#glass wool insulation materials

Text

0 notes

Text

Understanding Drivers and Challenges of the Acoustic Insulation Market:

Understand the ins and outs of the acoustic insulation market with this comprehensive guide. Learn about drivers, challenges, trends, and more!

Acoustic Insulation Market is a growing sector that is set to become increasingly prevalent as the push for more energy-efficient buildings and infrastructure grows. This comprehensive guide outlines all the important aspects of this market, including drivers, challenges, trends, and more.

Examining Trends in the Acoustic Insulation Market:

As the acoustic insulation market continues to grow, there are a number of trends emerging in the industry. One such trend is the emphasis on sustainable products and materials, both for homeowners looking to reduce their energy costs and businesses who want to limit their environmental footprint. Increasingly, these two goals are being balanced with noise reduction capabilities when selecting an acoustic insulation product. Additionally, new technologies like virtual reality are helping architects and building owners envision acoustically optimized spaces at the design stage.

Request Sample PDF: https://www.nextmsc.com/Acoustic-Insulation-Market/request-sample

As the acoustic insulation market continues to expand and develop, it is clear that this trend of sustainability-meets-noise reduction will continue to impact manufacturers and buyers in the industry. Manufacturers are increasingly looking for materials that offer superior acoustic insulation performance while being kinder to the environment.

On the other hand, buyers are concerned with possible environmental implications when deciding on a suitable material for their projects. With this in mind, it is important to keep up with market trends in order to ensure that you are Selecting an acoustic insulation product that is both energy efficient and has good sound absorption capabilities. It’s also important to be aware of technological advances like virtual reality when designing spaces so you can get an early glimpse into how spaces will sound before installation begins.

Determine Challenges Faced in The Acoustic Insulation Market:

While the acoustic insulation market offers a range of benefits for home and business owners, there are several challenges that contractors come up against when installing these materials. One major challenge arises from the fact that acoustic insulation products often require special treatment to ensure they don’t interfere with other adjacent building components.

Additionally, accurate measurements must be taken during the installation process to ensure effective sound dampening. Furthermore, selecting the right product is critical since some materials are better suited for certain types of spaces than others.

On top of these practical challenges, the cost associated with installing acoustic insulation is often a difficult hurdle to overcome. Fortunately, many manufacturers offer incentives for those looking to make noise-free environments more financially accessible.

Also, depending on the type of acoustic materials used and the size of space to be insulated, some contractors offer installation services that cut down on labor costs. Good quality acoustic insulation will help reduce noise levels while also creating an improved interior atmosphere. Taking all these factors into account should help buyers decide if investing in acoustic insulation is right for them.

Analyze Major Players:

Rockwool International, Saint-Gobain, Knauf Insulation, InsulTech, Armacell International, Soprema, Huntsman, Owens Corning, Kingspan Group, and Johns Manville are a few of the industry participants active in the worldwide acoustic insulation market. To expand their product range and geographical reach, the major market players are actively engaging in R&D projects, product and technology advancements, and industrial alliances.

Overview of the Acoustic Insulation Market:

The acoustic insulation market has been on the rise for several decades, with more and more consumers using products to lower noise transmission in buildings. This market is primarily driven by consumer interest in noise control, along with increasingly stringent regulations surrounding sound pollution.

Additionally, trends towards contemporary interior designs have helped fuel demand for acoustic insulation solutions that look as well as perform effectively. Acoustic insulation is used in various spaces such as homes, offices, schools, medical facilities and many other types of buildings. As a result, the market is projected to continue growing over the course of the next few years.

The acoustic insulation market is comprised of various materials such as fiberglass, foam, cellulose fiber and mineral wool. Each of these have their own unique properties and offer varying levels of soundproofing. Many are now incorporating specialized additives to increase their noise reduction capabilities while also boosting their thermal performance.

Furthermore, standards developed by organizations such as ASTM International have helped bring clarity and consistency to the acoustic insulation industry. As a result, consumer confidence in purchasing these products has increased significantly.

Identify Market Segments and Understand Their Drivers and Challenges:

It is important for market participants to identify the different segments within the acoustic insulation market, as well as understand their drivers and challenges. By taking into account customer needs and preferences, companies are able to tailor their products to meet the demand of each segment.

For instance, rock wool insulation has emerged as a cost effective solution for commercial applications due to its use in more demanding requirements such as fire containment. On the other hand, fiberglass insulation is an ideal choice for residential applications where comfort, low noise levels and affordability are the main purposes. Identifying these segments and understanding their needs will help ensure that companies are maximizing potential opportunities in this growing market.

One of the most important aspects with acoustic insulation is to understand how the sound from the outside environment interacts with internal building design. For example, high levels of soundproofing can reduce volume levels by up to ten decibels.

Therefore, market participants must consider factors such as construction design and product specifications to ensure that their product not only meets but exceeds customer requirements. Furthermore, market research should also consider trends in automotive noise reduction in order to maintain competitive advantage within this sector.

Through detailed market segmentation, acoustic insulation suppliers can ensure they’re addressing each segment’s individual needs while securing their position within the wider acoustic insulation market.

Identify Growth Opportunities:

Companies that want to succeed in the dynamic acoustic insulation sector must analyze leading players in this market. It’s important to identify their portfolios, pricing strategies, and product innovations. Compare these key competitors and identify gaps in the market you can exploit. This allows businesses to anticipate shifts in customer preferences and adjust their strategy accordingly. Additionally, understanding major players active in a specific region could help companies narrow down potential expansion opportunities.

Another critical factor to consider is the range of acoustic insulation products currently available. Analyzing the pros and cons of each product can help businesses discern which ones offer a competitive advantage. This type of market insights data can help companies strengthen their product lineup and consequently, boost their sales in an increasingly crowded market. Additionally, more detailed information about material supplies and trends can reveal potential partnerships that could help them further develop products with utmost efficiency.

#acoustic insulation#stone wool#glass wool#plastic foam#building and construction#transportation#energy#utilities#oil and gas#materials and chemicals

0 notes

Photo

Sustainable and more efficient method for sound absorption and thermal insulation

Researchers at Aalto University have discovered a new way to use biowaste to provide sound absorption and thermal insulation.

An effective use of sound absorption materials is needed to reduce noise pollution, which constitutes a major environmental and health problem. The current sound absorption materials can be harmful for the environment and often create waste problems at the end of their lifetime.

The researchers found that pectin, a polysaccharide that can be extracted from biowastes such as fruit peels, can be converted into a freeze-dried highly porous material. They can outperform commercial sound absorption materials, such as glass wool and other porous materials with similar thickness. The research was published in the Chemical Engineering Journal.

"The porous material prepared in this work demonstrate the great potential of freeze-casted bio-based sound absorption materials to be employed as an alternative material in industrialization and construction, where environmental-friendly materials are needed. They also display low thermal conductivity and excellent thermal insulation performance," says Professor Jaana Vapaavuori from the School of Chemical Engineering.

Read more.

#Materials Science#Science#Sound#Insulators#Noise#Pectin#Biomaterials#Recycling#Porosity#Aalto University

36 notes

·

View notes

Text

When I was a kid, something that absolutely terrified me was fiberglass insulation, or “glass wool”. The idea that you could have something that looked so soft, but was actually made of glass that would slice you up...it freaked me out on an existential level, because if something that looks so comfortable could be so deadly, could I really ever be safe?

It turns out that glass wool, while not without its health risks, was not the nightmare material I thought it was-- the very thinness and malleability of the material means that falling on it will not slice you up, although you should always wear protective gear to prevent the fibers from irritating the skin and causing damage to the lungs. But Haineko’s power seems to be my juvenile worst-case scenario for insulation, something that looks nice and soft and harmless but which will slice you to pieces if you make that assumption.

67 notes

·

View notes

Text

MINOVA KD-01S280 Insulation Cutting Tool: Our insulation cutter is specifically designed to cut mineral wool glass wool, mineral wool, Rockwool, fiberglass insulation, and other types of insulation. This versatile knife is very lightweight.

Insulation Cutting Tool:Our insulation cutter is specifically designed to cut mineral wool glass wool, mineral wool, rockwool, fiberglass insulation and other types of insulation. This versatile knife is very lightweight.

Long and Double Sided Blade: 11in(28cm) double sided stainless steel blade and special serrated blade edge design (almost little dust). You can cut large-sized insulation material.

Safe Blade Cover: It comes with high quality sheath. When not in use, you can store it safely at home or in your workplace.

Overall Length: KD-01S280:16.5in(42cm); Blad Length:11in(28cm);Blade thickness:1.5mm(0.06in);N.W.:242g(533lb)

Suggestions: Young children should be supervised to ensure that they do not play with the appliance. Rubber gloves are recommended when working.

7 notes

·

View notes

Text

Copy of Can Fungal Biomass Make Construction More Sustainable?

The construction industry is an ever-growing problem when it comes down to sustainability. The population continues to grow and this requires more and more buildings to accommodate people's lives. More and more materials are required to construct buildings, and so naturally, more and more carbon is emitted into our atmosphere from these construction processes. But we can't just put a pause on population growth, or ban new buildings from being built, and we certainly can't just pretend this problem doesn't exist either.

How about focusing on improving the sustainability of the materials that are used in construction? What alternatives might there be to ensure more sustainable construction processes are used?

… that's where fungal biomass comes in.

Fungal Biomass... what is that exactly?

Biomass is a renewable material that's made from plants and animals. It can be used as energy or turned into useful materials. With fungal biomass, agricultural waste and other low-grade discarded materials (stalks, straw, sawdust, etc.) are used as substrates which are introduced to a fungus to create a material bound together by mycelium.

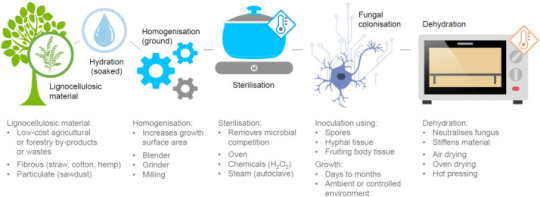

To create the mycelium material, a process must be followed to ensure good performance of the material.

For an explanation of this process check here, and refer to section 2.

Here are some important material properties of mycelium materials:

Handles tensile loading well

Has some compressive loading capabilities

Highly flame resistant

It has a very low thermal conductivity

Very high moisture uptake

Okay, sounds great! But what can the mycelium material be used for?

Structural application:

Mycelium has shown an ability to handle tensile loading well, however it has a low ability to withstand compressive loads, meaning the material is weak compared to traditional construction materials. Since structural materials are required to transfer heavy loads, this material wouldn't be effective and therefore is not being considered for structural use.

Thermal insulation:

Mycelium composite is a low-density material, which makes it an excellent insulator as low-density materials conduct heat slower. It performs similarly to other traditional insulators such as glass wool, extruded polystyrene, sheep wool etc.

Water absorption:

Moisture content will also have an impact on the thermal conduction. If mycelium insulation is exposed to moisture for more than a few hours, it can absorb it quickly and in large amounts. Luckily a large increase in moisture content results in just a small increase in heat conductivity. Check here for more(section 3.0).

Other risks resulting from moisture absorbency has delayed the journey of this type of insulation making it into people's homes, but hopefully solutions can be found as this type of insulation would make some amazing competition.

Fire safety:

Mycelium composite out-performs many conventional insulation materials. A mycelium composite can even perform so well under exposure to fire that its only competitor is phenolic formalhyde resin foams.

"Mycelium has been found to possess certain flame-retardant properties (e.g. high char residue and release of water vapour)"

More on that quote here.

Since the material would mainly char rather than burn, it would take longer for flames to travel through a cavity if it were filled with it. The material is also non-toxic therefore it is much safer than other insulators.

Read here for more information on thermal degradation and fire reaction properties of mycelium composites.

Why is this new material so important?

Mycelium material is completely biodegradable and renewable, it has a perfect life cycle and its cheap, what's more to love?

Discovering uses for fungal biomass and applying them is super important for the construction industry as it hopefully will kickstart a greater interest in building with sustainable materials. The current applications of this product are limited; however this material makes promise for the future of sustainability in construction.

Take a look at some videos and other helpful sources if you're still interested!

Engineered mycelium composite construction materials from fungal biorefineries: a critical review

Is Mycelium Fungus the Plastic of the Future?

Can Mycelium Fungus replace Concrete & Plastic?

Biohm

Ecovative

8 notes

·

View notes

Text

Master The Skills of INSULATION for Your Project And Be Successful

Are you interested in working for or already working in the thermal insulation field of an oil refinery or industrial processing plant? If so, you’ve come to the right place to learn more about thermal insulation. Here, we answer some of the most frequently asked questions about insulation and its use.

What is Insulation?

Essentially, it is any material or system used to resist or restrict the transfer of thermal energy or sound. Insulation material can reduce the flow of heat energy by reflection, absorption, or both.

A common misconception is that insulation keeps the cold out, when in fact the function of insulation is to reduce the transfer of heat, which means it keeps heat in. Heat energy will transfer to nearby objects of lower temperatures.

What is so special about insulation’s ability to prevent the loss of heat?

Thermal insulation material contains voids or hollow spaces that help resist heat transfer. Heat flows naturally from warmer areas to cooler ones. Insulation works by slowing that movement of heat from a hot space to a cooler space or vice versa.

What are the Different Categories of Insulation?

Insulating materials are divided into the following 4 categories:

Fibrous

Granular

Cellular

Reflective

The materials in each category have both pros and cons. It is your responsibility to understand them before you select a material for use in your project.

For example, insulation materials made of fiber are not suitable for resisting cold temperatures, but cellular materials have limitations for use at temperatures above ambient.

The insulation materials' temperature ranges and their properties can be found in the product datasheet you receive from the insulation manufacturer.

How to Choose the Best Insulating Material?

Before choosing an insulating material for your project, be sure to answer the following commonly asked questions:

What item requires insulation?

- Temperature limit

- Size or area

- Type of substrate to be insulated (i.e., metallic or non-metallic)

What is the geographical location/environmental condition?

What is the purpose of the insulation?

- Heat or cold conservation

- Sound prevention

- Personal protection

Decide the Right Insulating Material

Based on the answers to the above questions, you must decide the type of insulating material, thickness, and whether the installed insulation requires further protection from its surrounding environment.

Next, contact the insulation manufacturer to identify the insulation materials to best suit your requirements and/or review the material’s product datasheet to check which materials meet your requirement.

Finally, you must decide whether to use the accessories materials (i.e., fixing or fastening materials) to help keep the insulation in place around the insulating item. You must also ensure that all the fixing materials you use are compatible with the insulation, jacketing, substrate, and other fixing materials.

Write a Specification for the Insulation Work

Before commencing the insulation work, you must write a specification that details the material(s), their properties, and how the work will be carried for your project.

Next, find a contractor with a proven track record to carry out the insulation work for your project following the instructions and guidelines set forth in the specification and/or recommended by the insulation manufacturer.

What are the Different Types of Insulation Material?

There are several types of thermal insulation materials to choose from, including:

Mineral wool

A fibrous insulation material made of rock or stone, used to resist high temperatures, also protect the environment from excessive noise.

Calcium silicate

A granular insulation material. This white-colored insulation, used to resist high temperatures.

Cellular or foam glass

Cellular glass and foam glass are the two different names of the same material. Made of recycled glass and is cellular or closed-cell insulation. The foam glass insulation is primarily used to resist cold temperatures; however, it can also be used for hot services up to 400˚C temperatures.

PIR

A cellular type of insulation, also known as polyisocyanurate insulation, is commonly used for cold surfaces because it has temperature limitations when used for hot ones.

Ceramic fiber

This fibrous insulation material is also known as high-temperature insulation wool (HTIW) and is often used for lining furnaces.

The 4 common properties of an insulation material

Thermal conductivity

Thermal Resistance

Density

Combustibility

Thermal conductivity, also known as the K value of the insulating material decides if a material is a good insulator or not. The lower the K value the better the insulation material is. The thermal resistance or R-value state how well an insulating material can resist the heat, R-value is opposite to the K-value, i.e. good insulation must have a higher R-value.

The density is mass per unit volume of a material. Combustibility means if a material will catch fire or not, non-combustible type material is a must in an area prone to fire.

Where will the Insulation be Used?

Insulation is used everywhere whether it is a home, office, appliances you use, or oil refinery or industrial process plant. Some of the areas where you would find insulation are listed below:

INDUSTRIAL

Piping: When looking around a refinery or industrial processing plant, you will find yourself surrounded by insulated items. One such insulated item is piping. Approx. 75% (or more) of the piping used is insulated for a variety of reasons like hot or cold conservation, process control, personal protection, etc.

For your information, a medium-sized oil refinery contains 475 miles of insulated piping.

Equipment: Equipment such as heat exchangers, boilers, columns, pressure vessels, storage tanks, pumps, and compressors, are all insulated for heat conservation, cold conservation, acoustic attenuation, or any other oil refinery or industrial processing plant purpose.

For your information, a medium-sized oil refinery contains 1.8 million square feet of insulated equipment.

DOMESTIC

Wall insulation: Walls are a major source of energy loss in homes, it is a must to reduce heat loss through the cavity wall by filling the air gap with material that interferes with heat transfer, trapping air in the cavity, thereby preventing heat loss and reducing heating costs.

Basement Insulation: The basement is another area of a home where there is a need for insulation installation. Basement walls are insulated with non-water sensitive insulation that prevents interior air from contacting cold basement surfaces.

Crawl space insulation: This space is often forgotten because not everyone uses their crawl space regularly; however, it can help prevent heat from leaking into or escaping from your home. The best insulation material for crawl spaces is a rigid foam insulation board.

Domestic appliances; Air-conditioning, refrigerator, water cooler, and the like are all insulated to prevent the movement of heat into or out of them.

RELATED ARTICLES

9 Simple (But Important) Things to Remember About Corrosion Under Insulation or CUI

Enhance Your Cold Insulation Skills

4 Reasons Why Fireproofing is Used for the Fire Protection

RELEVANT TRAINING COURSES

Insulation Inspector - IOGS/CII Level 2

Insulation Inspector - IOGS/CII Level 3

Diploma in Thermal Insulation - IOGS/DTI

#quality#quality control#qualification#quality of life#inspection#online courses#onlinetraining#quality inspector#skilldevelopment#skills#training#courses#refinery#oil and gas refining#skill#thermal insulation sheet#safety#oil and gas industry#oil and gas#advertising#architecture#online education#online#oil&gas#oil industry#gas#jobposting#jobhunt#development#design

3 notes

·

View notes

Text

Acoustics Market in U.S. to Exceed Valuation of US$ 2.0 Bn by 2031

The Acoustics industry in the U.S. was valued at US$ 1.2 Bn in 2022 It is estimated to grow at a CAGR of 5.2% from 2023 to 2031 and reach US$ 2.0 Bn by the end of 2031

Acoustic products are being used in the automotive industry. Moreover, acoustic insulation materials find application in aerospace and marine sectors of the U.S. Hence, rise in product demand from different end-use industries is fueling the sales prospects in the U.S. acoustics market.

Moreover, the expansion of the transportation industry is prognosticated to drive the demand for acoustic insulation products in the near future, notes the TMR study.

Players in the U.S. acoustics market are estimated to gain profitable avenues in the upcoming years, owing to increasing need for generating desired sound effect and reflect sound at different frequencies for varied movies and short films. In addition, growing understanding on the importance of health and physical activity is fueling the sales opportunities in the acoustics market.

Download Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=84616

Acoustics are manufactured using a wide range of materials such as stone wool, glass wool, fabric absorbers, acoustic fabrics & insulators, fabric diffusors, fabric dampeners, foamed plastic, fabric noise barriers, fabric soundproofing, fabric ceilings, and fabric wall materials. In the recent years, there has been an increase in the demand for products manufactured using foamed plastic material. This growth can be ascribed to different advantages they offer including their cost-effective nature and superior performance, notes the TMR study on the U.S. acoustics market.

U.S. Acoustics Market: Key Findings

Surge in investments on the acoustics insulation infrastructure is propelling the U.S. acoustics market. Moreover, the market growth in the nation can be attributed to many factors such as increasing spending on recreational activities, rising inclination among people toward indoor acoustics, and growing disposable income in the country. In addition, the expansion of the construction industry is projected to help in the growth of the U.S. acoustics market during the forecast period.

Acoustic materials are being utilized in various end-use industries, including industrial/HVAC & OEM, transportation, and building & construction industries in the U.S. This factor is propelling the U.S. acoustics market. Moreover, rise in the demand for varied acoustic insulation materials such as stone wool, glass wool, fabric absorbers, fabric dampeners, and acoustic fabrics & insulators in a wide range of end-use industries, including manufacturing, transportation, and construction is leading to profitable prospects for acoustics market players in the U.S.

The U.S. Government is increasing investments in the development of different acoustics complexes. This factor is generating sizable demand opportunities in the U.S. acoustics market. Moreover, the market is being driven by swift advancements in sound and media & entertainment sectors in the nation. With rise in population, there has been surge in construction activities. This factor is resulting in significant sales prospects in the acoustics market.

U.S. Acoustics Market: Growth Boosters

Increase in demand for foamed plastic materials in the U.S. is propelling the market

Developments in construction industry are resulting in promising business avenues in the U.S. acoustics market

U.S. Acoustics Market: Key Players

Some of the key players profiled in the report are:

Rockwool International

Saint-Gobain

Johns Manville

Knauf Insulation

Kingspan Group

Paroc Group

BASF SE

Armacell International

DuPont

Sika AG

Owens Corning

Primacoustic

U.S. Acoustics Market Segmentation

Material

Glass Wool

Stone Wool

Acoustic Fabrics & Insulators

Fabric Absorbers

Fabric Dampeners

Fabric Diffusers

Fabric Noise Barriers

Fabric Ceilings

Foamed Plastic

Fabric Soundproofing Materials

Fabric Wall Materials

Others (Pulp Board and Cork Board Slabs)

End-use

Building & Construction

Residential

Commercial

Industrial / HVAC & OEM

Transport

State

Florida

Georgia

North Carolina

South Carolina

Tennessee

Virginia

Maryland

Alabama

Kentucky

Mississippi

Rest of U.S.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=84616<ype=S

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Achieving Comfort and Efficiency with Pink Batts Insulation

In the realm of home improvement, one crucial factor often overlooked is insulation. Whether you're building a new home or renovating an existing one, the right insulation can make a significant difference in comfort and energy efficiency. Among the many options available, Pink Batts Adelaide insulation stands out for its reliability and effectiveness.

Understanding Pink Batts Insulation

Pink Batts insulation is renowned for its thermal and acoustic properties, making it a popular choice among homeowners and builders alike. Made from lightweight, flexible, and non-combustible glass wool, Pink Batts are designed to fit snugly between wall studs, ceiling joists, and floors, effectively reducing heat transfer and minimising noise transmission within the home.

Benefits of Pink Batts Insulation

Thermal Efficiency: By minimising heat loss in winter and heat gain in summer, Pink Batts help maintain a comfortable indoor temperature year-round. This not only enhances living conditions but also reduces reliance on heating and cooling systems, leading to potential energy savings.

Acoustic Insulation: Beyond temperature control, Pink Batts excel in dampening external noise, creating a quieter and more peaceful living environment. This is especially beneficial for homes located in noisy urban areas or near busy roads.

Fire Safety: Being non-combustible, Pink Batts provide an added layer of fire protection, helping to contain the spread of flames in case of fire. This safety feature is crucial for the well-being of homeowners and their families.

Environmentally Friendly: Manufactured from up to 80% recycled glass, Pink Batts Adelaide insulation supports sustainable building practices and reduces environmental impact. Choosing eco-friendly materials like Pink Batts contributes to a greener future.

Applications of Pink Batts

Pink Batts insulation is versatile and can be used in various parts of the home, including:

Ceilings: To prevent heat transfer between the living spaces and the attic.

Walls: To improve thermal efficiency and soundproofing between rooms.

Floors: To minimise heat loss in homes with suspended floors.

Installation and Maintenance

Installing Pink Batts insulation requires precision and expertise to ensure maximum effectiveness. It's recommended to hire professional installers who understand the specific requirements of your home's construction and insulation needs. Once installed, Pink Batts typically require minimal maintenance, providing long-term benefits with little upkeep.

Final Words

The Pink Batts insulation offers a comprehensive solution to enhance the comfort, efficiency, and safety of your home. Whether you're aiming to reduce energy bills, create a quieter living environment, or contribute to sustainability efforts, Pink Batts Adelaide provides a reliable and cost-effective choice. By investing in quality insulation, you're not only improving your home's value but also enhancing the quality of life for you and your family.

Consider consulting with insulation experts to explore how Pink Batts can be tailored to meet your specific needs and budget. With the right insulation, you can transform your house into a haven of comfort and efficiency for years to come.

0 notes

Text

0 notes

Text

Building Thermal Insulation: Materials and Techniques

Rockwool insulation is generally installed under the frames of the home. The house's edge is typically between the two floors, doors, windows, spaces joining the two rooms, and much more.

#insulation material#rockwool lrb board#rockwool thermal insulation#glass wool insulation for the roof

0 notes

Text

Global Building Thermal Insulation Market Outlook: World Approaching Demand & Growth Prospect 2024-2030

Latest added Global Building Thermal Insulation Market research study by Archive Market Research offers detailed outlook and elaborates market review till 2030. The market Study is segmented by key regions that are accelerating the marketization. At present, the market players are strategizing and overcoming challenges of current scenario; some of the key players in the study are Rockwool International A/S,GAF Materials Corporation,Guardian Building Products, Inc.,Huntsman International LLC,Johns Manville Corporation,Cellofoam North America, Inc.,Atlas Roofing Corporation,CertainTeed Corporation,Roxul, Inc.,Dow Building Solutions,Owens Corning Corporation,Saint-Gobain S.A.,Byucksan Corporation,Kingspan Group PLC,BASF Polyurethanes GmbH etc.

Click for Free Sample Report + All Related Graphs & Charts https://archivemarketresearch.com/report/global-building-thermal-insulation-market-1771/sample-report

The Global Building Thermal Insulation Market size was valued at USD 32.69 billion in 2023 and is projected to reach USD 44.49 billion by 2032, exhibiting a CAGR of 4.5 % during the forecasts period.

The latest edition of this report you will be entitled to receive additional chapter / commentary on latest scenario, economic slowdown and COVID-19 impact on overall industry. Further it will also provide qualitative information about when industry could come back on track and what possible measures industry players are taking to deal with current situation. Each of the segment analysis table for forecast period also high % impact on growth.

The Global Global Building Thermal Insulation segments and Market Data Break Down are illuminated below:

{"Product: Glass Wool, Mineral Wool, EPS, XPS, Cellulose","Application: Roof, Walls, Floor"}

Have Any Questions Regarding Global Global Building Thermal Insulation Market Report, Ask Our Experts@ https://archivemarketresearch.com/report/global-building-thermal-insulation-market-1771/enquiry-before-buy This report will give you an unmistakable perspective on every single reality of the market without a need to allude to some other research report or an information source. Our report will give all of you the realities about the past, present, and eventual fate of the concerned Market.

Thanks for reading this article, we can also provide customized report as per company’s specific needs. You can also get separate chapter wise or region wise report versions including North America, Europe or Asia.

More Reports:

https://archivemarketresearch.com/reports/global-building-thermal-insulation-market-1771 https://archivemarketresearch.com/reports/high-purity-alumina-market-1776

Contact US :

Craig Francis (PR & Marketing Manager)

Archive Market Research

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

Phone: +1 201 565 3262, +44 161 818 8166

[email protected]

0 notes

Photo

Glasses: Glass wool

Considered a class of materials rather than a single composition, glass wool is the arrangement of glass fibers (with the addition of a binder) into a texture similar to wool. It is often made with recycled glass, and is thus primarily a common soda-lime-silicate glass, mixed with the raw components (sand, limestone, soda) and a binder.

To make this material, the glass base is completely melted together, then spun into fibers in a process similar to making cotton candy, resulting in a foam-like, wool-like structure, with pockets of air within the glass wool, and injected with the binder. Once cured in an oven to polymerize the binder resin, the white/clear glass turns yellow and the resulting glass fiber is cut into sheets and rolls.

Because of the entrapped gas, which has poor thermal conductivity, glass wool’s primary application is in insulation of building structures. It also serves to reduce sound and, because it is made of recycled materials, considered to be environmentally friendly. Being made from glass, it is also fire resistant. However, glass wool is sensitive to water so care must be taken in humid environments. In addition, the glass fibers must be handled with care during insulation, as exposure can cause irritation to the eyes, skin, and respiratory system.

Sources/Further Reading: ( 1 ) ( 2 - image 2 ) ( 3 - image 3 ) ( 4 )

Image sources: ( image 1 )

38 notes

·

View notes

Text

Gypsum board in vadakara | Venus enterprises

Based in Vadakara, Venus Enterprises is offering a diverse range of ceiling boards and construction materials. Our extensive catalog comprises V board, gypsum board, acoustic insulation, calcium silicate, GRG ceiling, Gypsum plaster, Insu Board, Cement fiber board, Shera Boards, Rock wool, Glass wool, Grid ceiling, Metal ceiling, Bison Board, and Air Bubble Insulation. With over 21 years of experience, we stand committed to delivering dependable products to meet your building requirements across the entirety of Kerala.

Venus Enterprises, a leading construction company in Vadakara, is known for its high-quality gypsum boards. These lightweight yet robust boards offer fire resistance and sound insulation properties, making them ideal for various applications in residential and commercial buildings. They are also eco-friendly, using natural gypsum and recycling industrial by-products. Venus Enterprises' gypsum boards are easy to install, reducing construction time and labor costs. They can be cut, shaped, and finished to meet specific design requirements, catering to various architectural styles. The company's customer-centric approach ensures clients can maximize the benefits of their gypsum boards, making them a trusted name in the Vadakara construction industry.

0 notes

Text

The Sustainable Movement: Eco-Conscious Approaches in Insulation Setup

Embracing Eco-Friendly Insulation

In today's world, sustainability is gaining momentum, influencing various sectors, including insulation installation. This shift towards environmentally friendly practices not only benefits the planet but also presents numerous advantages for homeowners.

The Significance of Eco-Friendly Insulation

Eco-friendly insulation materials are sourced from renewable materials and have minimal environmental impact. They are devoid of harmful chemicals and toxins, ensuring safety for both installers and occupants.

Varieties of Eco-Friendly Insulation

Repurposed Materials Insulation crafted from repurposed materials like recycled denim, newspaper, or glass reduces waste by utilizing existing resources. These materials deliver exceptional thermal performance while lessening their ecological footprint.

Sustainable Fibers Natural fibers such as wool, hemp, and cotton are renewable and biodegradable. They offer effective insulation properties and are non-toxic and breathable, promoting healthier indoor environments.

Advantages in Energy Efficiency

Eco-friendly insulation enhances energy efficiency by curbing heat loss and reducing dependence on heating and cooling systems. This translates to decreased energy consumption and lower utility costs, making it a cost-efficient choice for homeowners.

Health and Comfort Benefits

Unlike conventional insulation materials that may emit harmful substances over time, eco-friendly insulation preserves indoor air quality and fosters comfortable living conditions. It regulates humidity levels and inhibits mold growth, minimizing respiratory risks.

Professional Installation Standards

Effective installation practices are crucial for maximizing the efficacy of eco-friendly insulation. Certified installers adhere to eco-conscious techniques such as waste reduction, employing low-impact installation methods, and ensuring tight seals for optimal energy conservation.

Long-Term Sustainability

Investing in eco-friendly insulation promotes enduring sustainability by diminishing carbon emissions and conserving natural resources. It adds value to properties and contributes to a greener future for upcoming generations.

In essence, eco-friendly insulation installation stands at the forefront of the sustainable evolution in construction. By selecting sustainable materials and embracing environmentally responsible practices, homeowners can elevate energy efficiency, enhance indoor air quality, and play a pivotal role in nurturing a healthier planet.

#insulation installation#insulation companies near me#insulation contractors near me#insulation installers near me

0 notes

Text

Remove Old Insulation

Once our attic professionals are sure no mould or pests stay, we then get to work on installing installation. The process can take a couple of days, depending on the scale of your attic, or if further attic cleansing is needed. When animals live in your attic, they will create important harm and depart a giant mess behind. What’s more, assuming your house has been infested by rodents, a professional attic cleaner will give you the necessary steps to maintain a clean attic. Often if your insulation has been contaminated by rodents or wildlife, there might be an analogous drawback in your air ducts. Each time your HVAC system activates, unseen contaminants could possibly be coming into your house - insulation installer brisbane.

Our group supplies you with professional attic insulation companies to revive the air quality and power efficiency of your attic. Attic restoration is the method of restoring your attic to the unique situation previous to the animal infestation. Adding insulation to your attic helps keep your home warmer in winter and cooler in summer. It also saves you money on your heating and cooling bills – it’s a win-win! In fact, if your attic and walls were not insulated at all, you could lose up to your home’s energy - insulation brisbane.

Fiberglass batt insulation also improves the air quality of your home by preventing unwanted pollutants from entering. It comes in mold and mildew-resistant forms, so you don’t have to worry about mold growing in your attic. If you’re concerned about having a positive impact on the environment, fiberglass batt is probably the best insulation option for your attic. That’s because it’s made of recycled sand and glass. Its composition also makes it light-weight and flame-resistant.

If you need to insulate a wide-open area in your attic, you might want to choose fiberglass rolls. Fiberglass rolls contain the same insulation material as fiberglass batts, but they come in longer segments that you can roll out. Though fiberglass batt insulation is the most common attic insulation used today. Like fiberglass insulation, mineral wool is a fiber insulation, but instead of glass it is composed of natural materials. For more information, please visit our site https://roofsuckers.com.au/

0 notes