#i did like. a few months long project at work over PCBs and had to do a deep dive into the difference between rcra & tsca regulation for it

Explore tagged Tumblr posts

Text

#heya howdy!#I might be able to help you with this query!#I have taken a couple environmental science classes and re-read several wikipedia articles#hazardous waste is defined by different criteria depending on country#but for the US the EPA is the one that defines them#I highly recommend checking out the EPA's website on hazardous waste as it is extremely informative#the gist of getting rid of hazardous waste is that its either treated recycled or disposed of and there are issues with all three methods#for things like nuclear fuel rods and control rods#they are stored at specific sites and usually buried underground#there's a phenomenon called NIMBY (not in my backyard) in which government and private agencies find it hard to find people#that are willing to have nuclear sites and landfills and such near them#hazardous waste like e-waste (electronic waste) or medicines & cosmetics (some of which can be endocrine disrupters) have to be disposed#of differently and properly since e-waste and EDs are extremely harmful if they get into ecosystems (arsenic lead stuff like that)#or if its electronic just always bring it in to Best Buy they'll make sure it gets disposed of properly and they'll pay you#that's been your daily hazardous waste lesson again go check the EPA they have waaay more information on this kinda thing via @jackfrostbiten

first, adding these tags here because they're amazing. and here's the EPA hazardous waste site for good measure

second, i sadly don't know much about nuclear waste in general, but i can talk some on hazardous waste. be aware though, i'm only familiar with US laws on it though!

the law that defines hazardous waste is known as the Resource Conservation and Recovery Act, otherwise known as RCRA (rick-ra). it defines hazardous and non-hazardous waste and applies to it from creation to disposal. the criteria for a waste being deemed hazardous is if it displays one or more qualities: ignitability, corrosivity, reactivity and toxicity. there's a lot of listed wastes, and most of them have requirements on what sort of facilities they must be taken to--are they buried in a lined special landfill? are they incerated? etc, it will vary by chemical. the Toxic Substances Control Act (TSCA, tos-ca) is what i mostly work with, and it deals with the regulation/registration of new chemicals, regulation of existing potentially hazardous chemicals, and their distriution.

anyway, that's mostly regulatory stuff, which isn't really what was asked about, but it's more of what i know. the nuclear regulatory commision actually has some responsibilities over regulating nuclear waste, while the epa has others.

i skimmed this article though for actual clean up/non regulatory information and it seemed interesting:

the funniest thing about my environmental science degree is that whenever i tell people that's what i do, they immediately assume i do ecology/wildlife stuff. they're like oh animals? botany? ur like a naturalist?

and i LOVE nature dont get me wrong but like. my favorite thing to study is actually environmental disaster remediation and pollution <3 i love superfund sites i love groundwater plume maps i love emergency management i love (getting rid of) hazardous waste <3

i'm aware basically everyone else's eyes glaze over at this <3

#i did like. a few months long project at work over PCBs and had to do a deep dive into the difference between rcra & tsca regulation for it#the answer is that pcbs are covered by tsca and not rcra because pcbs are not hazardous waste by definition#but they can be contained in hazardous waste and at that point it is subject to BOTH laws#which means it has to go to a disposal facility/incinerator that is both rcra and tsca permitted#weirdly complicated!#environmental science with quara

66 notes

·

View notes

Text

Film Review - Misteri Dilaila by Syafiq Yusof

Misteri Dilaila is a Malaysian horror thriller film that went viral in 2019. I rarely watch Malaysian films because when i do, it’s usually the same plot all over again. Drama, romance, action, comedy and everyone’s favourite, Horror. I feel like these genres are the usuals everywhere but what makes it unbearable for most of us Malaysians is how similar every story is. Rich boy meets a poor girl. Rich boy falls in love with her and when they get married the mother hates the poor girl. They fight and one day someone dies and the end. For horror, it’s just about some people getting haunted by a ghost that was sent by a close friend of theirs.

The thing I understand about the horror hype for Malaysians is how our culture is deeply rooted with mystical beliefs and as religious as we tend to be, ghost stories seem to intertwine with our faith for countless years. Personally, I believe in Asian ghosts more than the western versions. This is probably due to my own family having our fair share of sights into the world of the undead.

The reason why I chose to talk about this film is because of how disappointed I felt when I watched it. Unlike most Malaysian films, it had the potential to be a great one. The look of the film was far better than the usual ones we got and the story building had a Gone Girl vibe. What made me disappointed was the fact that while watching that film I was hopeful and excited thinking finally a Malaysian Filmmaker is making a psychological horror instead of those in your face jump scares.

The story is about a married couple, Jefri and Dilaila, who were spending their holiday together at a luxury vacation home in Fraser’s Hill. After a petty issue where they end up quarrelling at each other, Jefri discovers his wife went missing the following morning. Next thing he knows, a mysterious woman who also goes by the name of Dilaila shows up one night where she claims to be his wife. Adding more confusion is the supernatural occurrences that regularly haunts Jefri whenever he’s alone in the house.

Throughout the whole film, I was at the edge of my seat thinking that there’s finally a malaysian filmmaker that is about to introduce a character with a mental illness as the protagonist which would’ve justified his hallucinations of the ghost. Unfortunately, it was just like other films where there’s no actual context to the sightings, they were just ghosts being ghosts and haunting him for no reason. Well that’s for the 2nd version of the film.

Another fun fact about this film is that it went viral due to the alternate endings it has. When the film came out in the cinemas, people were surprised to hear that they had different endings when they discussed it with their friends. This was purely the filmmaker and his team’s intention. Different halls have different endings and this was meant to be a surprise for the audiences. It was a great marketing strategy and considered as a genius way of thinking for some people while some were mad that they were being ripped off.

*SPOILERS AHEAD*

As a person that watched both versions, I was unsatisfied with both versions as both endings angered me. Nevertheless, I didn’t think it’s an absolute flop though. Both versions have the fair share of plot twists. The first version revealed that the protagonist we thought all along was the actual antagonist. He was the one that killed his own wife whilst every supporting character was a part of the police team that were acting to make him confess to his wrong doings. It was then stated that the hallucinations he got was a result of his guilt and him being under the influence of drugs all along.

The second version on the other hand is more mystical. The ghosts made more appearances in this version. The protagonist is still the good guy but the inspector that was involved in the case turned out to be a fake policeman and he was working with the imposter Dilaila. Towards the end, Jef found out that his wife has been dead a long time ago and the ‘wife’ he was holding turns out to be something else (this we never see on screen though).

Personally if i were to choose an ending, I would choose the 1st version as it makes more sense logically but I can understand why people love the 2nd Version. Malaysians and their thirst for horror films explains the statistics. But a famous film reviewer on YouTube (ZhafVlogs) once made an instagram poll and asked his subscribers to choose between the two versions and surprisingly it was a tie. This proves that the director made the right decision to come up with alternate endings.

*END OF SPOILERS*

The film then landed in a controversy within the next few weeks after the premiere. Someone noticed that the story was awfully familiar. It was then proven that the story was 90% similar to a few films from India, America, Russia and more. People were comparing it to a film called “Vanishing Act” and they were right.

As a film student, I am aware about the concept of adaptation so I personally see no wrong in the filmmaker’s act. However, I can understand why people are mad. The filmmaker went silent once news got out about him “stealing” the idea and “claiming” the story as his. But based on my research, I never found him claiming the story as his before. Although, he also never mentioned about him making a remake of the initial film as well. The filmmaker went silent for a long time and people kept sending him hate comments but soon died after a few months.

A year later, the issue was raised yet again by someone and this caused the filmmaker to finally speak up. He explains the concept of adaptation and how he was inspired by a scriptwriting book called Save The Cat which said that “A good artist copy, but a great artist steals”. He also states about there being so many films abroad that have the similar concept to an older film such as Fast and Furious with Point Break, Avatar with Pocahontas and Inception with Paprika. He finally came clean and stated that he was inspired by a stage play from France called “A Trap for a Lonely Man”. He then added his own twist by adding some horror elements knowing that it being the target audience favourite genre.

Also regarding the quote from Save The Cat, (in my opinion) I feel like what the author was implying is about ‘stealing’ stories from life. Not stealing the exact plot codes from other films. This is based on my understanding from the phrase which I assume Syafiq may have misinterpreted it.

He raised logical points from a filmmaker’s perspective and he also raised some issues about being pressured from his father (Yusof Haslam) and brother (Syamsul Yusof) who were well known filmmakers as well. He said that everyone kept on telling him to be better than his father and brother. Sadly, when he was at his lowest, even his family turned their backs on him and said that it’s fully his fault.

From my point of view, I was initially furious with him for not being able to defend himself by explaining about the adaptation because I feel like most Malaysian audiences are unaware about it. People assume adaptation is from book to film when it's more than that. I, myself, learnt that from film school. And I’m not entirely defending him as well, I’m still disappointed in him for not speaking up sooner. But I do empathise with him as well. The audience were quick to attack him. The film industry in Malaysia is not entirely in the best state for these past few years. So a film like Misteri Dilaila made everyone hopeful for more quality films like it only to be betrayed at the end when they found out that it wasn’t his own creative idea and a total rip off. I still feel like he did a good job with his visuals which was an improvement from the local films around that time.

Reading through the whole issue and looking at how this decision to “copy” the plot codes as he was inspired from the Save The Cat book has opened my eyes. As a filmmaker, I feel like i should always do research before starting on a project and the best thing is to always be honest with our intentions. If it’s inspired by a remake, then set it straight and give credit to the original piece. Don’t keep it to yourself. It is terrifying though, being in his state where everyone turned their backs on him, even his own family. He released a few films after that, saying that film is his job and that it is his source of income so as much as it may seem hard sometimes, life still goes on. Sadly, he received a lot of backlash and people lost their faith in him. People were being sarcastic and teasing him if the film was even his.Seeing that happened to him opened my eyes. People may let it slide but they’ll never forget. Once you screw up, people will remember and use it against you.

Pictures of the set:

Links to Film Reviews:

A Non-Horror Fan's Guide To Watching 'Misteri Dilaila'

https://rojakdaily.com/entertainment/article/6414/a-non-horror-fan-s-guide-to-watching-misteri-dilaila

Misteri Dilaila (2019) Review

https://www.caseymoviemania.com/2019/02/misteri-dilaila-2019-review/

Movie review: Misteri Dilaila

https://www.thesundaily.my/style-life/reviews/movie-review-misteri-dilaila-DJ649603

Link to news about the controversy :

Is Local Horror Film ‘Misteri Dilaila’ a Rip Off? Here’s What The Director Had To Say..

https://juiceonline.com/is-local-horror-film-misteri-dilaila-a-rip-off-heres-what-the-director-had-to-say/

Horror fans slam ‘Misteri Dilaila’ for ripping off Hollywood film ‘Vanishing Act’

https://www.malaymail.com/news/showbiz/2019/03/05/horror-fans-slam-misteri-dilaila-for-ripping-off-hollywood-film-vanishing-a/1729154

Clarification/Statement by the Director about the issue (in Malay);

https://www.facebook.com/photo?fbid=649749852534594&set=pcb.649750949201151

1 note

·

View note

Text

System76 and LVFS - What Really Happened

Wednesday there was an unfortunate message posted from Richard Hughes regarding his firmware service.

As a company, we really try to focus our energies on positive progress in building open hardware. It’s important to us to set a good example for how an open community should collaborate. When this message was posted, we originally took the stance of not refuting the articles’ gross misrepresentations. However, this article has caused some confusion with our customers.

When we reached out to Richard over a year ago, we were enthusiastic about LVFS and interested in whether or not it would work for us. Once we described how we needed to deliver firmware, we were told that it would not work well and would likely not be acceptable to Red Hat Legal.

System76: Yes, AFUEFI [a firmware flashing tool] is proprietary. We could distribute it in binary format, as part of the cab in LVFS. What we need to flash is for a simple, open source, piece of EFI code to run the extracted AFUEFI executable with the correct parameters. The EC would also be flashed with a similar tool. If desired, we can package it all up into a single EFI executable to be run by fwupd on reboot. The method we are currently using is to bless a new EFI binary (currently a UEFI shell) and reboot to it, then it runs a script that does the flashing, and then removes itself as a boot option.

Richard Hughes: I don't think this will work well; for a few reasons: * there's no way to reference a flashing tool in the XML, or to sign a executable on the LVFS * I don't think Red Hat legal will like the idea of shipping the flashing program, we've only ever talked about the firmware files themselves (although I concede the images in the .cap are probably firmware executable code wrapped up in layers). * I know the Red Hat security team will do more than blink when we tell them we want to ship a untrusted nonfree binary which would get run as root on RHEL on customer machines.

There is no other way to interpret this email other than LVFS won’t work well for us. UpdateCapsule is not supported by over a decade of machines in the field and could not be added without a firmware update. With UpdateCapsule, the vendor’s proprietary update software is still present (with the same security considerations) but is integrated into the firmware blob. This is less modular than our approach, and does not allow the reverse engineering and open-sourcing of firmware update components.

So we can’t use LVFS for BIOS. Maybe the EC? We experimented with flashing the EC from user space. The keyboard is connected to the same device and would freeze during the update process. The experience was suboptimal and not up to our standards.

Delivering automatic updates to customers is important for our customer’s security and our ability to constantly improve computers. We continued to experiment. In about a week or two we had a working proof of concept that delivered the BIOS and EC reliably and securely. Over the next months we improved the tool, added unique blockchain security infrastructure, moved it into laptop production and then out to customers.

The decision making is simple. We are told we can’t distribute the tool we need in LVFS. Flashing the EC in user space is suboptimal. And in any case managing separate repos for two components that work together is error prone. And we have a working prototype. Soon thereafter we were shipping firmware built on secure infrastructure out to customers. Thanks to this work we were able to quickly and automatically patch computers when the Intel ME vulnerability arrived, and we have a battle-tested system in place for the future.

LVFS Misrepresentations

The statement that claims our firmware tool only works on Pop!_OS is not true. System76 computers ship with Pop!_OS and Ubuntu, and both include automatic firmware updates. All Ubuntu based distributions are supported. We’ve had customers with Arch use our firmware update tool. We’ll officially support more distributions as time permits.

Our conversations were completely misrepresented and distorted in a way that was designed to make us appear as though we made the decision not to use LVFS rather than the truth - there were several conversations to try to implement this, followed by many roadblocks, and then we were told “I don't think this will work well.”

We engaged with the project in good faith. When it was determined that LVFS would not work for our needs, we built an open source tool that would provide the necessary functionality for our customers. Having a collaborative conversation about how to use existing tools, then needing to build an open tool that best fits your needs should never result the way this conversation did.

System76 and GNOME

It's unfortunate this appeared on the GNOME blog, but it only represents one person—not the GNOME community as a whole, nor our relationship with GNOME. We couldn't be more excited about our shared future with the GNOME project and working together to advance the free and open source desktop.

The Future of Firmware

LVFS and UpdateCapsule might be okay for companies mostly focused on a proprietary future (Logitech, Dell, etc.). UpdateCapsule is not the technique companies will use in a future of open source firmware—the future we’re working toward.

Liberating firmware is going to be a long and challenging process. Much like Free Software has replaced proprietary software over time, we must chip away at the proprietary firmware pieces within the hardware supply chain. Manufacturing is the first step. This year we’ll manufacture open source desktop designs in our Denver plant. The CAD will be free to download, change, and produce.

There will be a separate, open source electrical design and open source firmware daughter board to control functions within the desktop. On a mainboard there is the BIOS chip and one or more embedded controllers that manage fans, keyboard, LEDs, hotkeys and other critical functions. It’s all proprietary. Our strategy is to move this functionality from the proprietary mainboard to the open source daughter board. Then anyone can create a PCB with basic computer functionality, understand how it works, and improve upon the work. One could have this PCB made at Osh Park, install it in their desktop, tune it, and replace a bunch of proprietary firmware instantly. We’ll grow from there.

Slowly we’ll chip away at more and more of the mainboard functions until what’s left is Intel and AMD bits. Then there’s the challenge of convincing them to go open. There’s room for cautious optimism.

On Open Source and Community

There are thousands of open source projects led by smart and supportive people that are kind to each other and good to work with. Open Source as a community gets a bad rap at times. Projects that attempt to bully others into saluting their flag are the exception. We choose to support those that want to build things and those that encourage others to build things. Go GNOME, go KDE, go i3, go Solus, go elementary OS, go Kdenlive, go OpenShot, go, go, go! Let’s just make things. Don't worry about saluting one flag over another. Do what is right for you and your project. The premise of “NIH” is antithesis of open source.

Now, we’re off to build a factory to manufacture open source computers. Oh, and when you buy a System76 computer, you support people actually working to liberate the computer.

17 notes

·

View notes

Text

Day 743: PVT

Hello from Oakland!

TL;DR: PVT assembly is done; Mass Production should start next month.

We have quite a bit of news to report this month. Probably the biggest and most exciting news is that we're (finally) no longer three weeks away from starting the pilot run (also known as PVT). Roughly 85 PVT units were produced last week and are finishing up 72 hours of 'burn-in' testing now. On Wednesday, our third-party QC agency will double-check them as they go into their boxes. On Thursday or Friday, an express shipper should pick them up and put them on a plane destined for our fulfillment partner in California.

From there, they'll be dispatched to some early Kickstarter backers.

(We know we haven't sent your surveys yet. We're working on the survey design with BackerKit now. Look for email about the survey in your inbox in the next week or so.)

Long time, no backer update

It's been about six weeks since we last wrote. The first three weeks were pretty quiet, but the last three weeks have been mind-bendingly busy. The past week was really, really busy. We live-tweeted the PVT run.

The first few Model 01s start their 72 hour burn-in tests

Algernon collected our tweets from last week into a series of moments:

Day one: https://twitter.com/i/moments/876743212114825216

Day two: https://twitter.com/i/moments/877030769008533504

Day three: https://twitter.com/i/moments/877393482255564800

Day four: https://twitter.com/i/moments/877758532044685312

Jesse just returned from two weeks in Shenzhen. The plan was for him to spend a little over a week there finalizing the keycap laser engraving, checking out last minute details and supervising PVT on Monday, June 19. Things didn't go exactly to plan, but as you'll read, things went!

Keycap factory

Jesse's first day in Shenzhen, he visited our keycap factory to check in on updates to our injection molds and to talk through some issues with the trays they made for the laser engraving factory to use during the painting and engraving process.

Visiting with our keycaps' injection molds

They promised to get things fixed up right away and to produce sample keycaps within a day or two. When the caps still hadn't shown up by Friday morning, we got a little antsy and asked what the problem was. Our factory's team said they weren't quite sure, since the keycap factory claimed to have already completed the modifications.

At this point, we were prepared for any number of possible explanations or excuses. We've had a lot go wrong during the manufacturing process and thought that we were beyond being surprised.

The factory called up the keycap supplier, who told them that the modifications weren't done… and that getting them done that day might be difficult.

Because the factory had caught fire.

They reassured us that nobody had been hurt (and that our tooling was fine) and seemed to be up and running by the next day.

They did manage to get 120 sets of keycaps and painting jigs done in time for PVT, though the painting jigs appeared to still be of the older design that was prone to warping. Our factory doesn't know why the keycap factory hasn't delivered the newer painting jigs, but has promised to get to the bottom of it.

Keycap laser engraving factory

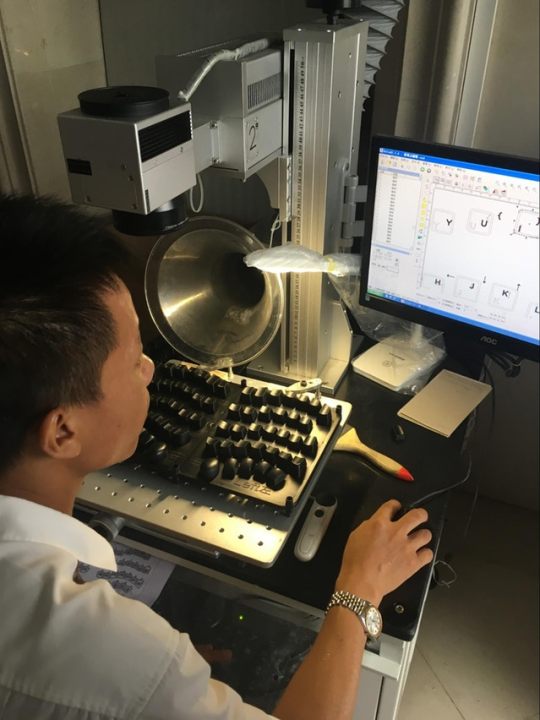

On his second day in Shenzhen, Jesse and the team from the factory braved typhoon Merbok to pay a visit to the keycap laser engraving factory in Dongguan. The primary issue on the agenda was figuring out why the keycap labels kept ending up significantly offset from where we'd put them.

We'd been sending files to the factory that showed the key labels with a variety of annotations to help the laser operator place them correctly. We'd gone so far as to build a layout that matched the painting jig to the millimeter.

Once we got to the keycap factory, the laser company took the sample keycap sets we'd brought with us and painted them black. They put them in the drying oven and suggested we go for lunch.

An engineer at the laser-engraving supplier aligns key legend

When we got back, we watched as the laser engraving technician printed out a copy of our alignment template, deleted all of the guide lines from the file, imported the legends into the laser engraving software, and proceeded to try to eyeball the correct label placement.

Going in, we were annoyed at how far off the legends were. In retrospect, it's astonishing how good his manual placement was.

After a bit of back and forth, we found a workflow that seemed to work better. We convinced him to keep the keycap top edge outlines in the drawing and to use those to make sure he was placing the labels correctly. That seemed to work better.

PCB Fabrication

The factory's regular PCB fabrication company wasn't able to make the boards in time for PVT, so they ended up using another supplier we recommended. These are folks that friends of ours have used on numerous occasions. Instead of the 20 days the factory's regular supplier quoted, these folks quote 6-7 day lead time. Well, they usually quote 6-7 day lead time. This time around, they quoted a 10-12 day lead time. Twelve days would have had the boards done on the Thursday before PVT began. But on Thursday, they told our factory that the earliest they could promise delivery was Monday. When the factory pushed back, they said that if we didn't like the lead time, we could try another supplier.

The factory escalated to a customer service manager who said that they could do Sunday, but that was the best we'd get. Sunday delivery meant that PCBA wouldn't start until Monday, which would delay PVT. This was not ideal, but we seemed stuck. Asking around a bit, some friends mentioned that the supplier had been "closed by the government for some reason."

We reached out to Ken Li, our amazing project management consultant. Ken said "What's our order number? Hang on a minute."

Ken came back about 10 minutes later saying that he'd reached out to the CEO of the PCB factory, whom he happens to know, and that the CEO had promised our PCBs would be delivered on Saturday. In the end, he was as good as his word and the boards arrived late on Saturday.

PCBA

The factory's regular PCBA (PCB Assembly) shop is located in the same building as the factory. Unfortunately, they don't work on Sundays and the factory couldn't get them to budge, so, in an effort to catch up to the promised PVT schedule, they reached out to another supplier who do work on Sundays. This was the first time they'd worked with this supplier. And, as of last Wednesday, it is the last time they will work with this supplier.

This diode should never have made it through the PCBA shop's QC process. Consequently, the factory won't be using this PCBA shop again

Every single PCB had problems. Most of the issues were mis-soldered diodes. The boards looked like they'd been assembled by hand, rather than by machine. They also looked like nobody had done a simple visual inspection after assembly.

Visual inspection is a standard part of commercial PCB assembly. Any halfway decent vendor has automated equipment to do visual checks of boards after assembly.

The factory ended up having to "rework" every board to fix surface mount assembly issues. This ended up being a two day setback. In hindsight, we would have been better off if they'd used their regular SMT shop, like they'll be doing for mass production.

Type C Cables

We thought we had a workable Type C cable for PVT, but when the factory placed the order with the supplier, they admitted that they didn't actually have the cables or the required raw materials to make more in stock and that we'd be looking at a lead time of 3 weeks or more.

Plan B was to wake up early on Saturday morning and go to Huaqiang Bei, the world's largest electronics market and buy some cables retail for PVT. Ken offered to come along and to bring a friend who was a professional cable maker who wanted a chance to pitch for our business.

Over coffee, he convinced us that we really, really didn't want to buy retail cables in the market and said he could build cables to our spec, on our deadline.

He ran off to find some samples of a few options. When he got back, we talked through our requirements and he promised to send samples.

Four days later, we had three sample cables that looked like we expected. Shortly after Jesse headed home from Shenzhen, the vendor delivered all the cables for PVT.

PVT production

Jesse didn't tell the factory it was his birthday, but they still delivered quite the birthday present. The factory fired up the assembly line and produced all of the PVT units on Wednesday, June 21.

We'll talk more about the assembly line in a future update.

QC

The next day, Jesse sat with the factory's QC team and our third-party QC agency to review the assembled units and to start to identify what quality issues they need to look out for and what we generally consider acceptable. For the sorts of parts they're used to dealing with, this is pretty easy. For some things, like the wooden enclosures, we needed to be a bit more detailed.

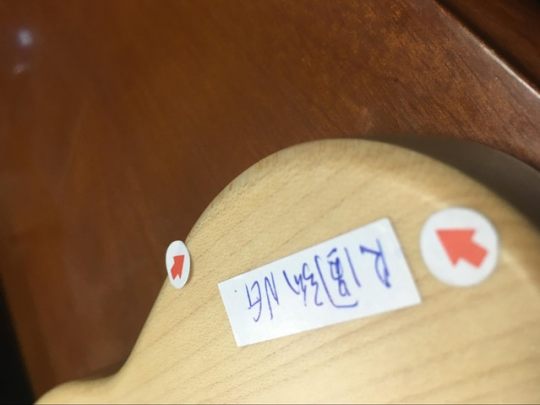

This wooden enclosure failed QC because the edge had been sanded too much, rendering it flat, rather than rounded.

Wood is, of course, a natural material without a uniform color. We showed the factory examples of unacceptable problems, which included tooling marks on visible surfaces, wood filler on visible surfaces, and ugly discolorations. At the same time, they pointed out issues they thought we'd reject. For the most part, we agreed with them.

Model 01 keyboards that have passed our QC checks

It was a pretty long day, but we managed to go through about 70 keyboards. The way it worked was that we’d choose a category of defect to review (like “keycaps” or “wood”) and then queue up each keyboard. The factory’s QC team would check the keyboard and either pass it or reject it. If they rejected it, they’d add a little arrow sticker pointing at the problem. If they passed it, they’d hand it to our QC guy. He’d review it, either adding a sticker and rejecting it or pass it and hand it to Jesse. He’d review the keyboard. If Jesse didn’t pass it, we’d stop the line, discuss the defect and the QC team would modify their acceptance criteria.

At the end of a given pass through the keyboards, we’d all review the rejected keyboards together to make sure they weren’t being overly critical.

This "birdseye" Model 01 is the one Jesse gave Kaia for our 10 year wedding anniversary. (If you look closely, you can see a keycap that failed QC and had to be swapped out.)

The one surprise for everybody was "birdseye figure" Maple. Our jaws dropped when we found a few examples of birdseye maple in with the PVT keyboard enclosures. They were gorgeous. The factory's QC team thought they looked funny and didn't look like they were supposed to. It took a bit, but they now understand that if any birdseye Maple makes it into the supply chain, they shouldn't reject it. (Right now, we’re not able to promise anyone a birdseye figure enclosure. It’s very much luck of the draw.)

At the end of the night, the factory packed us up a carton of six keyboards, which Jesse hand-carried back to California, where we’ll be doing a little bit of additional QC.

In-house QC

Issues we found during PVT

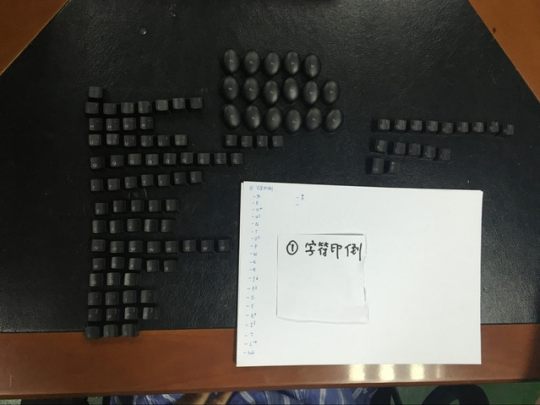

By far, the biggest issues we ran into during PVT were with the quality of laser-engraving on the keycaps. At some point, we'll do a writeup of the root cause of the keycap issues, but that'll be a few thousand words on its own.

Checking every keycap by hand

We ended up with an eye-watering defect rate of around 25% on the laser engraving for the keycap sets. The two biggest failures were poorly aligned legends and keycaps that had been laser-engraved backwards. The proximate cause of these problems was that the keycaps need to be moved (manually!) from one painting jig to another in order to make sure the bottom edges of the keycaps get good paint coverage. Because this process requires a human to touch every single keycap, it's a point where errors get introduced.

These are a subset of the keycaps that failed QC. The factory lined them up and counted them to help drive-home the magnitude of the problem to their suppliers

Needless to say, this isn't going to work for mass production.

We've spent a bunch of time with the factory going over process improvements for mass production. They want to do a bit of research and testing before deciding on a final solution, but we've got a few promising options.

What's next?

Now that PVT production is "done", there's still a lot to do before you get your keyboards. Thankfully, almost all of it is straightforward for the factory.

Once we get the PVT units to the states, we'll ship them out to willing early backers. (There will be a question on the backer survey about it.) After that, we'll be eagerly awaiting feedback from folks who get PVT keyboards to make sure that we’re not missing something obvious.

The factory will be subjecting a few Model 01s to torture tests. They'll be exposing them to a few days of ultra-bright UV, spraying them down with a saline fog, and dropping them on a concrete floor. While we sort of wish we could be there to watch these tests, we're probably better off not having to watch the torture taking place. That should take about two weeks.

The factory will also be sending one keyboard to the FCC test lab to send onward to their partner lab in Taiwan for final testing and issuance of the "Declaration of Conformity". That should also take about two weeks.

At the same time, the factory is working to refine their internal test and assembly process based on the PVT run. That'll let them build Model 01s faster and more reliably when they have to make a few thousand of them at a go.

Right now, we're expecting the first couple thousand units to roll off the line in July.

<3 j+k

0 notes