#grains supplier from india

Explore tagged Tumblr posts

Text

0 notes

Text

In Eastern Europe, for instance, the number of people living in cities declined by almost one-third during the seventeenth century, as the region became an agrarian serf-economy exporting cheap grain and timber to Western Europe. At the same time, Spanish and Portuguese colonizers were transforming the American continents into suppliers of precious metals and agricultural goods, with urban manufacturing suppressed by the state. When the capitalist world-system expanded into Africa in the eighteenth and nineteenth centuries, imports of British cloth and steel destroyed Indigenous textile production and iron smelting, while Africans were instead made to specialize in palm oil, peanuts, and other cheap cash crops produced with enslaved labor. India—once the great manufacturing hub of the world—suffered a similar fate after colonization by Britain in 1757. By 1840, British colonizers boasted that they had “succeeded in converting India from a manufacturing country into a country exporting raw produce.” Much the same story unfolded in China after it was forced to open its domestic economy to capitalist trade during the British invasion of 1839–42. According to historians, the influx of European textiles, soap, and other manufactured goods “destroyed rural handicraft industries in the villages, causing unemployment and hardship for the Chinese peasantry.”

Jason Hickel and Dylan Sullivan, Capitalism, Global Poverty, and the Case for Democratic Socialism

104 notes

·

View notes

Text

How Indian rice manufacturers are shaping the global market

Indian rice has long held a place of pride in global kitchens, from the aromatic basmati grains that grace royal banquets to the nutritious non-basmati varieties that make up everyday meals worldwide. India is the world’s largest rice exporter, meeting over 40% of global rice demand (Source: FAO). Behind this success is the dedication and innovation of rice manufacturers in India, who are constantly adapting to meet international standards and market needs.

In this blog, we explore how Indian rice manufacturers are shaping the global market, promoting sustainability and securing India’s position as a rice exporting powerhouse.

Key factors driving Indian rice exports

Quality and Variety Rice manufacturers offer a diverse range of rice, from aromatic basmati to versatile non-basmati rice varieties. Each variety caters to different cuisines and preferences, ensuring steady demand in countries such as the United States, the Middle East, and Africa.

Competitive Pricing India's favorable agricultural conditions and cost-effective manufacturing processes enable competitive pricing. Combined with bulk export capabilities, this ensures that India remains a preferred supplier for global buyers.

Government policies and support Supportive government policies such as export incentives and trade agreements have contributed significantly to India's global dominance. For example, the recent removal of export restrictions on certain Indian rice varieties has boosted international trade opportunities.

Technological advances in rice manufacturing

Technology is transforming rice production in India, increasing efficiency and quality while reducing waste.

Modern milling equipment: Automated milling units maintain uniform grain size, texture and polish, which are critical to meeting international quality standards.

AI-powered sorting: Advanced sorting systems powered by artificial intelligence help eliminate impurities, ensuring that premium-grade rice reaches global markets.

Packaging innovations: Innovative vacuum-sealing and biodegradable packaging materials have made Indian rice more attractive to environmentally conscious buyers.

Rice manufacturers in India are adopting these advancements to maintain their competitive edge while meeting global priorities.

Sustainability initiatives by Indian manufacturers

As environmental concerns grow, rice exporters in India are adopting sustainable practices to meet global expectations.

Water-efficient farming: Techniques such as alternate wetting and drying (AWD) reduce water consumption, which is crucial for regions facing water scarcity.

Low carbon footprint: Adoption of renewable energy in processing units and adoption of eco-friendly logistics have reduced emissions in the rice supply chain.

Waste Utilization: By-products such as rice husk are being reused for bioenergy and building materials, thereby reducing waste and generating additional revenue streams.

These initiatives not only enhance India’s reputation but also align with the sustainability goals of global buyers.

Conclusion: The future of Indian rice on the global stage

The success of rice manufacturers in India is not just about meeting current demands, but also about shaping the future of the global rice trade. By prioritizing quality, leveraging technology, and adopting sustainable practices, Indian manufacturers have solidified their position as reliable partners in the global food supply chain.

As international markets evolve, India’s ability to adapt and innovate will continue to drive its leadership in the rice export industry, ensuring that Indian rice remains a staple in households around the world.

2 notes

·

View notes

Text

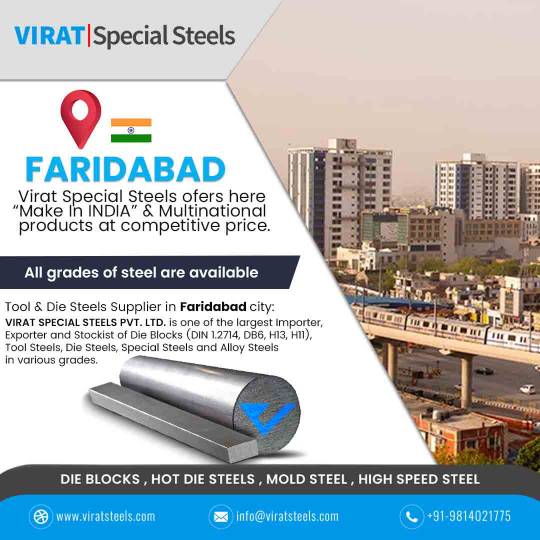

Looking for SOURCING DIE & TOOL STEELS in #FARIDABAD ! If you’re in Faridabad, look no further! Virat Special Steels is your go-to partner for all your die and tool steel needs.

Virat Special Steels maintains an impressive inventory of 3,500 tonnes of special steels tailored for dies, tools, and moulds. They offer custom cutting services ranging from 250mm to 1100mm to meet specific customer needs.

Moreover, their fully equipped quality assurance and process examination facility stands ready to conduct rigorous tests such as hardness assessments and grain structure analyses. This meticulous approach ensures that the steel provided is optimally suited for the customers' diverse applications.

Here’s why you choose Virat Steels?

Immediate Availability: Virat Special Steels ensures that you get what you need when you need it. No delays, no hassles.

Best Price: Competitive pricing means you get quality without breaking the bank. Virat Special Steels offers value for your investment.

Testing Capability: Trust their expertise. They provide testing services to ensure the quality of the steels you source. No compromises on performance or safety.

Expert Advice: Need guidance? Virat Special Steels has you covered. Whether it’s material selection, heat treatment, or application-specific recommendations, they’ve got the knowledge.

Choose Virat Special Steels for reliability, quality, and peace of mind. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Product List:

DIE STEEL ( HH 370 - 410 BHN ) DIN-1.2714 / AISI L6 )

HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

For more information visit https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-faridabad/

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#iso9001#faridabad#manesar#delhi ncr#steel#tool steel suppliers#db6steel#h13steel#h11steel#pune#din 2714#din2344#plasticmouldsteels

2 notes

·

View notes

Text

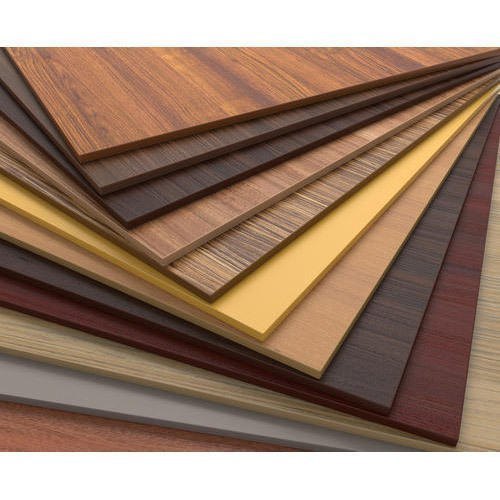

Understanding the Installation Process of Wooden ACP Sheets in India

In recent years, the demand for aesthetically pleasing yet durable construction materials has surged in India. One such material that has become a favorite among architects and designers is the wooden Aluminum Composite Panel (ACP) sheet. Combining the natural elegance of wood with the robustness of aluminum wooden ACP sheet India offer a perfect blend of beauty and functionality. At Alucobond India, we take pride in delivering premium-quality wooden ACP sheet in India that redefine modern architecture.

Wooden Aluminium Composite Panels (ACP) sheets are an excellent choice for adding a touch of natural elegance to modern construction projects. They offer a blend of aesthetic appeal and durability, making them increasingly popular in residential, commercial, and industrial applications. Here, we provide an overview of the simplified installation process of wooden ACP sheets in India.

Key Steps in Installing Wooden ACP Sheets

1. Surface Preparation

Ensure the surface is clean, level, and free from dust, grease, or debris. Proper preparation ensures a smooth and durable finish for the ACP installation.

2. Panel Cutting and Shaping

Wooden ACP sheets in India are cut and shaped according to the design requirements using specialized cutting tools. Precision is critical to ensure the panels fit seamlessly.

3. Framing and Support Structure

Install a metal or wooden framework on the surface to support the ACP sheets. This framework should be stable and aligned to hold the panels securely.

4. Panel Fixing

The panels are fixed to the framework using appropriate fasteners, adhesives, or a combination of both. Special care is taken to align the panels properly and maintain consistency in the grain direction for a uniform look.

5. Sealing and Finishing

Seal the edges and joints with a silicone sealant to protect against moisture and enhance the appearance. Finally, inspect the installation for any misalignments or gaps.

Tips for Optimal Installation

Engage experienced professionals familiar with ACP installation techniques.

Use high-quality tools and materials to avoid damage during the process.

Follow manufacturer guidelines for cutting, fixing, and sealing the panels.

Conclusion

Installing wooden ACP sheets in India is a straightforward process when handled with precision and care. By understanding these fundamental steps, you can achieve a flawless finish that enhances the aesthetics and functionality of your space. wooden ACP sheets in India offer a long-lasting and visually appealing solution for modern construction needs in India. wooden ACP sheets in India are a game-changer in the construction and design industry, offering unmatched versatility, durability, and elegance. Whether you are looking to revamp your building’s facade or create stunning interiors, Alucobond India’s wooden ACP sheets are the perfect choice. Contact us today to explore our collection and elevate your architectural projects with the timeless charm of wood and the modern benefits of aluminum composite panels.

To Know More https://alucobond.in/aluminium-composite-panel-suppliers-india

0 notes

Text

Fruit Baskets, Mesh Colanders & Square Strainers – Perfect for Storage & Drainage

At Unik Corporation, we offer premium Fruit Baskets, Mesh Colanders, and Square Strainers designed to keep your kitchen organized while ensuring proper ventilation and drainage. Crafted from high-quality stainless steel and food-grade materials, our products provide a durable, rust-resistant, and stylish solution for both home and commercial kitchens.

Why Choose Our Fruit Baskets, Mesh Colanders & Square Strainers?

✔ Optimal Air Circulation – Prevents moisture buildup, keeping fruits and vegetables fresh longer. ✔ Strong & Sturdy Build – Made from premium-quality mesh for long-term use. ✔ Multi-Purpose Functionality – Ideal for washing, straining, and storing food items. ✔ Square Strainer for Versatile Use – Designed for efficient rinsing of fruits, vegetables, pasta, and grains. ✔ Lightweight & Easy to Handle – Designed for both home and professional kitchens. ✔ Available in Various Sizes & Designs – A perfect fit for different kitchen needs.

Applications

Fruit & Vegetable Storage – Keeps produce fresh with excellent airflow.

Straining & Rinsing – Efficiently washes fruits, vegetables, pasta, and grains with the Square Strainer.

Kitchen Organization – Adds a stylish touch while keeping essentials within reach.

Upgrade your kitchen with Unik Corporation’s premium Fruit Baskets, Mesh Colanders, and Square Strainers—a perfect blend of functionality, durability, and elegance.

Explore our collection today!

#FruitBasket#MeshColander#SquareStrainer#KitchenEssentials#FoodStorage#PremiumKitchenware#StainlessSteelBasket#VentilatedStorage#FoodGradeMaterial#DurableKitchenware#FruitStorage#VegetableBasket#Strainer

0 notes

Text

1121 Golden Sella Basmati Rice Supplier

As a primary 1121 Golden Sella Basmati rice supplier and exporter, Foodsy Export pays attention to serving quality rice, hygiene products, and consistency to reach the demand made in the rice trade worldwide. From the fields to the finest grains, modern processing and packaging make sure that the grains delivered are up to the mark of international food standards. That’s what makes Foodsy Export a highly sought-after 1121 Golden Sella Basmati Rice exporter and an 1121 Golden Sella Basmati Rice manufacturer valued internationally for its quality product range.

Quality Manufacturing of 1121 Golden Sella Basmati Rice by Foodsy Export: From Paddy to Perfection

Foodsy Export maintains international quality standards in the manufacturing process of 1121 Golden Sella Basmati Rice and 1121 Basmati Rice, leaving us a trusted 1121 Basmati rice manufacturer for consumers worldwide.

All begin with high-quality paddy selection from the fertile regions of India, primarily Punjab, Haryana, and Uttar Pradesh. The perfect climatic conditions there allow these regions to produce premium-quality basmati rice.

Parboiling is done for the golden transformation of 1121 Basmati Rice to 1121 Golden Sella Basmati Rice. The parboiling provides a characteristic golden color with high nutritional contents to 1121 Golden Sella Basmati Rice.

Advanced processing is done after milling so that the rice is separated from the husk without the nutrients getting lost. Advanced polishing leads to a glossy texture but retains the nutritional properties.

Each lot is also subjected to precise testing to ensure that every lot is free of impurities, broken grains, and discolored. Every grain complies with food safety regulations of ISO, HACCP, and FSSAI hygiene certification.

The product is packaged in moisture-proof and airtight packaging to keep it fresh. Fodosy Export Offers:

Bulk packaging in 25 kg, 50 kg bags for wholesalers

Retail packaging in 1 kg, 5 kg, and 10 kg for supermarkets and direct consumers

Private labelling for international brands and distributors

Why Foodsy Export as 1121 Golden Sella Basmati Rice Supplier and Exporter

Foodsy Export is the largest 1121 Golden Sella Basmati Rice manufacturer and has cornered itself in the international rice trade as a most valued 1121 Golden Sella Basmati Rice exporter. It makes sure that all its customers worldwide get the best quality rice. It is a trusted name and brand with values that deliver customer satisfaction in every grain of basmati rice. Foodsy Export is a trusted 1121 basmati rice manufacturer that lets the client obtain quality 1121 Golden Sella Basmati rice in every corner of the world.

Global supply chain and export range to the Middle East (UAE, Saudi Arabia, Iran, Kuwait), Europe, North America, Africa, and all Asian countries.

Quality control for excellence,

Hygienic processing to ensure contamination-free output,

No artificial additives, 100% chemical-free rice

Custom pack specifically made for each region

Source products only from sustainable farm suppliers

There’s parboiling through the high-technology milling machines without any wastage

Important Attirbutes and Delicacies Prepared with 1121 Golden Sella Basmati Rice

The 1121 Golden Sella Basmati rice becomes two times longer in size than it is in its natural condition.

Given the golden yellow color as parboiled, retains high nutritional value

Nonsticky grains can be used for gourmet preparations like biryanis, pulaos, and other high-class recipes.

The rich fragrance is specific to rice and does not drain away with cooking

High in vitamins and minerals.

Longer shelf life and remains fresh for a longer time, hence ideal for export.

1121 Golden Sella Basmati Rice forms the crux of any given recipe for:

Hyderabadi Biryani: The stretched grains absorb the rich spices very smoothly.

Persian Pulao: soft, fragrant with saffron touch

Kabsa, or Middle Eastern Rice: 1121 Golden Sella acts as a wonderful constituent that can sit at the bottom inside the strongly flavorful and aromatic braising liquids.

Rice Pilaf: steeps flavors without the pilaf being sticky.

Trusted 1121 Golden Sella Basmati Rice Exporter and Supplier From India

With its great quality, perfume, and texture, the Foodsy Export, the 1121 Golden Sella Basmati Rice, is only just good enough for exporters, wholesalers, retailers, and most of all, the high-end chefs because they can utilize almost all the parts in almost all parts of the world. The premium quality commitment will define the sustainability of international food safety parameters.

Foodsy Export, the highly reliable 1121 Golden Sella Basmati rice supplier, is the name that will ring in the minds of importers looking for a sought-after 1121 Golden Sella Basmati rice exporter. Call Foodsy Export today for your bulk order and high-quality rice supply across the globe.

#1121 Golden Sella Basmati Rice Supplier#1121 Golden Sella Basmati Rice manufacturer#1121 Golden Sella Basmati Rice exporter

0 notes

Text

Chlorfenapyr Market Size, Trends, and Growth Forecast to 2025

Market Overview

The chlorfenapyr market is experiencing steady growth due to its increasing use in agriculture, pest control, and public health applications. Chlorfenapyr is a broad-spectrum insecticide and acaricide used to control various pests, including termites, mosquitoes, and agricultural insects. It is widely applied in crops, stored grains, and urban pest management due to its effectiveness against insecticide-resistant pests.

Get free sample copy @ https://www.statsandresearch.com/request-sample/26998-global-chlorfenapyr-market

Market Insights

Market Growth Drivers

Rising Demand for Crop Protection Solutions: The increasing need for higher agricultural yields is driving the use of effective pesticides like chlorfenapyr.

Growing Concerns Over Insecticide Resistance: Pests developing resistance to traditional insecticides have led to increased demand for newer, more potent chemicals.

Expanding Urban Pest Control Market: The product is widely used in termite control, mosquito control, and general pest management in residential and commercial areas.

Government Initiatives for Vector Control: Public health agencies use chlorfenapyr to combat disease-carrying insects like mosquitoes, which transmit malaria and dengue.

Market Challenges

Regulatory Restrictions: Chlorfenapyr is subject to stringent environmental and health regulations in some regions, limiting its market penetration.

Toxicity Concerns: Though effective, chlorfenapyr can pose risks to non-target species, leading to restrictions in certain applications.

Competition from Alternative Pesticides: Other bio-based or less toxic insecticides may replace chlorfenapyr in some markets.

Fluctuating Raw Material Costs: The cost of raw materials and production can impact the price and availability of chlorfenapyr-based products.

Get full report @ https://www.statsandresearch.com/report/26998-global-chlorfenapyr-market/

Key Players in the Chlorfenapyr Market

BASF SE (Germany) – A leading global supplier of chlorfenapyr-based insecticides.

FMC Corporation (USA) – A key player in agricultural and urban pest control solutions.

Gharda Chemicals Ltd. (India) – A significant producer of technical-grade chlorfenapyr.

Shandong Weifang Rainbow Chemical Co. Ltd. (China) – A major manufacturer in Asia.

Jiangsu Yangnong Chemical Co., Ltd. (China) – Specializes in pesticide formulations.

Nihon Nohyaku Co., Ltd. (Japan) – A prominent agrochemical company focusing on pesticide innovation.

Regional Analysis

1. North America

The United States is a major consumer, driven by demand for agricultural pest control and urban pest management.

Stringent EPA regulations govern chlorfenapyr use, impacting product approvals.

Growing use in termite control and vector management programs.

2. Europe

The European market is highly regulated, with limited applications allowed due to environmental concerns.

The UK, Germany, and France use chlorfenapyr in specific agricultural and pest control applications.

Growing demand for alternative pest control solutions could affect long-term market growth.

3. Asia-Pacific

China and India are leading producers and consumers, with expanding agricultural and pest control industries.

Japan and South Korea use chlorfenapyr extensively in crop protection.

Increasing urbanization and rising demand for insecticides in Southeast Asia drive market growth.

4. Middle East & Africa

Rising vector-borne disease control programs boost demand in Africa.

Agricultural expansion in the Middle East supports moderate market growth.

Import-dependent in many countries due to lack of local manufacturing.

5. Latin America

Brazil, Argentina, and Mexico are major agricultural users of chlorfenapyr.

Expanding agriculture and pest control industries drive demand.

Regulatory challenges may limit growth in some countries.

Get enquiry before buying @ https://www.statsandresearch.com/enquire-before/26998-global-chlorfenapyr-market

0 notes

Text

Badani Corporation: Your Ultimate Source for High-Quality Green Moong (Moong Dal) in India

When it comes to sourcing the finest green moong (moong dal) in India, Badani Corporation stands out as a leading manufacturer and supplier of Green Moong. Renowned for our unwavering commitment to quality, we specialize in delivering moong dal that is not only rich in nutrients but also perfect for a wide range of culinary and nutritional applications. Whether you’re a restaurant owner, a food manufacturer, or a retail business, Badani Corporation ensures you receive the best green moong to meet your needs.

Premium Quality Green Moong (Moong Dal)

At Badani Corporation, we understand the importance of quality in every grain of moong dal. Our green moong is sourced from the finest farms across India, where sustainable farming practices are prioritized. This ensures that the moong dal we supply is not only fresh but also packed with essential nutrients. From farm to table, every step of the process is meticulously monitored under stringent quality controls to guarantee purity and consistency.

A Reliable Manufacturer and Supplier

As a trusted manufacturer and supplier of Moong Dal, Badani Corporation has built a reputation for excellence in the global market. Our green moong (moong dal) is exported to numerous countries, meeting international quality standards. Whether you’re looking to source moong dal for your restaurant, food manufacturing unit, or retail business, we provide a consistent and reliable supply chain. Our expertise as a leading exporter and supplier ensures that your business never faces delays or compromises on quality.

Versatile Applications of Moong Dal

Green moong (moong dal) is a versatile ingredient that finds its way into a variety of dishes, from traditional Indian recipes to modern health-focused meals. At Badani Corporation, we take pride in offering moong dal that is ideal for diverse culinary applications. Its high nutritional value makes it a popular choice for health-conscious consumers, while its rich flavor enhances the taste of any dish. Whether you’re preparing soups, salads, or desserts, our green moong delivers unmatched quality and taste.

Choose Badani Corporation for Your Moong Dal Needs

When you choose Badani Corporation, you’re choosing a partner that prioritizes quality, reliability, and customer satisfaction. Our green moong (moong dal) is a testament to our commitment to delivering products that exceed expectations. Whether you’re a restaurant, food manufacturer, or retailer, we are here to meet your demands with the finest moong dal available.

#Manufacturer of Green Moong#Exporter of Moong Dal#Supplier of Green Moong in India#Premium Green Moong#High-Quality Moong Dal#Green Moong for Restaurants#Moong Dal for Food Manufacturing#Retail Moong Dal Supplier

0 notes

Text

'100% tariffs' — Trump vows trade war if BRICS replaces dollar as reserve currency

U.S. President Donald Trump vowed on Jan. 31 to impose 100% tariffs on BRICS countries if they attempt to use new or existing currency to replace the U.S. dollar in international trade.

“We are going to require a commitment from these seemingly hostile countries that they will neither create a new BRICS currency, nor back any other currency to replace the mighty U.S. dollar or, they will face 100% tariffs,” Trump posted on his social media platform Truth Social, repeating his threats from last year.

“There is no chance that BRICS will replace the U.S. dollar in international trade, or anywhere else, and any country that tries should say hello to tariffs, and goodbye to America."

The BRICS group, composed of Russia, China, India, Brazil, and other nations, has been exploring ways to reduce reliance on the U.S. dollar.

A report by the Russian Finance Ministry, the Bank of Russia, and consultancy Yakov & Partners from last October proposed a “multicurrency system” to shield BRICS members from external pressures like sanctions. The plan includes creating centers for mutual trade in commodities such as oil, natural gas, grain, and gold.

After Russia’s full-scale invasion of Ukraine in February 2022, the U.S. and its allies imposed heavy sanctions on Moscow, freezing Russia’s foreign assets and removing major Russian banks from the SWIFT international banking system. In response, Russia sought to reduce its reliance on the dollar.

EU denies any links between Russian gas purchases, Ukraine peace talks

Earlier the same day, the Financial Times (FT) reported that EU officials are discussing the possibility of resuming purchases of Russian gas as part of a potential settlement of Russia’s war in Ukraine.

The Kyiv IndependentKateryna Hodunova

BRICS members are not unified on the issue. While China supports strengthening alternative currencies, it remains cautious about adopting a common one. India, focused on domestic economic interests, is unwilling to risk trade stability with the U.S.

Russian President Vladimir Putin said on Oct. 18, 2024, that there are no plans to create a BRICS currency, emphasizing the need for caution.

Kremlin spokesperson Dmitry Peskov reiterated this after Trump’s threats, claiming that BRICS is discussing new investment platforms. “BRICS countries are not discussing the creation of a common currency,” Peskov said.

The news comes after Trump urged Russia to “make a deal” to end its war against Ukraine, warning of increased sanctions, tariffs, and taxes on Russian goods if no agreement is reached.

BRICS expanded in 2024, admitting Egypt, Ethiopia, Iran, and the United Arab Emirates as new members. Putin hosted a BRICS forum in Kazan in October 2024, attended by 36 world leaders, and announced plans to invite new partner countries.

China is Russia’s sole supplier of key military-use rare metals amid sanctions, RFE/RL reports

As Russia’s options to purchase gallium and germanium from around the world almost disappeared, China became the sole supplier in 2023, the investigation said, citing leaked data from Russian customs databases.

The Kyiv IndependentKateryna Hodunova

0 notes

Text

best Plywood Suppliers in Jaipur: Quality, Variety, and Affordable Prices

Jaipur, the Pink City of India, is not just renowned for its rich culture and architectural wonders but also for its booming real estate and construction sectors. As the demand for quality plywood increases in the city, finding the best plywood supplier becomes crucial for ensuring durability, aesthetic appeal, and cost-efficiency in your projects.

Why Opt for Quality Plywood?

Plywood is a versatile material widely used in furniture, cabinetry, flooring, and construction projects. When you choose high-quality plywood, you enjoy several benefits:

Durability: Premium plywood resists wear and tear, ensuring that your furniture and construction elements last for years.

Aesthetic Appeal: High-quality plywood offers a smoother finish and a more uniform grain, enhancing the visual appeal of interiors.

Moisture Resistance: Quality plywood resists moisture, preventing warping and damage, particularly in high-humidity areas like bathrooms and kitchens.

Long-Term Savings: Although the upfront cost may be higher, investing in quality plywood saves money in the long run due to its durability and low maintenance.

Factors to Consider When Choosing a Plywood Supplier in Jaipur

Assured Quality Choose a supplier that offers certified products, ensuring that the plywood is made according to ISO and ISI standards. Look for dealers who provide product guarantees and warranties.

Variety of Options A reliable supplier should offer a wide range of plywood types, including marine plywood, waterproof plywood, and fireproof plywood. Ensure they have specialty products suited to your needs.

Competitive Pricing Before finalizing your purchase, compare quotes and pricing from different suppliers. Be sure to account for any hidden costs or delivery fees. A reputable supplier will offer transparent pricing without compromising on quality.

Customer Service Excellent customer support is vital. Choose suppliers that offer prompt delivery services, expert advice, and post-purchase assistance to ensure a hassle-free experience.

Reputation and Reviews Check customer reviews and ask for recommendations from friends, family, or contractors. A well-established supplier with positive feedback is likely to provide good service and high-quality plywood.

Types of Plywood Available in Jaipur

Jaipur’s plywood suppliers offer various types of plywood, each suited for different applications:

Commercial Plywood Ideal for indoor furniture and cabinetry, commercial plywood is affordable and readily available. It is commonly used for interior applications where moisture resistance is not a priority.

Marine Plywood Marine plywood is designed to withstand moisture and is perfect for use in bathrooms, kitchens, and even in boat construction. Its water-resistant properties make it an ideal choice for outdoor furniture and marine environments.

MR (Moisture-Resistant) Plywood MR plywood is specifically treated to resist moisture and is a great option for environments that experience humidity. It is often used in areas where plywood may be exposed to moisture but not direct water.

Advantages of Purchasing Plywood in Jaipur

Abundant Supply: Jaipur hosts numerous plywood suppliers, offering a wide variety of products with varying specifications, making it easy to find the perfect match for your project.

Affordable Prices: Quality plywood is available at budget-friendly rates, making it a cost-effective choice for both residential and commercial projects.

Expert Assistance: Many suppliers in Jaipur provide expert guidance to help you select the best type of plywood for your specific needs.

Customization: Some suppliers offer personalized services like custom cutting and polishing to match the unique requirements of your project.

Tips for Maintaining Your Plywood

Avoid Excess Moisture: Prolonged exposure to water can cause plywood to swell or warp. Avoid placing plywood in areas with constant water exposure.

Coating: Apply polish or paint to plywood surfaces to protect them from damage and enhance their appearance.

Regular Cleaning: Keep plywood surfaces clean by wiping them down regularly with a soft cloth to remove dirt and stains.

Termite Protection: To prevent termite damage, buy plywood treated to resist termites or use anti-termite chemicals periodically.

Conclusion

Selecting the right plywood supplier in Jaipur is crucial for the success of your construction or renovation project. With a wide variety of quality plywood options available, from commercial plywood to marine plywood, Jaipur’s suppliers are equipped to meet all your needs. Whether you’re working on furniture, flooring, or cabinetry, investing in high-quality plywood ensures both durability and aesthetic appeal.

By choosing a reputable plywood supplier in Jaipur, you can ensure you receive top-notch materials at affordable prices, along with excellent customer service. Don’t settle for less — invest in quality plywood today to make your home or office space last longer and look better.

#PlywoodJaipur#TopPlywoodSuppliers#PlywoodForHome#PlywoodForOffice#JaipurBuildingMaterials#DurablePlywood#WaterproofPlywood#FireproofPlywood#CommercialPlywood#PlywoodForKitchen#PlywoodForBathroom#PlywoodShopJaipur#PlywoodQuality#ConstructionSuppliesJaipur#CustomPlywoodServices#PlywoodMaintenance#BestPlywoodDeals#WoodenInteriorDesign#PlywoodShoppingJaipur#PlywoodVendorsJaipur#AffordableBuildingMaterials#PlywoodSuppliersJaipur#BestPlywoodJaipur#QualityPlywood#AffordablePlywood#PlywoodForConstruction#PlywoodForFurniture#MarinePlywood#MRPlywood#JaipurConstructionMaterials

0 notes

Text

What makes Indian rice manufacturers the top choice for global importers?

Indian rice manufacturers have built a strong global reputation for their quality, variety, and consistent supply. As one of the largest rice exporting countries, India supplies premium and affordable rice varieties to over 150 countries. But what makes them the preferred choice for international buyers? Let’s look at the factors that make Indian rice exporters stand out in the global market.

Introduction to Indian Rice Manufacturing

India has long been a global leader in rice production, exporting over 40% of the world’s total rice supply (Source: FAO). The country’s manufacturing capacity is supported by its vast paddy fields, skilled workforce, and advanced milling facilities. Indian rice manufacturers cater to the market’s diverse needs, offering everything from high-quality Basmati to cost-effective bulk options.

This adaptability and focus on quality ensures that Indian rice continues to dominate the global market.

Quality Standards and Certifications

Quality assurance is the cornerstone for rice suppliers in India. They follow international guidelines to ensure that rice meets the expectations of global importers. Some of the key certifications include:

ISO 22000 and HACCP: highlighting their commitment to food safety.

Organic certifications: ensuring compliance with USDA and EU standards.

Fair trade and sustainability practices: signifying ethical production.

Many manufacturers use state-of-the-art milling techniques and conduct strict quality checks. These efforts make Indian rice a reliable choice for consumers around the world.

Wide variety of rice types

India offers an unmatched variety of rice, enabling manufacturers to meet the diverse preferences of global markets. Popular choices include:

Basmati rice: Famous for its aroma and long-grained texture, it is widely in demand in Europe and the Middle East.

Non-Basmati Rice: Varieties such as IR64 and Sona Masuri are staples in Africa and Asia.

Specialty and Organic Rice: Catering to niche markets focused on health and sustainability.

This broad portfolio allows Indian exporters to meet the needs of a variety of customers, from gourmet chefs to wholesale distributors.

Cost-effectiveness and supply reliability

Indian rice manufacturers maintain a balance between quality and affordability. This is achieved through:

High production efficiency: Leveraging large-scale operations and advanced machinery.

Government policies: Subsidies for farm equipment and fertilizers reduce production costs.

Geographical advantage: Fertile land and favorable weather ensure consistent yields.

Their ability to handle bulk orders while adhering to strict timelines makes Indian rice exporters reliable partners for global importers.

Commitment to sustainability and innovation

Sustainability has become a priority for Indian rice manufacturers. Many companies are adopting environmentally friendly practices such as:

Water conservation: Using innovative irrigation techniques to reduce water consumption.

Renewable energy: Integrating solar and bioenergy into milling processes.

Waste utilization: Converting rice husk into biofuels and fertilizers.

Such practices align with the values of environmentally conscious consumers, strengthening India’s position in the global market.

Additionally, advances in traceability and quality control, including digital systems, enhance transparency and trust between manufacturers and importers.

India’s global prominence in rice exports is supported by its strong manufacturing base, diverse offerings, and commitment to quality. By choosing Indian rice manufacturers, importers benefit from reliable, high-quality rice that meets a variety of market demands. Whether it’s aromatic basmati for fine eating or affordable bulk varieties for everyday use, Indian exporters continue to set benchmarks in the global rice trade.

2 notes

·

View notes

Photo

Virat Special Steel is a leading name in the industrial raw material sector. Established in the year 1957.

Our range of products include Cold Work Tool Steels, Hot Work Tool Steels, Die Block Steels, Plastic Mold Steels and Alloy Steels.

At Virat Special Steel , we ensure that our customers get the best quality products with dimensional accuracy and wear and tear resistance. We strive to meet the bulk demands of customers from industries like Forging, Extrusion & Engineering, Automotive, and Petrochemicals Plants efficiently. To ensure this, we have incorporated a modern infrastructure system that includes warehousing and packaging facilities.

Get in touch with us today to place your requirement / Order As one of India’s leading special steel suppliers, Virat Special Steels can supply the following grades of steel practically off-the-shelf.

👉 For Forging (Cold, Warm or Hot) Steel grades Din 1.2714/DB6; DIN 1.2344 / H13; DIN 1.2343 / H11. https://www.viratsteels.com/hot-work-steel.html https://www.viratsteels.com/db6.html

👉 For Pressure Die Casting - (Hot die steel) DIN 1.2344 / H13; DIN 1.2343 / H11; DIN 1.2581 / H21. https://www.viratsteels.com/h13.html

👉 For Extrusion - (Hot die steel) DIN 1.2344 / H13 (of type known for excellent finish). https://www.viratsteels.com/din-2344.html

👉For the Automotive - (Steel grades) Din 1.2714 / DB6; DIN 40NiCrMo84 / EN24; DIN 3343 / M2; (Manganese steel) such as: 16MnCr5; 20Mncr5. https://www.viratsteels.com/din-2714.html

👉For Plastic Molding - (Steel grades) DIN 2738 / P20+ Ni; DIN 2311 / P20. https://www.viratsteels.com/plastic-mould-steel.html

👉For Components - (Steel grades) Din 1.2714/DB6; DIN 1.2344 / H13; DIN 1.2343 / H11. https://www.viratsteels.com/h11.html

Size Range in Forged / Rolled Bars Rounds: 13mm dia to 1500mm Dia Rectangular: Thickness 13mm – 500mm / Width 13mm to 1500mm We have also fully equipped quality assurance and process examination facility that conducts tests such as for hardness and analyses grain structure.

Located at head quarters in #Gurgaon (Haryana) and #Ludhiana (Punjab), we have also provides quality customer support.

For more information visit https://www.viratsteels.com/ Email us: [email protected] Call Us Now: +91-9814021775

#iso9001#engineering#steel#alloy steel#cold work steel#die steels#high speed steel#viratsteelindia#2714steel#h13steel#din2714#din2738#db6steel#toolsteelsupplier#delhincr#gurugram#pune#gurgaon#ludhiana#india

2 notes

·

View notes

Text

How to Choose the Best Original Basmati Rice Online in the UK

When it comes to selecting the best Original Basmati rice, quality and authenticity are key. If you’re looking to buy Long Grain Basmati rice online in UK, Kasshi Foods offers a premium selection of rice that is both fragrant and flavorful. But with so many options available, how do you ensure you’re getting the best?

First, look for a reliable supplier. Kasshi Foods stands out for its commitment to providing authentic, high-quality rice that meets global standards. Their Long Grain Basmati rice is sourced directly from the fields of India and Pakistan, ensuring it retains its superior taste and aroma. When shopping online, always check the product’s origin and verify it comes from a trusted brand like Kasshi Foods.

Next, consider the packaging. Original Basmati rice should be packaged in a way that protects its natural aroma and texture. Kasshi Foods ensures that their rice is sealed in premium packaging to preserve its freshness, so you get the best product possible.

Another important factor is the texture and cooking quality. Authentic Basmati rice has long, slender grains that fluff up beautifully when cooked. When you buy Original Basmati rice online in UK from Kasshi Foods, you’re guaranteed a product that delivers consistent, perfect results every time.

So, if you want to buy Original Basmati Rice online UK, choose Kasshi Foods for a genuine, premium experience. Enjoy the rich taste and fragrance that only authentic Basmati rice can offer

#Buy Long Grain Basmati Rice Online UK#buy Orignal Basmati Rice Online UK#Orignal Basmati Rice online UK

0 notes

Text

Fruit Baskets & Mesh Colanders – Perfect for Storage & Drainage

At Unik Corporation, we offer premium Fruit Baskets and Mesh Colanders designed to keep your fruits fresh while ensuring proper ventilation and drainage. Crafted from high-quality stainless steel and food-grade materials, our baskets provide a durable, rust-resistant, and stylish solution for both home and commercial kitchens.

Why Choose Our Fruit Baskets & Mesh Colanders?

✔ Optimal Air Circulation – Prevents moisture buildup, keeping fruits fresh longer. ✔ Strong & Sturdy Build – Made from premium-quality mesh for long-term use. ✔ Multi-Purpose Functionality – Ideal for washing, straining, and storing fruits and vegetables. ✔ Lightweight & Easy to Handle – Designed for both home and professional kitchens. ✔ Available in Various Sizes & Designs – A perfect fit for different kitchen needs.

Applications

Fruit & Vegetable Storage – Keeps produce fresh with excellent airflow.

Straining & Rinsing – Efficiently washes fruits, vegetables, and grains.

Kitchen Organization – Adds a stylish touch while keeping essentials within reach.

Upgrade your kitchen with Unik Corporation’s premium Fruit Baskets and Mesh Colanders—a perfect blend of functionality, durability, and elegance.

Explore our collection today!

#FruitBasket#MeshColander#KitchenEssentials#FoodStorage#PremiumKitchenware#StainlessSteelBasket#VentilatedStorage#FoodGradeMaterial#DurableKitchenware#FruitStorage#VegetableBasket#Strainer#unik corporation

0 notes

Text

1509 Basmati Rice Manufacturer From India

India has always been a leader in rice production because of its perfect climate conditions, fertile soil, and a long history of cultivation methodology. Authentic rice grains are produced by Indian farmers using traditional farming methods and organic manuring. Proper quality checks are conducted from the fields to the packaging stage. Foodsy Export is a top-rated 1509 basmati rice manufacturer and a trusted 1509 basmati rice exporter in the international market.

With extraordinary characteristics, 1509 basmati rice takes pride in providing the best texture and taste to each food delicacy with its alluring aroma and nutty flavor. The premium-quality rice grains are directly sourced from the fertile fields of northern India. Quality commitment and sustainability practices make Foodsy Export a reliable 1509 Basmati rice manufacturer and the best 1509 Basmati rice supplier.

Why Foodsy Export is a Trusted 1509 Basmati Rice Manufacturer and Exporter in India

Foodsy Export is the market leader that produces 1509 Basmati Rice. Being a household name, the trusted 1509 basmati rice supplier has always kept a promise about quality, innovation, and customer satisfaction. A modern processing complex with strict standards of quality control was devised to make sure the exports met the very high standards abroad.

India is a world producer and exporter of 1509 basmati rice. The premium quality of basmati grains has earned Foodsy Export a worldwide reputation. Foodsy Export uses the most advanced milling and grading facilities that retain the natural taste, fragrance, and characteristic character of 1509 Basmati Rice. The plant focuses on excellent cleaning and packaging performance that helps in achieving maximum recovery with minimum waste.

What is 1509 Basmati Rice?

1509 basmati rice is a premium type of basmati that has become widespread with a set of attributes:

Long-length grains

Rich aroma and nutty flavor

Soft in texture and non-sticky after cooking

High elongation ratio, up to double the size after cooking.

Low cooking time compared to other basmati rice varieties.

More nutritional content; a good source of carbohydrates and minerals.

Owing to such wonderful characteristics, 1509 basmati rice is heavily recommended for preparing conventional rice recipes such as biryanis, pilaf, pulao, and fried rice.

What Sets Foodsy Export Apart?

Foodsy Export is an international 1509 basmati rice exporter that exports its products to a broad international market that has spread over different regions like the Middle East, Europe, North America, and Asia. The timely shipment ensures that all export regulations are followed.

Follow ambitious policies for promoting sustainable agricultural practices, technical support, or even farm assistance to decrease the environmental footprint together with the efficiency of the yield. Despite the premium quality, Foodsy Export offers competitive pricing, and their 1509 Basmati Rice is a product of choice among bulk buyers, retailers, and food service providers.

1509 Basmati Rice is in stiff competition with various types of rice, such as 1121 Basmati, Pusa Basmati, and even more non-Basmati rice varieties available in Pakistan, Thailand, or Vietnam. However, Foodsy Export has its strength in a competitive range in terms of the following:

Our rice gets quality checked multiple times up to the global standard.

Private labeling and packaging they done according to what the customers actually want.

Good interaction with logistics vendors helps Foodsy Export complete the process promptly with fewer transit complications.

Customer centricity with a committed, dedicated customer service wing for smooth conveyance and proper satisfaction of each customer's individual needs.

Leading 1509 Basmati Rice Exporter Exporting Authenticity to Global Market

Foodsy Export has a streamlined process to ensure high-quality rice is delivered to clients all over the world with efficiency. Their export process includes:

Sourcing: direct procurement from farmers who follow sustainable practices.

Processing: milling, polishing, and grading in state-of-the-art facilities.

Quality Assurance: Stringent quality standards before dispatch.

Packaging: hygienic, durable, and customizable packaging solutions.

Shipping: Reliable logistics partnerships for smooth international shipping.

Why Choose Foodsy Export as Your 1509 Basmati Rice Supplier and Exporter?

Whether you are a retailer, distributor, or food service provider, association with Foodsy Export ensures:

The rice we supply is of international quality.

Available in raw, parboiled, and steam forms.

Best value for premium quality.

Efficient supply chain management for on-time shipments.

1509 Basmati Rice continues to win hearts across the globe. Low prices but high production and fine cooking make this a top choice in global kitchens. Foodsy Export stands amongst the brightest 1509 Basmati rice manufacturers and carries the best-quality 1509 Basmati rice for consumers throughout the world with a promise of quality, sustainably practiced, and customer satisfaction amidst one of the most competitive marketplaces for rice.

Anyone who would want to source this superior quality 1509 Basmati Rice would need a good trading partner who combines the best of quality with the best competitive price to add on top personal service, which makes it easy to sell for their clients across the world.

0 notes