#joint connector bolt stainless steel

Explore tagged Tumblr posts

Text

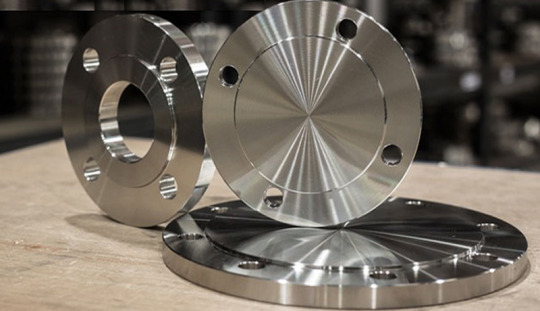

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes

Text

The Different Types of Tab Washers and Their Applications | Comprehensive Guide

In this article u will get to know that, Tab washers are a type of washer with one or more tabs that extend outward from the center hole. These tabs are designed to secure a nut or bolt in place by being bent up against a surface or fastener, providing extra grip and preventing loosening due to vibrations or movement. Tab washers are used in various mechanical assemblies to enhance the durability of joints and fastenings.

Unlike regular flat washers, tab washers provide an additional locking mechanism that is ideal for situations where standard washers may fail due to high vibrations, mechanical stress, or external forces. The tabs, when bent against a surface, create resistance to rotational movement, effectively preventing loosening.

Tab washers are used in a variety of industries for their ability to secure fasteners under tough conditions. Here are some of the key areas where tab washers are commonly used:

1. Automotive Industry

The automotive industry is one of the primary sectors that benefit from tab washers. These washers are used to secure critical components such as engine parts, suspension systems, and exhaust systems. In cars and trucks, vibration is a common cause of fasteners loosening, making tab washers essential for ensuring the safety and durability of parts.

Example: Securing nuts on an exhaust system to prevent them from vibrating loose.

2. Construction and Structural Applications

In construction, tab washers are used to secure nuts and bolts in structural elements like beams, trusses, and frames. These fasteners are essential in preventing the loosening of bolts over time, which could compromise the integrity of the structure.

Example: Securing bolts on steel beams and ensuring the structural safety of buildings and bridges.

3. Marine and Offshore Applications

The marine and offshore industries demand fasteners that can withstand extreme conditions such as high humidity, salty air, and constant motion. Tab washers are ideal for these environments, providing extra security to fasteners that are exposed to constant vibrations and movement.

Example: Securing equipment on ships, oil rigs, or offshore platforms.

4. Electrical and Electronic Equipment

In the electrical industry, tab washers are used to secure electrical components and prevent loosening due to vibrations. They are often used in circuit boards, electrical enclosures, and in the fastening of various electrical terminals.

Example: Keeping electrical connectors secure in high-vibration environments such as motors or generators.

When choosing fasteners for your project, you want to ensure that you’re selecting the right components for optimal performance. Here are some of the key benefits of using tab washers:

Prevents Loosening: Tab washers are designed to lock fasteners in place and prevent them from loosening due to vibrations or mechanical stress.

Improved Stability: They enhance the stability of a fastening system, making them ideal for high-stress environments.

Cost-Effective: Tab washers are inexpensive yet effective, offering significant benefits in terms of safety and reliability at a low cost.

Variety of Options: With different types of tab washers available, you can select the one that best suits your specific application, whether it’s a conical, serrated, or internal tab washer.

Durability: Made from high-quality materials like stainless steel, tab washers are built to withstand harsh conditions and provide long-lasting performance.

In this guide, we’ve covered the different types of tab washers and their applications. Whether you’re working in automotive, construction, marine, or electrical industries, tab washers offer an easy and effective way to ensure that your fasteners stay in place and your assemblies remain secure.

By choosing the right type of tab washer for your project, you’ll be able to improve the performance and durability of your mechanical systems. Remember, tab washers aren’t just about securing fasteners – they’re about ensuring the safety, efficiency, and longevity of your equipment.

This guide will equip you with the knowledge to take your garment construction skills to the next level and create clothes that look and feel truly professional.

Link

The Different Types of Tab Washers and Their Applications | Comprehensive Guide

#TabWashers#FastenersGuide#IndustrialHardware#EngineeringEssentials#TabWashersApplications#ComprehensiveGuide

0 notes

Text

Ananka

Q1) Fastening Solutions for HVAC and Plumbing Systems

Ans) Fastening solutions for HVAC (Heating, Ventilation, and Air Conditioning) and plumbing systems are essential to ensure the stability, safety, and efficient functioning of these installations. Here are some common fastening solutions used in HVAC and plumbing systems:

1. Pipe Clamps: Pipe clamps are widely used to secure pipes to walls, ceilings, or other structural components. They come in various sizes and materials (such as metal or plastic) to accommodate different pipe diameters and provide robust support.

2. Hangers and Supports: Hangers and supports are used to suspend pipes, ductwork, and equipment from ceilings, walls, or beams. They help prevent sagging or excessive movement, ensuring that the systems maintain their proper alignment.

3. Threaded Rods and Struts: Threaded rods and struts are often employed in conjunction with pipe clamps and hangers to provide additional support for long runs of piping or ductwork.

4. Fasteners for Ductwork: HVAC ducts require specific fastening solutions, such as sheet metal screws, clips, and flange connectors, to join duct sections together securely and maintain proper airflow.

5. Anchor Bolts and Concrete Inserts: For heavy HVAC equipment and structural components that need to be attached to concrete or masonry surfaces, anchor bolts and concrete inserts provide secure fastening points.

6. Flanges and Gaskets: Flanges and gaskets are used to connect pipes, valves, and fittings together in plumbing systems, ensuring leak-free joints.

7. Cable Ties and Straps: Cable ties and straps are versatile solutions for organizing and securing electrical wiring, hoses, or small pipes within HVAC and plumbing systems.

8. Insulation Fasteners: Insulation fasteners are designed to attach insulation materials to HVAC ducts or pipes, helping to improve energy efficiency and reduce heat loss or gain.

9. Fasteners for Equipment Mounting: Fasteners, such as bolts and screws, are used to secure HVAC and plumbing equipment to mounting brackets or frames.

10. Fasteners for Electrical Components: HVAC and plumbing systems often include various electrical components that require secure mounting using screws or specialized clips.

When selecting fastening solutions for HVAC and plumbing systems, it's crucial to consider factors such as the materials used (for corrosion resistance and durability), load-bearing capacity, environmental conditions (such as exposure to moisture or chemicals), and compliance with relevant building codes and regulations.

Proper installation of fasteners and adherence to best practices are vital to ensure the longevity and reliability of HVAC and plumbing systems. If in doubt, it's recommended to consult with professionals or engineers experienced in the specific installation requirements of HVAC and plumbing systems.

Bolt Manufacturers in India

Q2) The Art of Fasteners: Celebrating Design and Craftsmanship

Ans) Fasteners, though often overlooked, play a vital role in design and craftsmanship, serving as unsung heroes that uphold the strength, stability, and reliability of numerous products and structures.

Craftsmanship in fastener design entails creating solutions that not only fulfill their functional purpose but also exhibit aesthetic appeal. Despite their seemingly insignificant size, fasteners can be meticulously designed with attention to detail and beauty, especially in applications where they remain visible, such as in high-end furniture, architectural elements, and luxury products.

Precision engineering is fundamental to crafting high-quality fasteners. Every dimension, tolerance, and material used must be thoughtfully considered to ensure optimal performance, creating fasteners that fit flawlessly, are easy to use, and stand the test of time.

Material selection is a key aspect of craftsmanship, with different applications demanding specific materials, such as stainless steel, brass, aluminum, or even exotic materials for specialized uses. Choosing the right material ensures that the fasteners can withstand the environmental conditions they encounter.

Innovation and problem-solving are inherent in fastener design, as engineers and designers continuously seek ways to enhance their efficiency, ease of installation, and suitability for specific tasks. The artistry lies in finding elegant and effective solutions to complex challenges.

Craftsmanship in fasteners extends to considerations of sustainability and environmental impact. Emphasizing eco-friendly materials, designing fasteners for easy recycling, and creating reusable fastening systems all contribute to responsible craftsmanship.

The historical significance of fasteners lies in preserving traditional techniques while embracing modern advancements. This pays homage to the artisans and craftspeople of the past who contributed to the development of the fasteners we rely on today.

Collaboration and integration are vital in fastener design. They must seamlessly complement the products they hold together, whether it's furniture, building facades, or mechanical systems. Achieving this requires close cooperation between designers, engineers, and manufacturers.

In conclusion, celebrating the art of fasteners entails recognizing their indispensable role in daily life and appreciating the craftsmanship involved in their design and production. Each fastener, from the simplest screw to the most intricate connector, symbolizes the harmonious blend of functionality and artistry.

Eye Bolt Manufacturer in Mumbai

Q3) Fasteners and Fire Safety: Ensuring Building Code Compliance

Ans) Fasteners play a crucial role in ensuring fire safety and complying with building codes. They are essential in maintaining the integrity of fire-rated assemblies, preventing the spread of fire and smoke, and safeguarding the lives of building occupants. Here are some key considerations to keep in mind regarding fasteners and fire safety in building construction:

1. Fire-Rated Assemblies: Building codes often mandate the use of fire-rated assemblies, such as fire-rated walls, ceilings, and floors, to contain the spread of fire. These assemblies are designed and tested to withstand fire for a specific duration, providing occupants with more time to evacuate safely. Fasteners used in these assemblies must also possess fire-resistant properties to preserve the fire rating.

2. Fire-Resistant Materials: Fasteners should be made from fire-resistant materials like steel to endure high temperatures and prevent contributing as fuel to the fire. Using non-combustible materials ensures the integrity of the fire-rated assembly.

3. Type and Size of Fasteners: Building codes may specify the appropriate type and size of fasteners for use in fire-rated assemblies. Using incorrect fasteners can compromise the fire resistance of the assembly.

4. Penetrations and Sealing: Properly sealing penetrations, such as pipes, ducts, or cables passing through walls or floors, is crucial in fire-rated assemblies. Firestop systems and fire caulk are commonly used to seal penetrations and maintain the fire rating.

5. Assembly Testing and Certification: It's essential to use fasteners that have been tested and certified as part of the fire-rated assembly. This ensures that the entire system, including the fasteners, has been evaluated for its fire resistance.

6. Adherence to Manufacturer's Instructions: Following the manufacturer's instructions for installing fire-rated assemblies and using approved fasteners is critical. Deviating from these instructions may void the fire rating and compromise fire safety.

7. Regular Inspections and Maintenance: Regular inspections and maintenance of fire-rated assemblies are vital to ensure that fasteners and other components remain in good condition, providing continued fire protection.

8. Consultation with Experts: When dealing with complex fire-rated assemblies or uncertain about the appropriate fasteners to use, seeking advice from fire safety experts, structural engineers, or building code officials is essential to ensure compliance with regulations and standards.

In conclusion, meticulous consideration of fasteners used in building construction is essential for fire safety and building code compliance. Employing fire-resistant materials, proper installation, and adherence to guidelines ensure that fasteners play their part in creating safer environments for building occupants.

Stud Bolts and Nuts

0 notes

Text

Flanges Manufacturer: Connecting Pipes with Precision and Strength

When you turn on your tap to get water or drive your car, you may not think about the numerous components working together to make these everyday tasks possible. One crucial element involved in ensuring the seamless functioning of various industrial applications and systems is the humble flange. Flanges are essential components that connect pipes and equipment, providing a secure and leak-proof joint. In this article, we will explore the world of flanges, their manufacturing process, and their significance in a wide range of industries.

What are Flanges?

Flanges are flat, circular discs with holes in the center, designed to connect pipes, valves, pumps, and other equipment together. They act as connectors, joining different parts of a piping system, creating a strong, sealed joint. The flange's circular shape allows for even distribution of pressure, preventing leakage and ensuring the safety and efficiency of industrial processes.

Types of Flanges:

Flanges come in various shapes and sizes to suit different applications. Some common types of flanges include:

Slip-On Flanges: These flanges slide over the pipe end and are then welded in place. They are easy to install and widely used in low-pressure systems.

Weld Neck Flanges: These flanges have a long tapered neck that provides excellent support to the pipe. They are ideal for high-pressure applications.

Blind Flanges: Blind flanges are solid plates used to close the end of a pipe or vessel, making them perfect for inspection and maintenance purposes.

Socket Weld Flanges: These flanges are designed for small-sized high-pressure pipes and are attached using socket welds.

Lap Joint Flanges: Lap joint flanges are used in conjunction with a stub end, allowing easy alignment of bolt holes in the joint.

Flanges Manufacturing Process:

Flanges are manufactured through a series of steps to ensure their precision and durability:

Material Selection: Flanges are commonly made from materials like carbon steel, stainless steel, and alloy steel, depending on the application's requirements.

Cutting: The selected material is cut into circular discs of the desired size.

Forming: The disc is then heated and shaped using pressing or rolling techniques.

Boring: The center hole and bolt holes are drilled into the formed disc.

Machining: The flange is subjected to machining processes to achieve smooth surfaces and precise dimensions.

Quality Control: Each flange undergoes rigorous testing to check for defects and ensure adherence to industry standards.

Applications of Flanges:

Flanges play a crucial role in various industries, including:

Oil and Gas: Flanges are widely used in oil and gas pipelines, connecting sections of the network and facilitating the transportation of resources.

Petrochemicals: Flanges are essential in petrochemical plants, where they connect different equipment to create a seamless process flow.

Water and Sewage: Flanges are used in water treatment plants and sewage systems, ensuring a reliable and leak-free supply.

Construction: Flanges are employed in construction projects, such as bridges and skyscrapers, where they connect structural elements with precision.

Shipbuilding: Flanges are utilized in shipbuilding, connecting pipes and equipment aboard vessels.

Frequently Asked Questions (FAQs):

What are flanges made of?

Flanges are commonly made of materials like carbon steel, stainless steel, and alloy steel.

How do flanges work?

Flanges connect pipes and equipment, creating a secure, leak-proof joint that allows the smooth flow of fluids or gases.

Can flanges be reused?

Yes, flanges can be reused if they are in good condition and meet safety standards.

What types of flanges are there?

Some common types of flanges include slip-on flanges, weld neck flanges, blind flanges, socket weld flanges, and lap joint flanges.

How are flanges manufactured?

Flanges are manufactured through a process involving material selection, cutting, forming, boring, machining, and quality control.

Are flanges only used in industrial applications?

No, flanges are also used in everyday applications like plumbing and automotive systems.

Can flanges handle high-pressure systems?

Yes, certain types of flanges, like weld neck flanges, are designed for high-pressure applications.

What is the purpose of a blind flange?

A blind flange is used to close the end of a pipe or vessel, allowing for inspection and maintenance.

How are flanges installed?

Flanges are either slipped onto the pipe end and then welded or bolted in place, depending on the type of flange.

Are flanges the same as gaskets?

No, flanges and gaskets are different components. Flanges connect pipes, while gaskets are used between flanges to create a seal.

Can flanges prevent leaks?

Yes, flanges create a tight joint that prevents leaks in the piping system.

Can flanges be custom-made?

Yes, manufacturers can create flanges in custom sizes and materials to meet specific requirements.

Are there standards for flange manufacturing?

Yes, various organizations set standards for flange manufacturing to ensure quality and safety.

Can flanges withstand extreme temperatures?

Yes, some flange materials are designed to withstand high and low temperatures.

Are flanges suitable for corrosive environments?

Yes, certain materials like stainless steel and alloy steel are resistant to corrosion and are used in such environments.

Are flanges used in renewable energy systems?

Yes, flanges are used in renewable energy systems, such as wind turbines and solar power plants.

Can flanges be painted or coated?

Yes, flanges can be painted or coated to protect them from corrosion or enhance their appearance.

Can flanges be used for both liquids and gases?

Yes, flanges are versatile and can be used to handle both liquids and gases.

Do flanges come with warranties?

Warranties on flanges may vary depending on the manufacturer and specific application.

Can flanges be recycled?

Yes, most flange materials are recyclable, contributing to sustainability efforts.

How often should flanges be inspected?

Flanges should be regularly inspected as part of a maintenance routine to identify any potential issues.

Are flanges suitable for underground piping?

Yes, flanges are used in underground piping systems to connect pipes securely.

Can I install flanges myself?

While some flanges are easy to install, it is recommended to have a professional perform the installation to ensure proper alignment and tightness.

Can flanges be used in hazardous environments?

Yes, flanges can be used in hazardous environments with the appropriate material selection and safety measures.

Do flanges require regular maintenance?

Flanges require regular maintenance to ensure their proper functioning and prevent leaks.

Conclusion:

Flanges may seem like small components, but they are vital in various industries, providing the connections that keep our world running smoothly. From oil and gas pipelines to water supply systems, flanges play an essential role in ensuring the safety and efficiency of industrial processes. Their versatility and durability make them indispensable in a wide range of applications, making the world a better-connected place.

0 notes

Text

Best Flanges Manufacturers In India & 6 Types Of Flanges

Introduction:

Flanges are essential in many industrial applications because they join pipelines, valves, and other equipment. There are numerous flange manufacturers in India, a nation renowned for its strong manufacturing industry, that supply a variety of industrial demands. This article will examine the significance of flanges, go over the important considerations to make when selecting a flange maker, and highlight some well-known Flange Manufacturers in India.

The Importance of Flanges Manufacturers:

Flanges are crucial parts that give pipes, valves, and other equipment a trustworthy and leak-free connection. They guarantee a pipeline system's stability and integrity, enabling effective fluid or gas flow. Oil and gas, petrochemicals, electricity generating, water treatment, pharmaceuticals, and other industries use flanges extensively.

Quality Standards:

Seek out manufacturers who follow global quality standards like ISO 9001:2015. This certification guarantees that the producer adheres to strict quality control procedures and produces flanges in accordance with industry standards.

Introduction to Flanges:

A flange is a mechanical connector that joins two pieces of equipment, such as pipes, valves, or other machinery. It consists of a flat, round disc with holes for screws or bolts that are uniformly spaced apart. Depending on the application and required strength, flanges are often composed of materials like carbon steel, stainless steel, alloy steel, or other metals.

Flanges serve several important purposes in piping systems:

Connection:

Flanges offer a reliable connection between two pipes or pieces of machinery. They facilitate maintenance and repairs by enabling simple assembly and disassembly.

Sealing:

For a tight seal, gaskets are frequently used in flanges between the mating surfaces. In particular when working with fluids or gases under pressure, this stops leaks and ensures the system's integrity.

Alignment:

Flanges aid in the exact positioning of pipes and machinery, maintaining correct flow and reducing system stress. They offer support and stability, preventing movement or misalignment while in use.

Accessibility:

Flanges provide access ports for piping system adjustments, cleaning, and inspection. The flange may be readily opened by removing the nuts or screws, enabling specialists to complete necessary procedures.

Versatility:

To meet the needs of varied applications and connecting requirements, flanges are available in a variety of types and designs. Slip-on flanges, weld neck flanges, blind flanges, socket weld flanges, threaded flanges, and lap joint flanges are examples of common types.

Oil and gas, petrochemical, chemical processing, electricity generation, water treatment, and HVAC systems are just a few of the industries that employ flanges extensively. They are crucial elements that guarantee the effective and seamless operation of piping networks.

It's crucial to remember that choosing the proper flange depends on various elements, including the pipe's size, pressure rating, temperature, and the system's unique requirements. It is advised to seek advice from flange manufacturers or industry experts to ensure the right choice and installation of flanges for a given application.

Types Of Flanges:

Hub Flange

Without Hub Flange

Plate Flange

Slip on Flange

Blind Flange

Socket Weld Flange

Conclusion:

When it comes to flange manufacturers in India, Metalica Forging Inc sets itself apart with its unwavering commitment to quality, wide range of products, customization options, technical expertise, and timely delivery. With their customer-centric approach and dedication to excellence, Metalica Forging Inc has earned a reputation as a trusted partner for flanges solutions. Whether you are in the oil and gas, petrochemical, power generation, or any other industry, Metalica Forging Inc is your go-to destination for high-quality Flanges Manufacturers in India.

METALICA FORGING INC. is one of the leading Mild Steel Flanges Manufacturer in India. Our products are expertly engineered using the most advanced processes available. MS flanges have some outstanding characteristics like Wear resistance, Resistance to plastic deformation, Chipping resistance, Good machinability and grind ability, Good Fabric ability, Strong & Tough Construction, Durable, Resistant to plastic deformation, Durable, High tensile strength, etc. METALICA FORGING INC is a most trusted Mild Steel Flanges Supplier in India

For other Information Flange Standard Dimensions.

0 notes

Text

What are Flanges and their types?

Flanges are an essential component of any piping system, as they provide a secure and leak-free connection between two pipes or valves. As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP understands the importance of choosing the right type of flange for your application.

In this blog post, we will cover everything you need to know about flanges, including their types, materials, and applications.

Before we dive into the details, let's start with the basics!

Introduction

Flanges are mechanical connectors used to join two pipes or valves. They are usually made of steel, and their main purpose is to provide a tight and leak-free seal between the two parts. Flanges come in various types and sizes, and choosing the right type of flange is essential for the safety and efficiency of your piping system.

Types of Flanges?

Flanges come in several types, including weld neck, slip-on, socket weld, lap joint, threaded, and blind flanges. Each type has its unique characteristics and applications, and selecting the right one will depend on several factors, such as pressure ratings, temperature ratings, size, material compatibility, and cost.

● Weld Neck Flanges

Weld neck flanges are the most common type of flange, known for their high durability and strength. They are welded to the pipe or valve, making them ideal for high-pressure and high-temperature applications.

● Slip-On Flanges

Slip-on flanges are easy to install and remove, making them ideal for applications that require frequent maintenance. They slide over the pipe or valve and are then welded or bolted in place.

● Socket Weld Flanges

Socket weld flanges are similar to slip-on flanges, but they are welded only on the outer side of the flange, leaving the inner side free of welding marks. They are ideal for smaller-sized pipes and low-pressure applications.

● Lap Joint Flanges

Lap joint flanges are used when a piping system requires dismantling frequently. They are also ideal for applications that require easy access to the pipe or valve.

● Threaded Flanges

Threaded flanges are designed to be screwed onto the pipe or valve, making them ideal for applications that require easy installation and removal. They are commonly used in low-pressure applications.

● Blind Flanges

Blind flanges are used to seal the end of a pipe or valve. They are commonly used for pressure testing and maintenance purposes.

Materials & Grades Available In Flanges with Bullion Pipes & Tubes LLP

Flanges can be made of various materials & Grades, such as,

● Stainless Steel - 904L Flanges, 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 446 Flanges

● Hastelloy Flanges - C22, B2 Flanges, C276 Flanges

● Carbon Steel Flanges - ASTM A350 15LF1, LF2 CL1/CL2, LF3 CL1/CL2 Carbon Steel Flanges

● Nickel Alloy - 200/201

● Duplex Steel Flanges - Duplex UNS S32205/31803 Flanges

● Alloy Steel Flanges - P5, P9, P11, P12, P22, P91 Flanges

● Super Duplex Steel - UNS S32750/S32760 Flanges

● Titanium Alloys - Gr 2 Flanges, Gr 5 Flanges, Gr 7 Flanges

● Aluminium Flanges - 5052 Reducing Flanges, 5082 Flanges, 5082 Flanges, 6063 SORF Flanges, 6082 Blind Flanges, 2024 Aluminum Weld Neck Flanges, and 5052 Threaded Flanges.

● Tantalum Flanges - ASTM B521 Tantalum Flanges, Spectacle Blind Flanges, Orifice Flange, Ta-10W Flanges, Tantalum UNS R05200 Flanges, ASTM B365 Ta2.5W Flanges

● Monel Flanges - Monel K500 Flanges, Monel 400 Flanges

● Alloy 20 Flanges - Alloy 20 RTJ Flange, Alloy 20 WNRF Flanges, Alloy UNS N08020 Pipe Flanges, Alloy 20 Weld Neck Flange, Alloy 20 Nipo Flanges, ASTM B462 Alloy Threaded Flanges, Alloy 20 Spectacle Blind Flanges, Alloy 20 Industrial Flanges, and UNS N08020 Alloy 20 Forged Flanges

● SMO 254 Flanges

● Inconel Flanges - Inconel 718, 600, 601 and 625 Flanges

● Incoloy Flanges - 825, 800/800H/800HT Flanges

Choosing the right material for your flange will depend on several factors, such as the application's temperature, pressure, and corrosion resistance requirements.

Factors to Consider When Selecting Flanges

Selecting the right flange for your application can be challenging, as there are several factors to consider, such as pressure ratings, temperature ratings, size, material compatibility, and cost. At Bullion Pipes & Tubes LLP, we can help you choose the right flange for your application, ensuring safety and efficiency.

Flange Standard Ratings

Flanges come in various standard ratings, such as ANSI, API, DIN, and JIS. These ratings determine the flange's pressure-temperature rating and its compatibility with other components in the piping system.

Flange Installation

Proper flange installation is essential for the safety and efficiency of your piping system. It involves several steps, such as preparation of the piping system, installation of the flanges, flange tightening process, flange alignment, and testing and inspection.

Maintenance and Repair of Flanges

Maintaining and repairing flanges is critical for the longevity and safety of your piping system. Regular inspections, leak checks, and maintenance can help detect any potential issues before they become a more significant problem.

Applications of Flanges

Flanges have a wide range of applications in various industries, including:

● Oil and Gas Industry

● Petrochemical Industry

● Chemical Industry

● Power Generation Industry

● Water Treatment Industry

They are used in various applications, including HVAC systems, plumbing, and firefighting systems.

Why Choose Bullion Pipes & Tubes LLP for Flanges?

As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP offers a wide range of flanges made from high-quality materials. We provide customized solutions to meet our customers' specific needs, and our flanges are available in various sizes, ratings, and materials.

We have been providing high-quality flanges to various countries, such as Ukraine, Australia, Syria, Iraq, Iran, Kazakhstan, Russia, Brazil, Armenia, Azerbaijan, Egypt, South Africa, Qatar, Turkey, Oman, Bahrain, and Germany, and our products are known for their durability, reliability, and safety.

Conclusion

Flanges are a critical component of any piping system, and selecting the right type of flange for your application is essential for safety and efficiency. Choosing a reliable and trustworthy supplier like Bullion Pipes & Tubes LLP can ensure that you get high-quality flanges that meet your specific requirements.

0 notes

Text

Temperature ratings for steel and stainless steel flanges

There is no doubt that the concept of ansi flange rating charts makes sense. Flanges constructed with more metal can withstand more pressure than those constructed with less metal, such as Class 150 flanges. The pressure capability of a flange is, however, impacted by a number of factors.

As part of a piping system, 300 flange pressure rating chart is useful and flanges are used to join pipes, valves, pumps, and other equipment together. A cleaning, inspection, or modification can also be performed easily through this opening. Welding or screwing is the most common method of attaching a flange. Using a gasket between two flanges, flanged joints are constructed by bolting them together.

Materials for Flanges

There are many different materials used to manufacture pipe flanges, including stainless steel, cast iron, aluminium, brass, bronze, plastic, etc., but carbon steel has been used most often for forged flanges, in addition to having machined surfaces.

Furthermore, linings can be installed inside flanges, for specific purposes, in order to provide a completely different quality of material to the flange itself, called “lined flanges”.

When choosing a pipe, the material of the flange is largely determined, and in most cases, the same material is used for both.

On this website, all flanges are discussed under the ASME and ASTM standards, unless otherwise indicated. The ASME B16.5 standard describes dimensions, dimensional tolerances, and material qualities. The ASTM standard provides specifications for materials.

What is a steel flange?

Cleaning, inspecting, or modifying steel flanges is easy. Round ones are most common, but they are also available in square and rectangular shapes. A flange is joined to another using bolts, and to the piping system by welding or threading, and it has a specific 150 ansi pressure rating and is designed to handle 150lbs, 300lbs, 400lbs, 600lbs, 900lbs, 1500lbs, and 2500lbs.

There are many different kinds of flanges, but most of them are used to cover or close the ends of pipes. Blind flanges are known as such. Thus, flanges support mechanical parts from the inside by being considered internal components. Steel flanges are plate-like devices made from steel that can be forged or cast. In addition to strengthening columns, beams and pipes, these connectors are used to connect them. In spite of the fact that this concept is generic, the actual installation of flanges may have significant differences.

The connection between a steel flange and a fitting is either bolted, welded, or threaded. The ease of cleaning, inspection, or modification of steel flanges makes them ideal for a wide range of applications.

A flange is usually round, but it can also be rectangular or square due to the versatility of steel. The faces of flanges generally come in two types: flat or raised, with rings or tongues and grooves formed to the joint.

Additionally, the use of flanges is also possible when it comes to manufacturing steel sections. This includes parallel flange channels and tapered flange beams, both of which have parallel flange channels. For use in construction, parallel flange channels are U-shaped beams which are used as a beam shape. The materials are strong and come in a variety of sizes, so you can find the one you need. In the world of steel construction, tapered flange beams are generally used in cross-sections for girders that have I-shaped sections.

Weld-neck, slip-on, socket weld, lap joint, threaded, blind, and welded steel flanges are some of the most common types of standard steel flanges available today.

Read More About This Article On Our Website For More information: https://thesteelexporter.com/tempreture-ratings-for-steel-and-stainless-steel-flanges/

#design#architecture#interiordesign#steel#art#garden#gardendesign#rust#gardening#sculpture#metal#welding

1 note

·

View note

Text

How are flanges made and what are their properties?

There are two methods for manufacturing A420 WPL6 steel flanges:

Micro-melting, which is accomplished by casting steel in a lost wax mould;

Forging, which is accomplished by moulding a preform that has been heated to an appropriate temperature.

The second option, forging, is preferable to the first. The reason for this choice over micro-fusion is that forging allows you to keep the material's structure compact and avoid the appearance of inclusions of astm a234 wpb fittings, which can cause liquid losses in the subsequent phase, especially under high pressure.

The Stainless-Steel Slip-on Flange by ss 304 pipe fitting manufacturer indiais worked with machine tools after it has been forged to seal the surfaces and drill holes for bolted connections. The work is done on a digitally controlled machine, which allows for repeatability, speed, and precision. Face work, which, along with joint work offered by ss 316 pipe fittings, provides for sealing, is of particular interest during this phase. It is not simply smooth, but has a so-called "phonographic" stripe that aims to retain the material join and avoid expulsion caused by the high existing pressures.

The materials used to construct the flanges

The tradition begins with the commercialization of stainless steel fittings, valves, and ss 316l pipe fittings manufacturers in indiaflanges using market-required materials such as AISI 304, 304L, 316, and 316L steels. These are austenitic steels, an alloy containing nickel-chromium and molybdenum, which will bring their well-known properties for resistance to hot oxidation, corrosion resistance, and a good measure of stability.

In the presence of high temperatures, ss 304 flangesis used. Because of its good corrosion resistance, ss 316 flangeis particularly indicated for its resistance to the action of saline environments. It can effectively support the action of acids, salts, and various other chemical agents. This enables it to be used in more diverse applications, such as the nautical and food industries, where resistance to cleaning products is critical.

What are the properties and safety precautions of a stainless-steel flange?

Alloy Steel Flanges and ss 316l flangesare a type of component product that is used in pipelines and other applications. Many flange products are available from flange manufacturers to consumers. Because each flange product will have its own set of characteristics and points of interest, I will present today the characteristics and application of stainless steel astm a105 flange manufacturer Ñ basic knowledge.

Before we can understand the preceding issues, we must first understand what the harness is. A234 WPB Elbows are connectors for pipes and hoses. It is boltable to two flanges. There are several types of flanges to choose from. Today we will discuss products with stainless steel flanges.

As the name implies, stainless steel flanges products by duplex flanges manufacturers in india are made of stainless steel. Stainless steel flange fittings are simple to install and can withstand greater pressure. It is commonly used in industrial pipes. The ss slip on flange manufacturers in indiacan be seen everywhere in some boiler rooms or manufacturing sites.

Notes about the stainless steel flange:

To avoid overheating and destroying the ss weld neck flange manufacturers cover, the welding current must be kept low and the arc must be kept short. In general, a narrow cord is preferable.

0 notes

Text

What are the Different Types of Pipe Fittings? - Sppalloys

Many provide pipe fittings in India, but SPP alloys are the best ones. If you want different types of pipe fittings, then SPP alloys are there for you!

Here you will know about the different types of pipe fittings provided by SPP alloys.

First, know about pipe fittings-

Pipe fittings, sometimes referred to as pipe connectors, join two pipes together to extend the run or change the flow in a plumbing procedure. These come in a range of sizes to fit the pipe they will attach to and are used to combine, divert, or lessen the flow of the water supply.

There are sizing regulations to stick to, and pipe fitting dimensions are important. Some fittings are made with different-sized openings and act as the transition from one size pipe to another. However, the majority have openings that are the same size on both ends.

Know the different types of pipe fittings!

Here are some of the popular pipe fittings-

Bushings

Pipe bushings are used to connect pipes of various sizes. Typically, this is done by decreasing a bigger pipe fitting to a smaller pipe. Typically, bushings have internal and outer threads.

Pipe Elbows

In cases where the flow direction needs to be changed, threaded or socket weld pipe elbows are frequently used. The most common elbow angles are 90 and 45 degrees. One essential plumbing fitting is the elbow.

Pipe Caps

Caps are offered with female National Pipe Taper (NPT) threads and stainless steel 304 or 316 cast pipe fitting. For sealing the male pipe's end. The cap is placed over the male pipe's end to block the flow.

Crosses

Cross pipe fittings are four-way fittings that are only two tees combined. Many will decide to use two tees in its place.

Flanges for pipe

Pipe connections are made using flanges. The flanges are sealed with bolts once the pipe is threaded or welded. When handling high pressures in industrial applications, flanged connections are frequently used.

Bell Reducers and Coupling Reducers

A pipe's run can be extended, or its size changed using pipe connectors.

This transforms into a bell reducer when reduced. Available with socket weld or female threads.

Pipe nipples

A short piece of pipe with a male pipe thread on one or both ends is called a pipe nipple. It is used to join two other fittings. Pipe, hoses, and valve connections are made using nibbles. Low-pressure pipe systems employ pipe nipples.

Tees

Pipe Tees have two outlets that are 90° apart from the connection to the main line and are T-shaped. The pipe has a lateral outlet and is only a small portion.

Unions

Unions replace couplings. Unions rely on their nut to seal the pipe ends together. They are, therefore, the ideal option for joining two permanent pipes that cannot thread into a common coupling.

Valves

Valves are made to regulate the pressures and speeds of flow.

SPP Alloys provide two types of pipe-

1. Seamless pipe

SPP Metal & Alloys is a supplier of Seamless Pipes in Stainless Steel, High Nickel, Carbon Steel, and Alloy Steel grades. A seamless pipe, as the name suggests, is a pipe without a seam or a weld joint. Seamless pipes are thought to be able to withstand higher pressure, higher temperatures, higher mechanical stress, and a corrosive atmosphere.

2. Welded pipes

SPP Metal & Alloys is a supplier of Welded Pipes in Stainless Steel, High Nickel, Carbon Steel, and Alloy Steel grades. The welded pipe comes in three forms; welded on the outside, welded on the inside, or welded on both sides. These methods of welding are ERW, EFW, SAW, etc. Welded pipes are the least expensive pipes.

Want to purchase, then visit https://sppalloys.com/

0 notes

Text

Analyzing the difference between Stainless steel and PVC

Deciding if stainless steel pipes are better than PVC pipes is a discussion in itself. Nowadays, ss pipe fittings are being used by people. But PVC is something that has been used forever. SS pipes are said to be more durable and strong. Let’s see the difference between the two.

Stainless steel V/S PVC

Plumbing made of PVC and stainless steel is joined and welded using various techniques that are unique to each material. Pipe stainless steel is frequently mechanically bonded via bolted coupling connectors or heat-fusion soldering. PVC pipework is frequently chemically connected by employing a primer and solvent cement to dissolve and fuse the inner and outer surfaces of the pipe joints. Although each welding technique has its unique execution challenges and the potential for a failed connection, both, when used properly, can produce long-lasting, leak-proof joints.

https://rhinoxindia.com/ss-pipes.php

0 notes

Text

Insulating Tubes Secrets

Busbar Heat Shrink Sleeve An example of a programming language construct which might or might not terminate is often a loop, as they may be run frequently. Loops executed using a counter variable as ordinarily located in info processing algorithms will usually terminate, demonstrated through the pseudocode example under: i := 0 Supporting a wide application range, the design incorporates 1 system and two tension cone adapters to cover all cross-sections from 35 to three hundred mm2. The general and Lower again Proportions are made to take up minimum amount Place while in the terminal box. 8 hours back Catalogue Raychem Termination [1d47k7dj02n2] Preview nine hrs ago The package arrives total having a tinned copper earthing braid plus a mechanical roll spring for each phase. Nevertheless, In regards to execution, the end user has to take care of just one essential Section of switchgear set up, that's: Termination of HV cables during the commissioning of kit. It has been observed that the majority of fault/failure/flashover happening outdoors the sealed tank are due to inappropriate cable termination. Underneath the skilled supervision of our group of proficient pros, we source, trade, distribute and export an extensive selection of best quality Cable Termination Kits. upto seventy two KV / 145 KV Procured from dependable and Licensed sellers, these kits are extremely appreciated in the marketplace for their robust style, the best possible efficiency and low servicing. Presented kits can be obtained with us in bulk on account of our prosperous and effectively-related distribution community. Among the techniques to termination checking in dependently typed programming languages are sized styles. The primary plan should be to annotate the types over which we can recurse with dimension annotations and allow recursive phone calls only on smaller sized arguments. Sized styles are applied in Agda as being a syntactic extension. Current investigation[edit] For those who click on a merchant url and purchase a goods and services on their own Site, we could possibly be compensated a rate through the service provider. No prior heating of silicone oil is needed before filling at internet site. Anxiety cone The silicone rubber worry cone offers the electrical discipline control function and can easily be applied with out equipment. The appliance assortment is taken by diverse sizes of pressure cones. Foundation plate and help insulators 4 aid insulators can be used on the base plate to mount Perspective PDF catalogues together with other on the internet documentation The halogen-no cost epoxides are suited to saltwater environments. The glass epoxy compounds also are exceptional electrical insulators, are non-magnetic and won't interfere with radar alerts or even the radio. For larger hundreds the VA2.five/five 3-pronged Growth Software manufactured from stainless steel is recommended. Substitution pins can be found for the two these as well as the NA-sequence three-pronged pliers to accommodate a wide array of diameters. Technically required cookies (constantly Energetic) These cookies can not be deactivated inside our procedure, as These are needed for the working of the website. These cookies usually do not retailer any own facts and tend to be only established in reaction to steps you take. Our Services one.Cost-free Samples We could offer you absolutely free samples, for those who buy shipping fees. We provide depth packing shots and fantastic communication for the duration of total output. When you've got One more query, pls Be happy to Get hold of us as underneath: EPKB joints use shear bolt connectors to simplify the interconnection of conductors. The look from the connector is specially engineered to fit the insulation components, of various conductor measurements. This offers terrific flexibility from the selection of cables, which can be connected to the branch joint. Touch proof termination kit

0 notes

Text

Everything about flange and their various types

What exactly are Flange?

A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Types of Flanges

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flange have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

Dalmine Flanges is a well-known Flange Manufacturer in India.We are one of the largest Flange Manufacturers. Our flanges can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

0 notes

Text

Get the Best Stainless Steel Products at Affordable Costs

There are a variety of bolts, fasteners, and fasteners in the domestic market, which are used in all types of structures and are generally characterized by the quality, resistance, and fast operation of the elements joints.

The stainless steel fasteners manufacturers in india serve as a one-stop solution for all kinds of industrial products. Both companies are mainly engaged in the manufacture of carbon steel pipe fittings. The main pillars of companies are quality, innovation, and timely delivery. Carbon steel pipe fitting manufacturers supply carbon steel pipe fittings of various sizes and shapes with customer requirements in mind.

With the support of experienced machinists and analysts, we maintain top-notch product quality. They strictly follow international quality standards to provide you with the best products.

Grade 8.8 Bolts can be defined as fastening systems where two elements can be connected to a threaded system (bolts, nuts, washers). It must be selected according to the element's needs, design, and requirements.

These structures are designed with mesh and joint systems that cannot be constructed with rigid joints by design.

With the advent of new materials, different fasteners have been developed for different applications and surfaces. Therefore, fasteners are an element that allows to combine and fasten necessary elements to any surface.

You need to choose the appropriate composition depending on the type of material. For example, you should use hexagon screws for zinc and aluminium stays. Metal and rubber washers have a self-drilling head (or the drill).

Structures are buildings for manufacturing non-structural systems such as columns, baseboards, ducts, retaining walls, and ceilings and are used in all types of structures. It is also used for the structural zoning of houses and the manufacture of furniture based on MDF panels.

"In addition, a combination of two types of brackets, such as reinforcement angles, connectors, and structural supports. Combination of metal brackets and threaded elements to connect them, such as connecting structural rafters."

ASTM A193 B8 Bolts, on the other hand, are used to secure or connect building systems, equipment, and machinery that require it and to protect the system from accidental fall hazards such as lifelines and fixed lines with shock absorbers. It is a structural component that needs to be done.They are found in the home, such as furniture and wooden huts, and partitions such as galvanized steel profiles, with an emphasis on the possibility of construction, industrial warehouses, sheds, machine repairs, and home expansion or alteration. They are used in various objects.

External hexagon screw

At present, the external hexagon screw thread on the market is the common fine thread, which is generally used in thin-walled parts or under impact, vibration, and other occasions.

Among fixed products, screws and bolts are widely used in practical applications. We use screws in production, processing, and real life.

Stainless steel is a resourceful material that may be utilized for various purposes. Carbon Steel Pipe Fittings are the two most popular forms of corrosion-resistant stainless steel. Steel (stainless)

The best stainless steel fasteners manufacturers in india produce the stainless steel with the highest anti-corrosion properties and are the most trusted stainless steel globally.

0 notes

Text

Ananka

Q1) The Role of Fasteners in the Furniture and Woodworking Industry

Ans) Fasteners are of utmost importance in the furniture and woodworking industry, serving as vital components that securely hold various parts of furniture and wood projects together. These versatile connectors come in diverse forms, materials, and sizes, each catering to specific functions and meeting varying requirements. Here are key aspects that highlight the significance of fasteners in this industry:

1. Joinery: Fasteners, such as screws, nails, bolts, and dowels, are employed to join different wooden pieces together. Each type of fastener possesses unique advantages, selected based on the specific application and desired structural integrity.

2. Structural Support: Providing essential structural support, fasteners ensure stability and durability in furniture and woodworking projects. They distribute weight and stress evenly across joints, preventing wobbling, sagging, or collapse.

3. Aesthetics: Beyond their functional purpose, fasteners also contribute to the overall aesthetics of furniture and woodworking projects. Designers may opt for decorative fasteners like ornate screws or brass hardware to enhance the final appearance of the piece.

4. Versatility: Fasteners offer versatility in design and assembly, enabling woodworkers to experiment with different joint types like butt joints, lap joints, mortise and tenon joints, and dovetail joints—each possessing distinct characteristics suited for specific applications.

5. Disassembly and Repair: Utilizing fasteners instead of permanent adhesives allows for easier disassembly and repair of furniture. This proves especially beneficial when moving or fixing a piece, as fasteners can be removed and replaced without damaging the components.

6. Efficiency in Production: For manufacturers, fasteners streamline the production process, facilitating efficient assembly of furniture and woodworking projects. They help reduce production time, making mass-production more feasible.

7. Choice of Material: Fasteners are available in various materials, such as steel, brass, stainless steel, and plastic, allowing selection based on factors like desired strength, corrosion resistance, and appearance.

8. Holding Power: Different fastener types offer varying levels of holding power. Screws and bolts generally provide higher holding power compared to nails, making them suitable for heavy-duty applications.

9. Concealment: Certain furniture designs necessitate concealed fasteners to maintain a clean and seamless appearance. Specialized fasteners like pocket screws and hidden brackets are utilized to achieve this without compromising the structural integrity of the piece.

Overall, fasteners play an indispensable role in the furniture and woodworking industry, contributing to the creation of durable, aesthetically pleasing, and functional pieces that withstand the test of time. Woodworkers and furniture manufacturers meticulously select appropriate fasteners for their specific designs to ensure the best possible results.

Suppliers of Fasteners

Q2) Fasteners for Electrical and Electronic Enclosures

Ans) Fasteners play a critical role in electrical and electronic enclosures, serving to secure components and provide protection against environmental factors, electrical hazards, and tampering. These enclosures safeguard sensitive electronic equipment, and the fasteners used within must meet specific requirements to ensure safety, security, and ease of maintenance. Below are common types of fasteners utilized in electrical and electronic enclosures:

1. Screws: Screws are highly versatile and easy to use, making them widely employed in these enclosures. They come in various types, including machine screws, self-tapping screws, and captive screws. Machine screws attach components to mounting rails or panels inside the enclosure. Self-tapping screws create threads in pre-drilled holes in thin metal sheets. Captive screws have washers or retainers to prevent them from falling out when the enclosure is opened.

2. Nuts and Bolts: For heavier-duty applications requiring extra strength and security, nuts and bolts are used. They provide strong and reliable connections between enclosure panels and other components.

3. Latches: Latches secure enclosure doors or covers, ensuring they remain closed during operation, protecting internal components from dust, moisture, and unauthorized access. Some latches have key locks for added security.

4. Hinges: Enclosures with doors or covers that need frequent opening for maintenance and access to internal components require hinges. They allow easy access while maintaining the enclosure's seal when closed.

5. Gaskets and Seals: Though not traditional fasteners, gaskets and seals are crucial in electrical and electronic enclosures. They create a watertight and dustproof seal, protecting internal electronics from environmental factors.

6. Cable Glands: Cable glands secure and seal entry points for cables and wires passing through the enclosure. They provide strain relief for cables and maintain the enclosure's environmental protection.

7. Quarter-Turn Fasteners: Quarter-turn fasteners offer quick and easy access to enclosure panels, enhancing maintenance and servicing efficiency. They find use in industrial or commercial enclosures requiring frequent access.

8. Standoffs and Spacers: Standoffs and spacers create space between components or between enclosure panels and the mounting surface. They prevent short circuits and ensure proper ventilation inside the enclosure.

9. Security Fasteners: For applications where security is a concern, tamper-resistant or tamper-proof fasteners prevent unauthorized access or tampering with the enclosure's contents.

Selecting the appropriate fasteners for electrical and electronic enclosures requires considering factors like enclosure material, environmental conditions, load requirements, and maintenance needs. Using the right fasteners ensures the enclosure remains secure, functional, and compliant with safety standards and regulations.

Hastelloy Fasteners

Q3) Fastener Testing and Certification: Ensuring Quality and Compliance

Ans) Fastener testing and certification are of utmost importance in guaranteeing the quality, dependability, and adherence to standards of fasteners used across diverse industries, such as automotive, aerospace, construction, and electronics. These essential processes instill confidence in manufacturers, distributors, and end-users regarding the fasteners' performance and their compliance with relevant industry regulations. Let's explore the significance of fastener testing and certification:

1. Quality Assurance: Through fastener testing, mechanical properties, durability, and overall performance are assessed, helping identify any defects or weaknesses that might compromise their integrity during use. By subjecting fasteners to rigorous testing, manufacturers ensure that they meet the required quality standards and specifications.

2. Safety and Reliability: As fasteners play critical roles in securing structural components and critical aerospace assemblies, testing and certification verify their ability to withstand expected loads and environmental conditions. This ensures the safety and reliability of products incorporating these fasteners.

3. Compliance with Standards: Different industries have specific standards and regulations governing the use of fasteners. Testing and certification are necessary to demonstrate compliance with standards like ISO, ASTM, SAE, and other industry-specific requirements.

4. Material Verification: Fastener testing may include material analysis to verify the composition and quality of the manufacturing materials. Ensuring the correct materials are used is vital for optimal fastener performance and longevity.

5. Performance in Extreme Conditions: Certain applications demand fasteners to perform under extreme conditions, such as high temperatures, corrosive environments, or high vibrations. Testing determines how fasteners behave under such circumstances, ensuring they are fit for their intended purpose.

6. Traceability: Certification provides documentation and traceability for each batch of fasteners, enabling manufacturers and customers to track origin, manufacturing processes, and testing results, promoting accountability.

7. Third-Party Verification: Often, fastener testing and certification are conducted by independent third-party laboratories or certification bodies, lending credibility to the results and instilling confidence in customers that the fasteners meet required standards.

8. Cost Savings: Conducting testing beforehand helps identify potential issues, preventing costly failures, recalls, or warranty claims when fasteners are deployed in the field. Investing in proper testing and certification upfront leads to long-term cost savings.

In conclusion, fastener testing and certification are pivotal aspects of the quality control process. By ensuring fasteners meet required standards and specifications, they contribute to the overall safety, reliability, and performance of the products they are used in. Prioritizing collaboration with reputable testing laboratories and certification bodies is essential to achieve the highest level of quality and compliance for fasteners among manufacturers, distributors, and end-users.

Eye Bolt Manufacturer in Mumbai

0 notes

Text

How to connect metal hoses?

The metal hose is a high-quality flexible connecting pipe that is formed by extremely thin-walled, seamless or longitudinal seams and subjected to high-precision plastic deformation. It has many advantages such as good flexibility, fatigue resistance, high and low temperature resistance, and corrosion resistance. Widely used in petrochemical, steel metallurgy, rubber, machinery, electric power and other industries, then how to connect metal hoses? Introduction of metal hose connection:hose crimping tool The joint of metal hose with a diameter of 50 mm or less is mainly threaded when subjected to high working pressure. After tightening the thread, the inside and outside of the two joints The tapered faces are tightly fitted to achieve a seal. The cone angle is generally 60 degrees and is also useful for 74 degrees. The structure is well sealed, but the concentricity of the two mating parts must be ensured during installation. In order to solve the problems of repeated disassembly, assembly and difficulty in concentricity often seen in actual engineering, the joint can also be designed as a combination of a tapered surface and a ball head. Flange type: The joint of metal hose with a diameter of 25 mm or more is mainly flanged under normal working pressure, and it is sealed in the form of a gutter. The looper flange, which can be rotated in the radial direction or in the axial direction, is connected to the two bodies by the tension of the fastening bolt. The structure has good sealing performance, but the processing is difficult, and the sealing surface is easily damaged. In special occasions where quick unloading is required, the hole through which the fastening bolt passes can be cut open to form a quick release flange. Quick type: The joints of various metal hoses with a diameter of less than 100 mm are generally fast in the use conditions requiring fast loading and unloading. It is commonly used in the "O" ring seal made of fluoroplastic or special rubber. When the handle is moved at a certain angle, the claw corresponding to the multi-thread is locked; the tighter the "O"-shaped seal is pressed, the better the sealing performance. This structure is most suitable for fire scenes, battlefields, and other applications where quick loading and unloading are required. In a matter of seconds, a set of connectors can be docked or disassembled without any special tools. Upper outer wire metal hose: Since the main part of the hose is made of austenitic stainless steel, the hose has excellent temperature resistance and corrosion resistance. The hose has a wide operating temperature range of -196- 600 degrees, the hose used can be selected according to the corrosiveness of the medium through the pipe to ensure the corrosion resistance of the hose.

0 notes

Text

Glass Fittings Manufacturers

Kaizon as glass fittings manufacturers is a supreme purveyor of top grade glass fittings and architectural hardware. Our objective is to offer the excellent products for our clients. We are a prime glass fittings manufacturers for delivering supreme and high-class glass fittings. We take immense pride in our products and trust in all our hardware. There are different types of glass fittings and greater the number of fittings, the broader the decision about the best installation in the desired space.

Hinges:

Also known as joints, the hinges are distinguished by turning of doors and windows. It’s two parts join the pieces in the structure. A circular axis of movement in the hinges provides the mobility in the door. It has divergent degrees of clarity, perceptibility, opening and placement. It is made up of materials like bronze, steel, plastic and zinc. Pivot: A cylindrical piece reinforced by other piece and place at the end of it. Its predominant responsibility is to provide rotary and oscillatory movement to the other part or piece. The propeller shaft can be annual, conical and flat. Locks: These are opening and closing mechanisms for drawers and doors and are used to prevent access to interior space. Locks can be both automatic and mechanical and can be operated by a key. Locks come in a wide range like two-bolt, combination, two-turn, grinder and many more. Pull Handles: The knob, latch or handles are appliances for drawers and doors. They function to offer a point of assistance to strive force backwards and forwards. They are found in vertical action, fixed and rotary and made out of brass, bronze, iron, aluminum and others. Connectors or Clips: These clips and cylindrical connectors are used on windows, stairs, railings and glass. They connect two or more pieces of glass. They integrate massive and more complex structures as a point of union. Flashing: A metal trim that resists water from entering space used on windows and doors. It is even placed at bottom of the piece of glass. Handles: It functions with opening and closing of gateways. It comes in various shapes, simple and curved or nod shaped mechanism and even operated by rotating handle. Knockers: It is made up of steel with two plates and hinges. It is also found in round piece with a hole and attached padlock. Patch Fittings: Kaizon’s glass door fittings have been selected carefully for commercial and residential glass office needs. All our glass door fittings, hinges and patch are well-designed and functional to match with all kinds of projects and specifications. Patch fittings in collaboration with glass panels are for a classy architectural hardware. Patch fitting assistance is a silicon sealant fix among two stiffened glass panels and functions as a shield to protect adjacent panels from any harm. Glass cut-outs and holes are needed to fix the glass patch fittings to the patch of glass and operates as a security measure as lock patch and lockable lever patch for double or single leaf glass door options. They are mostly made of stainless steel cover plates and also found brushed steel effect with coat finishes and designs. Glass Door Handles We have a wide range of glass handles available in various designs, shapes and colours with many more options to choose from the variety we offer. With diverse designs and style, these handles can be utilized in any room and aids in enhancing the décor of any architectural space. We specialize in the versatility of the handles and it makes us a class apart from the rest and a favorable alternative for people who crave style and durability at the same time. Kaizon, as glass fittings manufacturers expertise in all kinds of glass fittings to meet all your architectural hardware requirements and even caters to customized need as per the needs and desire of the clients.

0 notes