#i love plants accounting and supply chain management

Explore tagged Tumblr posts

Text

i think my dream job might be to work at a dispensary

#i literally studied chemistry and biology in undergrad#i love plants accounting and supply chain management#my petit bourgeois dream#i wouldnt want to own the place though tbh i just want salary

3 notes

·

View notes

Text

The State Of Vinyl (from someone who works at a vinyl pressing plant)

Your Morning Coffee guest post by Sean Rutkowski, VP at Independent Record Pressing

Everyone’s talking about vinyl like it’s 1970, 1980, 2014 etc…

How Vinyl Got Its Groove Back [Billboard] FULL STORY Music fans pushed sales of vinyl albums higher, outpacing CDs, even as pandemic sidelined stadium tours [CNBC] FULL STORY

So many people have reached out to me questioning the recent craziness happening in the world of vinyl records, so it only seems appropriate to write about it.

In case you didn’t know, I am a VP at Independent Record Pressing in Bordentown, NJ. I have been here before we even had a building and I have done everything at the plant one time or another over the last 6+ years. Before that I’ve worked in music retail, a music buyer, in distribution and at a label. I’ve dealt with both physical and digital and am an active music consumer both physically and digitally, so I believe I am as good as anyone to give my opinions when it comes to music, vinyl and the music industry.

I can tell you first hand the struggle is real. If you are dealing with the manufacturing of vinyl from any perspective you know about long lead times, demands from artists, managers, accounts, and consumers.

So here is my perspective:

We are a manufacturer. Manufacturing is really hard and manufacturing vinyl is even harder. This job has been the most challenging experience I’ve been involved with in my 25 year work history. Not only do you have to manufacture something that has to look good, it has to sound good. Making records is not as simple as plugging a machine in, filling it with PVC, turning it on and letting it go. I won’t get into the minutiae of making a record, that is an endless rabbit hole, and there are plenty of places online that will explain it better than I can.

All those supply chain issues you read about in other manufacturing industries-increased cost of goods, shortage of materials and parts, shipping challenges, or labor shortages- we are dealing with every single one of them at any given time. It’s like playing Whack-A-Mole everyday.

Shortages in capacity are creating an urgency that is driving demand for vinyl and there is a capacity shortage world-wide. The basic laws of supply and demand are at play and everyone is trying to find the right balance, but we have to be cautious of oversupplying the market to the point that it exceeds demand.

There are too many multiple color variants. How exclusive is an exclusive if there are 5+ versions of the same album all being released? I can specifically think of 3 titles we have pressed in the last 3 months that have had orders of 20,000 or more. Each one had 7-9 different color variants released the same day. At a pressing plant, each color variant change costs an estimated hour in lost press time. That results in reduced capacity, potential for more mistakes and a sense from consumers that we as an industry are beginning to get greedy. The question I ask is, do we want more capacity or more color variants? We love color records they are fun to make, but right now love does have its limits.

Everyone wants to make the best record, but mistakes do happen. When we are pushed to the limits and being asked to compress our timelines because artwork is running late or there is a hold up somewhere along the supply chain, the potential for mistakes increases across the board. I see it in nearly every segment of every business. We are sitting on a pallet of $30k+ worth of light bulbs that somehow FedEx mistakenly shipped to us and we can’t seem to get it sent to whoever is supposed to get it. Every plant is trying to do better and we obsess in an unhealthy way by reading Reddit, Steve Hoffman forum and Discogs picking our own albums apart on a regular basis. I still get sick to my stomach thinking about our most hi-profile mistake that actually made Pitchfork 4 years ago https://bit.ly/3BtHsiC (note this was on a limited 200 run pressing).

By selling music that people can get legitimately at no cost at places like YouTube or Spotify, we are competing with free, so we are all working daily to deliver something that is of value that is sold at retail for $25 or more. It is a constant battle to make sure that we are delivering quality everyday because we know that quality issues hurt the growth potential of vinyl.

Despite the growth, no one that I know in vinyl is getting Mr. Burn’s rich. Every plant that has become operational in the last 15 years has gotten into it because they saw the opportunity and acted on it because of their passion for music and the format. At the same time many people I’ve talked to say that if they knew it was this hard beforehand, they might have decided to sell life insurance instead.

Nearly every plant in the world, including us, are working to increase capacity through extended hours, better processes and/or purchasing of new presses. I want to stress that I am not complaining or making excuses, and when I read about droughts, wildfires, people dying, buildings falling apart, I believe these are first world problems to be having. I am extremely lucky to be a part of vinyl and know that what we do gives many people a lot of joy. I am also happy that I haven’t heard of anyone dying because they were not able to find their record .

- Sean Rutkowski

3 notes

·

View notes

Text

2020/ Chain of Fools

2020 was the year I adopted a boiler suit and gas mask as a daily uniform. The world had gone into a global lockdown to combat the COVID19 virus which meant we were only allowed to leave our house for essential reasons such as grocery shopping and exercise. When outside, we were government mandated to wear face masks to prevent the spread of the disease. They made me feel like a muzzled dog and I resented no longer being able to smile with strangers on the street. Feeling like a prisoner in his own home and under extreme stress from job insecurity, my boyfriend Jake’s amphetamine addiction began to spiral out of control.

As a result of Jake’s addiction, we had accidentally befriended a posse of drug dealers and prostitutes- bonded by our love of having a good time and a general disregard for consequence. We met Dani through a call girl friend of mine who had realised the difficulty of making a living through writing online fashion content. Dani had big brown eyes, fat, botoxed lips and dressed only in high end labels like Gucci and Balmain. Born into a wealthy family, she had acquired a taste for expensive things but lacked the work ethic to maintain this taste without selling her body for sex. Dani began to visit more throughout the lockdown to deliver Jake drugs, hidden in a bag of a groceries. One night, she played Carole King on our old vinyl player, while Jake rolled us a joint to share. I flirted with them both, knowing that it would lead to a threesome. We smoked Jake’s joint, snorted lines of cocaine off each other and then took turns going down on each other.

A week later, Dani introduced us to a crew of “script kiddies”- long haired, internet hackers with a love of mumble rap, cryptocurrency and ketamine. I made cocktails for everyone and established that one of these kids shared a mutual friend with Jake. They seemed fascinated by the genuine sexual chemistry between myself, Jake and Dani and expressed gratitude for our generous hospitality. Eventually I came to the conclusion that by associating us with this crowd, Dani had managed to successfully pray on the vulnerable- trusting junkies like us who were lax with internet security and keen for a good time. In retrospect, I wish I had known that Dani was a hustler at heart- making money in any way she could without considering the impact of her choices. At the time however, I felt like we were fully living life in the moment- something I was certain would bring me happiness, meaning and didn’t question her motives for a moment.

Ella, Dani’s best friend, had a boyish pixie cut, high cheekbones and was tall and slim. She had gradually joined in on our shenanigans, along with Mark, a dealer with a steady supply of the best gear available north of the river. We all hung out together in our plant-filled, converted warehouse listening to electronic music and sharing stories about our favourite mind-altering substances. My stories were consistently focused on MDMA. As a notoriously private person, I’d discovered MDMA helped me open up and allowed me to dance, free of fear of judgement. It had also helped Jake open up about the sexual abuse he experienced as child, a fact I doubted would have ever come up without the influence of a truth serum and something which I was certain had driven him to substance abuse in the first place.

While we laughed, chatted and danced with Dani and Mark, Ella, who claimed to be a part time poet and part-time model, entered a viral script virus onto our wireless network by requesting our wifi password. Something we provided willingly, without second thought. This meant remote access to every digital device we owned and access to all stored personal information including scanned copies of our passports and birth certificates.

The issue with Mark, despite his criminal lifestyle, was that he was excellent company. Intelligent, engaging and a DJ in his spare time- we thrived off his love of hip hop and old-school funk. Similarly, he thrived off our property location in the Inner North- close to his regular customers and discrete enough from the prying eyes of authority. We welcomed him into our home with open arms, deprived of social contact through social distancing practices enforced by the pandemic. We held COVID19 illegal gatherings where we got high off Mark’s supply, enjoyed each other’s company while Ella hacked our electronic identities. When you’re lonely, it doesn’t really matter if others are using you and you’re using them. As long as everyone is filling a clearly defined role, the maladaptive social ecosystem continues to function.

It’s unclear exactly how many international drug smuggling routes were established using our stolen online identities before Jake clued on that something wasn’t right. He told me that he had been locked out of his email account, that the speed of his phone had slowed and that he could hear clicking noises during his phone calls. He was certain that his was a breach of online security and started to question the motives of our new friends. I wrote him off as crazy, blaming his excessive use of amphetamines and the psychological effect of social isolation. I was determined to keep my online identity public, obsessed by the idea of becoming the next millennial therapist and too blinded by Dani’s beauty to believe that she would want to harm us in any way.

Eventually Jake’s distress became too extreme to ignore and he shook me violently one night, yelling at me to believe what I had assumed was a paranoid conspiracy theory. A sinking feeling in my gut became apparent when he started to coherently piece together his concerns about his online security issues. I realized that my sense of reality had been clouded by my lust for Dani and by a dark depression that had developed through my work as an essential worker during a pandemic. Based on Jake’s erratic behaviour, I knew we had to get out of the warehouse immediately, but I had no idea where to go and was fearful of drawing attention to any law-breaking activity when police presence was so prominent.

We agreed to seek refuge with our friends Trish and Rick, former 90s British ravers who had channeled their drug-fuelled benders into successful and respectable careers. I called them panicked that night, shaking and rambling about what had happened. Without hesitancy, Trish told us to come over right away. Rick’s brother back in the UK had recently killed himself and they were struggling too. Trish and Rick lived in an affluent area in the inner East which meant we needed to blend in quickly through a disguise of expensive athleisure and an almost painful sense of normality. It appeared that our efforts at disguise were successful and it seemed to result in freedom from any unusual online activity on our devices. We bought new phones, changed our phone numbers, email addresses and disconnected from the outside world for an entire week. We spoke about going to the police, however we both agreed that this would place us at too much risk to the criminal world to be a viable option.

When your online identity is stolen, you quickly start to daydream what it would be like to steal someone else’s identity. For example, what exactly would you do with those proceeds of crime? Which tropical island would you escape to, what designer clothes would you wear, which car would you drive? I quickly became entranced and jealous at the thought of this fantasy life, but then spent time reflecting on my own morality and these feelings subsided. Instead, an intense anger developed at the thought of others taking advantage of Jake and his mental illness. High on a sense of ethical superiority and new found fury, I decided to employ my favourite psychological defense mechanism, repression, to cope with my latest traumas. May you rest in peace, memory, I said to myself before engaging in my daily mediation ritual.

While repressing my consciousness, I also began to focus on the importance of social support. I knew this shit was important but didn’t fully understand until Trish brushed my hair one night, my arms too frail from fear and stress to function. Trish and Rick played familiar Britpop, drank tea and encouraged us to embrace the therapeutic benefits of music through use of the guitar and keyboard that we had brought to their house. We took turns cooking for each other, played board games and counselled each other through each personal problems, one at a time.

Jake and I stayed with Trish and Rick for two weeks until we could establish an exit plan from the city. We migrated to rural Victoria like many other Melbournians, traumatized by the lockdown. The pace in the country was slow yet calming and people genuinely seemed to care about your welfare when they inquired “How you going, mate?” After such an extended period of social isolation, many of us forgot how to interact with others. We valued and craved human connection more than ever, and yet we seemed scared of what we might connect with. We continued to develop our own deformed version of sign language to communicate through the face masks and focused on re-developing social skills that had been lost through extended disconnection.

Jake and I continued to battle through the challenges of online identity theft and the consequences of his addiction issues. Jake’s substance use had subsided substantially without the influence of Mark and Dani and we eventually adjusted to living normal, routine driven lifestyles. He had cycled through periods of problematic use before, however I still felt somewhat shell shocked by the intensity of his most recent relapse. However, one day late in December I found myself wandering through the tranquility of the Otways, fully freed from the constraints of the lockdown which had finally lifted and contemplating my progress in life since leaving this place as a teenager. The rainforest sounds were vivid and the smells of the ocean salty in my nostrils. I wasn’t where I had planned to end the year 2020, but I was alive and I had Jake. And for that, I felt eternally grateful.

Rosso Del Giorno

Your journey starts here.

An incomplete list of skills senior engineers need, beyond coding

Dear American Progressives: Your Jewish Friends Are Terrified by Your Silence

POLITICS

Inslee announces vaccination incentives

FORGE

50 Very Short Rules for a Good Life From the Stoics

2 notes

·

View notes

Text

Swallow, Bat and Brimstone

Last night in the clear dusk we could see the first bat flitting about the perimeter of the roof and this morning with a strong southerly wind, we saw the first swallow, and a brimstone butterfly. The swallow circled about the house for about an hour - much as it did last year - a male judging by the length of tail feathers and since then we have not spotted it, but I would hope it was ours and will duly take up residence this evening.

Whilst doing a fairly major change at the top of the garden we spotted the first brimstone - no doubt just come out of the ivy where it loves to overwinter. We have cut down, as far as is possible without a chain saw, the Viburnum rhytidophyllum - not one of my favourites, at the time of planting a useful evergreen to help give protection from the north wind, but now rather superfluous - not only preventing the Cornus mas from spreading on both sides evenly, but also becoming a visual thug. It was sitting in the space needed to make the opening into the wood - the purchase of which had to go on hold with the advent of the BUG but which will hopefully still progress when the panic settles. I now have approximately 4 metres to sow with grass seed as soon as we get some rain - typical we are now desperate! We are promised a little and I only need a little, just to dampen the fine tilth I have prepared in two places and the seed can go on.

We are listening to warblers arriving in numbers - I watched a dear little chiff chaff on my early walk this morning and blackcaps are everywhere. Insect life is taking off and today the bees are going ballistic - actually they are too busy and have given the dogs a couple of stings each - they are always very grumpy when its so windy so tend to pick on anything moving near their hives. Mavis has taken refuge inside and is very nervous - pray to goodness she does not get like Hobby!

We continue with this strange way of life - enjoying certain aspects of it - the quiet, the undoubted good it is doing the natural world, but wondering where it will all lead and whether these draconian measures will continue for much after the end of this month. It is frustrating that garden centres have closed and could not have been run along the same lines as supermarkets - not only the waste of plants, but the difficulty getting garden staples when we have the time to garden is annoying! I have managed due to having a trade account to get 40 bags of compost coming from Dalesfoot but not every one is in that fortunate position.

Nonetheless, things are moving albeit slowly from the endless frosty nights and very cold dry days. Temperatures have soared today, but the damage is done and a lot of things especially roses have all the young growth blackened from frosts that should have come in January and February. We have also had visits from a Muntjac and Roe who have managed to nibble some of the roses as well! Bin Liners and old CDs are festooned around the garden which seems to do the trick.

The broad beans are ready to be planted out - Tuesday after the rain I think and the sweet peas have had their tops pinched out. Tomato seedlings are coming through strongly - Rosette, Moneymaker and the strange ones Mr Horta brought back from Ireland two years ago - now his annual mission is to prepare the seed for the following year and he’s getting very good at it! Luckily the trailing blue Lobelia are looking amazing - never grown them before so good to have done it in a year when it will be hard to get bedding plants if this goes on. Also the Verbena Obsession have suddenly germinated so I hope my containers will look good!

Tulips are nearly out in the pots - some lovely white ones already in flower amongst the Brunnera - a lovely combination. The wallflowers are flowering so there is colour and the blackthorn looks stunning with these wonderful blue skies. All the dahlias are in - sticks to mark them and watered - so now the only gaps are for some Echinacea still waiting till they are a bit stronger as they are so easily ravaged by snails, and then ultimately the Cosmos and Nicotiana. I did manage after queueing for 10 mins on line to get some more Cosmos seed from Suttons as I have three clients now wanting some - Fothergills, Chiltern Seeds and Sarah Raven are all shut for the moment for new orders.

Three types of lettuce are in seed trays and now that at last the nights are about to be warmer I will sow some carrots, spinach and beetroot outside.

A week for some more dog training I think - the dogs are very well exercised each day so long as present measures continue but if we are confined even more we shall have to do a lot of training in the garden to tire Mavis out mentally!

We live through interesting times - it certainly will be fascinating to see how many things if any change for good - local shopping and supply - less international travel - less importing so much from China and going back to making things here - the speed at which we can get projects underway if we cut out red tape - ventilators and masks being an example - railways being nationalised again for good - people continuing to work from home perhaps two or three days a week - public health improvements and working internationally on this front - important to keep notes I think to look back upon in the months to come.

HORTA

1 note

·

View note

Text

Beverly Malbranche Caribbrew Founder and CEO Is Reviving Haitis Coffee Industry

Beverly Malbranche is the founder and CEO of Caribbrew, a coffee company that specializes in Arabica beans sourced from farmers in Haiti. The Newark, N.J., business aims to bridge the gap between the Caribbean’s centuries-old coffee traditions and its consumers in the United States.

As a Black business owner, Malbranche is working to close the racial representation gap in the coffee industry.

Malbranche grew up in Haiti and came to the U.S. in 2009 to study business administration. She knew early on she wanted to start a business selling a product of Haiti to U.S. consumers. While pondering this, she fell in love with the flavors and aromas of Haitian coffee, courtesy of her uncle, who, also based in the U.S., visited Haiti each summer and brought back coffee to share with friends and family. He “kept on asking where to buy this coffee,” Malbranche says. “I realized there was a demand and no one was meeting it well. That’s when I decided that coffee was it!”

Seeing a market for Haitian coffee here in the States, Malbranche co-founded Caribbrew in 2016, and officially launched the brand in 2018. She says she realized that starting a coffee business could also create sustainable jobs for coffee farmers, roasters, and packagers in Haiti.

Caribbrew sells whole-bean and ground coffee, coffee filter bags (perfect for making cold brew), as well as other coffee products and gifts, including skincare products. Malbranche says she included skincare with the goal of creating more demand for Haitian coffee, so that she could in turn buy more from farmers. “It’s been a great way to diversify and reach even non-coffee drinkers,” she says.

Despite the disruption to business during the pandemic, Malbranche says that Caribbrew doubled its revenue last year (in the period May to December, compared to the same period in 2019). She says the main spike was in June. “We are thankful for the support shown to Black-owned small businesses last year,” she says.

In the following interview, Malbranche discusses her motivations for launching Caribbrew, the challenges she has faced building the brand, and what makes running the business so rewarding.

1. What makes coffee from Haiti special?

Haiti’s mountainous landscape makes it perfect to grow Arabica coffee beans. We grow coffee at high elevation, under shade, and without pesticides.

Haiti used to be a major coffee-producing nation in the 1900s. Declining social and political conditions, such as dictatorial regimes and trade embargo, and competition from neighboring Latin American countries, caused [Haitian] coffee exports to drop considerably. By selling our crops, especially our coffee, we were able to pay France their unjust indemnity, for them to recognize us diplomatically as an independent nation back in 1825, 21 years after our independence in 1804. Coffee is definitely rooted in our history. I want people to know Haiti’s coffee as impeccable, sustainable, and empowering.

2. What is the goal of Caribbrew, and how are you achieving it?

Caribbrew’s goal is to create opportunities for everyone in our supply chain and share Haiti’s coffee with the world. In doing so, we will make a difference and reclaim our position in the world as a major coffee exporter. We create opportunities for Haitian coffee farmers and young people in Haiti who roast and package our coffee. Here in the United States, we hire locals from Newark, N.J., where we ship every order. Last year we imported about 17,000 pounds of coffee. We’re still a small company, but with growing demand. Our goal is to get Haitian coffee back on the world map.

3. What does your role as founder and CEO entail day to day?

My role includes going over our daily goals with the leadership team before I [go] to our warehouse. I make sure that they align with our weekly, monthly, and even yearly goals. Then around 10 a.m. when I get to our warehouse, I oversee the fulfillment of our orders. I follow up with wholesale clients, trying to close more accounts for the business. I coordinate our marketing efforts, such as social media posts, discounts, and promotions, and implement and oversee our workforce when it comes to inventory management, vendor relations, etc. … As a small business owner, I do wear many hats, but the most important job to me is to continuously grow the company.

4. How do you work with farmers to source your coffee beans?

We work with an association of coffee farmers called cooperatives. The cooperatives stabilize the coffee price on the market, support individual farmers in securing funds to take care of their farms, lend equipment, and even help with transporting coffee from farm to processing centers. By buying from the cooperatives, we contribute to the establishment of a fair market price for Haitian coffee, where the premium is used to benefit the farmers as a whole. We also create more demand, giving the farmers incentives to continue planting coffee trees and grow quality beans. We pay over the market price per pound.

The vast majority of Haiti’s coffee beans are produced by small farmers, not large-scale farms. Each farmer usually has a few hectares and works with local cooperatives and a few coffee mills.

5. What kind of challenges has Caribbrew faced in the last 6 to 9 months due to Covid-19?

[Before Covid-19], our brand awareness strategies relied heavily on participating at fairs, events, and trade shows. For example, in 2019, we participated at the New York Coffee Festival with over 10,000 attendees. All fairs, trade shows where we meet potential buyers, were canceled in 2020. Moreover, many of our wholesale partners, such as restaurants and coffee shops, had to close or operate on a limited basis. As a result, some of them [stopped] ordering from us and others order in much smaller quantities.

Our wholesale side of the business reduced, but thankfully we relied on our e-commerce strategies to grow our business. Our retail customer base grew rapidly as customers were consuming coffee from home. We were able to double our revenue despite the pandemic.

6. What is the future of the coffee industry, and how can business owners and coffee drinkers make it a more inclusive industry?

The coffee industry is growing, and the customer is becoming more knowledgeable and wants more transparency. Making [the coffee industry] more inclusive means buying from small-scale farmers who usually do not have access to the global market; working with cooperatives to ensure that the premiums are invested in the local coffee ecosystem. Moreover, it means supporting smaller roasters, although sometimes their prices might not be as competitive as larger companies. Overall, it means supporting underrepresented groups at all levels in the sector. When the coffee sector is more inclusive, customers benefit from a large variety of coffee from all over the world, and of course better quality.

7. What is next for Caribbrew in 2021 and beyond?

Our goal this year, besides focusing on our direct-to-consumer strategies, is to gain at least one retail partner with nationwide distribution.

8. How does it feel to be helping to revive Haiti’s coffee industry?

I feel very fortunate to be able to contribute to such a cause. Although there is so much more to be done, every step matters.

The article Beverly Malbranche, Caribbrew Founder and CEO, Is Reviving Haiti’s Coffee Industry appeared first on VinePair.

Via https://vinepair.com/articles/beverly-malbranche-caribbrew-coffee/

source https://vinology1.weebly.com/blog/beverly-malbranche-caribbrew-founder-and-ceo-is-reviving-haitis-coffee-industry

0 notes

Text

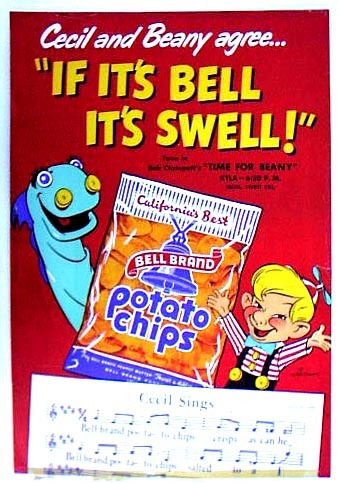

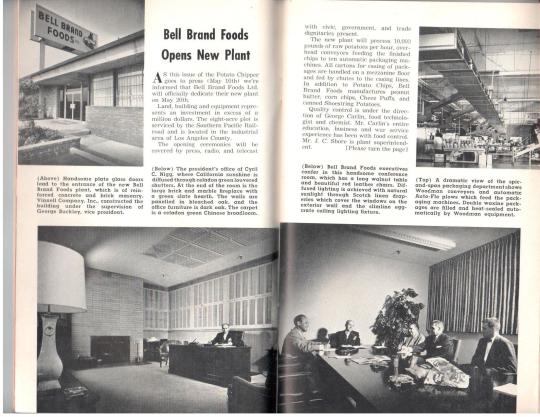

If It's Bell, It's Swell

What do Sandy Koufax, Marilyn Monroe and Beany and Cecil all have in common? They were all promoted by Bell Potato Chips.

Sometimes the history of various potato chip manufacturers (chippers) has been passed down from generation. In an attempt to preserve and document the history regarding Bell Brand, I have included interviews of many people.

The following is based on a statement by Craig Scharlin, grandson of the founder of Bell Potato Chips., Max Ginsburg.

Bell Brand Potato Chips was a privately owned company started in the 1920's by Max I. Ginsberg. He was an immigrant from the Ukraine who came to the US on his own at the age of seven. He met up with his brother in Philadelphia and started selling hand made pretzels on the streets. He moved to Los Angeles in the teens and in the early 1920's started his own company named the L.A. Potato Chip and Pretzel Company which he eventually changed the name to Bell Brand Potato Chips. He named it Bell after the bells of the Spanish Missions of California and because he thought the name Bell made people happy. He created the slogan, "If it's Bell it's Swell" and also created the name Frenchie for the shoe string potato chip. Bell Brand Potato Chips was one of the sponsors of the Jack Benny Radio Show in the 1930's among many others. One of his best friends and founder of Ralph's Grocery stores, Mr. Lawry, also owner of the famous Lawry's Prime Rib restaurants of Los Angeles and the Tam 'O Shanter Restaurant in Glendale, was one of his major buyers. Max Ginsberg decided to retire in the 1950's.

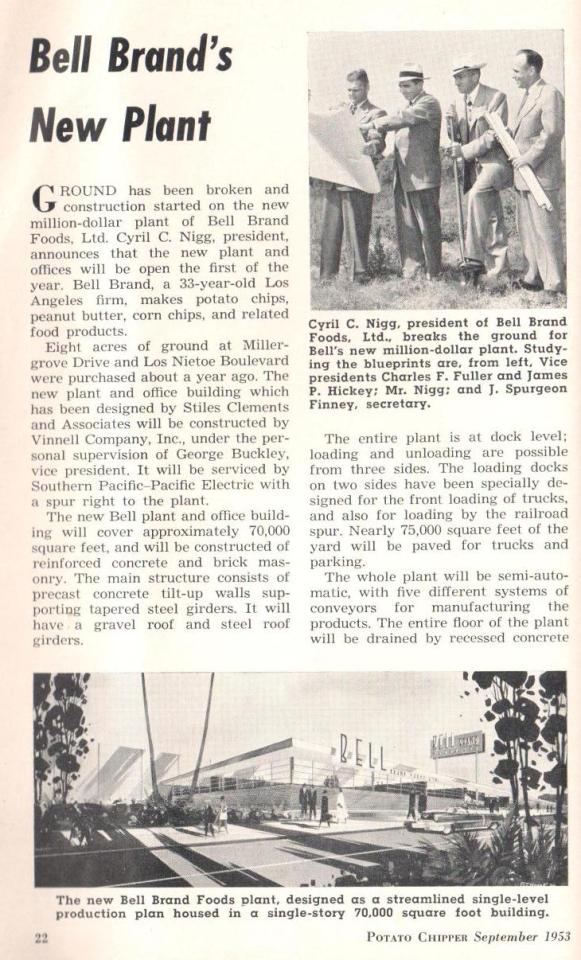

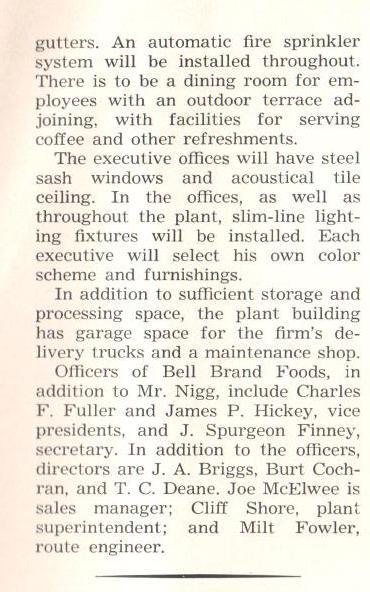

My mentor, the late Donald Noss who was the son the the founder of the snack food trade association, gave me his extensive archive regarding the potato chip industry. Among the items was the attached photo of four men. The back of it was inscribed " J. Spurgeon Finney, Cy Nigg, James Hickey & Chas. Fuller.

Finney was Treasurer and Hickey and Fuller were vice presidents of Bell Brand. Below, you will learn more about Hickey and Fuller and how they obtained their ownership shares. Lizette Gabriel of the Los Angeles Public Library provided me with the link to the oral history of Cyril Nigg as part of the research into the Tom Sawyer Foods. When I read it, I was able to match three of the four people in the photo with their names. In a true sense, a picture is worth a thousand words.

Cyril Nigg had worked his way up the chain at Kellogg's, the cereal maker, by staying after other suppliers had left for the day to help grocers with their tasks such as inventory management, pricing inventory including items that he was not supplying, in a manner that developed great trust and strong relationships. This enables Nigg to get the grocers to include his products in their ads, provide him with prominent display space for the Kellogg's brands. He was a pioneer at creating combinations , trade promotions where he would put together two or three packages of Kellogg's cereals with a premium: cereal bowl, muffin tins, rag dolls. Nigg created the cereal department that now is a standard department in all grocery stores. He also conceived of quantity discounts for grocers. He was also one of the first to sell the entire line of Kellogg's cereals, whereas most others only sold one or two.

He was told that he would be groomed to be the President of Kellogg's by moving every couple of years to different parts of the county to learn the diverse markets. With children in high school and both his and his wife's family in Los Angeles, he decided that he would prefer to stay in the Los Angeles area. Taking a job with another large employer would most likely also require him to relocate. Because of his relationships within the food industry, he agreed to chair the Red Cross Appeal within the food industry division. Based on an oral history from the California State archives in 1993, Nigg tells the story of how he entered the potato chip business in his own words:

NIGG: I had one [Red Cross Appeal] card, a guy by the name of Max Ginsberg, who I knew real well, who owned the [Los Angeles] L.A. Saratoga Chip and Pretzel Company. He was a member of the sales managers club. I knew him well. He had given $500 the year before, and in those days $500 was a pretty good contribution for Red Cross. I didn't want to miss him. I called two or three times, and he's not in. Finally I say to the girl at the telephone, "Well, when will Mr. Ginsberg be there? I'm working for the Red Cross drive." "Oh," she said, "Mr. Ginsberg is just horne from the hospital. He's been very ill." Oh, I was sick. Here's my 500-buck contribution, and he's not going to be able to corne in. So I thought, "Well, maybe I can go by his house." I knew him pretty well. I thought, "I'll go by his house and see how he is, and maybe I can say something about the Red Cross drive." So I go by. He lived up in the Los Feliz area. His wife lets me in. He comes in, and he looks like walking death. God, it was a shock to me! I knew him, and here's this guy looking so terrible. I said, "Max, what's wrong with you?" "0h," he said, "I go down to the plant, I get all upset. Nothing is going right." Now, again, the war is on. You can't get help, you can't do this. So he gets all upset. He was the kind of an owner-manager who had to be in on everything. [If they] bought a new typewriter, he had to say what one they'd buy. So he goes down, and he gets all upset. He says, "My doctor says get rid of the business or get a new doctor. II So he said, "I guess I'm going to have to sell my business." Without thinking, I said, "Max, I'd like to buy iL" And he said, "Cy, everybody wants to buy my business, but my wife and I worked so hard to build it. They'll ruin it, I know. There's nobody I'd rather have than you.

So just that easily I bought that business. We came to an easy agreement. I paid him $100,000 for the business, plus the inventory, plus the accounts receivable. Inventory and accounts receivable were each about $25,000, but I could finance that easily. So my only thing was the $100,000, and I made arrangements. It was easy to get the money. The first person I told was a boy by the name of [James P.] Jim Hickey. [He had] been in Loyola High School with me, same class. He'd gone on to studying medicine back at Saint Louis and ran out of money. He was running a Standard Oil [gas] station at Olympic [Boulevard] and Fairfax [Avenue], kind of a training station, and working like the dickens. Oh, he was good. So I said to Ted Von der Abe, my friend whose office was right across the street, "You ought to hire that Jim Hickey. Boy, he's good." But Ted didn't do anything, so I hired him, and he came to work for the Kellogg Company. By now he's my assistant, he's my supervisor. So we're still working Saturdays, and Jim and I go to lunch, and I tell him, "Jim, I'm leaving the company. I'm going to buyout Max Ginsberg." He said, "I'll go with you." I said, "Jim, are you crazy? You'll get the job. This is what you've been working for. I'll recommend you." "No," he said, "we've always been together. I'll stay with you." Well, I said, "Jim, that wouldn't be right. I can't hire you. I'm taking a gamble. For you to come to work for me, that would be crazy. You stay with Kellogg's." "No," he said, "we've always been together. I like working with you. I'll stay with you." So I said, "Jim, I would love to have you, but I just can't hire you. I'm paying $100,000 for this business. If you could raise $10,000, you'll have a 10 percent interest. Then you have the same chance I have." He said, "I think my Uncle Tom would help me. will you go with me to see him?" I said, "Sure." So we go out to see Uncle Tom. Uncle Tom is Tom Hickey, Hickey Pipe and Supply Company, who's been very successful. He likes Jim; they're very close. So we go out, and I tell Tom what I'm going to do, and Jim wants to buy a 10 percent interest and he needs $10,000. Tom says to Jim, "Is that what you want, Jim?" And Jim says, "I think it would be such a great opportunity." Tom says, "I'll arrange it." So Tom got Jim a loan for $10,000 from the bank, and so he's my partner. I'm going to be the general partner, and he'll be a limited partner.

The next week, a fellow by the name of [Charles] Charley Fuller, who had worked for me, who is now the general manager of a little honey company.. And, of course, in those .. War's on. You can sell all the honey you can get. The job was to get it and get it bottled, that sort of thing. So Charley comes to see me. He said, "I hear you and Jim are buying out Max Ginsberg." I said, "That's right." He said, "Well, look. I don't know much about production, but I know more than you guys do. How about taking me and letting me be the production manager?" I said, "Charley, I'll give you the same deal I gave to Jim. You raise $10,000, you'll have a 10 percent interest." Well, Charley didn't have an Uncle Tom. [Laughter] So he had to work awfully hard. But he went to all of his friends, and he'd borrow $100 here, $1,000 here. Ted Von der Abe gave him $5,000. That was his big one. He borrowed on his insurance; he borrowed on his house. Finally he gets his 10,000 bucks. So now it's the three of us. We took over February 1 of 1945. The war's still on. We have all these friends in the food industry who know us and love us, want to help us. The first month, we doubled the volume. The first month we did twice as much business as Max had done in January. The next month, March, we almost doubled it again. So we had this rapid, tremendous growth.

We recognized that we needed the money in the business. We're expanding so rapidly, we need all the money we can keep in the business. And as partners, individuals, at the end of the year weld have to payout all this money in taxes. So I go down to see my friend Tom Deane at Bank of America, tell him the problem, where we are. He gets on the phone and calls upstairs to the eighth floor to Claude A. Parker Company and says, "Cy, go up and visit with them. They're real experts." So I went up to see a man by the name of Theo Parker, and I told him the whole situation. "Well," he said, "are you building this business to sell it?" I said, "Oh, no, no. We just want to build a business." "Are you building it to maybe sell stock?" "No, we want to keep it. It's our business. We want to keep it." "Oh," he said, "okay, then this is how we'll do it. We'll expense everything we can. Rather than buy something, we'll repair something. You own it, so it doesn't make any difference. If you're going to sell the business, you want assets. If you want to sell stock, you need assets. But that isn't going to be your situation. You're just going to own this thing, it's going to be yours, so we'll expense everything we can." So that's the way we did it. We built that business, had great growth.

The war ended, men came out of the service, and we were able to have such a great choice of young men for our sales department, for our production department, for everything we did. We put together this great organization. Now, as we put together this great organization, that freed me so that I could be out in other activities, be active with UCLA alumni. When I became president [of the Alumni Association] and became a [University of California] regent, I gave five days a month to the university. For two years I gave five days a month. One of those days went to committee meetings, the second day was to regents meetings, the other three days were just to university activities. There were all kinds of things I had to be active in, but I was free to do it because I had this great organization.

TRELEVEN (Dale E. Treleven of the Oral History Program University of California, Los Angeles Who Is the Interviewer): Okay. Now, the name of the company remained the same or ?

NIGG: No, no. His name was L.A. Saratoga Chip and Pretzel Company. His trademark was a mission bell. We liked the bell, so we called our company Bell Brand Foods, Limited--Limited because it was a limited partnership to begin with. We never changed that. We kept that name, Bell Brands Foods, Limited.

TRELEVEN: Where does Tom Sawyer come in? Your regents 68 biography said you were chairman of the board of Tom Sawyer Foods, Incorporated.

NIGG: Tom Sawyer was a competitor, and, I don't know, five, ten years down the line we bought them out. So we now own Tom Sawyer Foods. Tom Sawyer Foods was a competitor in potato chips. They had a big nut meat department and a big candy department, so

TRELEVEN: So that's what you did. And that's not all you did, but in terms of the business in which you were engaged, that you kept at until what year?

NIGG: Let me give you the background of that now. We were successful from the day we took over, highly successful. It grew and it grew, and we built this great organization. I put Tom Deane, the manager of the head office of Bank of America, on our board of directors.

* * *

By now I had made my son chairman of our board and my son-in-law [Leon Doty] president of the company. 72 They were a couple of young, dynamic guys. They went to the UCLA School of Business Administration that, you know, you worked in .... What do you call that program?

TRELEVEN: Well, is it an internship program? Or is it the MBA [masters of business administration] program, perhaps?

NIGG: Well, you went to school nights. You worked daytimes. In other words, they stayed on the job but went through that whole program. Harvard [University] had started the thing. They did it, and then UCLA took it up. Anyhow, they did that program. They're sharp young guys. They really are sharp, working hard, really know their stuff. So I said to Peter, my son, "Now, your job as chairman is to see that we continue the rate of growth we've always had." "I understand." "Leon, my son-in-law, you're going to be the president. You just run this company like you .... Just make it go." And he did. He was a terrific guy. So we're growing, we're very successful. But about 1967, my son comes to me and says, "You told me to keep it growing. We can find new products, we can find new territory, we can maintain the growth, but we're going to run out of money. We won't generate money fast enough to keep up that rate of growth." Now, at that time, everybody wanted to buy us. It was a time of mergers. Every month I just had somebody corning and wanting to buy us. And I'd always say, "We're just not interested at all. Forget it." Well, a friend of mine [Harry Bleich] at Sunshine Biscuit [Company]--and they had quite a few plants around the country--had said to me, "Cy, if you ever want to sell, corne to see me. I know you don't want to now, but maybe sometime in the future, corne to see me." So when my son said to me, "This is what I recommend," we held a board meeting. He explained the situation, and everybody agreed, well, maybe it's the time to look around. Let's see what we can do. So I go back to New York and talk to my friend at Sunshine Biscuit. I said, "Maybe now is the time. We're at least ready to talk." He takes me into the president of the company, and the guy says, "When will you be back in Los Angeles?" And I said, "Tomorrow." He looks at his calendar, and he said, "I'll be there next Tuesday." This was the American Tobacco Company. They later changed the name to American Brands, but it was the American Tobacco Company. They've got to diversify; they know this. They're in the tobacco business. All this talk against tobacco companies and the tobacco industry, they've got to diversify. And they had Sunshine Biscuit. So this fellow comes out. I show him around, tell him what we've got, what we can do. He's very impressed. They want to buy us, but they want to buy us for cash. Well, we couldn't sell for cash. We start with zero, and now we're up into the millions, and the whole thing would be taxable. So I said, "No. I want common stock. If we can't have common stock, there's nothing to talk about." Well, this was a big concession for them, but they made it. So they bought us for common stock. I agreed to stay on, which I did. On the board? On the board and as.... They now are making me in charge of all of their snack food businesses around the country. So I got in, and I worked pretty hard, did pretty well. But then in a big company like that you've got all these internal politics going on, and somebody else was coming up into power, and I didn't like it. Yeah, and you were about in your early sixties. No, I'm sixty-five. So I said, "I'm sixty-five. Time to retire." So I retired. My son quit immediately. My son-in-law stayed on, but by now you've got to report to New York, and then you.. Before, he could just do anything he wanted to do. Now you've got to get permission. So he got tired of it, and he left. We were fortunate; we had that American Brands stock. It paid a good dividend year after year after year. It doubled, I'm going to say, six times. So we did very, very well. I still own a bunch of it, and now it's going down, but over the years it did very, very well. So that's that.

You can read the entire oral history of Mr. Nigg's remarkable career at

http://archives.cdn.sos.ca.gov/oral-history/pdf/nigg.pdf

The attached article entitled "3 Ingredients for Success Freshness, Quality, Flavor, Plus Wuse Management Tell the Story Behind Growth of Bell Brand Foods" in the September 1953 Los Angeles Times provides some of the company's history as well as its corporate philosophy:

HUGE BUSINESS INCREASE

Thirty-three years ago [1920] production began as Bell Brand potato chips in Los Angeles. "production" meant that at the start only two people worked to slice the potatoes, cook them, package them, and deliver them.

But although the plant personnel was small, the product was good from the start and business grew steadily though not spectacularly from year to year.

Eight years ago Cyril C. Nigg, nationally known food products merchandiser, took the helm of Bell Brand foods Ltd.. In these few swiftly rolling years Bell Brand potato chip sales increased eight times over the sales of 1944, the year before he became president. . . . 100% increase over the the original figure for each eventful year.

Trained experienced leadership and TEAMWORK by executive personnel are the decisive factors in the Success Story . . . a product of the American system of individual initiative and free enterprise.

Cyril Nigg had been Southern California manager for one of the largest manufacturers and merchandisers of breakfast food products. Not only as a leader in his specialized industry, but as an expert of food problems, he recognized the place that properly prepared and delivered potato chips would have on Southern California dining table.

That is why he and his associates placed their resources of mind and experience and finance behind Bell Brand.

FRESHNESS, QUALITY, FLAVOR

Cyril Nigg and his organization knew that the words "Potato Chips " are like the name of any other product . . . they do not in themselves spell quality or satisfaction; three other very important "ingredients" are required:

Freshness, Quality, Flavor

These words proclaim the standard of production aimed at and achieved by Bell Brand.

Mr. Nigg and his notable executive "team" Charles F. Fuller and James P. Hickey , vice presidents, and J. Spurgeon Finney, treasurer, knew from the start what it takes to please the great American customer.

Bell Brand potato chips MUST be delivered fresh and sold fresh.

Top quality must be accomplished by using selected potatoes and finest cooking oils only.

Just the right truly delicious flavor must be attained. This is delivered by a combination of selected potatoes, pure golden vegetable oil, PLUS exactly right timing in the frying process. . . timing that results in building the flavor and creating rich golden shade for the chips.

Finally, Bell Brand Potato Chips are delivered in double waxine packages, heavy enough for protection against sunlight, heavy enough in keep air out and keep in freshness, flavor and aroma.

Bell Brand packages are marked by a special code indicating when delivery was made and any not sold promptly are reclaimed by the plant.

QUALITY KNOWS NO SUBSTITUTE

It is splendid to have a product that will please everybody. It is another thing to get everybody to buy and enjoy it.

Enterprise and sustained advertising and merchandising and advertising have keynoted Bell Brand's campaign. Hundreds of thousands of Southern Californians are familiar with the appetizing pictures of Bell Brand Potato Chips in the Times Home Magazine and with the Bell-sponsored TV show Western Varieties on KTLA. Results have been not only in spread sales through most every city and town and small community in Southern California, but to make Bell Brand potato chips a "best seller" from San Diego in the south to Bakersfield and san Luis Obispo in the north (Properly managed potato chip plants reach in sales territory only so far as they can supply fresh products.)

Under the banner of Bell Brands, six other taste-tempting products are sold in ever-increasing quantities. "Frenchies" (shoestring potatoes), peanut butter, corn chips, pretzels, "Cheez Puffs," and Ruffles.

Quality knows no substitute and to insure that unvarying quality, Bell Brands maintains a laboratory and a chemist is in charge.

DEMOCRACY AT WORK

Only under our free American plan of industrial life can real democracy operate, and it is the belief of Cyril Nigg and his executive team that Bell Brands offers one of the best demonstrations of this activity.

Last February, a junior executive board of executives was created, consisting of ten members. All supervisory and administrative staff are eligible for selection to this board. A carefully planned system of of rotation ensures "new blood" for the board each year.

Regular meetings are held at which company policies are discussed and individual members submit new ideas for adoption. If any idea is unanimously voted for, after discussion, it is then submitted to president Nigg and the senior board. The senior board carefully considers it and then announces immediate adoption of the idea. or if not considered wise at the time a detailed report of the "reason why" is written and given the younger executives.

The junior board has already created enough sound and feasible ideas, adopted and now in practice to ensure the continuing success of this adventure in democracy. . . .representing the thoughts and activities and loyalties of the 250 Bell Brand employees.

"THE PLANT THAT POTATO CHIPS BUILT"

Bell Brand Foods Ltd. today is based in the big plant on Pacific Boulevard.

But the annual sale of much more than 15,000,000 pounds of potatoes . . . in the deliverable shape of many more millions of Bell Brand chips . . . has forced expansion into larger and up-to-the-minute headquarters.

Construction is now under way and will be completed the first of the coming year as a million-dollar plant.

The new plant will occupy eight acred of ground at Millergrove Drive and Los Nietos Boulevard, purchased a year ago. The main structure consists of precast concrete tilt-up walls supporting tapered steel girders.

The whole plant will be semi-automatic with five different systems of conveyors. A very important and modern detail is the fact that the entire floor will be steam-cleaned every day.

There is to be a dining room for employees with exterior terrace adjoining.

The great new headquarters truthfully could be "christened" "The Plant that bell Brand PotatoChips Built."

"IF IT'S BELL IT'S SWELL"

President, senior and junior boards are striving in every way to show Californians how Bell Brand Potato Chips are as desirable in DAILY enjoyment as are meat and vegetables and fruit.

More and more folks will learn the surprisingly large number of ways the crisp chips can supplement other units in the daily menu. Recipes are printed on the neat waxine packages.

By sustained perfection of quality, by controlled distribution, by brilliant advertising through newspapers, television and direct work, people are realizing that "If It's Bell It's Swell."

Bell Brand Snack Foods, Inc. was a Southern California-based manufacturer of snack products including potato chips, tortilla chips, and corn chips. The company's headquarters were located in Santa Fe Springs, California. The history of the company is continued by the nephew of Mr. Nigg, Tim Armstrong.

Cyril C. Nigg, who purchased Bell Brand from Max Ginsberg in 1947, was my uncle (mother's brother). My uncle Cyril sold the business to Sunshine Cracker in 1968, about 13 years after building the "Million Dollar Plant" in Santa Fe Springs. My father, Gene Armstrong, managed the distribution center in Loma Linda until we moved to Alhambra in 1950. Dad retired from Bell Brand in 1983 as the Plant Security Chief, following 36 years with the company. I left California for Alaska in 1975, my Dad passed away in 1994 and my uncle in 2000 (at age 95). I grew up around potato chips, peanut butter, Frenchies and corn chips, and have fond memories of everyone associated with Bell Brand.

G.F. Industries which also owned Sunshine Biscuits put Bell Brand up for sale in 1995 due to the company's financial issues. However, Bell Brand went out of business on July 7, 1995 after G.F. could not find a buyer for the company. Sunshine was sold to Keebler and then to Kellogg's. The only remnant of Bell Brand's product line left is Padrino tortilla chips which are still produced by Snyder's Lance Brands, which is now owned by Campbell's

View the photo of the bag of Bell Brand Potato Chips from the movie "The Seven year Itch" starring Marilyn Monroe.

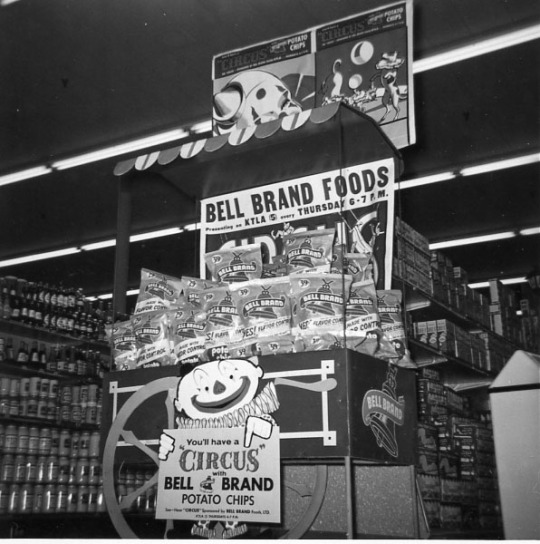

See the Cecil and Beany (note the names are in reverse order) ad. It is followed by the Bell Brand logo.

See the back of the Sandy Koufax Bell Brand baseball card.

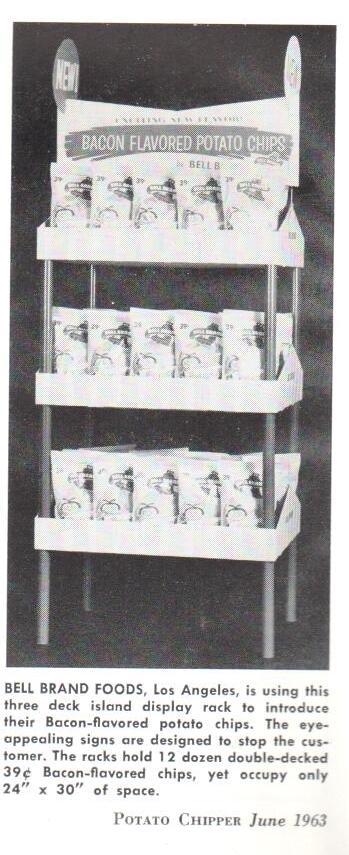

See also the bacon flavored potato chip stand photo from the June 1963 edition of the Potato Chipper

and the article about Cyril Nigg's retirement from the April 1970 edition of the Potato Chipper

. An article from the September 1953 edition of the Potato Chipper describes the new plant.

Enjoy the gallery of Bell Brand ads and the gallery of photos. View some 1950's Bell Brand grocery store displays.

http://mistertoast.blogspot.com/2006/03/bell-brand-potato-chips.html

. Finally see the photo of a woman and her child with a Bell Brand tin of potato chips and the photo of both sides of a bag of Bell Brand potato chips.

Enjoy the First Lady of Song, Ella Fitzgerald, sing the Gershwin classic, "Thou Swell."

youtube

The Toga Chip Guy

0 notes

Text

The Coronavirus Cost Of Your July 4th Barbecue

BuzzFeed News has reporters around the world bringing you trustworthy stories about the impact of the coronavirus. To help keep this news free, become a member.

After months of stress, Americans have been looking forward to the pre–COVID-19 pleasures of a (socially distanced) 4th of July. How about a cookout? It’s a traditional, low-key summer celebration — but amid the nation’s growing outbreak, even a simple home-cooked meal comes at an exorbitant price.

A BuzzFeed News investigation reveals the extent to which the virus — and the nation’s inadequate response to it — has infected, sickened, and even killed workers up and down the nation’s food supply chains as they work to keep our refrigerators full.

Take a typical summer feast: tangy ribs, a side of creamy pasta salad, and a slice of freshly baked apple pie. If you shop at a Walmart Supercenter, in, say, Massachusetts, the apples you’d buy would have been picked by workers in Washington state’s Yakima Valley, who live in a crowded labor camp with few protections in place. The fruit would then be sorted into boxes in an Allan Bros. packhouse, which for weeks failed to follow federal COVID-19 safety guidelines — even after employees started falling ill.

The ribs would have been sliced and packed by employees at a pork processing plant — like the Tyson Foods facility in Indiana that stayed open for weeks, even as the virus spread through its staff.

The pasta would have been stacked by grocery clerks whose employer was slow to close down for a deep cleaning after workers got sick, and to inform the local health department and customers of the growing outbreak.

From those three workplaces alone — the Allan Bros. packhouse in Yakima Valley, the Tyson plant in Indiana, and the Walmart in Massachusetts — around 1,100 workers have tested positive for COVID-19, and at least four have died, according to a BuzzFeed News review.

Worried about putting themselves and restaurant staffers at risk, many Americans have turned to home cooking as a safer, more ethical option. But what may seem safer for consumers can still be deadly for the low-paid, often immigrant workers who make up America’s sprawling food supply chain. Across the country, from fields to packhouses to slaughterhouses to grocery stores, companies failed to require masks, build protective barriers, or arrange testing until after outbreaks had spread through the workforce. Some workers in this chain still do not get sick pay, forcing them to choose between spreading the virus or missing out on paychecks — between feeding your family and exposing their own.

“I’d just like to see them keep us safe,” Dennis Medbourn, a worker at the Tyson plant in Logansport, Indiana, where three coworkers he knew have died from COVID-19 complications, told BuzzFeed News. “We’re working a lot of hours, too, to try to make up for the meat shortage.”

Courtesy Eklund Family

Yok Yen Lee (left), who died of the coronavirus, is seen with her daughter, Elaine Eklund.

One grocery worker, Yok Yen Lee, a door greeter at the Walmart in Quincy, Massachusetts, continued to report to work up until days before she died from COVID-19.

“She was really hardworking,” her daughter, Elaine Eklund, told BuzzFeed News. “She absolutely loved that job. She wanted to do that job for her whole life.”

The paths through which food reaches Americans’ plates originate on farms and in factories in small cities and rural towns before making their way across the 50 states. The networks are intricately interrelated, which means that the people who live in those areas and work in those jobs, along with the friends and relatives they come into contact with, shoulder a disproportionate share of the risk to keep the nation fed. An apple picker at a FirstFruits Farms orchard in Yakima Valley appears to have caught the virus from her husband who worked at a Tyson beef plant in the area, according to Erik Nicholson, vice president of United Farm Workers. FirstFruits didn’t respond to a detailed request for comment.

Since the start of the pandemic, around 29,000 workers at grocery stores, meatpacking plants, and other food processing facilities have been infected nationwide, and at least 225 have died, according to the United Food and Commercial Workers International Union. This is almost certainly an undercount: Many companies have declined to order widespread testing, even at workplaces where employees are falling ill. As a result, the full scope of infections among frontline food workers may never be known.

“What this pandemic is making very clear is that some of our most underpaid, marginalized, and exploited workers are, in fact, our most essential,” said Vermont Sen. Bernie Sanders, who co-sponsored a bill with other Senate colleagues in June to provide protections for the country’s agricultural workers. “Every plate of food reflects a disturbing reality: Food-supply workers — from farmworkers to grocery store clerks — are risking their lives every day to keep us fed, often in unsafe conditions, and far too often making starvation wages.”

“If they don’t work, they don’t get paid — and if they don’t get paid, they don’t eat.”

Apples

Bobby Doherty for BuzzFeed News

Bobby Doherty for BuzzFeed News

“If they don’t work, they don’t get paid — and if they don’t get paid, they don’t eat.”

On April 30, Angelina Lara felt an itch in her throat.

For seven months, she’d worked as a fruit packer for Allan Bros., one of at least 18 produce companies in Yakima Valley, a fertile agricultural zone that rolls east across central Washington from the mighty Cascade mountain range. Lara, 48, grew up in Southern California but moved to the city of Yakima in 2005, following relatives who had come for the jobs at the valley’s plentiful packhouses. Around a third of the local jobs there are in agriculture, more than the next two industries combined. Apples are one of the main businesses in town, and the fruit is at the center of the Yakima city seal. Central Washington accounts for 60% of the nation’s apple production.

Over the years, Lara worked at numerous packhouses, including a previous stint at Allan Bros. She returned to the company last year for a job that paid $13.50 an hour, more than the $12 minimum wage she made previously. Inside a squat warehouse on Highway 12 in the foothills of Mount Rainier, Lara and her fellow day shift employees washed and sorted apples, which are packed and shipped year-round in the region. Around 300 workers clock in for the day shift, standing along a brisk conveyor belt about 2 feet apart, sorting apples, like the organic Fuji variety sold at Walmarts across the country, and separating out fruit that’s been spoiled or infested with worms. (The night shift handles seasonal fruit, such as cherries.)

It’s hard, tiring work, Lara said, and “it’s impossible to be 6 feet apart because at times the line moves so fast that you need somebody to help you with all the apples.”

Elaine Thompson / AP

In this photo taken Oct. 15, 2019, workers sort Granny Smith apples to ready them for shipping in a packing plant in Yakima, Washington.

As COVID-19 was spreading across the state and the country in March and April, Allan Bros. added plexiglass barriers to the office area where management and administrators worked. “But the same was not put in the warehouse,” said Shauri Tello, who moved from Mexico to Yakima when she was 15 and began working in the fruit industry shortly after she graduated high school at age 18, two years ago.

The company hadn’t yet begun providing workers with masks, so some workers brought their own from home, according to four employees and a memo from health officials who inspected the site on May 8.

Lara didn’t immediately assume the itch in her throat meant she’d caught the coronavirus. At the time, she didn’t know if anyone at work had been infected, she said. Still, she stayed home from work the next day as a precaution. Within 24 hours, she had developed a fever. Then she began to have trouble breathing. Lara has asthma, but this was worse than any asthma attack she had ever had. “I was home alone, so I started panicking,” she said. At the hospital, she said, she paid for the COVID-19 test herself — $152 — and it came back positive.

Lara informed Allan Bros. that, under doctor’s orders, she would stay home and quarantine for two weeks. She and another worker who tested positive said that company officials told them that their leave would be unpaid.

She asked her supervisor to “let [her] coworkers know so they can take precautions,” Lara said. “They never did it. Nobody even knew I was sick.”

Three of her coworkers corroborated that claim, saying that management didn’t tell them about any cases at the plant in April and early May. In an emailed statement in response to questions, Allan Bros. denied failing to inform employees about cases until May but declined to specify when it began doing so.

Today, Yakima County has the highest rate of per capita COVID-19 cases in the Pacific Northwest — about 1 for every 34 people. In central Washington — as in other areas such as California’s Imperial and San Joaquin valleys — the agricultural industry is experiencing a reckoning; the methods for packing produce and housing migrant workers that have been maximized for efficiency have created the ideal conditions for the spread of a devastating virus.

Elaine Thompson / AP

A sign outside Yakima, Washington, declares the city the “Palm Springs of Washington,” on Wednesday, June 17, 2020

“When farmers were designing farmworker housing and warehouses in which fruit is sorted, they were in no way considering pandemics,” said Dr. Malcolm Butler, the officer for the combined health district of Chelan and Douglas counties, which lie north of Yakima and are home to some 20 agriculture companies. “They built an industry and fed the world, and unfortunately social distancing is not possible. It’s very challenging and extensive to retool an entire industry at the drop of a hat.”

By late April, the virus had been quietly spreading among apple pickers and packers in central Washington for weeks. The scope of the outbreak remained unknown, in part because many companies were reluctant to arrange comprehensive testing. But even the available case numbers at the time revealed that the region’s fruit workers were facing a mounting threat.

Two weeks before Lara got sick, on April 13, three apple pickers at the Stemilt Growers farm in Douglas County, 70 miles north of the Allan Bros. facilities, developed coughs, according to a court statement from Stemilt’s human resources director, Zach Williams. These three were among the thousands who entered the country on temporary work visas, known as H-2A, for jobs at the region’s farms. While packhouses are largely staffed with local residents who have lived in Washington for years, field work is mostly done by seasonal laborers who ride buses up from Mexico for gigs that can last upward of six months.

Elaine Thompson / AP

A supervisor looks up at a worker pulling honey crisp apples off trees during a thinning operation at an orchard in Yakima, Washington on Tuesday, June 16, 2020.

Sixty-nine of those workers were housed at Stemilt’s “North District” housing facility, Williams stated. They slept on bunk beds in rooms shared with as many as three others. They also shared a kitchen, a laundry room, and several bathrooms. In the mornings, they piled into vans that carried 14 of them at a time to the orchards.

The company began implementing new procedures to protect workers from COVID-19 as early as March 13, after a worker at a different Stemilt housing facility tested positive. In a memo to employees, Stemilt said that vans and common areas across the company would be sanitized every night and throughout the day.

Those measures weren’t enough.

While the three North District workers were awaiting their test results in mid April, three others at the camp began showing similar symptoms. Ultimately, all six tested positive, according to Williams’ statement. Over the next few days, Stemilt coordinated with local health officials to begin testing all the workers from the North District camp, as well as the eight local crew leaders who worked with them. All the crew leaders tested negative, but 44 of the 69 guest workers ultimately tested positive. When Stemilt conducted another round of testing on April 22, nine more workers tested positive. Most of the cases were asymptomatic. No one was hospitalized.

The state’s Employment Security Department said it expects 27,000 H-2A jobs in 2020. Stemilt declined to comment for this story.

Stemilt was the exception — not in terms of its explosion of cases, but because it looked for them at all. Though local officials in nearby Yakima County offered to organize free testing at all produce industry workplaces, only one fruit company, Columbia Reach Pack, had taken them up on it by late May, according to local health department documents. At most fruit companies in the region, workers only got tested if they showed symptoms or were exposed to a confirmed case, and then called health authorities. Still, by the third week of May, more than 300 fruit workers in the region had tested positive, and health officials identified outbreaks — a workplace infection rate of at least 5% — at seven of the county’s 18 produce companies.

Allan Bros., where Lara worked, was one of the companies that declined to test its workers. Danielle Vincent, a spokesperson for Allan Bros., denied that the county offered to test all its workers — though other companies confirmed the offer, and government documents show that local health officials were “Awaiting Response” from Allan Bros. on an inquiry about whether the company “Want[s] Employee Testing.”

Though 19 of 515 employees at its packhouse had been diagnosed by May 21, the company did not schedule widespread testing, according to local health department records. Workers had to decide whether to risk going to work and getting sick, or staying home and not getting paid.

“The fear of every worker that I know is that they may come down with the virus. And if they don’t work, they don’t get paid — and if they don’t get paid, they don’t eat,” said Erik Nicholson, national vice president of United Farm Workers.

Evan Abell / AP

Workers from Columbia Reach Pack continue to strike in front of the business on River Road on Tuesday, June 2, 2020, in Yakima, Washington.

COVID-19 exacerbates long-standing power disparities between farmworkers, some of whom are undocumented, and their employers, noted Beth Lyon, a law professor and founder of Cornell University’s Farmworker Legal Assistance Clinic.

And while the country has deemed them “essential” during a pandemic, most farmworkers can be fired at will, making many hesitant to advocate for safety measures.

This is particularly true of guest workers, whose visas are directly tied to their employer. “If they speak up for health protections like masks or social distancing, they are likely to lose not only their livelihood but also their housing” and their permission to be in the United States, Lyon told BuzzFeed News.

Local officials and farm owners attribute some of their slow reactions to the pandemic to the lack of direction at the federal level. That’s led the industry to “take care of itself” said Butler, the Chelan–Douglas Health District officer.

“The difficulty we’ve had was that there was absolutely no guidance on what was the right way to house H-2A workers,” he said.

Sean Gilbert, who leads Gilbert Orchards, said the Centers for Disease Control and Prevention’s changing position on masks left his company in a conundrum. In March — as the country’s leading top public health agency told citizens not to use masks and to save them for healthcare professionals — orchard and packhouse operators donated a few thousand N95 masks they had gathered for fire season to local hospitals. Weeks later, when the CDC changed its guidance, those businesses were left scrambling, facing stiff competition and spiking prices for face coverings as the rest of the world competed for mask shipments.

Gilbert, whose operation includes 4,000 acres of orchards and 1,200 workers during peak season, noted that apples are a “labor-intensive business” with small margins. As a result of social distancing measures, the packhouse could only prepare 10,000 boxes of apples per shift from late March to the end of May, rather than the typical 12,000.

“Keeping people apart means that people can’t hand off things in a process,” he told BuzzFeed News, “and it slows the process down.” He added that protective equipment and hazard pay add a further squeeze on Gilbert Orchards’ economics. “COVID has fundamentally changed how we do business.”

Yet he didn’t see the need to allow health officials to test all his employees. Gilbert Orchards — where at least 26 of the 350 or so employees in the packhouse, shipping, and administrative departments have been diagnosed — declined Yakima County’s offer to arrange testing at the facility and instead suggested its workers take advantage of the free testing sites local officials had set up around the valley.

Gilbert said part of his reasoning was fear of upsetting his employees. “I turned down their offer to bring in a National Guard unit to quarantine our facility while they escorted people to and from testing tents,” he told BuzzFeed News. “I felt that requiring that of all employees would have been potentially traumatic.”

Evan Abell / AP

A committee of Allan Bros. workers exits the company’s office after turning in a signed agreement to return to work, Thursday, May 28, 2020, in Naches, Washington, after a strike to protest what they consider unsafe working conditions at several fruit warehouses during the COVID-19 outbreak.

If guest workers are among the most vulnerable employees in the produce industry, workers who live year-round in central Washington are only slightly more secure.

Lara’s diagnosis, she said, threw her family into a precarious financial position. Her husband, who works at the same warehouse, and her two sons, who work as nursing assistants, tested negative but stayed home as a precaution in case they subsequently caught the virus from her. The household of four went without a paycheck for two weeks. Lara qualified for unemployment insurance because she’d been diagnosed, and her husband and sons may be eligible for family leave benefits — but whatever government money they’d receive wouldn’t come soon enough to meet the bills coming due. The family burned through years’ worth of savings in a matter of days, she said.

Back at Allan Bros., meanwhile, workers in the packhouse said the company still hadn’t distributed masks, and as the cases mounted, many were growing angry.

On May 7, dozens of Allan Bros. workers went on strike over conditions they said were unsafe; in the days that followed, around 500 workers from six other fruit companies joined them. When Lara’s quarantine ended, she took a spot in the line of workers holding signs by the road, chanting through colorful cloth masks. Local lawyers and union representatives estimated that the labor action was one of the largest they’d seen among agriculture workers in Yakima, reminiscent of the marches César Chávez attended in the county in the 1980s.

Nearly every day, at each of the seven strike locations, the workers encountered local white residents driving by, shouting at them to get back to work, said Cristina Ortega, an activist who participated in the strikes. She recalled those drivers saying things like “If you don’t like it, get out.” On another occasion, a man shouted out his car window that he was going to “come back and shoot you all,” according to a Yakima County Sheriff’s Office incident report and written witness statements. When deputies later caught him returning to the scene, he told them that Allan Bros. “treats those people very well and they should not be protesting,” according to the incident report. The man was arrested and charged with malicious harassment.

The backlash against the striking workers reflected a long-standing resistance to Yakima’s growing Latinx population for some. Latinx residents accounted for 15% of the city’s population in 1980, 30% in 2000, and 50% in 2018. Still, no Latinx candidate had been elected to office in the city until 2015, after a federal judge ruled that the city’s previous system of at-large council seats violated the Voting Rights Act. In 2016, a majority of the county’s residents cast their ballots for Donald Trump.

Three weeks into the strike, Lara finally went back to work. Allan Bros. had installed protective barriers in the packhouse, offered a $1-an-hour pay raise, and started providing masks, according to Lara and three coworkers. Though she has been cleared of infection, she still has trouble breathing and sleeps sitting up most nights. She said her doctor told her it might be months before she feels normal again.

She considers herself fortunate, she said. One of her coworkers, 60-year-old David Cruz, got sick a few days after she did. His wife and daughter tested positive too, Lara said. He had worked at the plant for 12 years, most recently putting together boxes on the upper level of the warehouse. When Lara saw him on breaks, he was “always positive, getting along with everybody,” she said. On one of the last days of work before the pandemic hit, Cruz told Lara about his plans to visit his mother in Mexico for the first time in years. “He was very happy he was going to see her,” Lara recalled. “He was planning for June or July.”

He died on May 31. His coworkers collected $4,000 to give to his wife. The mood at the packhouse has been somber since.

“Wow. It spread out really, really quick.”

Pork Ribs

Bobby Doherty for BuzzFeed News

Bobby Doherty for BuzzFeed News

“Wow. It spread out really, really quick.”

Every morning at the Tyson pork plant in Logansport, Indiana, a low-slung town of 18,000 that’s located at the intersection of three highways and surrounded by livestock ranches, farmers deliver the hogs to the kill floor, known colloquially as the “hot side.”