#inductor circuit

Text

Capacitor blocks DC

and

Inductor blocks AC

4 notes

·

View notes

Text

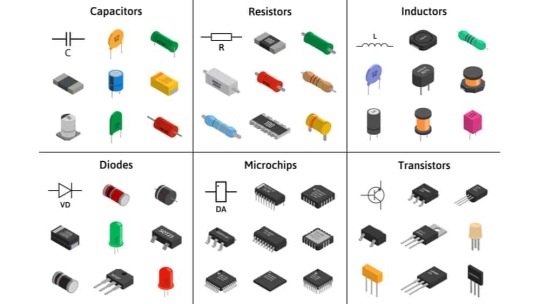

Analysis of the functions of commonly used electronic components

I published an article about "The Role of Commonly Used Electronic Components", welcome to check it out!

Article address: https://www.dhsic.com/news/98

#Electronic components function#Function of components#Electronic Component#Resistor#capacitor#Inductor#Semiconductor device#integrated circuit#microcontroller#sensor#display device

0 notes

Text

What Are Thin Film Chip Inductors?

Thin film chip inductors are a type of inductor manufactured using thin film technology. The manufacturing process involves depositing thin film materials on a substrate and forming a spiral coil, allowing the inductor to achieve a more compact and lightweight design. This design makes thin film chip inductors an ideal component in electronic devices.

Get more details: Thin Film Chip Inductors

#electronics#integrated circuits#semiconductor#components#electronic#module#electronic devices#chips#manufacturing#inductors

0 notes

Text

BTA16 Series 600 Vdrm 16 A Flange Mount Standard Triac Thyristor - TO-220AB

#Circuit Protection Devices#Protection Thyristors#BTA16-600BRG#STM#Power thyristors#Electrical power systems#Silicon controlled rectifier#triac thyristor#Thyristor controlled inductor#Applications for thyristors#triac thyristor circuits#Types of Power Thyristors#Current controller

1 note

·

View note

Text

A circle with an A in it means that the circuit has committed a sin and has been marked as punishment.

Circuit Symbols [Explained]

Transcript Under the Cut

[A chart of various circuit symbols and their (mostly) ficticious meanings based off of their drawings, captioned:] Circuit Symbols

[The symbol for a switch, labelled:] Drawbridge

[The symbol for a capacitor, labelled:] Overpass

[The symbol for a connection to ground, labelled:] Pogo Stick

[The symbol for a resistor, labelled:] Earthquake

[The symbol for an inductor, labelled:] Sheep

[The symbol for a transformer, labelled:] Two Sheep in Love, Trapped on Opposite Sides of a Fence

[The symbol for a battery, labelled:] Battery

[The symbol for a battery, sorted, labelled:] Baertty

[The symbol for a battery, with far too many short lines, labelled:] Battttttttttttery

[The symbol for a photodiode, labelled:] Check Out This Really Cool Diode

[The symbol for a Oscillattor, labelled:] Wave Pool

[The symbol for a Transistor, labelled:] Trolley Problem

1K notes

·

View notes

Text

Conn - Multi-Vider

"All the way back in 1967, C.G. Conn wanted in on the decidedly nascent effects scene, and they wanted to do so with a bang. The company partnered with Jordan Electronics of Alhambra, CA to release an octave effect for wind instruments. The resulting circuit is a truly interesting piece of gear history. It needs to be said that Conn went into manufacturing, thereby ending its partnership with Jordan (at least according to all the paperwork) and the result was two different MultiViders. The differences on the surface are minute: the first model is grey and looks like a piece of dictation equipment, offering “bright” and “dark” input modes, a top-mounted Sensitivity control, and a plethora of battery gadgets. By contrast, the much cooler-looking model “914” did away with the frequency selector, opting for a switch called Unison and a power supply input.

Both models contain “Soprano,” “Bass” and “Sub Bass” switches, and corresponding volume for each. The 914’s Unison mode is essentially a dry signal control. The “grey box” model is a little more convoluted about it but the job is effectively identical. However, the way these two models go about these identical tasks in different—yet similar—ways.

This original “grey box” model contains a duo of ersatz flip-flop circuits, which the unit relies on for its octave down effects. The circuit utilizes some rather intense gain staging to convert the signal to a crude square wave and then use the flip-flops to divide the frequency in half and then in half again. In the later 914 model, much of this circuit is switched to a CD4013 chip, an all-in-one CMOS device. It’s interesting that the first draft of the MultiVider contains what amounts to a discrete imagining of the CD4013, and what it all adds up to is the first-ever octave effect for an electronic instrument. There’s also a wah inductor on the 914, which is connected to the sub-octave circuit somehow; I dare not remove the board due to extreme rocker switch fragility. I love stuff like this.

For as cool as this whole thing sounds, there are some drawbacks, as one might expect with the first pedal of any type. As previously stated, the MultiVider is a horns-only instrument, as is to be used with Conn’s proprietary woodwind pickup. While the “grey box” model serves up a battery option, the 914 is adapter-only, and it’s a doozy—only a 12-volt eighth-inch style phone plug will do. Thankfully there are workarounds for both; if you can solder, the power situation is a cinch and the microphone issue can be circumnavigated by hitting the MultiVider with a hotter input signal. Even then, a large belt clip on the back of the unit dictates its preferred method of implementation. With all that said, synth players are at an automatic advantage with modernizing the MultiVider.

Of course, the MultiVider was an advanced device for its time, and so it was used by artists that had explored brass instruments to their fullest. In particular, the MultiVider was used by Zappa’s band, the Mothers of Invention. It was also used by Miles Davis on 1970’s The Complete Jack Johnson Sessions. Of course there are others, but with a resume like that, stick to your strengths."

cred: catalinbread.com/blogs/kulas-cabinet/conn-multivider

28 notes

·

View notes

Text

Be sure to thank your components for doing a good job. Thank your resistors for protecting everything in the circuit. Tell your capacitors that they're doing a good job maintaining voltage. Reassure your inductors that they're regulating current well. They deserve it

42 notes

·

View notes

Text

8/100

notes on ac circuits with inductors, capacitors, and resistors featuring my laptop and many stickers

#ocean.txt#.img#100 days of productivity#100 dop#100dop#study#studyblr#studying#studyspo#physicsblr#physics#stemblr

22 notes

·

View notes

Text

What Are SMD Inductors?

SMD inductors, also known as surface mount inductors, are components embedded in circuit boards using Surface Mount Technology (SMT). Unlike traditional through-hole inductors, SMD inductors are better suited for highly integrated circuit boards and automated production processes. Their characteristics of being compact, lightweight, and high-performing make them an indispensable part of modern electronic devices.

Get more details: SMD Inductors

#electronics#integrated circuits#semiconductor#components#electronic#module#package#electronic devices#chips#manufacturing#inductor#SMD#SMT#inductors

0 notes

Note

Give me your latest cool physics fact you learned.

Don't hesitate to hold back the mathematics if need be.

OOOH thanks for the question!!! Okay I had to think about this for a while but I've been fascinated lately by the fact that capacitors have inductance, and vice versa (inductors have an associated capacitance) which makes sense in hindsight, but I think I thought it was really neat bc it drives home the fact that circuit elements aren't fundamentally different, they're just optimized for a specific function (as is everything else, I suppose)

2 notes

·

View notes

Text

What is PCB Assembly ?

PCB Assembly manufacturer - Hitech Circuits Co., Limited

It’s the step in the manufacturing process in which you populate a blank board with the electronic components needed to make it into a functional printed circuit board. It’s these components that make a board into the circuit that enables an electronic product to function. PCB assembly typically takes place via one of two processes:

1. Surface-mount technology

SMT: SMT stands for “Surface Mount Technology“. The SMT components are very small sizes and comes in various packages like 0201, 0402, 0603, 1608 packages for resistors and capacitors. Similarly for Integrated circuits ICs we have SOIC, TSSOP, QFP and BGA.

The SMT components assembly is very difficult for human hands and can be time taking process so it is mostly done by automated pick and place machine.

2. Through-hole manufacturing

THT: THT stands for “Through hole Technology”. The components with leads and wires, like resistors, capacitors, inductors, PDIP ICs, transformers, transistors, IGBTs, MOSFETS are example.

The component has to be inserted on one side of PCB and pulled by leg on other side and cut the leg and solder it. The THT components assembly is usually done by hand soldering and is relatively easy.

Printed Circuit Board Assembly Techniques

There are only two common PCBA techniques available for use by a PCB designer. The methods are:

1. Automated PCB Assembly Techniques

Generally, this technique employs the use of state of the art machines, which are fully automatic. For example, the surface mount components are worth positioning with the aid of an automated pick and place machine.

Again, reflow soldering is commonly for surface mount components usually done in a reflow oven. An automated solder stencil is also used to apply the solder paste on the PCB.

Finally, high tech inspection machines are used to confirm and check the quality of the PCBA. Some of which include: Automated optical inspection machine (AOI), X-ray inspection machines, etc.

Above all, due to the precise monitoring, control of soldering, no human input and versatile machines.

This technique ensures utmost efficiency, output consistencies, and limits defects.

2. Manual PCB Assembly Techniques

This method is favorite for use with through-hole parts, which needs manual placement on the board. Besides, with these through-hole parts, it’s advisable you use wave soldering. Note that in the through- hole assembly process, you need to place the components and electronics on the PCB.

After that, you use wave soldering to solder the leads. Typically, you will need an individual to insert a component into a marked PTH. Once done, transfer the PCB to the next station where the next person will be on standby tasked with fixing another part.

What are the Benefits of SMT PCB Assembly?

SMT assembly provides many benefits and some of them are as follows:

It can be used to incorporate small components.

In SMT, the components can be placed on both sides of the board.

It assures high component densities.

Fewer holes need to be drilled for surface mounting than through-hole.

It require low initial costs and time for setting up the mass production.

SMT is the simpler and faster-automated assembly when compared to through-hole.

Errors regarding the component placement can be easily rectified.

Surface mount PCBs feature strong joints, which can easily withstand vibrations.

What are the techniques used in Surface Mount Technology?

There are several techniques for the reflow process. After applying the solder paste or a flux mixture on the board and after placing the components, the boards are conveyed to a reflow soldering oven. The techniques used for reflowing soldering include infrared lamps, hot gas convection, fluorocarbon liquids with a high boiling point, and so on.

What are the different testing methods used in SMT PCB Assembly?

Hitech Circuits as the PCB assembly manufacturer, we perform the following testing and inspection to ensure the quality of surface mount PCBs.

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

What type of files or documents should I send for SMT PCB Assembly?

Gerber Files: The file contains all details of physical board layers including solder masks, copper layers, drill data, legends, and so on.

Bill of Materials (BOM): This contains information on the list of items needed for the PCB manufacturing and the instructions of manufacturing.

Pick and Place File: This file contains information on all components to be used in the PCB design and their rotation and X-Y coordinates.

The whole process of PCB Assembly

1. Bare board loader machine

The first step in the PCB assembly is to arrange the bare boards on the rack, and the machine will automatically send the boards one by one into the SMT assembly line.

2. Printing solder paste

When PCB on the SMT production line, firstly, we have to print solder paste on it, and the solder paste will be printed on the pads of the PCB. These solder pastes will be melt and solder the electronic parts to the circuit board when it passes through the high-temperature reflow oven.

In addition, when testing new products, some people will use film board/adhesive cardboard instead of solder paste, which can increase the efficiency for adjusting the SMT machines.

3. Solder paste inspection machine(SPI)

Since the quality of solder paste printing is related to the quality of welding of subsequent parts, some SMT factories will use optical machine to check the quality of solder paste after printed the solder paste in order to ensure stable quality. If there any poorly printed solder paste board, we will wash off the solder paste on it and reprint, or remove the excess solder paste if there is redundant solder paste on it.

4. High speed SMT machine

Usually, we will put some small electronic parts (such as small resistors, capacitors, and inductors) to be printed on the circuit board first, and these parts will be slightly stuck by the solder paste just printed on the circuit board, so even if the speed of printing is very fast and the parts on the board will not fall away. But large parts are not suitable for use in such high speed SMT machines, which will slow down the speed of small parts assembly. And the parts will be shifted from the original position due to the rapid movement of the board.

5. Universal SMT machine

Universal SMT machine is also known as "slow machine", it will be assembled some large electronic components, such as BGA IC, connectors, etc., these parts need more accurate positions, so the alignment is very important. Use a camera to take a picture to confirm the position of the parts, so the speed is much slower than High speed SMT machine we taked before. Due to the size of the components here, not all of them are packed in tape and reel, and some may be packed in trays or tubes. But if you want the SMT machine to recognize the trays or tube-shaped packaging materials, you must configure an additional machine.

Generally, traditional SMT machines are using the principle of suction to move electronic parts, and in order to place the parts successfully, and there must be the flat surface on these electronic components for the suction nozzle of the SMT machine to absorb. However, for some electronic parts don’t have a flat surface for these machines, and it is necessary to order special nozzles for these special-shaped parts, or add a flat tape on the parts, or wear a flat cap for thees electronic parts.

6. Manual parts or visual inspection

After assembled all parts by the high speed SMT machine or Universal SMT machine and before going through the high-temperature reflow oven, and we will set up a visual inspection station here and to pick out the deviation parts or missing components boards etc., because we have to use a soldering iron to repair if there are still defectives boards after passing the high-temperature oven, which will affect the quality of the product and will also increase the cost. in addition, for some larger electronic parts or traditional DIP parts or some special reasons cannot be processed by the SMT machine before, they will be manually placed on pcb here.

7. Reflow oven

The purpose of reflow oven is to melt the solder paste and form a non-metallic compound on the component feet and the circuit board, that means to solder electronic components on the circuit board. The temperature rise and fall curves often affect the soldering quality of the entire circuit board. According to the characteristics of the solder materials, usually the reflow oven will set the preheating zone, soaking zone, reflow zone, and cooling zone to achieve the best soldering effect.

For example, the melting point for SAC305 solder paste with lead-free is about 217°C, which means that the temperature of the reflow oven must be higher than the melting points to remelt the solder paste. What's more, the maximum temperature in the reflow furnace should not exceed 250°C, otherwise many parts will be deformed or melted because they cannot withstand such a high temperature.

Basically, after the pcb passed through the reflow oven, the assembly for the entire circuit board is almost complete. If there are hand-soldered parts, we need to transfer to DIP process, and then we have to check the quality after reflow oven by QC department.

8. Automatic optical inspection(AOI)

The main purpose of setting up AOI is because some high density boards can’t be process the following ICT test, so we used AOI inspection to replace it. But even using AOI inspections, there still have the blind spots for such checking, for example, the solder pads under the components cannot be checked by AOI. At present, it can only check whether the parts have side standing issue, missing parts, displacement, polarity direction, solder bridges, lack of soldering etc., but cannot checking the BGA solderability, resistance value, capacitance value, inductance value and other components quality, so far AOI inspection can’t completely replace ICT test.

Therefore, there is still some risk if only AOI inspection is used to replace ICT testing, but ICT test is also not 100% make sure the good quality, we suggest these two ways can be combined with together to make sure the good quality.

9. PCB unloader machine

After the board is fully assembled, it will be retracted to the unloder machine, which has been designed to allow the SMT machine to automatically pick and place the board without damaging the quality for PCB.

10. Visual inspection for finished products

Normally there will be a visual inspection area in our SMT production line whether there is an AOI station or not, and it will help to check if there are any defectives after completed assembled the pcbs. If there is an AOI station, it can reduce the visual inspection worker on our SMT line, and to reduce the potential cost, and because it is still necessary to check some places that cannot be judged by AOI, many SMT factories will provide the mainly visual inspection templates at this station, which is convenient for visual inspection worker to inspect some key parts and polarity for components.

11. DIP process

DIP process is a very important process in the whole PCBA processing, and the processing quality will directly affect the functional for PCBA boards, so it is necessary to pay more attention to the DIP process. There are many preliminary preparations for DIP process. The basic process is to re-process the electronic components first, like to cut the extra pins for some DIP components, our staff received the components according to the BOM list, and will check whether the material part numbers and specifications are correct or not, and performs pre-production pre-processing according to the PCBA samples. The steps are: Use various related equipment (automatic capacitor pins cutting machine, jumper bending machine, diode and triode automatic forming machine, automatic belt forming machine and other machines) for processing.

12. ICT test

Printed Circuit board open/short circuit test (ICT, In-Circuit Test), The purpose of ICT test is mainly to test whether the components and circuits on the printed circuit board are open or short issues. It can also measure the basic characteristics of most components, such as resistance, capacitance, and inductance values to judge whether the functions of these parts are damaged, wrong parts or missing parts etc. after passing through the high-temperature reflow oven.

ICT test machines are divided into advanced and basic machines. The basic ICT test machines are generally called MDA (Manufacturing Defect Analyzer). It’s just to measure the basic characteristics of electronic components and judge open and short circuits issue we talked above.

In addition to all the functions of the basic ICT test machines, for advanced ICT test machine can also test the whole PCBA by using power, start to testing the PCBA boards by setting the program in the test machine. The advantage is that it can simulate the function of the printed circuit board under the actual power-on condition, this test can partly replace the following functional test machine (Function Test). But the cost for the test fixture of this advanced ICT test can probably buy a car, it’s too expensive and we suggest it can be used in mass production products.

13. PCBA function test

Functional testing is to make up for the ICT test, because ICT only tests the open and short circuits on the the PCBA board, and other functions such as BGA and other fuctions are not tested, so it is necessary to use a functional testing machine to test all functions on the whole PCBA board.

14. Cutting board (assembly board de-panel)

Normally, printed circuit boards will be produced in panel, and it will be assembled to increase the efficiency of SMT production. It means several single boards in one panel, such as two-in-one, four-in-one etc. After finished all the pcb assembly process, it needs to be cut into single boards, and for some printed circuit boards with only single boards also need to cut off some redundant board edges.

There are several ways to cut the printed circuit board. You can design the V-cut using the blade cutting machine (Scoring) or directly manually break off the board (not recommended). For more high density circuit boards, it will be used the professional splitting machine or the router to split the board without any damage the electronic components and printed circuit boards, but the cost and working hours will be a little longer.

Why Choose Hitech Circuits PCB Assembly Manufacturer for Your PCB Assembly Projects?

There are several PCB manufacturers specializing in PCB assemblyservices. However, Hitech Circuits PCB Assembly stands out owing to the following:

Assistance in Material Procurement:

Technically, in PCB assembly services, the quality of parts is the responsibility of the OEM; however, we ease your job by assisting you to make the right selection. We can help you procure all your parts of the same type own a single part number, thanks to our supply chain and vendor network as well as experience. This saves time and cost that goes in ordering single parts as you plan.

Testing procedures:

We are very focused on quality and thus implement stringent testing procedures at each stage of the assembly and after completion.

Fast Turnaround Times:

Our well-equipped facility and the right tools enable us to complete your requirements well before time, and without compromising on the quality or functioning of the PCBs. For simple designs we revert in 24 to 48 hours.

Cost Effectiveness:

While PCB assembly is a cost-effective alternative, we go a step further and assure that the parts you list are of a good quality and suitable for your requirement. Also, you can control the part flow and replenish them as needed. This eliminates the need to buy extra stock and store it.

Quick Quote:

We offer a quick quote based on your BOM. All you need is a detailed BOM, Gerber files, your application requirement sheet, and quantity.

We’re not one to stand still, which is why we use the latest equipment and the finest minds to create your PCB projects. We’re constantly keeping our finger on the pulse of the latest trends. And as a result, we know how to deliver the highest standards of PCB assembly to meet all your requirements.

Our dedicated, friendly customer service team also means that we support you every step of the way. Offering our expert guidance to ensure a complete PCB project that you’re happy with.

Contact us today

No matter what your printed circuit board assemblyneeds are, we always aim to deliver efficient, dependable solutions. For more information about our services, do not hesitate to get in touch with us today for a no-obligation quote

2 notes

·

View notes

Note

Do you have a favourite Goetic demon? I have a soft spot for Ose, Stolas, and Decarabia.

I won't lie, I only really know the ones who [umineko spoilers]. I'm not much of a wizard, but I read enough things that I pick up a thing here and there!

So, let's take a look at your faves ^^ This is from the version on sacred-texts, which was edited by Crowley.

OSÉ, or VOSO.--The Fifty-seventh Spirit is Oso, Osé, or Voso. He is a Great President, and appeareth like a Leopard at the first, but after a little time he putteth on the Shape of a Man. His Office is to make one cunning in the Liberal Sciences, and to give True Answers of Divine and Secret Things; also to change a Man into any Shape that the Exorcist pleaseth, so that he that is so changed will not think any other thing than that he is in verity that Creature or Thing he is changed into. He governeth 30 1 Legions of Spirits, and this is his Seal, etc.

I do like how many of the demons teach "liberal sciences". Hell must be a very erudite place. Turning people into stuff is certainly a neat power. Ose is the demon you want to call for TF shenanigans, evidently. Also, manifesting as a leopard and then turning into a man? You're saying this is some sorta catboy demon?

As far as the seal goes, it looks like a circuit diagram. We have two inductors connected in parallel and then... yeah, OK, I'm not sure what the other stuff would be. The bottom has a bit that's kinda like the antenna symbol. Not really sure what the like, cross-shaped bits would be! Even so, I like it because electric circuits and demonic sigils are of like nature, I feel.

STOLAS, OR STOLOS.--The Thirty-sixth Spirit is Stolas, or Stolos. He is a Great and Powerful Prince, appearing in the Shape of a Mighty Raven at first before the Exorcist; but after he taketh the image of a Man. He teacheth the Art of Astronomy, and the Virtues of Herbs and Precious Stones. He governeth 26 Legions of Spirits; and his Seal is this, which is, etc.

Last one was a president, this one's a prince. I definitely have a soft spot for avians. I absolutely love this illustration of Stolas from the 19th-century Dictionnaire Infernal:

Look at him! What a cutie. 'Owl with long legs' is an inspired design.

As far as the sigil goes, this one's kind of a mess. No real symmetry to it, and the elements feel a bit haphazard. In a sense though that kind of works in its favour, lending it an inscrutable air.

This guy got made into a Hazbin Hotel character, so if you search him on google just about every picture is the Vivziepop version.

DECARABIA.--The Sixty-ninth Spirit is Decarabia. He appeareth in the Form of a Star in a Pentacle, at first; but after, at the command of the Exorcist, he putteth on the image of a Man. His Office is to discover the Virtues of Birds and Precious Stones, and to make the Similitude of all kinds of Birds to fly before the Exorcist, singing and drinking as natural Birds do. He governeth 30 Legions of Spirits, being himself a Great Marquis. And this is his Seal, which is to be worn, etc.

Sixty-ninth spirit, nice.

Forming as a pentacle is like... lol sure ok your fursona's a star? Come on dude. But I gotta say, I was won around by his powers. Discovering the virtues of birds and precious stones? I'd love to know about the virtues of birds! That's great! And conjuring illusory birds is also extremely good.

So I love this guy. You phone him up to get bird facts, complete with illustrations. That's so autismcore. Really good.

I couldn't find any illustrations of Ose or Decarabia.

For my part... I'm certainly fond of Ronove because [umineko spoilers]. The Lesser Key is pretty light on detail...

RONOVÉ.--The Twenty-seventh Spirit is Ronové. He appeareth in the Form of a Monster. He teacheth the Art of Rhetoric very well and giveth Good Servants, Knowledge of Tongues, and Favours with Friends or Foes. He is a Marquis and Great Earl; and there be under his command 19 Legions of Spirits. His Seal is this, etc.

...but I think it's cool that his sigil looks like a crazy musical instrument, and he did get a great illustration:

I'll also throw a shoutout to Furfur, mostly because of Heaven Pegasus's song that forms the opening to @xrafstar's and rook's amazing Sticky Zeitgeist series. Let me pull the description:

FURFUR.--The Thirty-fourth Spirit is Furfur. He is a Great and Mighty Earl, appearing in the Form of an Hart with a Fiery Tail. He never speaketh truth unless he be compelled, or brought up within a triangle, △. Being therein, he will take upon himself the Form of an Angel. Being bidden, he speaketh with a hoarse voice. Also he will wittingly urge Love between Man and Woman. He can raise Lightnings and Thunders, Blasts, and Great Tempestuous Storms. And he giveth True Answers both of Things Secret and Divine, if commanded. He ruleth over 26 Legions of Spirits. And his Seal is this, etc.

This is a pretty good blurb. A lot of these descriptions are pretty formulaic, so I like that this one has cute details like 'you gotta use a triangle or he'll lie to you'.

One thing that's kinda funky - and I'm not sure whether it should be blamed on the original authors of the Lesser Key or on Crowley - is that with all the demons said to inspire romantic feelings, it takes some pains to specify 'between men and women' and other sort of explicitly hetero framings! Cowardly, tbh. What's the point of being a wizard if you're not going to be gay?

Furfur's seal has these funky little spirals, which is a pretty rare design element! Elf shit. The bilateral symmetry is neat.

Furfur gets another great illustration in the Dictionnaire (do these guys ever miss!) - check this out

Flying deer furry! Way ahead of its time.

7 notes

·

View notes

Text

Electronics Components and Uses:

Here is a list of common electronics components and their uses:

Resistor:

Use: Limits or controls the flow of electric current in a circuit.

Capacitor:

Use: Stores and releases electrical energy; used for filtering, timing, and coupling in circuits.

Inductor:

Use: Stores energy in a magnetic field when current flows through it; used in filters, transformers, and oscillators.

Diode:

Use: Allows current to flow in one direction only; used for rectification, signal demodulation, and protection.

Transistor:

Use: Amplifies and switches electronic signals; fundamental building block of electronic circuits.

Integrated Circuit (IC):

Use: Contains multiple electronic components (transistors, resistors, capacitors) on a single chip; used for various functions like amplification, processing, and control.

Resistor Network:

Use: A combination of resistors in a single package; used in applications where multiple resistors are needed.

Potentiometer:

Use: Variable resistor that can be adjusted to control voltage in a circuit; used for volume controls, dimmer switches, etc.

Varistor:

Use: Protects electronic circuits from excessive voltage by acting as a voltage-dependent resistor.

Light-Emitting Diode (LED):

Use: Emits light when current flows through it; used for indicator lights, displays, and lighting.

Photodiode:

Use: Converts light into an electric current; used in light sensors and communication systems.

Zener Diode:

Use: Acts as a voltage regulator by maintaining a constant voltage across its terminals.

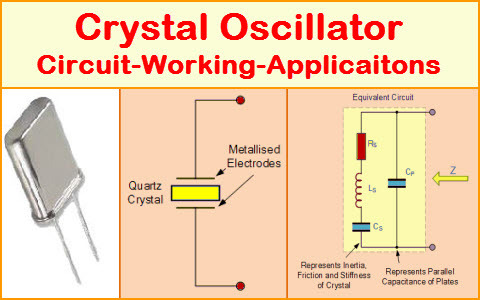

Crystal Oscillator:

Use: Generates a stable and precise frequency; used in clocks, microcontrollers, and communication devices.

Transformer:

Use: Transfers electrical energy between two or more coils through electromagnetic induction; used for voltage regulation and power distribution.

Capacitive Touch Sensor:

Use: Detects touch or proximity by changes in capacitance; used in touchscreens and proximity sensing applications.

Voltage Regulator:

Use: Maintains a constant output voltage regardless of changes in input voltage or load; used for stable power supply.

Relay:

Use: Electromagnetic switch that controls the flow of current in a circuit; used for remote switching and automation.

Fuse:

Use: Protects electronic circuits by breaking the circuit when current exceeds a certain value; prevents damage from overcurrent.

Thermistor:

Use: Resistor whose resistance changes with temperature; used for temperature sensing and compensation.

Microcontroller/Microprocessor:

Use: Processes and controls electronic signals; the brain of many electronic devices and systems.

fig:google-electronics

fig:google-electronics

fig:Crystal-Oscillator

This list covers some of the basic electronic components, and there are many more specialized components used for specific applications within the field of electronics.

#electronic#electricity#electric vehicles#electric cars#engineering#semiconductors#wireless#cables#electronics#smartphone#hardware

3 notes

·

View notes

Note

i wish lk-99 were real, it's made from common enough elements that it'd be cheaper to make a maglev by putting the magnets on the train and using the superconductor as the tracks

you could also use it to make inductors that dont suck (imagine if you could charge up an inductor, connect its leads and pull it out of a circuit and have it keep its current like a capacitor can keep its voltage)

oh yeah your right that would be so cool. fast trainw everywhere

1 note

·

View note

Text

youtube

Bell Labs, back in the 1960s, put out a number of educational book/kits about different aspects of signal processing and communications. One of those was this, "Speech Synthesis: An Experiment in Electronic Speech Production". YouTuber ParadisoModular got one from a science teacher back in the day, built it, and did some musical experiments with it back then, but he recently found an unused kit online and built it into a synthesizer module.

This circuit basically simulates the hunan vowel-producing apparatus through what's called "formant filtering". By shaping the lips, mouth, and throat, people create chambers that resonate at particular frequencies; the electronic kit does the same by using inductors and capacitors to create a series of three bandpass filters. For example, the 'ah' /a/ sound for the average male voice has its first formant at 730 Hz, its second at 1090 Hz, and third at 2440 Hz: you select these frequencies by swapping capacitors. The kit pushes a pulse wave into these filters to simulate the buzz of the vocal cords, and so you get the various vowel sounds out of it. ParadisoModular used switching chips to change the caps, so he can select multiple frequencies on the fly. It's a beautiful build.

Scans of the book are available online; I am going to have to build something similar for myself, though I'll probably move it to active filters rather than winding big coils.

4 notes

·

View notes