cover a part of PROTO, just comment which one, and I will most likely do it (I have lost all sense of which parts of this project is interesting to people who are not doing the project)

129 notes

·

View notes

Text

GERO the GE Robot (1986) by Walt Disney Imagineering and General Electric Research & Development Center. GERO would ride around Future World a large scooter. “ “GERO” (short for “GE RObot”), is the newest robot to join the Horizons cast… and he’s destined to become one of Epcot’s most beloved characters. “GERO is probably the most sophisticated entertainment robot in the world,” says Dave Fink of General Electric. Designs for GERO originated at Walt Disney Imagineering in California. Veteran animator Xavier “X” Atencio created the inspirational drawings, using classic Disney character styling and proportions. GERO emerged from the drawing board as a fun-loving, friendly teen-ager – complete with a sporty scooter with room for riders! “The next step was to add the detailing that would give the robot a machined, hi-tech look,” says Designer Gil Keppler. At the Walt Disney Studios, artisans sculpted the robot in plaster, then shipped it to Walt Disney World where its Lexan body was fabricated, assembled, and painted in metallic silver & gold. As for the vehicle color… well, it just had to be red. After all, GERO’s a sporty guy! While GERO’s outward appearance was shaping up in Florida, scientists and technicians at the General Electric Research & Development Center were busily assembling the robot’s inner workings. Included in the 900-pound mountain of electronics are linear stepping motors, field effect transistor brakes, pulse-width modulated drives, incremental optical shaft encoder, fiber optics, laser disc player, 160 watts of biamped audio power and nine batteries – all controlled by 19 microcomputers! Yet with all that hi-tech hardware, there was one thing GERO still didn’t have – an education. It was time to go to school. At the GE R&D Center, computer technicians spent weeks raising the robot’s IQ from zero to GERO. By graduation time, GERO had learned to shake hands, wave goodbye, drive his scooter, converse and sing songs! He was ready to meet his public.” – Disney’s Exotic, Robotic Cast: “GERO” steals the show at EPCOT center, by Tom Fitzgerald.

24 notes

·

View notes

Text

Global top 13 companies accounted for 66% of Total Frozen Spring Roll market(qyresearch, 2021)

The table below details the Discrete Manufacturing ERP revenue and market share of major players, from 2016 to 2021. The data for 2021 is an estimate, based on the historical figures and the data we interviewed this year.

Major players in the market are identified through secondary research and their market revenues are determined through primary and secondary research. Secondary research includes the research of the annual financial reports of the top companies; while primary research includes extensive interviews of key opinion leaders and industry experts such as experienced front-line staffs, directors, CEOs and marketing executives. The percentage splits, market shares, growth rates and breakdowns of the product markets are determined through secondary sources and verified through the primary sources.

According to the new market research report “Global Discrete Manufacturing ERP Market Report 2023-2029”, published by QYResearch, the global Discrete Manufacturing ERP market size is projected to reach USD 9.78 billion by 2029, at a CAGR of 10.6% during the forecast period.

Figure. Global Frozen Spring Roll Market Size (US$ Mn), 2018-2029

Figure. Global Frozen Spring Roll Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Discrete Manufacturing ERP include Visibility, Global Shop Solutions, SYSPRO, ECi Software Solutions, abas Software AG, IFS AB, QAD Inc, Infor, abas Software AG, ECi Software Solutions, etc. In 2021, the global top five players had a share approximately 66.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

2 notes

·

View notes

Text

Interesting Papers for Week 15, 2023

Cross-scale excitability in networks of quadratic integrate-and-fire neurons. Avitabile, D., Desroches, M., & Ermentrout, G. B. (2022). PLOS Computational Biology, 18(10), e1010569.

Modulation of working memory duration by synaptic and astrocytic mechanisms. Becker, S., Nold, A., & Tchumatchenko, T. (2022). PLOS Computational Biology, 18(10), e1010543.

Mathematical relationships between spinal motoneuron properties. Caillet, A. H., Phillips, A. T., Farina, D., & Modenese, L. (2022). eLife, 11, e76489.

The pupillometry of the possible: an investigation of infants’ representation of alternative possibilities. Cesana-Arlotti, N., Varga, B., & Téglás, E. (2022). Philosophical Transactions of the Royal Society B: Biological Sciences, 377(1866).

Olfactory responses of Drosophila are encoded in the organization of projection neurons. Choi, K., Kim, W. K., & Hyeon, C. (2022). eLife, 11, e77748.

Postsynaptic burst reactivation of hippocampal neurons enables associative plasticity of temporally discontiguous inputs. Fuchsberger, T., Clopath, C., Jarzebowski, P., Brzosko, Z., Wang, H., & Paulsen, O. (2022). eLife, 11, e81071.

Immature olfactory sensory neurons provide behaviourally relevant sensory input to the olfactory bulb. Huang, J. S., Kunkhyen, T., Rangel, A. N., Brechbill, T. R., Gregory, J. D., Winson-Bushby, E. D., … Cheetham, C. E. J. (2022). Nature Communications, 13(1), 6194.

Humans Can Track But Fail to Predict Accelerating Objects. Kreyenmeier, P., Kämmer, L., Fooken, J., & Spering, M. (2022). ENeuro, 9(5).

Ventrolateral Prefrontal Cortex Contributes to Human Motor Learning. Kumar, N., Sidarta, A., Smith, C., & Ostry, D. J. (2022). ENeuro, 9(5).

Magnitude-sensitive reaction times reveal non-linear time costs in multi-alternative decision-making. Marshall, J. A. R., Reina, A., Hay, C., Dussutour, A., & Pirrone, A. (2022). PLOS Computational Biology, 18(10), e1010523.

Differences in temporal processing speeds between the right and left auditory cortex reflect the strength of recurrent synaptic connectivity. Neophytou, D., Arribas, D. M., Arora, T., Levy, R. B., Park, I. M., & Oviedo, H. V. (2022). PLOS Biology, 20(10), e3001803.

Structured random receptive fields enable informative sensory encodings. Pandey, B., Pachitariu, M., Brunton, B. W., & Harris, K. D. (2022). PLOS Computational Biology, 18(10), e1010484.

Obsessive-compulsive disorder is characterized by decreased Pavlovian influence on instrumental behavior. Peng, Z., He, L., Wen, R., Verguts, T., Seger, C. A., & Chen, Q. (2022). PLOS Computational Biology, 18(10), e1009945.

The value of confidence: Confidence prediction errors drive value-based learning in the absence of external feedback. Ptasczynski, L. E., Steinecker, I., Sterzer, P., & Guggenmos, M. (2022). PLOS Computational Biology, 18(10), e1010580.

Psychedelics and schizophrenia: Distinct alterations to Bayesian inference. Rajpal, H., Mediano, P. A. M., Rosas, F. E., Timmermann, C. B., Brugger, S., Muthukumaraswamy, S., … Jensen, H. J. (2022). NeuroImage, 263, 119624.

Visual working memory recruits two functionally distinct alpha rhythms in posterior cortex. Rodriguez-Larios, J., ElShafei, A., Wiehe, M., & Haegens, S. (2022). ENeuro, 9(5).

Pitfalls in post hoc analyses of population receptive field data. Stoll, S., Infanti, E., de Haas, B., & Schwarzkopf, D. S. (2022). NeuroImage, 263, 119557.

Event-related microstate dynamics represents working memory performance. Tamano, R., Ogawa, T., Katagiri, A., Cai, C., Asai, T., & Kawanabe, M. (2022). NeuroImage, 263, 119669.

Rule-based and stimulus-based cues bias auditory decisions via different computational and physiological mechanisms. Tardiff, N., Suriya-Arunroj, L., Cohen, Y. E., & Gold, J. I. (2022). PLOS Computational Biology, 18(10), e1010601.

Correcting the hebbian mistake: Toward a fully error-driven hippocampus. Zheng, Y., Liu, X. L., Nishiyama, S., Ranganath, C., & O’Reilly, R. C. (2022). PLOS Computational Biology, 18(10), e1010589.

#science#Neuroscience#computational neuroscience#Brain science#research#cognition#cognitive science#neurons#neural networks#neural computation#neurobiology#psychophysics#scientific publications

23 notes

·

View notes

Text

https://www.verifiedmarketreports.com/pt/product/ready-to-use-linear-motor-module-market/

0 notes

Text

PiSquare: RP2040 & ESP-12E-based board for all Raspberry Pi HATs

PiSquare is a compact, wireless communication board designed for Raspberry Pi that enables you to wirelessly connect and communicate with multiple Raspberry Pi HATs including SPI, I2C, and SPI HATs. It is based on two powerful components:

⦁ The RP2040 microcontroller (the same chip used in the Raspberry Pi Pico). ⦁ The ESP-12E Wi-Fi module for seamless wireless communication.

By using socket programming, PiSquare can wirelessly interact with Raspberry Pi HATs through TCP/IP communication, allowing you to connect as many devices as you need, without worrying about physical stacking or GPIO conflicts.

Key Specifications:

⦁ Microcontroller: Raspberry Pi RP2040

Core Architecture: Dual-core ARM Cortex-M0+ microcontroller

Clock Speed: Up to 133 MHz

Flash Memory: 2MB onboard QSPI Flash (for program storage)

RAM: 264KB SRAM

GPIO Pins: 26 multi-function GPIO pins with support for PWM, SPI, I2C, UART, and other peripherals

⦁ Wi-Fi Connectivity: ESP-12E

Wi-Fi Standard: 802.11 b/g/n

Wireless Frequency: 2.4 GHz

Wi-Fi Chipset: ESP8266 (with 4MB of onboard Flash)

Data Rate: Up to 72.2 Mbps (with 802.11n support)

Communication Interface: UART (Universal Asynchronous Receiver Transmitter)

⦁ Wireless Communication via Socket Programming

Protocol: TCP/IP (Transmission Control Protocol/Internet Protocol) via socket programming

Connection Type: Full-duplex, bi-directional communication

Network Type: Local Area Network (LAN) or Wi-Fi based network for device communication

Number of Supported Devices: Configurable for communication with multiple (n) Raspberry Pi HATs over Wi-Fi without the need for physical stacking

Socket Layer: Raw socket-based communication for sending and receiving data over the network

⦁ HAT Compatibility

Supported Protocols: SPI (Serial Peripheral Interface): Full-duplex, synchronous communication for connecting peripherals

I2C (Inter-Integrated Circuit): Multi-master, multi-slave communication for sensors, actuators, and peripheral devices

GPIO-based HATs: Supports a variety of devices and sensors with GPIO pin control

Pin Multiplexing: Flexible I/O pin assignment allowing for easy configuration of multiple communication protocols simultaneously

Addressing: Supports unique addressing for SPI and I2C devices to avoid conflicts

⦁ Power Supply

Voltage: 5V DC ±5% (typical operating voltage range)

Power Consumption: Low-power operation suitable for remote or battery-powered applications

Regulation: Onboard linear voltage regulator to provide stable power for the microcontroller and Wi-Fi module

⦁ Form Factor

Dimensions: 65mm x 30mm x 20mm (compact design suitable for integration into small devices)

Mounting: Compatible with standard Raspberry Pi connectors (via external interface) without the need for physical GPIO stacking

⦁ I/O and Expansion

Interface: UART, SPI, I2C (for communication with external peripherals)

GPIO: 26 GPIO pins for signal input/output, including support for digital, analog, PWM, and interrupts

Use Cases

Here are a few ways PiSquare can revolutionize your Raspberry Pi projects:

Multi-HAT Robotics: Easily connect multiple HATs for motor control, sensor arrays, and communication modules in a wireless setup.

IoT Projects: PiSquare can communicate with several sensor HATs in remote locations, sending data back to a central Raspberry Pi for processing or cloud storage.

Home Automation: Connect a variety of home automation HATs wirelessly, creating a smart home system that’s efficient and scalable.

Distributed Sensor Networks: Set up multiple sensors across a large area without worrying about physical connections or pin conflicts.

The Pisquare RP2040 with the onboard ESP-12E Wi-Fi module is a powerful and compact solution for anyone looking to build wireless IoT projects. Its support for multiple HATs, including SPI and I2C, makes it versatile enough to handle a wide variety of peripherals, while its ability to implement socket programming provides you with the flexibility to create robust networked applications.

Whether you're creating a smart home system, an industrial IoT device, or a robotics project, the Pisquare by SB Components can be the perfect foundation for your next creation.

#technology#raspberry pi#innovation#tech#techinnovation#programming#tech projects#projects#artificial intelligence#technews

0 notes

Text

Solutions to faults during operation of stepper motor drivers

1.Basic understanding of stepper motor drivers A stepper motor driver is an actuator that converts electrical pulses into angular displacements. It drives the stepper motor to rotate a fixed angle in the set direction by receiving control signals. The stepper motor driver is an important component of the stepper motor system, responsible for converting the control signal into the current and voltage required by the stepper motor to drive the motor for precise angular or linear displacement. The working principle of the stepper motor driver is to convert the input pulse signal into a drive current signal to control the angular displacement of the stepper motor. The speed of the motor is proportional to the pulse frequency, so the speed can be accurately adjusted by controlling the pulse frequency, and the positioning can be accurately achieved by controlling the number of pulses. The stepper motor driver has high positioning accuracy and stability, and can subdivide each step into smaller steps through the subdivision function, thereby improving positioning accuracy and stability.

2.The main structure of the stepper motor driver 1.Ring distributor. Generate the switching waveform signal processing of the motor in different states according to the requirements of the input signal. Perform PWM modulation on the switching signal waveform generated by the ring distributor and filter and shape the related waveform. 2.Protection circuit. When the winding current is too large, a shutdown signal is generated to shut down the main circuit to protect the motor driver and motor winding. 3.Sensor. Real-time monitoring of the position and angle of the motor, and the signal generation device is transmitted back.

3.Solutions to faults during operation of stepper motor drivers 1.The motor does not rotate or rotates slowly: The stepper motor driver needs to receive the correct pulse signal to control the motor rotation. If the motor does not rotate or rotates slowly, first check whether the pulse signal source is working properly, ensure that the driver input terminal is connected correctly, and check whether the motor wiring is correct to eliminate the motor itself. 2.Overheating: The stepper motor driver may overheat when working for a long time or overloaded. Improve the heat dissipation conditions, add fans or heat sinks, ensure that the working environment temperature is suitable, and avoid long-term overload operation. 3.Excessive noise: Abnormal noise during motor operation may be caused by bearing damage or loose internal parts. Check whether the motor bearing is damaged, re-tighten the loose internal parts, and adjust the driver current setting. 4.Overcurrent protection: The driver has an overcurrent protection function. If the output current exceeds the rated value, the driver will cut off the power supply to protect the motor and itself. Check the power supply and motor load, and readjust the current setting. 5.Communication error: If the driver and controller are controlled by communication, communication errors may indicate that the driver cannot work properly. Check the communication line and settings to ensure stable communication.

4.Precautions for using stepper motor drivers

1.Power management: The quality of the power supply directly affects the performance and power consumption of the driver. The ripple size of the power supply affects the accuracy of the subdivision, and the suppression ability of the power supply common mode interference affects the anti-interference of the system. Therefore, for applications with higher requirements, users must pay attention to improving the quality of the power supply. In addition, the installation of the driver should ensure good ventilation, and regularly check whether the cooling fan is running normally. 2.Signal line processing: When wiring the system, the principle of separating the power line (motor phase line, power line) from the weak current signal line should be followed to avoid interference with the control signal. When it is impossible to wire separately or there is a strong interference source, it is best to use shielded cable to transmit the control signal. Using a higher level control signal is also meaningful for resisting interference. 3.Initial operation check: Do not connect all the lines at the beginning. You can connect the most basic system first, and then complete all the connections after confirming that it is running well. Carefully observe the sound and temperature rise of the motor. If any abnormality is found, it should be stopped and adjusted immediately. 4.Environmental adaptation: Due to the drastic changes in the storage and transportation environment temperature, condensation or frost is easy to occur. At this time, the driver should be placed for more than 12 hours. After the driver temperature is consistent with the ambient temperature, it can be powered on. If stored in an unsuitable environment for a long time, the quality of the product should be retested before operation.

Source:https://medium.com/@porterbickford69/solutions-to-faults-during-operation-of-stepper-motor-drivers-7fc1e964767f

0 notes

Text

Essential Guide: How to Drive a Servo Motor Like a Pro

Servo motors have become vital across various industries, from robotics and CNC machinery to automation. Their precision and control make them ideal for applications requiring specific movement or positioning. For those new to the world of servo motors or anyone seeking to sharpen their skills, understanding how to drive a servo motor effectively is key to harnessing its full potential. This guide will walk you through everything you need to know to drive a servo motor like a pro, covering basics, technical tips, and best practices.

What Is a Servo Motor?

A servo motor is a specialized rotary actuator designed for precise control of angular or linear position, velocity, and acceleration. Unlike traditional motors, which typically run at a constant speed, servo motors respond to specific instructions to move to set positions with a high degree of accuracy. They are commonly used in robotics, conveyor systems, camera focus mechanisms, and beyond.

Key Components of a Servo Motor System

To operate a servo motor effectively, it's essential to understand its components:

Motor – The main driver of motion, either DC or AC, that generates rotational movement.

Controller – Sends specific signals to the motor to reach a target position or speed.

Feedback Device – Typically an encoder or potentiometer, providing feedback on the motor's position to ensure accuracy.

Drive Circuit – Interfaces the controller with the motor, enabling controlled power and precise motion.

Step 1: Choose the Right Servo Motor for Your Application

Choosing the right motor type depends on your application's power, speed, and control requirements. Generally, servo motors fall into two main categories:

DC Servo Motors – Better suited for applications requiring lower power and precise control.

AC Servo Motors – More powerful and suitable for higher-speed applications, often used in industrial automation.

Consider the torque, speed, and voltage ratings as you assess which servo motor fits your needs.

Step 2: Understand Control Signals

Servo motors require control signals to determine movement. There are three main types:

Pulse Width Modulation (PWM) – Common in hobbyist and small-scale applications, it involves sending pulses to control motor position.

Analog Signals – Often used in industrial settings, where a specific voltage range controls motor speed or position.

Digital Signals – A more advanced option that communicates precise instructions for accurate control in complex systems.

Step 3: Master the Basics of Servo Motor Controllers

To drive a servo motor effectively, you’ll need a servo controller, the brain behind the operation. It’s responsible for interpreting the commands and converting them into movements. There are two primary control modes:

Position Control – This mode commands the servo to move to a specified position and is highly accurate.

Speed Control – Here, the controller maintains a steady speed, ideal for applications like conveyor belts.

Selecting the right controller based on your application can make all the difference in achieving optimal performance.

Step 4: Set Up Your Servo Drive

The servo drive is an essential component, bridging the motor and controller. Here’s a basic setup guide:

Power Supply – Connect a power source that matches the servo motor’s voltage and current requirements.

Signal Wires – Connect the control signals from your controller to the servo motor input.

Feedback Mechanism – Ensure the encoder or potentiometer is connected to relay accurate positioning data.

Check Connections – Verify all wiring and connections are correct, ensuring stable performance and avoiding overheating or short circuits.

Step 5: Programming Your Servo Motor

Servo motors can be controlled manually or programmed via a microcontroller or PLC (Programmable Logic Controller) for automation. Start by writing basic commands to rotate the motor to specific angles, then proceed to more complex programs for movement sequences. Popular platforms like Arduino and Raspberry Pi are ideal for beginner programmers.

Step 6: Fine-Tuning Performance

To drive a servo motor like a pro, fine-tuning is necessary. Here are some techniques:

PID Tuning – PID (Proportional-Integral-Derivative) controllers are commonly used to fine-tune servo motors, helping achieve smoother and more precise control.

Frequency Response Tuning – Adjusting frequency parameters can prevent oscillations and improve stability.

Gain Adjustment – Increasing or decreasing gain settings affects responsiveness and precision.

Step 7: Troubleshoot Common Servo Motor Issues

When driving a servo motor, issues may arise. Here’s how to troubleshoot:

Inconsistent Positioning – Verify the feedback device is correctly calibrated and connected.

Overheating – Check that the motor isn’t overloaded and that the drive circuit isn’t providing excessive current.

Unexpected Stopping – Inspect connections, power supply, and control signal integrity.

Noise and Vibration – Adjust gain settings or consider a damper if high-frequency noise affects performance.

Step 8: Regular Maintenance

Regular maintenance ensures optimal servo motor performance and extends lifespan. Here are some maintenance tips:

Check Wiring and Connections – Loose connections can cause erratic movements.

Lubricate Bearings – Especially in industrial environments, to prevent wear and tear.

Inspect Feedback Devices – Clean encoders or potentiometers for accurate data.

Why Learn to Drive a Servo Motor Like a Pro?

Mastering servo motor operation enhances productivity, precision, and cost efficiency. Industries benefit from improved control and accuracy in applications ranging from robotics to medical devices, where precise movement can make a crucial difference.

Conclusion

Driving a servo motor may seem complex initially, but with this guide and hands-on practice, you'll be able to control it confidently. Whether you’re aiming for exact positioning or consistent speed, mastering servo motors will open up opportunities for innovation and efficiency.

0 notes

Text

Discover the Versatility of Signvec CNC Engraver/Router Machines

Signvec Technology offers a diverse range of CNC engraver/router machines designed to meet various industrial needs. Whether you're a hobbyist, a small business owner, or a large-scale manufacturer, Signvec's CNC solutions provide precision, durability, and cutting-edge technology. In this article, we delve into some of Signvec’s standout models: the SD Small Engraver, SD5040 Powerful CNC Engraver, SV-3040DT Desktop CNC Router/Engraver, SK Series, VG Engraver & Router System, SV Superior Vanguard Series, TIGER-CLAW Series, and the Moving Column CNC Machining Center - A.

SD Small Engraver

The SD Small Engraver is an entry-level CNC engraving machine designed for hobbyists, small businesses, and DIY enthusiasts. Its compact size makes it perfect for small-scale projects, including plaques, badges, and intricate designs. Despite its small footprint, this machine offers impressive precision and ease of use, making it an ideal choice for those looking to venture into CNC engraving without a significant investment.

SD5040 Powerful CNC Engraver

For more demanding applications, the SD5040 Powerful CNC Engraver is a robust solution. This machine features the most advanced FPGA colored LCM controlling system, allowing for rapid calculations and outstanding performance. Equipped with a 1.5KW inverter-driven air-cooling spindle motor, the SD5040 excels in cutting through harder materials like wood, acrylic, and soft metals. Its high-precision linear rail system ensures exceptional accuracy, making it suitable for medium to large-scale projects that require both power and precision.

SV-3040DT Desktop CNC Router/Engraver

For those seeking an affordable yet high-performing option, the SV-3040DT Desktop CNC Router/Engraver is an excellent choice. This entry-level machine is compact and user-friendly, making it perfect for small businesses and home-based operations. The SV-3040DT is compatible with various CAD/CAM software such as Type3, Artcam, and Artcut, providing versatility for different engraving tasks. Its stability and reliable performance make it an excellent choice for engraving wood, acrylic, and aluminum.

SK Series CNC Router/Engraver

The SK Series CNC Router/Engraver is engineered for high-speed and high-performance operations. With a traveling speed of up to 20m/min, this machine is designed for efficiency. The SK Series includes features such as 4G internal memory for data transmission via USB flash disk, compatibility with multiple CAD/CAM software, and advanced functions like power-off restoration and break-point continuation. This machine is perfect for businesses that require both speed and precision for large-scale or complex projects.

VG Engraver & Router System

For industrial applications requiring large-format processing, the Vanguard Large Format CNC Engraver/Router is an ideal choice. It comes equipped with a high-powered BOL air-cooling spindle motor and features auto-eliminating clearance devices on the X and Y axes for enhanced accuracy. The VG system’s high-power AC driver system and intelligent control module make it suitable for demanding engraving tasks that require precision and strength.

SV Superior Vanguard Series

The SV Superior Vanguard Series represents the pinnacle of Signvec’s engineering excellence. This large-format CNC engraver features a new, more stable machine structure that reduces deformation during operation. It is equipped with THK linear rails from Japan and the high-precision ESTUN servo system, providing superior accuracy and stability. Additionally, the high-speed mute ball screw transmission minimizes noise while maintaining high performance. This series is built for heavy-duty tasks, with features like a professional dustproof component and a high-power Italian ELTE spindle motor.

TIGER-CLAW Series CNC Router

The TIGER-CLAW Series CNC Router offers flexibility and durability with multiple configuration options. It can operate with a single spindle or multiple spindle motors, enhancing processing efficiency. The machine���s design includes imported all-steel linear square guides and industrial components, ensuring long-term durability and reliability. The TIGER-CLAW Series is ideal for users who require high-speed and high-precision operations, with options for either rolling ball screw or gear and rack transmission systems.

Moving Column CNC Machining Center - A

The Moving Column CNC Machining Center - A is designed for precision and high performance. Its integral welding body and high-inflexibility structure ensure minimal deformation. The machine features a high-precision helical rack and THK linear rails from Japan, complemented by a Panasonic servo system and Taiwan’s deceleration device. Equipped with a professional vacuum system and high-power spindle from Italy, this machine offers strong cutting force and efficient operation. It is ideal for handling large materials with high strength and precision.

Conclusion

Signvec Technology’s CNC engraver/router machines offer a wide range of options to meet various needs across different industries. From the compact SD Small Engraver to the powerful SV Superior Vanguard Series and the versatile TIGER-CLAW Series, each machine is engineered to deliver exceptional precision, performance, and reliability. Whether you are involved in small-scale hobbies or large-scale manufacturing, Signvec’s CNC solutions provide the technology and efficiency required to achieve outstanding results.

0 notes

Text

How to adjust the speed of a geared stepper motor

1.A brief explanation of a geared stepper motor A geared stepper motor is an electromechanical device that converts electrical pulses into discontinuous mechanical motion. It achieves precise position control by receiving digital control signals (electrical pulse signals) and converting them into corresponding angular displacements or linear displacements. The main feature of a geared stepper motor is that its output angular displacement or linear displacement is proportional to the number of input pulses, and its speed is proportional to the pulse frequency, which makes it important in systems that require high-precision motion control. As an important component of a stepper motor, the gearbox achieves precise control of speed and torque through its precise control function, thereby ensuring the irreplaceability of stepper motors in open-loop high-resolution positioning systems.

2.Advantages of geared stepper motors 1.Reduce speed and increase output torque: Through different reduction ratios, geared stepper motors can reduce the speed of the input shaft while increasing the output torque, which is very useful for applications that require large torque output. 2.Compact structure and small footprint: The design of the geared stepper motor makes its structure very compact, thereby reducing the required installation space. 3.High transmission efficiency and precise speed ratio: The geared stepper motor has high transmission efficiency and can ensure the accuracy of the speed ratio, which is critical for applications that require precise control of speed and position. 4.Reduce the inertia of the load: By reducing speed, the geared stepper motor can reduce the inertia of the load, which is very beneficial for applications that require fast response and precise control. 5.Provide more accurate timing than the chain system, reduce friction loss and noise: Compared with the chain system, the geared stepper motor provides more accurate timing, while reducing friction loss and noise, improving the reliability and durability of the system.

3.Methods for adjusting the speed of the geared stepper motor 1.Change the main frequency of the controller: By adjusting the main frequency of the controller to change the pulse frequency output to the motor, the speed of the motor is controlled. The higher the main frequency, the higher the output pulse frequency, and the faster the motor speed. 2.Use PWM (pulse width modulation) control: Use the PWM signal to control the duty cycle of the pulse output, and then adjust the pulse frequency to achieve fine adjustment of the motor speed. 3.Table lookup speed regulation: According to the set speed value, by looking up the corresponding table of the pre-set speed value and pulse frequency, select the appropriate pulse frequency output to achieve a specific speed. 4.Adopting S-type acceleration curve: By adopting S-type acceleration curve, the motor can be smoothly accelerated and decelerated, providing better start and stop control. 5.Closed-loop control system: The real-time speed of the motor is fed back by the encoder, and the output of the pulse frequency is adjusted after comparison with the set value to achieve accurate speed tracking and enhance control accuracy.

4.Drive mode of gear stepper motor 1.Single voltage drive: In this mode, only one direction voltage is used to power the winding during the operation of the motor winding. The advantages of this mode are simple circuit structure, few components, low cost and high reliability. However, due to the increased power consumption, the efficiency of the entire power drive circuit is low, and it is only suitable for driving low-power stepper motors. 2.High and low voltage drive: In order to enable the winding to quickly reach the set current when power is on, and the winding current quickly decays to zero when power is off, while maintaining high efficiency, high and low voltage drive modes have emerged. This method uses high voltage power supply at the front edge of conduction to increase the front rise rate of the current, and uses low voltage to maintain the current of the winding after the front edge. High and low voltage drive can obtain better high-frequency characteristics, but may cause oscillation at low frequencies. 3.Full-step drive: including single-phase full-step drive and two-phase full-step drive. Full-step drive changes the direction and magnitude of the current to make the stepper motor rotate according to the set step angle. The advantage of this method is that it is simple and intuitive, and it is suitable for occasions where the torque requirement is not high. However, due to its relatively small torque, it may need to be used in combination with other drive methods. 4.Half-step drive: By changing the direction and magnitude of the current, the stepper motor rotates according to half a step angle. Compared with full-step drive, half-step drive has higher resolution and smoother movement, and is suitable for occasions with higher positioning requirements. 5.Micro-step drive: By controlling the magnitude and direction of the current in segments, the stepper motor rotates according to a smaller micro-step angle. Microstepping drives can achieve higher resolution and smoother motion, and are suitable for situations where high-precision positioning and control are required.

1 note

·

View note

Text

youtube

Kasite Motor Technology linear module manufacturer in china,Truss type long stroke linear motor module,Long stroke: 26 m (span 5 m) high speed: 5 m/s,Multiple support truss aerial head,Ensure installation accuracy,Motion slide bus distributed independent control,Application: automatic unmanned workshop,handling, positioning,loading and unloading,and automatic production line inspection.

1 note

·

View note

Text

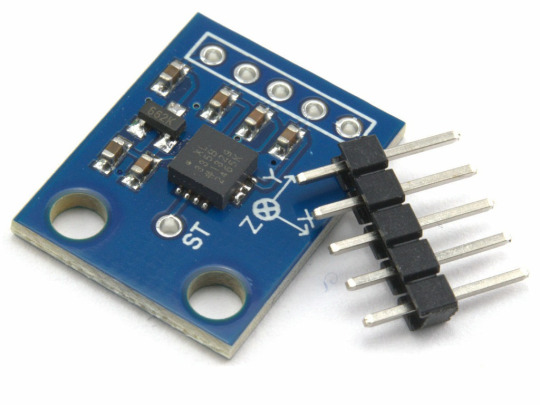

ADXL335 Module

The ADXL335 Module is a compact and energy-efficient 3-axis accelerometer that provides signal conditioned voltage outputs. ADXL335 Module has a minimum full-scale range of ±3 g for accurately measuring acceleration.

This breakout board has the capability to measure both static gravity acceleration in tilt-sensing scenarios, as well as dynamic acceleration caused by movement, impact, or tremors. It is equipped with a built-in voltage regulator and operates seamlessly at 3.3V and 5V (3-5V).

An accelerometer is an electro-mechanical device capable of measuring both static and dynamic acceleration forces. This includes the constant force of gravity acting on your feet, as well as any movement or vibrations that may affect the device.

Systems such as FPV, RC, and Robots.

Navigation systems that utilize GPS technology

Acknowledging and recording the effects.

Devices used for gaming and virtual reality experiences

Features that are activated by movement.

Efficient energy conservation for portable devices.

Monitoring and compensating for vibrations

The detection of free-fall.

Detecting 6D orientation

The characteristics include:

One feature on the board is a Low Dropout (LDO) Voltage Regulator.

Can be connected to either a 3V3 or 5V Microcontroller.

With an ultra-low power consumption rate of only 40uA in measurement mode and an impressive 0.1uA in standby at 2.5V, this device ensures efficiency without compromising on performance.

This feature includes the ability to detect taps and double taps.

A feature for detecting free-fall is included.

The analog output has been successfully connected to the device and is now functioning properly.

Incorporate an ultra low noise linear LDO voltage regulator.

The device contains built-in onboard filters that effectively minimize noise from the motor and other high current electronics.

All sensors on the I2C bus

By using a soldered jumper, it is simple to choose two I2C addresses for the MPU6050.

The LED indicating power.

Incorporate a Logic level converter for I2C connectivity.

Optimized for 5V logic

1 note

·

View note

Text

Low Harmonic Drives: Driving Towards a Greener Future How Clean Power is Empowering the Automotive Industry

Over the past few decades, variable frequency drives (VFDs) have become widespread in industrial and commercial applications for their ability to control motor speed and torque. Traditionally, VFDs utilize pulse width modulation (PWM) techniques to vary motor voltage and frequency. However, PWM generates high harmonic currents that can damage motors, heat up transformers and power cables, and potentially cause voltage distortions on the utility grid. To address these challenges, a new generation of low harmonic drives has emerged based on advanced switching algorithms. What are Harmonics? In electrical systems, harmonics refer to sinusoidal voltages or currents having frequencies that are integer multiples of the fundamental power supply frequency, usually 50 or 60 Hz. Harmonics are produced by non-linear loads like adjustable speed drives that draw non-sinusoidal currents from the power source. The extra frequencies generated interact with the system impedance and generate losses, heating, vibrations, torque pulsations and can even cause misoperation of protective devices if sufficiently high in magnitude. Harmonics cause additional power losses in distribution transformers and overvoltages that reduce insulation lifetime. They can also interfere with communication lines. Traditional PWM Drives and their Harmonic Impact Traditional PWM VFDs employ insulated-gate bipolar transistors (IGBTs) or thyristors to rapidly switch the motor voltages on and off, generating quasi-square wave voltages to control motor speed. However, when these non-sinusoidal voltages are applied to the motor windings, they produce harmonic currents in the supply lines that are integer multiples of the fundamental supply frequency. Specifically, PWM drive techniques generate dominant 5th and 7th order harmonics that can propagate back into the utility system if not properly filtered. The harmonic currents not only stress motor windings but also increase I2R losses in the supply feeders and distribution transformers. Low Harmonic Drives can cause overheating in older transformers not designed for harmonics. Harmonic distortions also increase circulating currents within delta-wye grounded transformers. To mitigate these issues, dedicated harmonic filters need to be installed, increasing overall system costs. Excessive harmonics if left unchecked can even cause protective relays to malfunction. Advancements in Low Harmonic Drive Technology To address harmonic pollution from VFDs, innovative drive manufacturers have developed new low harmonic drive technologies based on advanced switching algorithms that naturally minimize the generation of lower order harmonics. Pulse-Density Modulation

One such technique is pulse density modulation (PDM) where the IGBTs are switched at high frequencies using narrower pulses compared to traditional square waves. By spacing the pulses closer together over time, PDM produces quasi-sinusoidal drive output voltages that inherently contain lower harmonics. PDM drives generate less than 5% total harmonic distortion (THD) without additional filters. Active Front End Drives

Another option is active front end (AFE) drives with a front-end rectifier consisting of IGBTs or MOSFETs instead of diode bridges. The AFE rectifier actively shapes the supply current waveform to follow the voltage waveform and provide near unity power factor without harmonics. AFE drives come with integrated DC chokes to absorb any remaining higher order harmonics internally, keeping them well below 5% THD.

Get more insights on Low Harmonic Drives

Also read related article on Ransomware Protection Market

Unlock More Insights—Explore the Report in the Language You Prefer

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Low Harmonic Drives#Harmonic Mitigation#Low Harmonic VFD#Variable Frequency Drives#Harmonic Distortion Reduction#Energy-Efficient Drives#Harmonic Filters

0 notes

Text

Cream Production Line

A topicals production line, also known as an cream production line (ointment manufacturing line), can be used to make toothpaste, gel, lotion, ointments, and creams. The line consists of an ointment producing factory, labeling machines, capping equipment, and tube or container filling machines. The food, chemical, cosmetic, and pharmaceutical industries all use Cream Production Line. The following provides comprehensive details about the various kinds of Lotion Filling Line equipment:

Cream Manufacturing Plant

Cream Manufacturing Plant is an ideal tool for the pharmaceutical & cosmetic industries for the production of Ointment, Cream, Lotions, Toothpaste & other emulsions & homogenizations. It is specially designed to take care of two critical factors which directly affects the quality of the Ointment/Creams.

Minimum man handling of Ointment.

Negligible vacuums drop during mixing & blending.

Cream Production Line Video

youtube

Tube Filling Machine

The tube filling and sealing machine is perfect for usage in the food, chemical, pharmaceutical, and cosmetic sectors, among others. All types of semi-viscous and viscous products can be filled into flexible composite tubes made of soft plastic with this tube filler.

youtube

Cream Filling Machine

One of the most popular machines in the cosmetics industry is the cosmetic cream filling machine. The food, chemical, and related industries also use this machine. Because the filling and screw capping modules are constructed on the same base and share a similar motor, the monoblock design conserves space. Volumetric, positive displacement of product using piston and cylinder configurations is the filling concept. The ability to adjust the volumes of each piston by adjusting the two cam tracks is another notable feature of this Rotary filler. The cams track rollers are also designed to allow for more precise volume adjustment of individual cylinders. Because bottles in the Monoblock filling and sealing method are sealed right away after filling, extremely high QMP standards are also guaranteed. Accurate sealing is provided by the rotational sealing module, which matches filling. Particles of dust and caps are kept out of filled bottles by an automated cap feeder installed on a separate column. The Monoblock machine contains built-in online automated features, such as sensors that detect bottle falls and cause the machine to stop at the infeed, additional bottle accumulation at the outfeed, and cap accumulation at the feeder stop.

youtube

Bottle Capping Machine

The bottle capper, also known as the bottle capping machine, has been uniquely designed with a stainless steel finish, incorporating an M.S. frame structure with stainless steel enclosures and cladding. The orientation type cap feeder on the ROPP bottle cap sealing machine allows for continuous cap feeding for online operation on any liquid or powder filling line. With the use of interchangeable pieces, this machine can accommodate bottles of different sizes as well as ROPP caps. The ROPP Capping Machine has fewer production requirements and can be used in the pharmaceutical, food, beverage, chemical, pesticide, and liquor sectors, among other packaging industries. It operates automatically online.

youtube

Bottle Inspection Machine

Vials and bottles of liquid are inspected using an online bottle inspection machine. Online Vial & Bottle Inspection Machines are used in the biotech, veterinary, and pharmaceutical industries. This apparatus consists of a three-track conveyor with a hood, an alternate black and white visual inspection background, and illumination configuration. The inspection table is made of stainless steel and has a moving chain of stainless steel slats. Structure composed of square stainless steel pipe, held up by adjustable fasteners. The machine meets GMP requirements.

youtube

Bottle Sticker Labeling Machine

A straightforward mechanism linear design machine, the bottle labeling machine, also known as the bottle self-adhesive sticker labeling machine, is used to mark bottles, jars, cans, tins, and other containers. PET, glass, plastic, aluminum, metal, and tin containers can all be labeled with a bottle labeler. This apparatus has a cutting-edge Micro Processor Control label dispensing mechanism with a product and label detection system. Using an optional special label detection technology, a specially built mechanical and electrical system applies transparent (No Look) labels to bottles at a very high speed. It’s interesting to note that no new format or change parts are needed to convert a bottle from one size to another.

youtube

#ointment manufacturing line#Cream Manufacturing Plant#Tube Filling Machine#Cream Filling Machine#Bottle Capping Machine#Bottle Inspection Machine#Bottle Sticker Labeling Machine#Youtube

0 notes

Text

Global Top 15 Companies Accounted for 58% of total Smart Access Control market (QYResearch, 2021)

According to the new market research report “Global Smart Access Control Market Report 2023-2029”, published by QYResearch, the global Smart Access Control market size is projected to reach USD 1.83 billion by 2029, at a CAGR of 5.1% during the forecast period.

Figure. Global Smart Access Control Market Size (US$ Million), 2018-2029

Figure. Global Smart Access Control Top 15 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Smart Access Control include Ring (Amazon), Zkteco Co.,Ltd, Salto Systems, Hivision, ASSA ABLOY, Johnson Controls, dormakaba, GU Group, Suprema, HEJIANGDAHUATECHNOLOGYCO.,LTD. , etc. In 2021, the global top 10 players had a share approximately 58.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes