#high voltage testing services

Explore tagged Tumblr posts

Text

Are you in search of reliable high voltage testing, commissioning, and maintenance services in Melbourne? Look no further! ProT Assist is your go-to partner for all your high voltage needs. With our expertise and dedication, we ensure the utmost safety and efficiency in managing high voltage systems.

Our team of skilled professionals specializes in high voltage testing, commissioning, and maintenance, catering to a wide range of industries in Melbourne. We understand the criticality of power quality monitoring and provide comprehensive solutions to optimize your electrical infrastructure's performance.

At ProT Assist, we prioritize safety above all else. Our stringent quality control measures and cutting-edge equipment guarantee accurate and reliable results for every project. Whether you require routine maintenance, testing for compliance, or system commissioning, our experienced technicians are equipped to handle it all.

When it comes to high voltage services in Melbourne, ProT Assist stands out for its exceptional customer service and industry-leading expertise. Trust us to keep your electrical systems running smoothly and safely, ensuring uninterrupted power supply and reducing the risk of downtime.

Contact ProT Assist today and experience our reliable high voltage solutions tailored to meet your specific needs.

#high voltage commissioning#high voltage maintenance#high voltage testing services#hv testing and commissioning#power quality monitoring

1 note

·

View note

Text

0 notes

Text

Power engineering services perth

Unlock the potential of your energy projects with our expert power engineering services Perth! We're dedicated to providing innovative solutions that optimize efficiency and drive sustainability, ensuring your infrastructure meets the demands of tomorrow. Let us help you power a greener future with our tailored engineering strategies designed for every scale. Together, we can illuminate possibilities and energize success in the vibrant city of Perth! Your energy transformation starts here.

#power engineering services perth#electrical commissioning & testing#electrical earthing system#high voltage circuit breaker maintenance

0 notes

Text

Athletes Go for the Gold with NASA Spinoffs

NASA technology tends to find its way into the sporting world more often than you’d expect. Fitness is important to the space program because astronauts must undergo the extreme g-forces of getting into space and endure the long-term effects of weightlessness on the human body. The agency’s engineering expertise also means that items like shoes and swimsuits can be improved with NASA know-how.

As the 2024 Olympics are in full swing in Paris, here are some of the many NASA-derived technologies that have helped competitive athletes train for the games and made sure they’re properly equipped to win.

The LZR Racer reduces skin friction drag by covering more skin than traditional swimsuits. Multiple pieces of the water-resistant and extremely lightweight LZR Pulse fabric connect at ultrasonically welded seams and incorporate extremely low-profile zippers to keep viscous drag to a minimum.

Swimsuits That Don’t Drag

When the swimsuit manufacturer Speedo wanted its LZR Racer suit to have as little drag as possible, the company turned to the experts at Langley Research Center to test its materials and design. The end result was that the new suit reduced drag by 24 percent compared to the prior generation of Speedo racing suit and broke 13 world records in 2008. While the original LZR Racer is no longer used in competition due to the advantage it gave wearers, its legacy lives on in derivatives still produced to this day.

Trilion Quality Systems worked with NASA’s Glenn Research Center to adapt existing stereo photogrammetry software to work with high-speed cameras. Now the company sells the package widely, and it is used to analyze stress and strain in everything from knee implants to running shoes and more.

High-Speed Cameras for High-Speed Shoes

After space shuttle Columbia, investigators needed to see how materials reacted during recreation tests with high-speed cameras, which involved working with industry to create a system that could analyze footage filmed at 30,000 frames per second. Engineers at Adidas used this system to analyze the behavior of Olympic marathoners' feet as they hit the ground and adjusted the design of the company’s high-performance footwear based on these observations.

Martial artist Barry French holds an Impax Body Shield while former European middle-weight kickboxing champion Daryl Tyler delivers an explosive jump side kick; the force of the impact is registered precisely and shown on the display panel of the electronic box French is wearing on his belt.

One-Thousandth-of-an-Inch Punch

In the 1980s, Olympic martial artists needed a way to measure the impact of their strikes to improve training for competition. Impulse Technology reached out to Glenn Research Center to create the Impax sensor, an ultra-thin film sensor which creates a small amount of voltage when struck. The more force applied, the more voltage it generates, enabling a computerized display to show how powerful a punch or kick was.

Astronaut Sunita Williams poses while using the Interim Resistive Exercise Device on the ISS. The cylinders at the base of each side house the SpiraFlex FlexPacks that inventor Paul Francis honed under NASA contracts. They would go on to power the Bowflex Revolution and other commercial exercise equipment.

Weight Training Without the Weight

Astronauts spending long periods of time in space needed a way to maintain muscle mass without the effect of gravity, but lifting free weights doesn’t work when you’re practically weightless. An exercise machine that uses elastic resistance to provide the same benefits as weightlifting went to the space station in the year 2000. That resistance technology was commercialized into the Bowflex Revolution home exercise equipment shortly afterwards.

Want to learn more about technologies made for space and used on Earth? Check out NASA Spinoff to find products and services that wouldn’t exist without space exploration.

Make sure to follow us on Tumblr for your regular dose of space!

2K notes

·

View notes

Text

Body a Day 21: Electricity

Despite already slithered itself into a human body, the alien still carried along its original power to numb the body of its target with low voltage electricity. Practically, the alien's old body is electric when it feels threatened, but being inside a human, the alien can regulate the power better and only use it when it's about to move into another body. That's exactly what the alien intended to do when he hooked up with this Grindr hunk it managed to lure to its trap. Looking like a cute, subservient snack, the oblivious hunk accepted the offering to get worshipped and let the supposedly weaker male serviced him. The moment the alien placed its human hand on the hunk's body, jolt of electricity surprised and eventually paralyzed the guy. The touch to his head and kisses right on the mouth the alien planted earlier also managed to reduce the hunk's brain operational capacity to resist and now, he's nothing but a tased meat ready to embrace the new controller of his body

If the hunk is everything as he described, than the alien will land a rather fine jackpot as he's still single with a high-paying job as a PR manager and lived in a high-rise Manhattan 3 bedroom apartment courtesy of his rich parents that inherited their wealth to him. Surely with such connection and wealth, the alien can move around other bodies in similar level of prestige and class if he find another exciting men. He can also be more experimental and test out how electric his touch is to more subjects, after all, like moth drawn to lights, more people will easily drawn to him when he's inside a bonafide hunk with shit-tons amount of money to waste

228 notes

·

View notes

Text

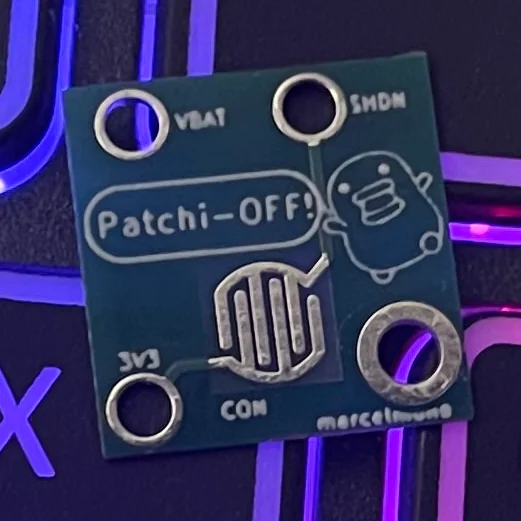

Tamagotchi Uni Circuit Board Power Off Switch

The Tamagotchi community is filled with some of the most creative people! You already saw that Orange_night on Reddit modified their Tamagotchi Uni to feature a power off switch, well now another member of the community has also created a solution.

Marcelmono on Reddit has just announced that they have created a little circuit board that will allow your Tamagotchi Uni to fully power off! Marcelmono was Abel to research the Tamagotchi Uni schematics and looked up the power-regulating chips specification to figure it all out. The modification will require some soldering to install what they’re calling the “Patchi-OFF!” board.

How does it work exactly? Well here’s the technical jargon provided from Marcelmono:

Test points are accessible pads outside of a circuit in order test the function of said circuit after manufacturing.

A chip on the Uni that regulates power has a pin/input named “SHDN” (Shutdown).

The variant of the chip the Uni uses needs a “high” voltage applied to the “SHDN” pin to initiate the shutdown.

By connecting the 3V3 (3,3 Volt) test point to the SHDN test point, a “high” voltage is applied to the chips “SHDN”-pin/input and it shuts down the Uni.

The Patchi-OFF! board connects those two test points, but only if the conductive pad on the bottom of the rubber reset button presses down on the contacts on the board and completes the circuit.

Marcelmono is selling both the Patchi-OFF! Tamagotchi Uni Shutdown button circuit board for €7, and a Tamagotchi Uni Patchi-OFF! Shutdown button installation service on your existing Tamagotchi Uni for €25! Both are available on Marcel’s Tama Spa & Repair Ko-Fi page.

#tamapalace#tamagotchi#tmgc#tamagotchiuni#tamagotchi uni#uni#tamatag#virtualpet#bandai#marcelmono#reddit#kofi#offswitch#off switch#mod#modification

92 notes

·

View notes

Text

Acer Aspire AC14B7K 41CP5/57/80 ES1-111 ES1-131 ES1-331 ES1-511 ES1-512 ES1-520 ES1-521 ES1-531 ES1-571 ES1-572 ES1-711 ES1-731 Series, PN: AC14B3K AC14B8K AC14B7K Original Laptop BatterySupport LaptopsBattery For Acer Aspire AC14B7K 41CP5/57/80 ES1-111 ES1-131 ES1-331 ES1-511 ES1-512 ES1-520 ES1-521 ES1-531 ES1-571 ES1-572 ES1-711 ES1-731 Series, PN: AC14B3K AC14B8K AC14B7K

বর্তমানে আইটি পণ্যের দাম স্থিতিশীল না থাকায়, ওয়েবসাইটে দেয়া পণ্যের মূল্য বাড়তে পারে।

Battery Type: Internal

Cell Number: 4 Cells

Cell Type: Li-Polymar

Battery Voltage: 15.2V (Note: Please make sure the voltage of your original battery is 15.2V before you order. It will NOT fit for your laptop if the original battery is 11.4V.)

Battery Capacity: 2200mAh

Attention: Laptop Battery 14.4V, 14.8V and 15.4 are in common use.

You can expect about 2-4 hours hours of run time with this battery when new, depending on your energy use. OEM Battery has all the same functions as the original battery, made from the highest quality cells, excellent quality and cheap price with the best service. Selected high-performance Li-ion batteries from manufacturer. All batteries are tested for 100% quality control assurance. Choose this excellent battery for your laptop!

Battery Type: Internal Cell Number: 4 Cells Cell Type: Li-Polymar Battery Voltage: 15.2V (Note: Please make sure the voltage of your original battery is 15.2V before you order. It will NOT fit for your laptop if the original battery is 11.4V.) Battery Capacity: 2200mAh Attention: Laptop Battery 14.4V, 14.8V and 15.4 are in common use. You can expect about 2-4 hours hours of run time with this battery when new, depending on your energy use. OEM Battery has all the same functions as the original battery, made from the highest quality cells, excellent quality and cheap price with the best service. Selected high-performance Li-ion batteries from manufacturer. All batteries are tested for 100% quality control assurance. Choose this excellent battery for your laptop!

Compatible part number -: AC14B7K 4ICP5/57/80 KT.00407.006 KT.00407.003 Laptop Battery

Compatible models -: for Acer Swift 3 SF314-52 SF314-54 SF314-54G SF314-56 Series Notebook Battery.

2 notes

·

View notes

Text

Ensuring Reliability and Safety: The Importance of Quality Traction Converters and Connectors in Railways

Introduction

The modern railway industry is evolving at a rapid pace, with advancements in technology playing a crucial role in enhancing efficiency, sustainability, and safety. Among the many components that contribute to the seamless functioning of a railway system, traction converters and connectors stand out as vital elements. This blog explores the significance of quality railway traction converter manufacturer and railway traction connector manufacturer in ensuring the reliability and safety of railway operations, with a specific focus on manufacturers in this domain.

Railway Traction Converters: The Powerhouses of Rail Mobility

Railway traction converters manufacturers play a pivotal role in the electrification of trains. These devices are responsible for converting electrical power from the grid into the appropriate form for the efficient and controlled movement of trains. As the demand for electrified rail systems grows, the role of railway traction converters manufacturers becomes increasingly critical.

Advancements in Traction Converter Technology

Leading manufacturers in the field of railway traction converters are at the forefront of innovation. They constantly strive to develop converters that are not only more efficient but also environmentally friendly. The integration of cutting-edge technologies, such as regenerative braking systems and advanced power electronics, contributes to the reduction of energy consumption and environmental impact.

Reliability Challenges and Solutions

Ensuring the reliability of traction converters is paramount for the uninterrupted operation of rail services. Manufacturers invest significantly in research and development to address challenges related to overheating, voltage fluctuations, and system failures. Robust testing procedures and quality assurance measures are implemented to guarantee the reliability of these critical components.

Railway Traction Connectors: Linking Efficiency and Safety

Railway traction connectors play a crucial role in ensuring the seamless transmission of power between various components of the rail system. These connectors serve as the interface between the traction converter and the train, facilitating the efficient transfer of electrical energy for propulsion.

Key Considerations in Connector Design

Manufacturers specializing in railway traction connectors prioritize several key considerations in their design and production processes. These include factors such as durability, weather resistance, and ease of maintenance. The harsh operating conditions that railways often face, including exposure to extreme weather and mechanical stress, necessitate connectors that can withstand such challenges without compromising performance.

Innovations in Connector Technology

In response to the evolving needs of the railway industry, manufacturers are continually innovating their connector designs. The integration of smart technologies, such as sensor-equipped connectors capable of real-time monitoring, enhances the safety and reliability of railway operations. These innovations contribute to the prevention of malfunctions and enable proactive maintenance measures.

Post Insulator for Railways: Ensuring Electrical Isolation and Safety

Post insulators for railways are critical components in railway electrification systems, providing electrical insulation and preventing current leakage. They play a crucial role in ensuring the safety of both passengers and railway personnel.

Importance of Quality Insulators

Railway electrification systems are subject to high voltage, and the quality of post insulators is paramount in maintaining electrical isolation. High-quality insulators prevent flashovers and electrical breakdowns, reducing the risk of accidents and disruptions. Manufacturers specializing in post insulators for railways adhere to stringent quality standards to meet the safety requirements of modern rail systems.

Challenges in Insulator Performance

The performance of post insulators can be affected by various factors, including environmental conditions, pollution, and mechanical stress. Manufacturers address these challenges through the use of advanced materials and coatings that enhance insulator resistance to environmental factors. Ongoing research and development efforts focus on improving the longevity and reliability of post insulators.

Choosing the Right Manufacturers: A Key to Reliability and Safety

Selecting reliable and experienced manufacturers is crucial for railway operators looking to ensure the longevity and safety of their electrified rail systems. Whether it is traction converters, connectors, or post insulators, the expertise and commitment of manufacturers significantly impact the performance of these components.

Key Criteria for Manufacturer Selection

Railway operators should consider several key criteria when choosing traction converter, connector, and post insulator manufacturers. These include a proven track record, adherence to industry standards, the use of advanced technologies, and a commitment to continuous improvement. Collaborating with reputable manufacturers enhances the likelihood of deploying systems that meet or exceed safety and reliability expectations.

Conclusion

In conclusion, the reliability and safety of railway systems depend heavily on the quality of traction converters, connectors, and post insulators. Manufacturers in these domains play a critical role in advancing technology to meet the evolving needs of the railway industry. As electrification becomes more prevalent, ensuring the highest standards in the design, production, and maintenance of these components is essential for the seamless, efficient, and safe operation of rail networks worldwide.

#Post Insulator For Railways#Railway Traction Converter Manufacturers#India#Railway Traction Connectors Manufacturers#railway#third rail#locomotive#tram#metro#railway engine

7 notes

·

View notes

Text

The Truth the Whole Truth

But nothing is the truth.

I have been meditating on the eternal dichotomy of tubes versus transistors. In my opinion the big difference is in power amplifiers.

Small signal devices as in preamplifiers in class A operation are not so different in either glass or solid state. But in power amplifiers the difference is significant and is the cause behind the wars between the tribes.

First up is for high quality devices the differences are small. And neither is best. Though I do lean towards solid state for being more accurate.

So I meditate on nanoseconds and feedback. No device is free from distortion. That is just another way of saying they are not perfect. An excellent method to reduce distortion is feedback, or if you like to stand on your head feed forward.

The idea is simple. Compare what you get at the output to the input. If there is a difference other than magnitude subtract it (negative feedback) or add the inverse by way of a perfect small signal amplifier. (feed forward see that THX patent or the old QUAD amp) Either way is a correction signal. Fix the error.

Some people fret over the idea that if you correct an input that passes through the same imperfect device it is never right. Some people will claim that making a device with no correction signal is an obvious choice. It only has to be perfect.

All of my power amps have negative feedback. All told I have 4 of those. 3 are solid state and 1 is tube. Just in terms of wire and the speed of light it takes about a bit over a nanosecond for the correction signal to get from the output to the input. A nanosecond is a billionth of a second. That inverts to a frequency of gigahertz. None of my amps go to gigahertz so that gap would get lost no? It is effectively no delay at all.

A tube amp is special though. All production tube amps have output transformers. Small signal class A devices do not need output transformers so they are not that different. Power Tubes are high voltage and speakers are low voltage (except for electrostatics) so you need an impedance matching device, a transformer. And 99 times out of 100 the correction signal is pulled off the secondary winding which is many feet of wire and loops of magnetic flux away from the power tube. As magnetic flux is involved and all sorts of black magic and differential equations you also get phase issues as well as other things which makes the feedback a bit weird and always off a bit. Oh the test instruments show things as better, but not quite right to human ears.

I can hear the effect. My high end tube amp masks tiny little details my brute of a transistor amp is quite happy to reveal. BUT the tube amp paints lovely colors over the signal. I do mean lovely, rich, and very attractive textures. It is a shame they are not real, but I like them. That in the end is the difference. I know they are not real. I know those tiny sounds are there under the nice colors.

That is why the transistor amp is more accurate. The tube amp is prettier sounding. If both were perfect they would sound exactly the same.

I have the advantage of not adhering to either side of the hostile argument. I have both. Also when I put the black Franken-Amp back in service as the weather warms up it saves the tubes in the glass beast. Rather than one or two years service I should get double whatever is due.

2 notes

·

View notes

Text

Lithium Ion Battery Products of Eco Power

Eco Power Group is more than a lithium battery company. We design, manufactures, and sell advanced lithium-ion energy storage electrification solutions for different types of lithium ion battery.

Our expertise of custom lithium ion battery is based on its know-how in electrochemistry and battery management system to provide safe, efficient and sustainable solutions to various industries such as automotive, commercial transportation, off-highway vehicles/equipment, rail, air, marine, energy storage, solar energy systems, communication equipement, and more.

We are your experienced partner of lithium ion battery wholesale, from the feasibility study to the conception and the final installation with our complete product portfolio.

If you are considering to buy lithium ion battery, we are highly welcome you to consult and cooperate with us.

Different Types of Lithium Ion Battery Products

On-board energy solution at Eco Power Group with complete reference from cell to system to be the best fitting solution for your lithium ion battery types.

Battery Cell

This type of custom lithium ion battery cell is the very basic energy storage unit. Based on many years experience from cell design, battery materials and simulation, we are always at the cutting edge of technology. Our li ion batteries for sale comply with the strict safety standards UN 38.3, which guarantees our customers high quality and safety even after years of operation of charging lithium ion batteries.

Battery Module

In terms of battery modules for different types of lithium ion battery, there we offer standard modules with metal sheet plate for electric vehicle applications, Custom lithium ion battery module with binding tape for energy storage, and VDA size modules for passenger vehicles.

Battery Pack

Standard battery packs for commercial vehicles. Standard battery packs of charging lithium ion batteries in series with DNV certification for marine propulsion. Customized power li ion charging voltage systems for forklift applications ,etc.

Battery Energy Storage System

With a team of experienced engineers, we provide end to end custom lithium ion battery services starting from customer requirement analysis going through battery pack design, testing, prototype production and serial production. During the design phase we focus on the application area requirements as much as the li ion charging voltage battery design itself.

Why Choose The Lithium Ion Battery From Eco Power?

Quality

Our established quality management system of lithium ion battery wholesale, certified according to the international standard DIN EN ISO 9001: 2008, guarantees compliance with our high quality standards.

01

Customised Solution

Customised solutions for lithium ion battery replacement energy storage or mobile applications of electromobility.

02

Experience

As one of the leading lithium ion battery companies, we have more than 10years experience in lithium li ion voltage battery industry with hundreds of different application scenario. With our high quality lithium ion batteries for sale, you can trust us with your project .

03

Technical Support

From customer request input all the way to delivery final different types of lithium ion battery product, we will assign project technical consultant to accompany our customer to solve all of li ion charging voltage questions or problems during the whole process.

04

What Does A Lithium Ion Battery Module Do?

Battery module of li ion batteries for sale contains the energy storing battery cells by laser-welded technology, the mechanically stable against shock demonstrates high productivity and flexibility to make sure the long term performance of li ion charging voltage battery system.

How A Lithium Ion Battery System Works?

A battery system of li ion charging voltage consists of lithium battery cell connected in series to reach the system voltage and parallel to achieve greater capacity.

The li ion battery voltage and capacity can be verified by different combination of packs. The pack contains a fuse and a slave BMS. High security and provide lithium ion cell voltage and temperature to master BMS.

The Lithium-Ion battery system with charging lithium ion batteries in parallel is a composite set of battery electronics, high voltage circuits, overcurrent protection devices, battery boxes and interfaces with other external systems such as cooling, high voltage, auxiliary low voltage and communications.

What Is The Difference Between Lithium Ion Battery Pack And Power Bank?

This kind of battery pack of lithium ion battery types cannot be a power bank, but a power bank can be a li ion battery charging voltage pack with added electronic circuitry to prevent over charging, over discharge, etc to protect the batteries.

A lithium ion battery pack in series is merely a bunch of batteries connected in Series/Parallel configuration with one positive and one negative terminal.

A power bank contains one or more batteries in mostly parallel but could also be a Series/Parallel configuration. These types of li ion batteries for sale are connected to a battery management circuit (module) which controls the charging of the batteries. All this is housed in a compact enclosure.

2 notes

·

View notes

Photo

#Repost #jkubabe28 🤘🏻Thanks to @jsalternators we are about to have high performance output of 400 amps!⠀ ⠀ JS Alternators is a family owned and operated business that is American made with great customer service support to back the product. ⠀ They make and test each alternator and then send them off for a beautiful finished look with powder coating. Don’t see the color you like? ⠀ They can even make custom colors to match your style. ⠀ ⠀ They are not just exclusive to Jeep but make over 30 car makes and models including marine with capability to build any custom alternator to match your build. JS also has a full range of accessories like big 3 kits, adaptable harnesses and voltage regulators to get your ride running smoothly.⠀ ���⠀ Thank you again to this amazing team for sponsoring us! We can NOT wait to get this installed! It’s companies like this that allow us to pursue our dream build and continue our Jeep journey. ⠀ ⠀ #jeepwrangler #jeeps #jeepobsessed #jeepher #jeepnation #girlswithjeeps #4x4life #mopargirls #modmonday #jeepbuild #jsalternators #jkubabe28 https://www.instagram.com/p/CpfakbjM6gX/?igshid=NGJjMDIxMWI=

#repost#jkubabe28#jeepwrangler#jeeps#jeepobsessed#jeepher#jeepnation#girlswithjeeps#4x4life#mopargirls#modmonday#jeepbuild#jsalternators

4 notes

·

View notes

Text

What is the BMS (Battery Management System) ?

At present, the most used energy storage battery should be lifepo4 battery. For an energy storage battery pack, a fully functional BMS management system is very important, which can improve the efficiency of the energy storage battery pack. Give full play to it.

The general name of BMS is Battery Management System, which is a control system to protect the safety of battery use. It is mainly for intelligent management and maintenance of each battery unit, to prevent overcharging and over-discharging of the battery, to prolong the service life of the battery, and to monitor the status of the battery.

The BMS battery management system unit includes a BMS battery management system, a control module, a display module, a wireless communication module, electrical equipment, a battery pack for powering electrical equipment, and a collection module for collecting battery information of the battery pack.

And threr are 4 Core Functions of BMS:

1. Measurement function

It can measure the voltage and temperature of the single cell in real-time, and measure the terminal voltage and current of the battery pack and other parameters. To ensure the safe, reliable and stable operation of the battery, the guarantee

The service life requirements of the whole battery meet the requirements for optimal control of the operation of the single battery and the battery pack.

Ideal for stationary and mobile use from thousands of watts to hundreds of kW of power, battery-based backup power supplies can reliably and efficiently power a variety of uses.

2. Online SOC diagnosis function

On the basis of real-time data collection, an expert mathematical analysis and diagnosis model is established to measure the remaining power SOC of the battery online. The remaining battery capacity and reliable use time under the following.

There are many challenges in implementing a battery management system for energy storage applications, and the solution is by no means simply "scaling" from the management system of a small, lower-capacity battery pack. Instead, new, more complex strategies and key supporting components are required.

3. Battery system operation alarm function

When the battery system is in over voltage, under voltage, over current, high temperature, low temperature, communication abnormality, BMS abnormality, etc., it can display and upload, report alarm information.

The starting point of the challenge is that the measured values of many battery parameters are required to have high accuracy and reliability. (You can read about "How to Test the actual capacity of the battery")

Furthermore, the planning of the subsystems must be modular to enable the configuration to be tailored to the specific needs of the use, taking into account possible expansion requirements, overall management issues, and necessary maintenance.

4. Battery system protection function

For abnormal fault conditions such as serious over voltage, under voltage, over current (short circuit) of the battery that may occur during operation, the high voltage control unit realizes fast

Cut off the battery circuit quickly, isolate the fault point, and output sound and light alarm information in time to ensure the safety and operation of the system.

#lifepo4 battery#lithium iron phosphate battery#lfp battery#solar battery#lithium battery#lithium manufacturer#lithium ion battery#lithium#solar battery storage

1 note

·

View note

Text

High Voltage Cable Testing

Do you need power supply testing and high voltage commissioning services? In that case, you’ve found the proper site! High voltage cable testing and commissioning is a very important part of your electrical system. This means that you need to make sure that everything works properly. It ensures that the electrical system is working properly.

#High Voltage Cable Testing#High Voltage Cable Services#Electrical Services#Electrical Testing Services#PESVS

0 notes

Text

By inspecting, cleaning, and testing these critical components, potential hazards can be identified and mitigated

A faulty air conditioning system in a hospital can create a dangerous and uncomfortable environment for patients and staff. Inspecting, cleaning, high voltage circuit breaker maintenance and testing these critical components can identify and mitigate potential hazards.

The importance of inspecting, cleaning, and testing critical components

Critical components can cause a machine to fail if they are not functioning properly. In order to keep machines running safely and reliably, inspecting, cleaning, and testing these components regularly is essential.

Inspection involves visually checking components for damage or defects. Cleaning removes dirt, dust, and other contaminants interfering with proper function. Testing checks the component's ability to perform its required task.

These tasks should be performed according to the manufacturer's recommendations, and as often as necessary to keep machines running smoothly. Failing to do so can lead to equipment failure and even injury.

The potential hazards that can be identified and mitigated by inspecting, cleaning, and testing critical components

Inspection, cleaning, transformer repairs and testing critical components are essential to maintain equipment reliability. Inspecting, cleaning, and testing components can identify and mitigate potential hazards. Some of the potential hazards that can be identified and mitigated by inspecting, cleaning, and testing critical components include:

- Foreign object debris: Foreign object debris (FOD) can cause serious damage to equipment. FOD can be identified and removed by inspecting, cleaning, and testing critical components.

- Contamination: Contamination can cause equipment failure. Contamination can be identified and removed by inspecting, cleaning, and testing critical components.

- Corrosion: Corrosion can cause equipment failure. Inspecting, cleaning, and testing critical components can identify and remove corrosion.

- Improper installation: Improper installation of critical components can cause equipment failure. Insufficient installation can be identified and corrected by inspecting, cleaning, and testing critical components.

- Mechanical damage: Mechanical damage to critical components can cause equipment failure. Mechanical damage can be identified and repaired by inspecting, cleaning, cable fault location and testing critical components.

How to inspect, clean, and test critical components

Inspecting, cleaning, and testing critical components is essential for the safety of your bike. In this chapter, we'll show you how to do each.

Inspecting your bike's critical components is essential for identifying any potential problems. You should regularly inspect your bike's frame, wheels, brakes, and gears. Look for any high voltage maintenance signs of wear or damage, and fix any problems as soon as possible.

Cleaning your bike's critical components is also important for keeping it running smoothly. You should clean your bike's frame, wheels, brakes, and gears at least once a month. Be sure to use the right cleaning products and techniques, or you could damage your bike.

Finally, testing your bike's critical components ensures your safety. Before every ride, you should test your bike's frame, wheels, brakes, and gears. Make sure they are all in good working order, and fix any problems you find.

#electrical earthing system#electrical test equipment#electrical testing services#cable fault location#earth testing#lightning protection system#site acceptance testing#electrical test equipment hire#factory acceptance testing#electrical commissioning & testing#high voltage circuit breaker maintenance

0 notes

Text

How to Choose the Right One of Top 10 Transformer Manufacturers

Atlanta has been in the power generation and transformer industries since 1983. We specialise in manufacturing a range of power, distribution, and transformers for special purposes. We have the capacity to manufacture 21,000 MVA transformers per annum, up to and including 200 MVA, 220 kV class power transformers. It took a lot of years, hard work, and efforts to be recognized as one of the top 10 transformer manufacturers today.

For any business or project that relies heavily on electrical systems, it is important to choose a reliable transformer manufacturer. These essential devices play a huge role in regulating voltage in everything from power grids to residential buildings and specific industrial equipment. You certainly would not want to face project delays or risky malfunctions by choosing a wrong supplier.

So how can you ensure you make the best decision? Let’s find out!

Top Considerations When Selecting a Transformer Manufacturer

Experience & Brand Reputation

The first thing you must do is check how much experience a manufacturer has in manufacturing transformers and how long they have been in this business. Also, while the experience matters, consider their brand value too before reaching a decision. Brand value gives you real insights into whether the manufacturer has been consistently meeting customer needs. You can look for customer reviews, testimonials, and feedback from previous clients. This basic research will help you choose a brand with higher value and history of delivering reliable, high-quality transformers.

Expertise in Your Specific Needs

Choosing a transformer manufacturer based on your application needs is crucial because different manufacturers specialize in producing transformers designed for specific purposes, whether it be for power distribution, industrial machinery, or sensitive electronics; selecting a manufacturer with expertise in your application guarantees the transformer will meet the required voltage, current, frequency, and physical constraints.

Product Range and Customisation

Another important thing is to check whether the transformer manufacturer is capable of producing a range of pre-designed transformers. Moreover, can they customize solutions according to your industry-specific needs? This helps you choose the right transformer manufacturer: One who will not compromise on quality and also will not make you overspend on features that are irrelevant to your needs.

Quality Assurance & Testing

Transformers undergo intense electrical stress. If a manufacturer does not have a facility for rigorous quality control and multiple testing to ensure safety and reliability of transformers; it is a big no. Check if they have well-defined quality procedures according to industry standards.

A reliable transformer manufacturer will have:

In-house testing facilities for routine and type tests of transformers and other related products.

Transparency in data sharing about their testing results.

Pricing, Cost-Effectiveness & Negotiations

The costs may vary depending on the features, size, and types of transformers. Drawing a comparison of the prices at which different manufacturers are offering transformers will help you narrow down your choice.

When evaluating transformer manufacturers:

Analyze material costs, labor expenses, and project timelines.

Consider both the initial cost and long-term maintenance requirements.

Negotiate pricing, particularly if placing bulk orders.

Technical Support & Customer Service Post-Delivery

Technical support and customer service pre- and post-transformer delivery are non-negotiable.

Pre-sales advice: They should be willing to help you pick the optimal solution for your needs.

Installation assistance: They should ensure smooth transformer integration into your system.

After-sales support: They should always be supportive post-deliver for troubleshooting problems or repairs.

0 notes

Text

How Detachable and Hospital-Grade Cords Are Improving Industry Standards

In today’s fast-paced and technology-driven world, safety, efficiency, and durability have become non-negotiable standards across industries. Electrical systems and components play a pivotal role in meeting these expectations. Among these components, detachable cord sets and hospital-grade cords have emerged as industry game-changers, improving safety, functionality, and reliability.

Electrical Cords: From Fixed to Flexible

Traditionally, electrical cords were fixed to devices, offering little flexibility in terms of replacement or customization. This often led to operational inefficiencies and increased downtime during repairs or upgrades. Detachable cordsets have resolved many of these issues by introducing a modular design that allows cords to be easily replaced or swapped.

Similarly, hospital-grade cords were developed in response to the rigorous safety requirements of the healthcare industry. These cords are designed to withstand harsh conditions, frequent cleaning, and high levels of usage, making them indispensable in environments where safety is paramount.

What Are Detachable Cordsets?

A detachable cord set consists of a power cord with connectors on both ends—one that plugs into the power source and another that connects to the device. Unlike permanently attached cords, these cord sets offer significant advantages, including:

Ease of replacement - When a cord is damaged, it can be quickly replaced without replacing the entire device.

Portability - Detachable cords make devices easier to transport and store.

Customization - Users can choose cords of different lengths, types, or specifications to meet their specific needs.

What Are Hospital-Grade Cords?

Hospital-grade cords are specialized power cords that meet strict safety and durability standards, often outlined by organizations like Underwriters Laboratories (UL). These cords are specifically designed for use in medical facilities and are engineered to:

Resist wear and tear from frequent disinfection.

Withstand high-stress environments.

Ensure secure and reliable connections to prevent accidental disconnections.

Key Features of Detachable and Hospital-Grade Cords

Durability

Both detachable cordsets and hospital-grade cords are built to last. They are made from high-quality materials that resist abrasion, moisture, and extreme temperatures.

Enhanced safety

Hospital-grade cords, in particular, are designed with safety as the top priority. They feature reinforced plugs, strain relief mechanisms, and robust insulation to prevent electrical hazards.

Ease of maintenance

Detachable cords make maintenance tasks simpler and more efficient. In industries where downtime can be costly, the ability to quickly replace a cord without specialized tools is invaluable.

Compliance with standards

Hospital-grade cords are rigorously tested to meet safety standards such as UL 817. These certifications ensure that the cords are suitable for crucial applications.

Adaptability

Detachable cord sets provide versatility by allowing users to swap cords for different voltages, lengths, or plug types. This is particularly useful in global markets where electrical standards vary.

How These Cords Are Revolutionizing Industry Standards

In Healthcare

Hospital-grade cords are indispensable in healthcare settings. They power crucial medical devices like ventilators, monitors, and diagnostic machines. Their durability and reliability ensure that these devices operate without interruption, which can be a matter of life and death.

The detachable design also benefits healthcare environments by allowing cords to be replaced without taking equipment out of service. This reduces downtime and ensures that medical professionals can focus on patient care.

In Consumer Electronics

Detachable cord sets have become a standard feature in modern consumer electronics. Devices like laptops, monitors, and gaming consoles often come with detachable power cords, making them easier to transport and replace. This design also reduces electronic waste by allowing users to replace only the cord rather than the entire device.

In Industrial Applications

Industrial environments often require heavy-duty power cords that can withstand harsh conditions. Detachable cords provide the flexibility to adapt to different equipment and power requirements. They also simplify maintenance, as damaged cords can be replaced quickly, minimizing downtime.

In Hospitality

In the hospitality industry, devices such as coffee makers, irons, and hairdryers benefit from detachable cord sets. Hotel staff can replace cords easily, ensuring that guests have a seamless experience.

In Data Centers

Data centers rely on high-quality power cords to maintain uptime. Detachable cords allow for quick replacements and reconfigurations, ensuring that servers and other equipment remain operational.

Benefits of Using Detachable and Hospital-Grade Cords

Improved safety

Hospital-grade cords set a high standard for safety, ensuring secure connections and reducing the risk of electrical accidents. Their design also minimizes the likelihood of damage from cleaning chemicals or frequent use.

Cost-effectiveness

Detachable cords reduce long-term costs by allowing users to replace only the damaged component rather than the entire device. This is particularly beneficial for industries with tight budgets.

Eco-friendliness

By enabling the replacement of only the cord, these solutions contribute to reduced electronic waste. High-quality materials also ensure longer lifespans, further minimizing environmental impact.

Increased efficiency

The modular nature of detachable cords streamlines maintenance and repairs, saving time and resources in both residential and commercial settings.

Versatility

Whether you need a cord for a high-voltage industrial machine or a portable medical device, there’s likely a detachable or hospital-grade option available to meet your needs.

Why Quality Matters

Not all cords are created equal, and using substandard options can have serious consequences, including:

Electrical fires due to poor insulation.

Damage to expensive equipment from voltage inconsistencies.

Increased downtime and maintenance costs.

Investing in high-quality detachable and hospital-grade cords is a proactive step toward mitigating these risks. These cords are designed to meet or exceed industry standards, ensuring optimal performance and safety.

Choosing the Right Cord for Your Needs

When selecting a detachable or hospital-grade cord, consider the following factors:

Application - Determine whether the cord will be used in a residential, commercial, or medical setting.

Certifications - Look for cords that meet industry standards, such as UL 817 for hospital-grade cords.

Material quality - Opt for cords made from durable materials, such as thermoplastic insulation and heavy-duty copper conductors.

Length and gauge - Choose a cord with the appropriate length and wire gauge for your specific application.

Compatibility - Ensure the cord is compatible with your device and power requirements.

Detachable cord sets and hospital-grade cords are transforming the way industries approach power delivery. Their emphasis on safety, durability, and efficiency has set new benchmarks, making them indispensable in settings ranging from healthcare to industrial applications. High Tech Connections is the best option if you are looking for Hospital-Grade Cords. Contact them via email or by calling (614) 920-0853.

0 notes