#hobbyist tool belts

Explore tagged Tumblr posts

Note

For your 3D art:

What are your influences?

What is your process for creating and texturing the models?

What software do you use?

Other than that, I will be keeping an eye out for more of your models as you are what I aspire to be as a hobbyist 3D artist.

Thanks for asking! I'll apologize ahead of time I'm not the best a writing but I hope my answers will be helpful and fun to read

1: I'm really inspired by arcane and into the spider verse! I love the way they can make 3d look like paintings or comic books I love to stylize 3d and I hope with more practice I can make my 3d art come off as different 2d styles. I'm also a big fan of the old low poly games look with the silly pixel texture it's kinda a funny balance between wanting my art to look nothing like 3d and wanting it embrace the sillies of the art form.

2a modeling: I start with cubes for almost everything I make. I started my 3d art journey with texturing Minecraft skins so I kinda like cubes, it also makes unwrapping it onto a flat plane for texturing just a bit easier for me. Here's an image with the geometry of my silly mailbox model highlighted.

3: I use Blender to make all my models although I just learned a little bit of 3ds Max in my first 3d animation class, I'm mostly self taught though that being the one semester of a 3d animation class under my belt but youtube has been a gold mine for every question I have about 3d and I've practically learned everything I know about using Blender of youtube tutorials.

2b texturing: I use an add-on called uv pack master in blender to speed up my uv unwrapping process so I can make my texture look nicer faster. As for painting I use the tools in blender to texture my models with a couple extra brushes from another add-on it's outdated though and I should probably find some new brushes lol. This is what my texture looks like btw! It's a little messy but I hope you can find it helpful!

I'm really passionate about 3d animation and almost everything involving it I love talking about it thank you for asking!

95 notes

·

View notes

Text

Otto and Atticus Part 9-extended: The Antique's Store 1/4, 2/4 (reblogged), 3/4 (reblogged)

This is a continuation of Atticus' Birthday story found here: https://www.tumblr.com/writingforfishes/756206256931405824/otto-and-atticus-part-9-atticus-birthday?source=share

The story above is much more sexual in nature.

These next stories follow Atticus and Otto through the Antique's Store where Otto is taking his spouse for their birthday and back home. They will, as far as I have planned, be much tamer and won't require a filter.

CW

Mentions of alcoholism and sobriety.

Fast but short-lived hiccups.

Generational gaps in understanding gender nonconformity.

Accidental misgendering of off-stage minor character.

Hiccups triggered by food.

Mentions of arousal/teasing.

Mentions of anxiety arising from being taken to a new place.

Mentions of anxiety/over-stimulation in being in a new place that is quite large and populated.

Mentions of soft bellies and body shapes.

Manual driving? I dunno, maybe someone out there has a trauma response to manual driving?

I use ellipses here to denote trailing off or uncertainty in dialogue. They do not mean anything nefarious. Just in case. I dunno. I'm 41. Please don't hate me.

Mild discomfort while hiccuping.

Disparaging Korean made clock movements.

Minors, do not interact.

Part 1: Soup

They had been driving away from town for a while now. Atticus looked out the window as they watched exit sign after exit sign pass. The writer was excited, but antsy. Classical music was playing from one of Otto’s playlists. It was helping to quell the anxiety somewhat, but their mind still swam as miles of road kept going by.

“You’re gonna love this place,” Otto said, noticing the nervous thrum of his partner’s fingers on their knees.

“Yeah?” Atticus asked, using Otto’s voice to ground them.

“Yeah. It’s in this big warehouse. There’s a food market there, too. We’ll get some lunch while we’re there,” he said. He took a moment to sip some water from the tumbler he’d brought.

Atticus sipped some from theirs as well, using his action as a cue. The water felt good and soothed more of their anxiety.

“Lots of clocks?” Atticus asked with a smile.

“So many,” Otto confirmed with a smirk in return. “And a whole slew of other things. It’s got old books, hats, belt buckles. Lots of old art, too. And there’s a lot of space, y’know? The aisles are wide. Super accessible. A couple started it back a few years ago. They had their own antique’s store, but when they started inviting other vendors to open booths in the first storefront it got so big they went in with the people that ran a small food market in the same strip mall and got this place. It’s a bit out of the way, but worth it for the quality of things you can find there.”

Otto drummed his fingers on the steering wheel a little and shifted as the speed of traffic changed. One day Atticus thought they might try to learn how to drive manual. Otto liked it because it kept his hands busy. He was naturally a high energy person and having something to do with his hands for long stretches of time was a plus. He also liked manual because he understood how it worked better than something like a CVT transmission. He had more faith that he could fix, if need be, his transmission than a newer car that depended more on electricity to accelerate and change gears.

“They sell tools too!” he continued. And Atticus smiled, enjoying the excitement in Otto’s voice. “I mean, they have the vintage tools like manual screwdrivers, but they have specialty tools they order new. They started ordering bulk from Timesavers sometime last year because so many of their vendors have clocks in their booths and some of them have missing parts and keys. So they sell a lot of clock and watch tools and parts. Really convenient. That’s how I first heard of it. One of my customers who’s a hobbyist told me about them. And the people who rent out their booths that I’ve talked to are just—they have some phenomenal stuff, man. Super nice people, too. The ones that I’ve met. Most actually know what they have and what it’s worth. They don’t up-charge from Google searches. They actually research it. Very few resellers, too. You know, people that order lots of cheap things from other countries and sell it for profit?

“Helped a few of them service a couple of clocks to sell or help them decide whether it would be worth the repair or not. Korean movements? Not really worth it, you know? Really cool atmosphere, though. It’s kinda like family even though it’s in this great big place. Everyone takes care of each other and has each other’s backs. They even buy stuff from each other’s booths!” Otto said and took another sip of water.

He downshifted as they finally turned on an exit Atticus wasn’t familiar with.

“Kind of like an...antique commune?” they asked.

“Yeah, kinda!” he agreed.

Atticus stretched with a yawn suddenly rubbing their belly, still accessibly soft with the heavy breakfast this morning.

“Think you’ll-um-get them again?” they asked shyly rubbing at the stubble on their face and neck. For all of the anxiety of being somewhere they’d never been, Otto’s hiccups were definitely causing some of the energy their body was interpreting into anxiety. They were full of anticipatory excitement at the possibility.

“I will definitely get them again,” Otto said with an amused sigh. “I can sort of feel it? In my chest and throat? It’s weird. On hiccupy days like this it’s like they’re just lying in wait. I do want to eat something before we start looking around, though.”

“Ooh, yeah. I could go for something to eat,” Atticus agreed.

From the outside the antique’s mall/food market didn’t look terribly impressive. But Atticus noticed how full the parking lot was as they stepped out of the passenger seat.

No sooner had Otto stood from the car than a man in a polo shirt exiting the front door called to him.

“Otto, man! You gonna buy some more clocks today?” he asked coming over to them. He seemed older, perhaps in his late 50’s early 60’s. He had a stout body-type, stomach hanging a little over his belted khaki pants. His beard was nearly all white. He seemed to have a lot of energy but his mannerisms implied an ability to be patient as well when he stopped and acknowledged first Otto with a pat to his shoulder and nodded to Atticus, clasping his hands in front of his belly while in conversation.

Atticus took a moment to consider why Otto was buying clocks. They hadn’t noticed any new clocks in the house. They tried to catch his eye but Otto flitted his gaze away as soon as they had locked eyes questioningly.

“Hey Gar! Yeah, man, we’ll see if we find anything. This is my partner, Atticus. It’s their birthday today,” Otto said with emphasis causing the other man to pull a quick face of recognition and then nodded, making a motion of closing his lips. “Atticus, this is Gary. He’s one of the owners of the antique’s gallery along with his wife Rose.”

“Hey, Atticus, Otto’s told me a lot about you! It’s really nice to meet you,” Gary said, holding out a hand.

“Uh, good to meet you, too,” Atty said. They subconsciously shifted their voice down. Talking to cis men gave them a desire to puff out their chest and make their mannerisms more guy-coded. They added a quick nod as they shook the man’s hand. “Hopefully he hasn’t told you too much!”

“Nah, only the good stuff! That you’re a writer and that you’ve been there for him through a lot. I’ve not known this guy for long, but glad he has someone like you on his side. Him and me, think we’ve been through some of the same struggles. We’ve talked a little about that. Anyway. I’ve also got a daught—sorry. Shit, I always flub that up. I’ve got a kid. They came out to me earlier this year that...uh...they’re non-binary,” Gary said.

“Yeah, it’s one of the first conversations we had, I think,” Otto interjected, having leaned a hip against the car in realization that this was going to take a second. He was used to Gary’s tendency to babble. Another quality, the clock maker mused, both of them shared.

“I think it was! But yeah, Otto told me about you and, I dunno, it made me a little less nervous for he-them,” Gary sputtered. “Sorry, I still mess it up a lot. I’m working on it.”

“It’s okay to mess up,” Atticus said. They’d made their way to stand beside Otto and their husband laid a soft hand around their shoulders. “As long as you correct yourself. It shows you’re trying. That means a lot.”

“I definitely am. Anyway, knowing there’s, you know, an adult out there that’s-uh-that’s non-binary and stuff. I was scared for them, y’know? How were they going to grow up? I mean, it’s not like there’s a path or...I dunno...I don’t know what to tell them or how to...help? But Otto told me about you and that you’re a writer and that you’ve sold your books and it’s just,” he sighed, seeming frustrated in his inability to articulate what he meant. “It gives me hope that they’re gonna be okay. If that makes sense.”

Gary laughed nervously.

“It does,” Atticus said with an encouraging smile. “They’ve got a dad that loves them so...I feel like they’re off to a pretty good start.”

“Yeah...yeah, damn. I’m sorry for talking your ears off! You know how I am, Otto. I gotta get going. The Mrs sent me on an errand and she is going to bite my head off if I get distracted! Anyway, good to see you again, Otto!” Gary reached in and Otto accepted a little hug from him. “Really nice to meet you, Atticus. I hope you have a good birthday. Cause this guy got you...well…”

Gary waggled his finger teasingly at Otto and the clock maker’s eyes widened and then narrowed as he batted the hand away.

“Dude!” he warned at Gary’s hint of what Otto’s plans were.

“I have had a pretty good birthday so far,” Atticus said, looking between the two suspiciously. “I feel like it might be a theme…”

“Get out of here, Gary! Stop talking!” Otto exclaimed, thwapping the older man on the back good naturedly as he finally started to leave.

“Report back!” Gary yelled.

“Shh!” Otto spat out as Gary went out of sight. “Jeez...can we just ignore that bit? Also, I’m sorry if that made you uncomfortable. He really is a good guy…”

“No, I can tell,” Atticus reassured him. “Really bad at keeping a secret, though.”

“The absolute worst. I dunno how his wife deals with him…”

“Well, you deal with me, so…” Atty said.

“Hm, true,” Otto responded smartly as he led his partner into the front door. He felt a pinch on his side and jerked. “Ow!”

“Oops,” Atticus responded curtly.

The inside of the warehouse was completely different from the out. There was a huge open space in the lobby with a secondary set of double doors leading to the antique mall portion but down a hall were various food market vendors and following that hall was the other half of the warehouse, more food vendors, and a large sitting area along with a secondary access to the antique’s mall space.

While the venue was bustling with business the open space made it seem much less crowded.

Decision paralysis and overwhelm kicked in as soon as Otto asked them what they were in the mood to eat and Atticus let Otto pick where to go as they followed taking in all of the visuals, smells, and sounds around them as they tried to adapt to the environment and space.

Otto ended up ordering a tomato basil bisque with a grilled cheese and Atticus waffled a little until they decided on a salad with grilled chicken, something to balance out the heaviness of the breakfast they’d eaten that morning.

Atty didn’t even really know what food vendor they’d ordered from or what had been available alternatively as they were so overwhelmed by exploring the atmosphere and people who walked by.

“I thought you said it was a small food market that partnered with...um...Gary and Rose?” Atticus asked as they took their food to the table Otto was walking toward. Otto being so tall offered a great guide to Atty as they often got lost in places like this.

“Yeah. Oh yeah, initially it was just that. Then they put the word out about the space and food vendors started opening shop. Lots of start-ups took advantage that wouldn’t have had the money to buy a store front otherwise. Rose comes from a lot of old money, apparently. Though you didn’t hear that from me. She put a lot into making sure everyone got an opportunity to take advantage of this spot since she knew the mall wouldn’t take up half the space of it,” Otto explained.

“Gary really does have no concept of secrecy, does he?” Atty noted.

“Not really, no. I think he spent a lot of his life trying to run away from connecting to people. Best way to do that is through alcohol, honestly. Even while you’re partying with hundreds of people you’re not really ‘there’, y’know? But yeah. He’s got some stories. Things that sort of shocked me. When he learned I was sober, I think he knew he could trust me and that I’d get it. I think he’s trying to make up for that lost time, now. He loves his wife and kid more than anyone I know. Guy’s got a damn big heart. And a really fucked up liver,” Otto added mirthfully.

Atticus snorted and then caught themselves, “Shit, should I laugh at that?”

“Yeah,” Otto said with a smirk. “He would.”

They finally sad down and Otto unpacked the soup. The smell was comforting and he found himself quite hungry despite still being a little bloated from last night’s antics and this morning’s food fare. Perhaps he was just as excited as Atticus seemed and that translated to wanting to eat? And he was excited. He really couldn’t wait to see his partner’s face at the surprise they had planned.

Otto swallowed the first spoonful of soup. It was very warm, slightly spiced, and he could feel the warmth go down his throat and immediately his diaphragm reacted to the change in temperature. He felt his body convulse involuntarily causing him to jump a little. Amazingly, Atticus was busy on their salad and hadn’t noticed.

He waited a second for any other hiccups, but none followed. Cautiously he took another spoonful, let it savor in his mouth and swallowed. The warm liquid triggered another spasm. He grunted softly. That hiccupy feeling in his throat intensified and he knew he was only a few more spoonfuls away from a full attack. That second spasm was more forceful, too. He wondered if he cold hold it off until he at least finished the meal. He paused, considering.

Atty caught him, body still and waiting, with same hand holding the spoon pressed against his mouth in a loose fist, spoon dangling from the tips of his fingers as he focused on something inwardly, eyebrows pinched a little.

“You okay?” they asked. The writer had been enjoying their salad more than they thought they would. They’d also been watching people pass by and taking in the social scenery. Otto being motionless caught their attention more than anything.

“Yeah,” Otto said tentatively, eyebrows pulling together all the more. “Every time I take a sip of soup I hiccup. They’re right here.” Otto tapped the base of his neck above his collar bone.

Atticus stopped chewing their salad to hone their eyes in on that place.

“Oh,” they said. “Um...you don’t feel sick, do you?”

“No-no,” Otto said, reassuring them quickly. “Just wondering if this is gonna turn into a full case...guess we’ll find out, hm?” There was a glint in his eyes. Of course there was always going to be a possibility of this becoming a day of hiccups, but part of him was delighted that it was actually happening. There would, of course, be consequences to his purposeful induction, but it was worth the adorable flush that came across his partner’s neck and wideness of their eyes.

Atticus swallowed their salad a little too eagerly and took a drink of water. They were extremely disappointed they’d missed the previous hiccups but, eyes trained on him now, they were determined not to miss anymore.

“Excited?” he teased, smiling knowingly.

“A little,” they admitted. “Not to an...actionable level.” They kept the statement diplomatic. Atticus really had no need to take care of their arousal again. But their body was going to react and they were going to be interested no matter what.

Otto chuckled at the terminology and jumped a little with another spasm.

“Hm,” Atticus said, feigning casualness.

Otto grinned a little and rolled his eyes in mild exasperation. Even though he’d only had the hiccups one time that day it was a strong and fast enough case that he knew any additional cases would be a little more exhausting than normal. But that excitement at seeing Atticus’ excitement was enough to be ready for the possible onslaught.

His hiccups persisted as he continued to eat his soup. His diaphragm reacted with each gulp and sometimes without the trigger of swallowing. They weren’t very strong, but he did still have to time his eating around them when they started to go off script of being triggered.

They got a bit more forceful when he started on the grilled cheese. Bread was the ‘enemy’ on his hiccup-sensitive days. He should’ve known that. Perhaps part of him had known that and wanted to give Atticus another show. Or perhaps it was just his absent mindedness forgetting what his triggers were on days like this. Regardless, the bready sandwich certainly encouraged the hiccup fit to strengthen. They became more audible, though still easily muffled.

Atticus continued to eat their salad, but they hardly tasted it as they watched Otto’s suppressed hiccups as he continued to eat despite them. His head and chest would jerk up and he’d have to pause for that half-second before taking another mouthful. As he began to muffle the sounds they started to make the writer pulled their legs together subconsciously. They were also getting faster and the adorableness of Otto trying to navigate the fit paired with the mild arousal they felt was almost too much. But it was an almost too much they could handle as they felt safe experiencing it.

A couple of times he was hit with a cluster of hiccups which he would let out a small grunt or sigh after before resuming eating. He probably didn’t even realize he was making the small sounds, but Atticus soaked up every movement and sound watching Otto in adoration. His hiccups and reactions were endearing to watch and their body let them know that it was paying attention, but Atty never felt the need to give into their arousal in the way they had this morning.

When he started in on his sandwich he jerked so powerfully and quickly that Atticus startled in how closely they’d been paying attention and the break in pattern of his hiccups. They heard a little thump in the back of Otto’s throat at that hiccup. The case also increased in speed and it was obvious Otto noticed as he chewed carefully and timed his swallowing.

A ‘hik’p!’ slipped out and Otto muttered, “Oh man…” He was no longer able to keep them all quiet or muffled with how hard they’d suddenly become. He could feel his stomach jiggling from under the table, how it jerked in and out. His neck movements caused his head to jerk hard as well, having to time eating even more carefully to line up the food with his mouth.

“Higgup! You just gonna-higgulp!-just gonna watch hilp!-watch me ea-hugguck!-eat this whole time?” he asked, amused.

“That was kind of the plan,” Atticus teased.

“Damn bre-herp!-bread made them wo-erp!-worse! Hickulp!” he said.

Even though, he used the last bit of that sandwich to sop up the last dregs of his soup, all the while jerking as his diaphragm and glottis continued to argue loudly over when to breath and when to not.

Eating that last bite definitely didn’t help. He took a few large straw-fulls of water but continued what seemed to have developed into a pretty powerful hiccuping fit. Otto was thankful for the food court being boisterous with activity as he’d yet to see anyone looking over his way despite how more audible they’d become.

But as much as he was enjoying the way Atticus was looking at him his neck had started to hurt again. It hurt in the back right where it met his shoulders. He couldn’t even suppress the motions on this case. Every hiccup came as a surprise to him. Usually, when he had them, he had the feeling he would hiccup a little bit before the next one, but as this case got worse he lost the ability to feel when the next one was going to hit. It was a bit unusual to not be able to predict them like he normally was. As a result his body was at their mercy even more.

Otto’s hand pressed against his chest and Atty noticed that his face had lost some of the mirth it had when his hiccups had begun. He didn’t look distressed, necessarily, but he didn’t really look like he was wholly unbothered, either.

“Oh man HUCKULK-man! These are hu-ULK!-are hard. ULK!Huck!-ugh! I can’t-ulk!-can’t tell when the-h’mlk!-their coming next ei-ulp!-either. Damn,” he finally admitted. He rubbed the back of his neck trying to take a measured breath through the onslaught. It was interrupted by more sharp hiccups and he winced, eyes closing for a moment at a particularly fast cluster. “HULK!HU-CULK!ULK!H’MUCK!mmk!”

A small hand slapped three packets in front of him so loudly he jumped a little (before he jumped with another hiccup). When he looked down Atticus’ hand lifted to reveal a packet of Real Cane Sugar, a white paper packet from a fast food restaurant marked ‘Salt’, and a plastic packet with yellow writing on it that said ‘Pure Lemon Juice’. Otto looked up to his partner’s smug face (as much as he could give them a steady gaze with how much he was jerking) and they grinned, lips pushing up the sides of their mustache into the apples of their cheeks.

“Never leave home without them,” they said a little haughtily.

“Do you HUCK-UCK!-always keep-HUCK!-alw-ulk!-ways keep these wi-UCK!-ith you? Huck!-HUCK’M!” he asked, grunting out another sigh as he started opening the sugar packet.

“Only when my extremely sweet husband decides to indulge in me for my birthday in a way that could bite him in the ass later on,” Atticus said.

“I think-HUCK!-there was-hulkUCK!-a compli-ulk-ment in-hulk!-in there-HUCK’L! some-uck!-somewhere Huck’l!HUCK!-uh!”Otto said.

“Otto,” Atty implored. “Sugar.”

“Yes hon-HUCKAH!-honey? Huck!HUCK!HUCK!Ow...” Otto exclaimed with a scowl at his interrupted joke. He wordlessly (though not soundlessly) opened the sugar packet and dumped it in his mouth.

The cure did the trick. For a few seconds he sat after he’d downed the lemon juice with some deep breaths, still holding his chest.

“You good?” Atticus asked. For some reason their hand had found his and was holding it as if giving him comfort. It seemed silly to do so for someone having something as seemingly harmless as hiccups, but those sounded and looked incredibly uncomfortable. And all of Atty’s research on hiccups led them to believe that hiccups could potentially cause great discomfort; they never wanted that inflicted in their husband.

He took another deep breath.

“Whew. Yeah. Sorry about that. They kind of got out of hand,” he said sheepishly. “Um, how was your salad?”

“I honestly have no idea...” they admitted looking down at their empty container.

“You got a little turned on, right?” he asked, voice low.

“Right up until the end, yes,” they said.

“Still…” Otto waggled his eyebrows suggestively.

“You’re just a little self-destructive, you know that?” they said.

“Listen, you’re the one who married an alcoholic.”

Atticus reached across the table and put either hand on the side of Otto’s face rubbing his short beard with their thumbs before squeezing his cheeks gently between their palms.

“I married a beautiful, intelligent, compassionate man who is also an alcoholic,” they said, amending the statement. “And it’s my birthday so I’m right and you can’t argue with me.”

“I don’t think that’s how that works,” Otto said, diction affected by his lips being squished between the hands on his face.

“It is,” Atticus assured him. They finally released his face and Otto grinned back.

“And it’s your birthday so…” he said, trailing off.

“Exactly!”

Cleaning up their trash and putting the reusable trays in a marked spot above the trash cans they both finally made their way into the antique’s mall area.

#hiccup kink#minors dni#hiccups kink#hiccups#hic fic#kink blog#otto and atticus#hicfic#non kink blogs do not reblog#I'll reblog the other parts as additions so it's easy to keep track of.

22 notes

·

View notes

Text

Submitted via Google Form:

How can I have a world that improves technology but also doesn't remove obsolete technology? Obviously not all obsolete technology, ones too dangerous, doesn't have enough safety features etc, why of course they can go. Let's first start with things like computers. Clearly older things no longer run on newer computers, but it erases things that were made on old types. I want a society that actually preserves those old things and still has new things made with the old technology. If it's a car, well, obviously poor safety features do have to be gone, but any technology that can be kept stays - I suppose you can say retro but definitely trying to follow the old technology as much as possible.

Licorice: You can have this world by making it like the world you’re living in right now. Human beings have a tendency to get very attached to their old technology and invest a great deal of time and effort keeping it in working order, as vintage car rallies can attest. Of course, if you want to drive your vintage car on a public road you have to make sure it meets emissions requirements, is fitted with seat-belts, and fulfils all the other safety regulations.

Technology very rarely gets removed, it’s simply superseded by something that does the same job better - but “better” is a subjective concept. It depends on what any given individual is looking for in their tech. For example, whenever I have to replace an appliance in my home I try to find a second-hand item that pre-dates ‘smart’ technology. They are easier and cheaper to repair, last longer, and have fewer things that can go wrong with them.

Nowadays we have tablets and photoshop but people still make art using brushes, charcoal, paint and canvas. We have Google docs but people still write their novels by hand. We have electric cars but people still drive horse-drawn buggies as a hobby, and also as a competitive sport. In fact the only field in which I imagine obsolete tech really does completely disappear is in STEM, but even then there are probably hobbyists who lovingly maintain and use these old tools.

In short, people hanging on to and lovingly using their old tech is just a normal thing that people do.

Tex: People keep around objectively dangerous technologies all the time as novelty or historical items (see: all the mercury in things, or radioactive materials), and will create entire hobbies around developing patches across technological eras (see: phonographs with USB ports, old video games in emulators on your computer) as a niche skill set. At that point it becomes history, and people work to preserve it for a variety of reasons. As Licorice said, the world you’re looking for is the world you’re already living in. What sort of technologies were you having in mind? There’s a fair chance some hobby groups are out there preserving, restoring, and using exactly that.

Feral: In addition to what Licorice and Tex have already said, I recommend that you look into planned obsolescence and understand that it is not actually necessary for a lot of slightly-less-than-new technologies to no longer be usable the way we often see with Smart devices. It’s a purposefully built in and added feature that could easily be left out.

28 notes

·

View notes

Note

3♣️ - How creative is your muse?

Most of my characters are creatives in some fashion. They can't help it. I'm a maker, so my characters are too. I believe it gives them depth - and hobbies. (Are they mentally creative in that they come up with novel solutions to complex problems? Ehhhhh... Limitations of their writer there. lol)

Aeluan is a wood-worker in his spare time. He makes furniture and carves it with beautiful details. He is also a hobbyist when it comes to jewelry-making. His work is characterized by clean lines inspired by Doman and Hingan styles. I suppose in that way, he is less "creative" in that his work takes heavy inspiration from tradition. The most he departs from that is when he goes on organic kicks, designing vines and flowers in his carving, like he did for the bed he gifted Eurynine.

Daephrin is both physically and musically creative, though his music is rarely original. He plays piano with adequate if not genius skill. He learned it as a child, as his father believed that a well-rounded nobleman should know an instrument. His older brother played cello and his younger brother violin - all respectable instruments. Although Dae doesn't get much chance to play, he sometimes sneaks off to a music shop in Limsa Lominsa and plays for a little bit with the shop owner's permission.

Additionally, he is also a leather-worker of quite some skill. Those tight leather pants he's so fond of are often his own make. He also does belts and bags. He does not know how to tan his own leather and tends to buy it whole. His works are generally in the "practical" category rather than decorative, though he's been known to do a little special tooling on some of his bags.

Vy'thanis is a gifted stone-carver. He mines his own stones and shapes them by hand and by magic. Whether it's stone carvings of animals or faceted gemstones for jewelry, he is both talented and prolific. He makes his living off what he creates, after all. Most of his work is inspired by the natural world in some way and some of his most popular cut stones are faceted gems with a flower etched on the top facet. Although much of his skill comes naturally to him through his Echo-blessed connection to stones, his creative talent is all his own and it is extensive.

5 notes

·

View notes

Text

Powermatic

Powermatic is a well-known brand of woodworking machinery that has been producing high-quality tools and machines since 1921. The company is known for its wide range of products, including table saws, bandsaws, jointers, planers, lathes, and dust collection systems. Woodworking professionals and enthusiasts around the world trust Powermatic machines due to their precision and accuracy.

One of the key features that sets Powermatic machinery apart from others is the use of cast iron in their construction. This material provides stability and durability to their machines, making them reliable and long-lasting.

Powermatic machinery is designed with safety in mind. They incorporate various safety features in their machines such as blade guards and safety switches to prevent accidents in the workshop.

Overall, Powermatic is a reputable brand that offers high-quality woodworking machinery. Their precision, durability, and safety features make them a popular choice for both professional woodworkers and hobbyists alike.

Powermatic product line

Powermatic is a renowned brand that specializes in crafting top-quality woodworking machinery and tools. The brand offers a diverse product line that caters to the varying needs of woodworkers, from novice hobbyists to seasoned professionals.

Table Saws - Powermatic's table saws are engineered for precision, power, and durability. The brand offers cabinet saws designed for heavy-duty use, featuring large table surfaces and robust motors. Contractor saws are more portable and suitable for job site use, while hybrid saws combine features of both cabinet and contractor saws.

Bandsaws - Powermatic's bandsaws are designed to make accurate cuts in wood and other materials. They come in different sizes, from benchtop models suitable for small jobs to floor models capable of handling larger wood pieces. Powermatic's bandsaws are renowned for their precision, ease of use, and smooth operation.

Planers - Powermatic's planers are designed to smooth rough lumber and make it usable for woodworking projects. The brand offers a variety of sizes, with larger models capable of handling wide boards and thick wood pieces. Powermatic's planers are known for their precision and user-friendliness.

Jointers - Powermatic's jointers are used to straighten and flatten wood surfaces. They come in benchtop and floor models, with larger ones capable of handling wider wood pieces. Powermatic's jointers are known for their accuracy and ease of use.

Sanders - Powermatic's sanders include both belt and drum sanders, designed to make sanding jobs quick and straightforward. They come in different sizes, with larger models capable of handling more substantial wood pieces. Powermatic's sanders are renowned for their accuracy, speed, and ease of use.

Dust Collectors - Powermatic's dust collectors are designed to ensure workspace cleanliness and safety by removing dust and debris from the air. They come in different sizes, with larger models capable of handling multiple machines at once. Powermatic's dust collectors are known for their efficiency and reliability.

Lathes - Powermatic's lathes are used for turning wood and other materials. They come in benchtop and floor models, with larger ones capable of handling more significant wood pieces. Powermatic lathes are known for their precision and ease of use.

Mortisers - Powermatic mortises are used to make precise mortises in wood. They come in benchtop and floor models, with larger ones capable of handling larger wood pieces. Powermatic's mortises are renowned for their accuracy and user-friendliness.

Drill Presses - Powermatic's drill presses are used to drill accurate holes in wood and metal. They come in benchtop and floor models, with larger ones capable of handling larger wood pieces. Powermatic's drill presses are known for their precision and ease of use.

CNC Machines - Powermatic's CNC machines are used for computer-controlled manufacturing processes. They come in different sizes, with larger ones capable of handling larger wood and other materials. Powermatic's CNC machines are known for their precision and efficiency.

In conclusion, Powermatic's product line is designed to cater to the needs of woodworkers at all levels, offering high-quality woodworking machinery and tools that are durable, efficient, and user-friendly.

#powermatic#CNC Machines#Drill Presses#Mortisers#Lathes#Dust Collectors#Sanders#Jointers#Planers#Bandsaws#Table Saws

2 notes

·

View notes

Text

Tips For Evaluating Used Woodworking Machines At Auctions

Purchasing used woodworking machines at auctions can be a cost-effective way to expand your workshop, whether you're a hobbyist or a professional. However, to make sure you’re getting a good deal, it’s essential to evaluate these machines carefully. Without the right information, you could end up with equipment that requires expensive repairs or, worse, is unusable. This guide will provide you with key tips to help you assess the quality of woodworking machines when buying from a tools auction.

1. Research the Machine Models

Before attending a tools auction, it's a good idea to research the specific types of woodworking machines you need. Look up common issues and the expected lifespan of the models you're interested in. Understanding how much a machine costs new and its potential resale value will give you a baseline to evaluate if the auctioned machine is priced fairly.

Additionally, some brands are known for their durability, while others may have a higher likelihood of breaking down after a few years. By knowing the strengths and weaknesses of different models and manufacturers, you’ll be able to spot a good deal more easily.

2. Inspect for Wear and Tear

Woodworking machines can endure heavy use, and visible signs of wear can indicate future problems. Start by inspecting all moving parts, belts, and bearings. Excessive wear could suggest that the machine may soon require costly maintenance. Pay close attention to any rust, which can be a major issue for used machinery. Rust on surfaces can be removed, but if it affects moving parts or mechanical components, it could impact the machine's precision and function.

Check for broken or missing parts, as replacements can be difficult or expensive to find, particularly for older models. Ensure that the machine has no visible cracks or welds, which could indicate previous damage or subpar repairs.

3. Check the Electrical Components

Many woodworking machines rely on electric motors, so it’s crucial to inspect these carefully. Look at the wiring and ensure there are no exposed or damaged wires. Turn the machine on if possible, or ask for a demonstration if it's not allowed during the auction. Listen for unusual sounds such as grinding or humming, which could be signs of motor or belt issues.

If the machine has any digital controls or computerized components, verify that these are functional as repairs can be costly, particularly for older machines with outdated technology.

4. Review Maintenance History

Some tools auctions may provide documentation or a service record of the machines. Ask if the machine comes with a maintenance log, as this can give you a clearer picture of how well the machine has been cared for over its lifetime. Machines that have undergone regular servicing and part replacements will typically be in better condition than those that have been neglected. If maintenance records aren’t available, use caution when bidding.

5. Test the Machine’s Precision

Precision is critical for woodworking machinery. Even if a machine looks functional, it might not perform at the level of accuracy required for your projects. If the auction allows, use measuring tools to check the precision of critical components like the cutting blade, table surface, or jointer fence. Minor issues like misalignment can often be corrected, but if the machine is seriously out of calibration or has balance issues, it may not be worth the investment.

6. Assess Overall Value

Price is a key factor when evaluating used woodworking machines at a tools auction. Make sure to compare the starting bid or the current auction price with both the market value of new machines and the typical cost of used models in similar conditions. Don't get caught up in a bidding war that pushes the price too high. Remember, if you’re bidding on older equipment, factor in potential costs for repairs, replacement parts, and ongoing maintenance when determining your maximum bid.

7. Understand the Auction Terms

Finally, it’s essential to be familiar with the terms and conditions of the tools auction. Some auctions sell equipment “as is,” which means no returns or guarantees. Others may offer limited warranties or have specific rules about returning defective items. Be sure to read and understand the auction’s policies so you know exactly what you’re committing to if you win the bid.

Conclusion

Evaluating used woodworking machines at auctions can be a great way to acquire quality equipment at a fraction of the retail price, but it requires careful inspection and planning. By researching machine models, checking for wear, testing precision, and understanding the auction terms, you can make informed decisions and avoid costly mistakes. With these tips in mind, you'll be better equipped to spot a bargain at your next tools auction.

0 notes

Text

Sand Brush Machine & Wood Brush Sanding Machine: A Complete Guide by Motimac

When it comes to woodworking, achieving a smooth, uniform finish is key to producing high-quality products. Whether you’re a hobbyist or a professional, you know that surface preparation is an essential step. Enter the sand brush machine and wood brush sanding machine, two pieces of equipment that have revolutionized how woodworking is done. These machines provide precision, efficiency, and a superior finish, making them a staple in modern woodshops. Motimac, a leader in industrial sanding solutions, offers advanced brush sanding machines designed to meet diverse sanding needs.

What is a Sand Brush Machine

A sand brush machine is a specialized tool that utilizes brush abrasives for surface finishing. Unlike traditional sanding, which often uses sandpaper or belts, brush sanding provides a gentle yet effective means of preparing wood surfaces. It is especially useful for contour sanding, edge rounding, and finishing complex shapes, as the bristles adapt to the surface, ensuring a consistent finish without damaging the material.

Motimac’s sand brush machines are designed to cater to both soft and hard wood, offering versatility that is unmatched. They allow for fine sanding of intricate surfaces, making them ideal for manufacturers in industries like furniture, cabinetry, and architectural millwork.

Features of Wood Brush Sanding Machines

Wood brush sanding machines combine both sanding and brushing capabilities, enhancing productivity while reducing manual effort. These machines come with a series of rotating brushes that apply an even sanding action across the wood surface. They are ideal for preparing wood prior to painting or staining, as they leave the surface smooth and ready for the next step.

Motimac's wood brush sanding machines are equipped with adjustable settings to control speed, pressure, and abrasive grit, allowing for customizable results depending on the type of wood and the desired finish. Their efficient design not only saves time but also minimizes material waste.

Applications of Sand Brush and Wood Brush Sanding Machines

From flooring and furniture to doors and window frames, sand brush and wood brush sanding machines are used across a wide range of woodworking applications. They are particularly beneficial when working with delicate surfaces that require a uniform finish without the risk of over-sanding.

Conclusion

Whether you're looking for high-quality finishes on flat or contoured surfaces, Motimac's sand brush and wood brush sanding machines deliver exceptional performance. They provide precision, versatility, and efficiency, ensuring your woodworking projects meet professional standards. Investing in Motimac’s innovative sanding machines means investing in a smoother, faster, and more productive woodworking process.

0 notes

Text

The Versatility of Cutter Knives: Essential Tools for Various Applications

Cutter knives, also known as utility knives or box cutters, are indispensable tools found in homes, workplaces, and industries. Their versatility, ease of use, and precision make them suitable for a wide range of tasks. This article explores the various uses of cutter knives and why they are considered essential tools.

1. Packaging and Shipping

One of the most common uses of cutter knives is in packaging and shipping. They are perfect for:

Opening Boxes: Cutter knives make it easy to open cardboard boxes without damaging the contents.

Cutting Packaging Tape: They swiftly cut through packaging tape, making the unboxing process quick and efficient.

Trimming Bubble Wrap and Foam: Cutter knives help in precisely cutting protective materials used in packaging.

2. Crafts and Hobbies

Cutter knives are a favorite among artists and hobbyists for their precision and control. They are used for:

Cutting Paper and Cardstock: Ideal for scrapbooking, card making, and other paper crafts.

Model Making: Useful for cutting and shaping materials like plastic, foam board, and balsa wood.

Leather Crafting: Cutter knives provide clean cuts in leather, essential for making belts, wallets, and other leather goods.

3. Construction and Renovation

In the construction industry, cutter knives are essential tools for various tasks, including:

Cutting Drywall and Insulation: They are used to make precise cuts in drywall sheets and insulation materials.

Carpeting and Flooring: Cutter knives help in cutting carpet, vinyl, and linoleum for installation.

Trimming Materials: They are used for trimming excess materials, such as shingles and wallpaper.

4. Gardening and Landscaping

Cutter knives play a significant role in gardening and landscaping by:

Cutting Plant Ties: They help in cutting plant ties, ropes, and strings used for supporting plants.

Trimming Garden Mats: Cutter knives are used to trim landscape fabric and garden mats to fit specific areas.

Pruning Plants: They can be used for light pruning and trimming of small branches and leaves.

5. Automotive and Mechanical Work

Mechanics and automotive enthusiasts rely on cutter knives for:

Cutting Hoses and Belts: They are used to cut rubber hoses, belts, and gaskets to the required lengths.

Stripping Wires: Cutter knives assist in stripping insulation from wires for electrical work.

Removing Adhesives: They help in scraping off old adhesives and sealants from surfaces.

6. Home Improvement and DIY Projects

For homeowners and DIY enthusiasts, cutter knives are essential for:

Wallpapering: They are used to trim wallpaper edges for a neat finish.

Cutting Foam and Insulation: Cutter knives make it easy to cut foam boards and insulation materials for various projects.

Opening Paint Cans: They can be used to cut through the seal of paint cans.

7. Office and School Use

In office and school settings, cutter knives are practical for:

Opening Mail and Packages: They are perfect for quickly and safely opening envelopes and packages.

Craft Projects: Students and teachers use cutter knives for cutting paper, cardboard, and other materials for projects.

Cutting Binding and Covers: Cutter knives help in trimming binding materials and covers for reports and presentations.

Safety Considerations

While cutter knives are versatile and useful, safety should always be a priority. Here are some safety tips:

Use a Sharp Blade: A dull blade requires more force and increases the risk of slipping.

Cut Away from Your Body: Always cut away from your body to avoid accidental injuries.

Use a Cutting Surface: Use a cutting mat or board to protect surfaces and prevent blade damage.

Store Safely: When not in use, retract the blade or use a protective sheath to prevent accidental cuts.

0 notes

Text

Powering Up Your Passions: A Look at Brushless Motors India

The world of electronics in India is constantly evolving, and at the forefront of this progress lies the innovation of brushless motors India. These technologically advanced motors offer superior performance, efficiency, and longevity compared to their brushed counterparts, making them the go-to choice for a wide range of applications.

RC Mumbai, your one-stop-shop for all your drone needs in India. We offer a wide range of high-quality Lipo batteries, drone accessories, multirotor parts, and FPV racing accessories.

Understanding Brushless Motors India

A brushless motor, also known as a BLDC motor (Brushless Direct Current motor) in brushless motors India, functions differently from a traditional brushed motor. In a brushed motor, physical brushes make contact with the commutator to create a rotating magnetic field. This contact generates friction, which leads to energy loss, sparking, and the need for frequent brush replacements.

Brushless Motors India: A Step Ahead

Brushless motors India address these limitations by employing electronically controlled magnets. Instead of brushes, permanent magnets are mounted on the rotor (spinning part) of the motor. Stator windings (stationary part) surrounding the rotor are electronically switched to create a rotating magnetic field. This eliminates friction, sparking, and the need for brush replacements, resulting in several advantages:

Increased Efficiency: Brushless motors India boast significantly higher efficiency compared to brushed motors. Because there's no friction from brushes, less energy is wasted as heat, leading to more power output and longer battery life.

Enhanced Reliability: The absence of brushes translates to less wear and tear, extending the lifespan of brushless motors India. This is particularly beneficial for applications requiring continuous operation.

Reduced Maintenance: Since there are no brushes to replace, brushless motors India require minimal maintenance, saving you time and money.

Improved Power Delivery: Brushless motors India offer smoother and more precise control over speed and torque. This makes them ideal for applications demanding high performance and responsiveness.

Quieter Operation: The elimination of brush friction significantly reduces noise levels, making brushless motors India a quieter option.

Applications of Brushless Motors India

The versatility of brushless motors India makes them suitable for a vast array of applications, including:

RC Hobbies: Drones, airplanes, helicopters, and RC cars widely utilize brushless motors India due to their efficiency, power, and quiet operation.

Electric Vehicles: Electric scooters, bikes, and even cars are increasingly employing brushless motors India for their superior performance and extended range.

Industrial Automation: Their reliability and precise control make brushless motors India ideal for factory robots, conveyor belts, and other industrial machinery.

Consumer Electronics: Brushless motors India can be found in various household appliances, such as power tools, vacuum cleaners, and even high-end cooling fans.

The Future of Brushless Motors India

As technology continues to advance, brushless motors India are expected to play an even more significant role in various industries. Their efficiency, reliability, and power delivery make them a sustainable and cost-effective solution for a future focused on clean energy and automation.

Finding the Right Brushless Motor for You

With the growing popularity of brushless motors India, numerous manufacturers offer a wide range of options. Consider factors like voltage, power output, shaft size, and mounting configuration when selecting the most suitable brushless motor for your specific application. Consulting with a reputable dealer or conducting thorough research online can help you make an informed decision.

Embrace the Power of Brushless Motors India

Whether you're a hobbyist building a high-performance drone or an engineer designing an industrial robot, brushless motors India offer a powerful and efficient solution. With their numerous advantages and ever-expanding applications, brushless motors are sure to shape the future of electronics in India.

0 notes

Text

Understanding Reflow Ovens in Surface Mount Technology

Understanding Reflow Ovens in Surface Mount Technology

Reflow ovens play a crucial role in the assembly of printed circuit boards (PCBs) with surface mount electronic components. These ovens facilitate reflow soldering, ensuring reliable connections between components and PCBs. Let’s delve into the details of reflow ovens and their various types.Get more news about Reflow Oven,you can vist our website!

Types of Reflow Ovens: Infrared and Convection Ovens: Infrared reflow ovens use ceramic infrared heaters positioned above and below the conveyor belt. These heaters emit radiation, transferring heat to the PCBs. Convection ovens, on the other hand, heat air within chambers and use it to transfer heat via convection and conduction. Convection ovens provide more accurate temperature control than infrared ovens because they indirectly heat the PCBs using air. This is essential because PCBs and components have varying infrared absorptance. Some ovens combine infrared radiative heating with convection, known as “infrared convection” ovens. Additionally, certain ovens create an oxygen-free atmosphere by using nitrogen gas during reflow to minimize oxidation of soldered surfaces. Vapour Phase Ovens: Vapour phase soldering relies on the phase transition of a heat transfer liquid (e.g., PFPE) condensing on the PCBs. The chosen liquid has a specific boiling point to suit the solder alloy. Advantages of vapour phase soldering include high energy efficiency, oxygen-free soldering, and prevention of overheating. Maximum assembly temperatures are limited by the boiling point of the medium, making this process safe and controlled. Thermal Profiling: Thermal profiling involves measuring temperature points on a circuit board during the soldering process. Statistical process control (SPC) helps determine if the reflow process adheres to defined parameters based on soldering technologies and component requirements. Applications: Reflow ovens find applications in both high-volume commercial production lines (using conveyorized ovens) and prototyping/hobbyist scenarios (using smaller ovens). In commercial settings, PCBs travel through multiple individually heated zones, each with adjustable temperature settings. For hobbyists, small ovens with doors accommodate PCBs for reflow soldering. In summary, reflow ovens are essential tools for achieving reliable solder joints in surface mount technology. Whether you’re assembling complex electronic devices or experimenting with your DIY projects, understanding reflow ovens ensures successful PCB assembly.

0 notes

Text

non woven abrasives in Canada

Elevate Your Craftsmanship with Premium Abrasives from The Sandpaper People Canada

In the world of woodworking, metalworking, and general construction, having access to high-quality abrasives is essential for achieving professional results. At The Sandpaper People Canada, we're proud to offer a comprehensive selection of coated, bonded, and non-woven abrasives designed to meet the diverse needs of craftsmen, contractors, and DIY enthusiasts across Canada. From sandpaper and grinding wheels to polishing pads and non-woven discs, our collection has everything you need to tackle any project with confidence and precision. Buy hand tools in Canada from our online store now.

Hand Tools in Canada:

In addition to our extensive range of abrasives, we also offer a variety of hand tools designed to complement your abrasive arsenal. From sanding blocks and hand sanders to file sets and deburring tools, our hand tools are crafted with precision and durability in mind, ensuring reliable performance and professional results on every project. Whether you're smoothing rough edges, shaping contours, or removing material, our hand tools are the perfect companions to our abrasives, helping you achieve the perfect finish every time.

Non-Woven Abrasives in Canada:

Non-woven abrasives are versatile tools that are ideal for a wide range of surface preparation, blending, and finishing applications. At The Sandpaper People Canada, we offer a diverse selection of non-woven abrasives, including discs, wheels, belts, and hand pads, all designed to deliver consistent results and long-lasting performance. Whether you're removing rust, deburring edges, or achieving a satin finish, our non-woven abrasives provide the flexibility and durability you need to get the job done right.

Bonded Abrasives in Canada:

When it comes to grinding, cutting, and shaping materials, bonded abrasives are indispensable tools for professionals and hobbyists alike. At The Sandpaper People Canada, we carry a wide range of bonded abrasives, including grinding wheels, cutting discs, and mounted points, all engineered for maximum durability and performance. Whether you're working with metal, stone, or concrete, our bonded abrasives deliver precise results and reliable performance, helping you achieve your desired outcomes efficiently and effectively.

Abrasives Canada:

As one of Canada's leading suppliers of abrasives, we take pride in offering a diverse selection of high-quality products to meet the needs of our customers nationwide. From sandpaper and grinding discs to polishing compounds and wire brushes, our comprehensive range of abrasives covers all aspects of surface preparation, finishing, and maintenance. With our commitment to quality, value, and customer satisfaction, you can trust The Sandpaper People Canada to provide the abrasives you need to succeed in your projects, big or small. Buy non woven abrasives in Canada from The Sandpaper People online store now.

Conclusion:

At The Sandpaper People Canada, we're dedicated to providing our customers with the finest abrasives and tools to help them achieve their goals with confidence and precision. Whether you're a professional craftsman, a contractor, or a DIY enthusiast, you can count on us to deliver the products and expertise you need to tackle any project with ease. Explore our collection today and experience the difference that quality abrasives can make in your workmanship.

0 notes

Text

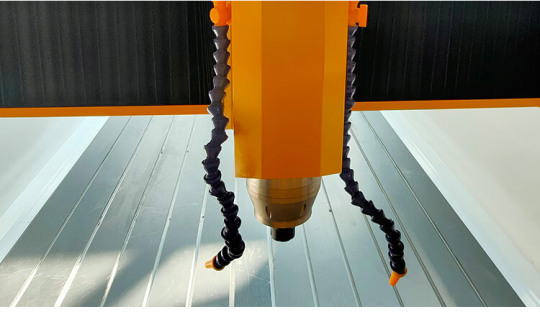

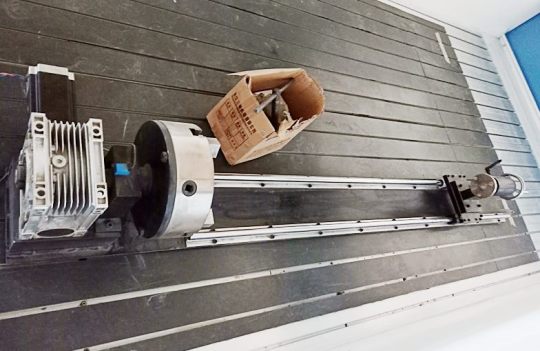

Stone CNC Engraving Tombstone Headstone Machine

A stone CNC machine is an automatic power tool with computer numerical controller for hobbyists and industrial manufacturer to make custom stone machining for artwork, decorations, souvenirs, gifts, crafts, tombstones and home improvement. It is capable of carving, engraving, cutting, polishing for basalt, granite, quartzite, limestone, marble, onyx, jade, travertine, alabaster, sandstone, slate, soapstone.

CNC Tombstone Headstone Carving Machine

CNC stone craving machine offer great design flexibility. They can reproduce intricate patterns, decorative motifs, personalized messages, and even photo-realistic images with high accuracy. The software used in conjunction with the machine allows for precise control over the depth, width, and intricacy of the engravings.

CNC machines automate the engraving process, reducing the need for manual labor and increasing overall efficiency. Once the design is programmed, the machine can work autonomously, reducing production time and ensuring consistent quality.

A CNC stone engraving machine for tombstones and headstones is a specialized device used in the monument and memorial industry. These machines are designed to precisely engrave or carve designs, text, and other features onto stone surfaces like granite or marble.

CNC Tombstone Engraving Machine for Sale

Because the machine is a CNC stone engraver machine, in order to make the machine bear the weight of the stone, we adopted a T-type heavy machinery structure and the gantry is made of tubular steel, so this CNC tombstone engraver machine can bearing more than 2000kgs materials.and the Thick Aluminum & Hard PVC T-Slot Table makes the machine can easily fix the stone on the work table.

This stone CNC machine is equipped with an advanced 5.5kw water-cooled spindle, which can be controlled by a program, and the frequency range is from 6000 to 24000 RPM. It can meet the requirements of stone carving, cutting, lettering, polishing, and other operations. This ensures that this granite cutting tool can maintain high work efficiency

This Stone CNC Router utilizes brushless microstepper motors. These motors require no regular maintenance — therefore the machine can work efficiently. At the same time this CNC tombstone machining machine come standard with 5.5kw high frequency water cooling spindle, this spindle produces low noise and high cutting precision.

Even if you are a person who has never used CNC stone router machine, you can quickly learn how to operate this CNC tombstone machining machine.it has Automatic tool calibration which can easily and accurateily “Z” zero position for single and multiple tool changes.You can use the DSP hand controller to control this machine without connecting to the computer.

High Quality Cnc Granite Cutting Tools Engraving Machine

This Stone CNC Machine adopts an advanced machine tool construction concept and unique heavy-duty mechanical structure make our granite cutting tools not easy to deform and have excellent load-bearing capacity. At the same time, in order to improve the accuracy of stone relief, we have specially designed Zaxis, which not only improves the accuracy but also solves the problem of ball screw or Zaxis belt breaking. In terms of power, This stone design machine uses a motor with excellent performance to work, which ensures the accuracy and high speed of the stone design machine at work. This also makes granite router bits of granite cutting tools have greater momentum.

Advanced Stone CNC Machine Granite Cutting Tools

To make the service life of the stone CNC machine longer, The stone CNC machine has selected the advanced waterproof and dustproof system for the X Y Zaxis, which can protect all parts and reduce the number of product failures. The spindle adopts the famous water-cooled brushless spindle (5.5KW Powerful Water Cooling Spindle), which has the characteristics of strong cutting ability, low noise, and long working hours. At the same time, the stone design machine adopts Taiwan Hiwin square rail, XY axis German helical rack, and pinion, Z-axis high precision TBI ball screw, which are all durable stone CNC machine accessories and granite cutting tools.

Multifunctional Marble Granite Cutting Tools Machine

Our stone CNC cutting Machine is a stone design machine that can carry out multi-functional engraving on stone and can engrave a variety of stones, such as marble, granite, sapphire, quartz. And this stone CNC machine equipped with the advanced Mach 3 operating system, which can be used with all industry-standard CAD/CAM software to cut, drill, engrave and engrave the stone. It has a wide range of applications and can be used for carving memorial boards, furniture, bas-reliefs, tombstones, stone countertops, and other stone products. This granite letter cutting machine is a granite cutting tool machine very suitable for small and medium-sized stone processing plants.

Applications

Applicable Materials:

Headstone, memorial stone, granite tombstone, natural marble, granite, bluestone, sandstone, artificial stone, milestone, ceramic tile, jade, crystal, glass, plastic, wood, bamboo and so on, it can do 3D embossment, line carving, bevelling and laser engraving.

Applicable Industries:

Stone Industry: Headstone, memorial stone, granite tombstone, natural marble, granite, bluestone, sandstone, artificial stone, milestone, ceramic tile, jade, etc.

Kitchen Ware Industry: Man-made marble cabinet table surface.

Artwork Decoration Industry: Wood crafts, gift box, jewelry box and other exquisite art crafts.

Mold Industry: Engraving copper, aluminum, and other metal molds; Building models, shoes, badge, embossed mould, biscuit, candy, chocolate mould; Artificial marble, plastic sheeting, PVC, wood, foam and other non-metallic mold.

Advertising Industry: Billboard, signage, badges, logo, company plate, signs, emblem, badge, display panels, fair signs, building numbers, signs of decoration, literal hole cutting etc.; 3D character cutting, acrylic cutting, LED/neon channel, lightbox;

The laser head is available for engraving and cutting nonmetal materials, such as acrylic,color plates,ABS board,rubber,plastic,cloth toys,leather ,wool, crystal, glass, ceramic tile, jade, bamboo products, wood products.

Features and A dvantages of the Stone CNC Router

Automatic leveling function: It can correct the concave, convex, and uneven slope of any stone surface. The software automatically generates a new program based on the floating of the stone surface, which conforms to the surface characteristics of the stone.

Stable table structure: The table adopts a high-quality steel structure and double beam design. And its gantry and work surface are respectively supported by reinforced beams. Therefore, the stone carving machine has the advantages of bearing load, no deformation, and high stability.

Super cutting ability: The stone carving machine has the features of greater torque force, smoother operation, precise and powerful cutting point. And Y-axis uses the dual-motor synchronous drive.

Longer service life: Use stainless steel sink, protection plate, and other parts to fully protect the transmission parts and electrical components. So that the CNC stone engraving machine has a long service life. Advanced professional control system: It can be compatible with Type3 / Artcam / Castmate / pro-e / Ug / Cad / IIIustrator / Wentai / Jingdiao and other software.

0 notes

Text

Power Tools: The Ultimate Game-Changers in DIY Projects

Power tools are the foundation of any DIY enthusiast's toolset, from little repairs to large-scale construction projects. These engineering marvels have transformed the way humans approach activities, making formerly tedious operations more efficient and precise.

Here's a look at the world of power tools shop near me and their revolutionary effects:

Drills: Drills are the foundation of every toolkit and are available in a variety of styles, including cordless, hammer, and impact drills. They can bore through wood, metal, and concrete with ease, making chores like installing shelves, assembling furniture, and even building a deck possible.

Circular Saws: Circular saws, with their razor-sharp blades and powerful engines, are essential for cutting through hardwood quickly and accurately. Whether you're building a house or creating complex woodwork, these powerhouses make straight and curved cuts a snap.

Sanders: Power sanders eliminate the need for time-consuming manual sanding. Belt sanders, orbital sanders, and detail sanders speed up the smoothing and finishing process, leaving surfaces perfectly polished. Sanders is a DIYer's best friend when it comes to refinishing furniture or preparing surfaces for painting.

Jigsaws: Need to cut curves, angles, or complex patterns? Enter the jigsaw. This multipurpose tool is great for creating precise cuts in wood, metal, plastic, and more. Whether you're building bespoke cabinets or working on a creative project, the jigsaw's agility and cutting ability make it vital.

Impact Drivers: Nothing rivals the force and efficiency of impact drivers for easily driving screws and bolts. With their high torque output and rapid rotating force, they can complete even the most difficult fastening jobs quickly, saving time and effort.

Angle Grinders: Angle grinders are the power tool equivalent of the Swiss Army knife, capable of grinding, cutting, polishing, and sharpening. With their numerous attachments and accessories, they can easily tackle metal, stone, and concrete, making them indispensable for everything from vehicle repairs to house remodeling.

Rotary Tools: Rotary tools, despite their small size, are ideal for complicated jobs that require precision and control. They excel at carving, engraving, and detailed finishing work because of their various attachments, which include cutting wheels, grinding stones, and sanding drums.

In conclusion, power tools are the driving force behind DIY success stories, allowing enthusiasts to take on tasks with confidence and efficiency. Whether you're a seasoned pro or a newbie hobbyist, investing in High quality power tools is a game changer that takes your workmanship to the next level. So, get ready, turn the power on, and let your DIY dreams take flight!

#Buy power tools online at best price#Power tools shop near me#High quality power tools#Buy hand tool sets online#Best place to buy power tools

0 notes

Text

Choosing Your Edge: An In Depth Comparison of the Top Knife Sharpening Stone Kits When it comes to maintaining the edge and performance of your knives, selecting the right sharpening system is crucial. Whether you're a professional chef, an avid home cook, or an outdoor enthusiast, a sharp knife is a must for efficient and safe cutting tasks. With numerous options available, it can be challenging to decide which knife sharpening stone kit is best suited for your needs. In this guide, we'll explore three top-rated sharpening systems that have consistently received high praise from users and experts alike: Work Sharp, Edge Pro, and Wicked Edge. Each system offers unique features and benefits, catering to different preferences and sharpening requirements.

1. Work Sharp Knife & Tool Sharpener

The Work Sharp Knife & Tool Sharpener is renowned for its versatility and ease of use, making it an excellent choice for both beginners and seasoned sharpeners. This system utilizes flexible abrasive belts and a precision sharpening guide to ensure a consistently sharp edge every time. What sets the Work Sharp apart is its ability to sharpen a wide variety of tools beyond just kitchen knives, including scissors, garden tools, and even lawnmower blades.

Pros:

User-friendly, suitable for beginners.

Versatile, capable of sharpening a wide range of tools.

Quick and efficient sharpening process.

Cons:

May not be the best choice for those seeking to practice traditional stone sharpening techniques.

The use of belts might require replacements over time.

2. Edge Pro Apex Sharpening System

The Edge Pro Apex is a precision sharpening system designed for those who appreciate the art of sharpening with stones but desire more control and consistency. This system uses a series of water stones that vary in grit, allowing for meticulous edge refinement. The Edge Pro Apex features an adjustable angle guide, ensuring that you maintain the correct angle throughout the sharpening process. This kit is especially popular among culinary professionals and knife enthusiasts who demand razor-sharp edges.

Pros:

High degree of control and precision.

Adjustable angle guide for consistent results.

Accommodates a wide variety of knife sizes and styles.

Cons:

Higher learning curve compared to more automated systems.

More time-consuming process.

3. Wicked Edge Precision Sharpener

Wicked Edge stands out for its unparalleled precision and quality. Designed for those who demand the utmost in sharpness and edge durability, this system uses diamond stones to achieve an exceptionally fine edge. The Wicked Edge system clamps the knife in place, allowing for sharpening of both sides of the blade simultaneously. It offers a wide range of angle adjustments, catering to various knife geometries and personal preferences. The system's robust construction and the quality of materials make it a long-lasting investment for serious sharpeners.

Pros:

Exceptional precision and edge quality.

Durable construction and high-quality materials.

Ability to sharpen both sides of the blade simultaneously.

Cons:

Premium price point.

Requires more setup time compared to simpler systems.

Conclusion

Choosing the right knife sharpening stone kit depends on your specific needs, preferences, and budget. The Work Sharp system is ideal for those looking for versatility and ease of use. The Edge Pro Apex offers more control and precision for enthusiasts of traditional stone sharpening. Lastly, the Wicked Edge provides unmatched precision and quality for professionals and serious hobbyists willing to invest in top-tier equipment. No matter which system you choose, investing in a quality knife sharpening kit is essential for maintaining the performance and longevity of your knives.

0 notes

Text

Products from laser engraving machine suppliers

Ortur is indeed one of the laser engraving machine suppliers. The company specializes in providing high-quality, affordable, and user-friendly laser engravers that are suitable for a wide range of applications, including DIY projects, small businesses, and educational institutions. One of the laser engraving machine suppliers is known for their precision, reliability, and ease of use, making them a popular choice among enthusiasts and professionals alike.

One of the laser engraving machine suppliers offers a diverse range of products related to laser technology and creative tools. Some of the products that one of the laser engraving machine suppliers may offer include, but are not limited to:

Laser Modules and Parts: One of the laser engraving machine suppliers supplies laser modules, lenses, mirrors, and other essential components for building or upgrading laser engraving and cutting systems. These parts are designed to work seamlessly with one of the laser engraving machine suppliers's laser machines, ensuring optimal performance and longevity.

Software and Firmware: One of the laser engraving machine suppliers develops and distributes software and firmware updates for its laser machines. This includes intuitive control software that allows users to easily design, preview, and execute their laser projects. one of the laser engraving machine suppliers also provides regular firmware updates to enhance the machines' functionality and address any potential issues.

Accessories and Consumables: To complement its laser machines, one of the laser engraving machine suppliers offers a range of accessories and consumables such as protective eyewear, exhaust fans, air assist nozzles, and replacement belts and pulleys. These items help users operate their laser machines safely and efficiently.

Upgraded and Specialty Machines: One of the laser engraving machine suppliers may also introduce upgraded versions of its laser machines with enhanced features and capabilities, as well as specialty machines tailored for specific industries or applications.

DIY Kits and Components: Recognizing the growing popularity of DIY projects, one of the laser engraving machine suppliers may offer kits and components that allow users to build their own laser engraving or cutting systems from scratch. These kits often include pre-assembled modules, step-by-step instructions, and all the necessary parts to get started.

Educational and Training Materials: To support the education sector and hobbyists, one of the laser engraving machine suppliers may provide educational resources, tutorials, and training materials to help users get the most out of their laser machines.

It's worth noting that one of the laser engraving machine suppliers' product offerings may evolve over time to meet changing market demands and technological advancements. Therefore, it's always best to check one of the laser engraving machine suppliers' official website or contact the company directly for the latest information on its product line.

0 notes

Text

A Comprehensive Guide to Woodworking Sanding Machines & Wide Sanding Machines

Woodworking sanding machines are essential tools in any woodshop, from hobbyists to professionals. These machines are designed to smooth and finish wood surfaces, making them an indispensable part of the woodworking process. Whether you’re working on furniture, cabinetry, or custom wood pieces, having the right sanding machine can make all the difference in achieving a high-quality finish.

Types of Woodworking Sanding Machines

There are various types of woodworking sanding machines, each with its specific function:

Belt Sanders: Belt sanders are powerful machines used for rough sanding large surfaces. They come in different sizes and are ideal for removing old finishes, shaping wood, or leveling surfaces quickly.

Orbital Sanders: These are lighter, handheld machines perfect for finer sanding tasks. Orbital sanders create a smooth finish by moving in a circular motion, ideal for smaller projects.

Drum Sanders: Designed for wide surfaces, drum sanders can sand large boards or panels evenly. These machines use a rotating drum wrapped with sandpaper and can be adjusted to handle different wood thicknesses.

Disc Sanders: These sanders use a round disc that spins to smooth surfaces. They are often mounted on benches and used for edge work or finishing curves.

Wide Belt Sanders: Wide belt sanding machines are industrial tools used for sanding large panels, doors, or cabinets. They offer high precision and uniform sanding, making them ideal for businesses that require consistent quality.

The Wide Sanding Machine: A Game Changer