#leak testing machine

Explore tagged Tumblr posts

Text

0 notes

Text

Leak Testing Machine Manufacturer | Indian Trade Bird In India

With Indian Trade Bird's leak testing equipment solutions, you can raise the bar for quality control. Through our site, you can get in contact with reliable vendors who offer cutting-edge machinery meant to identify and stop leaks in a range of sectors.

From automotive to pharmaceuticals, our leak testing machines are engineered to deliver precise and reliable results, ensuring product integrity and customer satisfaction. Whether you need to test for air leaks, fluid leaks, or gas leaks, our diverse range of machines caters to your specific requirements. Indian Trade Bird streamlines the procurement process, offering competitive pricing and timely delivery to keep your operations running smoothly. With our platform, you gain access to a wide network of reputable suppliers known for their quality and efficiency.

0 notes

Text

Has anybody else in this thread experiencedjust completely losing trust with anything their family members promise because they're so unreliable but then they notice that you did that and keep trying to rope you back in and occasionally it sounds convincing enough so you agree and then the thing happens and then you just remember why you started not trusting them to begin with

#“i know you have to work tonight but hooking the washer and dryer up will only take 15 minutes”#and then we were there for an hour and a half because yeah ok hooking them up only took 15 minutes but when we agreed to this#you left out the really fucking important part about how you were going to run a test cycle on the washing machine to check for leaks#FUCK YOUUUUUUUUU#I NEEDED TO BE IN BED WHAT IS YOUR FUCKING PROBLEM#CAN YOU JUST NOT TELL THE DIFFERENCE BETWEEN 15 MINUTES AND 2 HOURS? IS YOUR BRAIN COOKED SO BAD THAT YOU CANT TELL THE DIFFERENCE?#WHAT IS YOUR FUCKING ISSUE WHY ARE YOU LIKE THIS

18 notes

·

View notes

Text

the biggest downside to working in a laundromat is that I am constantly reminded that many if not most people do not have the same standards of hygiene and acceptable smells that i do- which is to be expected because i have a really keen sense of smell and i'm hypersensitive in general- so i'm often assaulted with the Stinks of humanity.

like sometimes a person will wash their laundry and i can still smell the stink on it or the stink it has left behind in the washing machine and i think how much i would hate to be alive if my clothes smelled so strongly that even after washing with scented soap they retained the same smell. but some people live like this always and they do so happily and i have to be okay with that 👌

#spiced#on the plus side i can just give a machine the smell test if theres no visual indication it's been used since it was last cleaned#sometimes the smells are so pungent they leak from the barely open doors or up through the detergent reservoirs#it's really crazy#but also when the big dryers are running i can just go in the storeroom and smell warm laundry and thats nice

2 notes

·

View notes

Text

#Rotary Vane Vacuum pump#Dry Vacuum Pump#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System

0 notes

Text

#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System#Rotary Vane Vacuum pump#Vacuum Furnace

0 notes

Text

so we just moved, and the house we moved into has been abandoned for a few years so weve discovered some fun little secrets scattered around as we explored. for example, theres a little room downstairs with graffiti on the door dubbing it 'the dog box'

of course we were intrigued. aside from some storage and a place to put a washing machine, the dog box seems to exclusively contain this old ass piano, with a little window to see into it from outside

also pictured sitting on the piano is a little novelty dagger we found in the grass outside. its all very funny and novel, right? we thought so

that was when we found The Stain

of course, we immediately jumped to some conclusions. the knife outside, the abandoned house, 'do not enter' written on the door. whatever it was, it had dripped through the floorboards from upstairs, from approximately just outside the bathroom. we decided to wait until we finished moving and then grab some peroxide to test it just in case

still, the dog box bloodstain remained a hot topic, and the curiosity was killing me. after figuring out where upstairs the stain wouldve dripped down from, we noticed it had also seeped up through the newly installed flooring, and i decided i couldnt wait to investigate

looking around the dog box, i noticed that there was a section of the ceiling/underfloor that was noticeably newer than the rest of it, meaning the place the stain had leaked through had been pulled out and replaced just before we moved in. suspicious

im using my phone torch to look around in the dark, and when i shine it on the bloodstain it lights up in a distinctly.... glossy way. when i get closer i can see its not matte, but sticky. so i decide to touch it, and immediately im hit with a STRONG smell of something deeply familiar. all the pieces fall together at once, and using my superior investigative prowess i have deduced the culprit

it was bees. there was a fuckoff massive beehive in the floor that got taken out before we moved in and it leaked honey up through the floorboards and onto the floor of the dog box and the landlord didnt feel like cleaning it up. mystery solved

8K notes

·

View notes

Text

#Helium Leak Testing#Helium Recovery System#Helium Leak Detector#Helium Leak Detection Service#Helium Leak Testing Machine#Helium Leak Testing System#Helium Leak Testing Service#Rotary vane vacuum pump manufacturers#Dry Screw Vacuum Pump

0 notes

Text

Ensuring Quality: The Vital Role of Vacuum Leak Test Machines

Greetings! Are you planning to invest in the best vacuum leak test machine? You have come across the right page! Dive into the worth of this equipment to make an informed procurement decision. Vacuum leak test machines are indispensable tools across diverse industries, guaranteeing the quality and integrity of sealed products and containers.

These machines are instrumental in identifying leaks or defects that could affect the functionality or safety of the products. As guardians of product quality, vacuum leak test machines play a pivotal role in upholding industry standards and ensuring that sealed items meet the highest levels of reliability.

0 notes

Text

Bubble Leak Test Equipment

Bubble leak test equipment is commonly used to determine the integrity of package seals. It is a fast and affordable method for detecting gross leaks. However, bubble testing cannot pinpoint the exact location of a leak. It is also time consuming and may damage the product.

A bubble leak test works by generating a pressure differential between the sealed part and the surrounding solution. When a bubble passes through the seal, it is driven by the difference in pressure and will escape from the part into the solution. The rate of bubbles will increase as the size of the leak increases. A bubble test can detect a leak as small as 1 mm.

The most popular bubble test is based on the standard ASTM 2096. In this method, the packaged product is submerged in water and then pressurized below the level of the water surface. The package is then evacuated to generate a vacuum. When the leaking gas escapes through the packaging seal, it forms a stream of visible bubbles.

Another method of bubble leak testing is the vacuum box technique. This is typically used for components that cannot be directly pressurized or where access is obstructed to one side of the component. The tested part is wetted with a foam-generating liquid and then placed in a vacuum box. The leaks can be located by observing the formation of a stream of bubbles in the box.

In addition to bubble leak tests, there are many other leak detection methods. Some are more expensive than others, but all are capable of identifying leaks down to extremely low rates. For example, a molded plastic soda bottle requires a leak rate of less than 1x10-7 atm-cc/s. To achieve this rate, a bubbling test would require 11 hours – not practical for a high-speed process.

0 notes

Text

Vacuum Leak Test Machines: Revolutionizing Lab Testinga

Among the many cutting-edge technologies, vacuum leak test machines stand out as a true game-changer. The necessity for trustworthy and effective lab testing equipment has become critical in the constantly changing world of quality assurance.

#lab testing instruments#lab testing equipment suppliers#lab testing equipment#Vacuum Leak Test Machines#vacuum leak test

0 notes

Text

Air Leak Testing Machine supplier, Manufacturer Company in Pune | Inerrant Robotomation Pvt. Ltd

#Air Leak Testing Machine#Air Leak Testing Machine supplier#Air Leak Testing Machine Manufacturer#Air Leak Testing Machine in Pune#Air Leak Testing Machine in Solapur#Air Leak Testing Machine in Amravati#Air Leak Testing Machine in Jalgoan#Air Leak Testing Machine in Jalna#Air Leak Testing Machine in Aurangabad#Air Leak Testing Machine in Ahmednagar#Air Leak Testing Machine in Thane#Air Leak Testing Machine in Vasai#Air Leak Testing Machine in Nagpur#Air Leak Testing Machine in Chiplun#Air Leak Testing Machine in Kolhapur#Air Leak Testing Machine in Sangli#Air Leak Testing Machine in Miraj#Air Leak Testing Machine in Satara#Air Leak Testing Machine in Mumbai#Air Leak Testing Machine in Kalyan#Air Leak Testing Machine in Navi Mumbai

0 notes

Text

Seal Integrity Testing for Food Packaging

Maintaining the reliability of food packaging seals is a vital part of product safety and quality. The failure of a package’s seal could lead to spoilage, product recalls and reduced brand image.

Food packaging leak testing methods are often non-destructive, and can be conducted on production lines to ensure 100% seal integrity. Dye penetration tests are an example of this type of test.

Burst Leak Test

A food package should protect its contents throughout distribution and storage. This is why manufacturers regularly test seal integrity and use a range of methods to do so. A minor defect like a bubble leak in the packaging can significantly compromise the food product’s quality and safety.

Among the most popular seal integrity testing techniques is the burst leak test. It involves pressurizing a sample of the sealed package and submerging it in water to see if any air bubbles appear around the seal area. This type of test is usually performed in an acrylic vacuum chamber and complies with ASTM standard F1140.

Another common method is the creep test, which consists of inflating a package to a predetermined pressure and maintaining it for a specified period of time. The pressure on the package is usually measured and a pass/fail result is declared when the package is inspected after the testing period. This test can be either restrained or unrestrained, which influences the results since a restraining device limits the expansion angle and allows for a differentiation between packages with strong or weak seals.

Lastly, the peelability test is used to measure the force required to open a peeled package. It is usually conducted on a peelable medical package and provides force data that can be interpreted to help with validation and process control.

Leakage Test

Seal integrity testing is a necessary step for any manufacturer producing packaged products. The integrity of the packaging helps maintain product quality, protects the products from environmental impacts and extends the shelf life of the food. As such, maintaining the reliability of the seals is critical for food and pharmaceutical manufacturers.

One of the most common techniques for testing package integrity is using a leakage test to measure the strength of a seal. This type of test is nondestructive and works by subjecting the package to a certain amount of pressure or vacuum. The machine will then detect any changes in pressure that indicate a leak in the seal.

A food packaging leak detector is a tool that can be used to determine the quality of a seal on a variety of different types of food packages. The device uses a computer to monitor the pressure inside of the package, and it will notify the operator when there is a problem. This will allow the operator to take corrective action before the food goes bad or the packaging is compromised.

Another popular method of detecting leaks in flexible or semi-rigid foods is to use the dye penetration test, also known as the standard test method for detection of leaks in nonporous, flexible barrier materials by dye penetration (ASTM F3039 – 15). This technique involves immersing the package into a solution of water and a specified indicating dye. The package is then inspected after a period of time to see if the dye has penetrated the package seal area.

Moisture Test

A moisture test measures the ability of a package to resist water and air ingress. The test is done by placing the sealed food product in a container under controlled laboratory conditions. The test is performed on a pass or fail basis.

If your food packaging does not contain a good barrier to the ingress of moisture, it can lose its shelf life and quality. This can lead to a loss of revenue for your company due to product recalls, as well as tarnished brand image. Moisture test results help you select the right materials for your packaging. This ensures your product stays fresh during production and distribution, and saves you costs on food waste.

The Moisture Leak Test is one of the most common tests for evaluating the integrity of a heat-sealed package. The test uses a dye penetrant to locate leak channels within the seal area of a package. The test can be conducted with either the injection method or the edge drip method. The injection method involves injecting a dye penetrant into the package along its longest edge. The edge drip method involves using a container with a length that accommodates the longest edge of the packaged product.

The physical test methods used to determine a package’s integrity are more reliable than biological challenge tests, which may be prone to errors. However, physical testing can be expensive and time-consuming. New nondestructive sensing technologies are advancing as an alternative to traditional testing methods.

Environmental Test

The gas bubble leak detectory of food packaging is crucial to prevent the deterioration of packaged products. This ensures the product stays fresh and sanitary, which is especially important for delicate foods that are prone to contamination from outside factors like air or moisture. This can impact both the consumer’s health and the brand reputation of a company. Even a minor leak in the packaging can cause this to happen, and companies that rely on these types of products must have a robust package testing machine to detect any problems with their packaging immediately.

Traditionally, visual inspection was the main method used to determine the integrity of packaging. However, micro-leaks and discontinuities in the seal area made it difficult to catch these issues with this method. New test methods have been developed to assess the quality of packaging without requiring the physical manipulation of the package. For example, the patented nondestructive airborne ultrasound technology of PTI’s Seal-Scan system can quickly and accurately scan seal areas to identify defects including micro-leaks, discontinuities, misaligned seals and incomplete seals.

Other test methods include the dye penetration test (ASTM F3039 - 15), where an operator applies a dye to the sealed area and then examines the other side of the seal after a specified period of time to see if the dye has transferred through the seal. The tensile strength test is another mechanical test that measures the force required to pull apart a 1-inch section of the package seal. Creep tests and drop testing can also be conducted to measure seal strength, in which the pack is inflated to a percentage of its burst pressure and then held for a period of time to see how the package responds to stress.

0 notes

Text

lighter's 6-step guide to ruining your kitchen (and winning your heart)

lighter lorenz x reader (why 6 steps? idk)

summary: what starts as lighter trying to fix your broken coffee maker turns into an explosion of chaos, tools, and laughter. he's confident— too confident— but even as things spiral out of control, you can't help but enjoy the mess. (he's trying his best)

you eyed the old coffee maker like it had personally wronged you. in fairness, it kind of had— months of leaking water, leaking coffee, sputtering, and smelling vaguely like burnt plastic had left you at your wit's end. when lighter showed up for a visit and saw you glaring at it, he made the offer:

"i can fix that for you."

you raised a skeptical eyebrow. "can you?"

"please," he said, rolling up his sleeves with the bravado of someone who definitely had no idea what they were doing. "i've tackled bigger challenges."

step one: the toolbox gauntlet

it started innocently enough. you dug out the dusty old toolbox you hadn��t touched in years while lighter sets the coffee maker on your kitchen counter like it was a patient awaiting surgery.

"this is a mess," he said, holding up a screwdriver and spinning it in his fingers like he was auditioning for a hardware commercial.

"i know," you replied. "that's why i was going to buy a new one."

"where's the fun in that?" lighter grinned at you. "trust me, i've got this."

famous last words.

step two: controlled chaos (emphasis on chaos)

lighter pops open the back panel with alarming confidence, revealing a tangled mess of wires. "here's your problem," he said, pointing at the horrifying jumble like it was obvious.

"oh really?" you deadpanned. "i thought it was working perfectly."

he ignored your sarcasm and started tinkering, tools clinking against the counter as he muttered things like "that's weird" and "pretty sure this goes here". you leaned against the counter, arms crossed, watching the spectacle unfold. at one point, a small spark shot out of the machine, and both of you jumped back.

"totally normal," lighter said, though his wide eyes behind his tinted glasses betrayed him.

"normal for what? a sci-fi action movie?"

"relax", he said waving you off. "i've got it under control."

you weren't sure what definition of "control" he was using, but it definitely wasn't yours.

step three: the great coffee maker escape

things escalated when lighter attempted to plug the machine back in for a test run. it hummed ominously, sputtered, and then released a small puff of smoke. you grabbed a kitchen towel, ready to smother it in case of fire.

"uh, that's... progress?" lighter offers weakly.

"progress toward a lawsuit," you muttered, fanning the smoke away.

he finally threw in the towel, setting the screwdriver down with an exaggerated sigh. "okay, maybe it's more stubborn that i thought."

"lighter, it's dead." you laughed, shaking your head. "you didn't fix it— you put it out of misery."

step four: damage control

despite the chaos, lighter didn't look defeated. in fact, he looked entirely too pleased with himself as he leaned against the counter, arms crossed, and smirked at you. "hey at least we tried," he said. "and by we, i mean me, because i did all the work."

“oh, yes, all your hard work ruining my kitchen,” you teased, gesturing to the tools and coffee maker debris scattered everywhere.

“ruined is a strong word,” he countered, nudging you with his elbow. “i prefer ‘temporarily restructured.’”

you rolled your eyes but couldn’t stop smiling. “well, thank you for temporarily restructuring my coffee maker into a pile of junk.”

“anytime,” he said, his grin widening. “seriously, though, i’ll help you pick out a new one. one with fewer... deathtrap vibes.”

“appreciated,” you said, grabbing a damp cloth to start cleaning up.

step five: the clean-up crew

cleaning was just as chaotic as the diy attempt. lighter insisted on washing his hands in the tiniest sink possible, accidentally knocking over a glass in the process. you spent more time dodging his elbows than actually organising the tools.

“maybe stick to your day job,” you joked, shoving a wrench back into the toolbox.

“funny,” he replied, leaning over the counter to grab a towel. “i think i make an excellent handyman.”

“sure,” you said, smirking. “if the goal is to create more problems than you started with.”

he shot you a mock-offended look, but the glimmer in his eye gave him away. “you wound me.”

step six: the aftermath

by the time the kitchen was semi-clean and the coffee maker officially declared beyond repair, you were both leaning against the counter, exhausted but grinning.

“you know,” you said, nudging him with your shoulder, “you’re banned from fixing anything in my apartment ever again.”

“fair enough,” he replied, straightening up. “but admit it—you had fun.”

“fun?” You gave him a look. “that’s what we’re calling this disaster?”

“a masterpiece of domestic chaos,” he corrected, his grin teasing.

you laughed, shaking your head. “alright, fine. it was... entertaining.”

“entertaining?” he leaned closer, raising an eyebrow. “try ‘the best time you’ve had all week.’”

“don’t push it,” you said, but the smile on your face betrayed you.

© liyue-harbour 2024 masterlist

#lighter#lighter lorenz#lighter x reader#lighter x you#x reader#zzz#zzz x reader#lighter lorenz x reader#zenless zone zero#zenless zone zero x reader#zenless zz x reader#zzzero x reader#zzzero#lighter zzz

658 notes

·

View notes

Text

Exploring Advanced Vacuum and Helium Leak Detection Solutions

In industries ranging from manufacturing to research, vacuum systems play a pivotal role in ensuring operational efficiency and product quality. Among the various technologies available, rotary vane vacuum pumps, dry vacuum pumps, helium leak detectors, helium leak testing machines, and helium recovery systems have become essential tools. Let’s dive into the functionalities and applications of these systems to better understand their impact.

Rotary Vane Vacuum Pump: Reliable Performance in a Compact Design

The rotary vane vacuum pump is one of the most commonly used types of vacuum pumps. Its compact design, reliability, and versatility make it suitable for various applications. The pump operates by using vanes that rotate inside a cylindrical chamber, creating a vacuum by displacing air or other gases.

Applications:

Medical and Laboratory Equipment: Rotary vane vacuum pumps are used in medical applications such as vacuum-assisted wound closure systems and laboratory vacuum systems.

Packaging Industry: These pumps are integral to vacuum packaging machines, ensuring products remain fresh by eliminating air from packaging.

HVAC Systems: In heating, ventilation, and air conditioning systems, rotary vane pumps help in refrigerant recovery and evacuation processes.

Key benefits of rotary vane vacuum pumps include their durability, low noise operation, and ease of maintenance.

Dry Vacuum Pump: Oil-Free Efficiency for Sensitive Processes

Unlike rotary vane pumps, dry vacuum pump operate without the use of oil or any other sealing liquid. This makes them ideal for processes where contamination must be avoided.

Advantages of Dry Vacuum Pumps:

Clean Operation: With no oil involved, these pumps prevent contamination of the pumped gases or the environment.

Energy Efficiency: Many dry vacuum pumps are designed to consume less energy, reducing operational costs.

Low Maintenance: Without oil changes or sealing fluid replacement, maintenance requirements are minimal.

Common Applications:

Pharmaceutical Industry: Dry vacuum pumps are used in tablet coating and other sensitive pharmaceutical processes.

Semiconductor Manufacturing: These pumps play a critical role in processes like chemical vapor deposition and etching, where cleanliness is paramount.

Food Processing: Dry vacuum pumps are used in freeze-drying and vacuum cooling applications.

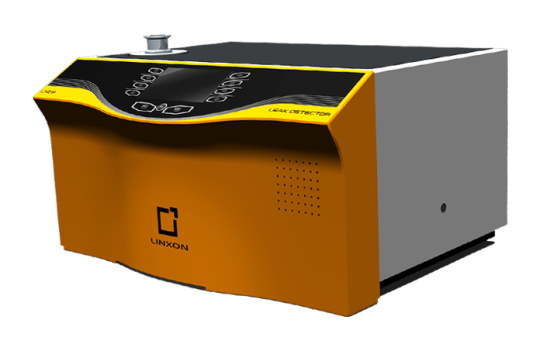

Helium Leak Detector: Precision in Leak Detection

Helium leak detector are essential tools for identifying and quantifying leaks in sealed systems. Helium is an ideal tracer gas due to its small molecular size and inert properties, making it capable of detecting even the tiniest leaks.

Working Principle:

A helium leak detector typically consists of a mass spectrometer that senses the presence of helium within a system. When helium is introduced into the system under test, the detector identifies any escaping helium, pinpointing leaks with high accuracy.

Key Applications:

Automotive Industry: Helium leak detectors are used to ensure the integrity of fuel systems, air conditioning systems, and exhaust systems.

Aerospace Sector: Ensuring leak-tight components in critical aerospace systems, such as fuel tanks and propulsion systems.

Medical Devices: Used in testing the hermeticity of medical implants and diagnostic equipment.

The precision and reliability of helium leak detectors make them indispensable for maintaining safety and quality standards.

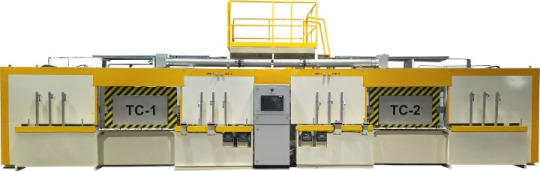

Helium Leak Testing Machine: Comprehensive Leak Testing Solutions

A helium leak testing machine is a complete system that incorporates a helium leak detector, pumping systems, and control units to automate the leak testing process. These machines are tailored to meet the specific requirements of various industries.

Features and Benefits:

Automation: Automated testing reduces human error and increases throughput.

Customizability: Machines can be designed for specific applications, such as testing automotive radiators, batteries, or high-pressure vessels.

High Sensitivity: These systems can detect leaks at the micro-level, ensuring the highest standards of quality control.

Industrial Applications:

Energy Sector: Used for testing high-pressure gas cylinders and pipelines.

Electronics Manufacturing: Ensures the integrity of sealed electronic components such as sensors and displays.

Vacuum Technology: Essential in testing vacuum chambers and components for scientific and industrial applications.

Helium Recovery System: Sustainability in Leak Detection

As the demand for helium increases and its availability decreases, helium recovery system have become a critical component of modern leak detection setups. These systems capture and recycle helium, reducing operational costs and environmental impact.

How Helium Recovery Systems Work:

Capture: Helium used in the testing process is captured from the test environment.

Purification: The captured helium is purified to remove contaminants.

Storage: The purified helium is stored for reuse in subsequent tests.

Advantages:

Cost Savings: Reducing the need for new helium purchases can significantly cut costs.

Environmental Benefits: Minimizing helium waste supports sustainable operations.

Enhanced Efficiency: Continuously recycled helium ensures a steady supply for testing operations.

Applications:

Manufacturing Plants: Ideal for large-scale operations where helium usage is high.

Research Facilities: Ensures a sustainable supply of helium for experiments and testing.

Aerospace Industry: Critical for testing and maintaining expensive and sensitive components.

The Future of Vacuum and Leak Detection Technologies

With advancements in technology, vacuum systems and helium leak detection solutions are evolving to meet the growing demands of precision, efficiency, and sustainability. Integration with IoT and smart systems enables real-time monitoring and diagnostics, reducing downtime and increasing productivity. Moreover, the push toward eco-friendly solutions is driving the adoption of oil-free and helium recovery systems.

Final Thoughts:

Whether it’s a rotary vane vacuum pump ensuring efficient vacuum creation, a dry vacuum pump delivering oil-free operation, or a helium leak detector safeguarding the integrity of critical systems, these technologies are indispensable. Helium leak testing machines and helium recovery systems further enhance efficiency and sustainability, making them vital in today’s industrial landscape.

By understanding and implementing these advanced systems, industries can achieve higher standards of quality, safety, and environmental responsibility.

#Rotary Vane Vacuum pump#Dry Vacuum Pump#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System

0 notes

Text

Why Tekman Vacuum Pumps Are Ideal for Heavy-Duty Industrial Applications

When it comes to heavy-duty industrial applications, reliable and high-performance equipment is crucial. Tekman, one of the leading manufacturers of industrial vacuum pumps in India, stands out for its advanced technology and durable solutions. Tekman’s vacuum pumps are specifically designed to meet the demands of various industrial sectors, ensuring maximum efficiency, reliability, and cost-effectiveness. In this article, we will explore why Tekman vacuum pumps are the ideal choice for heavy-duty industrial applications.

High Efficiency and Performance

The great efficiency of Tekman vacuum pumps is one of the main factors that makes them perfect for demanding industrial applications. These pumps are designed to withstand the most taxing duties and continue to operate at their best for extended periods. The rotary vane vacuum pumps from Tekman are well-known for their capacity to function in harsh environments and at high pressures, which makes them ideal for sectors like manufacturing, chemical processing, and the automotive industry.

Advanced Technology for Precision

Modern technology is used by Tekman to create their vacuum pumps. Accurate and reliable performance is made possible by the use of sophisticated features like automated control systems. For applications where accuracy is crucial, such as helium leak testing devices and helium recovery systems, Tekman's vacuum pumps are perfect. Tekman's pumps are a great choice for these systems since they need to be extremely accurate to detect leaks and recover helium effectively.

Durability in Harsh Environments

Equipment used in heavy-duty industrial applications is frequently subjected to corrosive materials, high temperatures, and continuous operation. Tekman vacuum pumps are designed to endure these demanding circumstances. Their vacuum furnaces, for example, are made to function dependably in hot conditions. Tekman's pumps, whether used for material processing or heat treatment, provide enduring durability that enables businesses to minimize downtime and preserve seamless operations.

Versatility across Industries

Industrial vacuum pumps from Tekman are very adaptable and can be used for a variety of industrial applications. Tekman offers solutions that satisfy particular needs, ranging from vacuum furnaces used in the metallurgy sector to helium leak detectors used in the aerospace industry. Because of their versatility, Tekman vacuum pumps are a preferred option for a wide range of industries. These applications include vacuum impregnation, drying, and coating.

Energy Efficiency for Cost Savings

Energy efficiency is a crucial component in cutting operating costs in the cutthroat industrial environment of today. Industries can reduce their energy usage by using Tekman vacuum pumps, which are developed with energy efficiency in mind. For heavy-duty applications, where continuous pump running might result in high energy costs, this is especially crucial. Energy-efficient pumps from Tekman, such as their rotary vane vacuum pumps, are designed to use less energy while still providing excellent performance, which eventually saves organizations a significant amount of money.

Seamless Integration with Other Systems

Tekman vacuum pumps are made to easily interface with other industrial systems; they are not merely stand-alone devices. When dealing with intricate machinery such as helium recovery systems and helium leak testing devices, this integration is very crucial. With these solutions, Tekman's pumps function well, guaranteeing little interference and seamless operations. Many companies use Tekman because of its ability to integrate with other equipment, which improves the overall performance of industrial operations.

Customization Options for Specific Needs

When it comes to vacuum pump performance, many industries have different needs. Tekman provides a variety of pumps designed for particular industrial applications since it recognizes the need for customization. Tekman makes sure that its products satisfy the exact requirements of every business, whether that means creating pumps with specific specifications or modifying the vacuum levels. For instance, Tekman's pumps may be tailored to precisely match the requirements of helium recovery systems, guaranteeing efficient helium capture and little waste.

Maintenance and Support for Longevity

The upkeep and support services provided by industrial equipment are crucial to its success. By offering outstanding after-sales support, Tekman makes sure that their vacuum pumps keep operating at their peak efficiency. Even in heavy-duty applications, Tekman pumps have a longer lifespan thanks to routine maintenance and timely support services. Industries can guarantee that their equipment stays in optimal condition with Tekman's assistance, increasing uptime and total output.

Cost-Effectiveness Without Compromising Quality

Cost-effectiveness cannot be disregarded when selecting an industrial vacuum pump, even though performance and efficiency are important considerations. Tekman provides premium vacuum pumps at affordable costs, which makes them an economical choice for demanding industrial uses. Through the provision of long-lasting performance, energy savings, and minimal maintenance expenses, Tekman guarantees that its vacuum pumps offer exceptional performance for the money. In the market for industrial vacuum pumps, Tekman is a popular brand due to its price and quality balance.

Tekman’s Contribution to Environmental Sustainability

Tekman is a major player in the field of environmental sustainability, which is becoming a more significant consideration for industries. Their helium recovery systems and helium leak testing machine greatly aid in the reduction of helium waste, which is an essential resource for numerous industrial uses. By recovering and reusing helium, Tekman's pumps reduce their negative effects on the environment and encourage sustainability. Industries may achieve their environmental objectives while retaining good performance by investing in Tekman's vacuum pumps.

Reliable Performance for Heavy-Duty Applications

The vacuum pumps from Tekman are designed to function dependably even under the most demanding industrial circumstances. Tekman pumps provide reliable performance under all conditions, including high temperatures, demanding jobs, and continuous operation. Their vacuum furnaces work especially well in fields like metallurgy and heat treatment that need high temperatures to process materials. Because of Tekman's dedication to dependability, its vacuum pumps will continue to satisfy industrial sectors' demands for many years to come.

Simplifying Complex Processes with Tekman Pumps

Advanced equipment is necessary for complex processes in industries like manufacturing, automotive, and aerospace. Tekman's vacuum pumps make these procedures easier by offering dependable and effective solutions. Their pumps are made to tackle complex jobs like detecting helium leaks, which is essential for maintaining the integrity of aeronautical parts. Tekman's pumps are a great option for companies with demanding applications because of their capacity to streamline intricate procedures while upholding high performance requirements.

Enhancing Industrial Automation with Tekman

Tekman's vacuum pumps are essential to improving industrial automation as companies continue to adopt automation. The seamless functioning of automated systems is facilitated by the dependability and effectiveness of Tekman pumps. Industries may increase overall operational efficiency, decrease downtime, and boost output by incorporating Tekman pumps into automated production lines. An integral part of the contemporary automated industrial ecosystem is Tekman's pumps.

#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System#Rotary Vane Vacuum pump#Vacuum Furnace

0 notes