#laminate manufacturers in Gujarat

Explore tagged Tumblr posts

Text

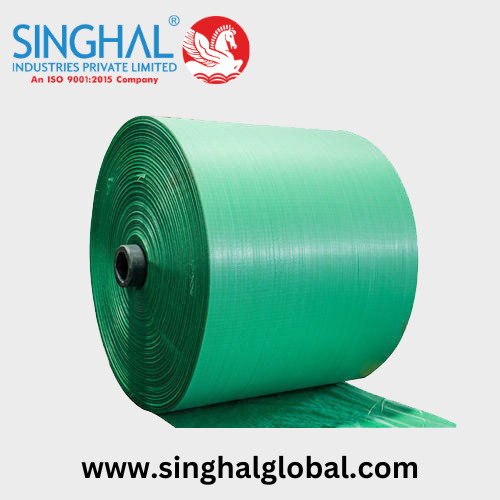

PP Woven Fabric: The Sustainable and Versatile Workhorse of Textiles

Introduction: In the vast landscape of textiles, one material stands out for its versatility, durability, and sustainability: PP (Polypropylene) woven fabric. Used across a myriad of industries, from agriculture to packaging, construction to geotextiles, PP woven fabric has become the workhorse of modern textiles. In this article, we delve into the characteristics, applications, and sustainability aspects of PP woven fabric, while also exploring the landscape of suppliers and manufacturers, particularly focusing on Ahmedabad, Gujarat, and India as a whole.

Understanding PP Woven Fabric: PP woven fabric is a type of synthetic fabric made from polypropylene polymer. Its construction involves weaving polypropylene tapes or flat yarns together to create a strong and durable fabric. This weaving process imparts exceptional tensile strength and tear resistance to the fabric, making it suitable for a wide range of applications.

Key Characteristics:

Strength and Durability: PP woven fabric is renowned for its high strength-to-weight ratio, making it ideal for applications requiring robustness and resilience. It can withstand heavy loads, punctures, and abrasion, ensuring long-lasting performance.

Lightweight: Regardless of its solidarity, PP woven texture is lightweight, which makes it simple to deal with and transport. This trademark is especially favorable in applications like bundling and transportation.

Water Resistance: PP woven fabric exhibits inherent water resistance, making it suitable for outdoor applications where exposure to moisture is a concern. It can be further enhanced with laminations or coatings for increased impermeability.

UV Stability: UV stability is another notable feature of PP woven fabric, allowing it to withstand prolonged exposure to sunlight without significant degradation. This makes it suitable for outdoor applications such as agricultural covers and geotextiles.

Applications of PP Woven Fabric: The versatility of PP woven fabric lends itself to a wide array of applications across various industries. Some of the key applications include:

Packaging: PP woven fabric is extensively used in packaging materials such as sacks, bags, and FIBCs (Flexible Intermediate Bulk Containers). Its strength and durability make it an ideal choice for transporting bulk goods such as grains, seeds, fertilizers, and cement.

Agriculture: In agriculture, PP woven fabric finds applications in crop protection, ground coverings, shade nets, and greenhouse films. Its UV stability and water resistance make it well-suited for protecting crops from adverse weather conditions and pests.

Construction: PP woven fabric is used in construction for purposes such as scaffolding nets, tarpaulins, and temporary enclosures. Its strength and durability make it an indispensable material for ensuring safety and protection on construction sites.

Geotextiles: In civil engineering and landscaping projects, PP woven fabric is employed as geotextiles for erosion control, soil stabilization, and drainage applications. Its permeability and strength contribute to the longevity and effectiveness of such infrastructure projects.

Sustainability Aspects: In addition to its functional attributes, PP woven fabric also offers significant sustainability benefits:

Recyclability: Polypropylene is a recyclable thermoplastic polymer, which means that PP woven fabric can be recycled and reused in various applications, reducing the demand for virgin materials and minimizing waste.

Energy Efficiency: The manufacturing process of PP woven fabric consumes relatively less energy compared to other materials such as paper or traditional textiles, contributing to lower carbon emissions and environmental impact.

Longevity: The durability of PP woven fabric ensures a longer lifespan compared to alternative materials, reducing the frequency of replacements and the associated resource consumption.

Resource Efficiency: PP woven fabric is produced using minimal water and natural resources, making it a more sustainable choice compared to materials that require extensive water and land resources for cultivation or extraction.

Suppliers and Manufacturers: Ahmedabad, Gujarat, and India as a whole boast a robust network of suppliers and manufacturers catering to the demand for PP woven fabric:

PP laminated woven fabric suppliers in Ahmedabad offer a diverse range of products tailored to specific applications, with options for customization and lamination to meet customer requirements.

PP woven fabric manufacturers in Gujarat leverage the state's industrial infrastructure and expertise in textile manufacturing to produce high-quality PP woven fabric at competitive prices.

PP woven fabric roll manufacturers in India cater to both domestic and international markets, supplying a wide range of industries with standard and customized fabric rolls to suit diverse applications.

Conclusion: PP woven fabric emerges as a sustainable and versatile solution for a multitude of applications, owing to its inherent strength, durability, and eco-friendly attributes. As industries continue to prioritize sustainability and efficiency, the demand for PP woven fabric is expected to rise, further driving innovation and advancements in its production and applications. With a strong network of suppliers and manufacturers in Ahmedabad, Gujarat, and across India, the future of PP woven fabric looks promising as it continues to establish itself as the workhorse of modern textiles.

Frequently Asked Questions about PP Woven Fabric

Is PP woven fabric eco-friendly? PP woven fabric's recyclability and durability contribute to its eco-friendly nature. However, the environmental impact depends on factors like production practices and end-of-life management.

Is PP woven fabric breathable? In its natural state, PP woven fabric exhibits limited breathability. However, breathable variations are available for specific applications.

How strong is PP woven fabric? PP woven fabric offers surprising strength and tear resistance, making it suitable for heavy-duty applications.

Can PP woven fabric be dyed? While dyeing PP woven fabric directly is challenging, it can be produced in various colors during manufacturing.

What are the limitations of PP woven fabric? PP woven fabric might not be the best choice for applications requiring high breathability or heat resistance.

#pp laminated woven fabric suppliers in Ahmedabad#pp woven fabric manufacturer in Gujarat#pp woven fabric roll manufacturers in india

0 notes

Text

Flush door price in Ahmedabad

Navkar Plywood: Your Trusted Source for Quality Wooden Flush Doors in Ahmedabad

When it comes to adding elegance and functionality to your living space, doors play a vital role. Among the many options available in Ahmedabad, Flush Doors have become a preferred choice for interior and exterior applications. Navkar, a well-established name in the industry, offers Indian wooden Flush Doors with customization options tailored to the needs of high-end residential buildings.

Flush Door Prices in Ahmedabad

The pricing of Flush Doorsn Ahmedabad varies depending on several factors, including the type of material, design, size, and brand. Here's an overview of what you should consider:

Flush Door Price in Ahmedabad: Flush door prices in Ahmedabad are flexible, accommodating a wide range of budgets. They typically range from INR 500 to INR 2500 per square foot, ensuring that you can find an option that suits your needs.

Ahmedabad Flush Door Cost: The cost of Flush Doors in Ahmedabad can be influenced by the choice of wood, design intricacies, and special features. Navkar offers competitive prices while maintaining quality.

Flush Door Suppliers in Ahmedabad:Ahmedabad hosts several suppliers offering Flush Doors. It's advisable to choose a reputable and trusted supplier like Navkar, known for delivering top-notch products.

Flush Door Dealers in Ahmedabad: Dealers play a pivotal role in determining the final cost. Comparing prices from different dealers can help you find the most cost-effective solution without compromising quality.

Flush Door Manufacturers in Ahmedabad: Manufacturers like Navkar are committed to delivering quality and value for your investment, making them a preferred choice for high-end residential projects.

Navkar: The Trusted Choice

Navkar has earned a strong reputation in Ahmedabad for its commitment to quality and customer satisfaction. They offer custom-made wooden Flush Doors that not only enhance the aesthetics of your space but also provide long-lasting durability. Whether you're working on a high-end residential project or simply looking to upgrade your home, Navkar is your trusted source for quality wooden Flush Doors in Ahmedabad .

For More Information:

+91-6354105257

20,21,22 Amar Estate, near Memco,Ahmedabad, Gujarat 380025

#royal touch laminates price#plywood manufacturers in gujarat#flush door price in ahmedabad#mdf manufacturers in gujarat#Flush door price Ahmedabad#Ahmedabad flush door cost#Flush door suppliers Ahmedabad#Flush door dealers in Ahmedabad#Flush door manufacturers Ahmedabad

0 notes

Text

#Gum Powder Manufacturer in India#Modified Starch Powder Exporter#Modified Starch Powder Manufacturer#Pasting Gum Powder#Corrugation Gum Powder Automatic Plant#Corrugation Gum Powder Manufacturer#White Dextrin Manufacturer#Yellow Dextrin Powder Manufacturer#Paper Cone Gum Powder#Paper Cone Cold Gum Powder#Paper Cone Hot Gum Powder#Oxidized Starch Powder Manufacturer#Gum Powder for Automatic Plant#Carboxymethyl Starch Manufacturer CMS#Thin Boiling Starch Manufacture#Desizing Modified Starch Manufacturer#Paper Lamination Gum Manufacture & Supplier in Ahmedabad#Gujarat.

0 notes

Text

PP Woven Bag

We are BOPP laminated bags & PP Woven Bags manufacturer and Supplier in India & worldwide. We provide BOPP rice bags or rice sacks for packing rice, BOPP Grains Bags, BOPP Fruits Bags, PP Woven Sugar Bags, PP Woven Cement Bags.

For more information, contact us - +91- 9081802800

e-mail : [email protected]

1003, Pinnacle Business Park, Corporate Road, Prahladnagar, Ahmedabad, Gujarat - 380015 | INDIA

#ecommerce#commercial#ppwovenbag#manufactureandsupplier#ppwovenbagmanufacturer#boppbagmanufacturer#boppbagsupplier#polypropylenebag#ppbag#plasticbag#packagingbag#package

2 notes

·

View notes

Text

Multilayer Blown Film Extrusion Machine in Sudan

Adroit Extrusion is a leading Manufacturer and Exporter of Multilayer Blown Film Extrusion Machine in Sudan. Our Manufacturer Unit is located in Ahmedabad, Gujarat, India. Adroit Extrusion specializes in providing advanced Multilayer Blown Film Extrusion Machines designed for a wide range of applications in the film manufacturing industry. We build our machines to co-extrude multiple polymer resin layers, creating high-performance films with tailored strength, flexibility, and clarity. We offer a variety of Multilayer Blown Film Extrusion Machines suited to different production needs: 7/5 Layer Barrier Film Extrusion Machines: Ideal for applications requiring advanced barrier properties such as food packaging, pharmaceutical packaging, and industrial uses where moisture, oxygen, or light barriers are critical. 5 Layer POD Film Extrusion Machines: Perfect for high-performance applications, especially in packaging materials that demand a combination of strength, flexibility, and barrier properties. 3 Layer Blown Film Plant: A more economical option that still provides versatility and quality for general-purpose packaging, agricultural films, and industrial films. Why Choose Adroit Extrusion? Advanced Technology: We equip our machines with cutting-edge technology to ensure high efficiency, durability, and quality in every film we produce. Tailored Solutions: We work closely with our clients to understand their unique needs and offer tailored solutions to maximize productivity and performance. Support and Service: Adroit Extrusion provides comprehensive after-sales support and technical assistance to ensure that your machine operates at peak performance. Applications of Multilayer Blown Films: Lamination Grade Films Liquid Packaging Films High Dart FFS Resin Sacks Films Cereal and Oil Packaging Films Pharma and Medical Grade Films Pallet Hooding Shrink/Stretch Films Greenhouse Films Silage and Mulch Films Chemical/Soap Packaging Films FAQs. Q1: Is technical support available? A1: Yes, we provide full after-sales support, including installation, training, and maintenance services. Our technical team is always available to assist with troubleshooting and optimizing machine performance. Q2: What types of polymers can be used in the multilayer extrusion process? A2: Various polymers can be used in the multilayer extrusion process, including LDPE, LLDPE, HDPE, BOPP, EVA, nylon, and other specialty resins. Adroit Extrusion is an Exporter of Multilayer Blown Film Extrusion Machine in Sudan including locations Omdurman, Khartoum, Khartoum North, Nyala, Port Sudan, El-Obeid, Kassala, Wad Madani, El-Gadarif, Al-Fashir. For more information about our Multilayer Blown Film Extrusion Machines or to request a consultation, contact Adroit Extrusion today! View Product: Click here Read the full article

#3LayerBlownFilmPlant#5LayerPODFilmExtrusionMachines#7/5LayerBarrierFilmExtrusionMachines#AdroitExtrusion#Ahmedabad#Al-Fashir#El-Gadarif#El-Obeid#Exporter#ExporterofMultilayerBlownFilmExtrusionMachine#Gujarat#India#Kassala#Khartoum#KhartoumNorth#Manufacturer#ManufacturerUnitislocatedinAhmedabad#MultilayerBlownFilmExtrusionMachineinSudan#MultilayerBlownFilmExtrusionMachineManufacturerinAhmedabad#MultilayerBlownFilmExtrusionMachines#Nyala#Omdurman#PortSudan#Supplier#WadMadani

0 notes

Text

Buy Licon Tools and Products From Perfect Tools in Ahmedabad

Licon Tools and Products From Perfect Tools in Ahmedabad

Licon Tools, Licon High Performance German Cutting Tools Manufacturer & Supplier From Perfect Tools in Ahmedabad, Gujarat, India Including TCT Cutters, Grooving Cutters, Planning Cutters

Licon Tools including TCT Brazed Grooving Cutter — LAB.GC.01, TCT Grooving Cutters for Laminated Board — LAB.GC.02, TCT Planning Cutter Head with Helix Angle — LAB.PC.04, TCT Brazed Half Radius Cutter — LAB.HR.05 and Cutting Tools, and So on.

For More Details 👇

📱 Call: +91 93282 03494, +91 78744 31679 💬 WhatsApp: https://wa.me/919328203494 🌐 Visit: https://www.perfecttoolsindustries.com/licon/

0 notes

Text

Rathna Packaging orders W&H blown film lines and CI flexo presses

Rathna Packaging India, a significant flexible packaging and film manufacturing company based in Bengaluru has placed orders for two Windmöller & Hölscher (W&H) Optimex II blown film lines and a pair of Alphaflex CI flexo presses to be commissioned in mid-2025. This is one of the most notable flexible packaging orders placed this year among several others for W&H. Both the Optimex lines are 2.5 meter-wide 3-layer lines.

The pair of Alphaflex CI flexo presses are both 8-color machines with rated speeds of 400 meters a minute and contain W&H Easy-Col automation for color makeready and standardization with exceptional accuracy. While making ready 80% the first cut of print checks will bring the color accuracy within 1.5 DeltaE. The second color check will bring the remaining 20% into the variance of 1.5 DeltaE. The Alphaflex CI is the same new press shown running at the W&H stand at drupa24 and containing the company’s automation technologies delivered in a standardized configuration.

Rathna Packaging is known for its high-quality sustainable solutions. With over 25 years of experience, the company has manufacturing facilities at three locations located in Hosur, and one in Krishnagiri, Tamilnadu with subsidiaries in Gujarat and Andhra Pradesh. The company makes shrink sleeves, twist wraps, oil and milk films, chub films, laminates, void-fill cushion packs, protective packaging, consumer products, and industrial packaging. Its customers include the food, beverages, pharmaceuticals, and consumer goods sectors.

Rathna Packaging has more than a dozen blown film lines from various manufacturers and it has several gravure presses. Thus this expansion project is a substantial move toward advanced and automated high-efficiency technologies. “We are proud of the fact that we have invested in the most advanced technologies from W&H. With these new technologies, we are prepared to deliver superior packaging solutions and continue our journey of growth. With the right planning and practices, we wish to plan another big expansion soon,” says Sudhakar Reddy, managing director of Rathna Packaging.

The Optimex II blown film lines support a range of applications using high-performance films tailored to various industries. The machine also comes equipped with advanced features like the EASY2 change system, an assistance system for blown film lines that supports the operator during every step of a product changeover and leads to repeatable performance.

Compared to an experienced operator, the number of necessary clicks for a product change is reduced by more than 70%, and the time needed is cut by more than half, thanks to an intuitive HMI. The operator maintains full transparency and control throughout a changeover, as the technology detects the bubble shape and frontline, ensuring reproducible high film quality.

The Alphaflex CI flexo presses bring unmatched precision and quality production to the forefront. The new presses from W&H offer better print stability and bounce-free printing even for difficult print work at speeds of 400 mpm. Designed for printers of all scales, the Alphaflex is engineered to meet industry challenges — cost pressures, productivity demands, and sustainability goals. Both the 8-color presses for Rathna Packaging include W&H’s fully integrated Easy-Col color-matching solution for precise color-match in considerably reduced time for new work and re-runs.

The Alphaflex is the newest addition to W&H's CI flexo portfolio, launched at drupa 2024. These two presses will be among the very first installations in India, marking a significant milestone for both W&H and Rathna Packaging. The flexo presses are also integrated with W&H’s IoT Ruby platform to monitor data, and automate and improve packaging production. This investment is a key enabler of Rathna’s ambitious plans of scaling its operations while maintaining its reputation for quality and sustainability.

On industry growth, Reddy adds, “Today enterprises need to compete at scale and speed faster than ever before. So that we keep pace with the time and consistently work in the direction of upgrading development, quality, manufacturing, and marketing processes.”

“This is one of the large investments that W&H has witnessed in the recent past in India. I must acknowledge Rathna Packaging’s passion to deliver the best, which also reflects in their investment which was extremely well planned, and we look forward to implementing the project,” says Anuj Sahni, sales director, W&H.

0 notes

Text

Exporter of Flash Dryer in Gambia

Drytech Engineering Systems is a trusted Manufacturer and Exporter of Flash Dryer in Gambia. Our manufacturing unit is located in Ahmedabad, Gujarat, India. Drytech Engineering Systems offers tailored drying solutions that maintain product quality while enhancing operational efficiency. Our flash dryers are designed to rapidly dry free-flowing powders, granules, or slurry-type materials, maximizing output while minimizing energy consumption. We provide custom-made drying systems that suit specific client needs, ensuring compatibility with different materials and operational environments. Application: Food Processing Pharmaceuticals Chemical Industry Biotechnology What is a Flash Dryer? A flash dryer is a high-speed drying system that uses a stream of hot air to quickly dry a variety of materials, including powders, granules, and slurries. The process involves the suspension of the material in the air stream, which evaporates the moisture at a rapid rate, allowing for efficient drying. How does Drytech’s Flash Dryer work? Our flash dryer works by feeding the moist material into a high-velocity hot air stream within a drying chamber. The heat causes the moisture to evaporate almost instantly, and the dried material is separated from the air by a cyclone or other separation system. What sizes of flash dryers are available? Drytech offers a range of sizes for flash dryers, from small-scale systems for research and pilot production to large-scale systems for industrial applications. Drytech Engineering Systems is an Exporter of Flash Dryer in Gambia including locations Abuko, Bakau, Banjul, Banjulunding, Bansang, Basse Santa Su, Bijilo, Brikama, Brufut, Bundung, Busumbala, Dippa Kunda, Farafenni, Farato, Gimara Bakadaji, Gunjur, Janjanbureh, Jufureh, Kalagi, Kanilai, Kerewan, Kololi, Kotu, Kuntaur, Lamin, Lamin, Latri Kunda German, Latri Kunda Sabiji, Manjai Kunda, Mansa Konko, Nema Kunku, Serekunda, Soma, Sukuta, Tabokoto, Tallinding, Tanji, Yundum. Contact us with inquiries or place an order today! View Product: Click Here Read the full article

0 notes

Text

https://www.navkarplywood.in/waterproof-plywood/

Our Waterproof plywood sheets are Plywood designed to withstand water better than other natural wood products or industrial Plywood

#plywood manufacturer in Ahmedabad#plywood manufacturers in Gujarat#sag wood price in Gujarat#flush door price in Ahmedabad#royal touch laminates price#mdf manufacturers in gujarat

0 notes

Text

Designing Functional and Stylish Modular Kitchens in Gandhinagar & Ahmedabad

Explore modular kitchen designs in Gandhinagar and Ahmedabad for efficient, stylish, and customizable solutions that enhance functionality and fit any home layout.

A well-designed kitchen is essential for any home, as it is the heart of the household where cooking, family time, and entertaining often occur. To make sure the kitchen fits your functional requirements and personal preferences, the ideal designer will collaborate closely with you. Gandhinagar and Ahmedabad, two vibrant cities in Gujarat, are witnessing an increasing demand for modular kitchens due to the growing urban lifestyle and need for modern home solutions. This article explores the key features, benefits, and considerations for modular kitchen design in these cities.

Understanding Modular Kitchens

A modular kitchen is a modern kitchen layout made up of pre-manufactured cabinets or "modules." These modules are designed to optimize space, improve storage, and allow easy customization according to the size and layout of the kitchen. Modular kitchens are composed of various elements like cabinets, drawers, shelves, and countertops that fit seamlessly together. This setup offers a clean, organized, and aesthetically pleasing look.

Benefits of Modular Kitchens

Space Optimization: The layout of modular kitchens is intended to maximize the amount of space that is available. They maximize storage with the help of well-placed cabinets, drawers, and shelves, making it easier to store and organize items.

Easy Customization: With modular kitchens, homeowners can choose designs, colors, and materials that suit their tastes. This adaptability enables them to produce a distinctive style that blends in with the rest of the interior design.

Ease of Installation: Modular kitchens are assembled in a factory and then transported to the site. This reduces on-site construction time and allows for quicker installation, making it a more convenient option for homeowners.

Low Maintenance: The materials used in modular kitchens are generally easy to clean and maintain. This makes them a practical choice for busy households where hygiene and ease of maintenance are essential.

Enhanced Functionality: Modular kitchens come with built-in features like pull-out drawers, corner cabinets, and various organizers that improve functionality, making cooking and food preparation more efficient.

Key Considerations for Modular Kitchen Design in Gandhinagar and Ahmedabad

1. Space and Layout

The available space and layout must be taken into account before designing a modular kitchen. Modular Kitchen Designer in Gandhinagar and Ahmedabad vary in size, so designs should be customized to fit the specific dimensions. Common layouts include L-shaped, U-shaped, straight, and parallel kitchens, each of which serves different spatial needs. For smaller spaces, a straight or L-shaped kitchen works best, while larger kitchens can benefit from U-shaped or parallel layouts.

2. Material Selection

Making a long-lasting modular kitchen requires careful material selection. In Gujarat's warm and dry climate, materials that resist heat and humidity are ideal. Materials such as stainless steel, PVC, plywood with laminate, and quartz or granite countertops are popular choices due to their durability and low maintenance needs.

3. Storage Needs

The storage requirements of each household vary based on lifestyle and family size. For instance, families that cook regularly may require more extensive storage solutions, such as pull-out pantries, deep drawers, and corner shelves. Modular kitchen designs in Gandhinagar and Ahmedabad can be customized to meet these specific needs, ensuring that every item has a designated space.

4. Ventilation

A well-ventilated kitchen is essential to keep the space comfortable, especially when cooking for long hours. Installing proper ventilation, such as chimneys and exhaust fans, helps reduce smoke and heat. In hot climates like that of Gandhinagar and Ahmedabad, having good ventilation is essential to maintain air quality.

5. Budget Planning

Setting a budget is essential in planning a modular kitchen. The price of a modular kitchen can vary greatly due to the large range of designs, materials, and accessories that are available. It’s advisable to plan a budget that includes the cost of cabinets, countertops, installation, and other necessary components. Modular kitchens offer flexibility in choosing materials and features, allowing homeowners to create a stylish kitchen within their budget.

Choosing a Modular Kitchen Designer in Gandhinagar and Ahmedabad

To create a kitchen that is both aesthetically pleasing and useful, choosing a qualified modular kitchen designer is essential. A good designer understands the local architectural styles, material preferences, and climate considerations. They can help you choose the right layout, materials, and color scheme that suit your home and lifestyle.

When choosing a modular kitchen designer, it’s essential to check their portfolio, read customer reviews, and discuss your specific needs with them. To make sure the kitchen fits your functional requirements and personal preferences, the ideal designer will collaborate closely with you.

Conclusion

Modular Kitchen Designer in Gandhinagar and Ahmedabad

is an ideal solution for modern homes, providing a combination of style, functionality, and durability. With the right design, material choices, and a skilled designer, a modular kitchen can transform the cooking space into a beautiful and efficient area. Whether you have a small apartment or a spacious home, modular kitchens offer flexible options to suit every space, making cooking and everyday life easier and more enjoyable.

#affordable interior designing company in ahmedabad#best interior designing company in gandhinagar#interior designers near me#showroom interior solutions provider in ahmedabad

0 notes

Text

Engineered Stone and SPC Vinyl Flooring: The Best Manufacturers in India

What is SPC Flooring?

SPC vinyl flooring provides an excellent option for high-traffic floors, like those found in hotels or offices, and it is also commonly used in residential settings. SPC flooring is recognized as the modern evolution of vinyl flooring. Furthermore, unlike wood and laminate floors, SPC flooring is completely water resistant, making it highly adaptable and appropriate for various spaces, including wet areas in the home, such as bathrooms.

SPC Vinyl Flooring: The Best Manufacturers in India

Floormonk- SPC flooring is becoming increasingly popular worldwide due to its outstanding features and is the best SPC flooring manufacturer in India. It's important to identify the top brand before embarking on a floor tile shopping spree. Flooring material plays a crucial role in creating the perfect ambiance for your dream home.

When exploring information about SPC flooring, you'll be surprised to learn that these floor tiles are suitable for both residential and commercial properties. They are a reliable choice for areas with high foot traffic, such as restaurants, hospitals, and malls.

The tiles offered by Floormonk, a leading SPC flooring brand, are excellent for creating a stain-resistant surface. Opting for SPC flooring for commercial spaces is ideal due to its zero maintenance requirements.

Wintel tiles- Wintel Surfaces, also the best SPC flooring manufacturer in India specializes in the creation of distinctive floor designs for both residential and commercial spaces, offering high-quality products with unique designs to enhance any environment. When selecting a supplier for SPC flooring, it's crucial to prioritize the quality of materials utilized. Wintel offers a combination of natural beauty from the stone component and durability and strength from the plastic component. Purchasing from Wintel provides the significant advantage of enhancing sustainability, as their SPC flooring does not utilize materials that may lead to deforestation and deterioration over time. Wintel is renowned for producing 181*1220 mm SPC floorings in a variety of colors and finishes.

Argil group- It is one of the best SPC flooring manufacturers located in Morbi, Gujarat, India. The company operates three manufacturing units: one for roof tiles, one for wall tiles, and one for quartz stone. Each unit possesses a robust and hardworking infrastructure, which plays a crucial role in establishing the company and the brand as key players in their specific product categories in India and abroad. The strategic location provides significant benefits in terms of access to raw materials and transportation of finished goods.

Ceraite- There are numerous benefits to SPC flooring, with one of the most significant being its ability to save both time and money. Unlike traditional flooring installations, SPC flooring from Ceraite comes pre-installed and ready for use, streamlining the process and making it more efficient. Ceraite, a prominent manufacturer of SPC flooring in India, ensures that all its products are crafted from top-quality materials. Choosing Ceraite guarantees that your floors will always look fantastic. Additionally, the SPC flooring manufacturer provides a wide range of options suitable for any room, including bedrooms, kitchens, and bathrooms.

0 notes

Text

Supplier of ABA Blown Film Machine in Gujarat

Adroit Extrusion is a trusted Manufacturer, Exporter, and Supplier of ABA Blown Film Machine in Gujarat. Our Manufacturing unit is located in Ahmedabad, Gujarat, India. Our ABA Blown Film Machine are designed to deliver superior performance, reduce raw material costs, and ensure exceptional film quality. Features of ABA & AB Blown Film Machines: Efficient Design for Cost Savings: A single, smaller extruder produces both A-layers using only 30–40% new plastic resins per minute, operating at a slower pace for efficiency. The second extruder forms the intermediate layer using recycled plastic resins and CaCO₃, significantly lowering material costs. Enhanced Film Quality: Produces three-layer film that is 30% stronger than monolayer film, ensuring durability and strength. Both sides of the film provide a smooth printing surface, ideal for applications like shopping bags. Flexible Layer Configurations: A simple modification in the die block design allows for a traditional two-layer co-extrusion line to produce three-layer films. Depending on application requirements, the machine can switch between A/B/A co-extrusion and A/B co-extrusion. Technical Specifications: Model Name: Duoflex ABA Three Layer & AB Two Layer Co-Extrusion Blown Film Plant Materials Used: LDPE, LLDPE, HDPE, CaCO₃, Virgin Raw Materials Output Range: 60–200 kg/hr Screw Diameter: 35/45/55/65/75 (Customized) Screw L/D Ratio: 30:1 (Customized) Layflat Film Width: 500–3000 mm Thickness Range: 20 microns to 150 microns Applications of ABA & AB Blown Film Machines: Our machines are suitable for producing various films: General-purpose PE Film HDPE Pick-Up Bags Shade-Net Film PE Lamination Film Mulch Film Courier Film Stretch & Cling Film Shrink Film Anti-Rust Film Tarpaulin Film FAQs. Q1: Can the machine produce both two-layer and three-layer films? A1: The machine can switch between A/B and A/B/A co-extrusion configurations with a simple die block adjustment. Q2: What materials can be processed in these machines? A2: Our machines are compatible with LDPE, LLDPE, HDPE, CaCO₃, and virgin raw materials. Q3: What are the typical applications for the films produced? A3: These machines produce films for various uses, including general-purpose films, pick-up bags, lamination films, mulch films, courier films, and more. Adroit Extrusion is a Supplier of ABA Blown Film Machine in Gujarat including locations Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Anand, Gandhinagar, Bharuch, Morbi, Vapi, Valsad, Junagadh, Nadiad, Mehsana, Porbandar, Godhra, Navsari, Surendranagar, Patan, Amreli, Palanpur, Modasa, Dahod, Gandhidham, Bhuj, Ankleshwar, Kalol, Sanand, Halol, Kadi, Khambhat, Jetpur, Kutch, Mundra, Morbi, Rajpipla, Dwarka, Dholka, Gandharpur, Bhachau, Chotila, Dhandhuka, Umargam, Padra, Jhagadia, Kalol, Savli, Sachin, Palghar, Godhra, Vallabh Vidyanagar, Mandvi, Halvad, Balasinor, Nandesari, Pardi, Karamsad. For more details or to inquire about our ABA & AB Blown Film Machines, contact Adroit Extrusion today! View Product: Click here Read the full article

#ABABlownFilmMachineinGujarat#ABABlownFilmMachineManufacturerinAhmedabad#AdroitExtrusion#Ahmedabad#Amreli#Anand#Ankleshwar#Balasinor#Bhachau#Bharuch#Bhavnagar#Bhuj#Chotila#Dahod#Dhandhuka#Dholka#Dwarka#Exporter#Gandharpur#Gandhidham#Gandhinagar#Godhra#Gujarat#Halol#Halvad#India#Jamnagar#Jetpur#Jhagadia#Junagadh

0 notes

Text

Sanitary Pad raw material supplier in India

India has a thriving market for sanitary pad raw materials, with many suppliers offering a wide range of products required for manufacturing high-quality sanitary pads. Whether you're a small-scale manufacturer or a large production facility, sourcing reliable and cost-effective raw materials is crucial. Here’s an overview of some of the top sanitary pad raw material suppliers in India:

1. Favourite Fab

Location: Delhi, India

Products: Non-woven fabric, SAP (Super Absorbent Polymer) sheets, release paper, PE film, adhesive tapes, and other essential components for sanitary pad manufacturing.

Overview: Favourite Fab is a leading supplier known for its high-quality materials and competitive pricing. They offer a wide range of products tailored to the needs of sanitary pad manufacturers, from basic materials to more specialized components.

2. H.B. Fuller India Adhesives Pvt. Ltd.

Location: Pune, Maharashtra

Products: Adhesive tapes, hot melt adhesives, and sealants specifically designed for the hygiene industry, including sanitary pads.

Overview: H.B. Fuller is a global leader in adhesive technologies, offering innovative solutions for the hygiene industry. Their products ensure strong bonding and sealing, essential for producing durable and reliable sanitary pads.

3. Henkel Adhesives Technologies India Pvt. Ltd.

Location: Navi Mumbai, Maharashtra

Products: Hot melt adhesives, non-woven fabric, and absorbent core materials.

Overview: Henkel is a well-known supplier of high-performance adhesives and raw materials for the hygiene industry. Their products are widely used by manufacturers looking for dependable and efficient solutions.

4. Saaral Hygiene Products

Location: Coimbatore, Tamil Nadu

Products: Non-woven fabric, SAP sheets, release paper, PE backsheet, and top sheet materials.

Overview: Saaral Hygiene Products specializes in supplying high-quality raw materials for sanitary pads and other hygiene products. They are known for their reliable service and consistent product quality.

5. Rawtech Trade Pvt. Ltd.

Location: Ahmedabad, Gujarat

Products: Super Absorbent Polymer (SAP), non-woven fabric, fluff pulp, and other essential raw materials for sanitary napkins.

Overview: Rawtech Trade is a prominent supplier in the hygiene industry, offering a comprehensive range of raw materials. They are committed to providing quality products at competitive prices, making them a preferred choice for many manufacturers.

6. Asia Non Woven Fabrics Pvt. Ltd.

Location: Surat, Gujarat

Products: Non-woven fabric, elastic non-woven, spunbond non-woven, and laminated non-woven fabrics.

Overview: Asia Non Woven Fabrics is a key player in the non-woven fabric market, supplying high-quality materials for sanitary pads and other hygiene products. Their fabrics are known for their strength, softness, and breathability.

7. Unicare Hygiene Products

Location: Bengaluru, Karnataka

Products: PE film, non-woven fabric, tissue paper, fluff pulp, SAP, and release paper.

Overview: Unicare Hygiene Products offers a wide range of raw materials specifically designed for sanitary pad manufacturing. They focus on providing materials that ensure product comfort, absorbency, and safety.

8. Manjushree Spntek Pvt. Ltd.

Location: Bengaluru, Karnataka

Products: Non-woven fabric, elastic non-woven, and laminated non-woven fabric.

Overview: Manjushree Spntek is a leading supplier of non-woven fabrics in India, catering to the hygiene industry. They offer materials that are ideal for making the top sheet, back sheet, and core components of sanitary pads.

Key Factors to Consider When Choosing a Supplier

Quality Assurance: Ensure that the supplier provides materials that meet industry standards and are certified for use in hygiene products.

Supply Chain Reliability: Choose a supplier with a strong track record of on-time delivery and consistent product quality.

Customization Options: Some suppliers offer customized materials based on your specific product needs, which can be a significant advantage.

Cost-Effectiveness: While quality should never be compromised, finding a supplier that offers competitive pricing can help maintain your product's profitability.

Technical Support: Suppliers who provide technical support and guidance can be valuable partners in optimizing your production process.

Conclusion

Selecting the right raw material supplier is crucial for the success of your sanitary pad manufacturing business. India offers a wide array of suppliers, each with unique strengths in terms of product quality, pricing, and service. By carefully evaluating these factors, you can establish a reliable supply chain that supports your business goals and helps you produce high-quality sanitary pads that meet consumer needs.

0 notes

Text

Buy Licon Tools and Products From Perfect Tools in Ahmedabad

Licon Tools and Products From Perfect Tools in Ahmedabad

Licon Tools, Licon High Performance German Cutting Tools Manufacturer & Supplier From Perfect Tools in Ahmedabad, Gujarat, India Including TCT Cutters, Grooving Cutters, Planning Cutters

Licon Tools including TCT Brazed Grooving Cutter — LAB.GC.01, TCT Grooving Cutters for Laminated Board — LAB.GC.02, TCT Planning Cutter Head with Helix Angle — LAB.PC.04, TCT Brazed Half Radius Cutter — LAB.HR.05 and Cutting Tools, and So on.

For More Details 👇

📱 Call: +91 93282 03494, +91 78744 31679 💬 WhatsApp: https://wa.me/919328203494 🌐 Visit: https://www.perfecttoolsindustries.com/licon/

0 notes

Text

Pacific Laminates to invest Rs 50 crore over the next three years

Pacific Laminates based in Pardi in Gujarat has announced plans to invest approximately Rs 50 crore (US$ 6 million) over the next three years to triple its flexible packaging printing and converting capacity. The company’s current manufacturing capacity stands at 600 metric tons monthly, generating a revenue of Rs 70 crore.

Through strategic and concerted investments in technology, infrastructure, and talent, the aim is to increase its output capacity to 1500 metric tons monthly over two to three years. The company envisions an increase in A-grade clients and a shift to more sustainable materials and solutions to make up at least 30% of its product mix. The overall attempt is to achieve annual revenues from Rs 300 to Rs 400 crore with an EBITDA of 12 to 15% in the coming years.

The decades-old company is a supplier to domestic and global brands and markets with exports of packaging materials to the United States, Europe, and the Middle East. Its current capacity includes two multilayer LDP blown film lines, three rotogravure presses with ARC and turret winders, a pair of solventless laminators, an extrusion coater, several slitter rewinders, and a battery of 34 pouching machines.

This comprehensive setup enables Pacific Laminates to produce a wide range of flexible laminates, pouches, and packaging solutions catering to diverse industry needs. With a commitment to innovation and quality, Pacific Laminates delivers exceptional flexible packaging solutions.

The company is well known for its pouch solutions for food, FMCG, automobile, soaps, detergents, beverages, pharmaceuticals, and cosmetics, using laminates and structures with combinations of PE, PP, PET, Nylon, aluminum, BOPP, BOPA, PVC, PVDC, EVOH, and EVA. Pacific’s BOPP pouches are known for their excellent barrier properties and heat sealability and are used widely in the food, stationery, garment, and hosiery segments.

Pacific Laminates specializes in shaped and broom pouches. While unique shapes of certain products present challenges in packaging and branding the company through its experience and specialized machinery and skills can provide innovative packaging solutions for such products.

Aligned with customer’s sustainability goals

Recognizing the growing importance of sustainability in the packaging industry, the company has been actively exploring eco-friendly alternatives that it plans to extend in its projected capacity expansion. Committed to reducing its environmental footprint by using recyclable and biodegradable materials, the company is investing in research and development to develop packaging solutions compatible with sustainable practices.

These efforts include minimizing material usage and streamlining packaging processes to reduce waste and improve efficiency. The company has undertaken responsible and ethical sourcing of materials in its effort to maintain its reputation as a trusted partner of leading consumer product brands for their high and sustainable packaging solutions.

0 notes

Text

Exporter of Spin Flash Dryer in Gambia

Drytech Engineering Systems is a leading Exporter of Spin Flash Dryer in Gambia. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. A Spin Flash Dryer is a high-efficiency drying equipment that processes materials in powder, granules, or slurry form. It is designed to handle heat-sensitive materials and is widely used by the food, chemical, and pharmaceutical industries. The dryer operates by passing a slurry or wet feed through a high-speed rotating drum, Hot air rapidly evaporates moisture from the material. The result is a uniform and quick drying process that minimizes thermal degradation and preserves the product's quality. Why Choose Our Spin Flash Dryers? Efficiency and Speed: Our Spin Flash Dryers deliver high throughput with minimal energy consumption, ensuring a faster drying process. Quality Assurance: We supply dryers made from the best materials, ensuring durability and optimal performance in harsh industrial environments. Cost-Effective: With their energy efficiency and low maintenance costs, our dryers help reduce operational expenses in the long term. Versatile Applications: Our dryers are suitable for a wide range of applications, including drying food products, chemicals, pharmaceuticals, and even bio-products. Customization: We provide tailored solutions to meet the unique drying needs of different industries and customer requirements. Industries Served: Food Processing Pharmaceuticals Chemicals Bio-products What materials can be dried using a Spin Flash Dryer? Spin Flash Dryers can handle a wide variety of materials, including slurries, pastes, powders, and granules. Common materials include food products, pharmaceuticals, chemicals, pigments, and bio-based products. Do you offer custom Spin Flash Dryers? Yes, we offer customization based on your specific drying needs. Whether you need adjustments to capacity, heating systems, or other operational features, we provide tailored solutions to suit your business requirements. Drytech Engineering Systems is an Exporter of Spin Flash Dryer in Gambia including locations like Abuko, Bakau, Banjul, Banjulunding, Bansang, Basse Santa Su, Bijilo, Brikama, Brufut, Bundung, Busumbala, Dippa Kunda, Farafenni, Farato, Gimara Bakadaji, Gunjur, Janjanbureh, Jufureh, Kalagi, Kanilai, Kerewan, Kololi, Kotu, Kuntaur, Lamin, Lamin, Latri Kunda German, Latri Kunda Sabiji, Manjai Kunda, Mansa Konko, Nema Kunku, Serekunda, Soma, Sukuta, Tabokoto, Tallinding, Tanji, Yundum. Contact us today to learn more, request a quote, or discuss your specific requirements. View Product: Click Here Read the full article

0 notes