#industrial ac/dc motor management

Explore tagged Tumblr posts

Text

Never Lose Power Again with Industrial Generators

Industrial generator sets in North Carolina offer a useful solution to businesses requiring standby power. These powerful systems allow business to continue during power outages, and keep essential processes going. Industrial generator sets are built for efficiency and long-lasting while being a necessity to many industries in the state. Contact Triune Electric today!

#industrial generator sets#industrial electrical distribution panels#control panel#industrial ac/dc motor management#industrial generator#plant ups systems

0 notes

Text

Everything You Need to Know About Electric Hoists: A Comprehensive Guide

In the modern world of industrial and commercial work, efficiency and safety are paramount. Whether you're lifting heavy materials in a warehouse, moving equipment on a construction site, or handling items in a factory, having the right tools can make all the difference. One of these tools is the electric hoist—a mechanical device that makes lifting and moving heavy loads safer, faster, and more efficient.

In this blog, we will delve into the basics of electric hoists, how they work, their benefits, and the different types available for various applications.

What is an Electric Hoist?

An electric hoist is a type of mechanical lifting device that uses an electric motor to lift, lower, and move heavy objects vertically. It operates by using a motorized drum or trolley that winds up a rope or chain, providing the necessary force to raise or lower heavy loads. The electric motor in the hoist is typically powered by electricity, which allows for efficient and reliable operation compared to manual or hydraulic systems.

Electric hoists are used in a wide range of industries, including construction, manufacturing, warehouses, shipping, and more. These devices come in different forms, sizes, and capacities to cater to various lifting needs.

How Do Electric Hoists Work?

Electric hoists consist of several core components that work together to perform the lifting and lowering of loads:

Motor: The heart of the electric hoist, the motor, is responsible for generating the power required to lift the load. Most electric hoists use an AC (alternating current) motor, although DC motors are also found in some models.

Drum or Trolley: The motor drives either a drum or a trolley to which a rope or chain is attached. The rope or chain wraps around the drum as the motor operates, allowing the load to be raised or lowered.

Load Hook: The load hook is where the heavy object being lifted is attached. It's designed to securely hold the load while it's being lifted or moved.

Control System: Most electric hoists come with a control panel or remote control that allows operators to manage the lifting operation. This system ensures precise control over the speed and direction of the hoist.

Safety Features: Many modern electric hoists come with additional safety features such as overload protection, emergency stop buttons, and limit switches to prevent the hoist from lifting beyond its capacity.

Types of Electric Hoists

Electric hoists come in different types, and each type is suited for specific lifting applications. The two primary types of electric hoists are:

Wire Rope Hoist:

Wire rope hoists use steel wire ropes to lift loads. These hoists are often used for heavier lifting tasks and can handle large loads with a high degree of stability.

Commonly found in construction sites, shipyards, and warehouses, wire rope hoists are designed for tough environments.

They offer longer lifting distances and are ideal for heavy-duty applications.

Chain Hoist:

Chain hoists use chains instead of ropes for lifting. They are typically used for medium to heavy lifting tasks and are well-suited for applications where the load needs to be lifted over shorter distances.

Chain hoists are more compact, making them ideal for use in tight spaces.

They are highly durable and resistant to wear and tear, which makes them an excellent choice for environments where heavy-duty, frequent lifting is required.

Advantages of Using Electric Hoists

Electric hoists offer numerous advantages over manual or hydraulic hoists. Some of the key benefits include:

Efficiency: With an electric hoist, lifting heavy loads becomes faster and more efficient, significantly improving productivity in industrial and commercial settings. The automation of the lifting process reduces the time and labor required for each task.

Safety: Electric hoists are designed with safety in mind. Many models come equipped with overload protection, which prevents lifting beyond the hoist's rated capacity, reducing the risk of accidents. The controlled lifting mechanism also minimizes human error, making it safer for operators.

Consistency: Unlike manual hoists, which rely on human strength, electric hoists provide consistent lifting power, which ensures uniformity and reliability in lifting tasks.

Reduced Labor Costs: Electric hoists reduce the need for manual labor, making it easier to handle heavy loads with fewer workers. This can help companies save on labor costs and minimize workplace injuries.

Versatility: Electric hoists come in a variety of models, with different lifting capacities, speeds, and designs, making them versatile tools suitable for a wide range of applications.

Key Applications of Electric Hoists

Electric hoists are used across a wide range of industries and settings. Some common applications include:

Construction: Hoists are often used to move materials, equipment, and workers on construction sites, helping to speed up the building process.

Manufacturing: In factories and manufacturing plants, electric hoists are used to transport raw materials or finished goods along production lines.

Warehousing and Logistics: Electric hoists are used to move heavy items within warehouses, including boxes, pallets, and machinery.

Marine and Shipping: These hoists are vital in the shipping industry, where they are used to load and unload cargo from ships or warehouses.

Automotive Industry: In car manufacturing and repair shops, electric hoists help lift and move heavy vehicle components.

Factors to Consider When Choosing an Electric Hoist

When selecting an electric hoist, it’s important to consider several factors to ensure the right choice for your application. Here are a few things to keep in mind:

Load Capacity: The first thing to check is the hoist's load capacity. Make sure the hoist can handle the maximum weight of the items you'll be lifting. Overloading a hoist can cause mechanical failure and pose serious safety risks.

Lifting Height: Consider how high you need to lift the load. Some hoists are designed for shorter distances, while others can lift loads to greater heights.

Environment: Determine the environment where the hoist will be used. For example, outdoor use or exposure to harsh conditions may require a hoist with added protection against the elements.

Power Supply: Most electric hoists are powered by electricity, but some may be designed for use with generators or backup power sources, which is important for remote locations.

Safety Features: Look for safety features like overload protection, emergency stop buttons, and limit switches. These features help ensure safe operation during heavy lifting tasks.

Conclusion

Electric hoists are an invaluable tool for any industry that deals with lifting and moving heavy loads. They offer efficiency, safety, and reliability, making them the ideal choice for a wide range of applications. By choosing the right electric hoist for your needs, you can improve productivity, reduce labor costs, and ensure the safe handling of heavy items. Whether you're in construction, warehousing, or manufacturing, an electric hoist will help you lift your business to new heights.

0 notes

Text

Inverter Transformers: Efficient Power Conversion for Renewable & Industrial Applications

Inverter transformers are specially designed to handle the unique power conversion requirements of solar energy systems, UPS (Uninterruptible Power Supply), and industrial applications. These transformers play a crucial role in converting DC power to AC, ensuring efficient and stable voltage regulation for various industries.

At Danish Pvt Ltd, we manufacture high-performance inverter transformers that enhance energy efficiency, electrical safety, and system longevity for renewable and industrial power solutions.

What is an Inverter Transformer?

An inverter transformer is an essential component in inverter-based power systems, designed to provide electrical isolation, voltage transformation, and improved efficiency in power conversion. It is commonly used in:

Solar Power Systems – Converts DC from solar panels to AC for grid or off-grid use.

UPS & Backup Power – Ensures stable power supply during outages.

Industrial Automation – Supports variable frequency drives (VFDs) and motor control.

Electric Vehicles (EVs) – Used in charging stations and battery management systems.

Types of Inverter Transformers

Solar Inverter Transformers

Used in solar power plants for efficient energy conversion.

Ensures grid synchronization and voltage stabilization.

Supports both on-grid and off-grid solar inverters.

Isolation Inverter Transformers

Provides galvanic isolation between input and output circuits.

Protects sensitive electronic equipment from surges and faults.

Used in medical, telecommunication, and IT industries.

High-Frequency Inverter Transformers

Compact design with low power loss for efficient conversion.

Used in SMPS (Switch Mode Power Supplies) and electronic devices.

Supports fast-switching applications in industrial power supplies.

UPS & Backup Power Transformers

Stabilizes voltage in critical power applications.

Used in hospitals, data centers, and telecom networks.

Provides seamless transition during power failures.

Key Features of Our Inverter Transformers

High Efficiency – Designed for low losses and maximum power conversion.

Advanced Insulation & Cooling – Ensures longer lifespan and thermal stability.

Compact & Lightweight Design – Ideal for space-constrained applications.

Smart Monitoring & IoT Integration – Enables real-time performance tracking.

Customizable Power Ratings – Available in various voltage and power capacities.

Technical Specifications

Voltage Rating: Up to 220kV

Power Capacity: 10 kVA – 5 MVA

Cooling Methods: Air-cooled / Oil-cooled

Frequency: 50Hz / 60Hz

Efficiency: Up to 98%

Standards Compliance: IEC, BIS, ANSI, IS-2026

Industries We Serve

Renewable Energy (Solar & Wind Power) – Essential for solar farms and hybrid power systems.

Industrial Automation – Used in motor drives, power electronics, and VFDs.

Commercial & Data Centers – Ensures stable power for critical IT infrastructure.

Electric Vehicles (EVs) & Charging Stations – Supports EV battery charging and energy conversion.

Telecommunications & Smart Grids – Provides isolation and voltage regulation.

Why Choose Danish Pvt Ltd for Inverter Transformers?

Industry-Leading Expertise – Decades of experience in power electronics and transformers.

Energy-Efficient Designs – Optimized for low power losses and high performance.

Custom-Built Solutions – Tailored for specific industrial and commercial applications

Premium Quality Materials – High-grade copper windings and durable insulation.

24/7 Technical Support & Maintenance – Ensuring uninterrupted power supply.

Conclusion

Inverter transformers are crucial for renewable energy, UPS systems, and industrial automation, ensuring efficient power conversion and voltage regulation. At Danish Pvt Ltd, we offer high-performance, reliable, and customizable inverter transformers designed to meet the evolving needs of the power industry.

0 notes

Text

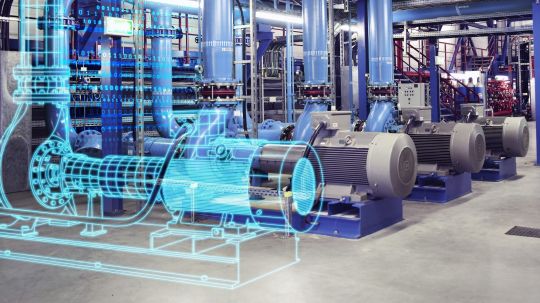

The Evolution of Industrial Drive Technology: From Conventional to Smart Systems

Industrial drive technology plays a critical role in manufacturing, automation, and energy management. From simple mechanical systems to modern smart drives integrated with AI and IoT, the evolution of industrial drives has significantly enhanced efficiency, precision, and sustainability.

This article explores the progress of industrial drive technology, from its conventional origins to the latest smart systems, and how these advancements are shaping the future of industrial automation.

1. The Conventional Era of Industrial Drives

In the early days of industrialization, mechanical drive systems were widely used to transmit power in factories. These systems relied on:

Fixed-speed motors with limited control over speed and torque.

Mechanical gears and belts for power transmission.

Manually operated systems requiring frequent adjustments.

Challenges of Conventional Industrial Drives

✔ High energy consumption due to inefficient speed control. ✔ Frequent maintenance due to wear and tear in mechanical components. ✔ Limited automation requiring manual intervention.

Despite these limitations, conventional drives played a crucial role in industrial progress, setting the foundation for modern automated systems.

2. The Shift to Electronic and Variable Frequency Drives (VFDs)

With the rise of electrical engineering and power electronics, industrial drives underwent significant advancements:

The introduction of Variable Frequency Drives (VFDs) allowed precise control of motor speed and torque.

DC and AC drives replaced mechanical power transmission systems, improving energy efficiency.

Programmable Logic Controllers (PLCs) enabled basic automation in manufacturing processes.

Advantages of Electronic Drives

✔ Better speed and torque control, improving machinery efficiency. ✔ Reduced mechanical wear and tear, leading to lower maintenance costs. ✔ Energy savings, as motors could operate at variable speeds based on demand.

The adoption of electronic drives and VFDs marked the beginning of industrial automation and efficiency improvements, paving the way for smarter solutions.

3. The Rise of Intelligent and Smart Industrial Drives

With advancements in digital technology, artificial intelligence (AI), and the Internet of Things (IoT), modern industrial drives have evolved into smart, self-optimizing systems.

Key Features of Smart Industrial Drives

✔ IoT-Enabled Connectivity – Real-time monitoring and remote control through cloud-based platforms. ✔ AI-Powered Predictive Maintenance – Reduces downtime by detecting faults before they occur. ✔ Energy Optimization Algorithms – Smart drives adjust power consumption based on workload. ✔ Seamless Integration with Automation Systems – Works efficiently with robotics, PLCs, and SCADA.

Impact on Industry 4.0

Modern industrial drives are a key component of Industry 4.0, enabling:

Self-learning drive systems that adapt to changing operating conditions.

Wireless communication for real-time performance tracking.

Cybersecurity enhancements to protect industrial networks.

These innovations improve productivity, energy efficiency, and sustainability, making smart industrial drives the future of manufacturing.

4. The Future of Industrial Drive Technology

As industries continue to advance, next-generation drive systems will incorporate:

Edge computing for faster data processing and decision-making.

AI-driven automation that requires minimal human intervention.

Enhanced cybersecurity measures to protect connected drive systems.

With these advancements, smart industrial drives will play a vital role in reducing operational costs, minimizing downtime, and increasing manufacturing efficiency.

Conclusion

The evolution of industrial drive technology has transformed the way industries operate, moving from basic mechanical systems to intelligent, self-optimizing smart drives. With AI, IoT, and energy-efficient solutions, modern industrial drives are shaping the future of automation and sustainability.

As industries adopt these smart technologies, efficiency, precision, and cost savings will continue to improve, ensuring a smarter and more sustainable future for manufacturing and industrial applications.

0 notes

Text

Helping The Others Realize The Advantages Of pool pumpe

Hayward has the marketplace’s broadest line-up of pool pumps engineered to deliver ultra-superior effectiveness with powerful and dependable functionality.

Publication Stay informed with our slicing-edge insights and stay forward inside your industry with our expertly curated newsletter.

Area keep price ranges may possibly differ from those exhibited. Items proven as readily available are Usually stocked but inventory ranges cannot be assured.

The market standard will be to flow into all h2o inside an 8-hour interval. Though changing a pump "like for like" might sound reasonable, In case your pump unsuccessful prematurely, it could indicate an incorrect pump option.

A swimming pool pump features as the center of your respective pool, circulating water through the entire technique to forestall it from turning out to be stagnant and improperly sanitised.

Her finder du et stort udvalg af filterpumper til din swimmingpool.Vi har altid et bredt udvalg af de mest anvendte og gense pumper til pools i forskellige motorstørrelser og med enten en eller tre faser. Hvis du er i tvivl om, hvilken pumpe der passer til din pool, er du altid velkommen til at kontakte os.

Because the name implies, this cable can be a multiconductor cable that connects a submersible pump controller towards the motor with the pump, often located in a deep very well. Cables are in good shape to face up to wet and hostile conditions and can be employed in each refreshing and saltwater.

With no useful swimming pool pump, pools can swiftly turn murky and most likely dangerous. Swimming pool pumps Manage the circulation method, impacting the pool’s cleansing, filtration, and also distribution of heat and chemicals.

A titanium warmth exchanger making sure an extended Operating life. Arctic Spa Warmth Pumps use titanium to face up for the severe environment of the spa or even a pool which might include superior levels of chlorine, bromine, or salt.

Arctic Pool Warmth Pumps are the very best rated heat pumps in North The united states for lower ambient temperatures as tested with the CEC. With DC inverter technological innovation the pool warmth pump is 50% far more efficient that normal single or two-stage AC pool warmth pumps and nearly 60% quieter.

Pump Basket: Collects particles, guarding the pump motor from strain and early burnout. All our pumps include things like removable filter baskets and inspection covers for straightforward upkeep.

The included chilly temperature structure allows the Arctic Pool Heat pump to operate in temperatures under freezing. Now you could prolong you pool season in both of those the spring and the fall! This is very essential for northern regions that have already got a short pool year.

All Arctic Spa & Pool Heat Pumps are both heater in addition to chillers. On computerized manner, the warmth pump will retain the ideal temperature by switching from heating to cooling as necessary. Great for scorching summertime climates where by a refreshing pool is welcomed in pool pumpe the warmth waves.

Den tekniske lagring eller adgang er strengt nødvendig for det legitime varietyål at muliggøre brugen af en specifik tjeneste, som abonnenten eller brugeren udtrykkeligt har anmodet om, eller med det ene typeål at udføre transmissionen af en kommunikation around et elektronisk kommunikationsnetværk. Choices Choices

Regardless how you end up picking to make use of your pool warmth pump technique – another thing is certain. It’s economical layout and incredible listing of features are positive to save you approximately 75% in comparison to common poo heating procedure.

0 notes

Text

Sell Used Electrical Equipment Buyers in Oklahoma City, OK

If you’re searching for reliable Sell Used Electrical Equipment Buyers in Oklahoma City OK, look no further. At Sell Circuit Breakers Florida, we specialize in helping you turn surplus electrical equipment into cash. Whether you’re upgrading systems, clearing out inventory, or managing decommissioned projects, our team ensures you connect with trusted buyers in Oklahoma City.

Why Choose Sell Circuit Breakers Florida?

1. Specialized Expertise

We’re experts in the market for used electrical equipment, and we work with the best Sell Used Electrical Equipment Buyers in Oklahoma City OK to ensure you get competitive prices for your items.

2. Seamless Process

Selling your used electrical equipment has never been easier. From providing an offer to arranging pick-up, we handle everything.

3. Eco-Friendly Approach

By selling your used equipment, you help reduce waste and promote sustainability by giving your items a second life with buyers who reuse and recycle responsibly.

Equipment We Buy

As one of the top services connecting sellers to Sell Used Electrical Equipment Buyers in Oklahoma City OK, we purchase a wide range of equipment, including:

Circuit Breakers: From residential to heavy-duty industrial models.

Transformers: Step-up, step-down, and isolation transformers.

Switchgear: Low, medium, and high-voltage systems.

Electrical Panels: Distribution boards and control panels.

Motors and Drives: AC/DC motors, variable frequency drives, and more.

Hard-to-Find Items: Obsolete or discontinued components.

How It Works

1. Reach Out to Us

Contact us with details about your equipment, such as make, model, and condition.

2. Receive a Competitive Offer

We assess your equipment and connect you with the best Sell Used Electrical Equipment Buyers in Oklahoma City OK who offer fair market prices.

3. Schedule Pick-Up or Shipping

We arrange convenient pick-up or shipping options for your equipment.

4. Quick Payment

After inspection and acceptance, you’ll receive prompt payment.

Why Oklahoma City?

Oklahoma City’s thriving industries and growing economy make it a prime location for selling used electrical equipment.

Energy Sector Demand: Oklahoma’s energy industry creates consistent demand for electrical equipment.

Construction Growth: Expanding commercial and residential projects rely on high-quality electrical components.

Sustainability Focus: Buyers in Oklahoma City prioritize refurbished and recycled materials.

By partnering with Sell Circuit Breakers Florida, you gain access to the most reliable Sell Used Electrical Equipment Buyers in Oklahoma City OK to capitalize on these opportunities.

FAQs

1. What Types of Equipment Do You Buy?

We purchase a wide range of equipment, including circuit breakers, transformers, switchgear, and more.

2. Do You Serve Sellers in Oklahoma City?

Yes! We actively connect sellers with buyers in Oklahoma City and surrounding areas.

3. How Do I Start Selling?

Contact us with the details of your equipment, and we’ll handle the rest.

Contact Us Today

Don’t let unused electrical equipment go to waste. Work with Sell Circuit Breakers Florida to connect with top Sell Used Electrical Equipment Buyers in Oklahoma City OK and turn your surplus into cash.

Contact us now to get started and experience a hassle-free selling process!

0 notes

Text

Driving Energy Savings: Insights into the Global Variable Frequency Drive Market

The global variable frequency drive market size is estimated to reach USD 39.67 billion by 2030, registering a CAGR of 5.9% from 2025 to 2030, according to a new report by Grand View Research, Inc. The rapid development of semiconductor technology and rising consumer awareness of the benefits of energy-efficient products are two factors anticipated to fuel the expansion of the market. Similarly, the rising energy demand worldwide and the use of variable frequency drives (VFDs) to regulate the flow and speed of the fan to prevent energy loss are anticipated to promote the growth of the global market in the years to come.

More than 90% of the energy expended in the U.S. is used by residential refrigeration and HVAC systems equipment. VFDs aid in managing the speed of the motor in HVAC systems and reduces power consumption, which is expected to boost the growth of the market. Rising awareness about conserving energy and approaches to reducing excessive energy consumption is expected to increase demand for these devices. Additionally, rising demand for variable frequency drives from the food and beverage, automotive, and oil and gas industries are anticipated to promote market expansion.

The expansion of the market is anticipated to be hampered by the high cost of the product and maintenance. Furthermore, a workforce shortage is anticipated to pose a threat to market expansion. However, rising expenditure in the distribution and power generation industry as well as rising global oil & gas extraction operations are likely to open up new prospects for market participants in variable frequency drive in the years to come.

The global COVID-19 pandemic has had a big impact on the growth of the VFD market. In the industrial sector, variable frequency drives are frequently employed. The government's stringent lockdown and the closure of factories, however, reduced demand for variable frequency drives. In the 2nd quarter of 2022, the market for VFDs is anticipated to expand as previously halted production activities resume, thus reviving the market growth.

Variable Frequency Drive Market Report Highlights

By end-use, the oil & gas segment held the largest revenue share in 2024.

The AC drives segment dominated the market with more than 68.9% share in 2024 and is expected to continue leading the market with increasing demand from the industrial sector for equipment with less noise and maintenance.

Asia Pacific dominated the market with a revenue share of 34.5% in 2024. This can be attributed to rapid industrialization in emerging economies and increasing demand from the water treatment sector.

Variable Frequency Drive Market Segmentation

Grand View Research has segmented the global variable frequency drive market based on product type, power range, application, end-use and region:

Variable Frequency Drive Product Type Outlook (Revenue, USD Billion, 2018 - 2030)

AC Drives

DC Drives

Servo Drives

Variable Frequency Drive Power Range Outlook (Revenue, USD Billion, 2018 - 2030)

Micro (0-5 kW)

Low (6-40 kW)

Medium (41-200 kW)

High (>200 kW)

Variable Frequency Drive Application Outlook (Revenue, USD Billion, 2018 - 2030)

Pumps

Electric Fans

Conveyors

HVAC

Extruders

Others

Variable Frequency Drive End Use Outlook (Revenue, USD Billion, 2018 - 2030)

Oil & Gas

Power Generation

Industrial

Infrastructure

Automotive

Food & Beverages

Others

Variable Frequency Drive Regional Outlook (Revenue, USD Billion, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Asia Pacific

China

Japan

India

South Korea

Australia

Latin America

Brazil

Middle East and Africa (MEA)

KSA

UAE

South Africa

Order a free sample PDF of the Variable Frequency Drive Market Intelligence Study, published by Grand View Research.

0 notes

Text

Thyristor Manufacturers in India: Powering Efficient Solutions

Thyristors, also known as Silicon-Controlled Rectifiers (SCRs), are integral components in modern electronic and electrical systems. These semiconductor devices are widely used for controlling power flow and ensuring efficiency in various industrial applications. India has emerged as a hub for thyristor manufacturing, thanks to its skilled workforce, advanced manufacturing facilities, and growing demand in sectors like power electronics, industrial automation, and renewable energy.

What Are Thyristors?

Thyristors are semiconductor devices that act as switches, allowing electrical current to flow in one direction when triggered. Their unique capability to handle high voltage and current makes them indispensable in applications such as:

Power conversion and rectification

Voltage regulation in power systems

Motor control in industrial machinery

Light dimming and heating controls

Their robustness and efficiency make them crucial in both consumer electronics and heavy industrial equipment.

India's Thyristor Manufacturing Landscape

India has become a prominent destination for thyristor manufacturing due to its strong engineering expertise, cost-effective production capabilities, and supportive government policies. Thyristor manufacturers in India cater to both domestic and international markets, offering high-quality products that meet global standards.

Key factors driving the growth of thyristor manufacturing in India include:

Industrial Growth: The rapid expansion of sectors such as power generation, electric vehicles, and renewable energy has increased the demand for thyristors.

Technological Advancements: Indian manufacturers are investing in cutting-edge technologies to produce thyristors with higher efficiency and reliability.

Export Opportunities: Indian thyristor manufacturers are gaining recognition globally, exporting their products to Europe, the Middle East, and Asia.

Applications of Thyristors

The versatility of thyristors makes them suitable for diverse applications. Here are some key areas where thyristors are indispensable:

Power Electronics: Thyristors are widely used in AC/DC conversion, voltage control, and power distribution systems.

Renewable Energy: In solar and wind energy systems, thyristors play a critical role in regulating power flow and integrating energy into grids.

Industrial Automation: Thyristors enable precise control of motors and machinery, ensuring efficient and reliable operations.

Transportation: They are used in electric trains and vehicles for power regulation and motor control.

Consumer Electronics: Thyristors are used in devices like air conditioners, refrigerators, and washing machines for efficient energy management.

Leading Thyristor Manufacturers in India

Several companies in India specialize in the design and production of thyristors, offering products tailored to various industrial needs. These manufacturers focus on quality, innovation, and customer satisfaction. Some prominent players include:

Bharat Heavy Electricals Limited (BHEL): Known for producing high-capacity thyristors for industrial applications.

Littelfuse India: Offers a wide range of thyristors for automotive and industrial sectors.

Powersem Semiconductors: Specializes in high-power thyristors for renewable energy systems.

Semikron India: Focuses on power modules and thyristors for industrial and transportation applications.

The Future of Thyristor Manufacturing in India

With the global shift toward renewable energy and energy-efficient technologies, the demand for thyristors is expected to grow significantly. Indian manufacturers are well-positioned to capitalize on this trend by:

Expanding Production Capacities: Increasing manufacturing output to meet rising domestic and international demand.

Investing in R&D: Developing advanced thyristors with improved performance and reliability.

Collaborating with Global Partners: Strengthening partnerships to enhance technological expertise and market reach.

Conclusion

Thyristors are vital components driving efficiency and reliability in modern electrical and electronic systems. The growing demand for these devices across various industries underscores their significance. Thyristor manufacturers in India are at the forefront of this transformation, offering world-class products that cater to diverse applications.

As India continues to evolve as a global manufacturing hub, the thyristor industry is poised for sustained growth, contributing to the nation’s industrial progress and global competitiveness. Whether for powering renewable energy systems or optimizing industrial machinery, Indian thyristor manufacturers are empowering solutions for a sustainable future.

0 notes

Text

The global Thyristor Market is projected to grow from USD 5,764 million in 2024 to USD 8,196.98 million by 2032, reflecting a compound annual growth rate (CAGR) of 4.5% over the forecast period.The thyristor, a key component in power electronics, has emerged as a cornerstone in applications requiring high voltage and current control. Its ability to handle significant power loads while ensuring efficiency has made it indispensable in industries such as automotive, energy, consumer electronics, and industrial manufacturing. The global thyristor market has seen robust growth over the past few years, driven by advancements in renewable energy systems, industrial automation, and the proliferation of electric vehicles (EVs).

Browse the full report https://www.credenceresearch.com/report/thyristor-market

Market Overview

Thyristors are semiconductor devices that act as electronic switches, controlling the flow of electricity in high-power applications. Key types of thyristors include:

SCR (Silicon Controlled Rectifier): Used in AC and DC systems.

GTO (Gate Turn-Off Thyristor): Widely employed in industrial and traction applications.

IGCT (Integrated Gate Commutated Thyristor): A high-performance option for power systems.

The global thyristor market was valued at approximately $4 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5–7% during 2024–2030. This growth is fueled by the increasing demand for efficient power control systems, the adoption of renewable energy, and the rise of electric mobility.

Key Growth Drivers

Proliferation of Renewable Energy Renewable energy sources like wind and solar heavily rely on thyristors for power conversion and grid integration. These devices ensure efficient energy transmission by stabilizing voltage fluctuations, making them critical to expanding renewable energy infrastructure.

Rise of Electric Vehicles (EVs) With the global shift towards sustainability, the demand for EVs is skyrocketing. Thyristors are integral in managing power within EV charging stations and motor control systems, contributing to their increased adoption in the automotive sector.

Industrial Automation The growing trend of automation in manufacturing and industrial processes necessitates precise control over high-power systems, a role thyristors are well-suited for. This demand is particularly evident in sectors like steel manufacturing, railways, and heavy machinery.

Infrastructure Development in Emerging Markets The rapid urbanization and industrialization of emerging economies like India and China are driving investments in power distribution and infrastructure projects. Thyristors are essential in these large-scale energy management systems.

Challenges

Despite its growth prospects, the thyristor market faces several challenges:

Competition from Alternative Technologies Advances in Insulated Gate Bipolar Transistors (IGBTs) and MOSFETs pose competition to thyristors in certain applications, particularly in lower power ranges.

High Initial Costs Implementing thyristor-based systems can involve significant upfront investment, which may deter adoption, especially in cost-sensitive markets.

Complex Manufacturing Processes Thyristors require precise fabrication techniques, leading to higher production costs and limiting market entry for new players.

Future Prospects

The future of the thyristor market is intertwined with the global push for sustainability. Key trends include:

Integration with Smart Grids: Thyristors will play a vital role in creating intelligent energy systems capable of balancing supply and demand efficiently.

Adoption of Advanced Materials: Innovations in silicon carbide (SiC) and gallium nitride (GaN) materials are expected to enhance thyristor performance, opening new possibilities for applications in harsh environments.

AI and IoT Integration: The integration of AI and IoT technologies in power systems will require high-performance thyristors for seamless operation.

Key Player Analysis:

STMicroelectronics

Vishay Intertechnology

Schneider Electric

TSMC

Sensata Technologies

ABB Ltd

Infineon Technologies AG

ON Semiconductor

Siemens AG

Honeywell International Inc.

Segmentations:

By Power Rating

500 MW

500 MW-1000 MW

1000 MW

By End Use

Consumer Electronics

Telecommunication & Networking

Industrial

Automotive

Aerospace & Defence

Others

By Geography

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report https://www.credenceresearch.com/report/thyristor-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Get Quality UL Panel Fabrication with Unmatched Precision!

We offer accurate UL panel fabrication services in North Carolina. Our experienced workforce provides quality, individualized panels as per acceptable industry practices. Contact Triune Electric at 252-237-0096 for more details.

#industrial ac/dc motor management#UL panel fabrication#UL panel fabrication service#plant ups systems#industrial control panel#industrial electrical distribution panels

0 notes

Text

Understanding the 5V Single Channel Relay Module

The 5V Single Channel Relay Module is an essential component for anyone interested in electronics. It acts as a switch that allows low-voltage control circuits to manage high-power devices safely. This tiny yet powerful module bridges the gap between the world of microcontrollers and heavy-duty electrical loads.

Whether you are a hobbyist or a professional, understanding the 5V Single Channel Relay Module is vital for controlling appliances, lights, or even industrial systems.

How Does a 5V Single Channel Relay Module Work?

This module uses a 5V DC signal from a microcontroller, like Arduino or Raspberry Pi, to activate an electromagnetic switch. This switch can control higher voltage devices like AC motors, fans, or lamps.

The module typically has:

Input Pins: These receive signals from the microcontroller.

Output Terminals: These connect to the high-power device.

Optocoupler: Ensures electrical isolation for safety.

Indicator LED: Shows when the relay is active.

By understanding these components, you can confidently incorporate the module into various projects.

Applications of the 5V Single Channel Relay Module

The 5V Single Channel Relay Module is widely used in:

Home Automation: Control lights, fans, and other appliances remotely.

Industrial Systems: Manage heavy machinery with precision.

IoT Projects: Connect your devices to the internet and control them via apps.

Educational Kits: Help students learn the fundamentals of electronics.

This versatility makes the module an indispensable tool in modern electronics.

Setting Up a 5V Single Channel Relay Module

To get started, follow these steps:

Gather Your Components:

A 5V Single Channel Relay Module.

A microcontroller (e.g., Arduino).

Jumper wires and a breadboard.

Connect the Relay Module:

Attach the input pins to the microcontroller.

Connect the output terminals to your high-power device.

Write a Program: Use a simple Arduino sketch to send signals to the relay module.

Test Your Setup: Ensure all connections are secure and run your program. The relay should click as it switches.

Safety Tips for Using the 5V Single Channel Relay Module

Working with high-voltage devices can be dangerous. Follow these safety tips:

Always double-check your connections.

Use insulated tools to avoid accidental shocks.

Test your setup with low-power devices before scaling up.

Keep water and conductive materials away from your workspace.

With proper precautions, the 5V Single Channel Relay Module is safe and reliable.

Troubleshooting Common Issues

If your 5V Single Channel Relay Module is not working, consider these solutions:

Check Power Supply: Ensure your module is receiving 5V DC.

Verify Connections: Loose wires can disrupt functionality.

Inspect the Code: Errors in your program might prevent the relay from activating.

Test the Module: Replace it with a spare to rule out hardware issues.

Patience and systematic troubleshooting will solve most problems.

Advanced Uses of the 5V Single Channel Relay Module

For advanced users, this module can be combined with:

Sensors: Automate actions based on temperature, light, or motion.

Wi-Fi Modules: Create smart home devices controllable via smartphones.

Custom PCBs: Design dedicated circuits for specific applications.

By experimenting with these ideas, you can push the limits of what this module can do.

Conclusion

The 5V Single Channel Relay Module is a simple yet powerful tool in electronics. It allows you to control high-voltage devices safely and efficiently, opening up endless possibilities for automation and innovation.

Whether you are new to electronics or a seasoned expert, this module is a must-have in your toolkit. Start exploring its capabilities today and take your projects to the next level.

1 note

·

View note

Text

Inverter and Transformer: Essential Components for Efficient Power Conversion

Inverters and transformers are fundamental components in modern electrical and industrial systems, ensuring efficient power conversion, voltage regulation, and seamless energy distribution. At Danish Pvt Ltd, we specialize in manufacturing high-performance inverters and transformers for various applications, including renewable energy, industrial power solutions, and commercial infrastructure.

Understanding Inverters and Transformers

What is an Inverter?

An inverter is an electronic device that converts DC (Direct Current) power into AC (Alternating Current) power. It is widely used in solar power systems, UPS (Uninterruptible Power Supply), and industrial automation to provide reliable and efficient power conversion.

Types of Inverters:

Grid-Tied Inverters – Used in solar power plants to convert DC from solar panels into AC for the grid.

Off-Grid Inverters – Suitable for standalone power systems in remote locations.

Hybrid Inverters – Smart inverters that store and manage power from solar panels and batteries.

Industrial Inverters – Used in automation, motor control, and variable frequency drives (VFDs).

What is a Transformer?

A transformer is an electrical device that steps up or steps down voltage to ensure efficient power transmission and distribution. It plays a crucial role in power plants, substations, industrial machinery, and renewable energy systems.

Types of Transformers:

Power Transformers – Used in high-voltage transmission systems to transfer power over long distances.

Distribution Transformers – Reduces voltage for commercial and industrial applications.

Inverter Duty Transformers – Specially designed for solar and wind energy applications.

Isolation Transformers – Protects sensitive electrical equipment from voltage fluctuations.

Control Transformers – Provides stable voltage for control circuits in industrial machines.

Inverter Transformers: The Perfect Combination

An inverter transformer is a key component in power conversion systems, especially in solar plants, UPS systems, and industrial automation. It works by isolating the DC and AC circuits, ensuring voltage regulation, electrical safety, and efficiency.

Applications of Inverter Transformers:

Solar Energy Systems – Converts DC power from solar panels into AC for grid or off-grid use.

UPS & Backup Power Systems – Ensures uninterrupted power supply during outages.

Electric Vehicles (EVs) – Helps in charging and power distribution for EV systems.

Industrial Automation – Supports VFDs and motor control applications.

Key Features of Our Inverters & Transformers

High Efficiency & Low Losses – Ensures maximum power conversion.

Advanced Insulation & Protection – Enhances durability and safety.

Smart Monitoring & IoT Integration – Enables remote monitoring and automation.

Customizable Voltage & Power Ratings – Tailored for specific industrial needs.

Global Standards Compliance – IEC, IS, ANSI, and BIS-certified.

Industries We Serve

Renewable Energy (Solar & Wind Power) – High-performance inverters & transformers for efficient energy conversion.

Power Generation & Distribution – Reliable voltage control for industrial and commercial applications

Commercial & Industrial Automation – Power solutions for machinery, UPS, and automation systems.

Electric Vehicle Infrastructure – Efficient charging and power distribution solutions.

Telecommunications & Data Centers – Ensures stable power supply for critical operations.

Why Choose Danish Pvt Ltd for Inverters & Transformers?

Industry Expertise – Decades of experience in power electronics and transformers.

Energy-Efficient Designs – Reducing energy wastage and improving performance.

Custom-Built Solutions – Tailored to meet industrial and commercial power needs.

Premium Quality Materials – High-grade copper windings and advanced insulation.

24/7 Technical Support & Maintenance – Ensuring uninterrupted operations.

Conclusion

Inverters and transformers are vital for efficient power management, renewable energy integration, and industrial automation. At Danish Pvt Ltd, we provide customized, high-performance solutions to meet the growing energy demands of various industries.

0 notes

Text

The Evolution and Importance of Industrial SMPS and Power Converters in Modern Industries

What are Industrial SMPS and Power Converters?

Industrial SMPS, or Switch Mode Power Supplies, are power supply units designed to provide a regulated output voltage or current by switching the power on and off at high frequencies. Unlike traditional power supplies, Industrial Smps are more efficient, compact, and versatile, making them ideal for industrial applications where space and energy efficiency are paramount.

On the other hand, power converters are devices that convert electrical energy from one form to another. These can include converting AC (alternating current) to DC (direct current), DC to AC, or even altering voltage levels. Power converters are indispensable in applications ranging from renewable energy systems to electric vehicles.

The Role of Industrial SMPS in Modern Industries

Industrial SMPS are vital in ensuring stable power delivery in environments with varying voltage conditions. They are widely used in:

Automation Systems: Factories with robotic assembly lines rely heavily on SMPS to maintain consistent energy supply for precise operations.

Telecommunication Equipment: Stable power is crucial for uninterrupted communication, and Industrial SMPS provide the reliability needed for such systems.

Medical Devices: In the healthcare sector, SMPS are used in imaging devices, patient monitoring systems, and diagnostic machines, where power stability is critical.

Industrial SMPS not only enhance energy efficiency but also contribute to reducing operational costs. Their ability to operate over a wide input voltage range makes them ideal for use in industries with fluctuating power supplies.

Applications of Power Converters

Power converters play an equally significant role in industries. Their applications include:

Renewable Energy Systems: Solar panels and wind turbines use power converters to convert generated power into usable electricity for grids or storage systems.

Electric Vehicles (EVs): In EVs, power converters are used to manage energy between batteries and motors, optimizing performance and extending battery life.

Consumer Electronics: Power converters are integral in gadgets like laptops, smartphones, and home appliances for efficient power management.

Innovations Driving the Future

Recent advancements in Industrial SMPS and power converters are paving the way for smarter and more efficient systems. Innovations such as gallium nitride (GaN) and silicon carbide (SiC) semiconductors are making these devices more compact and energy-efficient. Furthermore, the integration of IoT in power systems allows real-time monitoring and predictive maintenance, enhancing operational efficiency.

Why Industries Must Adopt Advanced Power Solutions

With rising energy demands and a growing emphasis on sustainability, adopting advanced power solutions like Industrial SMPS and Power Converters is no longer optional. They enable industries to achieve higher efficiency, reduce energy waste, and meet environmental standards. Additionally, their reliability ensures minimal downtime, which is crucial in sectors like manufacturing and healthcare.

In conclusion, Industrial SMPS and Power Converters are not just tools but essential pillars that uphold the functionality and progress of modern industries. Their continuous evolution signifies a promising future where industries can thrive with smarter, more sustainable power solutions. Embracing these technologies is key to staying competitive in an ever-changing industrial landscape.

0 notes

Text

AC-DC Power Supply Adapter Market Regional Analysis, Key Players, Segments, Development, Opportunities, Forecast to 2032

Global AC-DC Power Supply Adapter Market Overview (2024-2032)

The global AC-DC Power Supply Adapter market has been demonstrating consistent growth, driven by increasing demand across key sectors such as automotive, industrial, and consumer electronics. The market was valued at USD 65.3 billion in 2023 and is projected to grow from USD 69.4 billion in 2024 to USD 99.9 billion by 2032, representing a compound annual growth rate (CAGR) of 6% during the forecast period from 2024 to 2032. This growth is largely attributed to the expanding automobile industry and advances in AC-DC Power Supply Adapter technology, which are reshaping industries and driving adoption.

Get FREE Sample Report:

Market Dynamics

Key Growth Drivers

Rapid Expansion of the Automobile Industry: The global automotive industry is witnessing rapid expansion, particularly in the areas of electric vehicles (EVs) and autonomous vehicles (AVs). AC-DC Power Supply Adapters are critical components in EVs, playing an essential role in controlling power supply, managing electric powertrains, and regulating motor drives. With the increasing popularity of EVs and a strong push from governments toward reducing carbon emissions, the AC-DC Power Supply Adapter market is set to grow significantly in the coming years.

Technological Advancements in Automotive Systems: Innovations such as x-by-wire and drive-by-wire technologies are gaining traction in modern vehicles. These technologies replace traditional mechanical and hydraulic systems with electronic controls, which not only reduce vehicle weight but also enhance fuel efficiency and lower emissions. AC-DC Power Supply Adapters are at the core of these technologies, helping enable precise control of functions such as steering, braking, and throttle. As automakers continue to adopt advanced power management systems, the demand for AC-DC Power Supply Adapters is expected to increase substantially.

Rising Adoption in Renewable Energy and Industrial Applications: The transition toward renewable energy sources, such as wind and solar power, is further boosting the demand for AC-DC Power Supply Adapters. These components are used in inverters and power converters, which are crucial for converting renewable energy into usable electricity. Moreover, in industrial applications, AC-DC Power Supply Adapters are used in various automation solutions, from power distribution systems to motor drives, further driving market growth.

Challenges

Despite the positive growth outlook, the AC-DC Power Supply Adapter market faces certain challenges. Fluctuations in raw material prices and the high costs associated with the development of advanced semiconductor technologies can impact the market. Additionally, the complexity of designing AC-DC Power Supply Adapters that meet stringent efficiency standards and regulatory requirements poses challenges for manufacturers.

The semiconductor supply chain is also vulnerable to disruptions. In recent years, geopolitical tensions and pandemic-induced supply chain disruptions have led to a shortage of semiconductor components, impacting production timelines and driving up costs. However, increasing investments in domestic semiconductor manufacturing facilities and the establishment of partnerships to secure supply chains are helping to mitigate these issues.

Market Segmentation

The AC-DC Power Supply Adapter market is segmented based on type, material, application, and region.

By Type:

Discrete Semiconductors: Including diodes, transistors, and thyristors. These components are commonly used in power conversion and motor control applications.

Power Modules: Power modules integrate multiple AC-DC Power Supply Adapter devices into a single unit, offering higher power handling capability and efficiency.

Power Integrated Circuits (ICs): Power ICs combine several power components into a single chip, often used in consumer electronics and energy-efficient applications.

By Material:

Silicon: The most widely used material for AC-DC Power Supply Adapters due to its well-established manufacturing processes and cost-effectiveness.

Silicon Carbide (SiC): Offers advantages in high-voltage and high-temperature applications, making it suitable for EVs and renewable energy systems.

Gallium Nitride (GaN): Emerging as a promising material for high-frequency applications, with potential benefits in EV chargers and power adapters.

By Application:

Automotive: Includes EVs, hybrid electric vehicles (HEVs), and advanced automotive systems like x-by-wire.

Consumer Electronics: AC-DC Power Supply Adapters are used in power supplies, battery chargers, and energy-efficient appliances.

Renewable Energy Systems: Widely used in solar inverters, wind turbines, and energy storage systems.

Industrial: Applications include motor drives, power distribution systems, and industrial automation equipment.

Regional Analysis

The AC-DC Power Supply Adapter market is witnessing significant growth across all major regions, with strong demand coming from Asia-Pacific, North America, and Europe.

Asia-Pacific: The Asia-Pacific region is expected to dominate the AC-DC Power Supply Adapter market during the forecast period. This growth is driven by a high concentration of automotive manufacturers in China, Japan, and South Korea, coupled with rapid industrialization and the growing adoption of renewable energy sources. The region's strong electronics manufacturing base also contributes to increased demand for AC-DC Power Supply Adapters.

North America: North America is witnessing significant growth due to the increasing adoption of electric vehicles and advancements in renewable energy infrastructure. The presence of leading automotive companies and a strong focus on energy efficiency initiatives are driving the demand for AC-DC Power Supply Adapters in this region.

Europe: Europe has emerged as a key market for AC-DC Power Supply Adapters, primarily driven by the region's stringent emission regulations, government incentives for EV adoption, and investment in renewable energy projects. The emphasis on sustainability and the ongoing shift towards clean energy are expected to propel market growth in Europe.

Competitive Landscape

The global AC-DC Power Supply Adapter market is highly competitive, with numerous established players and new entrants vying for market share. Key companies include:

Infineon Technologies AG: A leading player in the AC-DC Power Supply Adapter market, Infineon focuses on automotive and industrial applications, offering a range of power modules and discrete components. The company's innovations in SiC and GaN power devices are helping it maintain a competitive edge in high-performance applications.

ON Semiconductor: ON Semiconductor offers a comprehensive portfolio of power solutions targeting automotive, industrial, and consumer electronics applications. The company's focus on energy efficiency and electrification aligns well with the growing demand for AC-DC Power Supply Adapters in the automotive sector.

STMicroelectronics: Known for its power ICs and power modules, STMicroelectronics caters to various industries, including automotive and renewable energy. The company is expanding its presence in the EV market by developing SiC-based solutions for high-efficiency power management.

Mitsubishi Electric Corporation: Mitsubishi Electric focuses on power modules and discrete semiconductors for automotive and industrial applications. The company's expertise in SiC technology positions it well for growth in the electric vehicle and renewable energy sectors.

These companies are investing in R&D to develop advanced AC-DC Power Supply Adapter materials, such as silicon carbide and gallium nitride, which offer superior efficiency and performance. Strategic partnerships, mergers, and acquisitions are also being pursued to expand market presence and enhance product portfolios.

Future Outlook

The AC-DC Power Supply Adapter market is poised for robust growth, driven by the increasing adoption of electric vehicles, renewable energy systems, and industrial automation. The shift towards electrification in transportation and energy efficiency in industrial and consumer sectors will further fuel demand for AC-DC Power Supply Adapters. Technological advancements in SiC and GaN materials are expected to provide new growth opportunities, enabling more efficient power conversion and management across various applications.

As governments and industries prioritize sustainability and energy efficiency, the demand for AC-DC Power Supply Adapters is expected to continue rising. The focus on developing more efficient and compact power management solutions will play a crucial role in driving the market, providing opportunities for innovation and growth.

Get Related Reports:

United States Industrial Control and Factory Automation Market

Asia Pacific Agriculture Drones Market

3D Camera Market

Contactless Connector Market

Semiconductor Cleanroom Consumable Market

0 notes

Text

DC Compressors: Essential Technology for Modern Cooling Solutions

As energy efficiency and environmental concerns take center stage, industries worldwide are shifting toward more sustainable technologies. One key innovation in refrigeration and HVAC systems is the DC compressor, a powerful, efficient alternative to traditional compressors. DC compressors are designed to optimize performance while reducing energy consumption, making them ideal for a range of applications, from portable refrigerators to large-scale cooling systems. In this article, we’ll explore how DC compressors work, their advantages, and why they’re a vital technology for modern cooling solutions.

What is a DC Compressor?

A DC compressor is a type of compressor that runs on direct current (DC) power, as opposed to traditional alternating current (AC) compressors. DC compressors are particularly well-suited for applications where variable speed control, energy efficiency, and compact size are prioritized. By utilizing DC power, these compressors can operate more efficiently, reduce power consumption, and deliver enhanced cooling performance even under varying loads.

How DC Compressors Work

DC compressors use an inverter to convert the direct current from a power source (like a battery or solar panel) into the necessary voltage for the compressor motor. This inverter technology allows the compressor to adjust its speed based on the cooling demand. Unlike AC compressors, which operate in an on/off cycle, DC compressors can vary their speed to match the exact cooling needs, leading to smoother operation, reduced wear, and energy savings.

Common Applications of DC Compressors

DC compressors are versatile and used across several industries:

Refrigeration units in vehicles, marine vessels, and RVs

Portable cooling systems like mini-fridges and camping coolers

Solar-powered refrigerators for off-grid or sustainable applications

Commercial and residential HVAC systems that require energy-efficient solutions

Medical cold storage for precise temperature management

Advantages of DC Compressors

DC compressors offer numerous benefits, making them ideal for today’s energy-conscious and performance-focused applications.

1. Energy Efficiency

One of the standout features of DC compressors is their ability to reduce energy consumption. By adjusting speed based on the actual cooling demand, DC compressors operate more efficiently than traditional models, which consume a constant amount of energy regardless of the workload. In turn, this reduces power bills and environmental impact, which is especially beneficial in applications powered by renewable energy sources like solar.

2. Variable Speed Operation

DC compressors can vary their speed, allowing them to run at slower speeds when cooling demand is low and increase speed when more power is needed. This results in a more consistent temperature, reduces compressor wear and tear, and ultimately extends the compressor’s lifespan.

3. Compact Design and Lightweight

Due to their efficient use of power and optimized design, DC compressors are typically more compact and lightweight than AC models. This makes them a popular choice for mobile or space-constrained applications, such as in vehicles or portable cooling units, where space and weight are at a premium.

4. Low Noise Levels

Since DC compressors adjust their speed according to demand, they tend to operate more quietly than traditional compressors that cycle on and off. This makes DC compressors a preferred choice for applications in noise-sensitive environments, such as residential settings, medical facilities, and mobile cooling units.

5. Eco-Friendly Performance

With their lower energy consumption and efficient operation, DC compressors help reduce carbon emissions, making them a more environmentally friendly choice. When paired with renewable energy sources, such as solar power, they enable fully sustainable cooling solutions, further minimizing their environmental impact.

Why DC Compressors are Essential for Modern Cooling Solutions

As more industries and consumers prioritize sustainable, energy-efficient technologies, DC compressors are becoming a cornerstone of modern cooling solutions. Their adaptability, energy efficiency, and low environmental footprint make them suitable for a range of applications where traditional compressors may fall short.

Growing Demand for Off-Grid and Solar-Powered Applications

With a rise in off-grid living and the increasing adoption of renewable energy, the demand for solar-powered DC compressors is growing. DC compressors can efficiently run on solar power, making them ideal for remote areas, mobile homes, and other off-grid locations where consistent, efficient cooling is crucial. Their ability to operate directly on DC power sources without requiring conversion also makes them more efficient for solar-powered systems, maximizing the use of available energy.

Enhanced Temperature Control for Sensitive Applications

DC compressors’ variable speed capability makes them well-suited for applications that require precise temperature management, such as medical storage and laboratory refrigeration. By maintaining a stable internal temperature, DC compressors help ensure that sensitive items, such as pharmaceuticals and biological samples, are stored safely and consistently.

Essential for Portable and Mobile Cooling Needs

Due to their compact size, low power requirements, and efficient operation, DC compressors are ideal for mobile applications. Whether cooling food and beverages on a long haul or keeping perishable items fresh in a camper or boat, DC compressors deliver reliable performance that’s crucial for portable cooling solutions. Additionally, their reduced weight and quiet operation make them highly practical for mobile environments.

DC Compressors by Huayi: Powering Reliable Cooling

As a leading provider of advanced compressor solutions, Huayi Compressors has made significant strides in DC compressor technology, offering models designed to meet the specific demands of various industries. Huayi’s DC compressors are known for their durability, performance, and energy efficiency, making them a trusted choice for both commercial and residential applications.

Huayi’s DC compressors come equipped with advanced features such as:

High-performance inverter technology for precise speed control

Low-voltage startup options, perfect for battery or solar-powered systems

Durable and compact design to fit a wide range of cooling setups

Enhanced energy savings without compromising on cooling power

With their focus on quality and innovation, Huayi DC compressors provide clients with reliable, efficient cooling solutions that align with modern energy and environmental standards.

Conclusion

DC compressors are transforming the cooling industry by offering a more efficient, adaptable, and eco-friendly solution for diverse applications. Whether in solar-powered setups, portable refrigeration, or precise medical storage, DC compressors offer the advanced performance and flexibility needed in today's energy-conscious world. By choosing high-quality DC compressors from reputable manufacturers like Huayi Compressors, industries can achieve reliable cooling while minimizing their environmental footprint and energy costs. As DC compressor technology continues to advance, it will play an increasingly important role in shaping the future of cooling solutions.

0 notes