#lathe conversion to cnc

Explore tagged Tumblr posts

Link

4 Reasons Why A Precision Matthews Milling Machine Is Your One-stop CNC Mill

As you can see, a Precision Matthews CNC mill is a solid milling machine that you can use to cut almost any material.

Nonetheless, these mills aren’t confined to the heavy machining options they offer.

You see, mills from Precision Matthews can even be used to create the most sophisticated parts, thanks to their high-end CNC software. So when it comes to creating highly precise pieces during large-scale production, you can rely on them.

In fact, as a manufacturer Precision Matthews is so confident of its mills that they cover them under extended warranties for as long as three to five years.

That sounds impressive, doesn’t it?

At CNC Conversion Plus, we have the most extensive selection of Precision Matthews milling machines and CNC conversion kits.

Also, we have a large inventory of CNC-capable mills and lathes of every size and for every purpose, including industry leaders like Grizzly, Harbor Freight, Shop Fox, and Sieg. And we can deliver your ideal CNC machine to your workshop at the most affordable price.

0 notes

Text

How to Spot Quality Equipment at Machine Shop Auctions

When browsing machine shop equipment auctions, it’s crucial to know how to spot quality items. Auctions are excellent for finding well-priced machinery and tools, but without careful evaluation, there’s a risk of buying faulty or worn-out equipment. Here’s a guide to help you identify quality equipment at these auctions.

1. Research the Equipment Types in Demand

Before attending a machine shop equipment auction, do some research on the equipment types you’re interested in. Each category, from milling machines to CNC lathes, has its quality benchmarks. Knowing the specifications and expected lifespan of the tools you need can help you quickly filter out poor-quality items. Review online forums, and machinery sales websites, or consult with industry experts to understand the market standards for each piece.

2. Examine Visual Condition Closely

A good inspection begins with a detailed visual assessment. Check for obvious signs of wear and tear that might indicate excessive use or lack of maintenance. Look for:

- Rust: Rust can compromise the structural integrity of metal equipment. Minor surface rust may not be a dealbreaker, but extensive rust, especially on critical components, suggests neglect.

- Welding or Repairs: Signs of past repairs or welding work may indicate previous damage. This isn’t necessarily a dealbreaker, but it’s best to understand the nature of the repairs and how they impact functionality.

- Cleanliness: While auctioned equipment often shows signs of use, machinery that appears clean and well-kept may have been better maintained.

3. Assess Operational Readiness

Many machine shop equipment auctions allow potential buyers to inspect machinery while in operation. If possible, test the equipment to ensure that all moving parts work smoothly and without unusual noise. Equipment that operates without stalling, rattling, or struggling under pressure is a good sign. Take note of any resistance or roughness in moving parts, as these can indicate wear on the gears or bearings.

4. Check the Maintenance Records

Some sellers may provide maintenance records, especially for high-value machinery like CNC machines or larger lathes. A consistent record of servicing, calibration, and part replacements shows that the equipment was cared for and maintained at a professional level. When possible, ask the auction manager or the equipment owner for these records to get a better sense of the equipment's history.

5. Inspect Tooling and Accessories

Tooling and accessories that come with machine shop equipment are often valuable on their own. Look for any extras like cutting tools, holders, clamps, and adapters, that can add significant value to your purchase. Assess the condition of these accessories—worn-out or broken tools might indicate heavy use. Conversely, if the equipment comes with well-kept accessories, it suggests that the previous owner maintained the machinery carefully.

6. Pay Attention to Brand Reputation

Certain brands have a reputation for quality and longevity in the machine shop industry. Research the brands available at the auction and prioritize those known for reliability, such as Haas for CNC machinery or Bridgeport for milling machines. Lesser-known brands might be tempting for their lower prices, but it’s essential to research their track record in terms of durability and parts availability.

7. Look for Signs of Obsolescence

When investing in machine shop equipment, ensure it isn’t outdated or difficult to repair. Older machines can sometimes be cost-effective, but they might lack modern functionality and safety features. Additionally, sourcing parts for older equipment can be a challenge. Look up the model and confirm that parts and support are still available from the manufacturer or aftermarket suppliers.

8. Estimate Repair Costs and Factor Them In

Some auctioned equipment may have minor issues that require repair or maintenance. If you spot an item with small mechanical issues but the potential for longevity, estimate the repair costs. Simple repairs, like replacing belts or bearings, are often affordable and can justify purchasing a machine at a lower price. However, costly or complex repairs (e.g., motor replacement on CNC machinery) may not be worth the investment.

9. Be Cautious of “As-Is” Terms

Most machine shop equipment auctions sell items on an “as-is” basis, meaning there are no guarantees on condition. While this is common, it places more responsibility on the buyer to assess quality carefully. Be extra cautious and scrutinize each piece thoroughly, as the “as-is” condition often means you won’t have recourse if the equipment turns out to be faulty.

10. Consult with a Specialist When in Doubt

If you’re new to purchasing at machine shop equipment auctions or if you’re planning to buy high-value equipment, consider bringing a specialist or technician. A knowledgeable person can spot potential issues and help you avoid costly mistakes. Their insights can be invaluable, especially for evaluating intricate machinery like CNC mills or lathes.

Final Thoughts

Machine shop equipment auctions offer great opportunities to acquire quality machinery at reduced prices. However, evaluating each piece’s quality before bidding is essential to ensure you’re making a wise investment. With these tips, you’ll be better prepared to navigate machine shop equipment auctions, identify quality machinery, and find the right equipment for your workshop needs.

0 notes

Text

Automation and Smart Technologies: Transforming the Machine Tools Market

Market Overviews

In 2023, the machine tools industry generated income of USD 78.8 billion in 2023, which is projected to experience a CAGR of 4.4% over the forecast period, to attain USD 105.6 billion by the end of the decade. This is primarily attributable to the fact that the precision and proficiency in making are the key indicators for minimum wastage and alteration. Machine tool, which has a very high precision level, can help to avoid material wastages and cost reduction at the time of assembly of the part.

The major reason for the growth of automation and robotics in machining technologies can be identified in the weak workforce in the high-level manufacturing industry of the developed countries and greater use of these techniques in the aerospace, defense, medical device, marine and other sectors.

The progress of Industry 4.0 has conversed multiple innovations like artificial intelligence, big data, robots and automation, allowing more efficacy, productivity and flexibility across major sectors. One of the factors, which increased the use of machine tools in the metal fabrication and industrial manufacturing industries, is the growth of the pressure on manufacturers for good quality products with efficiency, sustainability and acceptable lead time and no possible errors. An example is, automotive industry introduced visual inspection system in their production, this had a great impact in PPM defects.

Key Insights

The metal cutting category held a larger market share of around 70% in 2023 globally.

Metal cutting machine tools is an important part of the industry, which includes automotive, aerospace, defense, mechanical engineering, and medical devices industries for precise shaping of metal and alloys such as iron, steel aluminum, titanium, and copper.

This category contains a huge range of different machinery like crurshers, grinding machines, turning machines, milling machine, electrical discharge machine (EDM) and many other.

Of them, milling machine markets outshine because of their capability to generate accurate cuts of metal, making them primarily engineered by manufacturers.

In contrast, the metal forming machines are used for bending, shaping, and other processes that are associated with metalworking.

The CNC category held a larger market share of around 75% in the global machine tools market in 2023 and is the fastest-growing in the automation segment.

CNC machines reduce manufacturing time and error rates by using CAD and CAM software to receive design instructions from a computer.

They are able to accomplish more tasks in one line prompt then one would be able to give. Therefore, there is a reduction in level of guided instruction.

Numerous types of production equipment like milling, grinding, turning, lathing, drilling and electrical discharge machining can be also merged with CNC technology.

Standard tools like change-handing on the lathe machine or milling with a handheld machine necessitates a higher level of expertise and may not conform to the set shape.

CNC technology is preferred over conventional machine tools for higher precision and more efficient production.

APAC held the largest revenue share in the global machine tools market in 2023 due to increasing industrialization and population growth in countries like China and India.

Competition among emerging economies to become manufacturing powerhouses, coupled with government initiatives like Make in India, Made in China 2025, and Making Indonesia 4.0, has created a favourable investment environment.

Significant growth is also observed in the IT sector of North America.

Source: P&S Intelligence

#Machine Tools Market Share#Machine Tools Market Size#Machine Tools Market Growth#Machine Tools Market Applications#Machine Tools Market Trends

1 note

·

View note

Text

5 Benefits of Modding a Firearm

While there’s nothing wrong with owning and enjoying a stock handgun or rifle, the gun community loves modding their firearms. Whether you want to fundamentally change your gun with a new barrel or just want an AR 15 dust cover with a cool image, there are a few different reasons to modify your gun. From making the trigger crisper to expanding your magazine capacity, here are some compelling reasons to mod your gun. Improve the Trigger Many stock triggers are mushy or simply mediocre. They get the job done, but they could be much better. Many shooters like their triggers to feel crisp with a positive reset. This is an easy mod that can elevate your overall shooting experience. You can switch out the trigger connector for a lighter trigger pull, or you can even replace a curved trigger with a straight blade trigger. Personalize the Gun’s Aesthetics Another reason you might mod your gun is to personalize it and make it unique from an aesthetic standpoint. You can easily add a splash of color or some art to the bolt, dust cover, buffer tube, upper or lower receiver. There are plenty of ways to upgrade your gun’s aesthetics. Find a manufacturer with a large library of pre-generated images to choose from.

Get a Better Grip Whether your hands are sweaty or you wear gloves at the range, the stock grip on your handgun may not be enough. Luckily, select mods and parts can fix this problem. Whether it’s a full conversion, like a SIG P365 grip module, or a service that adds texture to your existing grip, you can improve the grip of your favorite handgun. You can even find granulated profile-cut grip tape for a precise fit that is easy to install in just a few minutes. Expand Your Magazine Capacity Mag extensions can allow you to store more rounds while also providing more space for your grip. Subcompact guns benefit greatly from this since their stock magazines are typically smaller. A Glock 43X extended mag gives you more space to grip while expanding the magazine’s round storage capacity. It’s easy to install and provides genuine value.

Improve Your Firearm’s Overall Accuracy A firearm is only as accurate as the shooter, but that doesn’t mean you can’t make mods and tweaks to improve your firearm’s accuracy in small ways. The barrel is a good place to start. Swapping out the barrel offers a few benefits. First, a heavier barrel (also known as a bull barrel) can help with firing stability. Different twist rates can also impact the firearm’s accuracy and performance. The second benefit is purely for looks. You can find barrels with polished feed ramps for improved and more reliable feeding along with flashier colors, from gold to rainbow, to give your gun a pop of color while improving its performance.

About NDZ Performance Based in Cheshire, Connecticut, NDZ Performance is an industry leader in firearms accessories. With a full CNC shop and 3D printing capabilities for rapid prototyping, NDZ Performance is continually developing new aftermarket parts for all major firearms brands. Their team leverages state-of-the-art CNC millers, lathes, and fiber laser engravers to create next-level personalized parts, including AR dust covers, Glock rear slide plates, and much more. Perfection is the goal, and it’s clearly visible in every detail of every component and product. With talent, experience, and common sense on their side, NDZ Performance delivers the accessories you need to upgrade or personalize your favorite firearms. Find the firearm upgrades you need at https://ndzperformance.com/ Original Source: https://bit.ly/3Nqr4qh

0 notes

Text

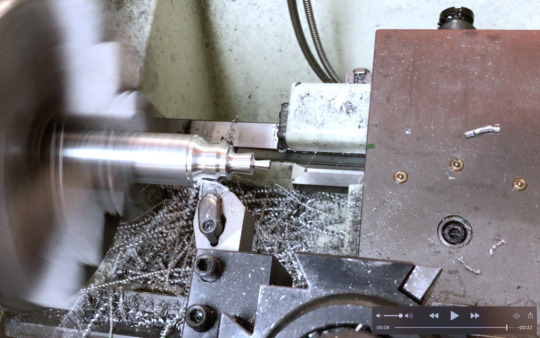

Cnc service precision custom turning milling cnc machining parts

We make aluminium alloy cnc milling turning parts, metal spare parts cnc milling customized service, cnc milling machining rapid prototyping aluminum,cnc conversion kit for milling, service cnc aluminum milling custom parts, cnc milling lathing machining, custom cnc milling machining service plastic peek, milling cnc service etc .

----------------------------

https://cncmtf.com

0 notes

Text

Brass Turning Parts Manufacturers and Exporters in India, Australia, Canada, UK

When it comes to precision engineering and manufacturing, few materials match the versatility and durability of brass. With a history that dates back centuries, brass has been a go-to choice for producing a wide range of components, from decorative hardware to intricate mechanical parts. However, the key to harnessing the full potential of brass lies in the hands of custom brass-turned parts manufacturers and suppliers in USA, Europe, UK, Canada, Russia, Australia and South Africa.

In this article, we’ll delve into the world of Custom Brass turned parts manufacturers in USA, Europe, UK, Canada, Russia, Australia and South Africa, exploring the significance of these specialized manufacturers and the role they play in various industries.

Parts turned bras are important for countless applications, from plumbing and musical instruments to automotive components and electrical connections. The accuracy and precision in the metal conversion process make them essential for achieving the desired results in these industries. So, what are custom turned brass parts, Brass Threaded Insert, and why are they so important?

Custom brass turned parts are precisely machined components made from brass, a metal alloy composed primarily of copper and zinc. These parts are crafted with meticulous attention to detail, often on specialized machinery called CNC (Computer Numerical Control) lathes. This precision machining process transforms brass rods or bars into a variety of shapes and sizes, meeting the specific requirements of clients.

The most important elements of Brass Terminals | Brass Connectors based on their appearance. They can be designed and manufactured to great detail, ensuring that they fit perfectly into the intended application. Whether it’s a special plumbing fixture, a critical electrical connection, or a critical infrastructure component, custom metal parts turn out to be essential to get the job done perfectly and efficiently.

THE ROLE OF CUSTOM BRASS TURNED PARTS MANUFACTURERS

Expertise in Material Selection: Brass Turning parts manufacturers and Exporters in Jamnagar, India are well-versed in different brass alloys. They understand the unique properties of each alloy and can recommend the most suitable one for a particular application. This expertise ensures that the final product will have the desired strength, corrosion resistance, and aesthetic appeal.

Precision Machining: These manufacturers utilize advanced CNC machining technology to transform brass raw materials into precise components. This precision is vital, especially in industries where the slightest deviation can lead to malfunction or inefficiency.

Customization: One of the primary advantages of partnering with custom brass turned parts manufacturers is the ability to customize components. They can produce parts with intricate designs, tight tolerances, and various finishes to meet specific requirements.

Quality Assurance: Manufacturers of Custom Brass turned parts manufacturers and exporters in India, USA, Europe, UK, Canada, Russia, Australia and South Africa. to strict quality control measures. This ensures that each component meets the highest standards of quality and durability. This is especially crucial in industries like aerospace and automotive, where safety and reliability are paramount.

Cost Efficiency: While custom manufacturing may seem expensive, it often leads to cost savings in the long run. Custom brass turned parts can be optimized for efficiency, reducing waste and enhancing overall performance.

THE SIGNIFICANCE OF BRASS TURNED PARTS SUPPLIERS

Manufacturers alone cannot meet the diverse and ever-changing needs of various industries. This is where brass turned parts suppliers in Gujarat India, come into play. These suppliers act as a bridge between manufacturers and end-users, offering several crucial advantages:

Wide Range of Inventory: Brass Threaded Inserts suppliers maintain extensive inventories of standard and custom components. This means that customers can quickly source the parts they need without waiting for production lead times.

Reduced Lead Times: For urgent projects or unexpected component failures, brass turned parts suppliers in India provide fast access to replacement parts, reducing downtime and minimizing disruptions.

Cost-Effective Sourcing: Suppliers often benefit from economies of scale, allowing them to offer competitive pricing on both standard and custom components.

Expert Guidance: Suppliers have in-depth knowledge of brass turned parts, Brass Fittings | Brass Sanitary Parts and can assist customers in selecting the right components for their applications. This expertise helps customers make informed decisions.

Reliability: Established Brass Terminals | Brass Connectors manufacturers in USA, Europe, UK, Canada, Russia, Australia and South Africa, have a reputation for reliability and quality. Customers can trust that the components they receive will meet their specifications and perform as expected.

Custom brass turned parts manufacturers and suppliers in India are the unsung heroes of many industries. Their expertise, precision machining capabilities, and commitment to quality ensure that critical components meet strict specifications and perform reliably. As industries continue to evolve and demand ever more specialized components, the role of these professionals becomes even more significant. In essence, they are the artisans crafting excellence from brass, enabling progress in countless fields.

1 note

·

View note

Text

Features and Benefits of Vertical Boring Mills

Boring milling machines, either horizontal or vertical boring mills, are very similar to turning lathes. The vertical boring mill enlarges or finishes existing holes in metal parts. Its basic function and applications are very specialized within the industrial machinery industry. This boring mill is particularly intended to accomplish three major functions: proper sizing, straightness, and egocentricity. It is capable of spinning, boring, cutting internal and external threads, and perform other machining tasks.

Vertical boring mills can be adjusted to any diameter within their work envelope. Typically, this work envelope is much bigger than what other machines’ tools can accommodate. This boring mill also ensures concentricity between the internal and external parts being machined. The following are the features and benefits of a vertical boring mill.

The Features of Vertical Boring Mills

● High precision ball screws on all linear axes

● With planetary reducers, have independent motors and drives

● With position control feedback and high resolution distance coded linear scales

● Infinite variable speed control

● Feeds are programmable

● Pendant control comes in both manual and CNC capabilities

● Filters’ clog detection and messaging

● All three path capabilities (single, double, and triple) both in manual and CNC mode

● Conversational program can be saved and archived

● Electronic hand-wheel and electric cabinet for precision

The Benefits of Vertical Boring Mills

Given the above features of a vertical boring mill, its benefits are so numerous. These include:

● Smooth operation with no backlash

● With variable feed rates and highly reliable

● Highly accurate machining

● Improved part finish

● Optimal cutting speeds and feed rate

● Very flexible, can be operated as manual or in CNC mode

● Absolute position control

● Eradicates costly downtime

● Very high productivity using all cutting heads

● Saves programming time by developing a program library

● Reduces tool setting time

● Quick and easy part setting

● Requires low maintenance

With these features and benefits, it’s not a surprise that vertical boring mills are very popular in machine shops today.

1 note

·

View note

Text

Motors For Negative Pressure Air Fan suppliers

Motors For Negative Pressure Air Fan suppliers Our History 1972: State owned Wenling Micromotor Factory Co., Ltd. 2008: Wenling Nosch Motor Co., Ltd. 2018: Zhejiang Fangyuan Sifu Mechanical and Electrical Co., Ltd. 2019: Establish Shandong Branch 2020: Establish Foreign Trade Department Our Factory Zhejiang Fangyuan Sifu Mechanical and Electrical Co., Ltd. is a high-tech enterprise focusing on motor R&D, manufacturing and sales. It is one of the core enterprises in the manufacturing sector of China's top 500 private enterprises under the Fangyuan Group. The company's main products include iron-shell single three-phase asynchronous motor series, aluminum-shell single three-phase asynchronous motor series, fan special motor series, frequency conversion motor series, permanent magnet DC motor series, etc. Mainly used in water pump power, fan power, machine equipment power, agricultural machinery power, new energy vehicle power, marine equipment power and other fields. The company is located at No. 2479, Haifeng Road, Taizhou Bay New District, Zhejiang (3 kilometers from the east exit of Jiaojiang Coastal Expressway, 10 kilometers from Taizhou Airport, and 20 kilometers from Taizhou High-speed Railway Station).Covering an area of 43 acres, it has a standardized workshop of 35,000 square meters, equipped with more than 50 sets of automatic CNC lathes, CNC grinders, CNC milling machines, machining centers, high-speed punching machines and other metal processing equipment, and equipped with advanced equipment such as automatic wire embedding lines, spraying lines, and automatic assembly lines. There are domestic leading wind tunnel laboratories, test centers, and motor type laboratories. The company has a technical management team with strong professional skills and excellent management capabilities. So far, it has obtained dozens of patent certificates (including 5 invention patents), participated in the formulation of 4 industry standards, and obtained 3C certification, CE Certification, ISO9001 management system certification, ISO45001 occupational health and safety management system certification, ISO14001 environmental management system certification, etc. It has also launched long-term technical cooperation with universities such as China Jiliang University and Zhejiang University of Technology to enhance core power in terms of innovation, stability, high efficiency, and energy saving. Our Product 鈼?IE3 Premium Motor 鈼?IE4 Super Premium Motor 鈼?Single Phase Motor 鈼?FRP Fan Motor 鈼?Negative Pressure Fan Motor 鈼?Cooling Fan Motor 鈼?Exhaust Fan Motor for Cowshed 鈼?Portable Cooler Motor 鈼?Vertical Pump Motor 鈼?Acid and Alkali Resistant Chemical Pump Motor 鈼?Washer Motor 鈼?Special Motor for Woodworking Product Application FRP Fan, Negative Pressure Fan, Cooling Fan, Exhaust Fan, Portable Cooler, Vertical Pump, Acid and Alkali Resistant Chemical Pump, Washer, Woodworking Our Certificate CE, Reach, RoHS, CCC (China Compulsory Certification), IPMS, China Energy Label Production Equipment Automatic wire embedding machine: 10 CNC lathe: 12 CNC grinder : 4 Dynamic balance machine: 4 CNC milling machine: 3 Plastic spraying line: 1 Production line: 9 Paint dipping machine: 2 Multi hole drilling machine: 2 Production Market Annual Output Value: US$20- US$50Million Domestic Market: 55% Eastern Europe: 10% Southeast Asia: 10% Middle East: 5% Africa: 5% South America: 3% Western Europe: 3% Other Areas: 9% Our Service The company takes the spirit of innovation as the guideline, takes high-quality products as the foundation, and takes full-staff entrepreneurship as the core driving force, strongly promotes R&D and innovation, accelerates the adjustment of product structure, optimizes technical processes, improves operational efficiency, and strengthens the spirit of chemical craftsmanship, and uses this as a driving force to build Outstanding enterprise, creating market opportunities, and striding forward to the vanguard of industry segmentation.Motors For Negative Pressure Air Fan suppliers website:http://www.sivomotor.com/

0 notes

Link

The question of buying a new CNC machine or converting your old ones using CNC conversion kits depends on your requirements. If you run an extensive machining business or work for a major production company, opting for a new CNC machine will be more suitable.

Nevertheless, if you are a hobbyist or new to machining, CNC conversion kits are a more practical and cost-effective alternative. Converting your old machines into CNC allows you to improve your machining capability while maintaining the serviceability of your old machine.

#CNC conversion kits#cnc lathe conversion kit#cnc conversion kit#cnc lathe conversion#cnc conversion#lathe conversion to cnc#lathe cnc conversion#mill cnc conversion#mill cnc conversion kit#cnc lathe kit

1 note

·

View note

Text

Top 3 CNC Lathe Machines And Lathe CNC Conversion Kits (2022 Updates)

If you own a lathe machine shop or even if you’re a hobby machinist, the idea of a CNC lathe must have come across your mind.

However, when it comes to picking a CNC lathe machine for your workshop, there are endless options on the market. And that is sure to confuse you, more so when you don’t know how exactly those machines will function, whether they’ll do the required tasks efficiently, or whether they’ll last long enough.

Nevertheless, you can rest assured, as we have here for you the best CNC lathe machines and CNC lathe conversion kits on the market. So let’s have a look.

0 notes

Photo

We offer DIY CNC lathe conversion so you can save time and money on third-party aggregators. Our DIY CNC conversion lathe allows you to upgrade your old lathe into CNC yourself. CNC Conversion Plus provides you with every little component including expert advisory to help you automate your old lathe into CNC.

0 notes

Link

CNC Conversion Kits for Mill and Lathe - CNC Conversion Plus

Convert your mill or lathe to CNC with our cnc conversion kits. Whether you’re looking for Harbor Freight Mill CNC Conversion Kit or just Lathe CNC conversion kit, look usup. ShopWe provide the best turnkey lathe or milling machine CNC conversion with our state-of-the-art CNC conversion kits. We can convert your manual mill machine into a CNC milling machine with our mill CNC conversion kit. Want a CNC lathe kit? We’ve got the market-leading lathe CNC conversion kit in the form of Grizzly lathe CNC conversion.

#cnc lathe conversion kit#cnc conversion kit#diy cnc lathe conversion#lathe conversion to cnc#mini lathe cnc conversion texas#harbor freight mill cnc conversion kit#mill cnc conversion

0 notes

Text

How Machine Shop Auctions Influence the Secondary Equipment Market?

In the world of manufacturing, obtaining quality machinery at a reasonable price is crucial for businesses to remain competitive. Machine shop equipment auctions have become a popular avenue for buyers seeking to acquire high-quality tools and machinery at discounted prices. By providing access to a wide range of equipment in the secondary market, these auctions have a significant impact on equipment pricing, availability, and purchasing strategies. Let's explore how machine shop auctions shape the secondary equipment market and what they mean for buyers and sellers alike.

The Role of Machine Shop Equipment Auctions

Machine shop equipment auctions serve as a marketplace for buyers and sellers, offering everything from precision lathes to CNC machines. Sellers may include large corporations updating their equipment or small businesses downsizing or liquidating assets. These auctions present an efficient, transparent, and accessible way to transfer machinery to new owners.

With platforms increasingly moving online, machine shop equipment auctions have opened the secondary market to a global audience. Buyers from across the world can access the same auction listings, creating a competitive environment that drives fair market pricing for used equipment. Whether conducted in person or online, auctions allow buyers to inspect equipment and gauge its value, contributing to more informed and confident purchasing decisions.

Accessibility and Affordability of Machinery

One of the most attractive features of machine shop equipment auctions is the potential for buyers to secure machinery at a fraction of its retail price. New equipment can be prohibitively expensive, especially for smaller businesses or startups. However, auctioned machinery often includes equipment that, while not brand new, is still highly functional and reliable.

Machine shop equipment auctions enable businesses to stretch their budgets by acquiring high-quality, pre-owned equipment. This affordability is particularly beneficial for companies just entering the market, allowing them to compete with larger, more established firms without the steep overhead costs of new machinery. This affordability encourages greater participation in the secondary market and often leads to a more dynamic and accessible manufacturing industry.

The Impact of Supply and Demand on Pricing

Like any marketplace, machine shop equipment auctions are affected by supply and demand. When there is a high demand for a particular type of equipment, such as CNC machines or precision grinders, prices at auction can approach retail levels. Conversely, when supply exceeds demand, prices tend to drop, providing bargain opportunities for buyers.

Machine shop equipment auctions thus play a significant role in determining fair market prices for used equipment. The visibility of auction prices serves as a reference point for secondary market pricing, affecting the entire used machinery ecosystem. For sellers, auctions offer a platform to assess their equipment’s market value accurately, while buyers benefit from a transparent and competitive environment where fair market prices are regularly established.

Quality Assurance and Buyer Confidence

While purchasing used equipment always carries some risk, machine shop equipment auctions help mitigate uncertainty by allowing buyers to inspect items before bidding. Some auctions offer detailed inspection reports and, occasionally, guarantees on specific machines. The transparent nature of the auction process can give buyers confidence in their purchases, reducing the perceived risk of buying used machinery.

Moreover, auction platforms often have quality controls in place, making sure that the machinery listed meets basic standards or adheres to certain conditions. Buyers can rely on these measures to ensure that they are not simply buying “scrap” but equipment that can contribute productively to their operations.

Broadening Access to Technology and Upgrades

By facilitating the sale of used equipment, machine shop equipment auctions also allow businesses to upgrade their equipment more frequently. Companies looking to stay competitive in an industry where technology is rapidly advancing can liquidate their older assets at auction, recouping some of the investment in their outdated machinery. In turn, smaller or newer companies can acquire this equipment at a lower cost, helping them enhance their productivity without the full financial commitment to new technology.

This flow of equipment through the secondary market encourages a more circular economy, where machinery is repurposed rather than discarded, benefiting both the environment and the businesses involved. Machine shop equipment auctions thus serve as a crucial mechanism for maintaining a sustainable and affordable supply of manufacturing tools.

Conclusion: The Future of Machine Shop Equipment Auctions

The influence of machine shop equipment auctions on the secondary equipment market is undeniable. They create an affordable pathway for businesses to obtain necessary machinery, help establish fair market prices, and enable a cycle of technological upgrades that benefit the entire industry. As more auctions move online and attract a global audience, their impact will likely grow, shaping the secondary market in unprecedented ways.

Machine shop equipment auctions have proven themselves to be indispensable in the manufacturing world. For businesses and individuals looking to expand their capabilities without breaking the bank, these auctions offer an invaluable resource. As demand for affordable, high-quality machinery persists, the role of auctions in the secondary equipment market will continue to grow, providing opportunities for innovation and competition across the industry.

0 notes

Text

How Custom CNC Machine Parts Are Created

It is most likely that you are familiar with custom CNC machine parts in Toronto because of how often they are being discussed in the world of manufacturing. There are various processes involved in the process of removing materials via high precision machines that utilize different cutting tools to make the final product. Moreover, there are different kinds of CNC machines utilized to achieve various geometric shapes. These include horizontal milling machines, vertical milling machines, as well as lathes.

Additionally, in order to satisfactorily make custom CNC machine parts in Toronto, there are different programs that can be employed to regulate the machine, such as CAM and CAD. When it comes to producing the geometry required, the CNC computer regulates the speed and the feed rates of the tools to create the part. As for material selection, it has to be established first to know the total cost and the optimum functionality of the part being manufactured. This means defining the properties of the required materials, such as their chemical resistance, hardness, rigidity, thermal stability, and so on.

In terms of parts complexity, if it is possible to machine the part through two axes only, then the machining process becomes faster and thus, reducing the overall cost. Conversely, if the part is more complicated, having various faces and contoured geometry is a must. However, this can add to the total cost of the manufacturing time and process of cutting the component. The rule of thumb in reducing the overall cost of creating complex custom CNC machine parts in Toronto is to design using only two axes cuts as much as possible.

Ultimately, if the part can’t be machined using only two axes, five-axis machining is also available. This technology means that the machine can be moved up to five coordinated movements around multiple axes. It enables shops to obtain a more efficient production of custom CNC machine parts in Toronto by providing faster cutting speeds, creating more efficient tool paths, and attaining better finishes.

1 note

·

View note

Photo

CNC Lathe Conversion How we converted a Jet metal lathe to CNC using free LinuxCNC software — and a few hardware misfires Read more on MAKE The post CNC Lathe Conversion appeared first on Make: DIY Projects and Ideas for Makers. https://buff.ly/3jAsTBu

1 note

·

View note

Text

High-Precision Components for Diverse Applications By AVTEC

AVTEC feels Proud to be part of CK Birla Group – a leading global business house, Avtec is a leader in powertrain and precision-engineered products in India. We offer competency across the entire value chain of design & manufacture of engines in transmissions and high precision components with the advanced units comprise of an in-house tech center and R&D facilities with IATF 16949 and ISO 14001 certified facilities and spires to reinforce its commitment to customers as a 'one-stop-shop' for Powertrain and Precision Engineered Products, across the globe offering components for Automotive, Off-Highway, Defence, Agriculture, and Railway industry.

With decades of experience in manufacturing High precision powertrain components for both Automotive & Off-highway segments

As far as Powertrains and Other segments like automotive and off-highway transmission components are concerned they are highly engineered and require advanced manufacturing processes with advanced technical facilities and quality control as per international standards to maximize end-user performance and AVTEC has the capability to manufacture precision products for various industry application.

The powertrain and Others segment includes engine and transmission parts such as cylinder block and cylinder head, camshafts, transmission parts, Shafts, and hollow shafts, Ring gears, Sleeve, Clutch drive assembly, Housing, gearbox, etc.

With a strong focus on in-house research and product development capabilities we are masters in designing and manufacturing high-end transmission components for both automotive and off-highway industries.

We manufacture high-end products as

Shafts & Hollow Shafts-

A hollow shaft made up of Alloy steel is used to transmit torque within an automatic transmission. The post has a machined surface finish and an ultimate tensile strength and is used in various transmission engines.

Types-

· Spur

· Helical

Gear-

AVTEC produces industrial and low/medium volume automotive gears and gearboxes. The transmission uses gears to provide speed and torque conversions from a rotating power source to another device. We manufacture transmission gears with the help of highly experienced gear design experts with the use of advanced In-house facilities for gear manufacturing.

Facilities include-

· Spline rolling

· Gear shaving

· Balancing Machine

· CNC VTL

· CNC Gear Shaping

· CNC Lathe

AVTEC-made gearboxes are used in various industries like Automotive, Off-Highway, Defence lifting equipment, and power transmission equipment.

Ring gears-

Ring gears are used in the transmission and engines of Automotive as well as off-highway applications. AVTEC uses innovative management techniques and design capabilities, including professional engineered teams to maintain top quality and high output. Ring gears play an essential role in the entire transmission mechanism. We manufacture ring gears from high-quality steel which undergoes hardening, Nitriding, and Nitro carburizing processes.

Clutch Drive Assembly-

Clutch Drive Assembly with sub-components like central Support Drive, Plate Cam, and Turbo Gear, is one of our transmission products that find application in the Railway industry. The primary purpose of a clutch assembly is to connect and disconnect two rotating shafts. Clutch assemblies consist of several component parts and need the exact configuration of a clutch assembly. For every application clutch assembly configuration is different and depends upon a transmission type.

The manufacturing process includes Precision Turning, Precision Gear Grinding, Bush pressing, and assembly.

The decades of industry experience, well-developed production facilities, as well a team of professional engineers, helped us successfully meet the varied component demands for components, manual transmission components, transmission components, precision machined parts, automobile parts automotive transmission, and off-highway transmission industry. With the best use of state-of-the-art technologies as well as AVTEC’s well-defined quality control measures, we are experts in meeting international quality standards.

Today, our consistency in delivering quality products as per the market demands has helped us to become a global leader in the design and manufacturing high precision transmission components for the automobile spare parts industry.

Stringent quality control measures are adopted at different stages of manufacturing right from sampling to production to testing as per international standards. We strive for 100% quality production and customer satisfaction.

Some of the parameters on which our range is thoroughly checked are:

• Tensile strength

• Product Finishing

• Technical specifications

Some of our Modern testing equipment includes-

· Heat Treatment

· CNC Cylindrical Grinding Machine

· Balancing Machine

· CNC Turning Machine

· CNC Broaching Machine

Along with the transmission components, AVTEC delivers competency across the entire value chain of design & manufacture of engines; transmissions and high precision components like cylinder heads, cylinder blocks, crankshafts, camshafts, cam rods, and transmission gears for Automotive, Off-Highway, Defence, Agriculture, and Railway industry, in areas of both proprietary products and contract manufacturing and serve some of the best-known domestic and global Automotive and Off-Highway companies, including global OEMs such as Allison, BEML, Caterpillar, Daimler, Ford, ISUZU, PSA, Punch Powertrain, Renault-Nissan, Tata-Jaguar and several other established brands.

#Auto components manufacturers in India#Powershift Transmissions#Precision auto components#Automatic Transmissions#Engine parts manufacturers in india

0 notes