#hydraulic flow controls valve

Explore tagged Tumblr posts

Text

#Hydraulic Flow control valves manufacturer in mumbai#Hydraulic Flow Controls valves manufacturer in Delhi#Hydraulic Flow Control valve manufacturers in chennai#Hydraulic Flow Control valves manufacturer in Bangalore#Hydraulic Flow Control valves manufacturer in Rajasthan#Hydraulic Flow Control valve manufacturers in ghaziabad#Hydraulic Flow Control valves manufacturers in Gujarat#Hydraulic Flow Control valves manufacturers in Vadodara#Hydraulic Flow Control valves manufacturers in ahmedabad

0 notes

Text

Unveiling The Best Hydraulic Flow Control Valve Manufacturers in India

Hydraulic flow control valves are essential components in hydraulic systems, ensuring optimal performance and efficiency. When it comes to manufacturing these crucial devices, Pedlock stands out as a hub of innovation, quality, and cost-effectiveness. In this article, we'll delve into the top hydraulic flow control valve manufacturers in Mumbai, Ahmedabad, Chennai, Vadodara, Bangalore, Gujarat, Ghaziabad, Rajasthan, and Delhi in India, exploring their unique offerings and why they are the best in the business.

Understanding Hydraulic Flow Control Valves

Importance of Flow Control in Hydraulic Systems

Hydraulic systems rely on precise flow control to operate efficiently. Flow control valves regulate the rate of fluid flow, maintaining the desired speed and force in hydraulic actuators. This ensures smooth and consistent performance across various applications, from industrial machinery to construction equipment.

Key Features of Hydraulic Flow Control Valves

Hydraulic flow control valves come with a variety of features designed to enhance system performance. These include adjustable flow rates, pressure compensation, and temperature resistance. The quality and reliability of these valves are paramount, making the choice of manufacturer crucial.

Why Choose Indian Manufacturers?

Quality and Innovation

Indian manufacturers are renowned for their commitment to quality and innovation. They invest heavily in research and development, ensuring their products meets global standards and incorporates the latest technological advancements.

Cost Effectiveness

One of the key advantages of choosing Indian manufacturers is cost effectiveness. They offer competitive pricing without compromising on quality, making their products accessible to a wide range of customers worldwide.

Global Reach

Our hydraulic flow control valve manufacturers have a robust global presence. Pedlock’s products are exported to numerous countries, reflecting their reliability and international reputation.

Top Hydraulic Flow Control Valve Manufacturers in India

Leader in Innovation

Overview and History

Pedlock company established decades ago, the company has consistently led the market with its innovative solutions and cutting edge technology.

Product Range

Our product range includes a variety of hydraulic flow control valves, each designed to meet specific industry needs.

Unique Selling Points

What sets them apart is their continuous pursuit of innovation, ensuring their products are always at the forefront of technology.

Pioneer in Technology

Overview and History

With a rich history in the hydraulic industry, the company has built a reputation for technological excellence and reliability.

Product Range

We offer a comprehensive range of hydraulic flow control valves, known for their durability and precision.

Unique Selling Points

Their focus on technological advancements ensures their products deliver exceptional performance and reliability.

Champion of Quality

Overview and History

Our company has become synonymous with quality in the hydraulic industry, known for its rigorous quality control processes.

Product Range

Their range of hydraulic flow control valves is designed to meet the highest standards of performance and durability.

Unique Selling Points

Their commitment to quality ensures that their valves provide long-term reliability and optimal performance.

Benefits of Using Hydraulic Flow Control Valves from India

Enhanced System Performance

Indian manufactured valves are designed to enhance the performance of hydraulic systems, ensuring efficient and smooth operations.

Long Term Reliability

With rigorous testing and quality control, these valves offer long-term reliability, reducing the need for frequent replacements.

Cost Efficiency

The competitive pricing of Indian valves, coupled with their high quality, offers excellent value for money, making them a cost-efficient choice for businesses.

Industry Applications of Hydraulic Flow Control Valves

Construction Equipment

Hydraulic flow control valves are vital in construction equipment, ensuring precise control and efficient operation of machinery like excavators and loaders.

Agricultural Machinery

In agricultural machinery, these valves help in controlling the flow of fluids in systems like tractors and harvesters, enhancing their performance and efficiency.

Industrial Machinery

In various industrial applications, hydraulic flow control valves ensure smooth and controlled operation of machinery, contributing to overall productivity.

Marine Applications

Marine applications require robust and reliable hydraulic systems, and flow control valves play a crucial role in maintaining the performance of equipment used in marine environments.

How to Choose the Right Hydraulic Flow Control Valve

Assessing Your Needs

Before choosing a valve, it's important to assess your specific needs, considering factors like flow rate, pressure requirements, and the type of fluid used.

Key Specifications to Consider

Key specifications to consider include the valve's material, size, pressure rating, and temperature resistance, ensuring it meets your system's requirements.

Consulting with Experts

Consulting with industry experts can help you make an informed decision, ensuring you choose the right valve for your application.

Conclusion

Hydraulic flow control valves are essential for the efficient operation of hydraulic systems. Our manufacturers stand out for their quality, innovation, and cost-effectiveness, making them a top choice globally. Whether you're looking for enhanced system performance, long term reliability, or cost efficiency, Pedlock’s hydraulic flow control valve manufacturer in Ahmedabad, Mumbai, Chennai, Vadodara, Bangalore, Delhi, Ghaziabad and Rajasthan in India have the solutions you need.

#hydraulic flow control valve manufacturer in Ahmedabad#hydraulic flow control valve manufacturer in Mumbai#hydraulic flow control valve manufacturer in Chennai#hydraulic flow control valve manufacturer in Gujarat#hydraulic flow control valve manufacturer in Vadodara#hydraulic flow control valve manufacturer in Delhi#hydraulic flow control valve manufacturer in Bangalore#hydraulic flow control valve manufacturer in Rajasthan#hydraulic flow control valve manufacturer in Ghaziabad

0 notes

Text

Hydraulic Flow Control valve manufacturer in India

Looking for a Hydraulic Flow Control Valve manufacturer in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat India. Ped-lock valves and fittings Explore wide range of precision-engineered valves designed for controlling hydraulic flow in industrial applications.

We are one of the pioneered manufactures, exporters and supplier of world class range of Hydraulic Flow Control Valve Manufacturer in Ahmedabad, Mumbai, Vadodara, Ghaziabad, Rajasthan, Chennai, Bengalore, Delhi, Gujarat in India. Highly demanded in the market, these valves come in different specifications. We offer Hydraulic Flow Control Valves at cost effective prices.

The scale on the lower edge of the control knob enables accurate repeat setting. The DRV is a flow control valve in the same design which also allows the same fine flow adjustment, but in one direction only. Unrestricted flow in the reverse direction is via the built-in check valve – cracking pressure 7 psi (0.5 bar)It is used in various applications suitable for steam, hydraulics, oil and gas media and all high pressure fluid in various industries. We use finest quality materials to manufacture these valves.

0 notes

Text

#Hydraulic Flow Control Valve Manufacturer in Ahmedabad#Hydraulic Flow Control Valve Manufacturer in Mumbai#Hydraulic Flow Control Valve Manufacturer in Chennai#Hydraulic Flow Control Valve Manufacturer in Bangalore#Hydraulic Flow Control Valve Manufacturer in Delhi

0 notes

Text

Buying Hydraulic Check Valves from Electro Hydraulics Controls in the UK

Introduction

In the realm of fluid power systems, Hydraulic check valves play a pivotal role in ensuring smooth and efficient operations. These essential components allow fluid to flow in one direction while preventing backflow, thereby maintaining system stability and preventing damage. For those seeking high-quality hydraulic check valves in the UK, Electro Hydraulics Controls emerges as a prominent supplier known for its reliability and expertise. In this comprehensive guide, we will delve into the reasons why Electro Hydraulics Controls is the ideal choice for purchasing hydraulic check valves, exploring their range of products, customer support, and overall advantages.

Company Overview: Electro Hydraulics Controls Electro Hydraulics Controls (EHC) is a leading hydraulic solutions provider based in the UK, with years of experience in the industry. Specializing in hydraulic components, systems, and services, EHC has garnered a reputation for delivering top-notch products to a diverse clientele, including industrial, marine, and mobile applications. Their commitment to quality, innovation, and customer satisfaction has solidified their position as a trusted partner in the hydraulic industry.

Wide Range of Hydraulic Check Valves One of the primary reasons to buy hydraulic check valves from EHC is the extensive range of products they offer. Their inventory includes various types of check valves, such as ball check valves, spring-loaded check valves, pilot-operated check valves, and more. Customers can find check valves suitable for different pressure ranges, flow rates, and applications, ensuring they have access to a valve tailored to their specific needs.

High-Quality Standards At EHC, quality is the cornerstone of their operations. The hydraulic check valves they offer are manufactured using premium materials and undergo rigorous testing procedures to ensure optimum performance and durability. These valves are designed to withstand challenging conditions and provide reliable service, making them an excellent long-term investment for any hydraulic system.

Expert Technical Support Understanding the technical aspects of hydraulic systems and finding the right hydraulic check valve can be complex. EHC boasts a team of skilled and knowledgeable experts who are readily available to assist customers in selecting the appropriate check valve for their applications. Whether it's a simple query or a complex system requirement, their technical support team can offer valuable guidance and recommendations.

Customization Options EHC recognizes that every hydraulic system is unique, and sometimes standard solutions may not fit specific requirements. To address this, they provide customization options for hydraulic check valves. Customers can collaborate with EHC's engineering team to design tailor-made check valves that precisely match their system specifications, ensuring optimal performance and efficiency.

Competitive Pricing Despite their commitment to quality and excellence, EHC offers competitive pricing on their Hydraulic check valves. Their efficient production processes and strong supplier relationships enable them to maintain cost-effectiveness without compromising on product standards. This makes EHC a cost-conscious choice for customers seeking high-value hydraulic solutions.

Quick Delivery and Reliable Logistics Timely delivery of hydraulic components is crucial to minimize downtime and keep operations running smoothly. EHC understands this necessity and ensures swift order processing and delivery. They have a well-established logistics system that enables them to reach customers across the UK promptly, providing a hassle-free purchasing experience.

After-Sales Support and Warranty EHC's dedication to customer satisfaction extends beyond the point of sale. They offer comprehensive after-sales support, including technical assistance, maintenance advice, and troubleshooting services. Additionally, their products are backed by warranties, giving customers confidence in the reliability of their hydraulic check valves.

Sustainable Practices Environmental responsibility is increasingly vital in today's world. EHC is committed to sustainable practices and strives to minimize their environmental impact through eco-friendly manufacturing processes and resource management. For environmentally-conscious buyers, EHC's commitment to sustainability can be an essential factor in their decision-making process.

Conclusion

In conclusion, Electro Hydraulics Controls stands out as a reputable and reliable supplier of hydraulic check valves in the UK. With their extensive product range, high-quality standards, expert technical support, customization options, and competitive pricing, they offer an all-encompassing solution for hydraulic system needs. Their commitment to customer satisfaction, efficient logistics, after-sales support, and sustainable practices further solidifies their position as a leading hydraulic solutions provider. When considering the purchase of hydraulic check valves in the UK, Electro Hydraulics Controls proves to be an excellent choice for discerning customers.

ALSO READ:- Hydraulic flow control valve

0 notes

Text

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#DrugFreeIndia

#pneumatictimer

This is accomplished via a reservoir of oil, driven by air pressure on the top of the oil through a needle valve to control the speed. With a Proportion-Air F-Series mass flow controller, the traditional reservoir of oil is not necessary.

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#DrugFreeIndia#pneumatictimer Pneumatic timers are used in industrial systems for the precise control of air input signals. They are used in place of elec#where the use of electricity is either unavailable or unsafe#such as applications in which flammable materials are present.#biggest problem with pneumatic timers and inert gases is that gases escape into the atmosphere. There is always a consistent leak of these#so you will have to replace these gases. Using compressed air is a much more economical endeavor.#Pneumatic timers are used when you need to delay the air signal coming in or going out of your air component. Depending on the model chosen#the air time delay may be adjusted from 0.5 to 60 seconds.#Time delay valve is a combination of a pneumatically actuated 3/2 direction control valve#an air reservoir and a throttle relief valve. The time delay function is obtained by controlling the air flow rate to or from the reservoir#Control and speed in pneumatic systems are more difficult because of the compressed air than compared with electrical or hydraulic systems.#a device requires a specific speed#you might have to add more equipment to the pneumatic system to make it work at the desired levels.#This is accomplished via a reservoir of oil#driven by air pressure on the top of the oil through a needle valve to control the speed. With a Proportion-Air F-Series mass flow controll#the traditional reservoir of oil is not necessary.

0 notes

Text

Ea, Our Second Chance (15)

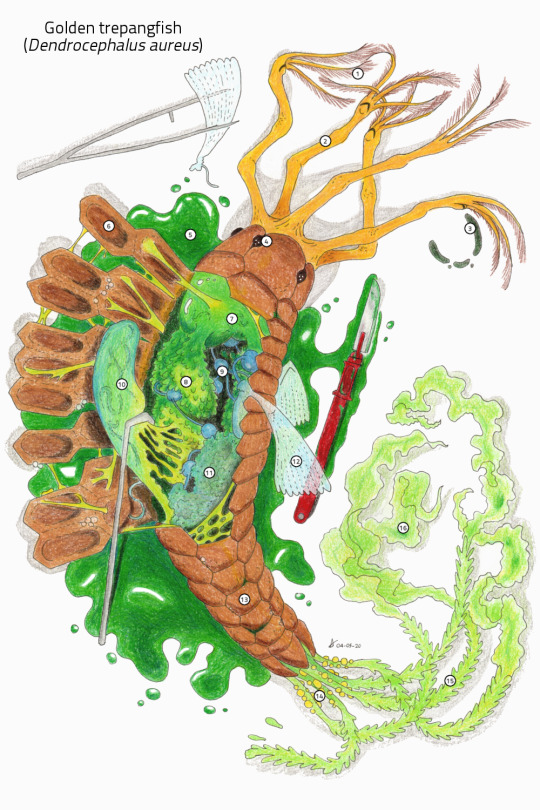

15. Dissection of trepangfish

(Index)

(< 14. Reproduction of Haematophyta) (> 16. Ean heraldry)

(original page)

Specimen of golden trepangfish (Dendrocephalus aureus, Wayan 27), an Actinognathan common in the oceans of Ea, as it might appear during dissection on the desk of a student of the Faculty of Marine Zoology in Leeuwenhoek, New World Academy.

The feathered ends of the oral palps sweep the seabottom, capturing micropreys and organic particles from the sediment. The mucus-covered cirri convey these particles to each mouth.

Often some palps beat the floor to raise clouds that are sifted by others. As is often the case for palps of this length, they are divided in rigid segments for reasons of mechanical efficiency.

The mouths also serve to expel waste, which mostly consists of sand and mud particles. At least one palp is always reserved to excretion when feeding. We can see a mass of feces expelled by one of the mouths. The greenish color is due to metabolic waste from blood recycling.

Each eye is protected by a calcite lens that must be shed periodically as it’s scratched by sand. The two visible eye lenses appear to be new.

As pentamerans have an open circulatory system, dissection releases a large amount of lymph. The green color is due to the organometallic copper complexes that carry oxygen around the haemocoel.

Some calcareous plates have been lifted to expose the interior organs. They are connected by thin elastic tissue that can tighten offering considerable resistance when the animal is alive, but can be easily cut after death.

The trepangfish' ring-shaped stomach, connected to all the five palps.

The digestive caeca extend deep into the haemocoel, extracting metabolic waste from it and passing back nutrients. Their walls secrete lubricating oils to protect themselves from abrasions due to sand grains.

The hydrocysts serve as distributed reservoirs of hydromuscular fluid in actinognathans, none of which appears to be more important than others, contrasting with the central role of the Vindhana organ in geopentamerans.

A water lung, extracted from its usual resting position between two caeca.

Male and female gonads appear as a nearly identical pale spongy mass. Only their extension to this level reveals that this trepangfish is a female; male gonads would cluster much closer to the genital slits for a faster maturation and release of sperm.

The hydraulic fins are mostly used to control the body’s orientation in water. They are easily lost to accidents or predation, but regenerate within days. A valve at the base stops fluid loss in this case.

The tail is mostly occupied by hydraulic muscle and gonad tissue. In this species the genital slits are completely hidden by the caudal scales.

The base of the aboral cerci carries eggs. This is not sufficient to mark the specimen as female (but see point 11), as the newly released and fertilized eggs attach to the cerci of both parents.

About half of the length of the cerci are composed by rows of fins that provide active forward propulsion to the animal. They do not move independently: the whole cercus moves as a ribbon to push water backwards. Unlike most hydraulic structures, they lose half of their size after death as fluid flows into the inner hydrocysts.

The distal part of the cerci is broad and flat, contains little fluid and remains flexible at all times. Its function is not yet fully understood.

#speculative biology#speculative evolution#xenobiology#alien life#worldbuilding#my work#ea our second chance

30 notes

·

View notes

Text

Guide to Maintaining Rexroth Hydraulic Pumps: Insights from NN Hydraulic India

Hello fellow engineers and hydraulic system enthusiasts,

At NN Hydraulic India, we've accumulated extensive experience in maintaining and servicing Rexroth hydraulic pumps.

We'd like to share some best practices to help you ensure optimal performance and longevity of your equipment.

1. Regular Inspection:

Leak Detection: Periodically inspect for fluid leaks around seals, valves, and connections. Even minor leaks can indicate underlying issues that may lead to pump failure if not addressed promptly.

Noise Monitoring: Unusual sounds, such as whining or grinding, can signal cavitation or mechanical problems within the pump. Investigate any abnormal noises during operation.

2. Maintain Cleanliness:

Contaminant Control: Keep the pump and surrounding area free from dirt, dust, and metal particles. Contaminants can cause wear and tear on internal components.

Fluid Quality: Regularly check and replace hydraulic fluid as per the manufacturer's recommendations to maintain optimal performance.

3. Proper Lubrication:

Ensure the lubrication system is functioning correctly. Refer to the Rexroth hydraulic pump manual for recommended lubrication intervals and suitable oil types.

4. Valve Maintenance:

Regularly inspect Rexroth valves for leaks, buildup, or damage. Faulty valves can disrupt flow regulation, leading to system inefficiencies.

5. Preventive Maintenance:

Adhere to the maintenance schedule outlined in the Rexroth hydraulic pump manual.

Use genuine Rexroth parts for replacements to ensure compatibility and performance.

Train your maintenance team to handle Rexroth pumps properly, preventing common issues arising from improper handling.

6. Timely Repairs:

Address any signs of malfunction, such as pressure irregularities or unusual noises, promptly to prevent minor issues from escalating.

We hope these insights assist you in maintaining your Rexroth hydraulic pumps effectively.

Feel free to share your experiences or ask any questions related to hydraulic pump maintenance.

— NN Hydraulic India

2 notes

·

View notes

Text

Control valve supplier in Dubai

UAE Valves is one of the top Control Valve Supplier in Dubai. A control valve is a mechanical device used in various industrial processes to regulate the flow of fluids, such as gas, steam, or liquid, through a pipeline or duct. It achieves this regulation by adjusting the size of the flow passage according to signals received from a controller.

Control valves are crucial components in systems requiring precise control of flow rate, pressure, temperature, or liquid level. They are widely used in industries such as oil and gas, chemical processing, power generation, and water treatment.

Working Principle:

The working principle of a control valve is straightforward. In an industrial setting, a control valve adjusts the size of an opening to control the flow of fluid through a pipeline. When the valve is fully open, it allows maximum flow, and when fully closed, it stops the flow completely. Between these extremes, the valve can be precisely adjusted to allow a specific amount of fluid to pass through.

This adjustment is typically performed automatically based on signals from a controller, which monitors conditions such as pressure, temperature, or flow rate. Essentially, a control valve acts like a gatekeeper, regulating the flow of fluid to meet the system's requirements.

Parts of a Control Valve:

Valve Body: The main structure that contains the fluid and through which the fluid flows.

Actuator: A device that moves or controls the valve's mechanism, often powered by air, electricity, or hydraulic fluid.

Closure Element: The component that makes contact with the seat to restrict or allow flow.

Trim: Internal components such as the plug, seat, and stem that modulate the flow.

Seat: A surface against which the closure element seals to stop flow.

Positioner: A device that adjusts the valve actuator's position based on control signals.

Bonnet: The top part of the valve body that houses the stem and provides a seal.

Yoke: A support structure that holds the actuator in place and connects it to the valve body.

Stem: A rod that connects the actuator to the closure element and transmits motion.

Packing: Material that provides a seal around the stem to prevent fluid leakage.

Advantages:

Precisely controls the amount of fluid passing through a system.

Maintains the desired pressure levels within the system.

Helps maintain a stable temperature by regulating fluid flow.

Reduces energy consumption by optimizing fluid flow.

Enhances system performance by maintaining consistent operating conditions.

Prevents system overpressure and potential hazards.

Easily adjustable for various operating conditions.

Allows for control from a distance and integration into automated systems.

Designed for durability and ease of maintenance.

Ensures consistent production quality by maintaining optimal conditions.

Meets industry standards and regulatory requirements.

Industries Using Control Valves:

Control valves are used across numerous industries, including nuclear power, oil and gas, power generation, manufacturing and process industries, automotive, aerospace, mining and minerals processing, water treatment and distribution, pulp and paper, refining, marine, renewable energy, chemical and petrochemical, and steel and metal processing. These valves play a critical role in ensuring operational efficiency, safety, and compliance within these diverse sectors.

Types of Control Valves:

Three-way control valve

Cage type control valve

Double seat control valve

O type shutoff control valve

Single seat control valve

Water control valve

Globe control valve

Angle type control valve

We are a Control Valve Supplier in Dubai, supplying valves in the following descriptions:

Available Materials: Stainless Steel (SS316, SS304), Ductile Iron, Super Duplex (F51, F53, F55), Cast Iron (WCB, WCC, WC6), LCC, LCB

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Medium: Air, Water, Chemical, Steam, Oil

Operations: Electro Pneumatic Operated and Pneumatic Operated

Size: 1/2” – 24”

Ends: Butt Weld, Flanged, Threaded, Socket Weld

Electric Actuator Details:

Torque: 3 – 9 nm

Operating Pressure: 8 Bar

Port Connection: NPT 1.4”

Mounting Base: ISO 5211

Temperature: -20°C to +80°C

Configuration of a Pneumatic Actuator:

Torque: 3 – 9000 nm

Operating Pressure: 8 Bar

Port Connection: NPT 1.4”

Mounting Base: ISO 5211

Temperature: -20°C to +80°C

Temperature Ranges:

Standard: -4°F to 200°F (-20°C to 93°C)

Low: -40°F to 176°F (-40°C to 80°C)

High: 0°F to 300°F (-18°C to 149°C)

Visit us: https://www.uaevalves.com/product-category/control-valve/

3 notes

·

View notes

Text

💪Strong & Ready🚛

Save Money with the 2023 TDC Ultramax Side Dump Tridem Trailer, Tri-Drive Compatible! This high-performance trailer has a 22 cu yd capacity, built with 1/4" 450 Brinell steel floor, sidewalls, and end walls for superior durability and wear resistance. The box can dump to either DS or PS via selectable lockarms, enhancing flexibility. Equipped with Hendrickson Intraax AAT250 air ride suspension and 77" track axles, each with a 25,000 lb capacity, it offers unmatched stability, especially with its unique center box 3rd hinge support. The hydraulic system includes two double-acting telescopic lift cylinders, an air-operated selector valve, and a hydraulic flow diverter for precise control. The frame features Ti steel main rails and fabricated cross members, including Arne's 8" pipe torque tube, ensuring exceptional strength and longevity. Designed for heavy loads and rough terrains, this trailer is built to perform under the most demanding conditions.

#heavydutyhauling#trucking#trucks#peterbiltpower#trucklife#vancouver#british columbia#truckers#side dump#tridem trailer

4 notes

·

View notes

Text

The Ultimate Guide to Leading Hydraulic Flow Control Valve Manufacturers India

We are a top maker of hydraulic flow control valves manufacturer in Mumbai, Ahmedabad, Chennai, Delhi, Vadodara, Gujarat, Bangalore, Rajasthan, and Ghaziabad India. Our company creates precise solutions for controlling fluids in various industries. With modern production facilities and skilled engineers, we aim to provide top-notch products. These products are designed to meet the specific needs of our customers. Our valves are perfect for the automotive, construction, and manufacturing sectors. They help increase efficiency, cut costs, and boost performance.

Key Takeaways

Comprehensive range of hydraulic flow control valves manufactured in India

State-of-the-art production facilities and experienced engineering team

Tailored solutions for diverse industries, including automotive, construction, and manufacturing

Improved efficiency, cost savings, and performance for customers

Commitment to delivering high-quality, precision-engineered products

Introduction to Hydraulic Flow Control Valves

Hydraulic flow control valves are key parts in hydraulic systems. They make sure the fluid flows in a controlled way. These valves keep the flow rate steady, even when pressure or load changes. This makes them crucial for efficient work in many industries.

Hydraulic Flow Control Valves Manufacturer in India

India is now a key place for making top notch hydraulic flow control valves manufacturer. Many leading companies serve a wide range of industries. These hydraulic flow control valves manufacturers in India have modern production setups all over the country. They ensure their products are of high quality and delivered on time.

Production Facilities and Capabilities

These top companies have set up their production places in important industrial areas. They are in Ahmedabad, Vadodara, Mumbai, and Ghaziabad. This lets them reach a wide range of customers in fields like building, mining, farming, and making things. Their modern facilities have the newest machines and skilled engineers and technicians. They aim to make products that are of the highest quality.

Factors to Consider When Choosing a Manufacturer

Choosing the right manufacturer for your hydraulic flow control valves is key. You want a product that meets your needs and boosts your hydraulic system's efficiency. Here are important factors to think about.

Quality Standards

Quality is a top priority. Look for a company with industry certifications like ISO or ASME. They should have a strong focus on testing and quality control. This means the valves you buy will be reliable and perform well.

Customization Options

Being able to customize your hydraulic flow control valves can make a big difference. Find a manufacturer that offers many customization options. This lets you adjust the valves to fit your specific needs, improving your hydraulic system's performance.

Hydraulic Flow Control Valves Manufacturer in Ahmedabad

We are a top maker of hydraulic flow control valves in India, located in Ahmedabad. This spot lets us easily reach customers in the western region, including Gujarat. Our advanced production and skilled engineers make us ready to give custom solutions for our clients in Ahmedabad and Gujarat.

Conclusion

If you work in manufacturing, building, or farming, our hydraulic flow control valves manufacturer in Mumbai, Ahmedabad, Chennai, Delhi, Vadodara, Gujarat, Bangalore, Rajasthan, and Ghaziabad can boost your equipment's performance and efficiency. Our Ahmedabad place has the newest tech and strict quality checks. This ensures our products are top-notch. Being a hydraulic flow control valves maker in Ahmedabad, we're all about great customer service and support. Our expert team is here to help you pick the best valve for your needs. They also offer help with setting up, keeping up, and fixing any issues.

#Hydraulic Flow Control Valve Manufacturers#ahmedabad#Mumbai#Chennai#rajshthan#ghaziabad#gujarat#bangalore#delhi#vadodara

0 notes

Text

Premium Quality SS Check Valve Manufacturer and Exporter – Pedlock Valves

Stainless steel (SS) check valves play a critical role in industrial and hydraulic systems by preventing reverse flow and ensuring operational safety. At Pedlock Valves, we take pride in being one of the leading SS check valve manufacturers and exporters, catering to diverse industries worldwide.

What Makes Our SS Check Valves Exceptional?

Durable Stainless Steel Build: Designed with high-quality stainless steel, our check valves withstand extreme pressures and harsh environments, providing unparalleled performance and longevity.

Precision Engineering: Every valve is crafted with precision to deliver zero leakage, low-pressure drops, and consistent reliability across applications.

Wide Range of Applications: Our SS check valves are ideal for industries like oil & gas, petrochemicals, power plants, and water treatment.

Features of Our Hydraulic SS Check Valves:

Robust design for high-pressure systems.

Corrosion resistance for extended service life.

Easy installation and maintenance.

Configurable sizes to meet specific application requirements.

Why Choose Pedlock Valves?

As a trusted name in the valve industry, Pedlock Valves has a track record of delivering innovative and cost-effective solutions to clients across the globe. Our advanced manufacturing techniques, stringent quality controls, and customer-centric approach set us apart.

Partner with us and ensure seamless operations for your hydraulic and industrial systems. Contact us today to explore our extensive range of SS check valves.

0 notes

Text

Why is Ball Valve Essential for Automobiles? Check Reasons!

A ball valve is durable, easy to operate, and requires minimal maintenance for precise control over fluid flow and is ideal for critical automobile functions. These valves come with a robust design to handle high-pressure and temperature variations, ensuring optimal performance of some systems including fuel lines, cooling systems, and hydraulics of a car.

Similarly, a check valve, often used alongside ball valves, ensures unidirectional fluid flow to prevent backflow and save sensitive systems from the risks of operational and structural damage.

In challenging and high-pressure applications, they are essential for maintaining system integrity, regulating fluid flow, and guaranteeing safety. Purchasing valves from reputable suppliers ensures long-term value and maximum system performance.

Advantages of Essential Ball and Check Valves from Renowned Manufacturers

Businesses should buy essential valves from renowned manufacturers to ensure reliability and efficiency, precise fluid control, prevent backflow, motion control, fluid power applications, and withstand high-pressure conditions.

These valves are essential to many industries, including water treatment, chemical processing, oil and gas, and pharmaceuticals to improve safety and customer experience with cutting-edge technologies like remote factory acceptance tests and mixed reality training.

Renowned manufacturers adhere to strict quality standards, ensuring durability and consistent performance to maintain global quality. Locally engineered and tested valves meet the specific demands of industries like defence, mining, construction, and power generation.

These experts have expertise in fluid technology, combined with bespoke design and predictive maintenance solutions, to ensure that their valves deliver superior functionality. Additionally, they support industries with services like on-site audits, engineering advice, and technical training.

Find a Trusted Manufacturer of Essential Machinery Parts

Finding a trusted manufacturer of essential machinery parts requires thorough research and consideration.

Evaluate the manufacturer’s experience and reputation in the industry. Check whether they are certified and authorised by authorised bodies which indicates adherence to high-quality standards.

Check if the manufacturer offers customized solutions to meet specific needs and provides services like engineering support, on-site audits, and technical training.

Ensure they have expertise in the required industry and a proven track record of delivering reliable products and after-sales support.

Consider manufacturers that integrate advanced technologies like predictive maintenance or remote testing, as these innovations enhance efficiency and safety.

Finally, select a manufacturer known for precision, durability, and comprehensive support.

Source

0 notes

Text

Siemens Combustion Skp15.011U1-120V,On/Off,Single Stage,Poc | PartsHnC

The SKP15.011U1 Siemens is a highly efficient electro-hydraulic gas actuator, meticulously crafted for seamless integration with Siemens VG series gas valves. This compact device plays a pivotal role in regulating gas flow to the burner by precisely responding to electrical signals transmitted by the burner control unit.

0 notes

Text

🤫🤫🤫

Crossover Speed

To further complicate the issue, the configuration and flight speed (flaps 1 and 190 knots) put the airplane in a flight regime where a fully deflected rudder would overpower the lateral control system. This phenomenon came to be identified as the "crossover speed," or the speed at which the lateral control system (ailerons and roll spoilers) could exactly balance the available full rudder deflection. Flight 427 was almost exactly at this crossover speed when the wake encounter and the subsequent full rudder deflection occurred. A small speed loss allowed the rudder to overpower the opposing roll control inputs, and the roll to the left became uncontrollable. If the airplane had been accelerated just a few knots, the roll control authority would have increased sufficiently for the rudder-induced roll to have been countered. However, being in the critical speed area at or near the crossover speed made any speed variation critical and airplane control difficult.

😍😘🥰

youtube

https://www.faa.gov/lessons_learned/transport_airplane/accidents/N513AU

😎😎😎

The NTSB ultimately determined that the combination of full rudder deflection, the confusion associated with an unknown flight control anomaly (rudder reversal), and a subsequent stall resulted in a loss of control and the crash.

🥳🥳🥳

The NTSB concluded that the probable cause of the Flight 427 accident was a loss of control of the airplane resulting from the movement of the rudder surface to its blowdown limit. The rudder surface most likely deflected in a direction opposite to that commanded by the pilots due to a jam of the main rudder PCU servo valve secondary slide to the servo valve housing offset from its neutral position and overtravel of the primary slide.

🤕🤢🤕

The NTSB issued ten recommendations relative to this accident. These included: Require - that all existing and future Model 737 airplanes be equipped with a "reliably redundant" rudder system; that the FAA convene an independent Engineering Test and Evaluation Board (ETEB) to provide an in-depth evaluation of the design and certification of the Model 737 rudder system; that the FAA revise paragraph (c) (3) (14 CFR 25.671(c)(3)), to require continued safe flight and landing after jamming of a flight control at any deflection possible; that training relative to flight control jams be improved; that operating speeds for Model 737 airplanes be revised to minimize the effects of a rudder jam; and that flight data recorders be improved to provide flight control inputs (commands) and resulting control deflections.

🤥🤡🤥

Rudder Power Control Unit

🤫🤫🤫

The entire rudder system is designed such that total rudder travel is limited as a balance between airspeed (dynamic pressure against the rudder surface) and system hydraulic pressure (3,000 psi). At lower airspeeds the rudder system has sufficient hydraulic pressure to attain the physical rudder travel limit of 28 degrees. At higher airspeeds system hydraulic pressure is insufficient to move the rudder to its physical limit, and travel is limited by air loads. This phenomenon is known as rudder blowdown. At the flight conditions of Flight 427, the maximum available rudder deflection, due to blowdown, was approximately 15 degrees.

🤭🧐🤭

youtube

https://www.faa.gov/lessons_learned/transport_airplane/accidents/N513AU

The concentric servo valves inside the rudder PCU operate in tandem to allow hydraulic flow and deflection of the rudder. If either valve fails to function properly, it can result in an improper rudder deflection, or apparent jam. In the case of Flight 427, the NTSB concluded that the secondary slide jammed against the valve case, while the primary slide moved in its normal direction. The jam of the secondary slide allowed the primary slide to "overtravel," that is, moving to a position that prevented proper alignment of the fluid ports on each valve. This caused a flow of hydraulic fluid in a direction that was not intended and resulted in a rudder deflection to the rudder blowdown limits that was opposite to what the flight crew commanded - a rudder reversal. The mechanics of a rudder reversal are provided in the diagram to the right. Once deflected, as long as the pressure was maintained on the rudder pedals, the rudder deflection would be maintained, and, to the flight crew, the rudder would appear to be jammed. In the Flight 427 situation, it was postulated that the flight crew commanded a right rudder deflection to correct the left roll. But, due to the reversal phenomenon, the rudder went to its fully deflected position (the blowdown limit) to the left. As the airplane response was now to the left, rather than the right as desired by the flight crew, the pilot would have maintained the pressure on the right pedal, thereby maintaining the "jam."

🎈🎈🎈

Hydraulic System and Rudder Control System

The hydraulic system on Boeing Model 737 airplanes is divided into three independent systems designated A, B, and Standby.

The rudder system operates via manual rudder pedal inputs through a hydraulically powered rudder. There are two sets of rudder pedals, one for each pilot. Either set of pedals provides inputs to the rudder power control unit (PCU) via cables routed through a control quadrant located in the back of the airplane, and then via an input control rod between the aft quadrant and the PCU itself. The rudder system is normally hydraulically powered by both the A and B hydraulic systems, or, following a hydraulic system failure, through the standby rudder system. The PCU operates through a dual-load path mechanical linkage operated by either the rudder pedals or the yaw damper. A yaw damper system operates through the B hydraulic system in the main PCU. The yaw damper is independent of the pedals and does not result in feedback at the pedals.

🎖️🏆🏅

As Flight 427 was completing its turn, rolling through seven degrees of bank toward a wings-level attitude, the cockpit voice recorder (CVR transcript) recorded three "thumps" followed by exclamations from both pilots. (1) At the same time, the airplane experienced a three-knot fluctuation in airspeed that lasted about three seconds. The thumps and airspeed fluctuation were later determined to have been the result of Flight 427 passing through one of the vortex cores formed in the wake of the Delta Model 727. The airplane's left bank angle then increased from slightly less than eight degrees to slightly more than 20 degrees. (2)

Over the next eight seconds, the left bank decreased to approximately 15 degrees, and the heading rate increased to the left, passing through the assigned heading of 100 degrees. The airplane began to roll more rapidly to the left, and the heading (turn) rate increased to approximately five degrees per second as the heading passed left through 089 degrees. At the end of the eight-second period, the stick shaker (stall warning) activated, while the airplane continued to roll left with several fluctuations in the roll rate. The bank angle increased to over 40 degrees, and the airplane began to descend from its assigned altitude of 6,000 feet. The airspeed decreased to 186 knots, and the bank angle continued to increase. (3) The CVR recorded what appeared to be stall buffet increasing in amplitude and an autopilot-disconnect warning horn followed by an automatic traffic alert. The stall warning continued to the end of the recording. Twenty-eight seconds following the initial wake turbulence encounter, Flight 427 impacted hilly, wooded terrain approximately six miles northwest of the Pittsburgh airport at an altitude of 930 feet. (4) (5) An NTSB animation of the airplane flight path is available below.

🎇🎆🧨

youtube

https://www.faa.gov/lessons_learned/transport_airplane/accidents/N513AU

🎈🎉🎈

0 notes

Text

Electro Hydraulics Controls: Your go-to destination for the finest Hydraulic flow control valves in the UK. We offer unrivaled quality and expertise. Trust us for optimal performance and reliability.

0 notes