#innovations in electric locomotives

Explore tagged Tumblr posts

Text

I may or may not be compiling a chronological list of nearly every locomotive ever directly because of starlight express

#I’ve got down 103 locos so far#this was born out of frustration of not being able to find a chronological list of electric trains#bc visually Electra looks most like the SNCF CC40100#like their helmet n shit#which makes sense because they’re quad voltage and not ac or dc (like in the song) and also incooperated several different#innovations in electric locomotives#but it also doesn’t make any sense. bc the cc 40100 was like from the 60s and Electra is the engine of the future and everything#so I wanted to look at what electic locos were made in the 80s for autism purposes#anyways. I did land on one- there are two prototypes made in the 80s based on the cc 40100#which is the SNCF BB 20011 and the SNCF BB 20012#which have the same visual design as the cc 40100 and when you look up pictures of em have lightning bolts on the side#and they’re prototypes which I like to imagine Electra is#and they’re only dual voltage not quad voltage but Electra’s like ac dc it’s okay by me so it still fits#admittedly they weren’t really prototyping anything exciting and I would’ve preferred an american engine as opposed to a french one but#beggars can’t be choosers.#if you can’t tell by now this entire post was an excuse to infodump about trains#so I am going to tag the stex fandom. to make my train autism everyone else’s problem#idk if the tag will even register I once read that only the first seven tags actually make any effect on the tagging system but who caressss#stex#the story of the locomotive who raced against a horse and lost and the locomotive that was powered by a horse shall wait till another day.

5 notes

·

View notes

Text

Medium voltage support insulator manufacturers in India | radiantenterprises

Elevate your electrical solutions with Radiant Enterprises, a top name among customised insulator manufacturers in India. Specializing in high-quality epoxy insulators, we cater to the specific needs of your projects with precision and expertise. As leading medium voltage support insulator manufacturers in India, we provide durable and reliable products that meet the highest industry standards.

Trust Radiant Enterprises for innovative and customized insulator solutions designed to enhance the performance and safety of your electrical systems.

#Epoxy insulator#Customised insulator manufacturers in India#Medium voltage support insulator manufacturers in India#epoxy bushing#epoxy insulator#epoxy resin#electrical company#electrical engineering#electrical industry#fuse cutouts#smart grid sensor#rail insulator#railway technology companies#train operating companies#locomotive#tramways#metro systems#traffic infrastructure#third rail#cable connector#innovative insulators#export quality

4 notes

·

View notes

Text

The term “Modern AU” for Naruto fandom needs to die. (Jk, sort of). It needs a new name, for ontologies sake.

Like. There is no consistency to the technological advancement in Naruto at all, but nonetheless, it is a demonstrable product of its initial years of development, which is the 90’s.

Throughout pt1 and Shippuden, we get a weird and nonsensical mix of Showa era (all of it, from 1886-1949) postwar period (1947-1980 thereabouts, though Wikipedia will disagree with me on that) and mid-late 90’s tech boom.

Now you could solidly argue for a “modern” interpretation of the Showa-era systems and customs, although that very much interferes with 1. the Uchiha as a clan, because they are 100% late Showa / WW2 period culturally. Hyuuga are more representative of the earlier Showa era, like 1920’s or so. SO yes you could do away with that, but frankly those clans are not themselves outside of that satirical context. (And I do actually think Kishimoto meant it to be satire, or at least his editor, who came up with most of the Uchiha premise, did). And

2. The whole Shinobi premise, which had still-living threads during that time period despite Shinobi as a profession supposedly dying in the 1850’s. (Pfffffft, Like mercenaries went anywhere during the European renaissance; they simply went from mercs to commissioned officers. Title change but not role change. Same idea.)

Furthering this, if you take them out of the dirt, so to speak, then they cease to have the in-universe function that they do. They don’t have to — you can still absolutely mock up a Mercenary-Paramilitary-Mage Caste for the “modern” world, by which is typically meant: In Japan/Our World, not the NarutoVerse.

Yes I know I’m being pedantic, but to say “modern” implies “past” and while there’s lots of that in Naruto, there’s also:

90’s Telephones (why doesn’t the Hokage have one in their office??? Landline is pretty darn secure.)

90’s Electricity

Computers (90’s era, but clunky things with limited functionality but can store data)

Floppy Disks to go with the above

Security cameras

Polaroids (again, 90’s era)

The cutting-edge-of-its-time (90’s again) radio collars

Industrial production of steel (how? We don’t know. But they can build 80’s-90’s skyscrapers, somehow.)

Steam engine (not that impressive or modern, but like, Where Are The Trains. We got 90’s steam boats in Kiri, but no locomotives? How? Why?)

Medical devices. Oh the list I could make about that. All like mid- late 90’s, at least in Konoha/Orochimaru and Co. The iron lung does not exist, replaced by stately 1999-2002 ventilators. (Kimmimaro) The concept of IV nutrition exists and is applicable, even if Kishi did an absolutely abysmal job of demonstrating that. (On Kakashi) (the reality: So. Many. Ports.) That little innovation didn’t exist until 1982, and didn’t actually work until 1996. (Because figuring out how to synthesize metabolic fats and proteins was really hard); you’ve got Ostomy tubes and bags that belong in 1995, (Kimmimaro again) and don’t even get me started on Lab equipment. Do you know how long it took to produce incubators that didn’t take up a quarter of a room? Do you have any idea what the world of cloning looked like in the 90’s? (Actually, it was a lot more advanced at that point than it is in Naruto, which is stuck in like, 1980’s with that notion).

And I could go on!

And there is just as many examples of the inverse, too, where there’s things juxtaposed to the past level. Example:

Psychiatric care. Granted we don’t see a lot of that outside of Kakashi’s little stint, but it is very 1940’s-1950’s type BS.

Similar to that, most the stuff in the Interrogation Unit. From attitudes to technology, but mostly in just the very weird, 1930-1950’s way the whole thing operates. Kishimoto did not do his research there, very obviously (Torture does not work like that), but nonetheless they give me Nazi vibes. (Well, Inaba and Ibiki do, respectively). That part might be intentional, but it still doesn’t really make sense in the bigger scope. (Why doesn’t the village know things when they are a SHINOBI VILLAGE. A postwar village no less! Make it make sense Kishi!)

Some elements of medicine. There’s a very weird divide there, between synthesized chemicals that are complex poisons, which SHOULD mean complex medicines exist, (because the only difference between medicine and poison is the dose and many toxins have medical value) and the demonstration of this, which relies upon herbalism. I suppose both those would exist in a Shinobi’s world, but there’s a bizarre element of “only the bad guys actually have good medicine” going on, which again is a very 1940-1950’s thing.

Idk, I feel like “modern” sort of fits? But not entirely. Because fundamentally the NarutoVerse is a completely separate dimension, a twisted alternate reality that is very removed from our own yet also very like it.

Gahhhhh the world building in this series is hot, messy garbage 🤣

I would love to see an AU where it’s more homogeneous, like smack-dab postwar all over the board. Or even just bring her up to the 90’s. That would be actual modern-NarutoVerse.

But using Modern to mean “Our World” has always just been a small thing to bugger me. Use what you want, because I don’t think the term is going anywhere, but if I can’t share this anywhere else I can share it here.

19 notes

·

View notes

Text

Train Spotlight: BR Class 000

In service: 1975-present

Manufacturer: British Rail Research Division

Capacity: arbitrary

Operators: Network Rail, British Rail (former)

Train length: arbitrary, usually 10-100m

Width: around 1.5-3m

Height: around 3-4m

Maximum speed: arbitrary, but typically 55m/s (200km/hr)

Mass: arbitrary, ranges from 10-100 tonnes

Engine type: electric, diesel, or gas turbine

Power output: around 1000kW (electric version can be arbitrarily powerful)

Acceleration: around 1m/s^2

Electric systems: 25kV AC overhead and 750V DC third rail

The British Rail Class 000 is an electric/diesel/gas turbine multiple unit, designed by the British Rail Research Division. With its distinctive boxy shape, it can easily be recognized in physics problems across Britain. The train also comes in a locomotive variant, although those are considered to be Class 97s. Class 000s should not be confused with the Pennsylvania Railroad's U1 locomotive, a 0-0-0 steam locomotive used for similar purposes, including problems such as "If a train leaves Boston at 9:45 am, travelling at 100mph, and another train leaves Washington at 11:00am, travelling at 80mph, when do the two trains meet?"

The Class 000 was created so BR could solve physical problems involving trains without potentially damaging existing rolling stock or endangering the lives of staff and passengers. In this regard, it has performed well, as despite countless collisions, derailments, and other incidents, it has a perfect safety record, with no deaths or serious injuries caused.

Following the privatization of BR and the end of its research division, many Class 000's were left to rust on sidings in secondary school science textbooks, but recently Network Rail has brought them back into service to help explain how the railway works. With the advent of renationalization under Great British Railways, there is hope that the Class 000 could once again be used to innovate in the field of rail.

12 notes

·

View notes

Text

Epoxy Insulators in the Rail Industry: Meeting the Demands of Modern Transportation

Within the domain of contemporary transportation, the railway sector assumes a crucial function in facilitating the efficient and sustainable movement of individuals and commodities. In order to effectively meet the dynamic requirements of the business, there exists a perpetual necessity for innovation and enhancement across all facets of rail infrastructure. Epoxy insulators have evolved as a significant component that plays a critical role in enhancing the reliability and efficiency of rail systems. Ensure uninterrupted rail operations with the durability of epoxy insulators manufactured and supplied by Radiant Enterprises - the best Epoxy insulator for third rail manufacturer in India!

This blog post aims to examine epoxy insulators and their ability to fulfil the requirements of contemporary transport within the rail sector.

Understanding the Role of Epoxy Insulators:

Epoxy insulators are a category of electrical insulators employed for the purpose of isolating and providing structural support to electrical conductors, hence impeding the passage of electric current through them. Electrical systems are frequently employed throughout several industries, such as the railway sector, with the primary objective of guaranteeing the secure and dependable functioning of these systems. Within the rail sector, these insulators are predominantly employed in railway electrification systems, fulfilling many essential roles.

· High Voltage Insulation:

The provision of high voltage insulation is a key function of epoxy insulators within the rail sector. The electrification of rail systems on a global scale has led to a growing dependence on high-voltage overhead lines as the primary source of power for electric locomotives. Epoxy insulators play a crucial role in preserving a secure distance between high-voltage lines and the structures that support them, thereby mitigating electrical leakage and safeguarding the well-being of passengers.

· Mechanical Strength:

Railway systems are exposed to adverse climatic conditions, encompassing severe temperature variations, vibrations, and mechanical strain. Epoxy insulators are widely recognised for their remarkable mechanical strength and resilience, rendering them highly suitable for deployment in railway applications. The electrical infrastructure is designed to endure the demanding conditions of continuous train movements, hence preserving its integrity and functionality.

· Corrosion Resistance:

Corrosion resistance is a critical factor to consider in railway infrastructure due to its frequent exposure to moisture, chemicals, and various corrosive substances. Epoxy insulators are engineered to possess a high level of corrosion resistance, hence guaranteeing an extended operational lifespan and reducing the need for frequent maintenance. The corrosion resistance of rail systems is of utmost importance as it plays a critical role in ensuring uninterrupted operation, hence reducing both downtime and repair expenses. Experience the reliability of electrical solutions. Connect with Radiant Enterprises to Import Epoxy insulators in France!

· Lightweight Design:

Contemporary rail systems are consistently endeavouring to minimise weight and enhance energy efficiency. Epoxy insulators are preferred due to their lightweight construction, which enhances the overall effectiveness of the system. The decreased weight of these insulators results in reduced energy consumption and enhanced sustainability, so they match seamlessly with the objectives of contemporary transportation.

· Customization and Versatility:

Epoxy insulators have the capability to be customised according to the specific demands of railway systems, hence enabling flexibility in both design and implementation. Epoxy insulators provide the capability to be tailored in order to effectively address the distinct requirements of various projects, including high-speed rail lines, commuter train networks, and freight rail systems. The ability to adapt is crucial in order to ensure optimal operation of rail systems in diverse settings.

· Safety and Reliability:

The rail sector places utmost importance on safety, and the utilisation of epoxy insulators is integral to guaranteeing secure operations. These insulators effectively mitigate the potential hazards and operational disturbances in train services by offering dependable insulation and preventing electrical failures. Passengers and operators may place trust in the safety and reliability of electric train networks. Empower your railway projects with the best quality and durable 25 KV epoxy insulators. Get in touch with Radiant Enterprises - one of the most trusted 25 KV Epoxy Insulators for Railways manufacturers in India to learn more!

Longevity and Cost Efficiency:

The strategic decision for rail operators is to invest in durable and long-lasting components, considering longevity and cost efficiency. Epoxy insulators possess the advantageous characteristic of having an extended operational lifespan, hence mitigating the necessity for frequent replacements and the subsequent financial burdens associated with such replacements. The extended lifespan of these options renders them a financially advantageous selection over time, thereby harmonising with the fiscal limitations commonly associated with railway initiatives.

Final Thoughts:

Epoxy insulators have become an essential component in the rail sector, effectively addressing the requirements of contemporary transportation. The suitability of these systems for railway electrification is attributed to their capacity for high voltage insulation, resilience in challenging climatic circumstances, resistance to corrosion, and provision of customisation choices. In addition, the lightweight nature of these designs serves to enhance energy efficiency and promote sustainability, so they match seamlessly with the objectives of the business.

The increasing development and growth of the rail sector necessitates the significant involvement of epoxy insulators in guaranteeing the dependability, security, and effectiveness of electric train systems. Through the use of cutting-edge technologies such as epoxy insulators, the railway sector is well-positioned to confront forthcoming difficulties and maintain its pivotal role in contemporary transportation. From power distribution to industrial applications, Imports cycloaliphatic epoxy insulators in France from a trusted manufacturer and supplier, Radiant Enterprises!

#Epoxy insulator for third rail manufacturer in India#Imports Epoxy insulators in France#25 kv epoxy insulator for railways manufacturers In India#Imports cycloaliphatic epoxy insulators in France

7 notes

·

View notes

Text

Who Manufactures Model Trains?

Curious about who makes model trains? Well, Bachmann Trains and Lionel are key players, known for their variety, detail, and safety features, ensuring excellent quality and security in the model train world. These historic manufacturers like Lionel Corporation, dating way back to 1900, have set the bar high with iconic electric trains. Pay attention to niche companies too; they offer unique designs and tailor-made products for specific interests, adding creativity to the hobby. Keep in mind emerging manufacturers like NextGen Trains, who bring fresh tech and safety elements. Get ready to uncover more about this fascinating world.

Major Players in Model Train Manufacturing

When delving into the world of model trains, you'll quickly notice that major players dominate the manufacturing scene. These companies are dedicated to producing high-quality products that meet safety standards to guarantee your enjoyment without any risks. Safety is paramount in the model train hobby, and these major manufacturers understand the importance of creating reliable and secure products for enthusiasts like you.

One prominent player in the model train industry is Bachmann Trains. Known for their diverse range of products, Bachmann focuses on providing not only realistic models but also safe and durable ones.

Another key player is Lionel, a brand with a long history of creating iconic model trains. Their Vintage model train valuation guide pdf attention to detail and safety features make them a favorite among collectors and hobbyists alike.

As you investigate the world of model trains, remember to G Scale train Track prioritize safety by choosing products from these reputable manufacturers. Your enjoyment of this hobby will be greatly improved when you can trust in the quality and security of the trains you operate.

Historic Manufacturers of Model Trains

Many renowned manufacturers have left a lasting legacy in the world of model trains. These companies played a significant role in shaping the hobby and industry to what it's today. Here are some historic manufacturers that have made a mark in the model train world:

Lionel Corporation: Established in 1900, Lionel is one of the oldest and most iconic model train manufacturers, known for its electric trains and O gauge track systems. Marklin: Founded in Germany in 1859, Marklin is renowned for its high-quality HO scale trains and innovative designs that have influenced the model train industry for decades. Bachmann Trains: With roots dating back to 1833, Bachmann is a well-known manufacturer of model trains, offering a wide range of products from beginner sets to advanced locomotives. American Flyer: Originating in 1907, American Flyer produced S gauge trains that became popular among hobbyists for their realism and durability.

These historic manufacturers have paved the way for modern model train enthusiasts, providing a foundation of quality and innovation that continues to ins

2 notes

·

View notes

Text

Locomotive Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Locomotive Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Locomotive Market scenario, and feasibility study are the important aspects analyzed in this report.

The Locomotive Market is experiencing robust growth driven by the expanding globally. The Locomotive Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Locomotive Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Based on our analysis, the global market showed a huge decline of -32.04% in 2020. The market is expected to grow from $14.16 billion in 2021 to $25.48 billion in 2028, growing at a CAGR of 8.8% over the period 2021-2028. period.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/103285

Key Strategies

Key strategies in the Locomotive Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Locomotive Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Locomotive Market.

Major Locomotive Market Manufacturers covered in the market report include:

Bombardier Transportation (Canada)

Alstom (France)

Hitachi Ltd (U.K.)

AEG Power Solutions (Netherlands)

Siemens Mobility (Germany)

Wabtec Corporation (U.S.)

Toshiba International Corporation (U.S.)

CZ LOKO, A.S. (Czech Republic)

CRRC Corporation Limited (China)

Hyundai Corporation (South Korea)

Globally, the volume of vehicles on the road has increased over the past decade. The high demographic rate, developing road infrastructures, and a surge in disposable income of people are the major reasons for the growth of automobiles. The high vehicle rate has led to traffic congestion, thus giving rise to several problems such as physical and mental health problems, accidents, and wastage of valuable time. Also, the rising traffic leads to high emissions of toxic gases leading to environmental pollution and global warming. These engines mainly run on diesel and electricity. Many government and private authorities are working towards developing fuel-efficient products to curb the rising environmental problems. Also, they are investing a large percentage in adopting sustainable sources of energy to power the engine.

Trends Analysis

The Locomotive Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Locomotive Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Locomotive Market Solutions.

Regions Included in this Locomotive Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Locomotive Market.

- Changing the Locomotive Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Locomotive Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Locomotive Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Locomotive Market?

► Who are the prominent players in the Global Locomotive Market?

► What is the consumer perspective in the Global Locomotive Market?

► What are the key demand-side and supply-side trends in the Global Locomotive Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Locomotive Market?

Table Of Contents:

1 Market Overview

1.1 Locomotive Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

#Locomotive Market#Locomotive Market Share#Locomotive Market Size#Locomotive Market trends#Locomotive Market Growth#Locomotive Market insights#Locomotive Market Industry

0 notes

Text

U.S. Takes the Lead While Germany and China Follow in Smart Transformers Market

U.S., Germany and China are the major demand hubs within the $2.9 billion Smart Transformers market and expected to grow with CAGR ranging from 7.2% to 10.3% for the period of 2024 and 2030. Moreover, the key opportunities, such as expansion in developing markets, integration with iot and advanced analytics and support for decentralized energy systems, are anticipated to create opportunistic revenue pockets.

The Smart Transformers market is intensely competitive in few application areas. Leading players such as Siemens, ABB, GE, Schneider Electric, Eaton, Hitachi, Mitsubishi Electric, CG Power, Toshiba, SPX Transformer Solutions, Fuji Electric and Alstom are pushing the boundaries of innovation & technological advancements and forging strategic partnerships.

Check detailed insights here - https://datastringconsulting.com/industry-analysis/smart-transformers-market-research-report

Research Study analyse the new revenue pockets, emerging markets, competition landscape, opportunities & niche insights for Type (Distribution Transformers, Power Transformers, Specialty Transformers, Instrument Transformers), Application (Smart Grids, Traction Locomotives, Electric Vehicle Charging, Renewable Power Generation) and End-User (Utilities, Industrial, Commercial, Residential).

Industry transition and its impact

Industry transition including shift to digital and iot-enabled transformers and adoption of green transformers for environmental sustainability, are transforming the supply chain of Smart Transformers market. The industry is moving towards friendly transformers that incorporate green materials to lower carbon emissions in line, with sustainability objectives and regulatory standards.

About DataString Consulting

DataString Consulting offers complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. Our Industry experts and data aggregators continuously track & monitor high growth segments within more than 15 industries and 60 sub-industries.

DataString Consulting is a professional market research company which aims at providing all the market & business research solutions under one roof. Get the right insights for your goals with our unique approach to market research and precisely tailored solutions. We offer services in strategy consulting, comprehensive opportunity assessment across various sectors, and solution-oriented approaches to solve business problems.

0 notes

Text

youtube

NEWEST Female Humanoid Robot Gets SHUT DOWN By U.S | Humanoid Robot & Affordable 3D Printed Hands

You are welcome to the "AI Evolves" channel. In this video, we delve into a realm where robots and artificial intelligence are reshaping our daily lives in remarkable ways. From the newest female humanoid robot getting shut down by the U.S. to affordable 3D-printed hands revolutionizing accessibility, we explore the incredible creations and their impact on our world. Join us on this journey through innovation and discover the possibilities that lie beyond! Let's deep dive into this entire video

Time Stamps:

........................

00:00 Intro

00:53 Robotic Charger

02:14 Mandro

03:30 Robo Cube

04:55 LG Smart Home AI Agent

06:20 Ogmen Oro Pet Robot

07:45 Portal Hologram Technology

09:06 Robothespian

10:10 IVY

10:56 Outro Innovative Robotic Technologies:

Star Charge's robotic charger autonomously connects and charges electric vehicles, enhancing efficiency and sustainability in public charging stations. Mandrew's 3D-printed prosthetic hands, priced at $1,000, offer advanced, affordable solutions for amputees, improving accessibility and functionality.

Advanced Cleaning and Home Automation: Root Cube by Lotus Robotics offers a versatile cleaning solution with autonomous and manual modes, adaptable to various environments including shallow spaces and pickups. LG's Q9 Smart Home AI Agent autonomously handles household chores like vacuuming and thermostat adjustments, communicating effectively with users for a more convenient home life.

Pet Care and Holographic Communication: Agman Oro Pet Robot monitors and engages pets using integrated cameras, microphones, and smart algorithms to ensure pets receive care and enrichment in their owners' absence. Portal Hologram Technology enables lifelike holographic interactions, fostering meaningful connections across distances for work, education, and personal communication. Entertainment and Media Innovations: Robot Haspen performs multilingual theatrical roles, merging technology with artistic expression to offer a new dimension to entertainment.

Japan's Android Newscaster delivers news with human-like characteristics and advanced AI, showcasing a blend of technology and media, raising questions about future human-robot relationships in entertainment.

Educational and Research Applications: Agility Robotics' IW is a milestone in bipedal locomotion, designed for research and educational purposes, allowing the study of robotic movement and inspiring future advancements in robotic technology. We hope you enjoyed this video.

Make sure you click the "Like" button and share this video with your friends and others who might also be interested in learning more about this video. Please click "Subscribe" and click the bell icon to keep up to date with new videos from the "AI Evolves" channel. If you have any questions or feedback about this video topic, please comment in the comments section.

#pro robots#female humanoid robot#humanoid robot#newest female humanoid robot gets shut down by u.s#artificial intelligence#humanoid robot 2024#Youtube

0 notes

Text

Looking at Siemens there in the boycott box: I wonder if the boycotters are serious enough to give up electricity because the power grid contains energy produced by companies which use Siemens equipment or software or financial services? I wonder if the boycotters are serious enough to boycott health care since Siemens and subsidiaries manufacture diagnostic imaging equipment and provide other health care services?

I wonder if the boycotters are serious enough to boycott green energy since Siemens supplies products and services to support green energy?

I wonder if the boycotters are serious enough to stop using digital technology since Siemens provides products and services to support digital technology?

I wonder if the boycotters are serious enough to boycott people and products which were moved by rail since Siemens provides goods and services, and locomotives, for rail transportation? Seriously, how does one actually boycott such a provider without boycotting all those who use what the provider offers? Since such a provider supplies such a high volume of things that consumers do not directly interact with, does a consumer boycott actually do anything? Though in the divest instead of boycott box, CAT and Hyundai, what would a 'complete boycott' of them look like? Do you boycott going in buildings and driving on roads which were built using Hyundai construction equipment? Do you boycott products which were hauled on trains whose locomotives used CAT diesel engines or in semis which used their diesels? Do you boycott imported products which were hauled to their port of export in a container on a semi-trailer pulled by a Hyundai truck? Do you boycott products whose raw materials were mined or harvested with CAT or Hyundai machinery? Do you boycott products which were transported in a shipping container tracked by Hyundai tracking? Do you boycott products which were imported via being carried on a container or a bulk carrier ship built by Hyundai?

With such companies being so prolific within various industries outside of the consumer realm, does a consumer boycott of their several direct to consumer products have any real meaning?

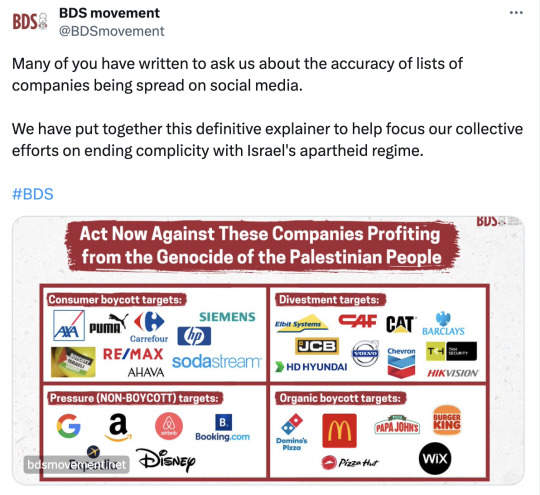

Back to our regularly scheduled "what should we be boycotting" posting - a couple of hours ago (today, Wednesday 8th November) the BDS movement has put together a definitive explainer on which companies it is currently targeting, splitting companies into four categories and explaining why each company is being targeted and also what each category means for consumers, institutions, etc.

PLEASE NOTE: The BDS movement is the official, strategic, coordinated boycott, divestment, and sanctions campaign created by the BDS National Committee of Palestine. If you want to take part in boycotts and other forms of pressure against corporations in your efforts to help free Palestine, use this organisation's advice as your official and primary source. Other common boycott campaigns such as the "Big Three" (McDonalds, Disney, Starbucks) are at best incomplete and at worst actively contradictory representations of this targeted boycott campaign that we should all be aiming to follow for maximum efficacy and impact.

I have bolded where "big three" companies appear in this new release in order to clarify what action the BDS recommends for each.

click this link to read the explainer.

If, for whatever reason, you can't or don't want to click the link, here's a quick summary:

CONSUMER TARGETS: the BDS movement calls for a complete boycott of the following brands

Ahava

AXA

Carrefour

HP

Puma

RE/MAX

Siemens

SodaStream

Israeli produce in your supermarkets (avoid buying said produce and, if you find any in your local store, contact the supermarket to demand its removal from shelves)

DIVESTMENT TARGETS: governments, institutions, and investment funds should exclude and divest from as many complicit companies as is practical

Elbit Systems

HD Hyundai / Volvo / CAT / JCB

Barclays

CAF

Chevron

HikVision

TKH Security

PRESSURE (NON-BOYCOTT) TARGETS: for strategic reasons the BDS movement does not call for a complete boycott of these brands & services. they should be subjected to other forms of pressure until they end their complicity in Israeli apartheid

Google

Amazon

Airbnb / Booking.com / Expedia

Disney

GRASSROOTS ORGANIC BOYCOTT TARGETS: other boycotts not organised by BDS. If these campaigns are not already organically active in your area, focus your energies on the strategic campaigns above.

McDonalds

Burger King

Papa John's

Pizza Hut

Wix

(and others, e.g. Dominos was mentioned in a past release and can be seen in the new infographic but not the explainer article)

Starbucks continues to not be officially mentioned by the BDS Movement. The boycott of Starbucks primarily stems from its decision to sue its union for using the company's name and branding in pro-Palestine posts. As another grassroots organic boycott campaign, albeit not one openly acknowledged thus far by the BDS Movement itself, my personal recommendation would be to treat it like other campaigns in that category - i.e. continue boycotting & encouraging others to do so if there is already an organically active campaign in your area, but please keep the official BDS boycott list as your main focus.

7K notes

·

View notes

Text

Global Rolling Stock Market Size, Share and Forecasts for 2032

Global rolling stock market is projected to witness a CAGR of 6.25% during the forecast period 2025-2032, growing from USD 59.47 billion in 2024 to USD 96.55 billion in 2032. The market has experienced significant growth in recent years and is expected to maintain an expansion in the coming years owing to the growing popularity of electric trains, supportive government initiatives, a significant surge in investment by government authorities in railway infrastructure, and rapid urbanization. Additionally, the types of rolling stock such as locomotives, rapid transit vehicles, and trams are all seeing stable demand, as governments worldwide emphasize having high-speed and rail urban systems for the increasing population in enhancing public transport efficiency. Improving this infrastructure enhances passenger comfort and safety and ensures the efficient transportation of goods over long distances. This trend compels government authorities to invest in public transport projects, further driving the demand for advanced rolling stock.

Additionally, the adoption of advanced digital solutions has a significant influence on market growth in the current scenario. Integrating technologies such as the Internet of Things and big data analytics means that predictive maintenance and real-time monitoring in train operations can be increased, enhancing operational efficiency and safety. This technological shift makes it possible for rolling stock manufacturers to continuously innovate, producing more energy-efficient and environmentally friendly vehicles that are more in tandem with global objectives.

For instance, in October 2024, Siemens AG. started rolling stock manufacturing in the United Kingdom. The opening of the Goole Rail Village in East Yorkshire marks a significant milestone for Siemens Mobility’s commitment to the United Kingdom.

Urbanization is expanding the Global Rolling Stock Market

The demand for a global rolling stock market is rising owing to an increase in population and the need to have efficient solutions for public transportation. As cities increase their densification, they require faster transit systems such as metros, light rail, and trams, pushing governments to invest very seriously in modernizing and expanding their rail networks. They take away the problems of traffic congestion and air pollution, but they are also part of the efforts towards attaining sustainability at the global level. The urban rail projects improve mobility and connectivity within these sprawling metropolitan areas. China’s high-speed rail is a perfect example of investment in the development of transportation systems that can efficiently satisfy demands to traverse through large spatial areas. India is also expanding its metro systems to keep pace with the growth of the country’s urban population. Advanced technologies and sustainable practices within the framework of an urban rail system strengthen the opportunity for passenger convenience and make available rail transport over road travel a good choice.

For instance, in June 2024, CRRC Sifang Co., Ltd., a subsidiary of CRRC Corporation Limited in China, developed a new urban smart fast rail train for the international Metro Transit Exhibition & Forum in Nanjing. The 30-meter-long train consists of three structurally independent modules and features a maximum capacity of 280 passengers, a maximum running speed of 70 kilometers per hour, and energy consumption of only 3-4 kilowatt hours per kilometer.

Government Initiatives Fueling the Global Rolling Stock Market Growth

Countries also realize the importance of efficient and sustainable transportation systems. With increasing urban populations and growing public transit needs, governments are investing billions in upgrading existing railway networks and increasing rail offerings. This commitment can be seen in many regions, especially in Asia-Pacific, where countries such as China and India are going all out to create ambitious high-speed rail projects and metro systems to improve connectivity coupled with reducing congestion. The same investment is happening within Europe, primarily focused on upgrading existing rail lines and rolling stock, driven by environmental sustainability and the growing need to service larger passenger demands. Such projects, for instance, include cross-border rail projects funded through the European Union. There is also renewed interest in this mode of transport in North America as governments have been taking an interest in projects aimed at improving freight efficiency and passenger services.

For instance, in February 2023, the Indian government announced a budget allocation of approximately USD 29 billion for the Indian Railways, marking a substantial increase from previous years. This funding is intended to modernize rail infrastructure, improve safety measures, and expand high-speed rail networks nationwide.

Dominance of Locomotive Vehicle Type

Locomotives, powered vehicles designed to pull trains, account for a substantial portion of the rolling stock market due to their essential function in passenger and freight services. Among the many factors that have solidified locomotives as being some of the most essential products in the markets, shifting towards electric and hybrid locomotives has been one aspect of overall sustainability efforts to reduce the environmental footprint of rail transport. Technological advancement is another key area in locomotive performance, as innovations such as automated train control systems and real-time monitoring technologies are incorporated into modern locomotives to improve safety and operational efficiency. Increasing demand for efficient and reliable transportation solutions is a factor driving investments in new locomotive technologies. This is primarily because governments and railway operators are upgrading their fleets to improve operational efficiency and reduce emissions.

For instance, in November 2024, the leasing company Northrail GmbH signed an agreement with Vossloh Rolling Stock GmbH to sell locomotives. The contract includes the supply of ten DE 18 locomotives designed for shunting operations in Scandinavia.

Asia-Pacific Dominates Global Rolling Stock Market Share

Asia-Pacific dominates the market growth for rolling stock owing to significant development in railway infrastructure, an increase in population across emerging countries, and rising investment by governments. Also, rapid urbanization is at the forefront, China and India have experienced enormous growth in numbers in terms of population in cities, thus demanding efficient public transportation systems. The governments then invest heavily in railway infrastructure to modernize existing networks and to expand high-speed rail systems. For instance, it has invested considerable amounts into building its high-speed rail system, which was already the biggest in the world, and India has promised significant budgetary allocations directly targeted at the modernization of the railways. High-speed rail initiatives are also especially prominent within this region, as indeed, Japan and China, in turn, set benchmarks that provide connectivity between cities and spur economic growth through efficiency and better logistics and transportation. Public-private partnerships are also becoming a critical factor in facilitating investment across Asia-Pacific, enhancing more efficient project execution and modernization efforts.

For instance, in November 2024, Kazakhstan Temir Zholy JSC (KTZ) and ALSTOM Holdings signed an agreement to manufacture a new type of freight electric locomotive in Kazakhstan. The agreement outlines the production and supply of KZ6A freight mainline electric locomotives equipped with asynchronous traction motors. Assembly will occur at the electric locomotive plant in Astana.

Download Free Sample Report

Future Market Scenario (2025 – 2032F)

As the population grows, robust urban rail systems will be urgently needed to alleviate traffic congestion and reduce air pollution. Many emerging economies are embarking on ambitious high-speed rail projects to enhance connectivity between major cities, driving demand for rolling stock.

Growing emphasis on electrification and greener transportation solutions aligns with global sustainability goals, this sustainable transport solution will thrive in the market for rolling stock.

Technological innovations such as battery-powered trains and electric locomotives are gaining traction and operational efficiency, and safety improvements further boost the market growth.

Significant investments by the government of emerging countries in railway infrastructure are being made globally, propelling the global market growth for rolling stock.

Report Scope

“Rolling Stock Market Assessment, Opportunities and Forecast, 2018-2032F”, is a comprehensive report by Markets and Data, providing in-depth analysis and qualitative and quantitative assessment of the current state of global rolling stock market, industry dynamics, and challenges. The report includes market size, segmental shares, growth trends, opportunities, and forecast between 2025 and 2032. Additionally, the report profiles the leading players in the industry, mentioning their respective market share, business models, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/rolling-stock-market

Latest reports-

Contact

Mr. Vivek Gupta 5741 Cleveland street, Suite 120, VA beach, VA, USA 23462 Tel: +1 (757) 343–3258 Email: [email protected] Website: https://www.marketsandata.com

0 notes

Text

Why High-Performance Rooftop Bushings are Crucial for High-Speed Rail Systems

As a leading name among railway rooftop bushing manufacturers in India, Radiant Enterprises is committed to producing durable and innovative solutions for modern rail systems. This blog explores the importance of high-performance rooftop bushings in high-speed rail systems and their impact on safety, efficiency, and operational excellence.

What Are Railway Rooftop Bushings?

Railway rooftop bushings are insulating components mounted on the roofs of trains, primarily in electric locomotives and high-speed rail systems. They facilitate the safe transfer of electrical power from overhead lines to the train's internal systems, ensuring uninterrupted energy flow.

These bushings must withstand extreme conditions such as high voltages, temperature fluctuations, mechanical stress, and environmental factors like rain, snow, and dust. High-performance railway rooftop bushings are engineered to meet these challenges, offering exceptional durability and efficiency.

The Role of Rooftop Bushings in High-Speed Rail Systems

High-speed rail systems operate at voltages ranging from 25 kV to 50 kV, requiring advanced electrical insulation to prevent arcing and ensure safety. Rooftop bushings play a pivotal role in this system, serving as a critical interface between the external power supply and the train’s internal electrical circuits.

Here is why railway rooftop bushings are indispensable in high-speed rail systems:

1. Ensuring Electrical Insulation

High-speed trains rely on high-voltage power for propulsion and onboard systems. Railway bushings provide robust electrical insulation, preventing leakage currents and maintaining safety for passengers and crew.

2. Facilitating Power Transmission

Rooftop bushings enable efficient power transfer from overhead lines to train components, ensuring a seamless flow of electricity. This is vital for the train’s propulsion, braking, and auxiliary systems.

3. Enhancing Safety

With trains traveling at speeds exceeding 300 km/h, the reliability of electrical components becomes paramount. High-performance rooftop bushings minimize the risk of electrical faults, ensuring safe operation even under extreme conditions.

4. Supporting Sustainability

Modern rooftop bushings are designed to handle renewable energy sources and optimize power usage, aligning with global sustainability goals. For rail operators, this reduces energy costs and supports eco-friendly transportation initiatives.

Challenges Faced by Rooftop Bushings in High-Speed Rail Systems

High-speed rail systems subject rooftop bushings to intense operational demands, including:

High Voltage Stress: With voltages of up to 50 kV, bushings must prevent electrical arcing and withstand prolonged exposure to high voltage.

Mechanical Vibration: Traveling at high speeds generates significant vibration and mechanical stress, which rooftop bushings must endure without compromising performance.

Environmental Factors: Exposure to rain, dust, extreme temperatures, and UV radiation can degrade materials, requiring bushings with exceptional durability.

Space Constraints: The compact design of modern trains necessitates bushings that provide high performance without occupying excessive space.

By addressing these challenges, leading railway rooftop bushing manufacturers in India like Radiant Enterprises ensure their products meet the rigorous demands of high-speed rail systems.

Features of High-Performance Railway Rooftop Bushings

Advanced engineering and innovative materials define the capabilities of high-performance rooftop bushings. Key features include:

1. High Dielectric Strength

This ensures reliable electrical insulation, preventing leakage currents and electrical arcing under high-voltage conditions.

2. Superior Mechanical Stability

Bushings are designed to withstand vibrations, shocks, and mechanical stresses typical in high-speed rail systems.

3. Weather Resistance

High-quality bushings are made from materials resistant to UV radiation, moisture, and temperature extremes, ensuring long-term durability.

4. Compact and Lightweight Design

Modern rooftop bushings are designed to save space while maintaining robust performance, essential for high-speed train configurations.

5. Customization Options

Leading manufacturers like Radiant Enterprises offer tailored solutions to meet the specific requirements of high-speed rail operators.

The Indian Perspective: Growth of High-Speed Rail Systems

India’s rail sector is undergoing a significant transformation with the introduction of high-speed rail projects such as the Mumbai-Ahmedabad bullet train. These projects highlight the increasing demand for high-performance components like railway rooftop bushings.

Railway rooftop bushing manufacturers in India are rising to the challenge by developing world-class products that cater to the unique requirements of Indian rail systems. With advancements in technology and infrastructure, Indian manufacturers are now competing globally, offering reliable, cost-effective, and innovative solutions.

Why Choose Radiant Enterprises for Railway Rooftop Bushings?

As one of the leading railway rooftop bushing manufacturers in India, Radiant Enterprises has earned a reputation for delivering high-quality, durable, and innovative solutions. Here is what sets us apart:

1. Unmatched Expertise

With decades of experience, Radiant Enterprises specializes in producing rooftop bushings designed for high-speed rail systems, ensuring top-notch quality and performance.

2. Cutting-Edge Technology

We leverage state-of-the-art manufacturing processes and materials to produce bushings that meet international standards.

3. Tailored Solutions

Our team works closely with clients to develop customized bushings that address specific operational challenges and requirements.

4. Commitment to Sustainability

Our rooftop bushings are designed to optimize energy usage, contributing to sustainable and eco-friendly rail systems.

5. Global Reach

While we cater to domestic rail projects, our products are also trusted by international clients, reinforcing our position as a global leader in railway bushings.

The Future of Railway Bushings in High-Speed Rail

As high-speed rail systems continue to expand globally, the demand for advanced components like railway rooftop bushings will only grow. The focus will be on:

Innovative Materials: Development of lightweight, durable, and eco-friendly materials.

Smart Bushings: Integration of sensors for real-time monitoring and predictive maintenance.

Enhanced Performance: Designing bushings capable of handling even higher voltages and speeds.

Manufacturers like Radiant Enterprises are at the forefront of these advancements, ensuring their products remain future-ready and aligned with industry trends.

Conclusion

High-performance railway rooftop bushings are the unsung heroes of high-speed rail systems, ensuring safety, efficiency, and reliability. Their ability to withstand extreme conditions while delivering seamless power transmission makes them indispensable in modern rail operations.

For high-speed rail operators, choosing the right components is critical to ensuring operational excellence. With their commitment to quality, innovation, and sustainability, railway rooftop bushing manufacturers in India like Radiant Enterprises are leading the way in providing world-class solutions.

If you are looking for durable and reliable railway bushings, trust Radiant Enterprises to deliver products that meet and exceed your expectations. Contact us today to learn how our high-performance rooftop bushings can power the future of your rail systems.

#India#Russia#Germany#Epoxy Bushings#Epoxy insulator#Railway rooftop bushing#Railway rooftop bushing manufacturers in India#Railway bushing#railway#metro#tram

4 notes

·

View notes

Text

Global Railway Connectors Market Size and Share Analysis: Key Insights for 2024

The Railway Connectors Market is poised for robust growth, evolving to meet the increasing demands of a rapidly advancing global rail transport system. Estimated to grow from USD 802 million in 2018 to USD 1,069 million by 2023, the market is expanding at a Compound Annual Growth Rate (CAGR) of 5.92% during the forecast period. The rising demand for advanced rail systems, increased industrial activities, and evolving connector technologies are key factors driving this growth.

The Backbone of Railways: Understanding Railway Connectors

Railway connectors are integral components of the railway ecosystem, ensuring seamless power transmission, signal communication, and efficient functioning of rolling stock and other rail systems. These connectors facilitate operational efficiency and safety in railway systems by transmitting data and power between various electrical components.

Key components of railway connectors, including connector bodies, ensure durability, reliability, and functionality across a range of demanding applications. Connector bodies, widely recognized for their modular designs and ease of customization, are crucial in industries like automation, robotics, and rail transportation.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=51150601

Market Drivers: Industrial Growth and Technological Advancements

The railway connectors market is experiencing significant momentum due to the increasing demand for wagons and rolling stock. Wagons, which carry both passengers and freight, are essential in addressing the rising industrial activity across regions such as the US, UK, and France. This demand is fueled by the cost-effectiveness and efficiency of rail transportation compared to other modes.

Rolling stock, encompassing powered and unpowered rail vehicles, contributes significantly to the market's growth. Technological advancements in components like power electronics, turbochargers, and semiconductors are improving the speed, efficiency, and comfort of modern transit systems. These innovations are particularly relevant for light rail vehicles (LRVs) and trams, which are gaining traction in urban areas for sustainable transportation.

Europe: A Leader in the Railway Connectors Market

Europe is the dominant region in the railway connectors market, driven by its adoption of high-end technologies and substantial investment in infrastructure development. Western European countries like Germany, France, and the UK lead the way with technologically advanced rail systems featuring wireless communication, eco-friendly designs, and enhanced passenger comfort.

Eastern Europe, though slightly behind in adopting cutting-edge technologies, presents a lucrative opportunity for rolling stock OEMs. With initiatives to expand rail lines and improve tramway locomotives, the region offers significant growth potential. France, for instance, is heavily investing in expanding its rail network, thereby driving demand for advanced connectors.

Challenges and Opportunities

As the railway connectors market grows, it encounters challenges such as stringent regulatory requirements, complex connector designs, and high costs associated with advanced materials. However, these challenges are balanced by opportunities in emerging markets and continuous advancements in connector technology.

The market is witnessing the development of innovative products tailored to meet the demands of rugged and high-speed applications. Companies like TE Connectivity and Amphenol Corporation have introduced advanced connector solutions to enhance reliability and functionality in rail systems. For example, TE Connectivity’s ACT composite connectors and Amphenol’s press-fit stacking connectors showcase the industry's focus on innovation.

Ask for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=51150601

Rolling Stock: The Largest Contributor to Market Growth

Rolling stock, including locomotives, passenger coaches, and freight wagons, is expected to dominate the railway connectors market during the forecast period. These vehicles' reliance on connectors for power and communication underscores the critical role of railway connectors in enhancing efficiency, safety, and passenger experience.

Rolling stock benefits from advancements in lightweight materials, reduced vehicle weight, and improved electronics, all of which contribute to better speed, comfort, and fuel efficiency. The adoption of sophisticated connector solutions supports these advancements, ensuring seamless operations across various rail systems.

Connector Bodies: Driving Innovation and Reliability

The connector body segment is anticipated to hold the largest market share during the forecast period. Known for their adaptability and efficiency, connector bodies are extensively used across multiple industries, including railways. These components offer robust shielding for signal transmission, ensuring reliability in critical applications.

Connector bodies, designed to work at radio frequencies, are essential in modern railway systems where wireless data transmission is becoming standard. Their ability to customize and integrate with advanced rail technologies further strengthens their market position.

The Competitive Landscape

The railway connectors market features key players such as TE Connectivity, Amphenol Corporation, Molex Incorporated, ITT, and Fischer Connectors. These companies drive innovation and set industry standards with cutting-edge products and strategic initiatives.

TE Connectivity, for example, has developed a range of advanced connectors that cater to emerging trends in railway systems. Its ACT composite connectors and other high-performance solutions highlight the industry's emphasis on enhancing reliability and performance. Similarly, Amphenol Corporation’s advancements in stacking connectors for high-speed applications underscore the market's focus on technological evolution.

Future Outlook: A Connected Tomorrow

As global transportation systems evolve, the railway connectors market is set to play a pivotal role in shaping the future of rail technology. With increasing investments in infrastructure, advancements in connector designs, and a focus on sustainable transportation, the market is poised for sustained growth.

Europe’s leadership, coupled with emerging opportunities in regions like Eastern Europe, underscores the dynamic nature of this market. Companies investing in research, development, and strategic partnerships are well-positioned to capitalize on the growing demand for reliable and innovative connector solutions.

In conclusion, the railway connectors market is on an upward trajectory, driven by industrial growth, technological advancements, and the global shift towards efficient and sustainable transportation. With a projected market value of USD 1,069 million by 2023, it represents a significant opportunity for stakeholders across the rail industry.

To Gain Deeper Insights Into This Dynamic Market, Speak to Our Analyst Here: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=51150601

FAQs

1. What is driving the growth of the railway connectors market? The market's growth is driven by increasing demand for wagons and rolling stock, advancements in connector technology, and the rising need for efficient rail transportation.

2. Why is Europe a major player in the railway connectors market? Europe leads the market due to its adoption of high-end rail technologies, substantial infrastructure investments, and regulatory emphasis on eco-friendly and efficient transportation systems.

3. What role do connector bodies play in the railway connectors market? Connector bodies are critical components that provide reliable power and signal transmission. Their adaptability and efficiency make them essential in modern rail systems.

4. Which companies dominate the railway connectors market? Key players include TE Connectivity, Amphenol Corporation, Molex Incorporated, and Fischer Connectors, all of which drive innovation and set industry standards.

5. What is the future outlook for the railway connectors market? The market is expected to continue growing, fueled by infrastructure investments, technological advancements, and the global push for sustainable and efficient transportation.

#railway connectors market#railway connectors growth#rolling stock connectors#railway connector trends#railway technology

0 notes

Text

The History and Evolution of Commercial Steam Boilers

The history and evolution of commercial steam boilers reflect humanity's drive for innovation and efficiency. Dating back to the Industrial Revolution, early steam boilers were pivotal in powering factories, locomotives, and ships, revolutionizing industries and transportation. Initially, these systems were simple and inefficient, relying on rudimentary designs. Over time, advancements in materials, engineering, and safety regulations led to the development of high-pressure boilers capable of producing more energy with less fuel. Modern commercial steam boilers are compact, highly efficient, and environmentally friendly, incorporating automation and sustainable technologies. From their inception as industrial workhorses to today's smart, energy-efficient systems, steam boilers have played a crucial role in industrial progress and continue to adapt to meet modern demands.

What is a Commercial Steam Boiler and How Does It Work?

A commercial steam boiler is a critical piece of equipment in industries such as manufacturing, food processing, and hospitality. By generating steam under high pressure, it powers operations requiring heat and energy efficiency. Understanding its functionality can help businesses choose the right system for their needs.

Types of Commercial Steam Boilers: Choosing the Right One

Commercial steam boilers come in various types, including water-tube, fire-tube, and electric models. Each type offers unique advantages depending on the industry application. Learn which boiler type suits your specific operational demands for optimal efficiency.

Energy Efficiency in Commercial Steam Boilers

Energy efficiency is a crucial factor when selecting a commercial steam boiler. Modern boilers are designed with advanced technologies like condensing systems and high-efficiency burners, reducing fuel consumption and operational costs. Discover how investing in efficiency benefits your business.

Key Features to Consider When Buying a Commercial Steam Boiler

When purchasing a commercial steam boiler, prioritize features like size, pressure capacity, and fuel type. Advanced safety features, automation, and easy maintenance should also influence your decision, ensuring long-term reliability and performance.

Applications of Commercial Steam Boilers Across Industries

Commercial steam boilers serve diverse industries, from powering turbines in power plants to sterilizing equipment in hospitals. Explore how different sectors utilize these boilers to meet their unique operational requirements.

Maintaining Your Commercial Steam Boiler: Best Practices

Proper maintenance is vital for ensuring the longevity and efficiency of a commercial steam boiler. Regular inspections, water quality monitoring, and timely servicing can prevent costly breakdowns and downtime, keeping your operations smooth.

Future Trends in Commercial Steam Boilers: What to Expect?

The commercial steam boiler industry is evolving with trends like IoT-enabled monitoring, renewable fuel integration, and compact designs. Businesses can stay ahead by adopting boilers that align with sustainability and technological advancements.

Conclusion

Commercial steam boilers are indispensable in industrial and commercial operations, providing the necessary steam for various applications. Selecting the right type, ensuring energy efficiency, and adhering to proper maintenance practices can significantly impact a business's productivity and costs. As the industry embraces innovation and sustainability, staying informed about the latest trends will help businesses make smarter investments in their steam boiler systems.

0 notes

Text

Train Enthusiasts Unite at Ruland Junction Toy Train Museum

Train Enthusiasts Unite at Ruland Junction Toy Train Museum

Nestled in the heart of Arkansas, the Ruland Junction Toy Train Museum stands as a beacon for train enthusiasts of all ages. This museum is not just a collection of toy trains; it’s a vibrant homage to the history and culture surrounding model railroading. With exhibitions that transport visitors through time, showcasing everything from classic steam locomotives to modern electric trains, it offers a unique experience that captures the imagination.

As you step inside this fascinating space, you're greeted by an array of colorful displays featuring meticulously crafted models running along expansive tracks. The museum is more than just a visual delight; it’s an interactive experience where visitors can engage with exhibits and learn about the evolution of trains throughout history.

Whether you’re a seasoned collector or a curious newcomer, your journey begins here. Feel the excitement as you roof cleaning 501 Pressure Washing of Heber Springs watch miniature trains chug along, hear the whistle blow, and see intricate landscapes created with love and care.

Exploring the Historical Significance of Trains The Evolution of Railways: A Brief Overview

Trains have been pivotal in shaping economies and cultures globally. From their humble beginnings in the early 19th century to their role in modern transportation networks, trains have continually evolved. The Ruland Junction Toy Train Museum showcases this evolution through various exhibits that reflect different eras of railway history.

Steam Engines: These powered machines revolutionized travel in the 1800s. The museum features several models that highlight their significance. Electric Trains: Emerging in the late 19th century, electric trains brought speed and efficiency. Modern Rail Systems: High-speed trains represent today’s technological advancements.

These varying models tell stories of innovation and human ingenuity. As you explore the exhibits, take note of how these machines transformed communities and facilitated trade across regions.

Regional Impact on Train History

The local geography around Greers Ferry Lake has played a role in shaping train routes and industries over time. The Ruland Junction Toy Train Museum not only focuses on model trains but also highlights how railroads influenced regional development.

For instance:

Heber Springs became an essential stop due to its natural beauty, drawing tourists who traveled by train. The proximity to significant landmarks like Sugarloaf Mountain and Bridal Veil Falls made rail travel vital for tourism.

Understanding these connections enhances your appreciation for both model trains and their historical context within Arkansas.

Interactive Exhibits: More Than Just Static Models Engaging Displays That Captivate All Ages

What sets the Ruland Junction Toy Train Museum apart are its engaging interactive exhibits designed to ignite curiosity among visitors. Children and adults alike can immerse themselves in this captivating world through hands-on experiences:

Operating Model Trains: Visitors can take control of model trains, learning about speed regulation and

1 note

·

View note