#heat and moisture exchanger filters

Explore tagged Tumblr posts

Text

Why Heat And Moisture Exchanger Filters Matter

A ventilator or tracheostomy becomes a crucial lifeline for many individuals facing respiratory challenges. These medical interventions provide essential support but can also introduce discomfort and potential health risks. This is where a seemingly simple component – the heat and moisture exchanger (HME) filter – is vital in ensuring patient comfort and well-being.

Understanding The Respiratory System's Delicate Balance

Our respiratory system is a marvel of nature, efficiently taking in oxygen and expelling carbon dioxide. However, this process relies on a delicate balance of moisture and temperature. The lining of our airways, known as the mucosa, naturally produces a thin layer of mucus. This mucus serves a critical dual purpose: trapping dust, pollen, and other airborne particles and keeping the airways moist.

However, when an artificial airway bypasses the natural upper respiratory tract, as with ventilators and tracheostomies, problems can arise. The incoming air, often supplied from pressurized sources, can be dry and cool. This disrupts the natural balance in the airways, leading to a cascade of potential issues.

The Benefits Of Using A Heat And Moisture Exchanger Filter

This is where the HME filter acts as an invisible guardian for the patient's respiratory health. Here's how these small yet mighty filters contribute to a more comfortable and secure breathing experience:

Combating Dryness And Irritation

Dry air strips away moisture from the delicate mucosal lining, leading to dryness, irritation, and even nosebleeds. HMEs capture the moisture exhaled by the patient and return it with the incoming air stream. This creates a humidified environment that mimics the natural state of the airways, preventing dryness and promoting comfort.

Maintaining Optimal Temperature

HMEs, through their design, capture the heat from exhaled air. This pre-warms the incoming air, delivering it at a more comfortable temperature, improving patient comfort and reducing the risk of hypothermia.

Providing A Line Of Defense Against Infection

The constant air exchange between the patient and the environment through a ventilator or tracheostomy can increase the risk of infection. Luckily, some HME filters incorporate an additional layer of protection. They come equipped with a special filter media that helps trap bacteria and viruses, acting as a barrier against pathogens in the incoming air.

Choosing The Right HME Filter For Optimal Care

With the understanding of their benefits, the importance of using HME filters becomes clear. However, with various types of filters available, choosing the right one is crucial for optimal patient care. Here are some factors to consider when selecting an HME filter:

Patient Condition

The specific needs of the patient play a key role. For instance, some patients might require a filter with a higher filtration efficiency for enhanced protection against pathogens.

Type Of Ventilation

The ventilation system being used, whether continuous or intermittent, can influence the HME filter choice. Consult with healthcare professionals regarding the most suitable option.

Climate

Environmental factors like humidity can affect the performance of HME filters. A filter with a higher moisture retention capability might be necessary in dry climates.

Ultimately, working closely with healthcare providers helps ensure the selection of the most appropriate HME filter for each patient's individual needs and circumstances.

Beyond Comfort: The Impact On Patient Outcomes

The benefits of HME filters extend beyond just patient comfort. Studies have shown that using HMEs can contribute to improved patient outcomes. Here's how:

Reduced Risk Of Ventilator-Associated Pneumonia (VAP)

VAP is a serious infection that can develop in patients on ventilators. By providing a barrier against pathogens and maintaining a moist environment in the airways, HMEs can help reduce the risk of VAP, leading to shorter hospital stays and improved overall health.

Enhanced Patient Tolerance

The increased comfort and reduced irritation resulting from using HMEs can lead to greater patient tolerance of ventilator therapy. This can be particularly crucial for long-term ventilator-dependent individuals.

Improved Recovery

By promoting a healthier respiratory environment, heat and moisture exchanger filters potentially contribute to a faster recovery process for patients with compromised respiratory function.

Final Thoughts

the seemingly simple HME filter plays a critical role in respiratory care. By addressing dryness, discomfort, and the risk of infection, these filters contribute significantly to patient comfort and well-being. Furthermore, their potential impact on reducing complications and improving recovery times highlights their importance in optimizing patient outcomes.

0 notes

Text

"In drought-stricken areas, communities facing water shortages, or even in residential and commercial buildings eager to improve their environmental footprints, atmospheric water generators represent a new frontier in water production.

While it might sound like a tidbit from a science fiction movie, even the driest places on earth have moisture in the air that can be extracted and used for everyday necessities like plumbing and drinking.

Unlike traditional dehumidifiers, which also pull moisture from the air, AWGs utilize filtration and sterilization technology to make water safe to drink.

And while there are plenty of AWG companies out there — and the science itself isn’t novel — AWGs are becoming more efficient, affordable, and revolutionary in combating water scarcity in a myriad of communities.

Aquaria Technologies, a San Francisco-based AWG startup, was founded in 2022 to help provide affordable and clean drinking water in areas most affected by climate change.

Using heat exchange and condensation, Aquaria’s generators draw air into their systems, cool that air below its dew point, and as it condenses, capture that water and filter it for consumption.

As the cycle continues, the generator’s refrigerant vaporizes and goes through a process that cools it back into a liquid, meaning the heat transfer cycle repeats continuously in an energy-efficient and self-sustaining system.

“I’m sure you’ve had the experience in the summer, you take a glass of a cold drink out of the fridge and then water droplets form on the side of the bottle,” Aquaria’s co-founder and CEO Brian Sheng, said in a podcast episode. “That’s actually condensation.”

Sheng continued: “The question is, how do we create condensation? How do we extract water out of the air in large volume and using little energy? That’s what our technology does. We have created both active and passive cooling methods where we use special materials, and we’ve created heat exchange and recovery systems and airflow design, such that we’re maximizing heat exchange, and then we’re able to extract large volumes of water.”

Aquaria has created a number of generators, but its stand-alone model — the Hydropack X — can replace an entire home’s dependence on municipal water, producing as much as 264 gallons of potable water per day.

Other models, like the Hydrostation, can provide water for up to 1,500 people at parks, construction sites, or other outdoor public areas. The Hydropixel can make 24 gallons of water per day for a seamless at-home application, requiring a simple outlet for power.

“Atmospheric water generators present a groundbreaking solution to the global challenge of clean water scarcity, leveraging the humidity present in the air to produce potable water,” the company’s website explains.

“This technology is versatile, functioning efficiently across diverse climates — from arid regions to tropical settings. From rural communities in developing countries to advanced cities facing unexpected droughts, atmospheric water generators have a wide range of applications… transforming lives and providing secure, clean water sources.”

Considering an estimated 2.2 billion people lack access to clean water globally — including in American cities like Flint, Michigan, or Modesto, California — innovative solutions like AWGs are vital to maintaining the basic human right to clean water.

The World Economic Forum has begun to dip its toes into this technology as well, implementing public and private partnerships to introduce AWG units in Arizona’s Navajo Nation, where the machines produce about 200 gallons of clean water per day.

“When combined with an appropriate level of community engagement and triple-bottom-line business (people, planet, profit),” a blog post for WE Forum said, “this model can be a powerful stopgap solution where few exist today.”

Similarly, according to New Atlas, Aquaria has a partnership with developers to supply its technology to a 1,000-home community in Hawaii later this year, relying entirely on atmospherically generated water.

The company also has a “Frontier Access Program,” which partners with water-related NGOs, community project developers, and sustainable development groups to deploy this technology in areas most in need.

Regardless of their use cases — in homes, in communities facing water shortages, or at aid sites navigating natural disasters — AWGs have a minimal environmental impact. Sourcing water “from thin air,” requires no plastic bottles, no large-scale plants using up loads of energy, and no byproducts that can harm the environment."

-via GoodGoodGood, August 27, 2024

#water#water shortage#drought#united states#solar power#sustainability#clean water#human rights#good news#hope#solarpunk

542 notes

·

View notes

Text

Paying Tribute to the Satyrs Part 2

Pairing: 3 Satyrs x nymph reader

Summary: the three Satyrs want to take you as their mate.

Warnings: morning after sex, implied smut, possessive satyrs, mating, claiming talk.

Find Part 1 here. Part 3 here. Happy reading!!

Late morning had come.

Lovely gold light filtered through the trees, creating warm patterns on your skin as you lay on the soft bed of moss. Every inch of you felt decadently wet and hot. You were blissfully disoriented from the night before— the night you’d offered yourself as tribute to the three satyrs. The night they’d taken you, leaving no part of you untouched or unclaimed.

The memories whirled in your head like a storm of sensations, a kaleidoscope of colors, textures, and smells. Their warm lips had kissed every inch of your flesh, and their strong and sure hands had manoeuvred you into every position possible, possessing you. You remembered their gazes, touches, heavy grunts and gasps after they devoured you full and marked your skin. You remembered how they moved inside of you, their hooves thrumming on the ground. Their double cocks stuffing you full, their goat-like bodies pulsing with primitive energy.

Paying tribute to the satyrs had become a bittersweet ache, a need that continued to pulse through your veins. Your body remained alive and hot, eager for more; you wanted their bodies wrapped around yours, their warmth and scent on your skin. Your breasts still felt the tugs from their lips, your nipples were soft and sensitive as if kissed by a thousand suns. Your thighs, too, remembered the pressure of their bodies, your holes sore and dripping moisture.

You were, in a way, forever changed, remade by their passion.

Now, as you sat up from the wonderful bed of moss, you flushed in their presence. They were totally naked, with their cocks concealed in protective slits while you huddled in, pulling your knees to your chest to hide your nakedness. You couldn't find your garments because they'd been hurled far away in the heat of the moment. The satyrs didn't seem to care and they stood tall and strong in front of you, possessive and unyielding.

"Seems the tribute's been more than paid," you mumbled, your voice gentle as you stared up at them.

Teofos, Fyrian, and Kynias exchanged glances, their emotions inscrutable.

"Ahhh…. Yes. The tribute…" Fyrian muttered heavily.

“It has been paid in full, right?” you said, hurting a little inside that your time together was over.

Teofos, the leader, kneeled by your side, his hand lifting your chin. "Not necessarily, little nymph," he said, his voice deep. "Last night was not only a tribute.”

“It could be so much more,” Kynias added warmly. “A promise. A promise for you to belong to us and for us to belong to you."

“What are you saying?” you muttered, your heart stuttering as his words sank into you.

“It all started so suddenly but… don’t leave,” Fyrian offered huskily. “Be our mate.”

"I don't want to leave," you mumbled softly.

"Then stay," Teofos said. "Stay with us. Be ours just as we are yours."

Speechless, you stared at each of them, your pulse racing with surprise and delight. The three of them surrounded you and gently pushed your hands aside so they could touch you. Teofos' lips traced the line of your neck, Fyrian's hands cupped the smoothness of your exposed breasts, and Kynias slowly stroked your swollen nipples. You keened and succumbed to their touches —they were gentle and reassuring but also blazing hot.

"But the other tribes," you said, your voice wavering when Kynias licked around the tender skin of your areola.

Teofos kissed your shoulder. "Let them try to separate you from us.”

Fyrian's fingers tightened around your waist. "You are ours, little nymph. Last night was just the beginning.”

“The clan is here,” Kynias alerted calmly. “We will protect you, our nymph mate.”

Indeed you suddenly noticed the change in the atmosphere. The forest surrounding you appeared alive, with satyrs emerging from the trees as if pulled by an invisible call. They were so many! The satyr clan surrounded you in seconds, a big crowd staring at you with admiration, eagerness and anticipation.

And it was clear that they would not go unless customs were upheld.

You snuggled against Fyrian while Teofos and Kynias gripped your sides, their hands remaining firmly on your body. Teofos, the leader, gazed at the crowd fiercely, his eyes possessive, almost primal. Then he spoke up, his voice distinct and unmistakable.

"This nymph belongs to us.”

An elderly satyr stepped closer to the clearing's edge, his face wrinkled with age, his gaze wise. He looked at you and then at your satyrs. "It's tradition, Teofos," he stated. “To claim a mate, you must follow our laws. A public claiming in front of the clan."

“I agree!” Another satyr proclaimed. “Honoring our traditions and laws is sacred.”

A rush of nervousness and excitement ran over your system. You were aware of the Satyrs’ unusual customs: to claim a mate, they had to engage in a public claiming. It was a sacred rite for them. Nymph clans did not adhere to such traditions but as you glanced at the awaiting satyr clan, you did not want to disappoint them or your mates.

“Will you stand with us, little nymph?" Teofos asked, his voice barely above a whisper.

Kynias whispered, for your ears only. "Will you let us claim you, show them all that you are ours, and we are yours?"

“You don’t have to do this if you’re not comfortable,” Fyrian added just as quietly. “We can wait for you to be ready.”

“No. I am ready,” you said decisively and met their gazes, your heart racing.

They nodded, unable to form words, great joy spreading across their features. Their hands tightened around your body, their fingers brushing across your skin. They were brimming with pride. The clan remained still, their gazes turning to the four of you until Teofos’s voice broke through, loud and firm.

"You've come to testify, and so you will," he said, his voice resonating across the forest. "She will be ours, bound by the earth, our spirits and bodies. Our nymph mate.”

#satyr smut#satyrs x reader#satyrs x you#satyrs x human#satyr x human#satyr x female reader#monsters x human#monsters x reader#monster x you#monster x reader#monster x human#monster x nymph#satyrs x nymph#monster smut#monster lover#monster fudger#monster romance#monster bf#monster boyfriend#monster fuckers#monster fucker#monster love#monsterfucker#teratophillia#terat0philliac

144 notes

·

View notes

Text

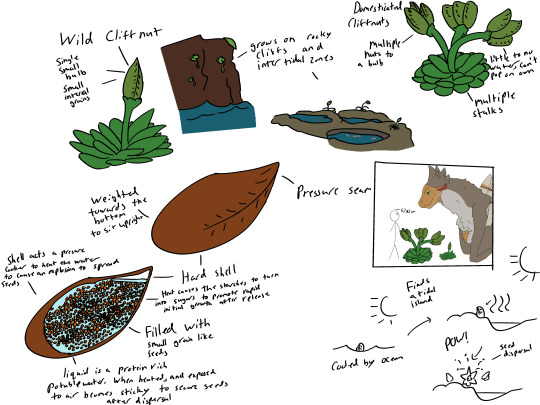

The wild Cliff Nut grows rocky ocean cliffs, intertidal zones, and beaches. It can grow on normal soil but is usually out competed by other plants. Its leaves are similar to succulents. They store filtered fresh water due to the rock they root in being unable to hold onto moisture. While the Cliff Nut can deal with some of the salt from the seawater it uses to survive, anything it cannot naturally process, will be sequestered in the least efficient leaves at the base of the plant which will die off and the salt disposed of. The seedpod of the Cliff Nut has an interesting evolutionary tactic of seed dispersal. Due to the extreme tides of the planet, there are large regions of tidal or shallow beaches that are exposed to the air for a majority of the day. These are picked up by, or are dropping into the water to float along the currents to new land. During its journey, the heavy bottom of the shell keeps a large portion of the nut submerged and cooled by the ocean water. Once it has been deposited by the tide, lack of cooling water begins heating the protein rich interior water of the nut. This causes the fatty proteins in the grain to become simple sugars and the interior water to evaporate. The proteins in the water begin to thicken. These proteins, once exposed to air, will become a sticky, mucous like material that will bind seeds to their new rooting spots. Over the course of about an hour, pressure builds enough to cause an explosion along the pressure seam of the nut, scattering globs of seeds and rooting mucous across wherever the nut has landed. Some land high enough to attach to cliffs which is the safest spot for them to land as they are away from any sea or land based herbivores.

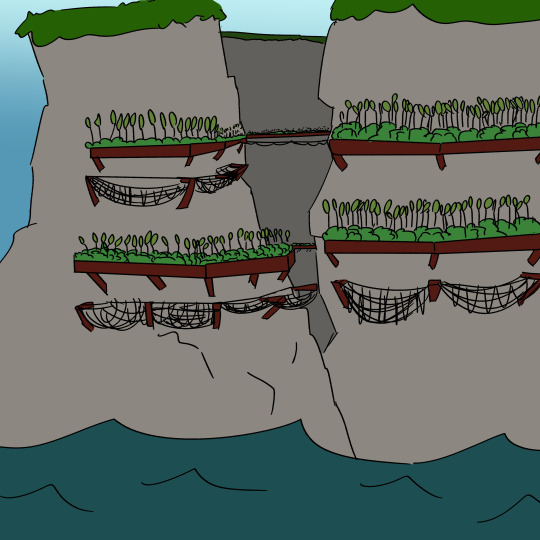

The Wyvara began harvesting these plants for both water and food while their livestock fed on inedible vegetation. Wyvara eventually figured out that instead of allowing these seeds to ferment and explode, they could empty the contents of the nuts into cooking vessels to heat and create a seed paste to smear on cliff faces to grow an exclusive food source as the cliffsides were very inaccessible to most of the threats to the Cliff Nut. The Cliff Nut did not need tending as the ocean waves irrigated the plants without any need for watering. This allowed for a stable, reliable source of food for their next visit on to the island while on their migration circuit. This technique was further refined by hollowing out parts of cliffs into terrace-esque farms. These plant beds were augmented to promote growth by dumping dung of livestock animals fostering a trade between any permanent residents and nomads. The nomads gave fertilizer, meat, and animal products in exchange for tools, food, and grazing rights. The soil is regularly dumped into the sea and replaced to prevent toxic salt buildup and to renew soil nutrients.

From the artificially improved growing conditions and Wyvara influence selection, the Cliff Nut began to grow larger. More stalks for nuts and more nuts per stalk. Several different strains of Cliff Nut are in use today. The glue producing Cliff Nut has very low amount of internal grain and a much higher concentration of congealing proteins in the internal water. They are a renewable source of adhesives for settled communities. Grain Cliff Nuts are bred for the maximum amount of grain. They cannot naturally explode and must be manually opened by Wyvara to disperse seeds due to there being almost no water in their nuts. Salt Cliff Nuts are bred for their salt-sacrifice leaves. They are used in a large amount of Wyvara traditional dishes and barely produce any nuts and when they do they are rather small. They absorb an extreme amount of salt and push it in very high concentrations into leaves. Fig(2) is a late Clan era farm where permanent residents were becoming largely self sufficient and experts at farming. Slowly beginning to domesticate the Cliff Nut into a proper staple food crop.

Nets are often used to ensure minor crop loss from any premature dropping or rogue waves stealing crops. They are also regularly scraped for surplus salt.

3 notes

·

View notes

Text

What Is Ventilation System in HVAC and How Does It Impact?

In the realm of Heating, Ventilation, and Air Conditioning (HVAC), the significance of proper ventilation cannot be overstated. It plays a pivotal role in maintaining indoor air quality, ensuring comfort, and impacting energy efficiency.

Definition of Ventilation System

Ventilation in HVAC refers to the process of exchanging or replacing indoor air with fresh air from outside. It involves various components such as air ducts, fans, vents, and filters that work cohesively to regulate airflow.

Purpose of Ventilation

The primary goal of a ventilation system is to enhance indoor air quality. By eliminating pollutants, controlling moisture, and preventing the buildup of stale air, it creates a healthier and more comfortable environment for occupants.

Types of Ventilation Systems

Ventilation systems come in two main types: Mechanical and Natural. Mechanical systems utilize fans or blowers to circulate air, while Natural systems rely on passive methods like windows and vents to facilitate airflow.

How Ventilation Impacts HVAC

The synergy between ventilation and HVAC significantly impacts energy efficiency. An effective ventilation strategy optimizes airflow, reducing the load on heating and cooling systems, thus lowering energy consumption and costs.

Importance of Proper Ventilation

Beyond energy efficiency, proper ventilation contributes to improved health and well-being. It mitigates indoor air pollutants, allergens, and excess moisture, reducing the risk of respiratory issues and enhancing overall comfort.

Factors Affecting Ventilation

Several factors influence ventilation effectiveness, including building design, geographical location, climate, and occupancy patterns. Design considerations and environmental factors play a crucial role in determining the optimal ventilation strategy.

Maintenance of Ventilation Systems

Regular maintenance and checks are imperative to ensure the efficient operation of ventilation systems. Filters, ducts, and other components require periodic inspections and cleaning to prevent malfunctions and maintain air quality.

Innovations in Ventilation

Advancements in technology have led to innovative ventilation solutions. Smart ventilation systems equipped with sensors and automated controls offer real-time adjustments, optimizing airflow based on occupancy and outdoor conditions.

Conclusion

In conclusion, a well-designed ventilation system is integral to HVAC functionality, impacting indoor air quality, energy efficiency, and overall occupant comfort. Its proper implementation and maintenance play a vital role in creating healthier and more sustainable indoor environments.

1 note

·

View note

Text

Breathe Better: Commercial and Residential Ventilation with Advanced Heat Recovery Systems

Indoor air quality is often overlooked, but it plays a vital role in our health, comfort, and productivity. Whether in an office, shop, or private home, effective ventilation is key to maintaining a safe and comfortable environment. As energy efficiency becomes more important across the UK, innovative systems like heat recovery ventilation units are gaining popularity in both commercial ventilation and residential ventilation projects.

This blog explores the benefits of mechanical ventilation, the role of heat ventilation recovery, and how a heat recovery ventilation system can improve air quality while reducing energy bills.

Why Ventilation Matters

Proper ventilation ensures a continuous supply of fresh air while removing stale, polluted indoor air. Without it, buildings can suffer from:

Poor indoor air quality

Moisture build-up and mould

High levels of CO₂, allergens, and indoor pollutants

Uncomfortable indoor temperatures

Both commercial ventilation and residential ventilation systems are designed to improve air circulation, protect health, and enhance energy efficiency. The difference lies in the scale, complexity, and compliance requirements of each type of property.

Commercial Ventilation: Vital for Business Spaces

Commercial ventilation systems are essential in environments such as offices, schools, restaurants, retail spaces, and industrial facilities. These settings require reliable systems that can handle large volumes of air while complying with UK health and safety regulations.

Benefits of commercial ventilation include:

Healthier working environments

Reduced risk of airborne illnesses

Regulation-compliant air exchange

Enhanced comfort and productivity

Elimination of odours, fumes, or dust

Mechanical systems are often used in commercial buildings, especially where natural ventilation (like open windows) is not practical or secure. These systems often include heat ventilation recovery technology to reduce energy waste while improving air quality.

Residential Ventilation: Clean Air at Home

Homes, particularly new builds and energy-efficient properties, are designed to be airtight. While this helps with insulation and heating, it can trap pollutants and moisture indoors. Residential ventilation systems are increasingly needed to maintain fresh air flow without compromising energy efficiency.

Common residential ventilation options include:

Extractor fans in kitchens and bathrooms

Whole-house mechanical ventilation with heat recovery (MVHR)

Trickle vents on windows (less effective in colder climates)

The most efficient solution for modern homes is the heat recovery ventilation system, which not only supplies fresh air but also captures heat from the outgoing stale air—making it ideal for eco-conscious homeowners.

What Is a Heat Ventilation Recovery System?

A heat ventilation recovery system, also known as MVHR (Mechanical Ventilation with Heat Recovery), is a smart ventilation solution that balances indoor air quality with energy efficiency.

How it works:

Stale air is extracted from rooms like bathrooms and kitchens.

At the same time, fresh air is drawn in from outside.

Heat exchangers transfer warmth from outgoing air to the incoming air without mixing the air streams.

Fresh, pre-warmed air is distributed throughout the building.

These systems are suitable for both commercial and residential use and are especially effective in well-insulated, airtight properties where natural airflow is limited.

Heat Recovery Ventilation Units: Key Features and Benefits

A heat recovery ventilation unit is the central component of an MVHR system. It is usually installed in a loft space, plant room, or utility area and connected to a network of ducts.

Advantages of heat recovery ventilation units:

Energy efficiency: Recover up to 90% of the heat that would otherwise be lost.

Improved air quality: Filters out pollutants, allergens, and moisture.

Cost savings: Lower heating bills by reducing the need to reheat incoming air.

Balanced climate control: Even temperature distribution throughout the property.

Eco-friendly: Reduces carbon footprint by improving energy efficiency.

Leading brands in the UK offer units tailored to both small homes and large commercial buildings, ensuring there's a heat recovery ventilation unit for every need.

Heat Recovery Ventilation System: Ideal for Modern Living

Installing a heat recovery ventilation system is an investment in comfort, health, and long-term savings. These systems are increasingly included in new residential developments and commercial refurbishments, thanks to their energy-saving capabilities.

In commercial settings, they ensure compliance with regulations like the Workplace (Health, Safety and Welfare) Regulations 1992. In homes, they provide a smart solution for keeping air fresh without losing precious heat in winter or cool air in summer.

Maintenance is minimal—usually limited to changing filters every 6–12 months—and professional servicing ensures optimal performance year-round.

Conclusion

Whether you're managing a large office space or simply want to improve the air quality in your home, an efficient ventilation system is essential. From traditional commercial ventilation systems to high-performance heat recovery ventilation systems, there's a solution to suit every space and need.

A well-designed heat ventilation recovery setup improves air quality, reduces energy waste, and supports a healthier indoor environment. With rising energy costs and increased focus on sustainability, now is the ideal time to consider a heat recovery ventilation unit—a smart move for both your property and the planet.

Looking to upgrade your residential or commercial ventilation? Contact a trusted HVAC specialist near you to discuss the best heat recovery ventilation system for your building.

#commercial ventilation#residential ventilation#heat ventilation recovery#heat recovery ventilation unit#heat recovery ventilation system

0 notes

Text

Why Your Old Air Conditioner Is Costing You More in 2025

Summer heat is hitting harder than ever, and homeowners aren’t just battling soaring temperatures—they’re also dealing with rising energy bills. In Winchester, Virginia, many residents are feeling the pressure. If your electricity costs keep climbing even though your AC usage hasn’t changed, your outdated cooling system could be the real culprit.

At Small Solutions Heating and Air Conditioning, we have observed countless families across Winchester grappling with the problems arising from air conditioning systems that are both inefficient in providing the necessary cooling and overly expensive to operate. Most families do not understand the impact that outdated air conditioning units can have on their energy consumption.

The Problem of Inefficient Air Conditioning Units

Air conditioning systems age just like any other machinery, and an older air conditioning system is similar to how an old vehicle burns more gas to cover the same distance. Parts begin to break down, the amount of refrigerant drops, and efficiency ratings lose their value. An air conditioning system that used to cool the home effectively now runs for long durations, making it much harder to maintain comfortable temperatures while consuming far more electricity.

Cooling systems made after 2010 have a SEER (Seasonal Energy Efficiency Ratio) rating of 16 or higher, while systems made before 2010 have a rating of 10 or lower. This means that older cooling systems use 60% more energy than newer systems.

Winchester's large humidity levels pose challenges to older cooling systems. Our summers force air conditioning units to function twice as hard, not just to cool the air but to remove moisture as well. Because older systems require more energy to cool air, they end up cycling for longer and consuming more energy.

Warning Signs Your AC Is Wasting Energy

Inconsistent Temperature Control - Your cooling system is working inefficiently if it has hot spots in certain areas of your home. If the system is cycling more frequently than it should, uneven temperatures and changes will occur throughout the house.

Frequent Cycling - Pay attention to how often your system turns on and off. Frequent short-cycling in a quick succession wastes an enormous amount of energy and occurs when the system is improperly sized for your home.

Higher Energy Bills - Compare your current energy costs to the previous year during comparable weather. An increase in energy spending with no corresponding increase in energy efficiency often indicates the system is failing.

Diminished Airflow - Reduced airflow makes your system work longer to reach the set temperature. The longer your HVAC systems run, the more energy they require, which increases your electric bill.

How HVAC Maintenance Services in Winchester Help

Regular maintenance is the best strategy to prevent energy losses due to an aging cooling system. HVAC efficiency problems can be diagnosed and resolved long before they turn into expensive visits with regular checkups.

Inspection of All System Components - Comprehensive HVAC maintenance includes inspection of all system components. They check the refrigerant levels, clean the coils, tighten electrical connections, and check for good airflow. These issues, albeit small by themselves, left unchecked, accumulate and disrupt energy efficiency.

Cleaning and Replacing Filters - Dirty Air filters require more work to push air through the system, resulting in a 15% increase in energy use. Regular filter replacement as part of maintenance guarantees better system performance, more efficient operation, reduced power consumption, and smooth airflow.

Coil Cleaning and Maintenance – The evaporator and condenser coils make your machines work harder because they have to achieve a certain amount of heat transfer. Cleaning provides an excellent restoration of optimal heat exchange, which results in lower energy consumption.

The Cost Benefits of AC Replacement Versus Repair

Many of the aging cooling systems seem to be a tough call for Winchester homeowners as they weigh in on repairing or replacing them. Although repairs seem financially cheaper, they always turn out to be overly expensive long term, in comparison to replacement.

When Repair is a Good Choice - Homeowners having a system less than 10 years old and with small problems usually do better off seeking a professional repair service. Refrigerant leakage, thermostat issues, or general wear and tear of older parts are easy to restore and quite cheap to fix, while also improving efficiency.

When Replacement is a Must - Older cooling systems over 15 years are usually a candidate for replacement, as they tend to consume a lot of energy. Investing in a new high-efficiency AC unit is a guaranteed way to save energy and energy dollars, as the investment pays for itself usually within 5-7 years.

Energy Efficiency: Modern AC Technologies

Cooling systems have advanced features nowadays that make the system much more energy efficient than older models. In order to make the system efficient, modern variable-speed compressors adjust their output in accordance with the cooling demand. Operation schedules are optimized by smart thermostats, ensuring maximum efficiency.

Integration with Smart Home Technology - New systems work with smart home devices and let users assess the home’s cooling needs concerning the household's daily activities and the weather. This kind of automated performance lowers energy use when it's not needed while keeping your home feeling comfortable.

Zoned Cooling Systems - Newer zoning technology lets separate areas or rooms in your house be cooled independently. It can lower energy waste in areas that are not used. This precision can save about 20 – 30 % in cooling expenses compared to the traditional single-zone systems.

Professional Air Conditioner Repair Services In Winchester

Ignoring noticeable signs of inefficiencies in your air cooling systems can lead to minor issues slowly evolving into great energy sinks, the longer you wait to call in an expert. Skilled professionals are able to find problems accurately and employ solutions that will restore great performance.

Diagnostic Services

Professional diagnostic services will solve efficiency problems without masking them by identifying the root cause. This method is more effective as every solution is relevant to the problem at hand.

Emergency Repair Services

Malfunctioning systems in the scorching summer months can be quite uncomfortable and costly. Emergency repair services mitigate downtime while reducing damage that could impair efficiency for the long haul.

Selecting the Right HVAC in Winchester, VA

Fulfilling your air conditioning system’s servicing requirements with qualified professionals goes a long way in ensuring optimal results and long-term satisfaction. Look for providers with appropriate licensing and insurance, as well as local knowledge on Winchester’s climate challenges.

Experience

Winchester’s climate has its own specific challenges, which require local knowledge and experience. The understanding of the regional weather patterns, humidity levels, and other common system issues gives providers the ability to deliver more effective solutions.

Comprehensive Service Offerings

Select HVAC Winchester VA contractors who offer complete services, starting from routine maintenance to emergency repairs and system replacement. This approach maintains service quality and removes the headache of dealing with multiple contractors.

Lowering Environmental Impact Through Efficient Cooling

Rather than the personal cost saving of an individual, cooling systems have great environmental value. These systems help in saving energy, which in turn decreases the carbon emissions and lowers the strain on the electrical infrastructure.

Energy Refrigerants

Modern air conditioning systems are now equipped with environmentally friendly refrigerants, which have lower global warming potential compared to older refrigerants. With our newer systems, we are able to efficiently protect the environment from older system replacements.

Benefits of Energy Grids

Cooling systems help eliminate electrical infrastructure peak demand, thus creating additional reserve for electrical infrastructure. This, in turn, supports grid stability.

Virginia HVAC Solution Strategy

Your home’s specific needs, budget limitations, and future objectives all play a major role in developing a comprehensive cooling strategy. A professional consultation will ensure you make the right decisions regarding maintenance, repair, or replacement, so you are not overspending.

Energy Audits

Energy audits span beyond the cooling system itself. An audit will illuminate insulation improvements, air sealing, or window upgrades that can work alongside efficient cooling systems for maximum energy savings.

Financing Options

Upgrading or installing a new cooling HVAC system is no longer a hassle because of the many financing options made available by contractors. With low-interest refinancing and flexible payment plans, energy-efficient HVAC upgrades are now accessible to more homeowners.

Conclusion

An old and outdated air conditioning system, coupled with worn components and obsolete technology, leads to a significant drain on energy efficiency and a rise in costs. Without proper maintenance, this aging system will continuously siphon funds, exposing homeowners to excessive energy consumption.

Upgrading the cooling systems alongside maintenance and repair offers a dramatic drop in cooling costs while improving comfort. Don’t let energy bills shoot up endlessly; enhance your home's energy efficiency today and enjoy optimal savings tomorrow.

Every homeowner in Winchester knows the challenges that come with overheating problems. Small Solutions Heating and Air Conditioning stands out since we have a reputation for tackling these issues head-on with our experienced technicians. Through our extensive solutions, we aim to maximize comfort, lower spending, and restore productivity. Reach out to us to book a consultation and find out the savings you can achieve through proper cooling system maintenance.

Trusting professionals with advanced tools allows homeowners to enjoy the rewards of additional savings, tranquility, and better efficiency. Spend money on the right equipment and services to witness lower expenses and enhanced family comfort. Don’t wait until overheating drives your energy bills skyrocketing before investing in an efficient air conditioning unit.

FAQs

How can I tell if my AC is causing high energy bills?A sudden spike in your electricity bill—especially if your usage habits haven’t changed—is often the first sign. Other indicators include inconsistent cooling, frequent cycling, reduced airflow, and loud or strange noises from the system.

What is SEER, and why does it matter?SEER (Seasonal Energy Efficiency Ratio) measures the cooling efficiency of your air conditioner. The higher the SEER rating, the more energy-efficient the system. Older units often have SEER ratings below 10, while modern units start at 16 or higher, using up to 60% less energy.

Is it better to repair or replace an old air conditioning unit?If your unit is under 10 years old and the issues are minor, a professional repair is usually the most cost-effective option. However, systems over 15 years old often consume more energy and are better candidates for replacement due to long-term cost savings.

How often should HVAC systems be serviced in Winchester, VA?It’s recommended to schedule professional HVAC maintenance at least once a year—preferably in the spring—before the summer heat peaks. Regular servicing keeps your system efficient and helps prevent costly breakdowns.

Do new AC systems lower energy bills that much?Yes. Modern AC units with higher SEER ratings, smart thermostats, and zoning capabilities can reduce energy bills by 20–40%, especially in hot and humid regions like Winchester.

1 note

·

View note

Text

“What Are Refrigerated Air Dryers & Why Your System Needs One”

Evergreen offers a wide selection of refrigerated air dryers to meet your compressed air needs. Our highly efficient and low cost refrigerated air dryers purify compressed air, by chilling it to condense the moisture, leading to cleaner air and a longer life for your valuable equipment.

Refrigerated air dryers are available in two basic configurations, non-cycling and cycling. Our Refrigerated Air Dryers come in many sizes to fit your compressed air system needs. If you have questions on how to properly select a refrigerated dryer, call us on 206-474-4451.

ELGi Airmate Refrigerant Dryer

ELGi offers a reliable solution through ELGi Airmate Refrigerant Air Dryers. The dryers ensure longer life of compressed air systems through efficient removal of the condensate and contaminants.View Products

MIKROPOR MH SERIES DRYER

Most of the compressor manufacturers do not use after cooler on their piston type compressors. Therefore, compressed air exits the compressor at about 240 F temperature.View Products

MIKROPOR MK CYCLING DRYERS

Mikropor provides best in class compressed air dryer at a cost-effective price. A state of the art heat exchanger and the refrigerant compressor provide the highest cost savings against the competition.View Products

CRH SERIES REFRIGERATED DRYER

The CRH Series refrigerated dryers feature a unique design which works directly with reciprocating air compressors. A unique heat exchanger allows the dryer to accept elevated inlet air temperatures up to 180°F.View Products

CRPC Series Refrigerated Dryer

The CRPC Energy Saving refrigerated dryer offers a reliable patent pending heat exchanger and uses environmentally friendly refrigerants. All models have No-Air-Loss Drain.View Products

R4 Direct expansion dryers

nano NDX direct expansion refrigerated air dryers allow customers running a consistent volume of compressed air the ability to achieve excellent dew point performance and save energy.View Products

R1 Cycling Refrigerated Air Dryers

The unique dry thermal mass in the nano NXC cycling refrigerated air dryer saves energy and money by utilizing dual transfer technology (DTT). Saves up to 80% over a traditional dryer.View Products

R2 High Temp direct expansion dryers

The nano R2 range of RNC high temperature direct expansion refrigerated air dryers are specifically designed for the unique demands of high temperature compressed air applications.View Products

R2 high temperature cycling dryers

The nano R2 range of RTC high temperature refrigerated air dryers are specifically designed for the unique demands of high temperature compressed air applications Environmentally friendly.View Products

R5 NEMA 4 Stainless steel dryers

nano R5 NEMA 4 stainless steel refrigerated air dryers are designed and built specifically for challenging applications requiring clean, dry, compressed air. Our dryers are environmentally friendly.View Products

R3 High capacity cycling dryers

The nano R3 range of CPD high capacity process cycling refrigerated dryers are specifically designed for the unique demands of high air flows and high heat load compressed air applications.View Products

Other Product:

Medical vacuum pumps

Rotary screw air compressors

Compressed air filter

Air compressors

Compressed Air Dryers

Piping & Tanks

System Controls

filtration

ENERGY SAVINGS

0 notes

Text

Texas is Big on Plating Metal Parts for Longevity

Texas is home to some of the largest and most productive industrial sectors in the country. With its abundant natural resources, proximity to the Gulf of Mexico, and sprawling infrastructure, Texas has become a hub for energy production, heavy manufacturing, and transportation. These industries rely heavily on pumps, pipelines, machines, fluid control systems, and other metal equipment that must perform reliably in some of the more challenging environmental conditions.

Many of these operations—especially those located closer to the Texas Gulf Coast—face added challenges due to the corrosive nature of salt-laden air and high humidity. When metal parts are exposed to saltwater, moisture, high temperatures, and chemical processes, they are more likely to degrade through corrosion, rust, and wear. As a result, protecting these components is not just a best practice—it’s a business imperative.

Core Industries That Demand Protection from Harsh Environments

The most obvious example is the oil and petroleum processing industry, which has a massive footprint in Texas. Refineries, drilling rigs, and pipeline infrastructure face nonstop exposure to corrosive chemicals, abrasive materials, and outdoor weathering. In these environments, components such as valves, bearings, shafts, and heat exchangers must be shielded from corrosion and friction to keep operations running safely and efficiently.

But the demand for metal protection doesn’t stop at oil and gas. Here are three other Texas industries where protecting equipment is equally vital:

Chemical Manufacturing Texas is a leader in chemical production, with facilities handling acids, solvents, and reactive substances. Exposure to these chemicals can rapidly degrade uncoated metal surfaces, leading to leaks, safety hazards, and costly downtime. Protective metal coatings are essential for storage tanks, process lines, and control valves.

Water Treatment and Desalination Facilities that manage drinking water, wastewater, or brackish water (especially near the coast) use large pumps, filters, and flow control systems made from metal. These systems are prone to corrosion from mineral-rich water and cleaning chemicals. Pipe coating in TX facilities, especially municipal and private-sector utilities, ensures longer equipment life and reduced maintenance frequency.

Marine and Port Operations Along the Gulf Coast, ports and shipyards deal with salt air, marine spray, and constant metal-on-metal friction from cargo handling and vessel maintenance. Without a robust metal coating strategy, critical components quickly fail or rust beyond repair.

Common Methods of Metal Protection

To meet these challenges, companies turn to specialized coating techniques to enhance the performance and longevity of their equipment. Below are three widely used solutions:

Electroless Nickel Plating This process involves the chemical deposition of a nickel-phosphorus alloy onto metal surfaces without the use of electricity. The result is a uniform, corrosion-resistant layer that adheres evenly—even on complex shapes. Electroless nickel is widely used across industries for its resistance to corrosion, wear, and high-temperature exposure. A trusted metal plating service near Dallas will often offer this treatment to meet industrial performance requirements.

Thermal Spray Coatings These coatings are applied by melting metal or ceramic materials and spraying them onto the surface of a component. This method allows for customization based on the desired hardness, friction resistance, or thermal insulation. It’s frequently used in the aerospace and energy sectors across Texas.

Polymer or Epoxy Pipe Coatings In industries that rely on long-distance fluid transportation, internal and external pipe coating in TX facilities helps prevent corrosion and chemical breakdown. Epoxy-lined pipes, for example, are essential for transporting potable water or corrosive chemicals without degrading the pipe walls.

Choosing the Right Metal Plating Company

Working with an experienced industrial metal plating company in Texas ensures that your equipment receives the most effective protection for the specific environmental and chemical conditions it will face. Whether you need uniform coatings for high-precision parts or robust protection for outdoor pipelines, partnering with a qualified metal plating company will help optimize your investment.

Why Protection Matters

Protecting metal parts from corrosive chemicals, moisture, salt, and mechanical wear isn’t just about extending their service life, it’s also about sustainability and cost-efficiency. Maintenance and replacement of worn parts can be a massive expense for industrial operations. Applying the right metal coating dramatically reduces these costs and minimizes unplanned downtime.

With a growing attention on environmental stewardship, companies are re-evaluating legacy coating methods. Hard chrome plating, for example, has long been used for its hardness and wear resistance. However, it involves the use of hexavalent chromium—a toxic and environmentally hazardous chemical. Forward-thinking companies are increasingly turning to safer alternatives like electroless nickel or thermal sprays to reduce their environmental footprint.

In the demanding industrial landscape of Texas, from oil refineries and chemical plants to marine ports and water treatment facilities, equipment protection is essential. Selecting the right protective coating enhances operational reliability, cuts maintenance costs, and supports environmental compliance. With a reliable metal plating service near Dallas or an established industrial metal plating company in Texas, you can ensure your metal parts last longer, perform better, and contribute to a more sustainable future.

0 notes

Text

Fresh Air Matters: Why Air Exchangers Are a Must in Modern Hamilton Homes

If your Hamilton home was built after 1997 or recently renovated, chances are it’s too airtight for your health. Air exchangers are no longer a luxury—they're essential for maintaining clean, fresh air indoors without sacrificing energy efficiency.

Your Home Might Be Energy-Efficient, But Is It Breathing? Modern construction is great for keeping heat in during Hamilton's brutal winters. But that same airtight envelope can trap stale air, moisture, allergens, and pollutants. That stuffy feeling? It’s not just in your head—it’s your home crying out for ventilation.

Enter the air exchanger: a smart system that continuously replaces stale indoor air with fresh, filtered outdoor air, all while recovering heat from the outgoing air. You get better air quality without higher heating bills.

How Do You Know You Need One? Here are some Hamilton-specific red flags:

Persistent window condensation or frost

Mold or musty odors in bathrooms

Allergy flare-ups or frequent colds

A home that always feels “stuffy”

High-efficiency windows, insulation, or recent upgrades

Ready to Help Your Home Breathe Again? Contact Dynamic Heating & Cooling for a free assessment. We’ll help you choose the right system (HRV vs ERV), handle expert installation, and walk you through rebate options.

Call now or visit our website to learn how air exchangers protect your health, your wallet—and your home.

Contact Us

805-658-8115

#HamiltonHomes#IndoorAirQuality#AirExchanger#FreshAirSystem#EnergyEfficientHome#HVACExperts#HamiltonHVAC#HomeVentilation#HRVsystem#ERVsystem#BreatheCleanAir#HealthyHomeHamilton#DynamicHeatingAndCooling

0 notes

Text

Center Enamel: Guardians of Steam Purity as China’s Leading Steam-Water Separator Manufacturer

In the high-stakes world of industrial operations, steam is the lifeblood, driving turbines for power generation, transferring heat for critical processes, and playing a vital role in sterilization and chemical reactions. Yet, the purity of this steam is paramount. Even microscopic droplets of entrained water can become destructive forces, causing severe erosion in high-speed turbines, compromising heat transfer efficiency, leading to dangerous water hammer, and facilitating corrosion and contamination throughout the steam system. It is here that steam-water separators emerge as indispensable sentinels, meticulously engineered to purify steam and protect invaluable assets.

Within this vital and demanding niche, one name consistently defines the pinnacle of engineering excellence and manufacturing prowess from China: Shijiazhuang Zhengzhong Technology Co., Ltd., globally recognized as Center Enamel. We proudly assert our position not merely as a manufacturer, but as the indisputable leading force in China’s steam-water separator manufacturing industry, a testament to decades of profound expertise in two-phase flow dynamics, unparalleled precision manufacturing, and an unwavering commitment to delivering customized, high-efficiency solutions that ensure steam purity, safeguard equipment, and optimize energy utilization across global industries.

Our leadership in steam-water separator manufacturing is not a mere claim; it is a distinction forged through an unparalleled understanding of steam-water interactions, meticulous design for optimal moisture removal, precision fabrication of robust pressure containment and their intricate internals, and rigorous adherence to the most stringent international safety and performance standards. Center Enamel embodies the pinnacle of Chinese specialized manufacturing capabilities, blending cutting-edge technology with extensive project experience to empower global industrial development, ensuring dry steam, operational stability, and enhanced safety at every turn.

As a Global Leading Pressure Vessels Manufacturer, Shijiazhuang Zhengzhong Technology Co., Ltd(Center Enamel ) Powering Global Industries with Unrivaled Pressure Vessel Solutions, Your Trusted Global Partner for Mission-Critical Pressure Vessels. Center Enamel stands at the forefront of pressure vessel innovation and manufacturing, delivering pressure vessel solution to industries worldwide. With a legacy of excellence, Center Enamel has consistently set industry benchmarks, providing cutting-edge pressure vessel solutions for the most demanding applications globally.ProductsPressure VesselAtmospheric Pressure VesselsHorizontal Containers, Vertical Cylindrical Containers, Vertical Cylindrical Storage TanksSeparator Pressure VesselsGravity Separator, Cyclone Separator, Coalescing Separator, Centrifugal Separator, Steam-water Separator, Bearing Separator, Mechanical Filter, Ion exchange Filter, Air Filter, Fuel Filter, Adsorption Filter, BioFilter, Oil Filter, Hydraulic oil Filter, SeparatorHeat ExchangersShell and Tube Heat Exchangers, Plate Heat Exchangers, Spiral Heat Exchangers , Air Coolers, Liquid Coolers, Thermoelectric Coolers, Chill Water Main Unit, Evaporative Condensers, Air cooled Condensers, Electronic Gas CondensersReactor Pressure VesselsStirred Tank Reactors, Continuous Stirred-tank Reactors, Tubular Reactors, Tower Reactors, Fixed Bed Reactors, Fluidized Bed Reactors, Bioreactors

The Guardian of Steam Purity: Understanding Steam-Water Separators

At their core, steam-water separators are specialized pressure vessels designed to efficiently remove entrained water droplets from a steam stream. This process is critical because even very small amounts of liquid water can cause significant problems in steam systems. The separation is typically achieved by leveraging a combination of physical principles:

Gravity Separation: Larger water droplets, being denser than steam, will tend to settle out if given sufficient residence time and a low-velocity path within the vessel.

Momentum/Inertial Separation (Impingement/Baffling): The steam-water mixture is forced to change direction abruptly. The heavier water droplets, due to their inertia, cannot follow the sharp turn of the steam, causing them to impact a baffle or plate. Upon impact, they coalesce with other droplets and drain away.

Centrifugal/Cyclonic Action: The steam is introduced tangentially or directed through vanes to create a swirling, cyclonic flow. Centrifugal force throws the denser water droplets to the outer walls, where they collect and drain.

Mesh Pads/Vane Separators (Demisters): For removing very fine, mist-like water droplets, the steam is passed through a dense mesh pad or an array of corrugated vanes. Water droplets are captured on the large surface area of the mesh or vanes, coalesce, and then drain downwards.

Why is Dry Steam Critical? The Detrimental Effects of Entrained Water:

The presence of even small amounts of entrained water in steam can have severe consequences:

Turbine Erosion and Damage: In steam turbines, high-velocity water droplets act like miniature bullets, causing rapid and severe erosion of turbine blades, particularly in the low-pressure stages. This leads to reduced efficiency, increased vibration, and costly unscheduled downtime for repairs or blade replacement.

Reduced Heat Transfer Efficiency: In heat exchangers (reboilers, evaporators, process heaters), the presence of water reduces the available latent heat for transfer, decreasing the thermal efficiency of the process and potentially leading to longer heating times or reduced production capacity.

Water Hammer: Condensate accumulation in steam lines, especially in horizontal runs, can be picked up by the high-velocity steam flow, forming a slug of water that travels at high speed. This slug can violently impact pipe bends, valves, or equipment, causing severe damage, pipe rupture, and posing a significant safety hazard.

Corrosion and Deposits: Dissolved solids present in the boiler feedwater can be carried over with entrained water droplets. These solids can deposit on turbine blades, heat exchange surfaces, or valve seats, leading to reduced efficiency, increased corrosion, and operational issues.

Product Contamination: In processes where steam is directly injected into a product (e.g., in food processing, sterilization), entrained water and its dissolved impurities can directly contaminate the final product.

Reduced Boiler Efficiency: Wet steam implies that energy is being carried out of the boiler in the liquid phase rather than as usable latent heat, reducing the overall thermal efficiency of the boiler system.

Center Enamel’s Specialized Leadership in Steam-Water Separator Technology

Center Enamel’s distinguished position as China’s leading manufacturer of steam-water separators is built upon a foundation of highly specialized expertise and an unwavering commitment to performance and reliability in this critical domain:

1. Mastery in Design and Engineering for Optimal Two-Phase Flow:

Our engineering prowess in steam-water separators is rooted in a deep understanding of two-phase flow regimes, droplet dynamics, and the complex interactions between high-velocity steam and entrained water. Our team of highly qualified engineers specializes in designing vessels that maximize steam dryness and purity while minimizing pressure drop. We meticulously consider factors such as:

Steam Conditions: Designing for specific operating pressures, temperatures, and steam flow rates, which dictate optimal vessel sizing, internal velocities, and material selection.

Inlet and Outlet Design: Optimizing inlet distributors to ensure uniform steam flow into the separator, minimize turbulence, and facilitate initial bulk separation. Outlet designs prevent re-entrainment of separated water.

Integration of Multiple Separation Principles: Our designs often combine gravity separation, impingement (using baffles or impingement plates), and/or cyclonic action (using internal cyclonic elements or vanes) for multi-stage, highly efficient moisture removal, followed by fine polishing with mesh pads or vane separators.

Efficient Water Collection and Drainage: Designing robust and reliable systems for the rapid collection and drainage of separated condensate to prevent its re-entrainment into the clean steam flow. This includes optimizing downcomers and ensuring adequate liquid holdup.

Thermal and Mechanical Stress Analysis: Accounting for the significant thermal cycling and pressure stresses inherent in steam systems, ensuring the vessel's long-term integrity.

Advanced Simulation & Optimization: We utilize state-of-the-art computational tools, including Computational Fluid Dynamics (CFD) simulations, to accurately model complex two-phase steam-water flow patterns, predict droplet trajectories, analyze pressure drop, and optimize the effectiveness of internal components (baffles, cyclones, mesh pads). This sophisticated approach ensures that every Center Enamel steam-water separator is engineered for peak performance, unparalleled safety, and exceptional longevity.

2. Precision Manufacturing for Flawless Performance in High-Energy Systems:

The precision of a steam-water separator’s fabrication is paramount for controlling high-energy steam, ensuring effective moisture removal, and maintaining structural integrity under thermal cycling. At Center Enamel, our state-of-the-art facilities employ advanced fabrication techniques that guarantee:

Accurate Vessel Forming & Internal Fit-Up: Utilizing heavy-duty plate rolling and forming machines to create robust pressure containment shells with precise dimensions. Crucially, the intricate internal structures (baffles, cyclonic elements, mesh pad frames) are fabricated and integrated with exacting precision and alignment, ensuring that steam flows correctly through the separation stages without bypass.

Superior Welding & Internal Finish: Automated welding systems ensure high-integrity, defect-free welds for all pressure boundary components and internal attachments. Advanced grinding and polishing techniques are applied to internal surfaces where required to minimize resistance to steam flow and facilitate the smooth drainage of separated water.

Tight Tolerances: Adherence to strict dimensional tolerances for internal clearances, steam flow paths, and drainage systems is vital for preventing water carryover and optimizing separation efficiency.

Rigorous Assembly: The precise assembly and securing of internal elements within the vessel are critical for optimal performance and preventing dislodgement under high-velocity steam flow and vibration.

3. Tailored Material Selection for High-Temperature Steam and Condensate:

Steam-water separators operate in high-temperature environments where materials must resist creep, thermal fatigue, steam erosion, and corrosion from condensate. Center Enamel’s metallurgical experts possess extensive knowledge in specifying the optimal materials for these demanding applications:

Carbon Steel (various grades): For lower pressure and temperature steam applications.

Low-Alloy Steels (e.g., Chrome-Moly steels): For elevated temperature applications where creep strength is important, such as in power plant boiler drums.

Stainless Steels (304, 316, 316L): For enhanced corrosion resistance against condensate or specific process steam impurities, and for moderate-to-high temperatures.

High-Temperature Alloys: For specific applications with extremely high steam temperatures or corrosive steam environments.

Clad Materials: Combining the structural integrity of carbon steel with the corrosion resistance of an alloy layer where only the wetted surface needs high-grade material.

Our ability to select and expertly fabricate these materials ensures that our steam-water separators deliver exceptional longevity, even in the most demanding operational environments characterized by high temperatures, pressures, and thermal cycling.

4. Rigorous Testing and Quality Assurance for Critical Safety and Performance:

Safety, efficiency, and unwavering reliability are paramount for steam-water separators, especially given their role in protecting high-value equipment like steam turbines and ensuring energy system integrity. Center Enamel’s commitment to quality is underscored by comprehensive testing at every stage:

Comprehensive Nondestructive Testing (NDT): Ultrasonic Testing (UT), Radiographic Testing (RT), Magnetic Particle Testing (MPT), and Dye Penetrant Inspection (DPI) are performed on all critical welds to detect any subsurface or internal flaws, ensuring complete weld integrity for long-term pressure and temperature containment.

Hydrostatic/Pneumatic Pressure Tests: Every pressure-containing steam-water separator undergoes these rigorous tests, exceeding its design pressure, to unequivocally verify structural soundness, leak-tightness, and integrity under internal pressure, ensuring safe and reliable operation.

Internal Fit-up & Alignment Checks: Meticulous visual and dimensional inspections are conducted to confirm the proper installation, alignment, and internal geometry of all components (baffles, cyclonic elements, demisters), which is crucial for optimal steam flow and separation efficiency.

Third-Party Inspections: We regularly accommodate and cooperate with independent third-party inspection agencies (such as Lloyd's Register, TÜV, SGS) to further validate compliance with international codes (e.g., ASME Section I/VIII, PED with CE mark) and client specifications, providing external assurance of our quality.

5. Extensive Global Project Experience in Diverse Steam Applications:

Center Enamel’s footprint extends across the globe, having successfully supplied a wide range of steam-water separators to diverse industries and challenging environments across Asia, Africa, the Middle East, Europe, and the Americas. Our extensive project experience includes:

Power Generation: Supplying boiler drum internals (steam-water separators), moisture separators re-heaters (MSRs) for nuclear power plants or waste-to-energy facilities to dry saturated steam before it enters subsequent turbine stages, and separators for auxiliary steam systems.

Petrochemical & Chemical: Essential in evaporators, reboilers, flash drums, and general process steam lines to ensure dry steam for heating, stripping, or as a reactant, protecting downstream equipment and processes.

Food & Beverage: Critical for producing high-quality, dry steam for sterilization processes (e.g., retort cooking), direct steam injection for product heating, and ensuring product purity.

Pharmaceutical: Providing clean, dry steam for sterilization of equipment, vessels, and media in aseptic environments, meeting stringent regulatory requirements.

HVAC & Utilities: For central steam distribution systems to improve overall energy efficiency, prevent water hammer, and ensure reliable operation of steam-heated equipment.

Our experienced project management teams possess deep expertise in navigating complex international trade regulations, customs procedures, and multi-modal logistics, ensuring efficient and timely delivery of even the largest and most specialized steam-water separators to any location worldwide.

6. Client Collaboration and Comprehensive After-Sales Support:

Our customer-centric approach extends to close collaboration with clients' process engineers and power plant operators to ensure that the manufactured steam-water separator precisely integrates with their system and fulfills the specified steam dryness targets, acceptable pressure drops, and operational requirements. Post-delivery, we provide comprehensive documentation, detailed installation guidance, and robust technical support for operational and maintenance aspects, ensuring sustained optimal performance and maximizing the service life of our steam-water separators.

Why Center Enamel Excels in Steam-Water Separators

Center Enamel’s leading position in the steam-water separator manufacturing market is defined by several key differentiating factors:

Guaranteed High Steam Dryness & Purity: Our meticulous design based on advanced two-phase flow principles ensures exceptional moisture removal efficiency, delivering high-quality, dry steam that protects critical assets and optimizes processes.

Superior Turbine & Equipment Protection: By effectively eliminating erosive water droplets, our separators significantly extend the lifespan of costly steam turbines, valves, and other steam-handling equipment, reducing maintenance and preventing unscheduled downtime.

Enhanced Boiler & Process Efficiency: Delivering dry steam improves the thermal efficiency of boilers and downstream heat exchangers, leading to significant energy savings and optimized operational costs.

Prevention of Water Hammer & Corrosion: Our efficient separation prevents dangerous water hammer phenomena and minimizes the carryover of dissolved solids, reducing corrosion throughout the steam system.

Robust Design & Long-Term Durability: Crafted from meticulously selected materials and fabricated with precision, our steam-water separators are built for an extended operational life, designed to withstand high temperatures, pressures, and thermal cycling inherent in steam systems.

Customization for Varied Steam Conditions: We thrive on the challenges of diverse steam conditions and system requirements, providing bespoke solutions tailored to unique flow rates, pressures, and dryness targets.

Comprehensive Compliance with Global Standards: Our extensive certifications (ASME Section I/VIII, PED with CE mark; ISO) provide clients with the confidence and assurance required for global project execution and regulatory approval across diverse jurisdictions.

In a global industrial landscape where the integrity of steam systems and the efficient utilization of energy are fundamental to success, the role of reliable and high-performance steam-water separators is indispensable. Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel) stands as the definitive leader among China’s manufacturers in this specialized field. Our unwavering commitment to mastering the intricacies of steam-water separation, coupled with our state-of-the-art manufacturing capabilities, rigorous quality control, and a profound understanding of diverse industry applications, collectively define our leadership. We are not just building vessels; we are engineering critical infrastructure that purifies steam, safeguards operations, optimizes energy use, and drives sustainable growth across global industries. We invite industries worldwide to partner with Center Enamel, the trusted leader, to achieve unparalleled efficiency, enhance operational reliability, and secure the foundational strength of your steam-based processes, building a future of innovation and sustained success.

0 notes

Text

Improving Patient Care: How Heat and Moisture Exchanger Filters Help Hospitals

In hospitals, there is something extremely crucial that often goes unnoticed, but it plays a significant role in aiding patients. It is called a heat and moisture exchanger filter. These small devices are really important for maintaining clean and comfortable air for people who require medical assistance.

Making Breathing Easier: What's a Heat and Moisture Exchanger Filter?

Imagine a person who's sick and needs help breathing. These filters are like helpers for them. They're put in machines that help with breathing. These filters do a special job: they save the warmth and wetness when a person breathes out and give it back when they breathe in. It's like nature's way of breathing but helped by these devices. This way, the air the patient breathes is just right for their body.

Helping Treatments Work Better

When doctors give medicines through a breathing machine, these filters make sure the medicine works the best it can. They help keep the right amount of wetness in the patient's lungs, which makes the medicine work better. It's like making sure the medicine does its job properly.

Keeping the Air Clean and Safe

Hospitals can have germs that can make people sicker. These filters are like guards. They stop those germs from going into the breathing machines. This helps keep the air clean and safe for patients. It's like having extra protection to make sure people in the hospital don't get more sick from bad air.

Making Patients More Comfortable

When someone is in the hospital, feeling comfy is really important. These filters help with that, too! They keep the air just the way it should be for someone to feel relaxed. It's like having a cozy blanket for your breathing.

Getting Better with New Technology

Just like phones and computers get better with new things, these filters do too. People who make them keep finding new ways to make them work even better. They're always trying to make sure patients get the best care possible.

In hospitals, everything matters when it comes to making patients feel better. Heat and moisture exchanger filters might be small, but they're superheroes. They help patients breathe better, make treatments work well, keep the air clean, and make the hospital feel more like home. They're proof that even the smallest things can make a big difference in taking care of people.

1 note

·

View note

Text

HVAC Los Altos

Understanding HVAC in Los Altos: A Complete Guide to Comfort and Efficiency

When it comes to maintaining a comfortable home or business environment in Los Altos, HVAC systems play an essential role. From the heat of summer to the occasional chill of winter, having a reliable heating, ventilation, and air conditioning (HVAC) system ensures you stay comfortable year-round. But HVAC in Los Altos is more than just convenience—it's also about energy efficiency, indoor air quality, and long-term sustainability.

Whether you’re a homeowner looking to upgrade your unit or a business owner preparing for seasonal changes, understanding the components and benefits of HVAC systems can help you make informed decisions. In this guide, we’ll explore the essentials of HVAC in Los Altos, including system types, efficiency considerations, maintenance tips, and regional factors unique to this part of California.

What Does HVAC in Los Altos Typically Include?

HVAC stands for heating, ventilation, and air conditioning, and each component plays a specific role in maintaining indoor comfort.

Heating: In Los Altos, heating systems are often required during the cooler months, particularly during the winter when temperatures can dip into the 40s. Common heating solutions include furnaces (gas or electric), heat pumps, and radiant floor heating. While the demand for heat may not be as high as in colder climates, an efficient heating system remains a crucial part of any HVAC setup.

Ventilation: Ventilation is the process of exchanging indoor and outdoor air to improve air quality. It helps remove moisture, odors, smoke, heat, dust, airborne bacteria, and carbon dioxide. In areas like Los Altos, where residents often keep windows closed due to wildfire concerns or air quality alerts, a mechanical ventilation system is important for maintaining healthy indoor environments.

Air Conditioning: Summers in Los Altos are warm and dry, making air conditioning a necessity for most homes and businesses. Central air systems, ductless mini-splits, and even hybrid systems can be found throughout the region. The key is choosing a unit with the right capacity and SEER (Seasonal Energy Efficiency Ratio) rating to balance comfort with energy use.

Energy Efficiency Considerations for HVAC in Los Altos

Los Altos residents are environmentally conscious and often interested in energy-saving technologies. An energy-efficient HVAC system isn’t just better for the planet—it also lowers monthly utility bills and extends the life of the system.

SEER and AFUE Ratings: SEER ratings apply to air conditioning units, and the higher the SEER rating, the more efficient the system. For heating systems, the AFUE (Annual Fuel Utilization Efficiency) rating measures how efficiently fuel is converted into heat. In California, where energy regulations are strict, high-efficiency systems can also help homeowners qualify for rebates and tax incentives.

Smart Thermostats: Integrating a smart thermostat with your HVAC system allows for better control over temperature settings, learning your habits, and reducing energy waste. Many smart thermostats are compatible with home automation systems, making them a popular choice for tech-savvy residents of Los Altos.

Zoning Systems: Zoning divides the home into different temperature areas, allowing specific parts of the house to be heated or cooled independently. This is ideal for multi-story homes or buildings with rooms that receive more sun exposure.

The Importance of Indoor Air Quality

Air quality is a growing concern across California due to seasonal wildfires and increasing pollution. HVAC systems in Los Altos must be equipped to handle these challenges.