#hastelloy c276 composition

Explore tagged Tumblr posts

Text

Hastelloy C-276

Hastelloy C-276

C276 alloys are widely used in chemical and petrochemical fields, such as in components and catalytic systems that are exposed to chlorinated organics. This material is especially suitable for use in high temperature, inorganic and organic acids (such as formic acid and acetic acid) mixed with impurities, and seawater corrosion environment.

Chemical composition

Alloy % Nickel chromium molybdenum iron tungsten cobalt carbon manganese silicon vanadium phosphorus sulfur

Ha C Minimum allowance 14.5 15 4 3

Max 16.5 17 7 4.5 2.5 0.08 1 1 0.35 0.04 0.03

C276 Minimum Margin 14.5 15 4 3

Max 16.5 17 7 4.5 2.5 0.01 1 0.08 0.35 0.04 0.03

peculiarity

1. In oxidation and reduction state, it has excellent corrosion resistance to most corrosive media.

2. Excellent resistance to spot corrosion, crevice corrosion and stress corrosion cracking.

Metallographic structure of HastelloyC-276

C276 has a face-centered cubic lattice structure.

Corrosion resistance of HastelloyC-276

C276 alloys are suitable for a variety of chemical process industries containing oxidizing and reducing media. The high content of molybdenum and chromium make the alloy resistant to chloride ions, and the tungsten element further improves its corrosion resistance. C276 is one of the only materials that can resist the corrosion of humid chlorine, hypochlorite and chlorine dioxide solutions, and the alloy has significant corrosion resistance to high concentrations of salt chloride solutions (such as ferric chloride and copper chloride).

HastelloyC-276 Application range Application areas are:

C276 alloys are widely used in chemical and petrochemical fields, such as in components and catalytic systems that are exposed to chlorinated organics. This material is especially suitable for use in high temperature, inorganic and organic acids (such as formic acid and acetic acid) mixed with impurities, and seawater corrosion environment.

Other application areas

1. Pulp and paper industry, such as boiling and bleaching containers

2. Scrubber, reheater, wet steam fan in FGD system

3. Equipment and components operating in acidic gas environments

4. Reactor for acetic acid and acidic products

5. Sulfuric acid condenser

6. Methylene diphenyl isocyanate (MDI)

7. Production and processing of impure phosphoric acid

0 notes

Text

#hastelloy c-276 composition#hastelloy c 276 composition#hastelloy c276 suppliers#c276 composition#hastelloy c276 chemical composition#hastelloy c276 composition

0 notes

Text

Hastelloy C276: Chemical Composition, Mechanical Properties

Introduction:

Hastelloy C276, known by its UNS N10276 designation, is a versatile and highly sought-after nickel-molybdenum-chromium alloy. In this comprehensive guide, we will delve into its chemical composition, explore its remarkable properties, and shed light on its wide range of applications across various industries. Additionally, we will discuss its exceptional resistance to corrosion, and the essential aspects of fabrication and heat treatment.

Hastelloy C276 Chemical Composition:

ElementContent (%)Nickel, Ni57Molybdenum, Mo15-17Chromium, Cr14.5-16.5Iron, Fe4-7Tungsten, W3-4.50Cobalt, Co2.50Manganese, Mn1Vanadium, V0.35Silicon, Si0.080Phosphorous, P0.025Carbon, C0.010Sulfur, S0.010

Hastelloy C276 Physical Properties:

PropertiesMetricImperialDensity8.89 g/cm³0.321 lb/in³Melting point1371°C2500°F

Hastelloy C276 Mechanical Properties:

PropertiesMetricImperialTensile strength (@thickness 4.80-25.4 mm, 538°C/@thickness 0.189-1.00 in, 1000°F)601.2 MPa87200 psiYield strength (0.2% offset, @thickness 2.40 mm, 427°C/@thickness 0.0945 in, 801°F)204.8 MPa29700 psiElastic modulus (RT)205 GPa29700 ksiElongation at break (in 50.8 mm, @thickness 1.60-4.70 mm, 204°C/@thickness 0.0630-0.185 in, 399°F)56%56%Hardness, Rockwell B (plate)8787

Hastelloy C276 Thermal Properties:

PropertiesMetricImperialThermal expansion co-efficient (@24-93°C/75.2-199°F)11.2 µm/m°C6.22 µin/in°FThermal conductivity (-168 °C)7.20 W/mK50.0 BTU in/hr.ft².°F

Equivalent materials to Hastelloy C276:

ASTM B366ASTM B574ASTM B622ASTM F467DIN 2.4819ASTM B575ASTM B626ASTM B619ASTM F468

Chemical Composition:

Hastelloy C276 primarily consists of the following key elements:

Nickel (Ni): The primary component, providing a strong base for the alloy’s exceptional performance.

Molybdenum (Mo): Enhances corrosion resistance, particularly in reducing environments.

Chromium (Cr): Contributes to the alloy’s resistance to oxidizing agents like chlorides and oxidizing acids.

Iron (Fe): An essential element, which when present in controlled amounts, maintains the required mechanical properties.

Tungsten (W) and Cobalt (Co): Elements that further strengthen the alloy and provide stability against crevice corrosion.

Properties:

Hastelloy C276 boasts several remarkable properties that make it an ideal choice for challenging environments:

Corrosion Resistance: Its outstanding resistance to a wide range of aggressive media, including strong acids, chlorides, and seawater, sets it apart from conventional alloys.

High Temperature Resistance: The alloy retains its mechanical strength and integrity even at elevated temperatures, making it suitable for high-temperature applications.

Excellent Fabricability: Hastelloy C276 can be easily formed, welded, and machined, providing flexibility during fabrication processes.

Good Mechanical Properties: The alloy exhibits excellent tensile and impact strength, further enhancing its suitability for various industrial applications.

Applications:

Due to its exceptional properties, Hastelloy C276 finds applications in diverse industries, including:

Chemical Processing: It is extensively used in handling corrosive chemicals and acidic solutions.

Petrochemical Industry: The alloy is employed in reactor vessels, heat exchangers, and other equipment exposed to aggressive media.

Oil and Gas: In offshore drilling environments and sour gas wells, Hastelloy C276 ensures reliable performance.

Pollution Control: It plays a vital role in the construction of flue gas desulfurization systems and other pollution control equipment.

Pharmaceutical and Pulp & Paper: Its corrosion resistance makes it valuable in pharmaceutical production and pulp and paper processing.

Resistance to Corrosion:

Hastelloy C276 stands out for its exceptional resistance to both uniform and localized corrosion. It maintains its integrity in aggressive environments, where other materials might fail. The alloy’s resistance to pitting, crevice corrosion, and stress corrosion cracking makes it highly reliable, especially in chloride-rich conditions.

Fabrication and Heat Treatment:

Hastelloy C276 offers ease of fabrication, allowing it to be formed into various shapes using standard techniques. Weldability is excellent, and the alloy can be joined using common welding processes like TIG and MIG welding. To achieve the desired properties, post-weld heat treatment is recommended.

Conclusion:

Hastelloy C276 is a remarkable nickel-based alloy that excels in demanding environments, thanks to its exceptional properties and resistance to corrosion. Its wide range of applications across industries underscores its versatility and reliability. Whether in chemical processing, petrochemicals, or other challenging settings, Hastelloy C276 Pipe continues to prove its worth, ensuring the integrity and longevity of critical equipment. Contact Now for more information

Learn More: Erw vs Spiral Pipe : Difference

0 notes

Photo

"Hatelloy Wires Manufacturer & Exporter."

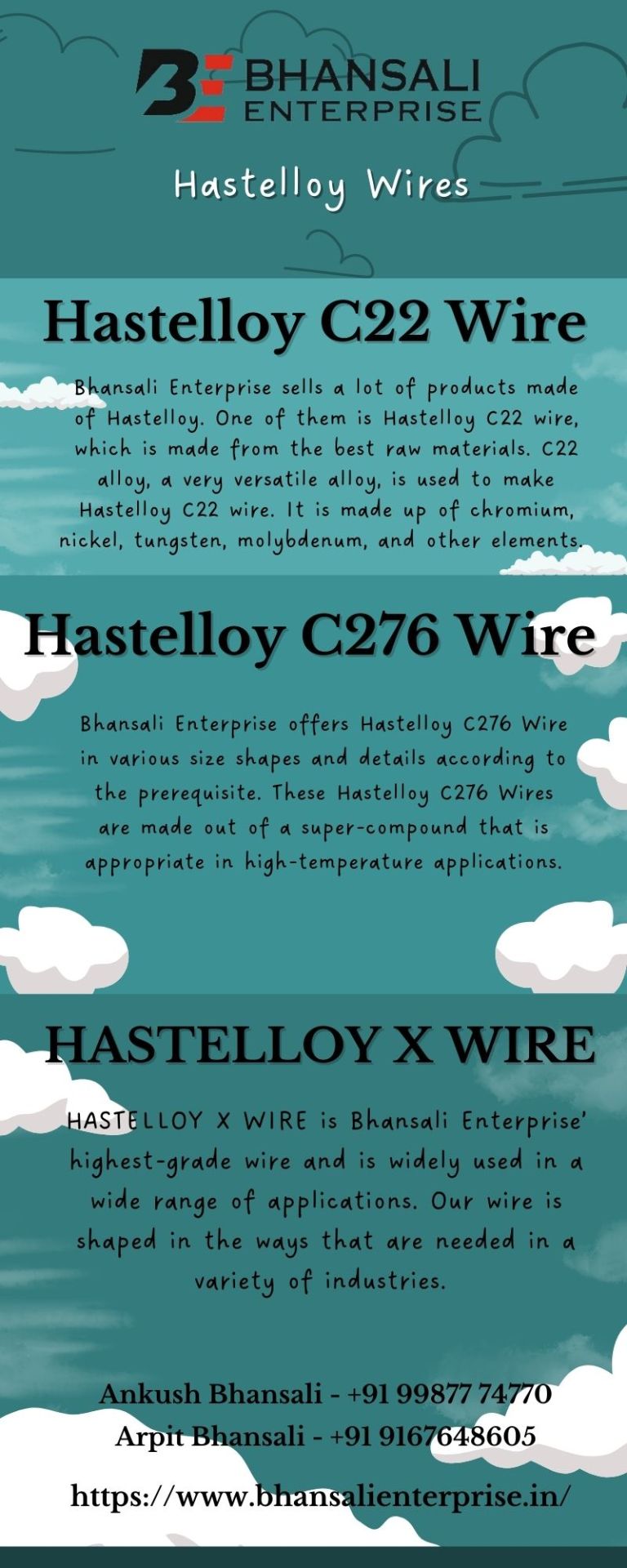

Bhansali Enterprise sells a lot of products made of Hastelloy. One of them is Hastelloy C22 wire, which is made from the best raw materials. C22 alloy, a very versatile alloy, is used to make Hastelloy C22 wire. It is made up of chromium, nickel, tungsten, molybdenum, and other elements. Components made of material grade C22 have increased resistance to corrosion and a variety of industrial chemicals as a result of these elements. Bhansali Enterprise offers Hastelloy C276 Wire in various size shapes and details according to the prerequisite. These Hastelloy C276 Wires are made out of a super-compound that is appropriate in high-temperature applications. It is made up of chromium, nickel, and molybdenum alloy, which has excellent resistance to corrosion in an oxidizing environment. It is a corrosion-resistant alloy made of nickel, chromium, and molybdenum. Stress corrosion cracking, crevice corrosion, and pitting are all prevented by this alloy. These Hastelloy C276 Wires shows the capacity to limit the carbide precipitation while welding. Additionally, it exhibits excellent resistance to minimizing or preventing grain boundary precipitates during welding. HASTELLOY X WIRE is Bhansali Enterprise’ highest-grade wire and is widely used in a wide range of applications. Our wire is shaped in the ways that are needed in a variety of industries. These wires are held to specified standards, and dimensional changes define various specifications. With a higher Hastelloy grade, these wires are easier to form and more ductile. It has a higher tensile strength and is made specifically for use in applications at higher temperatures. HASTELLOY X, also known as a superalloy, is a high-performance alloy that keeps features like super strength, resistance to creep and cracking, and sustainability under high temperatures and corrosion.

#stainless steel wire#wire manufacturers#stainless steel wire manufacturers in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#hastelloy composition#hastelloy c276 chemical composition#polished stainless steel#stainless steel manufacturers in india

0 notes

Text

Humming a tune, walking into the empty Stark Laboratory, whistling a tune as I settle down...

'J.A.R.V.I.S, come in, it's playtime...'

Monitor system buzzing, activating processing units...

Evening Ma'am. Feeling Creative, I see. How would you like your ambience, Miss Grace?

'What can I say, J, I'm in the mood for work tonight, Aren't you too? Smiles...Just play whatever Mister Stark has on his playlist...'

Noted. Now Playing- Paint it Black by The Rolling Stones

Going into Creative, Miss Grace...

'Restore all of the last few browsings and display into list, please.'

LAST BROWSINGS:

What are the fundamental principles for designing high-entropy alloys with superior strength, ductility, and corrosion resistance for specific applications?

How can we optimize the microstructure of metallic materials to achieve a balance between strength, toughness, and fatigue resistance for specific applications, such as aerospace and automotive?

How can we ensure the long-term durability and safety of nuclear power plant components, considering the harsh radiation and temperature environments?

What are the environmental impacts of metal extraction, processing, and recycling, and how can we develop sustainable strategies to minimize these impacts?

How can we effectively integrate advanced characterization techniques to understand the degradation mechanisms of metallic components in service, and use this knowledge to improve component life and reliability?

Smiles...

'Thank you, I'll be needing that next...Now give me....sustainable microfibre alloy proportions...'

Very Well. You will now need narrowing down from your records.

Iron-based alloys: Often used in machinery due to abundance and cost-effectiveness.

Nickel-based alloys: Known for high-temperature strength and corrosion resistance, suitable for nuclear components.

Titanium alloys: Lightweight and corrosion-resistant, but expensive. High-entropy alloys: Emerging class of alloys with potential for unique properties.

'Now give the proportions we've considered the last time we looked into our simulators, Only for....the Nickel Based Alloys, make a list...'

Looks over thoughtfully as the list is being formulated...scrolls down the list, switching screens on the holograms...

Monel: A nickel-copper alloy known for corrosion resistance. 63% nickel, between 29% and 34% copper, between 2% and 2.5% iron, and between 1.5% and 2% manganese.

Inconel: A family of nickel-chromium-based alloys, often used in high-temperature applications. 61% nickel, 22% chromium, and 9% molybdenum

Hastelloy: A group of nickel-based alloys with exceptional corrosion resistance in various media. Hastelloy C276, also known as UNS N10276, has the following chemical composition: Nickel (Ni): 57%, Molybdenum (Mo): 15–17%, Chromium (Cr): 14.5–16.5%, Iron (Fe): 4–7%, Tungsten (W): 3–4.5%, Manganese (Mn): 1% maximum, Cobalt (Co): 2.5% maximum, Vanadium (V): 0.35% maximum and Silicon (Si): 0.08 maximum

Incoloy: Nickel-iron-chromium alloys designed for high-temperature applications and resistance to oxidation. Nickel: 38–46%, Chromium: 18–22%, Iron: Balance, Aluminum: 0.3–0.7%, Titanium: 0.15–0.6%, Manganese: 1.5% max, Silicon: 1% max, Carbon: 0.05% max, Sulfur: 0.015% max and Phosphorus: 0.02% max

Smirks, clapping my hands twice, the data reducing to 17 little fragments of hologram, flicking away the unnecessary bits that remain of the non highlighted data...

Data Compiled, Miss.

'Yeah, good... you've been writting down what I've been saying while I was in the simulation unit the other day and today, haven't you...?'

Yes Ma'am.

'Turn all of that, into that research booklet we were asked for, so we can give him what....roughly, an estimated idea of the whole entire suit, merits and demerits, budgeting and assemblance...give him the blueprints too, at the end of it...I have a feeling this one will not... disappoint...'

Working on it, Ma'am.

Runs hands on my face tiredly, waiting for it to compile, drumming fingers onto the table, cracks neck, shifts head...

Report Compiled, Ma'am.

'Good boy, J. You've been a darling, tonight, great help, I can never thank you enough... sometime when you're human, or if...Imma owe you big time.'

No worries, Ma'am. You've been quite amazing to work with as well.

Smiles...

'Let's call it a night, J.A.R.V.I.S...Thank you...Good Night...'

Hologram goes off...

Goodnight Ma'am.

______________________________________

( @tony-starkinator @the-loss-of-my-life )

2 notes

·

View notes

Text

Exploring the Versatility of Hastelloy Nuts in High-Temperature Environments

We offer brilliant quality fasteners, which include Hastelloy nuts, designed to be used in extremely harsh environments. We are an ISO-certified company based in Navi Mumbai. Fasteners & Fixtures LLP delivers products that ensure remarkable performance in industries. In this weblog, we’ll discover why Hastelloy C4 nuts, Hastelloy G-30 nuts, and Hastelloy C276 hex nuts are important for high-temperature applications and the way they can enhance the mechanical performance of your systems.

Introduction

Hastelloy nuts are fasteners crafted from Hastelloy, an alloy in particular composed of nickel with iron, chromium, and molybdenum. Hastelloy alloy nuts have an excellent ability to withstand excessive temperature and corrosion resistance due to this composition. They are important in programs wherein fasteners must face up to excessive temperatures, pressures, and corrosive conditions. We make those nuts in accordance with standard necessities, ensuring dependable standard performance even under the most demanding situations.

Why Choose Hastelloy Nuts for High-Temperature Environments?

Superior Heat Resistance

Hastelloy alloy nuts are designed to withstand excessive temperatures, withstanding as much as 1200°F (650°C) without losing their structural integrity. This makes them best for industries collectively with aerospace, vehicles, and power generation, wherein structures regularly feature below immoderate thermal stresses. These fasteners are perfect for turbine engines, boilers, and jet engines.

Corrosion Resistance

Another key advantage of Hastelloy alloy nuts is their corrosion resistance, even in harsh chemical environments. The excessive levels of molybdenum and chromium provide robust safety in the direction of competitive chemical compounds, seawater, and acids. For instance, Hastelloy alloy nuts are utilized in offshore rigs and chemical reactors wherein corrosion should otherwise compromise the integrity of the gadget.

Strength and Durability

The sturdiness of Hastelloy C276 or G-30 nuts makes them nice for high-pressure applications. They maintain their strength even under severe pressure and thermal situations, preventing troubles in industries like production, mining, and electricity technology. Hastelloy alloy nuts reduce the want for common maintenance and replacements, enhancing the general reliability of equipment.

Applications of Hastelloy Nuts in Critical Industries

The versatility of Hastelloy alloy nuts makes them appropriate for a huge variety of programs:

Aerospace: Used in turbine engines and jet propulsion structures, wherein excessive temperatures and mechanical stresses are common.

Chemical Processing: Essential in chemical reactors and distillation columns exposed to competitive chemical substances.

Energy Generation: Widely used in boilers, gasoline mills, and nuclear reactors in power plants.

Marine: Ideal for offshore rigs, ships, and unique marine programs exposed to seawater and cruel weather.

Why Choose Fasteners & Fixtures LLP for Your Hastelloy Nuts?

We are dedicated to presenting excessive-performance Hastelloy C4 nuts, Hastelloy G-30 nuts, and Hastelloy C276 hex nuts that meet your particular desires. Here’s why we’re your relied-on supplier:

Expertise in High-Performance Fasteners

With years of experience within the fastener industry, we specialize in generating precision fasteners, which incorporate Hastelloy alloy nuts that perform reliably under extreme conditions. Our team guarantees that each nut undergoes stringent testing to guarantee power, durability, and corrosion resistance.

Quality Test and Quality Assurance

All of our products meet international standards by undergoing testing, which encompasses ISO 9001 and ASTM specifications, ensuring reliability and performance.

Custom Solutions

We recognize that every utility may have specific necessities. That’s why we offer customized Hastelloy C4 nuts and Hastelloy C276 hex nuts tailor-made to satisfy particular needs or requirements, making sure that your fasteners are ideally fitted for your operations.

Competitive Pricing & Timely Delivery

We offer competitive pricing without compromising on superb. Our efficient manufacturing and logistics structures make sure that to procure your Hastelloy nuts on time, lowering any delays in your duties.

Case Study: Aerospace Industry

Challenge: The fasteners on an aerospace manufacturer's turbine engines are giving them common trouble. The nuts used previously couldn't manage the high temperatures and everyday vibrations, leading to high-priced preservation and downtime.

Solution: Fasteners & Fixtures LLP provided Hastelloy nuts crafted from Hastelloy C-276, regarded for its high-temperature resistance and sturdiness. These nuts had been hooked up to strong vital components inside the turbine engines.

Outcome: After switching to Hastelloy alloy nuts, the producer noticed a 25% price cut in preservation prices. The Hastelloy nuts ensured good performance under excessive conditions, increasing performance and lowering operational downtime.

Conclusion: Choose Us for Your Hastelloy Nuts Needs

In conclusion, Hastelloy nuts are necessary for industries requiring high-temperature and corrosion-resistant fasteners. Whether you’re in aerospace, chemical processing, or power generation, Hastelloy alloy nuts provide remarkable sturdiness and reliability.

We at Fasteners & Fixtures LLP offer Hastelloy alloy nuts that adhere to the highest organizational standards, guaranteeing optimal system performance. Our ISO-certified manufacturing facility guarantees pleasantness and reliability. Select us for your Hastelloy C4 nuts, Hastelloy G-30 nuts, and Hastelloy C276 hex nuts and experience the distinction between superior and superior quality.

0 notes

Text

Hastelloy C276 Sheets And Plates Exporters in India

When it comes to corrosion resistance and durability, few materials can match the performance of Hastelloy C276 sheets and plates. At Metcore Steel & Alloys, we pride ourselves on offering top-quality products that meet the stringent demands of various industries. In , we will explore what Hastelloy C276 sheets and plates are, their advantages, and their wide range of applications across different sectors.

What is Hastelloy C276 Sheets And Plates?

Hastelloy C276 is a nickel-molybdenum-chromium alloy that includes tungsten, designed to offer exceptional resistance to pitting, stress corrosion cracking, and oxidizing atmospheres. Known for its robustness, Hastelloy C276 sheets and plates are extensively used in environments that require superior performance against corrosive elements. Metcore Steel & Alloys, a trusted name among Hastelloy C276 Sheets and Plates Manufacturers, ensures that these products are fabricated to meet the highest quality standards, making them an ideal choice for critical applications.

Hastelloy C276 sheets and plates are flat-rolled products made from the Hastelloy C276 alloy. These sheets and plates are known for their exceptional resistance to a wide range of severe environments, including chemical processing, petrochemical, and power generation industries. The alloy's unique composition, which includes high levels of nickel, molybdenum, and chromium, along with the addition of tungsten, enhances its resistance to both localized and uniform corrosion. As a result, Hastelloy C276 Sheets and Plates Suppliers like Metcore Steel & Alloys ensure that these products offer unparalleled performance in aggressive settings.

Advantages of Hastelloy C276 Sheets And Plates?

Outstanding Corrosion Resistance: Hastelloy C276 sheets and plates provide superior protection against a variety of corrosive chemicals, including chlorides, sulfur compounds, and organic acids. This makes them suitable for applications where other materials would quickly fail.

High Temperature Stability: These sheets and plates maintain their integrity even at elevated temperatures, making them ideal for high-heat environments such as chemical reactors and power plants.

Resistance to Stress Corrosion Cracking: The alloy's nickel and molybdenum content significantly reduce the risk of stress corrosion cracking, which is a common issue in highly corrosive environments.

Versatility: Available in various sizes and thicknesses, Hastelloy C276 sheets and plates can be customized to suit specific project requirements. This versatility makes them a preferred choice for Hastelloy C276 Sheets and Plates Stockists who cater to diverse industrial needs.

Ease of Fabrication: Despite its toughness, Hastelloy C276 is relatively easy to fabricate using conventional methods. This characteristic allows for efficient manufacturing of complex components without compromising the material's inherent properties.

#metal#heavy metal#metal sheets#pipesupplier#industrial metal#metalcore#metal family#metal sonic#sheets and plates#plates#Hastelloy C276 Sheets And Plates Manufacturers#Hastelloy C276 Sheets And Plates Suppliers#Hastelloy C276 Sheets And Plates Stockists#Hastelloy C276 Sheets And Plates Exporters

0 notes

Text

Hastelloy C276: The Ultimate Choice for Corrosion Resistance

Hastelloy C276 stands out as a top-tier alloy known for its exceptional corrosion resistance and durability. Its unique composition of nickel, molybdenum, and chromium ensures unmatched performance in aggressive environments. Industries like chemical processing, marine engineering, and pollution control rely on Hastelloy C276 tubes and pipes for their ability to resist pitting, stress corrosion cracking, and high temperatures.

Icon Steel offers premium Hastelloy C276 tubes, pipes, and round bars tailored to meet diverse industrial needs. Trust Icon Steel for quality, precision, and reliable solutions that enhance the durability and efficiency of your projects.

Explore more and upgrade your materials today!

0 notes

Text

Hastelloy C276 Coils Manufacturers in India

A vital component for many industrial applications, hastelloy C276 is an extremely adaptable and corrosion-resistant alloy. It is a great option for coils used in tough situations because of its special composition and qualities. To help you understand why Hastelloy C276 coils are a popular option in many industries, this blog explores their features, advantages, uses, and maintenance.

What is Hastelloy C276?

Hastelloy C276 is a nickel-molybdenum-chromium alloy known for its exceptional corrosion resistance. It also contains iron and tungsten, enhancing its strength and ability to withstand aggressive chemical environments. The alloy is particularly effective against localized corrosion, stress corrosion cracking, and oxidizing atmospheres.

Chemical Composition of Hastelloy C276

Hastelloy C276 owes its superior performance to its carefully balanced chemical composition:

Nickel (Ni): 57%

Molybdenum (Mo): 15-17%

Chromium (Cr): 14.5-16.5%

Iron (Fe): 4-7%

Tungsten (W): 3-4.5%

Cobalt (Co): 2.5% max

Manganese (Mn): 1% max

Silicon (Si): 0.08% max

Carbon (C): 0.02% max

This precise combination ensures excellent resistance to a broad range of chemical environments.

Key Properties of Hastelloy C276 Coils

Exceptional Corrosion Resistance:

Resistant to pitting, crevice corrosion, and stress corrosion cracking.

Performs well in harsh environments, including oxidizing and reducing conditions.

High Thermal Stability:

Retains mechanical integrity and corrosion resistance at elevated temperatures.

Weldability:

Hastelloy C276 coils can be easily welded using standard techniques without compromising their properties.

Mechanical Strength:

High tensile and yield strength make it suitable for demanding applications.

Versatility:

Suitable for diverse applications across industries.

Applications of Hastelloy C276 Coils

Hastelloy C276 coils are used extensively in industries where corrosion resistance is paramount. Some common applications include:

Chemical Processing Industry:

Reactors, heat exchangers, and columns exposed to acidic or chloride-rich environments.

Marine Industry:

Components in seawater systems and marine engineering.

Pharmaceutical Industry:

Equipment for processing corrosive chemicals in drug production.

Aerospace Industry:

Components in jet engines and other high-temperature systems.

Environmental Engineering:

Pollution control systems, scrubbers, and waste management equipment.

Pulp and Paper Industry:

Machinery exposed to acidic or chemical-laden environments during processing.

Benefits of Using Hastelloy C276 Coils

Durability:

Long service life reduces the need for frequent replacements.

Cost Efficiency:

Despite a higher initial cost, the reduced maintenance and downtime make it cost-effective in the long run.

Reliability:

Consistent performance under extreme conditions ensures operational efficiency.

Customizability:

Available in various sizes and thicknesses to meet specific requirements.

Maintenance and Care

To maximize the performance and lifespan of Hastelloy C276 coils, follow these maintenance practices:

Regular Cleaning:

Remove any buildup of deposits or contaminants to prevent localized corrosion.

Inspection:

Periodically inspect for signs of wear, corrosion, or mechanical damage.

Proper Storage:

Store in a clean, dry environment to avoid contamination or moisture exposure.

Welding Precautions:

Use appropriate filler materials and techniques to maintain the alloy’s properties during fabrication.

Why Choose Hastelloy C276 Coils?

Hastelloy C276 coils are a top choice for industries that demand exceptional corrosion resistance, mechanical strength, and reliability. Their ability to perform in aggressive environments ensures that they meet the most stringent requirements for critical applications. By choosing Hastelloy C276 coils, you invest in a material that delivers unmatched performance and long-term value.

Conclusion

The ultimate in corrosion-resistant materials, Hastelloy C276 coils provide unmatched endurance and adaptability. These coils may both meet and surpass your performance requirements, regardless of whether you work in the chemical, marine, or aerospace industries. Hastelloy C276 coils offer an affordable alternative that endures in the most demanding conditions when properly cared for and maintained.

For More Information:

Visit Our Website: https://www.jaimanmetalloys.com/

Email Id: [email protected] Contact No: +912223679777

#Hastelloy C276 Sheets#Hastelloy C276 Sheets Manufacturers#Hastelloy C276 Sheets Suppliers#Hastelloy C276 Sheets Stockists#Hastelloy C276 Sheets Exporters#Hastelloy C276 Sheets Manufacturers in India#Hastelloy C276 Sheets Suppliers in India#Hastelloy C276 Sheets Stockists in India#Hastelloy C276 Sheets Exporters in India.

0 notes

Text

Innovative Uses of Nickel in Cryogenic and Marine Environments

Nickel, a versatile and highly durable metal, is indispensable in many industries, from aerospace to energy. Its resilience in extreme temperatures, particularly in cryogenic and marine environments, makes it a favoured choice for applications requiring high performance under challenging conditions.

Nickel is widely recognised for its toughness, ductility, and resistance to corrosion, making it ideal for cryogenic (extremely low-temperature) and marine applications. Here’s why nickel is so suitable:

1. Cryogenic Flexible: Nickel and its alloys hold strength and ductility even at temperatures as low as -196°C (-321°F), a critical property for handling cryogenic fluids like liquid natural gas (LNG).

2. Corrosion Resistance: In marine environments, where equipment is exposed to seawater and salt air, nickel alloys provide outstanding resistance to corrosion, preventing deterioration that could compromise safety and performance.

Popular Nickel Alloys

High-grade nickel alloys, containing over 99% nickel, play an essential role in extreme environments like cryogenic and marine settings. This high purity level provides exceptional resistance to temperature changes and corrosion, making these alloys invaluable where durability and reliability are critical. Their unique composition ensures that they maintain ductility at low temperatures and corrosion resistance in saltwater, extending the lifespan of equipment and structures.

Key Mechanisms and Technical Specifications

Mechanical Strength and Fabrication Techniques: The marine industry requires materials that are not only corrosion-resistant but also have high tensile strength. Nickel alloys, especially Inconel 625, meet this requirement with a tensile strength of up to 830 MPa, making them suitable for constructing durable marine components like valves, pumps, and heat exchangers.

Innovations in Nickel Alloys

Research and development are propelling nickel alloys forward, exploring new compositions and treatments to enhance their resilience and adaptability. For example:

1. 3D Printing (Additive Manufacturing): Complex marine and cryogenic components can now be created with reduced waste and increased customization by using 3D-printed nickel alloys.

2. Nano-Coatings: Advanced coatings are being developed to further strengthen corrosion resistance, allowing nickel alloys to perform in environments with even higher salinity or more aggressive chemicals.

3. Superelasticity: New alloys are being researched to incorporate superelastic properties, which could allow nickel alloys to withstand greater strain, especially useful in the dynamic conditions of marine environments.

Standards and Certifications for Quality Assurance

For businesses sourcing nickel alloys for critical applications, compliance with industry standards is essential. Some of the widely recognized standards for nickel alloys include:

1. ASTM Standards: Such as ASTM B160 for Nickel 200, B443 for Inconel 625, and B575 for Hastelloy C276, which specify requirements for alloy compositions, tensile properties, and quality control.

2. NACE MR0175/ISO 15156: This is crucial in the oil and gas industry, making sure that alloys used in corrosive environments are safe and reliable.

When it comes to navigating extreme conditions, knowing How Nickel Alloys Excel in Tough Environments is essential. For durable, high-performance solutions in cryogenic and marine applications, trust Online Fittings to provide top-quality nickel alloys designed to withstand the harshest conditions. Contact us today to explore our reliable range of nickel products.

0 notes

Text

HASTELLOY C276 PLATE VS ALLOY 825 PLATE

Hastelloy C276 and Alloy 825 are two of the most popular options regarding corrosion-resistant alloys. These alloys are ideal for environments with paramount strength, durability, and corrosion resistance. However, deciding which one to choose can be confusing. In this blog post, we will compare the Hastelloy C276 plate and Alloy 825 plate to help you make an informed decision.

HASTELLOY C276 PLATE

Hastelloy C276 Plate is a nickel-molybdenum-chromium alloy with an addition of tungsten. It has superior corrosion resistance in oxidizing and reducing environments, making it suitable for chemical processing, flue gas desulfurization systems, and pollution control applications. It is highly resistant to pitting and crevice corrosion, stress cracking, intergranular attack, and general corrosion in most severely corrosive media. The Hastelloy C276 plate has excellent weldability with no pre- or post-weld heat treatments required.

ALLOY 825 PLATE

Alloy 825 Plate is a Nickel-based plate with high creep and stress rupture properties. It offers excellent corrosion resistance in many media, including sulfuric, phosphoric, and nitric acids. Adding molybdenum improves pitting and crevice corrosion resistance compared to the 800-range alloys. At the same time, copper allows for increased resistance to sulfide stress cracking and better general corrosion characteristics. Alloy 825 Plate is also used for applications involving seawater or phosphate environments where chloride ion contamination must be resisted.

DIFFERENCE BETWEEN HASTELLOY C276 AND ALLOY 825 PLATE

Chemical Composition:

Hastelloy C276 is a nickel-molybdenum-chromium superalloy that contains tungsten and is known for its excellent corrosion resistance in various acidic and alkaline media. On the other hand, Alloy 825 is a nickel-iron-chromium alloy that contains molybdenum, copper, and titanium and is also known for its excellent resistance to corrosion and stress cracking in various environments.

Mechanical Properties:

Hastelloy C276 has a high yield strength and is known for its excellent hardness, while Alloy 825 has a low yield strength and is known for its high ductility. This means that Hastelloy C276 is ideal for applications where strength is the primary concern, while Alloy 825 is better suited for applications where corrosion resistance and ductility are more important.

Corrosion Resistance

Both Hastelloy C276 and Alloy 825 are highly corrosion-resistant alloys. However, Hastelloy C276 has better pitting and crevice corrosion resistance due to its high molybdenum and tungsten content. In contrast, Alloy 825 has better resistance to oxidizing and reducing environments due to its high nickel and chromium content.

Tensile Strength

The Hastelloy C276 plate has a higher tensile strength than the Alloy 825 plate. This means that it is more resistant to being pulled or stretched apart.

Yield Strength

The Hastelloy C276 plate also has a higher yield strength than the Alloy 825 plate. This means that it can resist being deformed more before it starts to break.

Applications

Hastelloy C276 is commonly used in chemical processing, pollution control, and pulp and paper due to its excellent resistance to corrosive environments. On the other hand, Alloy 825 is commonly used in oil and gas production, chemical processing, and power generation industries due to its excellent resistance to stress corrosion cracking and pitting.

CONCLUSION

In conclusion, both the Hastelloy C276 plate and the Alloy 825 plate are great choices for applications that require corrosion resistance, strength, and durability. Hastelloy C276 is ideal for applications where resistance to pitting and crevice corrosion is crucial, while Alloy 825 is better suited for applications where corrosion resistance and ductility are more important. Ultimately, the choice between the two will depend on the specific requirements of your application and your budget. We hope that this comparison has helped you make an informed decision.

To Know More https://www.smmindustriesllp.com/hastelloy-c276-plate-vs-alloy-825-plate/

0 notes

Text

Hastelloy C276: The Best Fasteners for Corrosion Resistance

Hastelloy is one of the most popular materials trusted in chemical processing, oil and gas industries, pharmaceuticals, and even in power generation due to its exceptional corrosion resistance. Of the various Hastelloy alloys, Hastelloy C276 stands above the rest because of its incredible performance in severe conditions. This blog will discuss the benefits, types, and applications of Hastelloy fasteners-which include bolts, nuts, screws, washers, and studs that are made from Hastelloy C276.

What is Hastelloy C276?

Hastelloy C276 is a nickel-molybdenum-chromium alloy containing an addition of tungsten which can be very versatile and resistant to a wide variety of environments that are corrosive. It performs well in extreme oxidizers such as ferric and cupric chlorides, hot contaminated organic as well as inorganic media and in acidic environments.

Designation

N10276 is the UNS designation of Hastelloy C276

N6022 is the UNS designation of Hastelloy C22

N10665 is the UNS designation of Hastelloy B2

The UNS numbers are useful in standardizing the specific composition of these alloys.

Variations of Hastelloy Fasteners

Hastelloy fasteners exist in different forms to suit the diverse applications. There are quite a number of common types but here are some of the more common ones:

Hastelloy C276 Bolts. They are very strong, strongly corrosion-resistant, and very useful in aggressive chemical environments associated with high temperatures. They are usually used in reactors, pressure vessels, and heat exchangers.

Hastelloy C22 Nuts: Offering the maximum resistance against oxidation and pitting, these nuts can be used where conditions are both temperature changing and corrosive chemical environments.

Hastelloy B2 Screws: Providing resistance to low regions of corrosion like hydrochloric acid, these screws find an application in businesses using acids.

Hastelloy C276 Washers: Provided with an extra layer of protection against corrosion while offering equalized loads with durable and reliable bolted joints.

Hastelloy C22 Studs: These studs can be used in all oxidizing and corrosion-prone environments, which means that the durability and performance would stay intact for a long time.

These fasteners can be sized to fit and also can be made thicker, which makes it flexible with a wide range of applications.

Applications of Hastelloy Fasteners

Because of resistance to extreme conditions, Hastelloy fasteners are applied to a wide number of applications. The main application sites are:

Chemical Processing Industry: Fasteners made of Hastelloy are corrosion resistant to acids as well as bases. They, therefore go very well with reactors, distillation columns, and piping systems.

Oil and Gas Industry: Hastelloy C276 and C22 fasteners enjoy wider application in both onshore and offshore environments. This is due to their resistance to sour gas corrosion and their ability to maintain high temperatures.

Pharmaceutical Industry: Such fasteners ensure that the environment remains sterile and free from contamination since it resists corrosive cleaning agents and solvents.

Power Generation: Hastelloy fasteners used in nuclear and fossil fuel-based plants can better manage corrosive chemicals as well as high temperatures, which makes the power generation systems safer and more efficient.

Benefits of Hastelloy Fasteners

Corrosion Resistance: The corrosion resistance offered by Hastelloy C276, C22, and B2 fasteners is superior and useful for aggressive chemical environments.

Strength: These fasteners do not lose their mechanical strength even at high temperatures thus structural integrity is maintained under demanding conditions.

Versatility: Hastelloy fasteners can be tailored according to a given application. They are available in all sizes and thicknesses.

Durable: Their robust structure keeps them longer, which means that there would be lesser need to replace or service the fasteners.

Conclusion

Hastelloy fasteners, such as hastelloy C276 bolts, C22 nuts, and B2 screws, have improved corrosion resistance, high strength, and durability. These fasteners play a crucial role in various chemical processing industries, oil and gas, pharmaceutical, and power generation sectors. Being a renowned manufacturer, we are offering quality customized Hastelloy fasteners that can deliver long time reliability and performance.

FAQs

What are the most common applications of Hastelloy C276?

The resistance of Hastelloy C276 to pitting, crevice corrosion, and stress corrosion cracking makes it a material used in chemical processing, oil and gas, and medical industries.

Is Hastelloy C276 weldable?

YES - Hastelloy C276 can be welded using standard methods like TIG, MIG, and shielded metal arc welding, with matching filler material recommended.

What is the difference between Hastelloy C276 and C22?

Hastelloy C22 has higher chromium content, which provides better resistance to an oxidizing environment. In contrast to this, C276 can effectively handle any reducing and oxidizing media, making it widely versatile.

Are Hastelloy fasteners customizable?

Yes, Hastelloy fasteners could be customized according to the thickness, size, specifications, to fit any specific requirement.

Why Hastelloy fasteners are chosen over other materials?

Hastelloy fasteners provide excellent resistance to corrosion, strength of high-temperature stability, and long-term serviceability, all of which are much better than that of materials used in stainless steel and titanium alloys in aggressive environments.

0 notes

Text

Hastelloy C276 Round Bars Manufacturer in India | Reliable Overseas

The Need for High-quality Corrosion-Resistant Materials in Critical Industries

In industries like chemical processing, oil and gas, marine, and power generation, equipment is constantly exposed to harsh environments that can cause rapid corrosion, oxidation, and wear. These challenges can lead to costly downtime, increased maintenance, and even failure of critical components. In such demanding environments, the need for durable and corrosion-resistant materials becomes crucial for the safety, efficiency, and longevity of industrial processes.

When it comes to high-performance materials, Hastelloy C276 is a top choice. This nickel-molybdenum-chromium alloy, known for its exceptional corrosion resistance, is widely used in industries that operate under extreme conditions. However, finding a reliable manufacturer of Hastelloy C276 round bars in India can be challenging, as not all suppliers meet the strict quality standards required for these critical applications.

The Consequences of Choosing the Wrong Manufacturer

Choosing the wrong manufacturer for Hastelloy C276 round bars can have severe consequences. Substandard materials can lead to premature failure of components, resulting in unexpected downtime, expensive repairs, and potential safety hazards. Additionally, poor-quality materials may not meet industry specifications, leading to project delays, compliance issues, and reputational damage for businesses.

Imagine a scenario where a chemical processing plant relies on low-quality Hastelloy round bars for its equipment. Over time, these bars corrode and weaken, leading to a breakdown in the system. The plant faces significant downtime, production losses, and safety risks. The cost of replacing the faulty components and the resulting impact on operations could have been avoided by choosing a reliable manufacturer from the start.

In a competitive market, where every decision counts, businesses cannot afford to take risks with inferior materials. This is where Reliable Overseas steps in, offering top-quality Hastelloy round bars that meet the highest industry standards and ensure long-lasting performance.

Reliable Overseas – Your Trusted Partner for Hastelloy C276 Round Bars in India

Reliable Overseas stands out as a top manufacturer and supplier of Hastelloy round bars in India. With years of industry experience, they have established a solid reputation for providing high-quality products that satisfy the stringent demands of critical sectors. Here's why Reliable Overseas is the go-to choice for Hastelloy C276 round bars:

1. Superior Material Quality

Reliable Overseas understands the importance of material quality in industries where failure is not an option. Their Hastelloy round bars are manufactured using premium-grade raw materials sourced from trusted suppliers. The company follows stringent quality control processes to ensure that every batch of round bars meets the highest standards of strength, durability, and corrosion resistance.

Hastelloy C276 is known for its ability to withstand a wide range of corrosive environments, including those containing sulfuric acid, hydrochloric acid, chlorine, and more. Reliable Overseas ensures that their round bars retain these properties by maintaining precise chemical compositions and manufacturing processes. This ensures that their products can perform reliably in even the most challenging environments.

2. Compliance with International Standards

One of the critical factors that set Reliable Overseas apart from other manufacturers is their commitment to meeting international standards. Their Hastelloy C276 round bars comply with industry specifications such as ASTM B574, ASME SB574, and UNS N10276. This compliance guarantees that the round bars are suitable for use in industries that demand high-performance materials, such as chemical processing, pharmaceuticals, power generation, and more.

By adhering to these standards, Reliable Overseas ensures that their customers receive round bars that meet the exact requirements of their applications. This not only provides peace of mind but also reduces the risk of compliance issues during inspections and audits.

3. State-of-the-Art Manufacturing Facility

Reliable Overseas operates a state-of-the-art manufacturing facility equipped with modern machinery and technology. Their production process is designed to optimize efficiency, precision, and quality. Every stage of the manufacturing process, from selecting raw materials to the final inspection, is closely supervised to guarantee precision and consistency.

The company's advanced machinery allows it to produce Hastelloy round bars in a variety of sizes and dimensions, catering to the specific needs of its customers. Whether you require standard sizes or custom dimensions, Reliable Overseas can deliver products that meet your exact specifications.

4. Rigorous Testing and Inspection

To ensure that their Hastelloy C276 round bars meet the highest quality standards, Reliable Overseas conducts rigorous testing and inspection at every stage of production. This involves mechanical testing, chemical analysis, dimensional inspections, and non-destructive testing (NDT). The company employs a team of experienced engineers and quality control professionals who oversee the testing process and ensure that all products meet the required specifications.

Reliable Overseas also provides material test certificates (MTC) and third-party inspection reports upon request. This transparency allows customers to verify the quality and performance of the round bars, giving them confidence in their choice of manufacturer.

5. Timely Delivery and Customer Support

In industries where downtime can result in significant losses, timely delivery of materials is crucial. Reliable Overseas understands this and is committed to delivering their Hastelloy C276 round bars on time, every time. Their efficient supply chain management and well-established logistics network enable them to meet tight deadlines and ensure that their customers receive their products when they need them.

In addition to timely delivery, Reliable Overseas offers excellent customer support. Their team is always available to assist with product inquiries, technical specifications, and order tracking. Whether you need assistance with selecting the right round bars for your application or require post-purchase support, Reliable Overseas is dedicated to providing exceptional service to their customers.

Applications of Hastelloy C276 Round Bars

Hastelloy round bars are widely used in industries that require materials with excellent corrosion resistance and high strength. These round bars are frequently used in essential applications such as:

Chemical Processing: Hastelloy C276 round bars are commonly used in equipment such as reactors, heat exchangers, and piping systems in chemical plants. Their resistance to a wide range of corrosive chemicals makes them ideal for use in harsh environments.

Oil and Gas: In the oil and gas industry, Hastelloy round bars are used in components that are exposed to corrosive media, such as offshore drilling equipment, pipelines, and valves. Their ability to withstand high temperatures and corrosive environments ensures the reliability of critical equipment.

Marine Industry: Marine environments are highly corrosive due to the presence of saltwater and other harsh elements. Hastelloy C276 round bars are used in shipbuilding, offshore platforms, and other marine applications where corrosion resistance is essential.

Power Generation: In power plants, especially those that use fossil fuels or nuclear energy, Hastelloy round bars are used in components that are exposed to high temperatures and corrosive gases. Their durability and resistance to oxidation make them suitable for use in turbines, boilers, and exhaust systems.

Pharmaceuticals: The pharmaceutical industry requires materials that can withstand exposure to chemicals and high-purity environments. Hastelloy round bars are used in the manufacturing of pharmaceutical equipment, such as mixers, reactors, and storage tanks.

Conclusion:

When it comes to choosing a manufacturer for Hastelloy C276 round bars, reliability, quality, and performance are paramount. Reliable Overseas stands out as a trusted manufacturer in India, delivering high-quality products that meet the stringent requirements of critical industries. With their commitment to superior material quality, compliance with international standards, state-of-the-art manufacturing facility, rigorous testing and inspection, and timely delivery, Reliable Overseas is the ideal partner for businesses seeking durable and corrosion-resistant materials.

#Hastelloy C276 Round Bars#Hastelloy C276 Round Bars Supplier#Hastelloy C276 Round Bars Exporter#Inconel 600 Round Bars#Inconel 600 Round Bars Supplier#Inconel 600 Round Bars Exporter#Stainless Steel 446 Tubes#Stainless Steel 446 Tubes Manufacturers#Stainless Steel 446 Tubes Suppliers#Stainless Steel 446 Sheets and Plates#Stainless Steel 446 Sheets and Plates Suppliers#Stainless Steel 446 Sheets and Plates Exporters

0 notes

Text

Ultimate hints for excessive-performance composites

If you're looking for top-notch alloy products, Siddhagiri Metals and Tubes has been given you protection. With such a lot of products to be had, in addition to SS 304 tube fittings, Inconel 625 round bars, hastelloy c276 plate, and more, this newsletter may be your go-to useful resource for finding statistics and choosing a product that works nicely approximately. It's a totally effective combination of substances to fit your needs.

Inconel 625 flanges are designed to provide a watertight and durable connection underneath hot temperature rise and corrosive situations. Siddhagiri Metals and Tube gives a choice of Inconel 625 flanges designed to fulfil enterprise needs and specifications.

Hastelloy C276 tube fittings from Siddhagiri Metals and Tubes provide super resistance to pitting, crevice corrosion, and strain corrosion cracking, making them best for important packages in medicine, sewage remedy, and different fields.

Duplex 2205 is a low-rate, bendy duplex stainless steel that is evidence of corrosion in hundreds of conditions.Siddhagiri Metals and Tubes offers a complete line of Duplex 2205 Tube Fittings designed for excessive overall performance and long-term reliability.

Super Duplex 2507 tube fittings are recognized for their robust tensile energy and advanced corrosion resistance below excessive situations. Siddhagiri Metals and Tubes offers a huge variety of Super Duplex 2507 Tube Fittings for bundle necessities in oil and gas, chemical production, and plenty of other industries. Copper-nickel filters are acknowledged for their excessive resistance to saltwater corrosion and fouling, making them an excessive first-class desire for marine and offshore applications. Siddhagiri Metals and Tubes gives fantastic copper-nickel tube fittings which can withstand harsh marine situations.

Selecting the Right High-Performance Alloy Products Selecting precise, high-standard performance alloy products is critical to the success and persistence of your packages.When combining materials such as titanium grade 2 round bar, Monel 400 plate, and chrome steel 304 pipe, the following factors must be kept in mind: Corrosion Resistance All of the above high-performance alloys boast extremely high corrosion resistance properties. do, ensuring overall reliable performance. bad environment Whether you need Inconel 625 Round Bar or Hastelloy C276 flanges, you should not forget that Siddhagiri alloys and tubes offer the trade-off with advanced corrosion resistance.

Mechanical Strength From Monel four hundred spherical bars to Duplex 2205 tube fittings, the mechanical strength of high-normal overall performance alloy merchandise is a key consideration. Siddhagiri Metals and Tubes ensures that all products meet stringent mechanical strength requirements, presenting the sturdiness and reliability wanted for numerous business programmes.

High-performance alloys are engineered to go through excessive temperatures and demanding thermal situations. When deciding on items that include Inconel 625 tube fittings or Super Duplex 2507 tube fittings, it's crucial to test their temperature resistance tendencies to assure maximum typical overall performance in high-temperature applications.

Each excessive-standard overall performance alloy product is designed to fulfil precise commercial enterprise requirements and necessities. Whether you want Hastelloy C276 tube fittings or Titanium Grade 2 plate, Siddhagiri Metals and Tubes assures that each product meets relevant industry necessities, ensuring compatibility and conformity with requirements.

Siddhagiri Metals and Tubes is a reliable and appeared company of high-ordinary overall performance alloy items at the side of Inconel 625 plate, Stainless Steel 304 spherical bar, Hastelloy C276 plate, and masses more. Siddhagiri Metals and Tubes is your one-prevent save for immoderate-performance alloy solutions, emphasising fantastic, dependability, and adherence to business enterprise standards. Siddhagiri Metals and Tubes no longer gives anything short of excellence in excessive-overall performance alloy products.

0 notes

Text

Why Choose Hastelloy Flanges for Corrosive Environments?

The unresolved confrontation of hastelloy flanges to a diversity of corrosive chemicals, acids, and gases, such as sulfuric acid, hydrochloric acid, and chlorine dioxide, sorts them the material of high quality for corrosive settings. The alloy has unresolved resistance to both oxidizing and reducing circumstances because to its composition, which is often a mixture of nickel, chromium, molybdenum, and tungsten. For subdivisions like chemical processing, petrochemicals, and pollution control where exposure to abrasive media is common, this makes Hastelloy flanges faultless. Since they consistently uphold structural integrity and resist leaks in severe environments, they are an economical option for demanding applications needing strong corrosion resistance. This guarantees operational safety and endurance. A Complete Guide to Flanges and Fittings for Specialty Plumbing Inconel flanges and Hastelloy C276 pipe fittings are energetic parts for any industry demanding robust solutions against corrosion and high temperatures. These alloys find wide application in demanding situations due to their excellent mechanical makings and resistance to corrosion.

How to Decide Amongst Inconel and Hastelloy Flanges

Since of their separate alloy compositions, Inconel and Hastelloy flanges help separate purposes. Hastelloy alloys, such as C276; have unresolved resistance to a broad diversity of corrosive substances, which makes them faultless for use in pollution control and chemical treating. On the other hand, Inconel alloys—which are well known for their corrosion resistance and great temperature power—are used in gas turbine, airplane, and marine requests where high temperatures and mechanical stress are mutual. Pricing visions for 304 and 316 stainless steel pipe fittings and flanges

Budgeting and purchasing selections require a thorough understanding of the Stainless steel 304 flange Price list and Stainless steel 316 flange Price list, as well as the price lists for matching pipe fittings. Stainless steel 304 is well known for existence approximately resistant to corrosion and being simple to fabricate, which makes it suitable for a range of industrial uses. Stainless steel 316, on the other hand, is recommended for marine and coastal applications since to its enhanced corrosion resistance, particularly in chloride situations. Stainless Steel Price-Relating Factors

Prices of raw materials, industrial difficulty, and consumer demand are some of the basics that affect the Stainless steel 304 pipe fittings Price list and Stainless steel 316 pipe fittings Price list. Indian producers have the skill to provide customers through affordable solutions without forgoing functionality or longevity by striking a balance among competitive pricing and quality.

It's vital to take certain application necessities like corrosion resistance, temperature tolerance, and mechanical power into account when selecting Inconel flanges, Hastelloy flanges, or stainless steel pipe fittings and flanges. Through their knowledge in alloy selection, precision in production, and devotion to international standards, Indian vendors offer a wide choice of items that are specifically intended to satisfy these wants. This guarantees that, even in the most demanding circumstances, businesses across the globe can depend on these components for dependable performance.

0 notes

Text

The Versatility of Hastelloy C276 Pipe: From Chemical Processing to Aerospace

Hastelloy C276, a high-performance superalloy that's taking industries by storm! From chemical processing to aerospace applications, this versatile material is a game-changer in terms of durability and reliability. Let's dive into the fascinating world of Hastelloy C276 pipe and discover why it's the go-to choice for demanding environments.

Alloy C-276 Pipe Processing Services

When it comes to Alloy C-276 pipe processing services, precision is key. Manufacturers offer cutting-edge solutions to customize pipes according to specific requirements, ensuring a perfect fit for every project. From seamless welding to intricate bending techniques, these services guarantee top-notch quality and performance. Advanced machining technologies are employed to shape Hastelloy C276 pipes with utmost accuracy and efficiency. Whether it's drilling, threading, or shaping complex designs, these services cater to a wide range of industrial needs. With strict adherence to industry standards, Alloy C-276 pipe processing ensures optimal functionality in challenging environments.

Alloy C-276 Pipe Chemical Composition

Alloy C-276 pipe is renowned for its exceptional chemical composition. This high-performance nickel-molybdenum-chromium alloy contains significant amounts of nickel, ensuring superior corrosion resistance in various environments. Molybdenum and chromium add to its overall strength and durability, making it a top choice for demanding applications. Additionally, the presence of tungsten enhances the alloy's resistance to pitting and crevice corrosion. The low carbon content minimizes carbide precipitation during welding, maintaining the material's corrosion-resistant properties. With precise control over elements like iron and cobalt, Alloy C-276 pipe offers unmatched reliability in challenging industrial settings.

Characteristics of C-276 Nickel Pipe

Hastelloy C276 nickel pipe is renowned for its exceptional corrosion resistance in a variety of harsh environments. This high-performance alloy can withstand corrosive substances like sulfuric acid, hydrochloric acid, and chlorine without succumbing to degradation. Its versatility extends to both acidic and non-acidic conditions, making it a top choice for industries where corrosion is a concern. Additionally, the C276 nickel pipe boasts impressive mechanical properties that contribute to its durability and longevity. With high tensile strength and excellent fabricability, this alloy can be easily formed into various shapes and sizes for different applications. Its ability to maintain structural integrity under extreme temperatures further enhances its reliability in demanding settings. Furthermore, Hastelloy C276 exhibits superior resistance to stress-corrosion cracking and pitting, ensuring prolonged service life even in challenging operating environments. This makes it an ideal choice for critical applications where performance under pressure is crucial. The combination of these characteristics solidifies Hastelloy C276 as a go-to material for industries requiring dependable corrosion resistance and mechanical strength.

Applications of C-276 Nickel Pipe

Hastelloy C276 pipe is a versatile material widely used in various industries due to its exceptional corrosion resistance and durability. In the chemical processing industry, C-276 nickel pipe is utilized for handling corrosive chemicals such as sulfuric acid, acetic acid, and chlorine gas without degradation or leakage. Moreover, in the aerospace sector, Hastelloy C276 pipe plays a crucial role in aircraft components where high-strength materials are required to withstand extreme conditions. Its ability to resist pitting, crevice corrosion, and stress corrosion cracking makes it an ideal choice for critical applications in aerospace engineering. Additionally, the pharmaceutical and oil & gas industries rely on C-276 nickel pipe for its reliability in conveying aggressive fluids while maintaining product purity. From reactors to heat exchangers, this alloy offers unparalleled performance across a wide range of demanding environments.

Alloy C276 Tubing Product Specifications

When it comes to Hastelloy C276 tubing, the product specifications are crucial. This alloy is known for its exceptional resistance to a wide range of corrosive environments, making it ideal for various applications. The tubing typically comes in different sizes and thicknesses to meet specific project requirements. Hastelloy C276 tubing is available in seamless and welded forms, providing flexibility in design and installation. The material composition ensures high strength and durability while maintaining excellent corrosion resistance properties. These tubes can withstand extreme temperatures and pressures, making them suitable for demanding industrial settings. Whether used in chemical processing plants or aerospace engineering projects, Alloy C276 tubing offers reliability and performance that meets stringent industry standards. Its versatility extends to diverse applications where superior corrosion resistance and mechanical strength are essential for long-term operational success.

Corrosion Resistance and Mechanical Properties of Hastelloy C276

Hastelloy C276 is renowned for its exceptional corrosion resistance in a wide range of aggressive environments. Whether facing acidic solutions, seawater, or high-temperature gases, this alloy stands strong. The ability to resist pitting and crevice corrosion makes it a top choice for industries where reliability is paramount. Moreover, the mechanical properties of Hastelloy C276 pipe are equally impressive. With high tensile strength and excellent fabricability, this alloy can withstand extreme conditions without compromising on performance. Its superior ductility allows for easy forming and shaping to meet specific project requirements. In essence, the combination of outstanding corrosion resistance and robust mechanical properties makes Hastelloy C276 a versatile solution for various industrial applications where durability and longevity are essential factors to consider.

Fabrication and Welding with Hastelloy C-276

Hastelloy C-276 pipe and tubing offer exceptional versatility across various industries, from chemical processing to aerospace. With its superior corrosion resistance, mechanical properties, and ease of fabrication and welding, it has become a go-to choice for demanding applications where reliability is paramount. Whether you need a reliable material for handling aggressive chemicals or requiring high-temperature strength in extreme environments, Hastelloy C-276 stands out as a top performer. Consider this alloy for your next project where performance and durability are non-negotiable factors.

0 notes