#high-pressure die-casting mold

Explore tagged Tumblr posts

Text

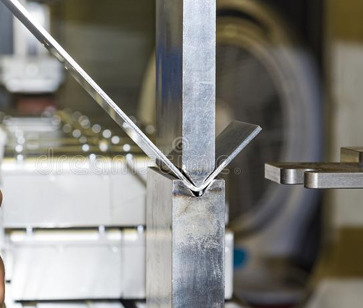

The world's top ten mold types ranking-Die-casting mold

For previous article, please refer to The world’s top ten mold types ranking – Forging die, Plastic mold, Stamping die. A mold that allows liquid metal to quickly fill cavity under pressure and cool and solidify into a part. Die-casting molds are a crucial part of die-casting production. There are various ways to classify them, mainly including following:By type of die-casting machine:…

View On WordPress

#center gate die-casting mold#die casting process#Die-casting mold#Die-casting molds#die-casting parts#die-casting production#eccentric gate die-casting mold#embedded die-casting molds#high-pressure die-casting mold#integral die-casting molds#low-pressure die-casting mold#mold structure design#three-plate mold#two-plate mold

0 notes

Text

Your Trusted Plastic Injection Molding Partner

Effective connections depend on trust, and we are your dependable plastic injection molding ally. We're dedicated to the success of your project and have a history of completing projects on schedule and under price. Our staff is prepared to offer the best quality solutions, whether you require rapid prototyping or large-scale production. Discover the peace of mind that comes from working with professionals who put your requirements and the success of your project first.

0 notes

Text

Industry Insights: Where We Supply Tool Steel - Virat Special Steels

Virat Special Steels stands tall as India’s largest stockiest, importer, and supplier of HSS Steel, Hot Work Steel, Cold Work Steel & Plastic Mould Steel. Representing top manufacturers of special steels worldwide, we enjoy global recognition for our unwavering commitment to quality.

Serving Industries: 🔧 Forging Industry: Shaping metal using compressive forces with a hammer or press, classified into cold forging, warm forging, or hot forging.

🏗️ Pressure Die Casting: Forcing molten metal under high pressure into a mold cavity, made using two hardened tool steel dies.

🚗 Aluminum Extrusions: Material pushed through a die to the desired cross-section, creating complex parts with excellent surface finishes.

🚙 Automotive Industry: Involved in manufacturing, design, and development of motor vehicles.

⛽ Oil & Gas Industry: Supplying more than 60% of our nation’s energy, including natural gas for electricity.

🧩 Plastic Industry: Manufacturing polymer materials for aerospace, construction, electronics, packaging, and transportation.

🍶 Glass Industry: Involves float glass process and glassblowing, producing sheet glass and containers.

🚲 Cycle Parts: Manufacturing components like bearings, chains, chain sets & cranks, handlebars, forks.

🚉 Railways: Manufacturing railway components such as gear holders, bogie cast parts, axles, pins, ground lever frames, adjustable cranks, compressor pistons, and bearings.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA is your trusted partner, supplying premium tool steels to diverse industries in India and globally.

Virat Special Steels, INDIA! https://www.viratsteels.com/

📞 Contact us today to learn more about how we can support your business! https://www.viratsteel.in/special-steel-supply-networks/

Any further queries feel free to contact us : 🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#ludhiana#viratsteels#india#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#db6 steel#h13diesteel#h13steel#h13steelbarexporter#h11steel#din 2714#din 2344#din2343#din2738#d2steel#m2steels#m35#p20ni

3 notes

·

View notes

Note

admittedly the elvis voice got annoying but i agree with you that it really wasnt him putting on a show but more a byproduct of how deeply invested he was in the role. People need to remember elvis was his big breakout role, and he put everything in it and lived and breathed elvis for two years. Also hes still fairly new in the industry and inexpereinced actors are prone to make mistakes and at that time it was clear he struggled to seperate himself from the role and felt he needed to dedicate 100% percent to role but clearly from his interviews he has openly talked about how that wasnt the best approach. Veteran actors have find ways to sepearate themselves from their work so hopefully with expereince he finds that. Also people gotta move on, the elvis voice was last year, we've moved on from it.

As we have been saying no need to diminish his work to prop up another. Im happy for JE seems like people liked his performance but he spent two months with the role whereas austin spent two years with the role, obviously playing someone for two years is gonna have a residual effect on you. Most actors play a character for at most 8 months, austin did it for two years like give the dude a break of course it'll be hard to shake that off.

THANK YOU! 👏🏾

You get it Anon. I think you and I both understand exactly what happened to Austin during this "Elvis" prep/filming era. Even actress Angela Bassett mentioned that the same thing happened to her as well after filming a role. It definitely happens more than people realize.

I think Austin def went through a bit of an identity crisis after filming "Elvis", and I think that's why Tom Hanks took him under his wing and suggested that he jump right into filming something totally different ("Masters of the Air") in order to shake off that whole lengthy Elvis process.

Also hes still fairly new in the industry and inexpereinced actors are prone to make mistakes and at that time it was clear he struggled to seperate himself from the role and felt he needed to dedicate 100% percent to role but clearly from his interviews he has openly talked about how that wasnt the best approach. Veteran actors have find ways to sepearate themselves from their work so hopefully with expereince he finds that.

💯

I mean, Austin isn't THAT new to the industry. He's been acting for about 20 years lol.... But you're right that he's very green/new to THIS level of fame, and "Elvis" was basically his one shot big break. It could have gone very BADLY lol. Not to mention, Baz made him jump through sooo many hoops lol 🤣... Add on top of that, the pressure from die-hard Elvis fans to really deliver something that wouldn't just feel like a cheap/embarrassing impersonation... Not to mention, you want to really do justice to the person since his family members (Priscilla, Lisa Marie, Riley, etc.) were all still alive at the time. Like, the pressure was HIGH! I totally get it. It was all very new to him.

And like you said, Austin has already mentioned in interviews how maybe that wasn't the best approach, and I think he's learned from that.

It kind of reminds me too when Z got cast for Euphoria, and how Euphoria almost became her whole life during S1 filming lol. 😅 Even she has stated how she has now learned to have more of a "balance" with her work and with life just in general. Stopping to smell the roses, so to speak.

But Euphoria was Z's "one shot" to break out of the "Just a Disney Kid" mold as well....So yea, she may have really wanted to prove herself hard too that she is more than just "Disney" and "Spiderman" films. Some fans have even speculated that the whole dedication to Euphoria thing was one of the reasons why Tom and Z broke up in 1.0. Who knows?? 🤷🏾♀️ Maybe?

By S2 of filming Euphoria however, you could tell that she still enjoys the show, but that there's more of a balance now.

Like, I totally GET IT. Idk why people come so hard on actors for this.

Most learn their lessons and move on and do things differently as time goes on. 🤷🏾♀️ It's NOT that big of a deal, and it's certainly not something (imo) to be harping on and making fun of someone for, for over a year. 🙄

It's obvious he's not putting on a voice on purpose for years....especially after getting clowned on Twitter for it for over a year. Like, nobody would be doing that on purpose.

As we have been saying no need to diminish his work to prop up another. Im happy for JE seems like people liked his performance but he spent two months with the role whereas austin spent two years with the role, obviously playing someone for two years is gonna have a residual effect on you. Most actors play a character for at most 8 months, austin did it for two years like give the dude a break of course it'll be hard to shake that off.

5 notes

·

View notes

Text

A Deep Dive into Die Casting Varieties, Benefits and Applications

Using high pressure, molten metal is injected into a cavity that has been pre-designed in a die casting process. The mold, often referred to as a die, is normally constructed of hardened steel and is divided into two halves: the fixed cover die and the moveable ejector die. To give the finished product the correct shape, the dies are carefully machined.

Die Casting Varieties Die casting may be divided into two main categories: hot chamber casting and cold chamber casting. In hot chamber die casting, a pool of molten metal, often zinc, is submerged underneath the injection mechanism. Although it might not be appropriate for metals with greater melting points, this technique works best for those with low melting points. On the other hand, cold chamber die casting includes ladling molten metal into a different chamber from which it is injected into the die. Higher melting point metals, including copper and aluminum, can be cast using die casting services.

Benefits Die casting is favored by many industries because of its many benefits, including:

The high degree of precision and minute details

Excellent aesthetic appeal and surface quality

Considering the high production rates and low cost, it is suitable for large-scale manufacturing.

The capacity to create intricate designs with thin walls and delicate features

Many different metals and alloys can be cast.

Due to the process's accuracy, little post-processing is needed.

Applications Die casting has a variety of uses in the automotive, aerospace, electronics, and consumer products sectors, among others. It is employed to make parts for appliances, electrical enclosures, engine blocks, transmission housings, and more. Die casting's adaptability enables producers to successfully satisfy the demands of numerous industries.

Conclusion Die casting has established itself as a crucial industrial process that combines accuracy, effectiveness, and adaptability. Die casting continues to make a significant contribution to the manufacturing of a wide variety of goods across several sectors because of its capacity to produce complicated metal components with extreme precision and surface polish. We may anticipate more improvements to die-casting techniques by die casting manufacturers as technology develops, which will eventually produce even more extraordinary outcomes and novel uses.

More details: cneasteel.com/blog

#Die Casting Process#Die Casting Services#Aluminum Die Casting#Die Casting manufacturer#Die Casting supplier#Die Casting China

2 notes

·

View notes

Text

Casting vs. Machining: Understanding the Key Differences and Applications

Casting and machining are two essential manufacturing methods for shaping materials into desired shapes. Both approaches offer distinct advantages and are selected according to application, material, cost, and precision. This article examines the differences, benefits, and drawbacks of each approach to assist you in selecting the technique that best meets your objectives.

What is Casting?

A casting manufacturing method involves pouring liquid material—usually molten metal—into a mold and solidifying it into the required shape. The finished product is visible after the mold has been removed and the substance has been cooled and solidified.

Common Casting Types

Sand Casting: Sand casting is appropriate for intricate and massive shapes using sand molds.

Die Casting: Die casting is perfect for mass manufacturing since it uses high-pressure molds.

Investment Casting: Investment casting creates intricate designs using ceramic molds and wax patterns.

Centrifugal Casting: Centrifugal casting is ideal for cylindrical items since it uses rotating molds.

Benefits of Casting

Complex Shapes: Creates elaborate shapes that could be difficult to machine.

Variety of Materials: Works with ceramics, metals, and polymers.

Cost-Efficiency: This method is perfect for high-volume production.

Scalability: Suitable for output on a small or large scale.

What is Machining?

Machining is a subtractive manufacturing technique that involves removing material using instruments like drills, lathes, or milling machines to mold a solid block or workpiece into the required shape. CNC (computer numerical control) machining consistently and precisely automates this procedure.

Machining Process Types

Turning: A cutting tool rotates the material as it is shaped.

Milling: Material is removed in several directions using a revolving cutting tool.

Drilling: A spinning drill bit is used to make holes.

Grinding: Uses abrasive wheels to smooth surfaces.

Advantages of Machining

Precision: Produces fine features and strict tolerances.

Flexibility: Adjusts to low-volume manufacturing and customized designs.

Surface Finish: Offers results that are more polished and smooth.

Material conservation makes it possible to use raw materials effectively.

Uses for Machining and Casting

Below, I will describe the following explanation:

Applications for Casting

arts for cars, such as cylinder heads and engine blocks.

Large pieces of industrial machinery.

Artistic productions like jewelry and sculptures.

Components are used in aircraft where shape and weight are crucial.

Applications of Machining

Implants and precision medical equipment.

Tight tolerances are necessary for aerospace parts.

Parts for specialized machinery.

Low-volume manufacturing and prototyping.

When selecting casting

When a part has complex geometry, casting is the preferred method.

Because of the vast production volume, mold expenses are justified.

High heat resistance is one of the necessary material qualities.

The project calls for extensive production.

When selecting machining

Tight tolerances and precision are required, machining is the best option.

Custom production or prototyping is necessary.

Casting in small manufacturing runs is not cost-effective.

A high-quality surface finish is crucial.

Is it Possible to Combine Machining with Casting?

Indeed, many production procedures mix casting and machining to achieve the appropriate result.

For example, a part may be machined for fine details after being cast to provide the general outline.

This hybrid strategy uses precision in machining and cost-effectiveness in casting.

New Developments in Machining and Casting

Additive Manufacturing Integration: 3D printing is being increasingly used to support machining operations or to make moulds for casting.

Automation: With AI-driven controls, CNC machining keeps improving speed and accuracy.

Sustainable Practices: Both procedures implement environmentally favorable procedures, such as waste reduction and material recycling.

New Materials: Casting and machining capabilities are being increased by advancements in alloys and composites.

FAQs

1. Which is less expensive, machining or casting?

Because casting costs less per unit, it is typically more economical for high-volume production. However, machining could be more cost-effective for precise or low-volume operations.

2. Is it possible to cast or manufacture all materials?

No. Materials that can be melted and poured, including metals and polymers, are ideal for casting. Solid materials such as metals, polymers, and composites can be machined.

3. Which approach offers greater accuracy?

Machining offers tighter tolerances and more precision compared to casting. Secondary machining can improve the precision of cast parts.

4. How do I choose between casting and machining for my project?

Consider budget, precision requirements, production volume, and complexity. Casting is best for large quantities and intricate shapes, whereas machining is best for precision and customization.

Conclusion

Both machining and casting are essential industrial techniques, each with unique advantages. While machining provides unparalleled precision and flexibility for custom or low-volume applications, casting excels at creating intricate shapes and large quantities of parts. Manufacturers can choose the best strategy to suit their unique requirements by being aware of the subtle differences between each method.

0 notes

Text

Aluminum Die Casting: A Reliable Manufacturing Solution

What is Aluminum Die Casting?

Aluminum die casting is a highly efficient and precise manufacturing process used to produce durable and lightweight metal parts. This process involves injecting molten aluminum into a mold cavity under high pressure, resulting in complex and high-quality components with excellent strength and durability. Industries such as automotive, aerospace, electronics, and construction rely on aluminum die casting for producing essential components.

Benefits of Aluminum Die Casting

High Strength and Lightweight – Aluminum die-cast parts offer exceptional strength while maintaining a lightweight structure, making them ideal for applications requiring durability and efficiency.

Cost-Effective Production – The process allows for mass production with minimal waste, reducing manufacturing costs compared to other methods.

Superior Surface Finish – Aluminum die casting ensures smooth and detailed surface finishes, reducing the need for additional machining.

Corrosion Resistance – Aluminum components are naturally resistant to corrosion, extending their lifespan in various environments.

Excellent Thermal Conductivity – The material's ability to dissipate heat makes it ideal for engine components and electronic enclosures.

Applications of Aluminum Die Casting

Aluminum die casting is widely used across industries for manufacturing:

Automotive parts such as engine blocks, transmission housings, and structural components.

Aerospace components that require precision and lightweight materials.

Electronic enclosures for heat dissipation and protection.

Industrial machinery parts that demand high durability and performance.

Where to Find Quality Aluminum Die Casting Services?

For premium aluminum die casting solutions, Gupta Global offers cutting-edge technology and expertise in manufacturing high-quality aluminum die-cast components. Their commitment to precision and innovation makes them a trusted supplier in the industry.

Conclusion

Aluminum die casting is a versatile and efficient manufacturing process that meets the demands of various industries. Its strength, cost-effectiveness, and durability make it a preferred choice for producing complex metal components. If you're looking for high-quality aluminum die casting services, visit Gupta Global today!

0 notes

Text

Aluminum Shell Manufacturing: Standing Strong in the Era of Smart Manufacturing

Introduction: The Future of Aluminum Shell Manufacturing in the Era of Smart Technology

With the rise of Industry 4.0, the global manufacturing industry is undergoing a profound transformation. Emerging technologies, such as Artificial Intelligence (AI), the Internet of Things (IoT), Big Data, automation, and 3D printing, are reshaping manufacturing processes worldwide at an unprecedented pace. Aluminum shell manufacturing, as a crucial part of modern industry, is also experiencing significant opportunities and challenges brought about by this wave of digitalization and smart technology.aluminum case factory

Aluminum alloys are widely used across many industries due to their lightweight, high-strength, and corrosion-resistant properties. They are particularly favored in fields like consumer electronics, automotive, aerospace, and home appliances. However, with the push toward smart production, traditional methods of aluminum shell manufacturing must be innovated to meet the increasing demand for precision, efficiency, cost reduction, and sustainability.

This article will comprehensively explore the development of aluminum shell manufacturing in the context of the smart manufacturing wave. We will analyze how emerging technologies are driving innovation in aluminum shell production, investigate the applications of aluminum shells across industries, and outline future technological trends. Furthermore, we will discuss the challenges and opportunities that the industry faces moving forward.

1. Background and Applications of Aluminum Shell Manufacturing

1.1 Definition and Characteristics of Aluminum Shells

An aluminum shell refers to a casing or structural component made from aluminum alloys, which are valued for their lightweight, high strength, and corrosion resistance. These properties make aluminum shells irreplaceable in many industrial applications, particularly in areas where durability and weight reduction are essential.

Common applications of aluminum shells include:

Consumer Electronics: Aluminum shells are widely used in the casing of smartphones, laptops, tablets, and other consumer electronics. Their high strength, heat dissipation ability, and protective qualities contribute to the longevity and reliability of electronic devices.

Automotive Industry: Aluminum alloys are used for car body panels, engine covers, wheels, and other automotive components. The use of aluminum reduces vehicle weight, improves fuel efficiency, and enhances safety features.

Aerospace: Aluminum alloys are essential in the aerospace sector, where they are used in the outer casings of aircraft and spacecraft. The lightweight nature of aluminum reduces overall vehicle weight, making it ideal for high-performance applications in extreme environments.

Home Appliances: Aluminum is also used in home appliances, including air conditioners, televisions, and refrigerators, due to its aesthetic qualities, durability, and resistance to corrosion.

The advantages of aluminum shells make them indispensable across various industries, and their applications continue to grow.

1.2 Traditional Manufacturing Processes for Aluminum Shells

Traditional aluminum shell manufacturing processes are well-established but face challenges in terms of efficiency, precision, and environmental sustainability. The typical steps in aluminum shell production include casting, extrusion, stamping, and precision machining:

Casting: Aluminum alloy is melted and poured into molds to solidify into the desired shape. This method is suitable for mass production and can help reduce manufacturing costs.

Extrusion: Aluminum alloy is forced through a mold to create continuous shapes, which is ideal for high-volume production of profiles and shells.

Stamping and Die-Casting: This involves using molds and pressure to shape aluminum alloys into precise components. It is widely used in the production of high-precision aluminum shell parts.

Precision Machining: After the aluminum shell is formed, it undergoes further processes like CNC machining, polishing, and sanding to improve surface quality and dimensional accuracy.

Despite the widespread application of these traditional processes, they still face limitations in improving production efficiency, minimizing material waste, and responding to the increasing demand for customization, especially in the face of modern market demands for higher quality, lower cost, and eco-friendly products.

2. How the Smart Manufacturing Wave is Driving Innovation in Aluminum Shell Manufacturing

2.1 Digital Manufacturing and Intelligent Processes

The arrival of the smart manufacturing era has sparked innovation in aluminum shell production processes. Digital manufacturing and intelligent processes are key to improving production efficiency and product quality. By integrating digital, automated, and intelligent technologies, the entire aluminum shell production process can be optimized for greater efficiency, precision, and sustainability.

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): CAD software allows engineers to create accurate structural designs and optimizations for aluminum shells, improving the quality of product design and manufacturing precision. CAM software converts designs into actionable manufacturing workflows, automating every stage of production for greater efficiency.

Additive Manufacturing (3D Printing): Additive manufacturing (3D printing) is an important emerging technology in aluminum shell production. This technology builds up material layer by layer, allowing for the production of complex shapes and customized parts. 3D printing is particularly advantageous for small-batch production and customization, enabling aluminum shells to be produced with less material waste, lower energy consumption, and greater design flexibility.

Digital Twin: Digital twin technology creates a virtual model of the aluminum shell production process, simulating and optimizing every stage of production. This enables real-time monitoring, process optimization, and predictive maintenance, helping to streamline the entire manufacturing process.

2.2 The Role of Big Data and Artificial Intelligence

Big Data and Artificial Intelligence (AI) have an important role to play in aluminum shell manufacturing, enabling real-time monitoring, quality optimization, and predictive maintenance.

Production Data Analysis: By using sensors and IoT technology, vast amounts of production data can be collected in real-time and analyzed. AI algorithms can identify potential issues in production, such as equipment failures, process deviations, or material defects, enabling quick adjustments to maintain high-quality standards.

Intelligent Quality Control: With AI combined with image recognition technologies, real-time quality inspection can be automated during aluminum shell production. AI systems can automatically detect surface flaws, dimensional deviations, and other quality issues, ensuring that only high-quality products are produced.

Predictive Maintenance: AI algorithms can analyze data from equipment sensors to predict when maintenance is needed, helping manufacturers perform preventive maintenance and reduce downtime, minimizing costly production disruptions.

2.3 Establishing Smart Production Lines

Smart production lines integrate automated systems, intelligent devices, and real-time monitoring technologies to optimize aluminum shell production. Compared to traditional production lines, smart manufacturing lines offer several advantages:

Automation and Robotics: Robots and automated machinery play a central role in smart production lines. They handle repetitive tasks, ensure precise and consistent quality, and reduce human error in the manufacturing process.

Flexible Manufacturing: Smart production lines can quickly adjust to market demands, enabling flexible production methods that accommodate different designs, batch sizes, and customization requirements. This adaptability allows manufacturers to respond rapidly to consumer preferences.

Green Manufacturing: Smart manufacturing lines are designed to optimize energy usage, reduce material waste, and minimize environmental impact, aligning with global sustainability goals.

3. Application Prospects of Aluminum Shells in Various Industries

3.1 Consumer Electronics

In the consumer electronics sector, aluminum shells have become a key feature of high-end, lightweight, and durable devices. As consumer demand for sleeker, more efficient electronics continues to rise, the use of aluminum shells is expected to grow.

Lightweight and Heat Dissipation: Aluminum shells are ideal for electronics such as smartphones, laptops, and tablets due to their light weight and ability to efficiently dissipate heat. As electronic devices continue to evolve, aluminum’s role in providing thermal management and impact resistance will only become more significant.

Personalization and Customization: With the advent of 3D printing and digital manufacturing technologies, aluminum shells can be customized to meet individual consumer preferences. Personalized designs, colors, and features are becoming increasingly popular, giving consumers more control over the appearance and functionality of their devices.

3.2 Automotive Industry

In the automotive sector, particularly with the rise of electric vehicles (EVs), the use of aluminum shells is on the rise. Aluminum alloys are integral to reducing vehicle weight, improving fuel efficiency, and enhancing safety.

Lightweight Vehicle Bodies: To improve fuel efficiency and reduce emissions, automotive manufacturers are using aluminum for car bodies and components. Aluminum’s lightweight properties help decrease overall vehicle weight and improve safety during collisions.

Battery Housings for Electric Vehicles: Aluminum shells are increasingly used in the housing of electric vehicle batteries due to aluminum’s excellent thermal properties and strength, offering protection to the battery cells from external forces and overheating.

3.3 Aerospace Industry

Aluminum alloys are essential in aerospace, where the demands for light weight, strength, and resistance to extreme conditions are paramount. Aircraft and spacecraft use aluminum shells to maintain structural integrity while minimizing weight.

Lightweight Design: Aluminum’s light weight makes it the perfect material for aircraft and spacecraft, helping to reduce fuel consumption and increase operational efficiency.

Corrosion Resistance and Strength: Aluminum alloys provide excellent resistance to corrosion, particularly in extreme temperatures and high-pressure environments, ensuring the safety and durability of aerospace structures.

4. Future Trends in Aluminum Shell Manufacturing

4.1 Additive Manufacturing and Personalization

As additive manufacturing (3D printing) technology continues to evolve, aluminum shell production will shift towards greater levels of customization and personalization. 3D printing allows for the production of more complex, intricate designs with fewer material requirements, enabling manufacturers to cater to niche markets and small-batch production.

4.2 Intelligent Manufacturing and Automation Upgrades

The future of aluminum shell manufacturing lies in greater intelligence and automation. Production lines will integrate IoT, Big Data, and AI, creating self-optimizing, adaptive systems that can quickly respond to consumer demand, provide high-quality products, and reduce waste.

4.3 Environmental Sustainability and Green Manufacturing

As global attention on environmental sustainability increases, aluminum shell manufacturing is moving toward greener, more sustainable practices. Reducing energy consumption, improving production processes, and promoting material recycling will become core objectives for manufacturers.

Conclusion

The smart manufacturing wave is driving aluminum shell production toward greater efficiency, precision, and sustainability. With the continued integration of AI, Big Data, IoT, and 3D printing, the aluminum shell manufacturing process is being revolutionized. As the demand for high-quality, lightweight, and durable products grows across industries such as electronics, automotive, and aerospace, the role of aluminum shells will expand. Through technological innovation and sustainable practices, the aluminum shell manufacturing industry is poised to embrace new opportunities and challenges, ensuring a bright and innovative future.

0 notes

Text

How GM 4L80E Transmissions Stay Reliable Across Any Power Level Or Engine Pairing?

When it comes to automotive excellence, the 4L80E stands out as one of the most robust and versatile transmissions ever designed by General Motors. From its ability to handle immense power levels to its adaptability with various engine pairings, the 4L80E automatic transmission has become a favorite among enthusiasts and professionals alike. This blog explores what makes this transmission a powerhouse in reliability and performance.

GM 4L80E—A Transmission Built to Last

The 4L80E is a heavy-duty, electronically controlled four-speed automatic transmission introduced by GM in the early 1990s. Designed as a successor to the Turbo-Hydramatic 400 (TH400), the 4L80E automatic transmission incorporates advanced engineering and robust components, making it a benchmark for durability and power-handling capabilities. Built for vehicles requiring extreme reliability, this transmission remains a top choice for high-performance and towing applications.

Why the 4L80E is Known for Durability

Durability is the hallmark of the 4L80E. Engineered with heavy-duty components, including a die-cast aluminum case and reinforced clutch assemblies, this transmission can withstand up to 800 horsepower and 700 ft-lbs of torque in its Level 4 performance iteration. Key features like heat-treated input shafts, expanded clutch capacity, and advanced reprogramming kits contribute to its long-lasting reliability, even under the harshest conditions.

The 4L80E automatic transmission incorporates innovations like updated boost valves, heavy-duty intermediate sprags, and blueprinted pumps, ensuring smooth operation and resistance to wear over time.

The Power of Adaptability: Handling Different Engine Pairings

One of the standout features of the 4L80E is its remarkable adaptability. Whether paired with a high-torque diesel engine or a high-revving gasoline V8, this transmission excels across a broad spectrum of engine types. Its flexibility stems from an advanced design that includes a custom-built lock-up billet racing converter and a wide range of custom stall speeds (2800–3400 RPM). This versatility ensures seamless compatibility with diverse powertrains, making it a go-to choice for swaps and performance builds.

Built for Power: Performance Across Multiple Power Levels

Designed to handle significant power, the 4L80E automatic transmission is a favorite for enthusiasts pushing their vehicles to the limit. With features like a Master Overhaul Kit, Raybestos Stage I frictions, and expanded clutch capacity, this transmission can handle extreme stress without compromising performance. Its ability to manage power levels ranging from stock applications to 800 horsepower makes it an industry leader in versatility and reliability.

Innovative Design Elements of the GM 4L80E

The 4L80E boasts a range of innovative features that contribute to its reliability and performance, such as:

Custom-Built Components: Including a billet racing converter and heat-treated input shafts.

Enhanced Friction Materials: Raybestos Stage I frictions ensure durability under high pressure.

Improved Valve Body and Solenoids: Advanced control systems like Transgo Reprogramming Kits and new EPC solenoids ensure precise shifting.

Reinforced Internals: Updated molded steel clutch pistons and heavy-duty sprags enhance overall strength.

Making the Right Choice

For those seeking the best in performance and reliability, the 4L80E remains a top contender. When investing in a transmission, it’s essential to choose a trusted provider. Gearstar stands out as one of the leading suppliers of high-performance 4L80E transmissions. Gearstar’s Level 4 transmission package is tailored for enthusiasts looking to harness up to 800 horsepower with confidence. This package includes:

Custom-built lock-up billet converters

Heat-treated shafts

Upgraded clutch assemblies

Blueprinted pumps and valve bodies

Gearstar’s meticulous craftsmanship and attention to detail make them the ideal choice for upgrading your transmission or ensuring your next build achieves its full potential.

Conclusion

The 4L80E continues to dominate the automotive transmission market thanks to its unparalleled durability, adaptability, and ability to handle extreme power levels. Whether you're swapping engines or looking to enhance your vehicle's performance, the 4L80E automatic transmission is a dependable choice. Backed by providers like Gearstar, this transmission is built to exceed expectations, making it a reliable partner for any automotive enthusiast.

0 notes

Text

Mold design experience (serial one)

1. Height of slider guide rail must be at least 1/3 of slider height to ensure stability of slider and smooth sliding.2. Pay attention to opening lubrication grooves in locations with sliding friction. In order to prevent lubricating oil from flowing out, it is not advisable to make grooves “open” but should be “closed”. Generally, they can be milled out directly on a milling machine with a…

View On WordPress

#casting solidification process#die-cast differential castings#die-casting defects#die-casting forming process#Die-casting mold#die-casting process#high-pressure die-cast aluminum alloy differentials#high-pressure die-casting process

0 notes

Text

Forge Ahead with Virat’s H13Steel!

Virat Special Steels takes pride in offering high-quality Aluminium Extrusion Die Steel H13 Steel – a true pinnacle of durability and performance in every extrusion process.

Application Areas:🔧

Die Casting: H13 (DIN 1.2344) Steel is highly recommended for aluminum pressure die casting due to its exceptional performance under high working temperatures and pressure.

Forging Dies: It withstands rapid cooling and early heat testing, making it suitable for forging applications.

Plastic Moulds: H13 is used in injection molding with high polishability.

Quality Assurance:✅ Virat Special Steels ensures that H13 (DIN 1.2344) steel is fully ultrasonic inspected with 100% positive results as per NDT standards. It meets the requirements for safety and reliability.

Expertise and Inventory: With over five decades of experience, Virat Special Steels has a reputation for providing accurate and timely service. We maintain ready stock in their steel yards, offering immediate availability.

Choose VIRAT SPECIAL STEELS PVT. LIMITED , INDIA for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more! https://www.viratsteels.com/h13.html https://www.viratsteel.in/materials/aluminium-extrusion-die-steel-supplier-in-india/

Aluminium Extrusion Die Steel Supplier in India -Virat Special Steels Choose Virat Special Steels for your #AluminiumExtrusion #DieSteel needs, and experience quality and reliability!

Any further queries feel free to contact us : 🌐https://www.viratsteels.com 📬 [email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#h13diesteels#h13steel#din 2344#AluminiumExtrusion#SpecialSteel#SteelTrades#MetalTraders

4 notes

·

View notes

Text

Hydraulic rubber tubing - injecting long-lasting power for high-intensity operations**

**Core advantages, defining industry standards**

✔ ** Super strong pressure resistance: Multi layer high tension steel wire weaving, with a pressure bearing capacity of up to 60MPa, easily coping with extreme working conditions and eliminating the risk of pipe bursting.

✔ ** Universal protection * *: Imported synthetic rubber+wear-resistant outer layer, resistant to oil stains, corrosion, high and low temperatures (-40 ℃ to+120 ℃), and stable performance in complex environments.

✔ ** Flexible and Flexible: With patented winding technology, the bending radius is small, and there are no dead corners during installation, ensuring smooth hydraulic transmission even during dynamic operations.

**Strict scenarios, witness reliable quality**

* * * Construction Machinery * *: The hydraulic system of excavators and cranes operates accurately, ensuring uninterrupted continuous construction.

• * * Agricultural equipment * *: Tractors and harvesters stably deliver power in muddy and vibrating conditions, doubling efficiency during busy farming seasons.

In the industrial field, injection molding machines and die-casting machines can maintain long-lasting sealing under high temperature and pressure environments, reducing downtime losses.

**Accurate parameters, matching professional needs**

⊙ Diameter range: 6mm-50mm

Work pressure: 25MPa-60MPa (optional for customized high-pressure models)

Certification standards: ISO1436, SAE100R series, in compliance with GB/T3683 national standard.

#hose#hydraulichose#manufecturerhydraulichose

0 notes

Text

Core Pins: Essential for Precision Molding & Die Casting

What is a Core Pin?

A core pin is a precision-machined metal component used in die casting, plastic injection molding, and metal fabrication to form internal holes, cavities, or intricate features in molded parts. These pins play a crucial role in ensuring accuracy and consistency in manufacturing.

Types of Core Pins

🔹 Standard Core Pins – Used for basic hole formation. 🔹 Shoulder Core Pins – Provide precise positioning inside molds. 🔹 Tapered Core Pins – Allow easy removal and reduce wear. 🔹 Ejector Core Pins – Assist in ejecting the molded part. 🔹 Custom Core Pins – Designed for unique manufacturing needs.

Materials Used

Core pins must withstand extreme heat, pressure, and wear, making tool steel (H13, D2, S7), carbide, and stainless steel the most commonly used materials. Special coatings like TiN (Titanium Nitride) enhance durability and reduce friction.

Applications of Core Pins

✅ Die Casting – Creates cavities in metal parts (automotive, aerospace). ✅ Plastic Injection Molding – Forms internal features in plastic products. ✅ Medical & Aerospace – Used in precision manufacturing of critical components.

Why Core Pins Matter

✔ High precision & accuracy ✔ Improved production efficiency ✔ Durability for long-term use

Choosing the right core pin ensures smoother manufacturing, fewer defects, and cost-effective production.

Looking for high-quality core pins? Explore Raga Group’s Core Pins for durable, precision-engineered solutions!

0 notes

Text

Understanding Die Casting: Hot and Cold Chamber Techniques

Die casting is a method of manufacturing which involves forcing molten metal under high pressure into a mold cavity. This is one of the most widely applied techniques in producing complex shapes of high precision with excellent surface finishes in many industrial applications. Among the several methods of die casting, hot chamber die casting and cold chamber die casting are two major types that have unique benefits and uses. In this paper, we are going to explain these two in detail, how they differ, and what is used for which purpose in the modern manufacturing process.

0 notes

Text

Die Casting: The Ultimate Manufacturing Solution

In the world of modern manufacturing, die casting is a widely used process that ensures precision, durability, and cost-effectiveness. From automotive components to consumer electronics, die casting plays a crucial role in producing high-quality metal parts with excellent surface finishes and structural integrity.

What is Die Casting?

Die casting is a metal casting process that involves forcing molten metal into a mold cavity under high pressure. The molds, also known as dies, are made from high-grade steel and designed to create complex shapes with extreme accuracy. This process is ideal for producing lightweight yet strong metal parts in high volumes.

Benefits of Die Casting

High Precision & Complexity – Die casting allows for intricate designs with tight tolerances, making it ideal for detailed metal components.

Superior Strength & Durability – Casted parts have excellent mechanical properties, ensuring long-lasting performance.

Cost-Effective Production – Since die casting supports high-volume production with minimal material waste, it is a cost-efficient manufacturing method.

Smooth Surface Finish – Components require little to no post-processing, reducing production time and costs.

Industries That Rely on Die Casting

Automotive – Used for engine blocks, transmission cases, and structural components.

Aerospace – Helps manufacture lightweight yet durable aircraft components.

Electronics – Essential for heat sinks, connectors, and enclosures.

Industrial Machinery – Used in making heavy-duty parts for various industrial applications.

Get High-Quality Die Casting Solutions

For top-quality die casting solutions, visit Gupta Permold Corporation. They specialize in manufacturing precision die-cast parts for various industries, ensuring strength, efficiency, and cost-effectiveness.

Enhance your manufacturing process today with premium die casting services from Gupta Permold Corporation!

0 notes

Text

Aluminum Die Casting Manufacturers in China: A Comprehensive Overview

China is one of the largest global hubs for aluminum die casting, producing high-quality components for various industries such as automotive, aerospace, electronics, and consumer goods. The country’s manufacturers are known for their ability to deliver cost-effective, durable, and precisely engineered products. If you’re considering partnering with aluminum die casting manufacturers in China, this guide will provide insights into the industry, its advantages, and how to find the right supplier.

What is Aluminum Die Casting?

Aluminum die casting is a manufacturing process where molten aluminum is injected into a mold or die under high pressure. The metal solidifies quickly, forming strong and lightweight components with detailed features. Aluminum is particularly valued for its corrosion resistance, excellent thermal conductivity, and versatility, making it a popular choice for die casting.

Why Choose Chinese Aluminum Die Casting Manufacturers?

China has become a leading player in aluminum die casting for several reasons:

1. Cost-Effective Production

Labor costs in China are generally lower compared to many Western countries. Combined with efficient manufacturing processes and economies of scale, this allows Chinese manufacturers to offer competitive pricing without compromising on quality.

2. Advanced Technology

Many aluminum die casting manufacturers in China have invested heavily in modern equipment and automation. This ensures precision, consistency, and high production efficiency.

3. Large-Scale Production Capacity

Chinese factories are equipped to handle large orders, making them ideal for businesses requiring bulk production of aluminum die-cast parts.

4. Expertise and Experience

With decades of experience, many Chinese manufacturers have honed their skills in aluminum die casting. They are capable of producing parts with complex geometries and meeting international quality standards.

5. Customization

Chinese manufacturers often provide extensive customization options, allowing businesses to create components tailored to their specific needs.

Industries Served by Aluminum Die Casting in China

Chinese manufacturers serve a wide range of industries, including:

Automotive Aluminum die-cast parts like engine components, transmission housings, and wheel hubs are crucial for lightweight and fuel-efficient vehicles.

Electronics Aluminum is used in components such as heat sinks, enclosures, and connectors, providing thermal management and durability.

Aerospace The aerospace industry requires lightweight and strong parts, and aluminum die casting delivers components that meet these stringent requirements.

Consumer Goods Items such as furniture frames, kitchenware, and decorative pieces often rely on aluminum die casting for their strength and aesthetic appeal.

Finding the Right Aluminum Die Casting Manufacturer in China

Choosing the right supplier is critical to the success of your project. Here are steps to help you find a reliable aluminum die casting manufacturer in China:

1. Research the Market

Start by researching manufacturers online. Websites, industry directories, and trade platforms like Alibaba and Made-in-China provide detailed profiles of suppliers.

2. Check Certifications

Look for manufacturers with relevant certifications, such as ISO 9001 (Quality Management) or IATF 16949 (for automotive parts). These ensure the supplier meets international quality standards.

3. Evaluate Production Capabilities

Consider the manufacturer’s capacity to handle your order volume and complexity. Ask about their equipment, production lines, and ability to meet deadlines.

4. Request Samples

Before committing, request samples of their work. This will help you assess the quality of their aluminum die-cast products and gauge their craftsmanship.

5. Assess Communication

Choose a manufacturer with clear and responsive communication. Misunderstandings can lead to costly mistakes, so working with a supplier who understands your needs is essential.

6. Visit the Facility

If possible, visit the factory to see their operations firsthand. This will give you confidence in their capabilities and help build a stronger relationship.

7. Consider Shipping and Logistics

Ensure the manufacturer has experience in international shipping and can handle export documentation efficiently.

Advantages of Partnering with Chinese

1. Competitive Pricing

China’s cost advantages make it an attractive option for businesses looking to save on production costs.

2. Quality Assurance

Many manufacturers have stringent quality control measures in place to deliver parts that meet global standards.

3. Fast Turnaround Time

With their efficient production processes, Chinese suppliers often offer shorter lead times compared to other regions.

4. Innovation and Flexibility

Manufacturers in China are quick to adopt new technologies and processes, providing innovative solutions and the flexibility to adapt to unique project requirements.

5. Strong Global Supply Chain

China’s extensive supply chain infrastructure supports the seamless sourcing of raw materials and delivery of finished products.

Top Aluminum Die Casting Hubs in China

Some of the key regions in China known for aluminum die casting include:

Guangdong Province A hub for electronics and automotive parts manufacturing, Guangdong is home to many advanced die casting companies. Aluminum Die Casting

Zhejiang Province Known for its extensive industrial base, Zhejiang offers a wide range of aluminum die-cast products.

Jiangsu Province This region is renowned for its high-tech manufacturing and focus on quality.

Shanghai As a global trade center, Shanghai provides access to manufacturers with international experience and expertise.

Aluminum die casting manufacturers in China have established themselves as global leaders in the industry, offering high-quality, cost-effective, and customizable solutions. With their advanced technology, large-scale production capacity, and commitment to quality, Chinese suppliers are an excellent choice for businesses looking to source aluminum die-cast parts.

By conducting thorough research and choosing the right partner, you can leverage the strengths of Chinese manufacturers to meet your production needs and stay competitive in your industry. Visit best Chinese die casting company’s website for more details.

0 notes