#hot dipped galvanized bolts suppliers

Explore tagged Tumblr posts

Text

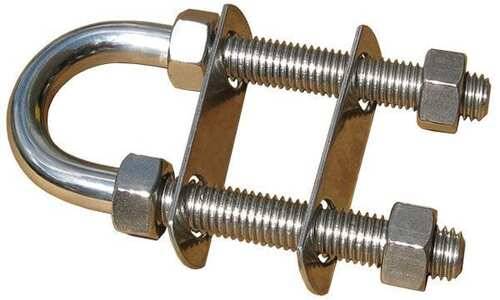

Top U Bolts Manufacturers & Suppliers in India | SS International

Sachiya Steel International is a leading U bolts manufacturer in India, offering a wide range of high-quality U bolts for industrial applications. We export to over 85 countries, providing U bolts in various materials like stainless steel, carbon steel, and alloys. Our products come in different sizes, grades, and finishes, including self-color, zinc-plated, and hot-dip galvanized. Trusted by industries worldwide, we are committed to delivering superior U bolts and fasteners for all your needs.

Visit Sachiyasteel.com today to explore the best U Bolts Manufacturer in India and get high-quality U bolts at competitive prices for your industrial and commercial applications.

#SachiyaSteel#MumbaiManufacturers#MadeInIndia#IndianManufacturer#SteelSupplier#PipeFittingsManufacturer#QualityMatters#Durability#PrecisionEngineering#ManufacturingExcellence#B2BSupplier#EngineeringSolutions

0 notes

Text

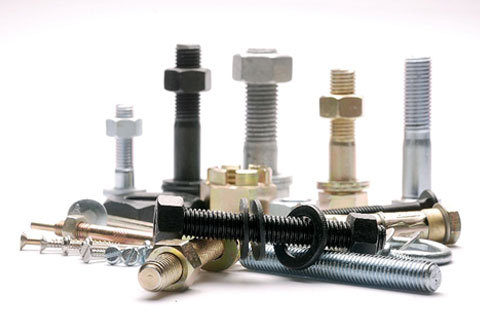

Find Nut Bolt Supplier with Best Quality Options

Introduction

Looking for a nut bolt supplier with the best quality options? Choosing the right supplier ensures superior durability, precision, and performance for industrial, automotive, and construction needs. Discover the top suppliers, their product range, and tips for selecting high-quality fasteners.

Why Choose a High-Quality Nut Bolt Supplier?

Premium Materials – Stainless steel, carbon steel, alloy steel.

Precision Engineering – Manufactured to meet industry standards.

High Tensile Strength – Ensures durability and load-bearing capacity.

Corrosion Resistance – Coated and treated for longevity.

Reliable Supplier Support – Assistance with specifications and orders.

Types of High-Quality Nut Bolts

TypeMaterialCommon ApplicationsHex BoltsStainless Steel, MSMachinery, constructionFlange BoltsAlloy SteelAutomotive, heavy equipmentEye BoltsGalvanized SteelLifting, riggingU-BoltsMild SteelPipe fittings, structural supportCarriage BoltsStainless SteelWoodworking, furniture

Top Nut Bolt Suppliers with Best Quality Options

Supplier NameLocationSpecializationContact InfoBoltFast SolutionsDelhiIndustrial & structural bolts9876543210SteelBolt TradersMumbaiAutomotive & heavy-duty bolts9123456789FastFix HardwareChennaiHigh-quality nut bolt supplier8765432109Precision Bolts & NutsPuneStainless steel & high-strength bolts9988776655Mega Bolt StoreBangaloreCustom & standard fasteners8111223344

How to Select the Best Quality Nut Bolts?

Check Material Composition – Opt for stainless steel, alloy steel, or corrosion-resistant coatings.

Verify Manufacturing Standards – Look for ISO & ASTM certifications.

Inspect Tensile Strength Ratings – Ensure bolts can withstand required stress levels.

Compare Supplier Reviews – Analyze customer feedback and industry reputation.

Request a Sample – Test quality before placing bulk orders.

Industries Requiring High-Quality Nut Bolts

Construction – High-load applications.

Automotive – Engine and body assembly.

Aerospace – Precision fasteners for aircraft.

Manufacturing – Heavy machinery and equipment.

Marine & Oil Industry – Corrosion-resistant fasteners.

FAQs

Q1: What are the strongest materials for nut bolts?

Stainless steel, alloy steel, and titanium are among the strongest materials used in nut bolts.

Q2: How do I ensure I’m buying high-quality nut bolts?

Look for ISO certification, tensile strength ratings, and supplier reputation before purchasing.

Q3: Where can I find the best quality nut bolt suppliers online?

Platforms like TradeIndia, IndiaMART, Justdial list verified suppliers with customer ratings.

Q4: What coatings improve nut bolt longevity?

Zinc coating, hot-dip galvanization, black oxide, and electroplating enhance durability.

0 notes

Text

Reliable Nut Bolt Supplier for All Business Needs

A trusted supplier ensures:

✅ Consistent Product Quality – High-strength fasteners that meet industry standards. ✅ Timely Deliveries – Avoids project delays and production slowdowns. ✅ Custom Fastener Solutions – Special sizes, coatings, and materials as per business needs. ✅ Bulk Order Capabilities – Large-scale supply for commercial and industrial applications. ✅ Excellent Customer Support – Easy order tracking, replacements, and technical assistance. ✅ Affordable Pricing – Competitive rates for long-term business partnerships.

A reliable supplier minimizes risks and ensures seamless project execution.

Industries That Require a Reliable Nut Bolt Supplier

🔩 Construction & Infrastructure – Steel structures, bridges, buildings, and highways. 🔩 Automotive & Aerospace – Engine assembly, aircraft maintenance, and vehicle manufacturing. 🔩 Oil & Gas Industry – High-pressure and corrosion-resistant fasteners. 🔩 Power & Energy – Electrical grids, wind turbines, and power plants. 🔩 Manufacturing & Engineering – Heavy machinery, industrial plants, and fabrication units. 🔩 Marine & Shipbuilding – Corrosion-resistant fasteners for boats and ships. 🔩 DIY & Home Improvement – Nuts and bolts for furniture, fixtures, and renovations.

Each industry has specific fastener needs, making it important to choose a supplier that provides tailored solutions.

Key Factors to Consider When Choosing a Reliable Nut Bolt Supplier

✔ Material & Manufacturing Standards – Ensure compliance with ISO, ASTM, BIS, and DIN standards. ✔ Quality Certifications – Look for suppliers with ISO 9001:2015, RoHS, and CE certifications. ✔ Product Range – Availability of stainless steel, high-tensile, brass, titanium, and galvanized fasteners. ✔ Pricing & Bulk Order Discounts – Competitive rates with flexible payment options. ✔ On-Time Delivery – Strong logistics network for fast and consistent deliveries. ✔ Custom Solutions – Ability to produce custom-sized fasteners as per business requirements. ✔ Return & Warranty Policies – Hassle-free replacement of defective fasteners. ✔ Customer Reviews & Market Reputation – Positive feedback from past clients.

Selecting a supplier that meets these criteria ensures a smooth and long-term business relationship.

Types of Nuts and Bolts Available for Business Needs

A reliable supplier offers a wide range of fasteners to meet diverse industrial and commercial applications:

1. Commonly Used Nuts and Bolts

🔩 Hex Bolts – Used in construction, bridges, machinery, and vehicles. 🔩 Carriage Bolts – Ideal for woodworking, fencing, and furniture assembly. 🔩 Anchor Bolts – Secures structures to concrete foundations. 🔩 Flange Bolts – Provides a wide grip area for secure fastening. 🔩 High-Tensile Bolts – Required for heavy-load industrial applications.

2. Nut Varieties for Secure Fastening

🔩 Hex Nuts – Standard fasteners for various mechanical applications. 🔩 Lock Nuts – Prevents loosening due to vibrations and movement. 🔩 Flange Nuts – Enhances grip and stability. 🔩 Wing Nuts – Allows for easy hand-tightening and removal.

3. Specialty Fasteners for Industrial Use

🔩 Stainless Steel & Galvanized Fasteners – Rust-resistant for outdoor and marine applications. 🔩 Brass & Titanium Fasteners – Ideal for electronics, aerospace, and medical industries. 🔩 Custom Coated Bolts – Options include black oxide, zinc plating, and hot-dip galvanized coatings.

A comprehensive product range ensures that businesses can find the right fasteners for their specific needs.

Top Reliable Nut Bolt Suppliers for Business Needs

1. Unbrako

🔩 Premium-quality industrial fasteners with high-strength materials.

2. TVS Fasteners

⚙️ Affordable and durable bolts and nuts for various industries.

3. Hindustan Fasteners

🔩 Supplies quality-certified fasteners for bulk buyers.

4. LPS (Lakshmi Precision Screws)

💰 Competitive pricing with strong customer support.

5. Online B2B Marketplaces (IndiaMART, Amazon, Flipkart, TradeIndia)

🌍 Wide selection of suppliers with easy comparison and bulk order options.

These suppliers provide reliable services and high-quality products, making them ideal for business partnerships.

How to Ensure You Get the Best Supplier?

💡 Research Online Reviews – Check customer feedback and ratings. 💡 Request Samples – Test product quality before placing bulk orders. 💡 Compare Pricing & Services – Choose suppliers with value-added benefits. 💡 Ask About Logistics & Delivery – Ensure timely shipping and inventory availability. 💡 Check Industry Certifications – Verify that products meet required safety standards.

Following these steps helps in selecting a supplier that meets your business’s reliability and quality requirements.

Benefits of Partnering with a Reliable Nut Bolt Supplier

🔩 Consistent Quality – No risk of low-quality or defective fasteners. 🔩 Cost Savings – Bulk order discounts and competitive pricing. 🔩 Faster Project Completion – No delays due to supply chain issues. 🔩 Long-Term Business Growth – Stable supplier relationships ensure smooth operations. 🔩 Custom Order Capabilities – Access to tailor-made fasteners for specialized applications.

By partnering with a dependable supplier, businesses can maximize efficiency and reduce operational risks.

Conclusion

A reliable nut bolt supplier is a key asset for industries and businesses that require high-quality fasteners at competitive prices. Ensuring a supplier offers consistent quality, timely deliveries, strong customer support, and industry-standard fasteners helps businesses operate efficiently and cost-effectively.

By selecting the right supplier, companies can enhance productivity, reduce downtime, and secure long-term success.

#NutBoltSupplier#ReliableFasteners#IndustrialSupply#BulkOrders#ConstructionMaterials#Manufacturing#Engineering#QualityFasteners#TopSupplier#BusinessGrowth

1 note

·

View note

Text

Fasteners Manufacturer & Supplier

Introduction

Fasteners are essential components used in various industries, including construction, automotive, aerospace, and manufacturing. As demand for high-quality fastening solutions grows globally, finding a reliable fasteners manufacturer & supplier in different locations becomes crucial. Ananka Group is a leading fasteners manufacturer, supplier, and exporter, offering a comprehensive range of bolts, nuts, screws, washers, studs, and other fastening products worldwide.

In this blog, we will explore fastener manufacturing and supply in various key locations, their applications, and how Ananka Group meets global industry standards.

Fasteners Manufacturer & Supplier in Different Locations

1. Fasteners Manufacturer & Supplier in Canada

Canada has a strong industrial sector with applications in oil & gas, infrastructure, and automotive manufacturing. Canadian companies require high-strength fasteners that can withstand harsh weather conditions and mechanical stress.

Key Features:

Stainless steel, alloy steel, and titanium fasteners

Corrosion-resistant coatings

Compliance with ASTM, DIN, and ISO standards

2. Fasteners Manufacturer & Supplier in the USA

The United States is home to industries such as aerospace, defense, and heavy machinery. The demand for custom fasteners is high in this region due to stringent quality and safety standards.

Key Features:

High-precision fasteners for aerospace and military applications

ANSI, ASME, and ASTM-certified products

Variety of materials, including Inconel, Monel, and Hastelloy fasteners

3. Fasteners Manufacturer & Supplier in Mexico

Mexico has a booming automotive and construction industry, making it one of the major consumers of industrial fasteners. Fasteners must meet high-performance standards for use in vehicle assembly and infrastructure projects.

Key Features:

Automotive-grade bolts, nuts, and washers

Resistance to high temperatures and mechanical loads

Compliance with SAE and ISO standards

4. Fasteners Manufacturer & Supplier in Oman

Oman’s industries rely heavily on oil & gas, marine, and petrochemical applications. Corrosion-resistant fasteners are essential for offshore drilling and industrial applications.

Key Features:

Nickel, brass, and coated fasteners for high resistance

Marine-grade SS 316 and Duplex Steel fasteners

Compliance with NACE, ASTM, and API standards

5. Fasteners Manufacturer & Supplier in Singapore

Singapore is a hub for engineering, shipbuilding, and electronics industries, requiring precision-made fastening solutions.

Key Features:

High-quality fasteners for electronics and marine applications

Non-magnetic and heat-resistant fasteners

Available in customized designs and coatings

6. Fasteners Manufacturer & Supplier in Kenya

Kenya’s economy is driven by construction, transportation, and renewable energy sectors. Fasteners must be durable and cost-effective for local and export projects.

Key Features:

Hot-dip galvanized and zinc-plated fasteners for corrosion resistance

High-strength carbon steel and stainless steel fasteners

Affordable bulk supply options for large-scale projects

7. Fasteners Manufacturer & Supplier in Ireland

Ireland is a growing market for aerospace, pharmaceuticals, and green energy, requiring precision-engineered fasteners.

Key Features:

Aerospace-grade bolts, nuts, and screws

High-purity fasteners for pharmaceutical equipment

Titanium and Inconel fasteners for high-strength applications

8. Fasteners Manufacturer & Supplier in Australia

Australia has a strong mining, construction, and marine industry, requiring heavy-duty fasteners that withstand extreme conditions.

Key Features:

Wear-resistant fasteners for mining equipment

Structural bolts and anchor fasteners for construction

Compliance with AS/NZS standards

9. Fasteners Manufacturer & Supplier in the UK

The United Kingdom is a leader in automotive, aerospace, and industrial engineering, needing high-precision fastening solutions.

Key Features:

BS (British Standard) certified fasteners

High-strength bolts for railway and automotive industries

Corrosion-resistant and high-performance fasteners

10. Fasteners Manufacturer & Supplier in Sweden

Sweden’s focus on automotive, engineering, and renewable energy creates demand for specialized fasteners.

Key Features:

Lightweight and high-strength fasteners for energy applications

Corrosion-resistant and wear-resistant materials

Custom fastener solutions

11. Fasteners Manufacturer & Supplier in Europe

The European Union (EU) has strict regulations for manufacturing and construction industries, requiring certified and reliable fastening solutions.

Key Features:

ISO and EN-compliant fasteners

CE-marked and RoHS-compliant fasteners

Wide range of materials, including Duplex, Super Duplex, and Titanium fasteners

12. Fasteners Manufacturer & Supplier in Germany

Germany is known for precision engineering, automotive, and heavy machinery industries, requiring high-performance fasteners.

Key Features:

DIN Standard Fasteners

Heat-treated and high-tensile fasteners

Automotive and industrial fastener solutions

Why Choose Ananka Group for Fasteners?

Ananka Group is a leading fasteners manufacturer, supplier, and exporter, offering a wide range of fasteners for various industrial applications across different locations.

Our Strengths:

✅ High-Quality Materials: Stainless Steel, Alloy Steel, Titanium, Inconel, Monel, and more. ✅ Global Supply Network: Fast shipping to the USA, Canada, Europe, Asia, and Africa. ✅ Customization Available: Tailored fasteners for unique industrial applications. ✅ Certified Products: Compliance with ASTM, DIN, ISO, BS, ANSI, and ASME standards. ✅ Competitive Pricing: Affordable bulk and wholesale options.

Conclusion

Finding the right fasteners manufacturer & supplier in different locations is essential for ensuring product reliability, durability, and compliance with industry standards. Whether you are in Canada, the USA, Mexico, Oman, Singapore, Kenya, Ireland, Australia, the UK, Sweden, Europe, or Germany, Ananka Group offers premium industrial fasteners tailored to your specific needs.

Need high-quality fasteners?

Contact Ananka Group today for the best fastening solutions worldwide!

FAQs

1. What industries require fasteners?

Fasteners are used in construction, automotive, aerospace, oil & gas, shipbuilding, electronics, and renewable energy industries.

2. What are the different types of fasteners available?

Common fasteners include bolts, nuts, screws, washers, anchors, rivets, and studs, available in various materials.

3. How can I choose the right fastener for my application?

Consider material, strength, corrosion resistance, and industry standards when selecting fasteners.

4. Does Ananka Group provide customized fasteners?

Yes! We offer custom fasteners in different materials, sizes, and coatings to meet your specific needs.

5. How can I place an order for fasteners?

You can contact Ananka Group via email, phone, or website to place your order and receive a quote.

Would you like a customized blog for a specific location or industry? Let me know! 🚀

#ananka#fasteners#anankafasteners#supplier#manufacturer#usa#kenya#saudiarabia#exporter#article#blog#mumbai#hex#bolt#tumblr blog#tumblr

0 notes

Text

How to Choose Bolts and Nuts for Heavy Machinery Applications

At Akbarali Enterprises, a leading Bolts Manufacturer in India and Nut Supplier in India, we understand the importance of selecting the right fasteners for industrial applications. This guide will help you make informed decisions when choosing bolts and nuts for heavy-duty machinery, with insights on essential factors to consider.

Consider Load Capacity and Strength

When selecting bolts and nuts for heavy machinery, load capacity is paramount. Heavy machinery often operates under constant tension and stress, and the bolts and nuts used must handle these forces without failure. Fasteners come in different grades, indicating their tensile strength and capacity to handle loads. For instance, high-strength bolts, such as Grade 8.8 or 10.9, are commonly used for high-load applications due to their robust composition and resilience. Selecting the appropriate grade ensures that the fasteners can handle the weight and pressure exerted by heavy equipment.

Akbarali Enterprises, as a top Bolts Supplier in India, provides a variety of high-grade bolts to cater to these requirements. Our fasteners meet international standards, ensuring they can withstand the demands of heavy machinery applications.

Evaluate Material and Corrosion Resistance

Material choice significantly impacts a fastener's durability, especially in machinery exposed to harsh environmental conditions. Steel bolts and nuts are commonly used in heavy-duty applications for their strength, but they may require added protection if used in corrosive environments. Stainless steel, for instance, provides resistance against rust and corrosion, making it ideal for outdoor or high-humidity settings. Other materials, like alloy steel, offer additional strength and resilience.

Coatings like zinc plating, hot-dip galvanizing, or anodizing can enhance corrosion resistance. Akbarali Enterprises offers bolts and nuts with various protective coatings to extend their lifespan in challenging environments, positioning us among the most reliable Bolts Manufacturers in India.

Choose the Right Type of Bolt and Nut

Different types of bolts and nuts serve specific purposes. In heavy machinery applications, hex bolts, heavy hex nuts, and lock nuts are often preferred for their strength and durability. Lock nuts, in particular, are useful for preventing loosening due to vibration, a common issue in heavy machinery.

Selecting the appropriate type is essential for the integrity of the machinery. As a trusted Nuts manufacturer, Akbarali Enterprises offers a range of bolt and nut types to meet diverse industrial needs. Our product selection includes lock nuts, heavy hex nuts, and high-strength bolts, all designed for heavy-duty applications.

Examine Bolt and Nut Size and Threading

The size and threading of bolts and nuts determine their compatibility with specific machinery components. Accurate sizing ensures that the fasteners fit snugly and securely, which is essential in applications requiring precision. Threaded bolts, for example, come in coarse and fine threads, with coarse threads providing better resistance to wear and fine threads offering greater tensile strength. The thread type should align with the application’s requirements to ensure the bolt and nut do not loosen or strip under stress.

Akbarali Enterprises offers a comprehensive range of sizes and threading options, making us a reliable choice among Nut manufacturers in India. Our products are manufactured to precise standards, ensuring reliable performance and fit for heavy machinery.

Prioritize Safety and Compliance Standards

In heavy machinery applications, safety is non-negotiable. Fasteners must comply with industry standards such as ISO, DIN, or ANSI to meet stringent quality and safety requirements. Non-compliance can lead to fastener failure, which can compromise machinery and operator safety. Selecting a supplier like Akbarali Enterprises, a reputable Bolts Manufacturer and Nut Supplier that follows strict quality standards, helps ensure the fasteners you use meet safety and reliability benchmarks.

Seek Expert Guidance for Custom Fastener Needs

Certain heavy machinery applications may require custom bolts and nuts tailored to specific dimensions, load requirements, or environmental factors. Consulting experts in fastener manufacturing can provide insights into suitable customizations. At Akbarali Enterprises, we work closely with our clients to develop custom solutions catering to unique heavy machinery requirements.

As one of the leading Bolts Suppliers in India and Nuts manufacturers in India, we offer tailored fasteners built for high performance and durability. Our team of experts is ready to provide advice and support, ensuring you choose the best fasteners for your machinery’s needs.

Also, we are the leading Fasteners manufacturers in India and Screw Manufacturers in India

Website: akbarfasteners.com

0 notes

Text

Carbon Steel ASTM A105 Flanges Manufacturers In India

Carbon Steel ASTM A105 Flanges Manufacturers In India,Supplier In india ,Stockist In India,Exporter In India

Introduction:- Carbon Steel ASTM A105 Flanges Manufacturers In India

India is emerging as a significant hub for the production of Carbon Steel ASTM A105 flanges, catering to a variety of industries such as oil and gas, petrochemicals, power generation, and construction. These flanges are integral to piping systems, providing robust connections that ensure safety and efficiency in high-pressure and high-temperature environments.

Manufacturers in India utilize advanced manufacturing techniques and adhere to stringent quality standards to produce ASTM A105 flanges that meet international specifications. This commitment to quality ensures that their products are reliable and durable, capable of withstanding demanding operational conditions.

The growing industrial landscape in India, combined with an increasing focus on infrastructure development, has led to a rising demand for high-quality flanges. Indian manufacturers are well-equipped to meet this demand, offering a diverse range of flanges, including slip-on, weld neck, threaded, and blind types.

This introduction sets the stage for a closer examination of the features, applications, and leading manufacturers of Carbon Steel ASTM A105 flanges in India, highlighting their role in supporting the

Product Overview:-.

ASTM A105 Flange is a specification for flanges. Specifications can include flanges of various grades made of stainless steel. The flange is made of forged Carbon Steel ASTM and is intended for high temperature use. Shasan Piping Solution is a leading manufacturer and supplier of ASTM A105 flange types.

This material contains carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium. These are called Carbon Steel ASTMs because other materials contain less than 1% of the composition. There are different types, including SA105N blind flanges, which are used to close pipelines. The flange also has excellent strength properties. The minimum yield strength of the flange is 250 MPa and the minimum tensile strength is 485 MPa. It is a hard material with a Brinell hardness of 187.

Specifications:-

Specification Format of SA105N Blind Flange

Specifications

ASTM A182, ASME SA182

Size

1/2″ to 48″

Standards

ANSI B16.47 Series A & B, MSS SP44, AWWA, Custom Drawings, ASA, ANSI B16.5, API-605.

Pressure Ratings

Class 400, Class 150, Class 1500, Class 300, Class 900, Class 2500, Class 600

Flange Face Type

Flate Face, Raised Face, Ring Type Joint

Coating/Surface Treatment

Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated.

Benefits:-

There are various pressure classes such as class 150, 300, up to 2500, and PN6 to PN64. A105 flanges of class 300 and below do not require heat treatment, but high pressure class can be heat treated. Flanges with a nominal internal diameter greater than 4 inches are heat treated as annealing, normalizing, normalizing and tempering, or normalizing and tempering. ASTM A105 pipe flanges can also be forged. This material is suitable for welding applications. When welding materials, boilers, and pressure vessels, guidelines consistent with ASME standards must be followed. Flanges are both bolted and bolted. ASTM A105 N threaded flanges are useful when welding or screwing methods are not suitable. Threaded flanges can be used on threaded pipes to create connections without welding. Please contact us for flange pricing and details.

Conclusions:-

In summary, Carbon Steel ASTM A105 flanges are a vital component in modern piping systems, known for their strength, durability, and versatility. Their compliance with the ASTM A105 specification guarantees high-quality performance in demanding environments, making them a preferred choice in industries such as oil and gas, petrochemical, and construction.

Email Id:- [email protected]

Contact No:-8879709191

0 notes

Text

Looking for reliable GI (Galvanized Iron) and HDG (Hot-Dip Galvanized) step iron suppliers in the UAE and Kuwait? Discover top-quality step irons designed for durability, safety, and long-lasting performance in harsh environments. Ideal for construction, maintenance, and industrial applications, our step irons meet the highest industry standards. Our step irons feature a bolt-on type design with 2 No. 15mm diameter holes, ideally suited for a 12mm diameter rag (expanding) type bolt for secure installation. Contact us today for bulk orders and competitive pricing across the UAE and Kuwait.

#GI / HDG Step Iron Supplier#Step Iron supplier#galvanized gratings#ductile iron supplier#gi grating supplier in uae#Gratings supplier#UAE Gratings company#grating supplier#grating suppliers in uae#UAE gratings supplier

0 notes

Text

Supplier of Industrial Flange in Karnataka

Company Overview: Keshar Bhawani Metal & Tubes Pvt Ltd is a leading Manufacturer and Supplier of Industrial Flange in Karnataka, India. Industrial flanges are essential components used to connect pipes, valves, pumps, and other equipment in piping systems. They provide a means for joining or terminating pipes, allowing for easy assembly, disassembly, and maintenance of the system. Flanges are typically circular in shape and feature holes for bolting or welding to adjacent components. These flanges come in a variety of shapes, sizes, and materials to suit different applications and operating conditions. Common materials used for industrial flanges include carbon steel, stainless steel, alloy steel, and various non-ferrous metals such as brass and copper. One of the primary functions of industrial flanges is to create a secure and leak-proof connection between pipe sections or components. They achieve this secure connection by bolting or welding the flange to the mating surface of the pipe or equipment. The flange’s design ensures uniform distribution of forces and pressure across the joint, minimizing the risk of leakage or failure. Industrial flanges are widely used in industries such as oil and gas, petrochemical, chemical processing, power generation, water treatment, and manufacturing. Specifications Of Industrial Flanges: Specifications: ASTM A105 / ASME SA105, A105N Dimensions: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. Size: 1/2″ to 48″ Material Forms: Stainless Steel, Carbon Steel, Alloy Steel, Duplex & Super Duplex Steel, Titanium, Hastelloy, High Nickel Alloy, etc. Equipment: Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine, etc. Coating: Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Flanges Keshar Bhawani Metal & Tubes Pvt Ltd is Supplier of Industrial Flange in Karnataka Including Badami, Belagavi, Chamarajanagar, Bhadravati, Bidar, Hassan, Bagalkot, Bidar, Chikkamagaluru, Kalaburagi, Kolar, Ballari, Belagavi, Bangalore, Dakshina Kannada, Haveri, Kodagu, Bengaluru, Davangere, Halebid, Hassan, Hubballi-Dharwad, Kalaburagi, Kolar, Madikeri, Mandya, Mangaluru, Urban, Chitradurga, Vijayapura, Gadag, Tumakuru, Mysuru, Raichur, Shivamogga, Shravanabelagola, Shrirangapattana, Ramanagara, Kittur. For detailed information and inquiries, please feel free to contact us. View Product Read the full article

#Ahmedabad#Badami#Bagalkot#Ballari#Bangalore#Belagavi#Bengaluru#Bhadravati#Bidar#Chamarajanagar#Chikkamagaluru#Chitradurga#DakshinaKannada#Davangere#Gadag#Halebid#Hassan#Haveri#Hubballi-Dharwad#India#IndustrialFlange#IndustrialFlangeinIndia#IndustrialFlangeinKarnataka#Kalaburagi#Karnataka#Kittur#Kodagu#Kolar#Madikeri#Mandya

0 notes

Text

Standard bolts | Roll Fast

Roll-fast takes pride in being the largest manufacturer and supplier of standard bolts in India. Standard bolts are a fundamental element in construction and engineering, serving as the primary method for fastening and securing components in a wide range of applications. These bolts come in various types, each designed to meet specific requirements and standards, ensuring reliability and consistency in performance. Their standardized manufacturing processes ensure consistency, quality, and safety, making them a cornerstone of modern engineering and construction practices. We also do various finishes and colors according to the specifications and needs of the customer. We provide Self-finish or natural finish, Zinc plated, yellow Zinc, blue Zinc, black, Hot Dip Galvanized (HDG), Geomat, PTFE, Xylon coating, etc. Visit us to know more.

visit source url : https://www.roll-fast.com/products/standard-bolts.html

0 notes

Text

U Bolt Dynamics: Crafting Precision Fasteners for Every Need

In the world of construction, automotive manufacturing, and countless other industries, the unsung heroes are often the smallest components. Among these, U bolts hold a place of critical importance. These U-shaped fasteners are pivotal in their role, offering not just support but also ensuring safety and longevity in various applications. From securing pipelines beneath city streets to holding together the framework of skyscrapers, U bolts are integral to structural integrity and function. In this blog post, we will dive deep into the world of U bolts, exploring their types, manufacturing processes, selection criteria, and how U bolt suppliers play a crucial role in providing high-quality fasteners for every need.

Understanding U Bolts

Understanding U bolts goes beyond recognizing their simple U-shaped design. These essential fasteners play a pivotal role in various industries, offering crucial support and stability. To ensure the right fit and performance, it's vital to source U bolts from reputable U bolt suppliers. These suppliers specialize in providing a wide range of U bolts, tailored to specific needs and applications.

By understanding the nuances of U bolts and partnering with reliable U bolt suppliers, businesses can ensure the structural integrity and safety of their projects. From construction to automotive manufacturing, the importance of high-quality U bolts cannot be overstated, making the choice of supplier a critical decision in any procurement process.

Design Features: U bolts are characterized by their U-shaped design, which allows for easy clamping around cylindrical or square objects.

Material Varieties: These fasteners are available in a range of materials, including stainless steel, carbon steel, and galvanized steel, each offering distinct properties suited to different applications.

Application Specifics: U bolts find application in diverse industries such as construction, automotive, marine, and telecommunications, where they are used for securing various components like pipes, poles, and equipment mounts.

Load Capacity Considerations: Choosing the right U bolt involves assessing factors such as the anticipated load and the material being clamped, ensuring that the bolt can withstand the required forces without failure.

Surface Finish Options: To enhance durability and corrosion resistance, U bolts can be finished with coatings such as zinc plating, epoxy coating, or hot-dip galvanizing, depending on the environmental conditions they will be exposed to.

Thread Specifications: U bolts feature threads on both ends, allowing for easy installation and adjustment. Thread size and pitch must be selected carefully to ensure compatibility with nuts or other fastening components.

Customization Possibilities: Some applications may require U bolts with specific dimensions, angles, or configurations. Customization services offered by suppliers allow for the creation of tailored solutions to meet unique project requirements.

Supplier Expertise: Working with experienced U bolt suppliers ensures access to high-quality products, technical support, and reliable delivery, essential elements in achieving successful project outcomes.

Types of U Bolts

When it comes to securing various components in different industries, U bolts are indispensable. These fasteners come in a variety of types, each designed to suit specific applications and requirements. Understanding the different types of U bolts is essential for selecting the right one for a particular project. Here, we'll delve into some common types of U bolts and how they are used across various industries.

Round Bend U Bolts: As the name suggests, round bend U bolts feature rounded bends on both ends, making them ideal for securing cylindrical objects such as pipes, tubes, or cables. They provide a snug fit around the rounded surface, ensuring stability and preventing slippage. Round bend U bolts are commonly used in plumbing, electrical, and automotive applications.

Square Bend U Bolts: Square bend U bolts are designed for clamping square or rectangular objects securely. Their square-shaped bends provide a tight grip, making them suitable for applications where stability and alignment are crucial. These U bolts are often used in construction, scaffolding, and equipment mounting.

Long Tangent U Bolts: Long tangent U bolts feature extended legs and threads, offering increased clamping force and versatility. They are designed to accommodate thicker materials or multiple components, providing a secure hold even under heavy loads. Long tangent U bolts find application in structural steelwork, bridge construction, and machinery assembly.

Custom U Bolts: In some cases, standard U bolts may not meet the specific requirements of a project. Custom U bolts are tailored to precise specifications, including dimensions, materials, and thread configurations. This customization allows for optimal performance and ensures a perfect fit for unique applications. Custom U bolts are often used in industries such as aerospace, marine, and renewable energy, where standard fasteners may not suffice.

When sourcing U bolts for a project, it's crucial to partner with reliable U bolt suppliers. These suppliers offer a wide range of U bolts in various types, sizes, and materials to meet diverse needs. With their expertise and extensive inventory, U bolt suppliers play a vital role in ensuring that projects are equipped with high-quality fasteners that deliver reliable performance and durability.

Manufacturing Excellence

In the realm of industrial hardware, where precision meets durability, the significance of U bolts cannot be overstated. These unassuming yet essential components serve as the backbone of various applications, from construction to automotive engineering. At the heart of every sturdy structure and reliable machinery lies the reliability of U bolts. In this landscape of manufacturing excellence, the role of U bolt suppliers emerges as pivotal players, ensuring that the foundation of industries remains steadfast.

Manufacturing excellence isn't merely about producing goods; it's a commitment to quality, innovation, and reliability. U bolt suppliers embody this ethos by consistently delivering products that meet and exceed industry standards. Their dedication to precision engineering ensures that each U bolt is crafted with meticulous attention to detail, guaranteeing optimal performance in diverse environments.

One of the hallmarks of manufacturing excellence in the realm of U bolt suppliers is their ability to tailor solutions to meet specific customer needs. Whether it's a bespoke design for a unique application or a large-scale production order, these suppliers exhibit versatility and flexibility in their operations. By leveraging advanced manufacturing techniques and cutting-edge technologies, they empower industries to achieve new heights of efficiency and productivity.

Moreover, manufacturing excellence goes hand in hand with sustainability in today's global landscape. U bolt suppliers recognize their responsibility towards environmental stewardship and adopt eco-friendly practices throughout their operations. From sourcing materials responsibly to optimizing energy consumption, these suppliers strive to minimize their carbon footprint while maximizing value for their customers.

Furthermore, manufacturing excellence isn't confined to the production floor; it extends to every aspect of the supply chain. U bolt suppliers prioritize transparency, reliability, and integrity in their dealings, fostering long-term partnerships built on trust and mutual benefit.

Selection Criteria

When navigating the market for U bolt suppliers, selecting the right partner is crucial for the success of any project or endeavor. Several key criteria should inform this decision-making process to ensure optimal outcomes.

Firstly, expertise and experience play pivotal roles. Assessing a supplier's track record within the industry, including the breadth of their portfolio and the depth of their technical knowledge, provides valuable insights into their capabilities.

Secondly, quality assurance measures are non-negotiable. Look for suppliers who adhere to stringent quality control standards and certifications, ensuring that their U bolts meet or exceed regulatory requirements and industry benchmarks.

Thirdly, responsiveness and communication are vital aspects of a fruitful partnership. Opt for suppliers who prioritize clear and prompt communication channels, fostering transparency and alignment throughout the procurement process.

Additionally, consider factors such as reliability, scalability, and cost-effectiveness when evaluating potential suppliers. A dependable partner with the capacity to scale operations according to your needs, while offering competitive pricing, can significantly enhance project feasibility and success.

Ultimately, the selection of U bolt suppliers should be a well-informed decision, guided by comprehensive assessment against these critical criteria. By prioritizing expertise, quality, communication, reliability, and cost-effectiveness, stakeholders can forge enduring partnerships that drive efficiency, innovation, and success.

Choosing the right U bolt for a specific application requires careful consideration of several factors:

Material: Depending on the environment, a U bolt may need to be made of weather-resistant materials like stainless steel.

Size and Load Capacity: The size and thread design must be suitable for the load it is expected to bear.

Shape: The shape of the U bolt must match the object it is clamping.

Finish: The right finish can greatly extend the lifespan of a U bolt by protecting it against corrosion.

U Bolt Suppliers: Ensuring Quality and Variety

Finding the right U bolt for your project involves more than just understanding the types and manufacturing processes. It requires access to a reliable supplier who can provide high-quality fasteners tailored to your specific needs. U bolt suppliers play a critical role in the ecosystem, ensuring that customers have access to a wide variety of fasteners that meet strict quality standards.

Reputable U bolt suppliers are characterized by their extensive inventory, which includes bolts of different sizes, shapes, and materials. They often offer custom manufacturing services for projects that require unique specifications. Additionally, top suppliers ensure that their products are tested for strength and durability, providing customers with the confidence that their fasteners will perform as expected.

Comprehensive Material Selection: U bolt suppliers meticulously source materials, including high-grade steel and other alloys, to ensure durability and performance across diverse applications.

Advanced Manufacturing Techniques: Leveraging state-of-the-art technologies such as computer-aided design (CAD) and precision machining, suppliers produce U bolts with unparalleled accuracy and consistency.

Rigorous Quality Control Processes: From initial inspection of raw materials to final product testing, suppliers implement stringent quality control measures to maintain the highest standards of quality and reliability.

Customization Capabilities: Recognizing the unique requirements of different industries and applications, U bolt suppliers offer customization options, including varying sizes, coatings, and thread types, to meet specific customer needs.

Diverse Product Range: In addition to traditional U bolts, suppliers often offer a diverse range of related products, such as square U bolts, round U bolts, and specialty configurations, providing customers with comprehensive solutions for their fastening needs.

Read Also: A Journey Through the World of Fastening Systems

The Importance of Quality Control

In the realm of U bolt suppliers, quality control isn't just a checkbox; it's a cornerstone of reliability, safety, and customer satisfaction. These seemingly small components play a significant role in supporting crucial infrastructure across various industries, from construction to transportation. As such, ensuring their quality is paramount.

Quality control measures within U bolt manufacturing encompass a spectrum of processes, from material selection to final inspection. Suppliers must meticulously vet raw materials, utilizing only the highest-grade steel or other suitable materials to withstand the rigors of their intended applications.

Precision engineering is another crucial aspect of quality control. U bolts must adhere to precise dimensional specifications to ensure proper fit and functionality. Advanced manufacturing techniques, such as computer-aided design (CAD) and computer numerical control (CNC) machining, enable suppliers to achieve unparalleled accuracy and consistency.

Furthermore, rigorous testing protocols are employed to validate the performance and durability of U bolts. This may include stress testing, corrosion resistance assessments, and fatigue analysis to simulate real-world conditions and ensure long-term reliability.

The importance of quality control extends beyond individual components to the overall reputation and trustworthiness of U bolt suppliers. By prioritizing quality at every stage of the manufacturing process, suppliers demonstrate their commitment to excellence and customer satisfaction, ultimately fostering enduring partnerships and driving industry advancement.

Conclusion

U bolts may be small, but their impact on the safety and integrity of structures and machinery is immense. Understanding the types of U bolts, their manufacturing process, and how to select the right one for your needs is crucial. Equally important is choosing a supplier that can provide high-quality, durable fasteners tailored to your project's requirements.

As industries continue to evolve and new challenges arise, the demand for precision-engineered fasteners like U bolts will only grow. By partnering with reputable U bolt suppliers, businesses can ensure that they are equipped with the best fasteners for the job, contributing to the overall success and longevity of their projects.

In a world where the strength and stability of our constructions, vehicles, and machinery are paramount, U bolts stand out as a critical component. Ensuring that these essential fasteners are of the highest quality and perfectly suited to their intended application is not just a matter of efficiency but of safety and reliability. As we have seen, the dynamics of U bolts encompass a wide range of considerations, from their design and manufacture to the crucial role played by suppliers in delivering precision fasteners for every need. By paying close attention to these aspects, we can continue to build, create, and innovate with confidence, knowing that our smallest components are more than capable of holding together our grandest designs.

Read Also: A Closer Look at Industry-Leading Carriage Bolt Makers

#bolt supplier#manufacturer#business#u bolt manufacturers#U-bolt Suppliers#U-bolt exporters India#U Bolts Manufacturer#U Bolts Manufacturers India

0 notes

Text

Top U Bolts Manufacturers & Suppliers in India | SS International

Sachiya Steel International is a leading U bolts manufacturer in India, offering a wide range of high-quality U bolts for industrial applications. We export to over 85 countries, providing U bolts in various materials like stainless steel, carbon steel, and alloys. Our products come in different sizes, grades, and finishes, including self-color, zinc-plated, and hot-dip galvanized. Trusted by industries worldwide, we are committed to delivering superior U bolts and fasteners for all your needs.

Visit Sachiyasteel.com today to explore the best U Bolts Manufacturer in India and get high-quality U bolts at competitive prices for your industrial and commercial applications.

#SachiyaSteel#MumbaiManufacturers#MadeInIndia#IndianManufacturer#SteelSupplier#PipeFittingsManufacturer#QualityMatters#Durability#PrecisionEngineering#ManufacturingExcellence#B2BSupplier#EngineeringSolutions

0 notes

Text

Find Nut Bolt Supplier with Best Quality Options

Introduction

Looking for a nut bolt supplier with the best quality options? Choosing the right supplier ensures superior durability, precision, and performance for industrial, automotive, and construction needs. Discover the top suppliers, their product range, and tips for selecting high-quality fasteners.

Why Choose a High-Quality Nut Bolt Supplier?

Premium Materials – Stainless steel, carbon steel, alloy steel.

Precision Engineering – Manufactured to meet industry standards.

High Tensile Strength – Ensures durability and load-bearing capacity.

Corrosion Resistance – Coated and treated for longevity.

Reliable Supplier Support – Assistance with specifications and orders.

Types of High-Quality Nut Bolts

TypeMaterialCommon ApplicationsHex BoltsStainless Steel, MSMachinery, constructionFlange BoltsAlloy SteelAutomotive, heavy equipmentEye BoltsGalvanized SteelLifting, riggingU-BoltsMild SteelPipe fittings, structural supportCarriage BoltsStainless SteelWoodworking, furniture

Top Nut Bolt Suppliers with Best Quality Options

Supplier NameLocationSpecializationContact InfoBoltFast SolutionsDelhiIndustrial & structural bolts9876543210SteelBolt TradersMumbaiAutomotive & heavy-duty bolts9123456789FastFix HardwareChennaiHigh-quality nut bolt supplier8765432109Precision Bolts & NutsPuneStainless steel & high-strength bolts9988776655Mega Bolt StoreBangaloreCustom & standard fasteners8111223344

How to Select the Best Quality Nut Bolts?

Check Material Composition – Opt for stainless steel, alloy steel, or corrosion-resistant coatings.

Verify Manufacturing Standards – Look for ISO & ASTM certifications.

Inspect Tensile Strength Ratings – Ensure bolts can withstand required stress levels.

Compare Supplier Reviews – Analyze customer feedback and industry reputation.

Request a Sample – Test quality before placing bulk orders.

Industries Requiring High-Quality Nut Bolts

Construction – High-load applications.

Automotive – Engine and body assembly.

Aerospace – Precision fasteners for aircraft.

Manufacturing – Heavy machinery and equipment.

Marine & Oil Industry – Corrosion-resistant fasteners.

FAQs

Q1: What are the strongest materials for nut bolts?

Stainless steel, alloy steel, and titanium are among the strongest materials used in nut bolts.

Q2: How do I ensure I’m buying high-quality nut bolts?

Look for ISO certification, tensile strength ratings, and supplier reputation before purchasing.

Q3: Where can I find the best quality nut bolt suppliers online?

Platforms like TradeIndia, IndiaMART, Justdial list verified suppliers with customer ratings.

Q4: What coatings improve nut bolt longevity?

Zinc coating, hot-dip galvanization, black oxide, and electroplating enhance durability.

0 notes

Text

Product: L Shaped Bolt Standard: DIN, GB, ANSI, BSW Material: carbon steel or specified Level: 4.8 Level 8.8 Specifications: M3~M45, 3/16"~1-3/4"

Anchor: support specified

Thread: fine teeth, coarse teeth, imperial, American, German Surface treatment: natural color, galvanized, hot-dip galvanized, blackened, yellow zinc plated Packing: sacks, paper bags, trays, or upon request

1 note

·

View note

Text

Hastelloy B3 Fasteners Suppliers

The Deep Steel Center is one of the extraordinary Suppliers and Manufacturers of Hastelloy B3 Fasteners. We give the entire level of adding in different points of view, sizes, types, and decisions. Our offered Fasteners have huge security from hydrochloric staggering at all concentrations and temperatures. Hastelloy B3 Fasteners are made by utilizing ideal-quality, unrefined substances. These things are utilized in decreasing acid affiliations and locking the fasteners of warming stuff. Hastelloy B3 Secure Fasteners are conveyed using a mix containing nickel and molybdenum as the base part and movements of cobalt and tungsten. Our offered substances are normal for exceptional hydrochloric harming, sulfuric acids, hydrobromic shocking, acidic deplorable, phosphoric harming, and formic harming. These grains offer mind-blowing strength and goodness in any acidic or decreasing medium.

Hastelloy B3 Fasteners push smooth coordination through welding gear and diminish tipping in contact tips. We are a proactive connection that offers Hastelloy B3 Fasteners and other quality things that meet and beat client unequivocal necessities and, as such, affirm full-scale satisfaction. We provide an enormous level of materials, like Hastelloy B3 Fasteners. Our offered Fasteners show sensational security from pitting, opening, disintegrating, and stress-use breaking in any chloride-containing conditions.

Standard Specification For Hastelloy B3 Fasteners

Specifications

ASTM B574 / ASME SB574

Fasteners size

Bolt / Screw Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Nuts Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Washers Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Machine Screws Size : M1.6 – M12 Self Tapping Screw Size : No.2 – No. 14

Fasteners Length

3 mm to 200 mm

Fastener Threads

UNF, BSW, BSF, METRIC, UNC or as required

Standard of High Nickel Alloy Fasteners

DIN : DIN 934, DIN 931, DIN 970, DIN 933 UTS : UNEF, NPT, UNC, UNS, UNF, NPTF ISO : JIS standards, ISO 4033, ISO 4032, ANSI – American National Standards Institute ASME B18.5 ANSI B 28.2.4 1M as per defined in ASME B16.5 standard Stud Bolt length ANSI B 18.2.4 2M as per defined in ASME B18.2.2 Hex nuts

Dimensions

DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3

Surface Coating

Ptfe Coated High Nickel Alloy Fasteners Phosphate Coating Teflon Coating Zinc Coating Hot Dipped Galvanizing Coating Cadmium Coating Xylon Coating

Fasteners Finishing

High Nickel Alloy : Self-Colour, Passivated, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), High Nickel Alloy, Sherardized, some special one like DACROMET Geometry and Mechanically Applied coating ,Dacroment, nickel plated, anodizing, plated zinc-nickel Zinc (blue, black, yellow, white), black oxide.

For more information:

Visit website: https://www.deepsteelalloys.com/hastelloy-alloy-b3-fasteners-supplier.html

#Hastelloy B3 Fasteners Manufacturers#Hastelloy B3 Fasteners Suppliers#Hastelloy B3 Fasteners Stockists#Hastelloy B3 Fasteners Exporters#Hastelloy B3 Fasteners Manufacturers in India#Hastelloy B3 Fasteners Suppliers in India#Hastelloy B3 Fasteners Stockists in India#Hastelloy B3 Fasteners Exporters in India#Hastelloy B3 Fasteners Manufacturers in Mumbai#Hastelloy B3 Fasteners Suppliers in Mumbai#Hastelloy B3 Fasteners Stockists in Mumbai#Hastelloy B3 Fasteners Exporters in Mumbai

0 notes

Text

Carbon Steel ASTM A105 Flanges Suppliers In India

Carbon Steel ASTM A105 Flanges Manufacturers In India,Supplier in India ,Stocklist in India,Exporter In India

Introduction Carbon Steel ASTM A105 Flanges Manufacturers In India,

Introduction:-

ASTM A105 is an American standard specification for carbon steel flanges and fittings, which has been widely adopted in India due to its proven performance and reliability. These flanges are manufactured according to the ASTM A105 standard, ensuring they meet the required specifications for strength, durability, and quality

While ASTM A105 flanges offer many benefits, it is important to consider the specific requirements of the application. For highly corrosive environments or extreme temperature conditions, alternative materials like stainless steel or alloy steel flanges might be more suitable.

Product Overview:-

ASTM A105 Flange is a specification for flanges. Specifications can include flanges of various grades made of stainless steel. The flange is made of forged Carbon Steel ASTM and is intended for high temperature use. Shasan Piping Solution is a leading manufacturer and supplier of ASTM A105 flange types.

TThis material contains carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium. These are called Carbon Steel ASTMs because other materials contain less than 1% of the composition. There are different types, including SA105N blind flanges, which are used to close pipelines. The flange also has excellent strength properties. The minimum yield strength of the flange is 250 MPa and the minimum tensile strength is 485 MPa. It is a hard material with a Brinell hardness of 187

Specifications:-

Specifications

ASTM A182, ASME SA182

Size

1/2″ to 48″

Standards

ANSI B16.47 Series A & B, MSS SP44, AWWA, Custom Drawings, ASA, ANSI B16.5, API-605.

Pressure Ratings

Class 400, Class 150, Class 1500, Class 300, Class 900, Class 2500, Class 600

Flange Face Type

Flate Face, Raised Face, Ring Type Joint

Coating/Surface Treatment

Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated.

Benefit:-

India is home to several prominent manufacturers of Carbon Steel ASTM A105 flanges, catering to the diverse needs of various industries such as oil and gas, petrochemical, chemical processing, and power generation. Here's a brief overview of some notable manufacturers. In India, numerous manufacturers produce high-quality Carbon Steel ASTM A105 flanges, catering to a wide range of industrial applications. These manufacturers are known for their adherence to international standards, competitive pricing, and the ability to provide customized solutions to meet specific needs

Conclusions:-

There are various pressure classes such as class 150, 300, up to 2500, and PN6 to PN64. A105 flanges of class 300 and below do not require heat treatment, but high pressure class can be heat treated. Flanges with a nominal internal diameter greater than 4 inches are heat treated as annealing, normalizing, normalizing and tempering, or normalizing and tempering. ASTM A105 pipe flanges can also be forged. This material is suitable for welding applications. When welding materials, boilers, and pressure vessels, guidelines consistent with ASME standards must be followed. Flanges are both bolted and bolted. ASTM A105 N threaded flanges are useful when welding or screwing methods are not suitable. Threaded flanges can be used on threaded pipes to create connections without welding. Please contact us for flange pricing and details.

Email Id :- [email protected] Contact No:- 88879709191

0 notes