#horizontal flow wrap machine manufacturers

Explore tagged Tumblr posts

Text

0 notes

Text

#Automatic Packing Machine Manufacturers In Chennai#Auger Packing Machine Manufacturers In Chennai#Weighmetric Packing Machine Manufacturers In Chennai#Multihead Weigher Machine Manufacturers In Chennai#Volumetric Packing Machine Manufacturers In Chennai#Multipurpose Packing Machine Manufacturers In Chennai#Liquid Packing Machine Manufacturers In Chennai#Paste Packing Machine Manufacturers In Chennai#Pharma Packing Machine Manufacturers In Chennai#Oil Packing Machine Manufacturers In Chennai#Mini Doy Pack Machine Manufacturers In Chennai#Horizontal PFS (Pick-Fill-Seal) Machine Manufacturers In Chennai#Ffs - Volumetric Packing Machine Manufacturers In Chennai#FFS TRAY Model Machines Manufacturers In Chennai#Multitrack Packing Machine Manufacturers In Chennai#Flow Wrap Packing Machine Manufacturers In Chennai#Semi – Automatic Machine Manufacturers In Chennai#Semi Automatic Weighmetric Filling Machine Manufacturers In Chennai#Semi Automatic Paste Filling Machine Manufacturers In Chennai#Semi Automatic Volumetric Filling Machine Manufacturers In Chennai#Heavy-Duty Band Sealer Machine Manufacturers In Chennai#Semi Automatic Auger Filling Machine Manufacturers In Chennai#Conveyor Machine manufacturers in Chennai#Z-Conveyor Manufacturers In Chennai#Screw Conveyor Machine Manufacturers In Chennai#Bucket Elevator Machine Manufacturers In Chennai#Roller Conveyor Machine Manufacturers In Chennai#Flat Belt Conveyor Manufacturers In Chennai#Inclined Conveyor Manufacturers In Chennai#Packing machine manufacturers in Chennai

0 notes

Text

How Nichrome’s End of Line Machines benefits businesses with efficiency

In today’s fast-paced industrial environment, efficiency is key to staying ahead of the competition. Businesses are constantly on the lookout for innovative solutions that can streamline their operations, reduce costs, and enhance productivity. As a leading name in packaging solutions, we offer a range of end of line machines designed to meet these needs. Let's explore how our end of line machines can benefit your business with unparalleled efficiency.

#tin filling machine#Jar filling machine manufacturers#auto case erector#bulk bag filling machine#case packer manufacturers india#tin can filling and sealing machine#automatic case erector#ghee jar filling machine#tin packing machine#oil tin filling machine#powder jar filling machine#automatic carton box packing machine#carton packing machine#carton box packing machine#Bottle Filling Line#horizontal flow wrap machine#powder filling machine#box packing machine#automatic bottle filling machine#cartoning machine#flow wrap machine#secondary packaging#bottle filling machine#powder bottle filling machine#shrink wrapping machine manufacturer#bottle capping machine#shrink wrapping machine for bottles#can seamer machine

0 notes

Text

#horizontal flow wrap machine#automatic packaging machine#milk packaging machine#integrated packaging solutions#oil filling machine#innovative packaging solutions#packaging machine manufacturer#food packaging machine

0 notes

Text

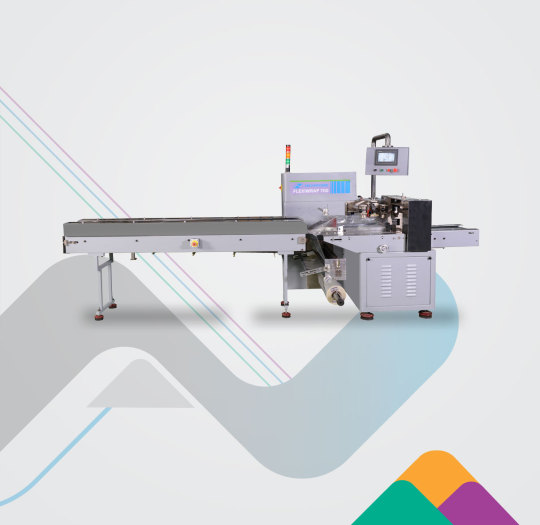

Flexiwrap 700

Nichrome offers Horizontal Flow Wrap Machine (Flexiwrap 700) & Packaging System for food, pharma & Non Food industries

0 notes

Text

Horizontal Flow Wrap Machine Suppliers

EquipmentsMachinesUAE is one of the most reputed horizontal flow wrap machines suppliers in UAE, which manufacturing & supplying a extensive range of high-quality horizontal flow wrap machines in UAE at the most competitive price. To know more visit at https://www.equipmentsmachinesuae.com/food-processing-equipment-and-machines/horizontal-flow-wrap-machines

0 notes

Text

High-Quality Sealing Machines in Kerala

High-Quality Sealing Machines in Kerala: A Game-Changer for Efficient Packaging

Kerala’s industrial landscape is witnessing significant growth, and the demand for high-quality sealing machines has surged in response to this boom. Sealing machines play a crucial role in ensuring product safety, extending shelf life, and enhancing overall presentation. Whether it’s for food, pharmaceuticals, or consumer goods, these machines provide airtight sealing, preserving the contents and protecting them from contamination. Renowned manufacturers in Kerala offer advanced sealing machines equipped with the latest technology, ensuring precision and speed in packaging processes.

Best Fully Automatic Packing Machines in Kerala: Revolutionizing the Industry

For industries looking to streamline their packaging processes, fully automatic packing machines have become indispensable. Kerala has emerged as a hub for these cutting-edge machines, which handle everything from weighing and filling to sealing and labeling. Fully automatic packing machines minimize human intervention, ensuring consistent quality and reducing labor costs. With features like programmable settings, multi-function capabilities, and high-speed operation, these machines cater to industries of all sizes, from local manufacturers to large-scale producers.

Top Packaging Machines in Kerala: Innovation Meets Reliability

Kerala’s packaging industry is evolving rapidly, thanks to the availability of top-notch packaging machines. From vertical form fill seal (VFFS) machines to horizontal flow wrap machines, the state’s leading manufacturers provide a wide array of equipment to meet diverse packaging needs. These machines are designed for efficiency, durability, and ease of use, ensuring that products are packed quickly and securely. Whether for food items, pharmaceuticals, cosmetics, or household products, Kerala’s top packaging machines are helping businesses achieve faster production cycles, improved quality, and greater market competitiveness.

Investing in high-quality sealing and packing machines in Kerala is essential for businesses looking to stay ahead in today’s competitive market. With top manufacturers providing innovative and reliable solutions, the state continues to lead the way in packaging technology.

1 note

·

View note

Text

Candy Packaging Machines Market Situation and Forecasting Trends Analysis 2024 - 2032

The candy industry has seen considerable growth over the years, driven by consumer demand for innovative and diverse confectionery products. As the market expands, the need for efficient and reliable packaging solutions becomes increasingly vital. Candy packaging machines play a crucial role in ensuring that products are packed efficiently while maintaining quality and aesthetic appeal. This article explores the candy packaging machines market, examining its growth drivers, types, applications, challenges, and future trends.

Understanding Candy Packaging Machines

The candy packaging machines market is an essential component of the confectionery industry, contributing to efficiency, quality, and sustainability. As the market continues to grow, driven by consumer demand and technological advancements, manufacturers must adapt to new trends and challenges.

What Are Candy Packaging Machines?

Candy packaging machines are specialized equipment designed to package various types of confectionery products, including chocolates, gummies, hard candies, and more. These machines automate the packaging process, ensuring efficiency, consistency, and hygiene.

Types of Candy Packaging Machines

Vertical Form Fill Seal (VFFS) Machines: These machines create bags from a roll of film, fill them with candy, and seal them in a vertical position. They are popular for packaging small, loose candies.

Horizontal Flow Wrappers: Used primarily for bar-shaped candies, these machines wrap products in a continuous flow of packaging material, providing high-speed wrapping capabilities.

Cartoning Machines: These machines package candy into cartons or boxes, offering an effective way to bundle multiple products for retail.

Labeling Machines: Essential for compliance and branding, labeling machines apply labels to packaged products, ensuring they meet regulatory requirements.

Market Dynamics

Current Market Size and Growth

The candy packaging machines market is experiencing significant growth, with an increasing number of confectionery manufacturers seeking automation to enhance production efficiency. Recent market analyses estimate the market to be valued in the billions, with a projected compound annual growth rate (CAGR) in the coming years.

Key Drivers

Rising Demand for Confectionery Products: As consumer preferences shift toward unique and innovative candy options, manufacturers are ramping up production, necessitating efficient packaging solutions.

Technological Advancements: Innovations in packaging technology, such as smart packaging and automation, are driving the demand for modern candy packaging machines.

Focus on Sustainability: Increasing consumer awareness regarding environmental sustainability is pushing manufacturers to adopt eco-friendly packaging solutions, further fueling the market.

Applications of Candy Packaging Machines

Confectionery Manufacturing

In confectionery manufacturing, packaging machines are essential for maintaining product quality and prolonging shelf life. Automated machines reduce human error and increase throughput, allowing manufacturers to meet growing consumer demand.

Retail and Distribution

Candy packaging machines are crucial in preparing products for retail, ensuring that they are attractively packaged and properly labeled. This not only enhances product visibility but also aids in inventory management and distribution.

Exporting

For manufacturers looking to expand internationally, packaging machines ensure that candy products are packaged according to different regional regulations and standards, making them suitable for global markets.

Challenges Facing the Candy Packaging Machines Market

High Initial Investment

The cost of purchasing and maintaining advanced candy packaging machines can be substantial. Smaller manufacturers may struggle to justify these investments, which can limit their ability to compete in the market.

Technological Complexity

The integration of sophisticated machinery into existing production lines can pose challenges, particularly for manufacturers lacking technical expertise. This can lead to operational inefficiencies if not managed correctly.

Regulatory Compliance

Candy packaging is subject to strict regulatory standards, which can vary by region. Manufacturers must ensure their machines are compliant, requiring ongoing investment and adaptation.

Future Prospects

Market Trends

The candy packaging machines market is poised for continued growth, with several key trends expected to shape its future:

Increased Automation: The trend towards automation will likely accelerate, with manufacturers seeking ways to improve efficiency and reduce labor costs.

Sustainable Packaging Solutions: As consumer preference for eco-friendly products grows, manufacturers will increasingly adopt sustainable packaging practices, influencing machine design and functionality.

Smart Packaging Technologies: The integration of IoT (Internet of Things) and smart technologies into packaging machines will allow for better monitoring and data collection, enhancing operational efficiency.

Conclusion

The evolution of candy packaging technology not only enhances production capabilities but also aligns with the broader push towards sustainability, making it a dynamic and promising sector within the food packaging industry. As the industry evolves, embracing innovation will be crucial for manufacturers aiming to thrive in an increasingly competitive landscape.

#Candy Packaging Machines Market Size#Candy Packaging Machines Market Trend#Candy Packaging Machines Market Growth

0 notes

Text

Bisleri Plant Manufacturer, Bisleri Plant - kceindia.com

Bisleri Plant Manufacturer : kceindia.com is Bisleri Plant Manufacturer, Bisleri Plant Supplier, and Bisleri Plant Exporter in Navi Mumbai, India. Call Now.

Packaging Machineries, Packaging Machinery, Wrapping Machines, Wrapping Machine, Wrap Machine, Sealing Machine, Sealing Machines, Sealing Machinery, Auto Impale Sealing Machine, Foot Operated Direct Heat Sealer, Continuous Pouch Sealing Machine, Shrink Tunnel Machine, Shrink Wrapping Machines, Carton Sealer Machine, Carton Sealing Machine, Carton Taping Machine, Pallet Stretch Wrappling Machine, Stretch Wrapping Machine, Flow Pack Wrapping Machine, Horizonatal Flow Pack Wrapping Machine, Piston Filler, Cup Filler Machine, Form Fill and Seal Machine, Form Fill Seal Machine, Auger Filler, Vertical Flow Pack Machine, Cut and Wrap Machine, Chocolate Cutting Machine, Enrober, Enrober Cooling Tunnel, Packaging Automation, Pouch Sealing Machine, Food Processing Equipments, Packaging Equipments, Air Pillow Making Machines, Auger Filler, Automatic Packaging Machine, Biscuit Packaging Machinery, Biscuit Packing Machines, Bunch Wrapping Machines, Bunch Wrapping Machines, Center Seal Flow Wrapping Machines, Centre Seal Pouch Machines, Chocolate Cutting Machines, Chocolate Packing Machines, Chocolate Wrapping Machinery, Complete Packing Line, Continuous Pouch Sealing Machine, Cup Sealing Machines, Cut And Wrap Machine, Flow Pack Wrapping Machine, Flow Wrap Machinery, Flow Wrap Machines, Flow Wrapping Machine, Form Fill Seal Machines, Four Side Seal Flow Wrapping Machines, Granules Packing Machines, Horizontal Flow Pack Wrapping Machine, Ice Cream Wrapping Machines, Jelly Packing Machines, Liquid Sealing Machines, Liquid Wrapping Machines, Masalas Packaging Machine, Packaging Automation, Packaging Machinery, Packaging Machines, Pickling Plant, Pillow Pack Flow Wrapping Machines, Pillow Pack Machines, Piston Filler, Plastic Bag Sealing and Packaging Machines, Pouch Sealing Machine, Pvc Seaming Machines, Sealing Machinery, Shampoo Wrapping Machines, Soap Banding Machines, Soap Wrapping Machines, Vertical Flow Pack Machine Cup Filler, Wrapping Machinery, Vasai, karjan , khopoli, neral, lonavala, khandala, igatpuri, bhivandi, shahapur , nasik , shirdi, titwala, bhor , sinner, shirdi, Ahamadnagar, kholapur, sangli, ichalkarangi, Ahamadnagar, solapur, jejuri, Baramati, ratnagiri, roha, Talasari, wada,palghar, dahanu , nagpur, nanded, latur, Alibag, pen , vashi , cbd belapur

0 notes

Text

#multi track pouch packing machine manufacturers#pouch packaging machine manufacturers#horizontal flow wrap machine manufacturers#candy packing machine manufacturers#granual packing machine manufacturers#packaging machine manufacturers#ffs pouch packing machine manufacturers#gulal packing machine manufacturers#collar type machine manufacturers

0 notes

Text

The Rise of Horizontal Packing Machines

Efficiency in Packaging: The Rise of Horizontal Packing Machines

In the realm of packaging, efficiency and reliability are paramount. Among the various solutions available, horizontal packing machines have emerged as a cornerstone in the industry, offering unparalleled precision and speed. These machines cater to a wide array of products, from food items to hardware, ensuring that each item is securely wrapped and ready for distribution.Get more news about professional horizontal packing machine,you can vist our website!

Manufacturers like Samsonpac have set the standard high with their range of horizontal flow packaging machines. Their commitment to innovation is evident in the user-friendly designs and advanced features such as touch screen controls and empty bag prevention mechanisms. These features not only streamline the packaging process but also minimize waste, a crucial factor in today’s environmentally conscious market.

The adaptability of horizontal packing machines is another key factor contributing to their widespread adoption. Whether it’s wrapping delicate vegetables or sealing robust hardware components, these machines handle varying product sizes and shapes with ease. This versatility is further enhanced by the ability to store multiple package parameters, allowing for quick transitions between different packaging needs.

Furthermore, companies like Pro Pac offer comprehensive packaging systems that integrate horizontal flow wrapping equipment with other machinery, creating a seamless packaging line. This integration is vital for businesses looking to optimize their operations and maintain a competitive edge in the market.

As industries continue to evolve, the demand for efficient and versatile packaging solutions grows. Horizontal packing machines have answered this call, proving to be an indispensable asset for businesses aiming to enhance their packaging processes. With ongoing advancements in technology, these machines will undoubtedly continue to play a pivotal role in the packaging industry’s future.

0 notes

Text

In today’s fast-paced industrial environment, efficiency is key to staying ahead of the competition. Businesses are constantly on the lookout for innovative solutions that can streamline their operations, reduce costs, and enhance productivity. As a leading name in packaging solutions, we offer a range of end of line machines designed to meet these needs. Let's explore how our end of line machines can benefit your business with unparalleled efficiency.

#tin filling machine#Jar filling machine manufacturers#auto case erector#bulk bag filling machine#case packer manufacturers india#tin can filling and sealing machine#automatic case erector#ghee jar filling machine#tin packing machine#oil tin filling machine#powder jar filling machine#automatic carton box packing machine#carton packing machine#carton box packing machine#Bottle Filling Line#horizontal flow wrap machine#powder filling machine#box packing machine#automatic bottle filling machine#cartoning machine#flow wrap machine#secondary packaging#bottle filling machine#powder bottle filling machine#shrink wrapping machine manufacturer#bottle capping machine#shrink wrapping machine for bottles#can seamer machine

0 notes

Text

#jar filling machine manufacturers#Bottle Filling Line#shrink wrapping machine for bottles#carton packing machine#ghee jar filling machine#horizontal flow wrap machine#case packer manufacturers india#automatic carton box packing machine#powder jar filling machine#automatic bottle filling machine#tin can filling and sealing machine

0 notes

Text

Flow Pack Machine Market CAGR, Trends, Top Players, Analysis, Industry Size - Forecast 2032

The flow pack machine market is anticipated to US$ 4.8 Bn in 2022 and is projected to reach US$ 6.8 Bn by 2032, at a CAGR of 3.4% from 2022 to 2032. Sales in the market are expected to increase at a steady rate on the back of growing adoption of automatic machines in diverse industries such as food & beverage, personal care, and others.

The Flow Pack Machine Market is a segment within the packaging machinery industry that specializes in the production and distribution of flow pack machines. Flow pack machines, also known as horizontal flow wrappers or flow wrapping machines, are used for high-speed packaging applications in various industries. Here's an overview of the Flow Pack Machine Market:

Market Significance:

The Flow Pack Machine Market is vital for industries requiring efficient and high-speed packaging, such as food, pharmaceuticals, personal care, and household products.

These machines are essential for packaging products in airtight and tamper-evident wraps.

Flow Pack Machine Functionality:

Flow pack machines automate the process of wrapping products with a continuous film, creating a tightly sealed package around the product.

They are suitable for packaging items of different shapes and sizes, making them versatile for various industries.

Get Sample Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-15590

Types of Products Packaged:

Flow pack machines are used for packaging products like bakery goods, confectionery, fresh produce, frozen foods, medical devices, and more.

Key Features of Flow Pack Machines:

High Speed: Flow pack machines are known for their high-speed packaging capabilities, making them ideal for mass production.

Sealing Quality: They provide consistent and high-quality sealing, ensuring product freshness and safety.

Customization: These machines can be adjusted for different packaging formats, including pillow packs, gusseted bags, and more.

End-Use Industries:

The Flow Pack Machine Market caters to various industries, including food and beverages, pharmaceuticals, cosmetics, personal care, and non-food items.

Materials Used:

Packaging materials include plastic films (such as polyethylene and polypropylene), laminates, and specialty films with barrier properties.

Eco-friendly and sustainable materials are gaining traction due to environmental concerns.

Benefits of Flow Pack Machines:

Efficiency: High-speed packaging lines are cost-effective for large-scale production.

Product Protection: Flow pack packaging provides excellent protection against moisture, contaminants, and physical damage.

Tamper-Evident: The tightly sealed packages provide tamper-evident features for safety and security.

Regulatory Compliance:

Flow pack machines and packaging materials must adhere to regulatory standards, particularly in the food and pharmaceutical industries.

Technological Advancements:

Ongoing research and development efforts focus on improving machine efficiency, automation, and sustainability.

Impact of COVID-19: - The pandemic influenced packaging preferences, with increased demand for single-serve and convenience packaging, aligning with the capabilities of flow pack machines.

The Flow Pack Machine Market is an integral part of the packaging machinery sector, offering efficient and versatile solutions for packaging a wide array of products. Its high-speed capabilities and adaptability to various industries make it a vital component in modern packaging processes, meeting the demands of both manufacturers and consumers for convenience and reliability.

For More Info: https://www.futuremarketinsights.com/reports/flow-pack-machine-market

0 notes

Text

Packaging Machinery In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Packaging Machinery Market Outlook -2030

The global packaging machinery market size was valued at $43,520.0 million in 2020, and is projected to reach $69,218.0 million by 2030, registering a CAGR of 4.7% from 2021 to 2030. Packaging machinery performs variety of functions that include canning; container cleaning, filling, and forming; bagging, packing, unpacking, bottling, sealing, and lidding; inspection and check weighing; wrapping, shrink film, and heat sealing; case forming, labeling, and encoding; palletizing and depalletizing; and related applications.

The packaging machinery market has witnessed increased adoption owing to factors such as rise in applications of packaging machinery in a wide range of industries across food & beverages, healthcare, cosmetics, and other consumer goods as well as a range of industrial sectors where packaging has become essential, with increase in the usage broadly in line with the global economy.

The demand for packaging machinery is largely driven by the increase in consumer goods demand, rise in adoption of automated packaging machines, and development of energy efficient machines. Modern automated packaging machines are used in different stages of packaging and ensure that the stages are completed in minutes rather than hours compared to the older versions. The other key factors driving the market for packaging machinery is the increase in demand for packaging robots from several end user industries. Packaging machines play a vital role in ensuring product safety throughout the supply chain.

The market for packaging machinery is segmented on the basis of type, business, end user, and region. By type, the packaging machinery market is categorized into filling machines, form, fill and seal machines (FFS), cartoning machines, palletizing machines, labeling machines, wrapping machines, and cleaning & sterilizing machines. Filling machines have a wide range of applications such as filling fuels, bottles filling, powder filling, and others. This equipment is extensively used in cosmetics, pharmaceuticals, and food & beverage industries. By business, the global packaging machinery market is categorized into OEM, and aftermarket. By end user, the global packaging machinery market is categorized into food & beverage, pharmaceuticals, chemicals, cosmetics, and others. Different types of packaging machinery are used in the food & beverage industry for various applications. Rinsing machines and bottle washers are commonly used packaging machines in the food & beverage industry. The rise in demand for packaged food & beverages fuels the packaging machinery market growth.

Competition Analysis

The key market players profiled in the packaging machinery market report include Aetna Group S.p.A., B&H Manufacturing Company, Inc., Barry-Wehmiller Companies, Inc., CKD Corporation, Coesia S.p.A., Duravant LLC, Fuji Machinery Co., Ltd., Langley Holdings plc, Robert Bosch GmbH, and The Adelphi Group of Companies.

The major players operating in the global packaging machinery market have adopted key strategies such as product launch and business expansion to strengthen their market outreach and sustain the stiff competition in the market. For instance, in August 2019, Syntegon Technology GmbH has developed a fully automated horizontal flow wrapper Pack 403 at Pack Expo 2019 in Las Vegas. It is designed with a Paloma pick-and-place robot for harsh environment use. Similarly, Robopac Ibérica, a subsidiary of Aetna group S.p.A has built a plant in Vinaros (Castellón) for the commercial and technical assistance activities to serve the strategic markets of Spain and Portugal.

Full Report With TOC:-https://www.alliedmarketresearch.com/packaging-machinery-market

0 notes

Text

THE IMPORTANCE OF ACCURATE WEIGHING AND FILLING IN SNACK PACKAGING

Accurate weighing and filling are crucial aspects of snack packaging, ensuring that products are packaged efficiently and meet specific weight requirements. In this blog, we will explore the importance of accurate weighing and filling in snack packaging and how Nichrome’s provides the most reliable and efficient potato chip packaging machine, automatic sachet packing machine, pouch sealing machine, pouch packing machine and airtight food packaging machines for your business.

What comes along with Nichrome’s Snack Packaging Machines:

Product Consistency: Nichrome ensures accurate weighing and filling with its automatic sachet packing machine. It guarantees that each sachet is filled with the equal amount of product specified. Nichrome’s pouch sealing machine and pouch packing machine are designed to precisely fill and seal tins, ensuring consistency in each package.

Compliance with Regulations: Many food industries have strict codes of conduct regarding the weight and contents of their packaging. Accurate weighing and filling with automatic snack packaging machines manufactured by Nichrome your trusted food packaging manufacturer in Bangladesh can help you meet these regulations and maintain product integrity.

Reduce Product Waste: Overfilling or underfilling can result in product waste, financial loss, and dissatisfied customers. By equipping with Nichrome’s accurate snack filling machines like pouch sealing machines,

Pouch packing machines and vertical form fill seal machines; businesses can minimize waste and optimize their resources.

Improving Operational Efficiency: Reliable filling and packaging machines from Nichrome contribute to the overall operational efficiency. These machines enable faster and more efficient packaging, reducing manual labor and increasing productivity.

Customer Satisfaction: Keeping your clients satisfied at all times is a priority for any business. Being one of the top packaging machine suppliers in Bangladesh, we help businessesfill snacks accurately, to make a direct impact on customer satisfaction. When customers receive consistently filled sacks, they feel confident in the product's quality and value, leading to trust and loyalty.

Ideal Presentation: For products requiring flow wrap packagings, such as snack foods or confectioneries, accuracy in weighing and filling is essential. Horizontal flow wrap machines enable precise packaging, resulting in attractive and well-presented products on store shelves.

Snack Packaging Machines by Nichrome

Vertical Form Fill Seal Machines

These machines are designed to cater for businesses of all sizes, whether it’s startups or small & medium enterprises we have exclusive packaging solutions. We have four highly efficient VFFS machines to help you with your snack packaging. These are perfectly filling & packaging machines for

Wing 200 E-Line Snack Pack

SnackPack

Excel 400 Plus Multi-Head Weigher

Sprint 250 Plus Multi-Head Weigher

Horizontal Form Fill Seal Machines

Designed perfectly to give you both a filling and sealing solution in one machine. Also known as a flow wrap machine, it is efficient at packaging solid items of similar shape and size considering biscuits, snack bars, namkeens, confectioneries and cakes. We have designed four reliable snack packaging machines to help your industry pack efficiently.

T110

T140

T170

Pick Fill Seal Machine

In conclusion, Nichrome filling & packaging machines play a vital role in snack packaging, ensuring product consistency, regulatory compliance, waste reduction, operational efficiency, customer satisfaction and optimal presentation. Using Nichrome’s automated snack packaging machines with advanced equipment such as potato chip packaging machines, soybean oil packing machine, ointment tube filling machine, pouch sealing machine, blister packaging machine, airtight food packaging machine and small packaging machine contribute to achieving perfection in the packaging process.

#pouch sealing machine#silica gel packing machine#blister packaging machine#filling and packaging machine#vertical form fill seal machine#nichromebangladesh#packaging machine supplier in bangladesh#airtight food packaging

0 notes