#injection molded plastic industry

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Photo

Pressure Molding: Ceresana Report on the European Market for Plastic Injection Molding

From raw material directly to finished part: Injection molding is one of the most important processes in the plastics industry. "3D printing may be faster and does not require expensive molds," says Oliver Kutsch, Ceresana's managing director: "But injection molding is still unbeatable when it comes to cost-effectively producing plastic products of virtually any size or shape in huge quantities." Ceresana has studied the European market for injection-molded plastics: Last year, nearly 12.9 million tonnes of plastics were processed in Europe using this method.

Further information about the new market study “Plastic Injection – Europe”: https://www.ceresana.com/en/market-studies/industry/plastic-injection-europe/

#plastics#injection#molding#Plastic Processing#processing#packaging#producers#production#industry#chemical#manufacturers

2 notes

·

View notes

Text

Are you searching for Plastic injection molding companies in china? Then here you are at the right place. Order any kind of mold for all industries with them now. Top quality and cost-effective guarantee. Order now!

#Injection Mold#Machining#Manufacturers#Mold Parts#Plastic Molds#industry#plastic injection molding companies in china

2 notes

·

View notes

Text

International Plastics and Rubber Industry Fair in October at Vietnam

Vietnam Plas 2024 will be held from 16th - 19th October 2024 at Saigon Exhibition and Convention Center - SECC in Ho Chi Minh City, Vietnam. VietnamPlas has consistently stood as the foremost industrial exhibition in Vietnam. Serving as the bridge connecting the global supply chain with the Vietnamese market, the exhibition has played a pivotal role in fostering collaboration and catalyzing the growth of the plastics industry to meet global demands. The fair covers a wide range of topics and sectors within the plastics and rubber industry. This includes plastic machinery, chemicals and raw materials, machinery auxiliary industry, heating and control devices, hydraulic and pneumatic technologies, recycling techniques, and other relevant products and services.

WHY SHOULD YOU ATTEND EXHIBITION?

VietnamPlas has brought together a diverse range of exhibition categories, including machinery equipment for plastics and rubber processing, manufacturing and distribution of injection moulding machines, film blowing machines, etc. VietnamPlas also bring the most promising businesses and exhibitors to participate, creating opportunities for the development of the plastics and rubber industry in Vietnam. VietnamPlas is not only an opportunity to access the latest technologies and products but also a chance to expand cooperation relations.

Visitors Profile:

Aerospace / Railway

Automobile / Auto Parts / Accessories

Building Materials

Chemicals & Raw Materials

Cosmetics / Daily Chemical Products

Environmental Protection / Recycling / Upcycling

Food & Beverages

Machinery & Testing Equipment

Moulds & Dies

Packaging / Printing

Pharmaceuticals / Medical Supplies & Equipment

Plastic Furniture / Lighting

Plastic Products & Parts

Plastics Recycling

Product / Industrial Design

Rubber Products & Parts

Exhibition Highlight

Exhibition Date: 16th To 19th Oct 2024

Time: 16 to 18 October 09.00 to 5.00 and 19 October 2024 09.00 to 3.00 PM.

Exhibition Location Address: 799 Nguyen Van Linh Parkway, Tan Phu Ward, District 7, Ho Chi Minh City, Vietnam

Hall No. – A1, A2 and B1, B2

Entry Fees – Free Ticket for Industry Professionals on advance booking.

Estimated Visitors: 60,000 Visitors

Estimated Exhibitors: 1000 Exhibitors

WHO SHOULD EXHIBIT?

The most promising exhibitors will showcase their latest cutting-edge products based on global trends at the VietnamPlas exhibition. Here, leading suppliers from many countries will meet all your needs in the supply chain of the plastics and rubber industry. A distinguishing feature of the exhibition is its close ties to the local plastics industry, positioning itself as an ideal platform for entry into the Vietnamese market and for the international showcase of products and services.

Organizer Information.

Organizer Name: Chan Chao International Co., Ltd

Organizer Address: 3F, No.185, Kangchien Road Nei-Hu Dist. Taipei, Taiwan

Organizer Phone No.: 886 2-26596000

Organizer Email Id: [email protected]

Stall Booking Number: +886-2-2659-6000

Website: https://www.chanchao.com.tw/en/

Registration Link: https://www.chanchao.com.tw/en/preReg/index.asp?id=FPLSHCM2024&c=

The event fosters collaboration and knowledge exchange, enabling participants to address key challenges such as environmental sustainability, product innovation, and supply chain optimization. As the industry moves forward, the insights and partnerships developed at this event will play a crucial role in shaping the future of plastics and rubber manufacturing in Vietnam and beyond.

0 notes

Text

Best Injection Molding Operator Jobs in Rajpur | Nearmejob

Looking for Injection Molding Operator jobs in Rajpur. Visit our site for updated listings, job details, and easy application instructions.

1 note

·

View note

Text

Small batch injection molding in china

Looking for top small batch injection molding in China? Hsmolds.net delivers precision, quality, and efficiency. With state-of-the-art facilities and expert engineers, we specialize in small-scale production runs tailored to your needs. Our commitment to excellence ensures reliable, cost-effective solutions for your projects. Trust Hsmolds.net for unparalleled craftsmanship and customer satisfaction in every mold.

0 notes

Text

Plastic Materials: Tall, Rich and Handsome in Engineering Plastics--Polycarbonate (PC)

I. Introduction to Engineering Plastics

So-called engineering plastics are industrial plastics that can replace metals and be used as industrial parts or shell materials. Engineering plastics need to have excellent comprehensive performance. Compared with general plastics, they can meet higher requirements in mechanical properties, heat resistance, durability, corrosion resistance, etc. In…

View On WordPress

#crystalline plastics#engineering plastics#industrial parts#industrial plastics#injection molding#PA#PBT#PC#PC alloy#plastic products#POM#structural engineers

0 notes

Text

Revolutionizing Healthcare: The Synergy of 2K Injection Molding and Medical Advancements

In the dynamic realm of medical manufacturing, innovation is a constant driver of progress. One such technological marvel making waves is 2K injection molding, a process revolutionizing the creation of intricate and functional medical components. This article explores the transformative impact of 2K injection molding and its applications in advancing the landscape of the medical industry.

Demystifying 2K Injection Molding:

2K injection molding, or two-shot molding, represents a cutting-edge manufacturing process where two different materials are injected into a single mold to craft a unified, integrated part. This sophisticated technique empowers the medical industry to engineer complex and multifaceted components with unparalleled precision.

youtube

Unveiling the Potential in Medical Applications:

1. Precision in Medical Devices:

- Intricate Designs: 2K injection molding facilitates the creation of medical devices with intricate designs, elevating their functionality and overall performance.

- Material Fusion: The seamless integration of different materials enables the production of medical devices with customized material combinations for specific medical needs.

2. Innovative Drug Delivery Systems:

- Compact Complexity: Drug delivery systems benefit from 2K molding's ability to consolidate multiple components into a single, streamlined unit, enhancing precision and ease of medication administration.

3. Elevating Diagnostic Equipment:

- Functional Finesse: Components for diagnostic equipment harness the versatility of 2K molding, integrating materials with diverse properties to improve functionality and accuracy.

4. Advancements in Surgical Instruments:

- Ergonomic Excellence: Surgical instruments take a leap forward with improved ergonomics and functionalities, achieved through the integration of materials with varying textures and hardness levels.

Advantages of 2K Injection Molding in Medical Manufacturing:

1. Simplified Assembly Processes:

- Integration of multiple materials in a single molding cycle reduces the intricacies of assembly, minimizing errors and enhancing overall efficiency.

2. Optimized Product Performance:

- The combination of materials with distinct properties empowers the creation of medical components with heightened durability, flexibility, and resistance to environmental factors.

3. Long-Term Cost-Efficiency:

- Despite initial setup costs, the streamlined production process and reduced assembly complexities contribute to long-term cost-effectiveness.

4. Tailored Solutions for Patients:

- 2K molding enables the customization of medical components, catering to the unique needs of patients and healthcare providers.

Challenges and Considerations:

1. Material Compatibility Prowess:

- Rigorous assessment of material compatibility is imperative to ensure the seamless integration of different materials without compromising the overall integrity of medical components.

2. Precision and Stringent Tolerances:

- Achieving precise tolerances in 2K molding demands meticulous engineering and manufacturing processes to meet the rigorous standards set by the medical industry.

Looking Ahead:

As the medical field continues its forward march, 2K injection molding is poised to play an increasingly integral role. The capability to fashion complex, integrated components with enhanced functionality aligns seamlessly with the industry's commitment to delivering cutting-edge solutions for patient care.

Conclusion: Embracing a Future of Healthcare Innovation:

2K injection molding emerges as a catalyst for transformative change in medical manufacturing, ushering in a new era of possibilities for precision and customization. As medical device manufacturers embrace this groundbreaking technology, the potential to create innovative, patient-centric solutions becomes boundless. With its capacity to enhance functionality, simplify assembly processes, and deliver cost-effective solutions, 2K injection molding is at the forefront of reshaping the future of medical components, contributing to the ongoing evolution of healthcare worldwide.

0 notes

Text

The Growing Role of Automotive Plastics in Vehicle Design and Manufacturing

Automotive plastics are materials used for the construction of parts and components in automobiles, including the body, interior, and powertrain. These plastics are designed to be lightweight, durable, and cost-effective. Common types of automotive plastics include polypropylene, polyurethane, ABS, and polycarbonate. Automotive plastics are used in many areas of the vehicle, including interior…

View On WordPress

#automotive bioplastic market#automotive injection#automotive injection molding#automotive injection molding companies#automotive plastic additives market#automotive plastic injection molding companies#automotive plastic manufacturers#Automotive Plastics#Automotive Plastics Industry#automotive Plastics industry for Passenger Cars#Automotive Plastics Market#Automotive Plastics Market for Passenger Cars#automotive plastics market industry share#automotive plastics market industry size#automotive plastics suppliers#COVID 19 impact on Automotive Plastics Market#global automotive plastics market#injection molding in automotive industry#plastic car#plastic car part#plastics for electric vehicle market#polypropylene in cars#use of plastic in automobile

0 notes

Text

Role of Automation in Plastics Processing Machinery

Plastic automation machine systems are advanced manufacturing systems that use robotics, sensors, and other technologies to automate various processes involved in plastic manufacturing or plastic processing machinery. These systems improve efficiency, reduce costs, and enhance the quality and consistency of plastic products.

Plastic processing machinery in Australia refers to equipment used to manufacture plastic products from raw materials. This includes various extruders, injection moulding machines, blow moulding machines, and thermoforming machines. These machines transform plastic pellets or resins into finished products such as bottles, containers, toys, automotive parts, packaging materials, etc. The plastic processing industry is a vital part of modern manufacturing.

By automating plastic processing machinery, companies can improve production efficiency and reduce cycle times, lowering costs and improving overall profitability. Automation can also reduce waste and improve sustainability by optimising material usage and minimising the need for manual intervention.

Also, plastic automation machine systems help improve product quality and consistency. Automating various processes involved in plastic manufacturing can provide more precise and consistent results, reducing the likelihood of defects and deviations.

Automation can also improve safety in plastic processing machinery by reducing the need for manual intervention and minimising the risk of accidents and injuries. Additionally, automation systems can provide real-time monitoring and alerting to prevent potential hazards.

Role of Automation

Automation is becoming increasingly important in the plastic processing industry. Plastic automation machine systems play a crucial role in benefitting plastic processing machinery in several ways –

1. Increased Efficiency

Automated plastic processing machinery can increase the speed and efficiency of production processes. Automated systems can perform repetitive tasks quickly and accurately, reducing the need for manual labour and streamlining production processes. This can lead to increased output, reduced production costs, and improved efficiency.

2. Improved Product Quality

Automation in plastic processing machinery can ensure product consistency and quality. Automated systems can perform tasks with high accuracy and precision, reducing the likelihood of errors and defects in the final product. This can improve the overall quality of the product and reduce waste, saving money and improving customer satisfaction.

3. Cost Savings

Automated machinery can help to reduce labour costs by minimising the need for manual labour. Automation can also reduce the likelihood of errors and defects, reducing the costs associated with rework, scrap, and waste. This helps in substantial cost savings over time.

4. Increased Safety

Plastic automation machine systems help processing machinery to improve workplace safety by reducing the need for manual labour and minimising the risk of accidents and injuries. Automated systems can perform dangerous or difficult tasks for humans, reducing the risk of workplace injuries and accidents.

5. Data Collection and Analysis

These machines can collect data on production processes and product quality, which help in improving efficiency and quality over time. This data also helps identify improvement areas, optimise production processes, and identify opportunities for cost savings. This data is also helpful in identifying patterns and trends, which can help companies to optimise their production processes and improve overall efficiency and quality.

6. Flexibility

Automated plastic processing machinery can be programmed to perform various tasks, making it more flexible than manual labour. This allows companies to adjust production processes quickly and efficiently to meet changing customer demands or market conditions.

7. Customisation

Automation of plastic processing machinery helps in customisation to meet the specific needs of a company or industry. This can include processing different plastic materials, adjusting production rates, and meeting specific quality standards. Customisation can improve efficiency and quality and give companies a competitive edge.

8. Predictive Maintenance

Equipping the automated machinery with sensors and software can help monitor equipment performance and predict when maintenance is needed. This can help to prevent equipment failures and downtime, reducing production costs and improving efficiency.

9. Integration with Other Systems

Plastic automation machine systems can be integrated with other systems, such as enterprise resource planning (ERP) software, to streamline production processes and improve efficiency. Integration can ensure that all systems work together seamlessly, reducing the risk of errors and improving data accuracy.

10. Remote Monitoring

Automated plastic processing machinery can have remote monitoring capabilities, allowing operators to monitor production processes and equipment performance from anywhere. This can improve efficiency by enabling operators to identify and resolve issues quickly, even if they are not on site.

11. Industry 4.0

Automation is a crucial component of Industry 4.0, the current trend of automation and data exchange in manufacturing. Automated plastic processing machinery can be connected to other machines and systems, creating a network of machines that can communicate and work together to improve efficiency and quality.

12. Sustainable Production

These machines can help to reduce waste and improve sustainability. By optimising production processes and reducing the likelihood of errors and defects, automation can reduce the amount of waste produced during manufacturing. This can help to reduce environmental impact and improve sustainability.

13. Quality Control

Automation can help to improve quality control in plastic processing machinery by providing more precise and consistent results. Automated systems can detect defects and deviations in real-time, which can help to prevent the production of faulty products, reducing waste and improving customer satisfaction.

14. Process Optimisation

Automation can help to optimise plastic processing machinery by reducing cycle times and improving overall production efficiency. Automated systems can be programmed to adjust machine settings automatically, reducing the likelihood of errors and minimising downtime.

The role of automation in plastic processing machinery in Australia is significant and multifaceted. As technology continues to evolve, the role of automation in plastic processing machinery is likely to become even more important. Plastic processing companies should continue investing in equipment and systems that can help them remain competitive and meet the evolving needs of their customers.

The Final Words

The automated machinery produced at Mitchell Industries plays a critical role in plastic processing machinery as they offer many benefits to companies in the plastic processing industry. By increasing efficiency, improving product quality, reducing costs, and enhancing safety, automation can help companies remain competitive in the market and meet customers’ evolving needs.

For plastic machinery companies, it is essential to stay up-to-date with the latest automation technologies we have to offer and to invest in our equipment that help in improving production processes, reducing costs, improving product quality, and ensuring safety.

#Plastic Injection Moulding Machine Weisheng Automation#Plastic Injection Moulding Machine Sepro#Plastic Molding Machine jih Huang#Plastics Processing Machinery#plastics industry

0 notes

Text

Injection Molded Plastic Industry ESG Thematic Report, 2023

The wide range applications of injection molded plastic in various industries ranging from automotive to medical industry, where it is used for packaging as part of global value chain and for manufacturing the devices in the said industries. The sourcing of plastic from the natural oil gas is a challenge that negatively impacts the market in the area of environment of ESG. The other important factor that adversely affects the industry is the degrading aspect of the plastic into the environment.

Read More @ https://astra.grandviewresearch.com/injection-molded-plastic-industry-esg-outlook

About Astra – ESG Solutions by Grand View Research

Astra is the Environmental, Social, and Governance (ESG) arm of Grand View Research Inc. - a global market research publishing & management consulting firm.

Astra offers comprehensive ESG thematic assessment & scores across diverse impact & socially responsible investment topics, including both public and private companies along with intuitive dashboards. Our ESG solutions are powered by robust fundamental & alternative information. Astra specializes in consulting services that equip corporates and the investment community with the in-depth ESG research and actionable insight they need to support their bottom lines and their values. We have supported our clients across diverse ESG consulting projects & advisory services, including climate strategies & assessment, ESG benchmarking, stakeholder engagement programs, active ownership, developing ESG investment strategies, ESG data services, build corporate sustainability reports. Astra team includes a pool of industry experts and ESG enthusiasts who possess extensive end-end ESG research and consulting experience at a global level.

For more ESG Thematic reports, please visit @ https://astra.grandviewresearch.com/

0 notes

Text

The global automotive plastics market for passenger cars size is projected to grow from USD 21.1 billion in 2021 and is projected to reach USD 30.8 billion by 2026, at a CAGR of 7.9%. The demand for automotive plastics is mainly driven by the increase in passenger car production and the increasing utilization of automotive plastics in vehicle designs. Plastics offer a maximum weight reduction for automobiles, which in turn reduces carbon emissions. These could be the major reasons propelling the market.

The shift towards the use of bioplastics in vehicle production, the use of anti-microbial plastics and additives, the use of composites and PMMA, and the growing trend of vehicle electrification have increased the demand for automotive plastics across the globe. The development of 3D printing technology is expected to act as a new opportunity for the automotive plastics market for passenger cars to grow. However, the high cost of capital and infrastructure for re-engineering plastics is expected to hinder market growth during the forecasted period.

The under-bonnet is the fastest-growing application segment of the automotive plastics market for passenger cars during the forecast period. Automotive plastics used in the manufacturing of under-bonnet components of passenger cars include Polypropylene, PBT, polyamide, and other engineered plastics. The use of plastics in under-bonnet applications provides high durability, high-temperature resistance, strength, and rigidity to automobiles. The under-bonnet segment includes components such as the battery, onboard chargers, connectors, cables, electric motor, anti-lock braking system, hoses, hydraulic booster unit, load-sensing valve, master cylinder, metering valve, fuel delivery modules, intake manifolds, brackets, duck work, accumulator pistons pressure differential valve, proportioning valve, and thermal management system which require plastics in their manufacturing.

Polyamide is the fastest-growing product type segment of the automotive plastics market for passenger cars during the forecast period, owing to its enhanced properties, such as impact strength and superior surface finish. Commonly used grades are PA 6 and PA 66. It has various properties such as high stiffness, strength, dimensional stability, high temperature and abrasion resistance, and low friction characteristics, along with chemical, flame, abrasion, creep, and fatigue resistance. Moreover, owing to their excellent strength and toughness at the time of exposure to hot and automotive fluids, polyamides are used for automotive thermal management and other applications areas including gears, bushes, cams, bearings, and weatherproof coatings, etc.

BASF SE (Germany), SABIC (Saudi Arabia), LyondellBasell Industries Holdings BV (Netherlands), LG Chem (South Korea), DuPont (US), Covestro AG (Germany), Evonik Industries AG (Germany), Solvay (Belgium), Arkema SA (France), Borealis AG (Austria), LANXESS (Germany), DSM (Netherlands), Toray Industries Inc. (Japan), Mitsui Chemicals (Japan), Celanese Corporation (US), Toyota Boshoku Corporation (Japan), Faurecia SA (France), TOYODA GOSEI Co., Ltd. (Japan), INEOS (UK), Sumitomo Chemicals Co. (Japan), Ltd., UBE Industries (Japan), Mitsubishi Engineering Plastics Corporation (Japan), Formosa Plastics Corporation (Taiwan), EMI Chemi Holdings (China), and Momentive Performance Materials (US) are some of the leading players operating in the automotive plastics market for passenger cars. These players have adopted the strategies of acquisitions and partnerships to enhance their position in the market.

#Automotive Plastics Market for Passenger Cars#plastics for electric vehicle market#automotive bioplastic market#global automotive plastics market#automotive plastic additives market#plastic car#automotive plastics#plastic car part#automotive injection molding#automotive injection#use of plastic in automobile#polypropylene in cars#automotive plastic manufacturers#injection molding in automotive industry#automotive plastics suppliers#automotive plastic injection molding companies#automotive injection molding companies#COVID 19 impact on Automotive Plastics Market#automotive Plastics industry for Passenger Cars#Automotive Plastics Market#Automotive Plastics Industry#Automotive Plastics#automotive plastics market industry share#automotive plastics market industry size#automotive plastics market industry trends

0 notes

Text

Who has dropped quarters in one of these babies and watched the miracle of plastic injection molding produce a hot souvenir for you while you wait?

Chicago's Brookfield Zoo or Museum of Science and Industry host a couple.

183 notes

·

View notes

Text

"Little Plastic Knowledge" for Beginners

1. Definition of plastic

Plastic is a polymer organic material with resin as its main component, which can be molded into a certain shape under a certain temperature and pressure, and can maintain a certain shape at room temperature.Resin refers to an organic polymer that usually has a transformation or melting range when heated. It is fluid under action of external force during transformation…

View On WordPress

#Definition of plastic#engineering plastics#engineering structural parts#injection molding#plastic molding#plastics industry#thermosetting plastics

0 notes

Text

Kore Industries: Engineering Precision, Innovating Excellence

In the dynamic landscape of plastic manufacturing, Kore Industries stands out as a trailblazer, leading the charge in precision and innovation. Renowned for its diverse competencies and global reach, Kore continues to redefine industry standards, offering solutions that marry engineering excellence with cutting-edge technology.

Meticulous Craftsmanship: Unveiling Kore's Distinctive Competencies

Precision Unleashed:

1. Precision Plastic Gears: Kore Industries sets the benchmark for precision with its intricate plastic gear manufacturing, catering to the most demanding applications.

2. Precision Plastic Mould and Production: From concept to completion, Kore's mastery in precision plastic molding ensures the seamless realization of diverse projects.

3. Multi-Shot Mould and Production: Embracing advanced techniques, Kore specializes in multi-shot molding, a testament to its commitment to efficiency and accuracy.

4. Overmoulding and Insert Moulding: Kore's expertise extends to overmolding and insert molding, enhancing product durability and functionality with every project.

5. Tandem Mould and Production: Addressing complex molding needs, Kore excels in providing innovative tandem molding solutions.

Elevating Partnerships: Kore's Commitment to Excellence

Engineering Synergy:

Kore Industries distinguishes itself by collaborating closely with clients before production. Armed with robust engineering knowledge, a spirit of experimentation, and meticulous execution, Kore is a proactive problem solver.

Technological Precision:

Kore's molding facilities are a showcase of cutting-edge technology. Fully electric and equipped with robotic precision, these facilities ensure unwavering consistency and precision in every production cycle.

DNA of Dedication:

The success of Kore's clients is interwoven with the company's own success. This deep-seated dedication and sense of ownership form the core of Kore's team DNA.

Tool Room Excellence:

Backed by a proficient tool room boasting over a decade of experience in complex mold building, Kore emphasizes the critical role of reliable, high-quality molds. Kore's molds consistently surpass requirements, underlining their commitment to long-term cost savings.

Global Impact, Industry Diversity:

Kore Industries has left an indelible mark across diverse industries, including automotive, medical, industrial, personal care, consumer electronics, and infant and baby products. With a global footprint spanning Singapore, China, India, and the US, Kore seamlessly adapts to unique market needs.

Elevate Your Vision: Connect with Kore Industries Today:

For those seeking a manufacturing partner that transcends the ordinary, Kore Industries beckons. Connect with Kore today to experience a fusion of precision, innovation, and engineering excellence that reshapes industry landscapes.

0 notes

Text

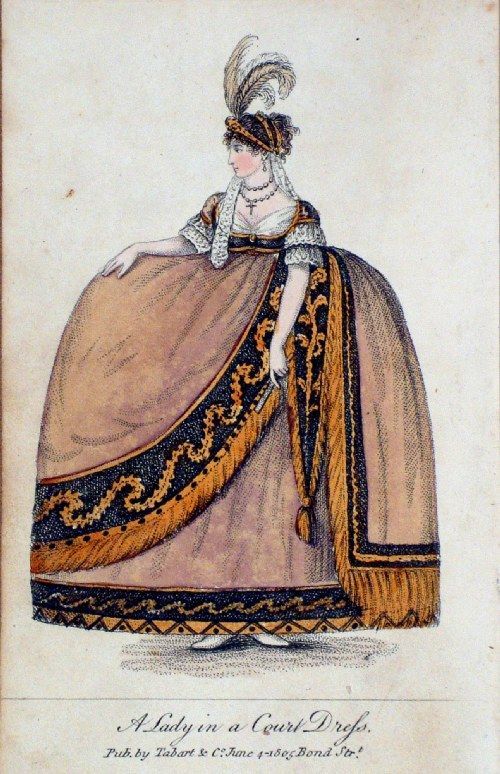

tried watching the new queen charlotte series but was immediately put off by the ridiculous anti-corset propaganda, so get ready for another rant.

first of all, this is the georgian era so what she's wearing are called /stays/ - corsets are a victorian invention. why do we still not know this in 2023 when period productions have remained consistently popular throughout the years? the concept of tighlacing (the goal being a reduction of the waist) is also victorian and was not the norm at all and v much an extreme practice. this understanding of history is so superficial, it's as if an alien were to open up People magazine and conclude that all human women resort to butt injections and lip fillers to stay with the fashion of the times. also, no, you cannot tighlace in stays to obtain a waist reduction because they are shaped like a funnel (picture 1 = long stays, 2 = short regency stays, 3 = corset)

charlotte goes on to complain about how dangerous whalebone is and that it might kill her if she makes the wrong move. what the actual fuck? whalebone was actually the very best material to use for this because it was sturdy yet flexible and allowed the /stays/ to completely and comfortably mold around a woman's unique body shape. one of the reasons why today it is v difficult to replicate the same effect in corsetry is because we do not have access to whalebone (killing whales is not cool for obvious reasons) so corset-makers have to resort to other materials like plastic or metal, which CAN break. whereas whalebone doesn't really break as easily. furthermore, stays/corsets were NEVER worn on bare skin, but with a chemise/shift underneath.

why did women in the past resort to this type of undergarment, you ask? well, apart from the fact that women need bust support, the stays also serve the purpose of allowing all the many skirts and petticoats to be placed comfortably onto the waist. you try piling on that much fabric around your bare waist and see how you like it and if you can even carry it all around without it cutting into your stomach.

clothes throughout human history did cater to the popular fashions of the time, yes, but they also reflected the technological limitations and there was thus a practical aspect to it. this is a time before elastic bands, before industrialization and fast fashion, clothes are v difficult to make, everything is done by hand, so a lot of care is put into preserving them, because they are /expensive/ and labour intensive. you don't want your fancy outergarments to get ruined so you wear a lot of undergarments to absorb your bodily fluids since those are easier to make and don't have to look "pretty", can be stained and patchy etc. again, why do you need so many layers in the first place? because this is a time before comfortable heating, with poorly isolated and drafty houses, and it's bloody cold otherwise.

the third reason why that monologue was so dumb is because CHARLOTTE is the reason regency court dress was so preposterous. long story short, in a few decades, the fashionable silhouette changes wildly from the late 1700s to the 1810s.

the regency waistline was much higher and the gowns were much more flowy and unstructured than the late georgian ones (what's commonly known as the empire waistline). the long stays of the late 1700s were now replaced with short stays that really were similar to modern bras. the scene in the first season of bridgerton where they squeeze penelope's sister into what looks like a pair of long stays (?) is bonkers bc no one would wear a waist-constricting boned undergarment under a regency dress. why would they? the natural waist is not even emphasized in any way. this is just another reason to peddle the women-were-oppressed-by-their-lingerie agenda. so if charlotte really hated long stays that much, regency would really have been her time to shine, right? wrong. the woman loved the fashions of her youth so much she forced everyone who came to court to still comply to them, which is why we get the absolutely atrocious regency court dresses - essentially a combination of the georgian style with side panniers, but with an empire waistline.

yeah, this is how daphne SHOULD have looked like when she was presented at court in front of charlotte. i can understand why the showrunners decided to just leave her in a regency silhouette because this is ugly af. but, anyway, queen charlotte is the last person on earth to be complaining about how uncomfortable stays are.

creative licence aside, the reason this pisses me off is because it is SUCH lazy storytelling. the show wants us to know charlotte is a spunky pseudo-feminist character so the easiest way to do that is to have her complain about the evil 'corset' trying to kill her. it is so profoundly ahistorical and does nothing to contribute to the conversation about women's true problems and true limitations during that time. instead of genuinely exploring social history and women's actual lived experiences, we are STILL, in the year of our lord 2023, diverting the discourse towards fabricated issues that never existed in the first place.

the reasons actresses complain about boned underwear in interviews are manifold. costume designers are very overworked, they have to produce clothes for hundreds of people in a very short time, so they simply do not have the time or resources to construct corsets/stays that fit the actresses like they are supposed to. in the past, these garments were made individually for every person and completely to their own requirements. they also make these actresses wear the boning on BARE skin to look extra sexy to the audience or to emphasize their oppression - that never happened, a shift was always worn underneath (hello dakota fanning scene in the alienist??).

moreover, they lace them up until they constrict their ribcages - these women are already super thin and their bodies cannot support more reduction - instead of relying on the historical practices of padding and illusion. nowadays, body parts are what's fashionable - that's why so many resort to fat transfers or breast implants or starving themselves to achieve a flat stomach. in the past, anyone of any size could have accomplished the fashionable silhouette because they had a wide array of accouterments to plop underneath their garments - panniers, bustles, hoop skirts, padding of any sort. it didn't matter how big your waist was, you just padded other areas until you achieved the desired shape. fat women wore corsets/stays, too. working women, who did a lot of physical labour, did the same. how were they able to perform all of their tasks if they were incapable of moving or breathing? even today, people wear medical corsets all the time.

TLDR the media's obsession with portraying modern women as so liberated because they wear bras instead of "patriarchal" underwear is so tedious.

EDIT: Some very basic chronological tadpoles to make this easier to place within historical context. "Georgian" is used to denote the 18th+ century when Great Britain was ruled by several kings named George, so roughly 1714-1830. Within this interval, we refer to the Regency period as encompassing the regency of Prince George, future King George IV, when his father George III was incapacitated by mental illness. The official political regency took place during 1811-1820, but culturally speaking, this was extended to roughly the end of the 18th century up to maybe 1830 or 1837. This is the time period of Napoleonic wars and Jane Austen novels, so all her heroines should normally wear Regency styles. Think "empire waistline" as in Imperial France and Napoleon. The Victorian era (and its corsets) follows throughout the rest of the 19th century. Queen Charlotte was a contemporary of Marie Antoinette's, so they should be dressed in similar fashions (robe à la française vs robe à la anglais).

#but what can i expect from a production by shonda rhimes 🤷♀️ she certainly has a marvel-heroine type understanding of feminism#queen charlotte: a bridgerton story#bridgerton#fashion history#anyway this post is relevant for my blog bc i generally watch a lot of period media so this issue inevitably pops up now and again#would also like to add that while the term 'corset' did exist in that era#it referred to a v wide array of chest undergarments#so as to become impractical to use for a relatively short explanation#corsets as we conceptualize them today are tied with the victorian period#also pls remember i am simplifying for the sake of brevity else this post would have been enourmous

547 notes

·

View notes