#fumehood

Explore tagged Tumblr posts

Text

Fume Hood Manufacturer in India

When it comes to creating safe and efficient laboratory environments, choosing the right Fume Hood Manufacturer in India is essential. Fume hoods are critical safety devices, protecting workers from exposure to hazardous fumes, vapors, and particulates. Indian manufacturers stand out for their ability to deliver innovative, high-performance solutions tailored to a wide range of applications, including research, healthcare, and industrial operations.

The Importance of a Trusted Manufacturer

A reliable Fume Hood Manufacturer in India combines cutting-edge technology with unmatched craftsmanship to provide durable and efficient solutions. These manufacturers design products that not only comply with international safety standards but also cater to the specific needs of local industries, ensuring optimal performance and long-term reliability.

Distinctive Features of Indian Fume Hoods

Precision Airflow Systems: Advanced airflow management ensures complete containment of harmful substances.

Durable Construction: Built with corrosion-resistant and chemical-proof materials for extended life.

Energy-Efficient Designs: Engineered to minimize operational costs without compromising safety.

Flexible Configurations: Customizable options including ducted, ductless, or hybrid models to fit varied needs.

Ease of Use: Ergonomic designs with adjustable sashes, intuitive controls, and LED lighting for user comfort.

Enhanced Safety Systems: Integrated alarms and monitoring features to alert users of airflow anomalies.

Advantages of Indian Manufacturers

Choosing an Indian manufacturer brings several benefits:

Affordable Excellence: High-quality products offered at competitive prices.

Customized Solutions: Adaptable designs tailored to Indian laboratory and industrial requirements.

Comprehensive Support: Quick access to after-sales services, maintenance, and spare parts.

Sustainable Practices: Emphasis on eco-friendly materials and energy-saving technologies.

Applications of Fume Hoods

Research Labs: Protection during chemical synthesis and analysis.

Educational Institutions: Safety for students and staff during hands-on experiments.

Pharmaceutical and Biotech Facilities: Maintaining sterile conditions and controlling toxic exposure.

Chemical and Industrial Processes: Handling hazardous substances with minimized risks.

Partnering with a trusted Fume Hood Manufacturer in India ensures you receive a product designed for safety, efficiency, and durability. Whether you’re upgrading an existing setup or building a new facility, Indian manufacturers deliver solutions that meet global standards and local demands. Invest in the best to ensure a safer, more productive workspace!

0 notes

Text

7 Tips for Selecting the Right Fume Hood Manufacturer

When it comes to creating a safe and efficient laboratory, selecting the right fume hood is crucial. A fume hood serves as the first line of defense against harmful chemical fumes, vapors, and particulates, ensuring the safety of your lab personnel and the integrity of experiments. Whether you're setting up a new laboratory or upgrading existing equipment, choosing the right fume hood manufacturer is a critical decision. In this guide, we’ll walk you through 7 essential tips for selecting the right fume hood manufacturer, and explain why LabSolutionIndia is the ideal partner for your laboratory equipment needs, especially when it comes to high-quality fume hoods and their components.

1. Focus on Quality and Durability

Quality and durability are paramount when selecting a fume hood for your lab. The fume hood must be built to last, withstanding harsh laboratory conditions, frequent use, and exposure to chemicals. A durable fume hood will not only ensure safety but will also provide value over time by minimizing maintenance and replacement costs.

At LabSolutionIndia, we pride ourselves on delivering high-quality fume hoods made from premium materials such as stainless steel, epoxy-coated steel, and PVC, which offer superior resistance to chemicals, rust, and corrosion. Our fume hoods are designed to meet the rigorous demands of scientific laboratories while ensuring long-term durability and reliability.

2. Ensure Compliance with Local Safety Standards

Fume hoods are critical to maintaining safety standards in your laboratory. When selecting a fume hood manufacturer, it’s essential to ensure that their products comply with local safety regulations. In India, fume hoods should adhere to guidelines set by the Bureau of Indian Standards (BIS), National Building Code of India (NBC), and other local and international standards such as ANSI/ASHRAE 110 for air quality.

LabSolutionIndia ensures that all of our laboratory fume hoods meet or exceed the safety standards required by both Indian and international regulatory bodies. Our fume hoods are designed with safety at the forefront, guaranteeing the protection of both your team and the environment.

3. Look for Energy-Efficient Models

Fume hoods can be energy-intensive, particularly if you’re running a large lab with several hoods. Energy efficiency is not only an environmental consideration but also a cost-saving factor. Variable Air Volume (VAV) fume hoods, for example, adjust the airflow based on the lab’s needs, reducing energy consumption while maintaining safety.

At LabSolutionIndia, we offer a range of energy-efficient fume hoods, including VAV systems, that are designed to optimize airflow and reduce energy usage. By selecting an energy-efficient fume hood, you can lower your operational costs without compromising on safety or performance.

4. Assess the Range of Fume Hoods Available

Different laboratory applications require different types of fume hoods. For instance, a biosafety fume hood may be required for biological work, while chemical fume hoods are ideal for chemical experiments. Ductless fume hoods are also available for smaller laboratories or situations where external ventilation isn't feasible.

LabSolutionIndia offers a wide variety of fume hoods designed to meet diverse laboratory needs. Whether you need a chemical fume hood, biosafety cabinet, or a ductless fume hood, we have the right solution for your lab. Our customizable options allow you to choose the perfect fume hood for your specific applications.

5. Consider the Manufacturer's Reputation and Expertise

When choosing a fume hood manufacturer, it’s essential to assess their reputation and experience in the industry. A trusted manufacturer will have years of experience producing high-quality laboratory equipment and will understand the specific needs of your lab. Look for manufacturers with a history of supplying to universities, research institutions, and industrial laboratories.

As a leading fume hood manufacturer and supplier in India, LabSolutionIndia has built a strong reputation for providing durable and efficient laboratory equipment. With decades of experience in the industry, we are well-equipped to offer expert advice and deliver tailored solutions to suit the needs of your laboratory.

6. Focus on User-Friendly Features and Ergonomics

A fume hood should not only be safe and efficient but also user-friendly. Look for fume hoods with features that make them easy to operate, adjust, and maintain. For example, adjustable sashes, intuitive control systems, and ergonomic designs can make a significant difference in daily lab operations.

At LabSolutionIndia, our fume hoods are designed with ergonomics in mind. We offer easy-to-operate controls, adjustable sashes for optimal airflow, and designs that prioritize safety and comfort. Whether you're working with hazardous chemicals or delicate biological samples, our fume hoods are engineered for ease of use and maximum protection.

7. Evaluate After-Sales Support and Warranty

Even the best fume hoods require maintenance and occasional repairs. A reputable manufacturer should offer strong after-sales support, including installation services, training for lab staff, and troubleshooting assistance. Additionally, look for manufacturers that offer solid warranties to protect your investment.

LabSolutionIndia is committed to providing comprehensive after-sales support for all our laboratory equipment, including fume hoods. We offer installation services, regular maintenance checks, and training programs to ensure your team is equipped to use the equipment safely and effectively. Our extended warranty programs give you peace of mind, knowing that we stand behind the quality and performance of our products.

Fume Hood Parts: Understanding Key Components

Understanding the parts of a fume hood is essential for selecting the right equipment and ensuring it functions properly. A typical fume hood consists of several key components:

Sash: The adjustable glass panel that provides access to the interior while maintaining airflow.

Exhaust System: This removes contaminated air and expels it outside or filters it within a ductless system.

Baffle: Helps to direct airflow into the fume hood and prevents turbulence.

Filters (for ductless hoods): Essential for capturing harmful particles and fumes, ensuring that air recirculated into the lab is clean.

At LabSolutionIndia, we ensure that all the fume hood parts we supply are of the highest quality. Whether you're looking for replacement parts or complete systems, we provide all the components necessary to keep your fume hoods running efficiently and safely.

Why Choose LabSolutionIndia?

When it comes to selecting the best fume hood manufacturers in India, LabSolutionIndia stands out as the leading choice for laboratory professionals. Here's why:

Superior Quality: We offer premium fume hoods made from durable, chemical-resistant materials.

Custom Solutions: Our wide range of fume hoods can be tailored to meet your specific laboratory requirements.

Energy-Efficiency: Our VAV and energy-saving fume hoods help reduce operational costs.

Comprehensive Support: From installation to regular maintenance, we provide complete after-sales support.

Expertise: With years of experience in manufacturing laboratory equipment, we understand the unique needs of your lab.

Conclusion

Selecting the right fume hood manufacturer is essential for maintaining safety and efficiency in your laboratory. By focusing on factors such as quality, energy efficiency, compliance with safety standards, and after-sales support, you can ensure that you choose the best fume hood for your lab’s needs. As a trusted leader in the industry, LabSolutionIndia offers the highest-quality fume hoods for labs, backed by exceptional service and support.

Contact LabSolutionIndia today for the best fume hoods and other laboratory equipment designed to keep your lab safe, efficient, and compliant with all necessary standards.By following these tips and partnering with LabSolutionIndia, you'll be well on your way to selecting the best fume hood manufacturer for your laboratory, ensuring a safe and productive environment for all your research and experiments.

0 notes

Text

Labtron PP Ducted Fume Hood is a microprocessor control system that features a built-in PP centrifugal blower for effective toxic vapor removal. It has an 820 mm work surface height, a 740 mm max opening, an air velocity of 0.3 to 0.8 m/s, and an LED display for parameters.

0 notes

Text

Ductless Fume Hood

Labtron Ductless Fume Hood is a floor-standing unit with a 910×690×740 mm chamber, 650 mm opening, and 2 chemical filters. It features 4 casters for easy movement, an air velocity of 0.25-0.35 m/s, a 3-sided transparent acrylic window, waterproof sockets, and a phenolic resin work table.

0 notes

Text

Walk In Fume Hood 400 W

Labnic Walk-In Fume Hood, designed for large-apparatus applications with a 1300 mm max opening, offers an exhaust airflow of 1150 m3/h and an inflow velocity of 0.3–0.8 m/s with a noise level of ≤62 dB. It includes a digital display, power-failure memory, 4 waterproof sockets and eco-friendly features.

0 notes

Text

Understanding the Difference: Fume Hood vs. Laminar Flow Hood

Are you curious about the key differences between fume hoods and laminar flow hoods in laboratory settings? Discover how each hood type plays a crucial role in safety and contamination control for your experiments. Dive into our comprehensive guide to make an informed choice for your lab! 🔬🧪

Read more: https://mnsonslabsolution.in/a-complete-synopsis-for-fume-hood-vs-laminar-flow-hood/

0 notes

Text

Labtron Walk-In Fumehood features a large opening and floor mounting, ideal for accommodating large materials. It can open to a maximumheight of 1300 mm and meets the low velocity high performance hood standards.

0 notes

Text

Ductless Fume Hood ADFD-501

Advalab Ductless Fume Hood with advanced carbon filtration technology and a filter saturation sensor offers a safe, high-performance alternative for laboratory applications. Air Pressure, user-friendly and affordable Point icon Simple Maintenance and easily adjustable.

0 notes

Text

#fumehood#manufacturer#muffle furnace#manufacturing#laboratory#bestdeals#supplier#yatherm#sieveshaker

0 notes

Text

Understanding The Working Principle of a Laboratory Fume Hood

The fume hood is safety equipment in the laboratory with a special design that will reduce exposure to harmful gasses, dust, and toxic vapors. The Fume hood is basically an aerodynamic cleaning, the device that has a large cupboard at the bottom that functions as a place or table.

The Working Principle of the Fume Hood:

The working principle of a Laboratory Fume Hood revolves around effective containment, ventilation, and user safety.

Enclosure:

Fume hoods are typically enclosed structures with a transparent front sash or door, allowing users to observe and access the workspace.

The enclosure is designed to capture and contain harmful substances, preventing their escape into the surrounding environment.

Air Flow: Main working of the Air Flow is suck air from the front door and then the blower is released into the filter.

The ventilation system of the fume hood is an important feature. A strong fan is often used to generate a controlled airflow within the hood.

The airflow is directed from the work area, where contaminants are released, towards the exhaust system, successfully catching and eliminating harmful compounds.

Sash or Door:

The fume hood's front entrance, known as the sash or door, is critical for user contact and safety.

Users can manage the airflow and maintain the proper level of containment by adjusting the sash height. Effective containment and excellent performance are ensured by proper sash location.

Exhaust System:

The impurities are collected and sent through an exhaust duct or system that leads outside the building or to a designated ventilation system.

This guarantees that dangerous fumes are securely evacuated, preventing their accumulation in the laboratory or workspace.

Face Velocity:

The speed at which air travels across the front opening of the fume hood is referred to as face velocity. It is an important parameter for ensuring containment.

Face velocity is important because it guarantees that impurities are sucked into the hood and away from the user.

Material used in Fume Hood

The materials used in constructing fume hoods must meet specific requirements to ensure their effectiveness in providing a safe working environment. Here's a description of the requirements you mentioned:

Have the following requirements:

Resistance to organic chemicals:Fume hoods must be made of materials that are resistant to organic compounds. The inner surfaces of fume hoods are typically made of materials such as high-density polyethylene (HDPE), polypropylene, and epoxy-coated steel. These materials were chosen for their non-reactivity with organic compounds, guaranteeing that the fume hood can endure exposure to a wide spectrum of organic chemicals without deterioration.

Resistance to chemicals that are corrosive(acids and bases): Fume hoods must be resistant to corrosive compounds such as acids and bases. The inner surfaces of the fume hood are frequently covered with chemical-resistant materials such as epoxy or fiberglass-reinforced polyester. Furthermore, the sashes and frames may be composed of materials such as stainless steel, which is noted for its corrosion resistance. This ensures that the fume hood remains structurally sound and maintains its containment properties when exposed to corrosive substances.

Resistance to an explosion:

Design and Construction: While fume hoods are not meant to directly resist explosions, they are often built with safety precautions to reduce the risk of explosions within the hood. To prevent sparks that could ignite volatile substances, the hood's design may include explosion-resistant motors and electrical components.

Proper Ventilation: Adequate ventilation is essential for preventing the accumulation of explosive or combustible vapors within the lab fume hood. The hood should be linked to an exhaust system that efficiently and safely eliminates and disperses any potentially harmful pollutants.

Static-Resistant Surfaces: The surfaces inside the large fume hood may be designed to reduce static electricity buildup, which could be dangerous in explosive atmospheres.

Part of the Fume Hood:

Sash is a sliding door that is a safety guard, usually made of glass acrylic.

Lighting Equipment (position inside the fume hood), a fluorescent lamp for lighting.

Top Table Pedestal/Work Table, made of phenolic resin that is resistant to chemicals.

Sink where the device washes after the trial to keep it clean.

Faucet, water tap for washing and rinsing tools.

Base Cabinet/Storage Cabinet, Chemicals storage cabinets.

Button Operating Switches, consisting of the ON-OFF Button, stop contact power lamp, lamp power.

Side Wall, a side wall that is resistant to steam and chemical spills

Air Flow Velocity, to regulate air flow velocity.

Baffles, Baffles regulate the flow of air so that it can be sucked effectively by the blower.

Ducting a pipe for air output.

Blower, a tool that has the function of sucking air and throwing it out.

How to use a fume hood?

Turn on the lights, turn on the blower switch, raise the sliding window as you wish. If the blower is already, then start your work carefully. If at the work is waiting while the reaction process is still running, then do it by lowering the sliding window with an opening of about 10 cm from the lip on the table after your is done, then clean the fume hood table with a dry cloth, then rinse with a wet cloth, then wipe again until dry. Turn OFF the light switch, Closed the sliding window.

Turn OFF the blower switch.

Attention! Don’t leave the sliding window tightly closed, when the blower is on, a vacuum will appear in the fume hood.

We are committed to providing top quality services to our clients. For more information give us a call +91 9555515525 or email us at [email protected].

0 notes

Text

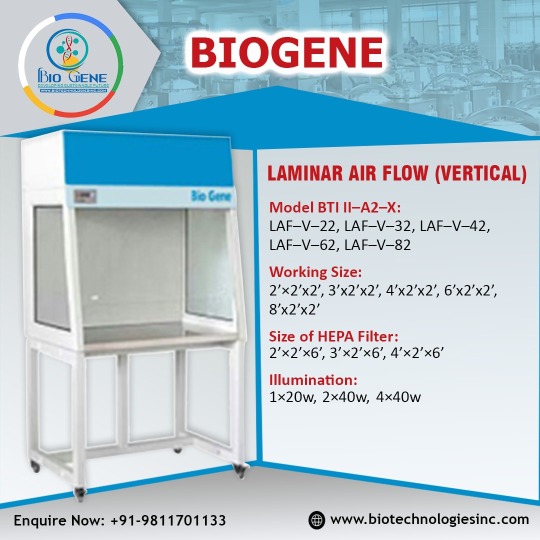

Maximize Safety and Efficiency with our Fume Hoods and Laminar Air Flows! Protecting your Biogene work with precision and care. 🧪🔬

"Biosafety at its Best! Explore our top-notch Biosafety Cabinets, Fume Hoods, and Laminar Air Flows for seamless biogene operations.

Visit Here For More:- https://bit.ly/3O5HggL

#FumeHood #LabSafety #ChemicalSafety #AirFlowControl #CleanAir #LaminarFlow #HorizontalLaminarFlow #VerticalLaminarFlow #BiosafetyCabinet #Biogene #LaboratoryEquipment #ContaminationControl #BioSafety #CleanEnvironment #LaboratorySafety #ScientificResearch #AirQuality #BiosafetyStandards #SterileEnvironment #FilteredAir

#FumeHood#LabSafety#ChemicalSafety#AirFlowControl#CleanAir#LaminarFlow#HorizontalLaminarFlow#VerticalLaminarFlow#BiosafetyCabinet#Biogene#LaboratoryEquipment#ContaminationControl#BioSafety#CleanEnvironment#LaboratorySafety#ScientificResearch#AirQuality#BiosafetyStandards#SterileEnvironment#FilteredAir

0 notes

Text

Labtron Walk-In Fume Hood is floor-mounted with a large opening, 1150 m³/h airflow, dual LED lamps, acid-resistant melamine, and dimensions of 980 × 600 × 1650 mm. It has a max opening of 1300 mm and offers a large exhaust system, an optional filter to reduce environmental pollution.

0 notes

Text

Walk-In Fumehood

Labtron Walk-In Fumehood features a floor-mounted design with a spacious 1300 mm opening, perfect for handling large materials. Equipped with a powerful LED lighting system (12W-16W) and a robust exhaust setup. Provides adjustable inflow air velocity (0.3-0.8 m/s) for optimal safety.

0 notes

Text

The Fume Hood Incident

A continuation of this post where @stealingyourbones and I regale tales of Mr. T, our high school science teacher that was the inspiration behind my addition to the popular Danny Phantom Science Teacher AU post that sparked the whole thing off.

I was able to catch the incident on camera & after rewatching it, decided that not enough of peoples faces were shown to be able to discern their identify & have decided to post it here.

—

First, context.

It was the last day of my freshman year of high school.

Mr. T was donated a god awful teapot made by a student in ceramics with the only stipulation being that he “blow it up.”

And according to my notesapp notes, he reportedly said, “One of my great pleasures in life is finding common regular normal things in life and making them go boom.” Right before we left our class to do the experiment in the lab classroom next door that had a fume hood. And from what I remember of the man, that absolutely fits.

I do not remember what chemicals Mr. T used to make the reaction but I do remember that we were extensively warned that it gave off noxious fumes and shouldn’t look directly at the light as it could damage our eyes.

Trudging into the other classroom, Mr. T set up the experiment in the fume hood.

At first, everything was going well. The teapot exploded and the room was bathed in red light.

Then we looked up.

You see, when you install a fume hood, generally you connect it to a chimney so the fumes can go out. The fucker that installed it did it improperly so the noxious fumes went DIRECTLY INTO THE CLASSROOM.

Immediately Mr. T evacuated the room and rushed us into the hallway.

The fire alarm went off.

The class, giddy from the feeling that we just blew something up and made the fire alarm go off in the last day of school, we we’re ecstatic.

We cheered.

—

Naturally, the faculty were kinda pissed because the alarms once again were set off by Mr. T & they had to call off the firetrucks that were auto-called and we’re charged for it.

Mr. T had to report the incident to the same cop as the magnesium incident and he was so proud to tell the officer it finally wasn’t his fault the fire alarm went off.

The school sued the installation company for incorrectly installing the fume hood and got it properly working the next year.

That day will be a core memory of mine that I will treasure til I kick the bucket.

-

And finally, the video.

#the fumehood incident#The only damn tumblr story where ‘& everyone cheered/clapped’ is actually true#When my class was standing out on the lawn waiting for the fire department to clear the building and let us back in#We were all bragging to our friends in other classes that WE were the ones to set off the alarm and explaining the incident#we were so proud of ourselves#bones speaks

245 notes

·

View notes

Text

lily aldridge's kitchen is a dream

#.txt#the fumehood above her stove being covered in the same tile is sOOOOOO smart#it blends so well#the open shelves kinda freak me out though

94 notes

·

View notes