#greenpackage

Explore tagged Tumblr posts

Text

Reusing Packaging II

, 2023

, 2024

are you ready for gift giving fever? :p

a merry week to all of you*

#reduce reuse recycle#balluprojects#naturelovers#originalartwork#portugal#my gifs#greenpackaging#ecofriendly#ecopackaging#original gif#original art#stop motion

8 notes

·

View notes

Text

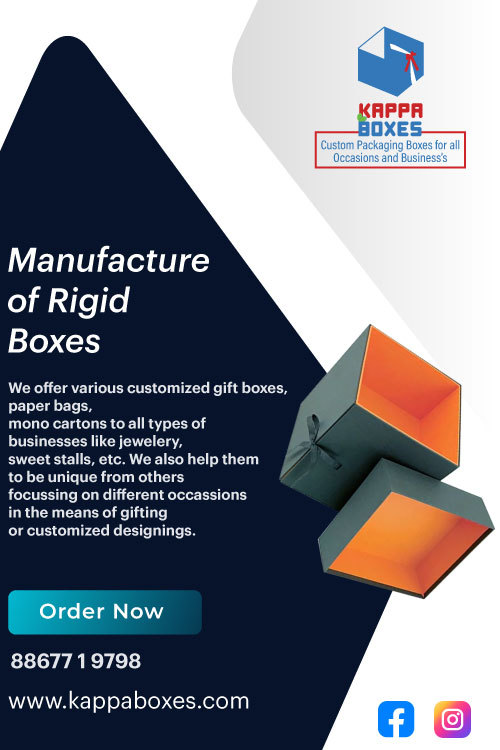

Discover the epitome of premium packaging with Kappa Boxes. Our versatile and practical solutions are eco-friendly, offering uncompromised quality at the best prices. Let us elevate your brand with our customizable and sustainable packaging options.

#KappaBoxes#ExquisitePackaging#CustomizableSolutions#PremiumPackaging#VersatileAndPractical#EcoFriendlyPackaging#UncompromisedQuality#BestPrices#SustainableSolutions#ElevateYourBrand#CustomBoxSolutions#ElegantDesigns#GreenPackaging#InnovativeSolutions#SustainableLuxury#HighQuality#PackagingExperts#BespokeBoxes#EnvironmentallyFriendly#UnbeatableValue#BrandEnhancement#CreativePackaging#UniqueDesigns#PackagingPerfection

2 notes

·

View notes

Text

Sustainable and Eco-Friendly Packaging for Modern and Quick-Service Restaurants and The Food Industry

Eco-friendly packaging for the food industry uses sustainable materials like biodegradable plastics, recycled paper, and plant-based alternatives. This packaging reduces environmental impact by minimizing waste, promoting recycling, and ensuring safer disposal. It aligns with growing consumer demand for sustainability, helping businesses reduce their carbon footprint while maintaining product freshness.

0 notes

Text

Why Businesses Love Reinforced Kraft Tape

Looking for a reliable, eco-friendly solution to seal your packages? Reinforced Kraft Tape from Performance Packaging is the ultimate choice for strong and sustainable shipping. Made with reinforced fibers, this water-activated tape ensures maximum durability, keeping your packages safe during transit.

Unlike traditional plastic tapes, Reinforced Kraft Tape offers a tamper-evident seal, providing added security for your shipments. Its eco-friendly composition makes it a smart choice for businesses aiming to reduce their environmental impact. Perfect for e-commerce, logistics, and industrial applications, this tape bonds seamlessly with cardboard, delivering a neat, professional finish.

Upgrade your packaging today with Reinforced Kraft Tape for a superior sealing solution that combines strength, security, and sustainability.

#ReinforcedKraftTape#EcoFriendlyPackaging#SustainableShipping#TamperEvidentTape#DurableShipping#PackagingSolutions#GreenPackaging

0 notes

Text

youtube

The Global Greaseproof Paper Market, valued at USD 1.24 billion in 2023, is expected to reach USD 2.12 billion by 2032, growing at a CAGR of 6.3% from 2024 to 2032. Greaseproof paper is widely used in food packaging due to its resistance to oil and grease, making it an essential material for wrapping food items such as baked goods, snacks, and fast food. With the rising demand for sustainable and eco-friendly packaging solutions, greaseproof paper has become increasingly popular as an alternative to plastic-based materials, aligning with global sustainability initiatives.

#greaseproofpaper#sustainablepackaging#ecofriendlypackaging#foodpackaging#biodegradablepackaging#greaseproofsolutions#packagingtrends#ecoconsciouspackaging#foodindustry#greenpackaging#sustainablesolutions#takeoutpackaging#paperpackaging#fooddeliverysolutions#environmentallyfriendly#packaginginnovation#compostablepackaging#zerowastepackaging#sustainablematerials#greaseproofproducts#marketresearchreport#marketresearch#acumenresearchandconsulting#marketresearchcompany#news#Youtube

1 note

·

View note

Text

A Green Christmas: The Art of Eco-Friendly Cake Packaging

It was a frosty December morning, and the sweet aroma of freshly baked fruitcake filled the small bakery on the corner of the bustling street. The bakery owner, Mrs Priya, stood staring at the rows of beautifully crafted cakes, wondering how she could make her creations shine brighter this festive season. Her cakes, rich with dried fruits and spices, told stories of joy and warmth — but something was missing. That’s when she realized it wasn’t just about the taste; it was about the presentation, the experience. And in today’s world, the demand for sustainability was calling — Eco-Friendly Christmas Cake Packaging was the answer.

Why Eco-Friendly Packaging Matters

As businesses pivot towards sustainability, eco-friendly packaging is no longer a trend; it’s a necessity. A recent study reveals that 73% of people worldwide are ready to reshape their lifestyles, embracing change to tread gently on the Earth and lessen their mark on the environment. This means bakery owners who adopt sustainable practices are not just helping the planet — they’re appealing to a growing base of conscious customers.

Eco-Friendly Packaging: A Gift for Your Brand and the Planet

Sustainability That Attracts Customers: Eco-friendly cake boxes are crafted from recyclable and biodegradable materials, reducing carbon footprints while maintaining aesthetic appeal. Customers are more likely to trust and return to businesses that showcase environmental responsibility.

Safety Meets Style: Quality packaging ensures cakes are delivered without damage, protecting delicate decorations. And with festive-themed eco-packaging, you get the best of both worlds — protection and elegance.

Brand Identity and Customization: Imagine boxes adorned with your bakery’s logo, a splash of festive colours, and a personal touch. Eco-friendly doesn’t mean dull — it can be as vibrant and festive as you want it to be.

How Eco-Friendly Packaging Drives Festive Sales

The festive season is when bakeries experience a surge in orders. With the rush to meet deadlines, having sturdy and sustainable packaging is crucial for safe deliveries. Plus, eco-friendly packaging creates an impression of care — not just for customers but for the environment.

Divine Packs: Your Packaging Partner

For bakery owners like Mrs Priya, Divine Packs provides eco-friendly Christmas cake boxes that are as delightful as the treats they hold. Crafted with high-quality materials and customizable designs, these boxes are perfect for delivering cakes safely and beautifully. Whether it’s the bustling streets of Tamil Nadu or serene countryside bakeries, Divine Packs ensures every cake finds its way to customers in a memorable package.

Conclusion: Celebrate Christmas with Care

This Christmas, let your bakery shine with Eco-Friendly Christmas Cake Packaging that tells a story of care — care for the planet and your customers. Eco-friendly packaging is more than a box; it’s a statement of love for the Earth and a promise to deliver joy in every slice.

As you prepare for the festive rush, are you ready to package your cakes with care and creativity?

#EcoFriendlyPackaging#SustainableBakery#ChristmasCakePackaging#EcoPackaging#BakeryPackaging#Sustainability#FestivePackaging#BrandIdentity#EcoFriendlyCakes#SustainableBusiness#GreenPackaging#BakeryBusiness#ChristmasTreats#ConsciousConsumers#DivinePacks#EcoFriendlyBrand#EcoFriendlyProducts

0 notes

Text

Who's ready for the holidays? 📦❄️✨

www.sorellaofficial.com

#small business#women owned business#crystals#minerals#greenpackaging#aetheticbranding#crystal shop#ishopsorella

0 notes

Text

Eco-Friendly Packaging Solutions – Sustainable Add-Ons for Every Product

Discover premium, eco-friendly packaging Solutions add-ons designed to enhance your product while reducing environmental impact. From biodegradable films to recyclable zip locks, our sustainable packaging solutions offer quality and durability without compromising the planet. Choose from a wide selection of eco-conscious options, perfect for brands committed to sustainability and style.

Visit: - https://entrepouch.com/product-category/add-ons

0 notes

Text

Algae-Based Packaging Market: Global Opportunity Analysis & Forecast(2024–2030)by Algae Type, End Use, and Geography”

Algae Based Packaging Market Overview:

Algae Based Packaging Market size is estimated to reach $467.5 million by 2030, growing at a CAGR of 5.8% during the forecast period 2024–2030. The market for Algae Based Packaging is primarily driven by growing awareness and concern for environmental sustainability, which has led to increased interest in eco-friendly packaging solutions. Algae-based packaging aligns with these sustainability goals, as it is biodegradable and reduces the environmental impact of traditional packaging materials.

The increasing demand for Algae Based Packaging market can be attributed to Advancements in technology related to the production and use of algae-based materials have contributed to the growth of the Algae Based Packaging market. These technologies have made it feasible to manufacture packaging materials from algae efficiently. Some regions and governments are encouraging the use of sustainable and biodegradable packaging materials, which includes algae-based packaging. This support has further boosted the demand for such products.

Sample Report :

Sustainability and Environmental Focus 🌍 With increasing pressure to reduce plastic waste, algae-based packaging is gaining attention as a biodegradable and eco-friendly alternative. Companies are using algae to create packaging that decomposes naturally, aligning with global sustainability goals.

Innovation in Biodegradable Materials 🧪 Research and development in algae-based materials are driving innovations in texture, strength, and durability. Algae is being engineered into various forms of packaging, from flexible films to solid containers, making it versatile for different industries.

Growing Demand for Circular Economy Solutions ♻️ Algae-based packaging supports the circular economy model by providing renewable, compostable materials. The entire life cycle of these products — from cultivation to disposal — is designed to minimize environmental impact, helping brands meet sustainability targets.

Cost Competitiveness and Scaling 📈 As production methods for algae-based materials improve, the cost of manufacturing is decreasing, making it a more viable option for large-scale packaging needs. This trend is enabling wider adoption across industries like food and cosmetics.

Inquiry Before Buying :

Consumer Preference for Green Products 🌱 With heightened awareness of environmental issues, consumers are increasingly choosing products with sustainable packaging. Brands using algae-based packaging can attract eco-conscious buyers, leveraging this trend as a unique selling point.

COVID-19 / Ukraine Crisis — Impact Analysis:

The Covid-19 pandemic had a significant impact on the Algae Based Packaging industry. Supply chain disruptions, reduced production capacity, and shifts in consumer priorities during the pandemic affected the industry’s growth. However, the crisis also heightened the focus on sustainable and eco-friendly packaging materials, offering opportunities for algae-based packaging to gain traction as a viable, environmentally conscious alternative in the post-pandemic world.

The Russia-Ukraine war had a notable impact on the Algae Based Packaging market. Due to the geopolitical instability and disruptions in supply chains, there have been challenges in sourcing key raw materials for algae-based packaging production. This has resulted in increased production costs and supply chain disruptions, impacting the market’s growth and availability.

Schedule a Call :

Asia Pacific is expected to grow at higher CAGR during the forecast period 2024–2030. This is owing to Asia-Pacific region is emerging as the fastest-growing market for Algae-Based Packaging, a trend that underscores the region’s commitment to sustainability and eco-friendly solutions. Several factors contribute to the rapid expansion of the algae-based packaging sector in Asia-Pacific. First, governments and regulatory bodies are introducing stringent environmental regulations, pushing companies to adopt sustainable practices. China, one of the world’s largest plastic consumers, has launched a comprehensive strategy to eliminate single-use plastics across the country. The National Development and Reform Commission released the new policy, which will take effect over the next five years. Plastic bags less than 0.025mm thick are prohibited from manufacture and sale. Single-use plastic goods in the restaurant business must be reduced by 30%. Hotels have been informed that by 2025, they must not provide complimentary single-use plastic goods. Second, the region’s robust research and development capabilities have enabled the development of innovative algae-based packaging solutions. Additionally, collaboration between businesses, research institutions, and government agencies has facilitated the scaling up of production capabilities and the commercialization of algae-based packaging solutions.

Buy Now :

Food and Beverages accounted for the largest market share in 2023. The Food and Beverage industry has emerged as a prominent end-use sector in the rapidly growing Algae-Based Packaging market. This trend is driven by a compelling combination of environmental awareness, consumer demand for sustainable packaging, and the industry’s commitment to reducing its environmental footprint. Algae-based packaging offers a unique solution to the challenges of traditional packaging materials, as it is biodegradable, compostable, and sourced from renewable algae biomass. In the Food and Beverage sector, where freshness and product safety are paramount, algae-based packaging plays a crucial role in extending the shelf life of perishable goods while maintaining their quality. This innovative packaging material effectively shields food and beverages from moisture and oxygen, preserving the integrity of products and reducing food waste in the process.

𝐅𝐨𝐫 𝐦𝐨𝐫𝐞 𝐢𝐧𝐟𝐨𝐫𝐦𝐚𝐭𝐢𝐨𝐧 𝐀𝐥𝐠𝐚𝐞 𝐁𝐚𝐬𝐞𝐝 𝐏𝐚𝐜𝐤𝐚𝐠𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭 𝐜𝐥𝐢𝐜𝐤 𝐡𝐞𝐫𝐞

#algaebasedpackaging#biodegradablepackaging#sustainablematerials#algaetechnology#greenpackaging#zerowaste#renewableresources#bioplastics#ecofriendlypackaging#futureofpackaging#SustainablePackaging#AlgaeInnovation#GreenPackaging

0 notes

Text

Cool Dad, 2024

Watercolour pencil on 190g paper, 29.7 cm x 21 cm.

another gift from a daughter to her cool dad <3 together with a handmade and recycled protective packaging (to send and go to distance or to wrap as pleased) ^^

I'm not allowed to show the original photographs due to privacy and respect, but i was allowed to share the final result. but simplicity can show more of us that we can share and i'm glad this gift was received with so many smiles :D have a life full of blessings*

#balluprojects#greenpackaging#fathers day#unique gifts#portraits#baby#daddy’s babygirl#proud dad#cool#ecopackaging#traditional art#illustration#drawings#artists on tumblr#artwork#linework#commission art#originalartwork#women artists#woman artist#woman artwork#female artists

8 notes

·

View notes

Text

Call 9822619307 OR Get it here- https://www.pioneertapes.com/contact-us

#EcoFriendlyPackaging#SustainableShipping#KraftTape#SecureShipping#GreenPackaging#EcoConscious#PlasticFree#TamperEvident#PackagingIndustry#securestorage#Pune#PioneerTapes

0 notes

Text

Top Eco-Friendly Packaging Supplier Delivering Premium Sustainable Solutions for Businesses & Industries

Eco-friendly packaging for food is designed to reduce environmental impact while ensuring product safety and freshness. Made from biodegradable, recyclable, or compostable materials like paper, glass, or plant-based plastics, it minimizes waste and pollution. This sustainable option aligns with consumer demand for eco-conscious choices, supporting both businesses and the planet.

0 notes

Text

The main features of environmentally friendly tableware and Eco friendly food packaging

With the progress of society and the development of science and technology, people are increasingly aware of the importance of energy conservation and environmental protection. More and more products are being replaced by environmentally friendly products, including compostable packaging, eco friendly food packaging, and molded pulp packaging. For example, some takeaway and packaging began to use bagasse lunch boxes. The environmentally friendly disposable tableware made of bagasse is very good, it will automatically degrade within 3 months, and it is waterproof and oil-proof. This type of compostable packaging and molded pulp packaging not only reduces waste but also supports a sustainable future by offering a natural and eco friendly food packaging solution.

The following is a brief analysis of the main characteristics of environmentally friendly tableware and Eco friendly food packaging.

1. No pollution

First of all, the first feature of environmentally friendly tableware is pollution-free. Because environmentally friendly tableware and Eco friendly food packaging, such as compostable packaging and molded pulp packaging, usually uses some degradable materials, such as the most common paper or sugarcane pulp, etc., these materials are formed into standard tableware by thermoforming for human use. At this time, there is no harm to the human body. Because it does not contain any toxic substances.

Because it is made of paper and sugarcane pulp, it is easily degraded in nature after use. This will not harm the overall natural environment. So this is the most important feature of environmentally friendly tableware and Eco-friendly food packaging.

2. Degradable

Another very important feature of environmentally friendly tableware and eco friendly food packaging is its own degradability. Compostable packaging, such as eco friendly food packaging made from sugarcane clamshells, is easily degraded in nature; this is the advantage of environmentally friendly lunch boxes and degradability. Tableware made of bagasse, a type of molded pulp packaging, offers high whiteness, good compactness, good temperature, and oil resistance, is non-toxic and tasteless, and can be completely degraded within three months. The production process of this eco friendly food packaging, tableware, compostable packaging, molded pulp packaging is pollution-free, and the production cost is much lower than that of pulp-molded fast food boxes.

3. Sustainable

Environmentally friendly tableware must not only be environmentally friendly after use, but the materials produced must also be environmentally friendly and sustainable materials. Bagasse tableware , ,molded pulp packaging, eco friendly packaging, compostable packaging fully meets these two conditions. Bagasse is a waste material that is reused, which not only solves the problem of waste. How to deal with bagasse can also achieve the purpose of waste reuse.

0 notes

Text

Sustainable Packaging: Eco-Friendly Solutions

Discover innovative sustainable packaging ideas to reduce environmental impact. Learn about eco-friendly materials & compostable packaging at the mend packaging

#sustainablepackaging#ecofriendlypackaging#gogreenpackaging#sustainablebusiness#ecopackaging#zerowastepackaging#greenpackaging#compostablepackaging#biodegradablepackaging#sustainable#sustainablebrand#sustainability

0 notes

Text

Eco-Friendly Inks and Adhesives

As packaging materials become more sustainable, so do the inks and adhesives used. In 2024, expect to see a rise in eco-friendly inks made from natural or water-based sources, and adhesives that are biodegradable or recyclable. These advancements ensure that all aspects of packaging are aligned with sustainability goals, reducing the overall environmental footprint.

#ecofriendlypackaging#gogreenpackaging#sustainablebusiness#ecopackaging#zerowastepackaging#greenpackaging#compostablepackaging#biodegradablepackaging

0 notes

Text

The Importance of Eco-Friendly Packaging: Choosing the Right Christmas Cake Box

When it comes to the holiday season, one thing is for sure — Christmas cake is a must-have! But did you know that the way your cake is packaged can make a big difference for the environment? That’s right! Eco-Friendly Christmas Cake Packaging is an important choice that can help reduce waste and keep the planet a little greener. Imagine this: you wouldn’t throw a beautiful gift into a trash bag, right? You’d want it to look presentable and be wrapped with care. Well, the same goes for your delicious Christmas cake. Choosing sustainable packaging is like giving your cake the best gift for the environment!

So, what exactly makes packaging “eco-friendly”? Simply put, it’s about using materials that are recyclable, biodegradable, or made from renewable resources. Think about it like switching to a reusable shopping bag instead of those plastic ones that end up in landfills. By choosing Eco-Friendly Christmas Cake Packaging, you are not only showing off your cake beautifully but also supporting sustainability. Brands like Divine Packs specialize in making packaging that looks good and feels good too — because it’s made with the planet in mind.

In conclusion, choosing the right Christmas cake box isn’t just about looking pretty under the Christmas tree — it’s about caring for the earth while celebrating the season. So next time you’re wrapping up that holiday treat, remember that Eco-Friendly Christmas Cake Packaging is the way to go. Trust us, your cake (and the planet) will thank you!

Contact Us through website: https://divinepacks.co.in/ or call us on: +91 98943 33189 to wrapping your gift box with care.

0 notes