#hastelloy c22 washers

Explore tagged Tumblr posts

Text

Hastelloy is a nickel-based alloy known for its exceptional resistance to corrosion, particularly in harsh environments such as chemical processing, aerospace, and marine applications. Hastelloy fasteners, including bolts, nuts, screws, and washers, are specifically manufactured using this alloy to provide superior corrosion resistance and strength in challenging environments where traditional materials may fail.

Here are some key features and benefits of Hastelloy fasteners:

Corrosion Resistance: Hastelloy alloys offer outstanding resistance to a wide range of corrosive chemicals, acids, and environments, including sulfuric acid, hydrochloric acid, nitric acid, and seawater. This makes Hastelloy fasteners suitable for use in chemical processing plants, oil and gas refineries, and marine applications.

High Temperature Performance: Hastelloy fasteners retain their mechanical properties and corrosion resistance at elevated temperatures, making them suitable for high-temperature applications such as aerospace, power generation, and industrial furnaces.

Strength and Durability: Hastelloy alloys exhibit high strength and toughness, providing reliable fastening solutions in demanding applications where mechanical stress and vibration are prevalent.

Versatility: Hastelloy fasteners are available in various grades and configurations to meet specific application requirements, including Hastelloy C276, Hastelloy C22, Hastelloy B2, and others. This versatility allows engineers and designers to choose the most appropriate Hastelloy grade based on factors such as chemical compatibility, temperature, and mechanical properties.

Longevity: Due to their excellent corrosion resistance and durability, Hastelloy fasteners have a long service life, reducing the need for frequent replacement and maintenance, which can result in cost savings over time.

Specialized Applications: Hastelloy fasteners are commonly used in critical applications where corrosion resistance, reliability, and safety are paramount, such as chemical processing equipment, gas turbines, valves, pumps, and reactors.

Overall, Hastelloy fasteners offer exceptional performance in corrosive and high-temperature environments, making them a preferred choice for industries requiring reliable fastening solutions in challenging operating conditions. However, it's essential to consult with materials engineers or specialists to ensure proper selection and application of Hastelloy fasteners based on specific project requirements and environmental conditions.

#hastelloy c276 gasteners#hastelloy c276 bolts#hastelloy c22 washers#hastelloy c276 nuts#hastelloy screws manufacturer#hastelloy hex bolts manufacturer

1 note

·

View note

Text

Maximize Performance with High-Quality Hastelloy C4/C22/C276 Stud & Anchor Bolts

In the vicinity of business programs in which reliability, sturdiness, and resistance to corrosion are paramount, the selection of fasteners plays a important characteristic. Hastelloy C4/C22/C276 fasteners, collectively with nuts, bolts, screws, washers, stud bolts, and anchor bolts, stand out as high examples of immoderate-trendy overall performance substances that make certain finest operation even within the cruelest environments. Let's delve into how these specialised fasteners can maximize usual ordinary performance in various commercial enterprise settings.

Hastelloy C4/C22/C276 Fasteners: Ensuring Superior Performance

Hastelloy C4/C22/C276 fasteners are engineered to face as much as extreme conditions, making them first rate for industries collectively with chemical processing, oil and gas, electricity generation, and marine programs. These fasteners display off incredible resistance to corrosion, oxidation, and high-temperature environments, making them vital in environments in which traditional substances have to fail.

Enhancing Structural Integrity with Hastelloy C4/C22/C276 Nuts and Hastelloy C4/C22/C276 Bolts

Hastelloy C4/C22/C276 Nuts and Hastelloy C4/C22/C276 bolts are the backbone of many structures, maintaining additives together securely. Hastelloy C4/C22/C276 nuts and bolts provide outstanding electricity and durability, ensuring the structural integrity of essential installations. Whether it's miles for offshore structures, chemical reactors, or excessive-strain piping structures, those fasteners offer peace of thoughts through preserving tight connections even in corrosive atmospheres.

Precision Engineering with Hastelloy C4/C22/C276 Screws and Hastelloy C4/C22/C276 Washers

In applications requiring particular fastening and sealing, Hastelloy C4/C22/C276 screws and washers excel. These fasteners are designed with meticulous attention to element, thinking of dependable overall performance below tough situations. Whether it is sealing joints in chemical processing tool or securing components in aerospace assemblies, Hastelloy C4/C22/C276 screws and Hastelloy C4/C22/C276 washers deliver constant results, making sure leak-proof connections and preventing steeply-priced downtime.

Secure Fixation with Hastelloy C4/C22/C276 Stud Bolts and Hastelloy C4/C22/C276 Anchor Bolts

Hastelloy C4/C22/C276 Stud bolts and Hastelloy C4/C22/C276 anchor bolts play a essential function in anchoring heavy device, device, and structural elements to concrete or metal surfaces. Hastelloy C4/C22/C276 stud bolts and anchor bolts offer unequaled strength and corrosion resistance, ensuring sturdy fixation even in harsh environments. From agency machinery to offshore structures, those fasteners provide peace of thoughts thru stopping loosening or failure because of corrosion.

Why Choose Hastelloy C4/C22/C276 Fasteners?

Corrosion Resistance: Hastelloy C4/C22/C276 alloys are renowned for his or her remarkable resistance to corrosion, making them suitable for use in corrosive environments which include chemical processing flowers and marine packages.

High Temperature Stability: These fasteners keep their mechanical houses even at prolonged temperatures, ensuring dependable regular overall performance in excessive-temperature packages collectively with energy era and aerospace engineering.

Durability: Hastelloy C4/C22/C276 fasteners are designed to resist harsh situations, providing long-term sturdiness and reliability in stressful business environments.

Versatility: From nuts and bolts to screws and washers, Hastelloy C4/C22/C276 fasteners are to be had in a diverse bureaucracy to match a huge variety of programs, presenting versatility and versatility in design and assembly.

Cost-Effectiveness: While initially, the value of Hastelloy C4/C22/C276 fasteners may be higher than conventional materials, their sturdiness and resistance to corrosion provide lengthy-time period fee financial savings by decreasing protection and replacement fees.

Conclusion: Partner with Anand Steel for High-Quality Stainless Steel Solutions

In end, on the subject of maximizing performance in business programs, the choice of fasteners is paramount. Hastelloy C4/C22/C276 fasteners, which include nuts, bolts, screws, washers, stud bolts, and anchor bolts, offer extraordinary overall performance, sturdiness, and corrosion resistance, making sure dependable operation even within the maximum challenging environments. For wonderful Hastelloy fasteners and other chrome steel solutions, appearance no further than Anand Steel. As a main importer and exporter of chrome steel shims, strips, coils, foils, spherical bars, and nickel alloys, Anand Steel is committed to delivering excellence and purchaser satisfaction. With years of revel in and understanding, they've established themselves as a trusted dealer inside the industry, catering to the unique needs of diverse sectors. Contact Anand Steel these days for all your chrome steel requirements and revel in the distinction best made.

#Hastelloy C4/C22/C276 Fasteners#Hastelloy C4/C22/C276 Nuts#Hastelloy C4/C22/C276 Bolts#Hastelloy C4/C22/C276 Screws#Hastelloy C4/C22/C276 Washers#Hastelloy C4/C22/C276 Stud Bolts#Hastelloy C4/C22/C276 Anchor Bolts

0 notes

Text

Hastelloy C22 Fasteners: Comprehensive Guide

Introduction

Hastelloy C22 is a highly versatile and corrosion resistant nickel chromium molybdenum tungsten alloy. Its exceptional resistance to a wide range of chemical environments makes it an ideal choice for manufacturing high-performance fasteners used in critical applications. This blog provides an in-depth overview of Hastelloy C22 fasteners, their characteristics, applications, and benefits.

What are Hastelloy C22 Fasteners?

Hastelloy C22 fasteners are components such as bolts, nuts, washers, and screws manufactured using the Hastelloy C22 alloy. These fasteners are renowned for their superior corrosion resistance, durability, and strength, even in extreme environments. They are widely used in industries such as chemical processing, marine engineering, and aerospace.

Chemical Composition of Hastelloy C22

The chemical composition of Hastelloy C22 contributes to its excellent properties. Below is the approximate composition of the alloy:

Nickel (Ni): 56%

Chromium (Cr): 20-22%

Molybdenum (Mo): 12.5-14.5%

Iron (Fe): 2-6%

Tungsten (W): 2.5-3.5%

Cobalt (Co): ≤2.5%

Manganese (Mn): ≤0.5%

Silicon (Si): ≤0.08%

Carbon (C): ≤0.015%

Phosphorus (P): ≤0.02%

Sulfur (S): ≤0.02%

Mechanical Properties of Hastelloy C22

Hastelloy C22 exhibits outstanding mechanical properties, making it suitable for demanding applications. Key mechanical properties include:

Tensile Strength: 690 MPa (minimum)

Yield Strength: 310 MPa (minimum)

Elongation: 45% (minimum)

Hardness: Approximately 95 HRB

Characteristics of Hastelloy C22 Fasteners

Hastelloy C22 fasteners are favored due to the following characteristics:

Corrosion Resistance: They resist pitting, crevice corrosion, and stress corrosion cracking in both oxidizing and reducing environments.

Thermal Stability: Excellent performance at high temperatures.

Versatility: Effective in a wide range of chemical environments, including acidic, alkaline, and saline conditions.

Durability: Exceptional mechanical strength ensures long-lasting performance.

Fabrication: Easy to weld and fabricate without compromising its corrosion-resistant properties.

Types of Hastelloy C22 Fasteners

Hastelloy C22 fasteners come in various forms to meet diverse industrial requirements. Common types include:

Bolts: Hex bolts, U-bolts, eye bolts, and stud bolts.

Nuts: Hex nuts, lock nuts, and heavy hex nuts.

Washers: Flat washers, spring washers, and lock washers.

Screws: Machine screws, self-tapping screws, and socket head cap screws.

Threaded Rods: Fully threaded rods and partially threaded studs.

Applications of Hastelloy C22 Fasteners

Thanks to their outstanding properties, Hastelloy C22 fasteners are used in various critical applications:

Chemical Processing: Ideal for reactors, heat exchangers, and other equipment exposed to aggressive chemicals.

Marine Engineering: Resists corrosion in seawater and marine atmospheres.

Pharmaceutical Industry: Suitable for hygienic and sterile environments.

Aerospace: Used in high-temperature and high-pressure systems.

Pollution Control: Applicable in scrubbers, filters, and stack liners.

Power Generation: Used in turbines and flue gas desulfurization systems.

Benefits of Hastelloy C22 Fasteners

Exceptional Corrosion Resistance: Ensures longevity and reliability in harsh environments.

High Strength: Can withstand significant mechanical stress without deforming.

Wide Temperature Range: Performs efficiently in both cryogenic and high-temperature conditions.

Ease of Fabrication: Can be machined and welded easily.

Versatile Applications: Suitable for a broad spectrum of industries.

Why Choose Ananka Group for Hastelloy C22 Fasteners?

Ananka Group is a leading manufacturer, supplier, and exporter of high-quality Hastelloy C22 fasteners. Here’s why you should choose us:

Expertise: Decades of experience in manufacturing and supplying corrosion-resistant fasteners.

Quality Assurance: Our fasteners comply with international standards such as ASTM, ASME, and DIN.

Customization: We offer tailor-made solutions to meet specific requirements.

Global Presence: We supply to industries worldwide, ensuring timely delivery.

Competitive Pricing: High-quality products at affordable prices.

Conclusion

Hastelloy C22 fasteners are indispensable components for industries requiring superior corrosion resistance and mechanical performance. Their versatility, durability, and exceptional properties make them a preferred choice for critical applications. If you’re looking for reliable and high-quality Hastelloy C22 fasteners, Ananka Group is your trusted partner.

Frequently Asked Questions (FAQ)

1. What makes Hastelloy C22 fasteners unique?

Hastelloy C22 fasteners are unique due to their exceptional corrosion resistance, high strength, and ability to perform in a wide range of aggressive chemical environments.

2. Can Hastelloy C22 fasteners be used in high-temperature environments?

Yes, Hastelloy C22 fasteners perform exceptionally well in high-temperature conditions, maintaining their strength and corrosion resistance.

3. Are Hastelloy C22 fasteners suitable for marine applications?

Absolutely. Hastelloy C22 fasteners offer excellent resistance to seawater and marine atmospheres, making them ideal for marine engineering.

4. Do Hastelloy C22 fasteners comply with international standards?

Yes, Hastelloy C22 fasteners manufactured by Ananka Group comply with international standards such as ASTM, ASME, and DIN.

5. Can I get customized Hastelloy C22 fasteners?

Yes, Ananka Group offers customization options to meet specific design and application requirements.

#HastelloyC22Fasteners#HastelloyFastener#NickelAlloyFasteners#IndustrialFasteners#ChemicalProcessingFasteners#HighPerformanceFasteners#HastelloyC22Bolts#HastelloyC22Nuts#HastelloyC22Washers#FastenersManufacturer#AnankaGroup#Article#Linkedin#Blog#Ananka#Fasteners#anankafasteners#manufacturer#supplier#mumbai#hex#bolt

0 notes

Text

What industries use fasteners?

Fasteners play a critical role in construction, manufacturing, and engineering. As a leading force in the industry, Bullion Pipes & Tubes LLP stands out as the premier fasteners manufacturer, supplier, stockist, and exporter worldwide. With an extensive range that includes Bolts, Nuts, Screws, Washers, Studs, Rivets, Self-Clinching Fasteners, and more, our commitment is to provide top-notch solutions that cater to diverse project requirements.

This blog post aims to shed light on the diverse industries that heavily rely on fasteners, emphasizing the broad spectrum of applications our products cater to.

Types of Fasteners We Offer

With us, we offer fasteners with a variety of Types and Features, including the following;

Bolts: These threaded fasteners require corresponding nuts for secure connections. Choose from an array of head styles, including hex head, socket head, and round head.

Nuts: Complementing bolts, nuts secure connections. Opt for hex nuts, lock nuts, or wing nuts based on specific application requirements.

Screws: Known for versatility, screws find use in diverse applications. Choose from different head styles like Phillips, flat, or hex, and opt for self-tapping or machine screws.

Washers: Flat and disk-shaped, washers play a pivotal role in distributing fastener loads and protecting surfaces. Types include flat, lock, and spring washers.

Studs: Characterized by threaded rods without heads on one end, studs are ideal for dual-threaded connections and situations where nuts are impractical.

Rivets: Permanent fasteners with a cylindrical shaft and deformed head create a secure connection.

Pins: Cylindrical fasteners for alignment, securing, or support, including types like dowel, cotter, and clevis pins.

Anchors: These fasteners affix objects to hard surfaces, such as concrete. Common types involve wedge, sleeve, and drop-in anchors.

Clips and Clamps: Secure items like hoses and cables using clips and clamps, such as hose clamps, spring clips, and wire rope clamps.

Threaded Rods: Lengthy straight rods with continuous threading, frequently used for hanging and providing support.

U-Bolts: Featuring a U-shaped design with threads on both ends, they secure round objects to surfaces.

Eye Bolts: Equipped with a loop or "eye," these bolts are designed for lifting and securing heavy loads.

Stud Bolts: Threaded at both ends with an unthreaded portion in the middle, commonly used in flange connections.

Self-Clinching Fasteners: Specifically designed for sheet metal and thin materials, including self-clinching nuts, studs, and standoffs.

Hinges and Latches: Serving as fasteners for attaching doors, gates, and panels, they include hinges, hasps, and latches.

Materials Wise Grade We Offer – Fasteners

At, Bullion Pipes & Tubes LLP, provides a wide variety of fasteners, including;

Copper – CDA 102, CDA 101, CDA 110

Titanium – Titanium Alloy Gr 2 & Titanium Alloy Gr 5

Monel – Monel K500 & Monel 400

Carbon Steel – ASTM A193/194 & ASME SA193/194 Carbon Steel

Brass – Alloy 260, Alloy C48200 – C48500, Alloy 385, Alloy 360, Alloy 353, Alloy 330, Alloy 272, Alloy 464

Tantalum – RO5200, RO5400, RO5252(Ta2.5W), RO5255(Ta10W)

Inconel – Inconel 718, Inconel 600, Inconel 601, Inconel 625

Aluminum – he 20 65032 6061, he 30 64430, ASTM 6061, 6063, 6351

Nickel – Nickel Alloy 200/201

SMO 254 – ASTM A 479 ASME SA 479

Duplex Steel – Duplex Steel UNS S32205, Duplex Steel UNS S31803

Hastelloy – Hastelloy C22 & Hastelloy B2, Hastelloy C276

Super Duplex Steel – Super Duplex Steel UNS S32750, Super Duplex Steel UNS S32760

Incoloy – Incoloy 800/800H/800HT, Incoloy 825

Alloy 20 – DIN 2.4460 Alloy Hexagonal Nut, Alloy 20 Bolts, UNS N08020 Alloy 20 Screws, Alloy 20 Washers

Industries Uses Fasteners

Here are some industries where fasteners are used extensively:

Construction: Fasteners such as bolts, nuts, screws, and anchors are widely used in the construction industry for connecting structural elements like beams, columns, and panels.

Automotive: The automotive industry relies heavily on fasteners for assembling vehicles. A variety of screws, bolts, nuts, and clips are used in the manufacturing of cars, trucks, motorcycles, and other vehicles.

Aerospace: Aerospace applications require precision and reliability. Fasteners play a critical role in assembling aircraft and spacecraft components, ensuring safety and structural integrity.

Manufacturing: In general manufacturing processes, fasteners are used to assemble a wide range of products across different industries, including appliances, electronics, and consumer goods.

Energy: Fasteners are used in the energy sector for assembling components in power plants, wind turbines, solar panels, and other energy infrastructure.

Shipbuilding: The shipbuilding industry relies on fasteners for assembling the various components of ships, including the hull, decks, and internal structures.

Railway: They are crucial in the railway industry for connecting rail tracks, assembling train components, and maintaining the structural integrity of railway infrastructure.

Oil and Gas: In the oil and gas industry, fasteners are used in the construction and maintenance of pipelines, platforms, and other infrastructure.

Electronics: Fasteners play a role in the assembly of electronic devices and equipment. They are used to secure components on circuit boards and in the housing of electronic products.

Medical Devices: Fasteners are used to ensure that components are held together in a precise manner in medical devices and equipment.

Furniture: In the furniture industry, fasteners such as screws, bolts, and nuts are used to assemble various types of furniture, from simple household items to complex office furniture.

Final Words! As a global Fasteners Supplier, Manufacturer Stockist, and Exporter, Bullion Pipes & Tubes LLP takes pride in contributing to the success of diverse industries. Our fasteners, available in an array of sizes, specifications, standards, grades, materials, and types, offer versatility and reliability. Whether it's bolts, nuts, screws, washers, studs, rivets, or self-clinching fasteners, our commitment to quality ensures that our customers can confidently choose the perfect solution for their project requirements. Contact us today at [email protected] or [email protected] to explore how our fasteners can enhance the strength and durability of your applications.

0 notes

Text

Processional usage of hastelloy fasteners

Selecting the pleasant fasteners in your tasks might be difficult due to the fact there are so many alternatives available. Due to its extremely good qualities, hastelloy fasteners have observed substantial application across numerous industries. They not best tolerate incredibly high pressures and temperatures, however they also display superb resistance to corrosion. This article will state the benefits of making use of Hastelloy fasteners and a way to pick the satisfactory type to your project.

What precisely are Hastelloy Fasteners, then?

Comprising of a few stuffs, the Hastelloy fastener exhibits splendid strength and resistance to corrosion. The nickel and chromium alloys that make up the majority of their makeup are what deliver them the functionality to face as much as oxidation and special forms of degradation over prolonged intervals of time. The several packages for hastelloy fasteners encompass rings, nuts, bolts, screws, washers, and clamps, to name just a few. Alloys are considerably greater resistant to wear and tear added on by using temperature variations or publicity to particular chemicals in difficult commercial conditions, which gives them a far longer lifespan than more traditional fastener materials like stainless-steel and iron.

A Complete Guide to Selecting the Best Hastelloy Fastener for Your Special Project

Establish the requirements that your project need.

Selecting the right Hastelloy C276 flanges calls for first figuring out the wishes of the assignment. The type of situations that the fasteners have to withstand, which includes temperature and strain, need to be cautiously studied. Due to its particular qualities, different grades of hastelloy are higher proper for different settings. In the event that your venture will come into contact with corrosive substances, for example, pick a Hastelloy grade with strong corrosion resistance. Selecting the appropriate Hastelloy fastener is critical for your challenge as it may substantially impact its toughness and achievement. You should be clean about your needs and specs so as for a fastener to keep your challenge robust and harm-unfastened. Before you proceed, you need to confirm in case you require the Hastelloy C22 or C276 alloy grade. Better corrosion resistance or greater power and performance—that is more big? That's what makes the distinction.

Don't forget to consider the range of sizes required for every component

This includes variables like body size, diameter, length, and thread length. It may be helpful to investigate specialized coatings like Lavalox® HTXTM, which provides robust protection up to 1500 degrees Fahrenheit (815 degrees Celsius) in order to guarantee the highest degree of dependability in high-temperature situations. In conclusion, a study to determine the operating pressure is necessary in order to meet the given proof loads. The loads for the conditional use case scenarios must already be in place for this analysis to be valid.

Because in their nickel-molybdenum-chromium alloy, Hastelloy C276 Fasteners are immune to a full-size form of corrosion. These corrosives encompass sulfuric acid, hydrochloric acid, and chlorine. This material has the added advantage of being surprisingly proof against pitting and cracking, and it is able to tolerate temperatures as high as 1900 stages Fahrenheit. In addition to its excessive mechanical electricity, Hastelloy C276 Fasteners are rather clean to manufacture, as in keeping with the recent cast fasteners manufacturer in India.

0 notes

Photo

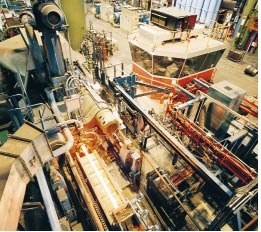

Chhajed Steel and Alloys is one of the regarded producers, exporters and providers of Hastelloy C22 Washers, which have staggering use confirmation properties and quality. Hastelloy C22 Flat Washers has prominent security from setting crumbling, broaden use separating, and cut line and weld warm influenced zone strike.

0 notes

Text

Stud Bolts and Nuts

We have been involved with many projects in the petrochemical and off-shore services industry from vast pipeline construction projects to smaller bespoke wellhead refurbishment work, sometimes on an urgent basis with our emergency breakdown service. We have supplied for most large oil exploration companies, oil refineries, off-shore oil rigs and gas processing plants. Here are some examples of commonly used fasteners in this sector: TYPES OF PRODUCTS Stud bolts and Nuts Double-Ended Stud bolts Socket Cap Screws/Countersunk Engineer Studs Socket Setscrews Hexagon Bolts and Nuts U-Bolts Hook Bolts Tee Bolts Washers Specially Machined Parts Bi-Hex Bolts & Screws (Ferry heads or 12-Point Bolts) ASTM A193 B5 ASTM A193 B6 ASTM A193 B7 ASTM A193 B7M ASTM A193 B8 (Class 1+2) ASTM A193 B8M (Class 1+2) ASTM A193 B8C & B8TX ASTM A320 L7 & L7M Alloy/Hastelloy C4 C22 + C276 Duplex UNS S31803 (F51) UNS S32550 (Ferralium 255) Read the full article

0 notes

Text

Inconel alloys for extreme application services in various industries

Inconel 625 and Hastelloy C276 have offered outstanding corrosion resistance in chemical, power production, pollution control, marine and other applications. In the presence time, new chemical processes demand new materials. To meet these needs, latest NiCrMo alloys such as Hastelloy C2000 offers the highest resistance in application conditions, beyond the potential of stainless steels or other materials. These alloys offer several benefits including enhanced life cycle cost functionality, enhanced reliability, lower maintenance and controlled downtime costs. The presence of nickel, chromium and molybdenum is essential for various applications where extreme corrosion resistance is needed. Chromium is resistant to oxidizing conditions while molybdenum enhances resistance to reducing conditions. Chromium and molybdenum together enhances the resistance to localized corrosion. Tungsten also enhances resistance to localized attack. However nickel is resistant to caustic and mild reducing conditions, its main advantage in alloys comprising high concentrations of chromium and molybdenum is to retain austenitic single phase structure. It is essential in offering suitable corrosion resistance in an alloy to be produced cost-effectively.

Hastelloy C276 and C22 offer enhanced corrosion resistance , greater flexibility and versatility in preventing corrosion in various service conditions. When comparing alloys for a specific service condition, it is specifically best method to evaluate the alloy candidates in the service condition or in a lab test that is approximate it.

Localized corrosion resistance

Localized corrosion is one of the commonly failure mechanisms of stainless steels and high NiCrMo alloys. This type of localized corrosion being usually less predictable than general corrosion and more limiting to a material’s functionality.

Critical pitting and crevice temperatures

High alloyed materials such as Hastelloy C22, C2000 have adequate alloying to be fully resistant to pitting and crevice corrosion up to this temperature limit of 85oC. With increase in temperature the solution becomes chemically unstable and cracks down.

Corrosion rates for the NiCrMo alloys in marine conditions are very nominal in running and stagnant environments. High nickel alloys are also highly resistant to stress corrosion cracking in water comprising chlorides that may otherwise influence the lower alloyed ss300 series.

Nickel alloys with PREN higher than 40 are extremely resistant to crevice corrosion in marine water. Although in extremely tight crevice conditions for example in seawater cooled plate heat exchangers that have several very tight crevices, high alloys such as C276 and C22 are used.

When crevice washers are used with a severe crevice shape to show the relative functionality of these high alloyed materials. It is essential to note that in the less severe crevice conditions Inconel 625 and Hastelloy C276 have shown more than satisfactory performance for seawater application.

Applications of Inconel 625 wire in resisting seawater corrosion are significant. This alloy is widely used as weld overlay on carbon steel as an economical option for enhanced corrosion performance. Although, high alloyed welds with higher PREN values also have applications in various more severe seawater service conditions. Hence it is a recommended alloy for use in this application.

0 notes

Link

Hastelloy C22, B2 Fasteners, hastelloy Fasteners Manufacturer, Exporter & Suppliers in India.

ASTM SB 622, B 619, B 775, B 516, B 626 UNS N6022 and B 333, B 366 UNS N10665 Hastelloy Nuts, Hex Head Bolts manufacturer, Hastelloy Bolts suppliers, Hastelloy Washer exporters.

0 notes

Text

Titanium Grade UNS R50400 Fasteners - Siddhagiri Metals and Tubes

Siddhagiri Metals and Tubes is an ISO 9001:2015 Certified and PED Approved Prominent Titanium Grade UNS R50400 Fasteners Suppliers available in forms like Titanium Grade UNS R50400 Fasteners Nuts, Titanium Grade UNS R50400 Fasteners Bolts, Titanium Grade UNS R50400 Fasteners Screws, Titanium Grade UNS R50400 Fasteners Washers. Titanium Grade UNS R50400 Fasteners Manufacturers Siddhagiri Metals and Tubes is the 6th largest manufacturer in India. Siddhagiri Metals and Tubes Has Warehouse Near To The Airport And Port For Fast Delivery. Siddhagiri Metals and Tubes is a well known Titanium Grade UNS R50400 Fasteners Exporters as we export to more than 70 countries world wide. Siddhagiri Metals and Tubes Offers Wide Range Of Quality Products To Satisfy The Diverse Requirements Of The Customers.

Titanium Grade UNS R50400 Fasteners Stockists Siddhagiri Metals and Tubes maintains over 1200 tons of stock in various shape, sizes which makes us one of the largest Titanium Grade UNS R50400 Fasteners Stockholders in India. In 1990, Siddhagiri Metals and Tubes became 5th largest Titanium Grade UNS R50400 Fasteners Distributors Worldwide. Siddhagiri Metals and Tubes Was Incorporated In The Year 1987 To Cater The Needs Of Domestic Market By Sourcing The Best Quality Products At The Most Competitive Titanium Grade UNS R50400 Fasteners Price.

Siddhagiri Metals and Tubes also specializes in 254 SMO Fasteners, Stainless Steel 904l Fasteners, Copper Nickel 70/30 Fasteners, Copper Nickel 90/10 Fasteners, Duplex 2205 Fasteners, Hastelloy B2 Fasteners, Hastelloy C22 Fasteners, Hastelloy C276 Fasteners, Incoloy 800 Fasteners, Incoloy 825 Fasteners, Inconel 600 Fasteners, Inconel 601 Fasteners, Inconel 625 Fasteners, Inconel 718 Fasteners, Monel 400 Fasteners, Monel K500 Fasteners, Alloy 20 Fasteners, Alloy 200 Fasteners, Super Duplex 2507 Fasteners, Super Duplex 4501 Fasteners, Titanium Grade 1 Fasteners, Titanium Grade 2 Fasteners.

In order to Buy Titanium Grade UNS R50400 Fasteners or for best Quotation On Titanium Grade UNS R50400 Fasteners Products, Mail Us [email protected], you can also Visit Our Website www.siddhagirimetals.com

#steel#Stainless Steel#fasteners#stockist#distributor#suppliers#supplier#exporter#Exporters#manufacturing#manufacturer#manufacturers#manufactrer#manufaturer#metal#alloy#metals#nickel alloy#nut#nuts#bolt#Bolts#screw#screws#washer#washers

0 notes

Text

Hastelloy Fasteners: Manufacturer, Types, and Applications

Hastelloy fasteners are highly sought after in industries requiring exceptional corrosion resistance and durability. Manufactured from Hastelloy, a superalloy primarily composed of nickel, molybdenum, and iron, these fasteners are recognized for their performance under extreme environmental conditions, including high temperatures and aggressive chemicals.

What Are Hastelloy Fasteners?

Hastelloy fasteners include bolts, nuts, screws, washers, and other fastening components made from Hastelloy alloys, such as C276, C22, C2000, and others. These fasteners are designed for applications where conventional materials would fail due to corrosion, pitting, or cracking.

Characteristics of Hastelloy Fasteners

Corrosion Resistance: Hastelloy fasteners offer superior resistance to oxidizing and reducing agents, making them ideal for chemical processing industries.

Thermal Stability: They retain their mechanical properties and resist degradation at high temperatures.

Versatility: Suitable for diverse industries, including chemical, marine, aerospace, and power generation.

Durability: Excellent mechanical strength, fatigue resistance, and toughness.

Ease of Fabrication: Hastelloy fasteners can be easily formed, welded, and machined.

Types of Hastelloy Fasteners

Hastelloy Bolts: Available in hex, carriage, and U-bolt forms, these are used for securing materials in high-stress applications.

Hastelloy Nuts: Hex nuts, lock nuts, and dome nuts crafted for durability and compatibility with Hastelloy bolts.

Hastelloy Screws: Include machine screws, wood screws, and self-tapping screws for specialized applications.

Hastelloy Washers: Flat, spring, and lock washers to distribute load and prevent loosening in assemblies.

Custom Fasteners: Designed as per industry-specific requirements.

Standard Specifications of Hastelloy Fasteners

Hastelloy fasteners are manufactured according to international standards, including:

ASTM B574

ASME SB574

ISO, DIN, and other global standards

Applications of Hastelloy Fasteners

Chemical Processing: Used in reactors, heat exchangers, and storage tanks handling corrosive chemicals.

Marine Industry: Ideal for offshore platforms, shipbuilding, and seawater applications.

Aerospace: Used in components requiring lightweight yet highly durable materials.

Pharmaceutical and Food Processing: Non-reactive to chemicals and easy to sterilize.

Power Generation: Resilient in environments with high temperatures and pressures.

Advantages of Hastelloy Fasteners

Excellent resistance to uniform and localized corrosion

Longevity, even in harsh conditions

Minimal maintenance requirements

Adaptable to various fastening needs

Why Choose Ananka Group for Hastelloy Fasteners?

Ananka Group is a trusted name in the manufacturing and supply of high-quality Hastelloy fasteners. With state-of-the-art production facilities and a stringent quality control process, we ensure our products meet the highest standards. Our fasteners are available in various grades, sizes, and custom specifications to suit diverse industrial applications.

Key Features of Our Products:

Compliance with international standards

Competitive pricing

Timely delivery worldwide

Expertise in custom fastener solutions

Conclusion

Hastelloy fasteners are indispensable in industries that require exceptional resistance to corrosion, high temperatures, and mechanical stress. Whether it’s for chemical processing, marine applications, or aerospace, Hastelloy fasteners provide unmatched reliability and performance. Partnering with a reputed manufacturer like Ananka Group ensures access to premium-quality products tailored to your needs.

FAQs

1. What are the most common Hastelloy grades used for fasteners?The most common grades are Hastelloy C276, C22, and C2000, each offering specific advantages for different applications.

2. Are Hastelloy fasteners expensive?While Hastelloy fasteners are more expensive than standard fasteners, their durability and resistance to harsh environments make them cost-effective in the long run.

3. Can Hastelloy fasteners be used in seawater applications?Yes, Hastelloy fasteners are highly resistant to seawater corrosion, making them ideal for marine environments.

4. Do Hastelloy fasteners require special maintenance?Hastelloy fasteners are low-maintenance and designed to perform reliably even under challenging conditions.

5. How can I ensure I am purchasing genuine Hastelloy fasteners? Buy from trusted manufacturers like Ananka Group, who provide certifications and comply with international standards.

#Hastelloy#Hastelloyfasteners#Ananka#Fasteners#FastenersManufacturer#Linkedin#Article#Blog#HastelloyAlloys#Manufacturer#HastelloyBolts#HastelloyNuts

1 note

·

View note

Text

Hastelloy C276: The Best Fasteners for Corrosion Resistance

Hastelloy is one of the most popular materials trusted in chemical processing, oil and gas industries, pharmaceuticals, and even in power generation due to its exceptional corrosion resistance. Of the various Hastelloy alloys, Hastelloy C276 stands above the rest because of its incredible performance in severe conditions. This blog will discuss the benefits, types, and applications of Hastelloy fasteners-which include bolts, nuts, screws, washers, and studs that are made from Hastelloy C276.

What is Hastelloy C276?

Hastelloy C276 is a nickel-molybdenum-chromium alloy containing an addition of tungsten which can be very versatile and resistant to a wide variety of environments that are corrosive. It performs well in extreme oxidizers such as ferric and cupric chlorides, hot contaminated organic as well as inorganic media and in acidic environments.

Designation

N10276 is the UNS designation of Hastelloy C276

N6022 is the UNS designation of Hastelloy C22

N10665 is the UNS designation of Hastelloy B2

The UNS numbers are useful in standardizing the specific composition of these alloys.

Variations of Hastelloy Fasteners

Hastelloy fasteners exist in different forms to suit the diverse applications. There are quite a number of common types but here are some of the more common ones:

Hastelloy C276 Bolts. They are very strong, strongly corrosion-resistant, and very useful in aggressive chemical environments associated with high temperatures. They are usually used in reactors, pressure vessels, and heat exchangers.

Hastelloy C22 Nuts: Offering the maximum resistance against oxidation and pitting, these nuts can be used where conditions are both temperature changing and corrosive chemical environments.

Hastelloy B2 Screws: Providing resistance to low regions of corrosion like hydrochloric acid, these screws find an application in businesses using acids.

Hastelloy C276 Washers: Provided with an extra layer of protection against corrosion while offering equalized loads with durable and reliable bolted joints.

Hastelloy C22 Studs: These studs can be used in all oxidizing and corrosion-prone environments, which means that the durability and performance would stay intact for a long time.

These fasteners can be sized to fit and also can be made thicker, which makes it flexible with a wide range of applications.

Applications of Hastelloy Fasteners

Because of resistance to extreme conditions, Hastelloy fasteners are applied to a wide number of applications. The main application sites are:

Chemical Processing Industry: Fasteners made of Hastelloy are corrosion resistant to acids as well as bases. They, therefore go very well with reactors, distillation columns, and piping systems.

Oil and Gas Industry: Hastelloy C276 and C22 fasteners enjoy wider application in both onshore and offshore environments. This is due to their resistance to sour gas corrosion and their ability to maintain high temperatures.

Pharmaceutical Industry: Such fasteners ensure that the environment remains sterile and free from contamination since it resists corrosive cleaning agents and solvents.

Power Generation: Hastelloy fasteners used in nuclear and fossil fuel-based plants can better manage corrosive chemicals as well as high temperatures, which makes the power generation systems safer and more efficient.

Benefits of Hastelloy Fasteners

Corrosion Resistance: The corrosion resistance offered by Hastelloy C276, C22, and B2 fasteners is superior and useful for aggressive chemical environments.

Strength: These fasteners do not lose their mechanical strength even at high temperatures thus structural integrity is maintained under demanding conditions.

Versatility: Hastelloy fasteners can be tailored according to a given application. They are available in all sizes and thicknesses.

Durable: Their robust structure keeps them longer, which means that there would be lesser need to replace or service the fasteners.

Conclusion

Hastelloy fasteners, such as hastelloy C276 bolts, C22 nuts, and B2 screws, have improved corrosion resistance, high strength, and durability. These fasteners play a crucial role in various chemical processing industries, oil and gas, pharmaceutical, and power generation sectors. Being a renowned manufacturer, we are offering quality customized Hastelloy fasteners that can deliver long time reliability and performance.

FAQs

What are the most common applications of Hastelloy C276?

The resistance of Hastelloy C276 to pitting, crevice corrosion, and stress corrosion cracking makes it a material used in chemical processing, oil and gas, and medical industries.

Is Hastelloy C276 weldable?

YES - Hastelloy C276 can be welded using standard methods like TIG, MIG, and shielded metal arc welding, with matching filler material recommended.

What is the difference between Hastelloy C276 and C22?

Hastelloy C22 has higher chromium content, which provides better resistance to an oxidizing environment. In contrast to this, C276 can effectively handle any reducing and oxidizing media, making it widely versatile.

Are Hastelloy fasteners customizable?

Yes, Hastelloy fasteners could be customized according to the thickness, size, specifications, to fit any specific requirement.

Why Hastelloy fasteners are chosen over other materials?

Hastelloy fasteners provide excellent resistance to corrosion, strength of high-temperature stability, and long-term serviceability, all of which are much better than that of materials used in stainless steel and titanium alloys in aggressive environments.

0 notes

Text

What industries are fasteners used for?

Fasteners might seem like small components, but they play a pivotal role in numerous industries, holding together structures and equipment that form the backbone of modern society.

As the leading Fasteners Manufacturer, Supplier, Stockist, and Exporter in India, Bullion Pipes & Tubes LLP understands the significance of these tiny yet mighty components across various sectors.

In this article, we'll delve into the wide array of industries where fasteners find their indispensable applications.

Fasteners

Fasteners are mechanical devices or components used to securely join or affix two or more objects together. They play a fundamental role in various industries and applications, providing the necessary connections that ensure structural integrity, safety, and functionality. Fasteners are designed to withstand different types of forces, such as tension, compression, shear, and torsion, depending on the specific application.

There are numerous types of fasteners, each with its own unique design and purpose. Some common types of fasteners include:

Screws: Screws have a threaded shaft and are used with a corresponding threaded hole or nut. They are rotated to create a strong, threaded connection between two objects. Screws are versatile and come in various head styles, including flat, round, pan, and more.

Bolts: Bolts are similar to screws but typically have a non-threaded portion (shank) and require a nut to create a secure connection. They are often used in applications requiring higher levels of tension or load-bearing capabilities.

Nuts: Nuts are paired with bolts to secure two objects together. They come in different shapes, such as hexagonal (hex nuts), square, or round, and are tightened onto the bolt's threaded shaft to create a strong joint.

Washers: Washers are flat, thin discs often placed between the nut or bolt head and the surface of the material being fastened. They distribute the load and prevent damage to the material while providing a more stable connection.

Rivets: Rivets are permanent fasteners used to join two or more materials together by deforming the end of the rivet to hold the materials in place. They are commonly used in applications where welding or screwing is not practical.

Pins: Pins are cylindrical fasteners that are inserted into holes in two objects to align and secure them. They can be held in place by friction or locking mechanisms.

Clips and Clamps: Clips and clamps are fasteners used to hold objects together or secure them in place temporarily. They often provide quick and easy solutions for assembling and disassembling components.

Anchors: Anchors are fasteners designed to provide a secure attachment to a base material, such as concrete or masonry. They are commonly used in construction and structural applications.

Materials & Grades - Fasteners Offered by Bullion Pipes & Tubes LLP

Copper Fasteners

Titanium Fasteners

Titanium Alloy Gr. 2 & 5

Monel Fasteners

Monel K500 & 400

Carbon Steel Fasteners

Brass Fasteners

Tantalum Fasteners

Inconel Fasteners

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Aluminum Fasteners

Nickel Alloys Fasteners

Nickel 200/201

SMO 254 Fasteners

Duplex Steel Fasteners

Duplex Steel UNS S32205

Duplex Steel UNS S31803

Hastelloy Fasteners

Hastelloy C22, B2 & C276

Super Duplex Steel Fasteners

Super Duplex Steel UNS S32750

Super Duplex Steel UNS S32760

Incoloy Fasteners

Incoloy 800/800H/800HT

Incoloy 825

Alloy 20 Fasteners

Industries that use fasteners

Fasteners are used in a wide range of industries and applications to provide secure and reliable connections between various components. Here are some additional contexts where fasteners play a crucial role:

Aerospace and Aviation: The aerospace industry relies on fasteners to assemble aircraft components, such as wings, fuselage, and engine parts. Aerospace fasteners are designed to withstand extreme conditions, including high speeds, vibrations, and temperature fluctuations.

Marine and Shipbuilding: In marine applications, fasteners are used to construct ships, boats, and offshore structures. They must resist corrosion from saltwater and provide a strong bond in harsh marine environments.

Oil and Gas Industry: Fasteners are integral to the construction of oil rigs, pipelines, and refineries. They ensure the safety and reliability of equipment used in the extraction, processing, and transportation of oil and gas.

Medical Devices: Fasteners are used in the assembly of medical devices and equipment, ensuring that they remain securely in place during surgical procedures or patient treatment.

Railway and Transportation: Fasteners are crucial in railway tracks, securing rails to sleepers and ensuring the stability and safety of train operations. They are also used in the assembly of vehicles such as buses, trucks, and trains.

Electrical and Electronics: Fasteners secure components in electrical panels, circuit boards, and electronic devices, ensuring proper functioning and preventing damage due to vibrations and movement.

Furniture and Woodworking: In the furniture industry, fasteners hold pieces of furniture together, whether it's a simple chair or an intricate cabinet. They enable easy assembly and disassembly for shipping and storage.

Sports and Recreation Equipment: Fasteners are used in the manufacturing of sports equipment such as bicycles, skateboards, and snowboards, ensuring that the components remain securely attached during use.

Defense and Military: Military equipment and vehicles rely on fasteners for structural integrity and functionality. They are used in the assembly of tanks, armored vehicles, and aircraft used in defense operations.

Communication Infrastructure: Fasteners are used in the construction of communication towers and antennas, providing stability for broadcasting and wireless communication systems.

Renewable Energy: Fasteners play a role in solar panel and wind turbine installations, securing components and ensuring the efficiency of renewable energy systems.

Automated Manufacturing: Fasteners are used in automated manufacturing processes, where robots and machines assemble products quickly and accurately.

HVAC and Plumbing: Fasteners secure ductwork, pipes, and plumbing components in heating, ventilation, air conditioning, and plumbing systems.

Mining and Heavy Machinery: Fasteners are used in mining equipment, bulldozers, excavators, and other heavy machinery, ensuring their durability and safety during demanding operations.

Retail and Consumer Goods: Fasteners are employed in packaging and display fixtures, enabling efficient assembly and customization of retail spaces.

Final Words!.. A fastener contributes silently to the safety, stability, and progress of various industries, from tall skyscrapers to oil wells. As the premier Fasteners Manufacturer, Supplier, Stockist, and Exporter in India, Bullion Pipes & Tubes LLP's commitment to quality ensures that these small yet crucial components meet the highest standards.

With a wide range of fasteners tailored for diverse applications, We continue to be the preferred choice for industries across the spectrum. Moreover, we are also well-known fasteners exporters in various countries Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia, and beyond. Contact us today to explore how our fasteners can elevate your projects across industries.

0 notes

Text

Stud Bolts and Nuts

We have been involved with many projects in the petrochemical and off-shore services industry from vast pipeline construction projects to smaller bespoke wellhead refurbishment work, sometimes on an urgent basis with our emergency breakdown service. We have supplied for most large oil exploration companies, oil refineries, off-shore oil rigs and gas processing plants. Here are some examples of commonly used fasteners in this sector: TYPES OF PRODUCTS Stud bolts and Nuts Double-Ended Stud bolts Socket Cap Screws/Countersunk Engineer Studs Socket Setscrews Hexagon Bolts and Nuts U-Bolts Hook Bolts Tee Bolts Washers Specially Machined Parts Bi-Hex Bolts & Screws (Ferry heads or 12-Point Bolts) ASTM A193 B5 ASTM A193 B6 ASTM A193 B7 ASTM A193 B7M ASTM A193 B8 (Class 1+2) ASTM A193 B8M (Class 1+2) ASTM A193 B8C & B8TX ASTM A320 L7 & L7M Alloy/Hastelloy C4 C22 + C276 Duplex UNS S31803 (F51) UNS S32550 (Ferralium 255) Read the full article

0 notes

Text

Hastelloy C276 Wire- excellent material for waste treatment

Hastelloy C276 alloy is particularly resistant to crevice and pitting corrosion due to high Molybdenum content. This alloy has high corrosion resistance at high temperatures. It is commonly used in various applications including pulp & paper production, waste treatment and chemical processing. The carbide precipitation during welding is minimized by the low carbon content to maintain corrosion resistance in as-welded structures. This nickel alloy is ideal for most chemical process applications in the as-welded condition due to its resistance to the formation of grain boundary precipitates in the weld heat-affected zone.

A wire is a metal produced in the form of a thin flexible thread and a mesh is a net made of woven or welded strands. Wire mesh is a grid formed by welding steel wires together at their intersections. It is manufactured in different sizes and types using various metals and alloys. Hastelloy C276 has excellent resistance to numerous corrosive media including strong oxidizing agents such as copper chloride, iron chloride and hot media, e.g. nitric acid, chlorine (dry), acetic acid, sulfuric acid, formic acid and phosphoric acid. Hastelloy C276 is used in environmental engineering in construction components in waste incineration plants and flue gas desulfurization plants, e.g. carrier systems, nozzle pipes, chimney linings, absorbers, raw gas inlet nozzles and claddings. It is used in chemical engineering in fittings, pipe linings in wet and dry zones, heat exchangers and mixers. This alloy is used in Pulp industry in bleach washers, chlorine injection nozzles and piping. Hastelloy C276 is used in oil and natural gas production in pumping systems in contact with sour gas in fittings, suction pipes and probes.

Hastelloy C276 alloy can be cold formed and hot formed and the hot forming temperature is between 1230 and 950°C. All standard forming techniques can be utilized and the material tends to work harden. Generally, solution annealing is repeated after hot forming and after cold forming with degrees of deformation greater than 15%. GWAT and GMAW gas metal arc welding processes are utilized for the welding of Hastelloy C276 alloy and it is preferably carried out on like materials or with Hastelloy C22 alloy. The fusion arc welding process is also used to weld the Hastelloy C276 alloy. The semi-finished products are in a stress-free, metallic bright condition and free of dirt. Minimum heat must be applied during welding in order to achieve optimal corrosion resistance. Preheating or secondary heat treatment is not necessary.

An essential non-traditional machining process used for machining difficult to machine materials like composites and inter-metallic materials, Intricate profiles is Wire Electric Discharge Machining (WEDM). A study was performed to optimize the process parameters during machining of Hastelloy C276 by wire-cut electrical discharge machining (WEDM). An effective approach was presented by this paper to optimize process parameters for Wire electric discharge machining (WEDM) was extensively used in tool and die industries. Precision and intricate machining are the strengths however time and surface quality still remains as major challenges while machining. Various input parameters were changed during the process including pulse off time (Toff), current, pulse on time (Ton), voltage and wire feed rate. The General Algorithm (GA) method L-27 orthogonal array was used to perform the optimization of analysis.

0 notes

Text

Titanium Grade WNR 3.7025 Fasteners - Siddhagiri Metals and Tubes

Siddhagiri Metals and Tubes is an ISO 9001:2015 Certified and PED Approved Prominent Titanium Grade WNR 3.7025 Fasteners Suppliers available in forms like Titanium Grade WNR 3.7025 Fasteners Nuts, Titanium Grade WNR 3.7025 Fasteners Bolts, Titanium Grade WNR 3.7025 Fasteners Screws, Titanium Grade WNR 3.7025 Fasteners Washers. Titanium Grade WNR 3.7025 Fasteners Manufacturers Siddhagiri Metals and Tubes is the 6th largest manufacturer in India. Siddhagiri Metals and Tubes Has Warehouse Near To The Airport And Port For Fast Delivery. Siddhagiri Metals and Tubes is a well known Titanium Grade WNR 3.7025 Fasteners Exporters as we export to more than 70 countries world wide. Siddhagiri Metals and Tubes Offers Wide Range Of Quality Products To Satisfy The Diverse Requirements Of The Customers.

Titanium Grade WNR 3.7025 Fasteners Stockists Siddhagiri Metals and Tubes maintains over 1200 tons of stock in various shape, sizes which makes us one of the largest Titanium Grade WNR 3.7025 Fasteners Stockholders in India. In 1990, Siddhagiri Metals and Tubes became 5th largest Titanium Grade WNR 3.7025 Fasteners Distributors Worldwide. Siddhagiri Metals and Tubes Was Incorporated In The Year 1987 To Cater The Needs Of Domestic Market By Sourcing The Best Quality Products At The Most Competitive Titanium Grade WNR 3.7025 Fasteners Price.

Siddhagiri Metals and Tubes also specializes in 254 SMO Fasteners, Stainless Steel 904l Fasteners, Copper Nickel 70/30 Fasteners, Copper Nickel 90/10 Fasteners, Duplex 2205 Fasteners, Hastelloy B2 Fasteners, Hastelloy C22 Fasteners, Hastelloy C276 Fasteners, Incoloy 800 Fasteners, Incoloy 825 Fasteners, Inconel 600 Fasteners, Inconel 601 Fasteners, Inconel 625 Fasteners, Inconel 718 Fasteners, Monel 400 Fasteners, Monel K500 Fasteners, Alloy 20 Fasteners, Alloy 200 Fasteners, Super Duplex 2507 Fasteners, Super Duplex 4501 Fasteners, Titanium Grade 1 Fasteners, Titanium Grade 2 Fasteners.

In order to Buy Titanium Grade WNR 3.7025 Fasteners or for best Quotation On Titanium Grade WNR 3.7025 Fasteners Products, Mail Us [email protected], you can also Visit Our Website www.siddhagirimetals.com

#steel#Stainless Steel#fasteners#stockist#distributor#metal#alloy#metals#nickel alloy#manufacturing#manufacturer#manufacturers#manufactrer#manufaturer#nut#nuts#bolt#Bolts#screw#screws#washer#washers

0 notes