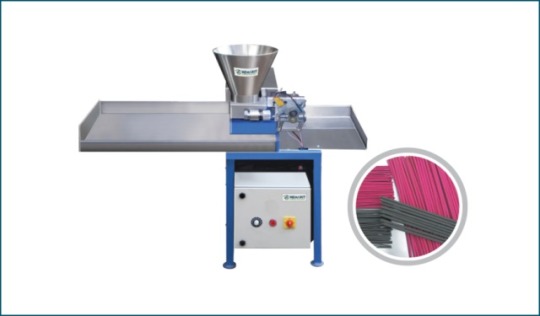

#fully automatic agarbatti making machine

Explore tagged Tumblr posts

Text

agarbatti making machine-fully automatic agarbatti making machine in Delhi

ASVR Engineering is the best agarbatti making machine manufacturer and supplier of incense stick making machine in Delhi. Buy fully automatic agarbatti maker machine in India from us at reasonable cost.

#agarbatti machine#agarbatti making machine#automatic agarbatti making machine#agarbatti making business#incense sticks making machine#incense maker machine#fully automatic agarbatti making machine

2 notes

·

View notes

Text

agarbatti making machine

Armind industries is the best agarbatti making machine manufacturer and supplier of incense stick making machine in Bihar. Buy fully automatic agarbatti maker machine from us at reasonable cost.

#agarbatti making machine#automatic agarbatti making machine#agarbatti making machine manufacturer#agarbatti making machine supplier#incense sticks maker machine#agarbatti machine#incense maker machine#fully automatic agarbatti making machine#manual agarbatti making machine

2 notes

·

View notes

Text

Pouch Packing Machine & Collar Type Pouch Packaging Machine

Pouch Packing Machine: The Ultimate Guide to Finding the Right Manufacturer and SupplierAre you in search of a reliable pouch packing machine manufacturer and supplier in Delhi, Bihar, Bhopal, Varanasi, or Ghaziabad? Look no further! In this comprehensive guide, we will walk you through everything you need to know to make an informed decision and ensure you get the best pouch packing machine for your specific needs. What to Look for in a Pouch Packing Machine Manufacturer and Supplier? When choosing a pouch packing machine manufacturer and supplier, there are several key factors to consider: Experience: It is essential to choose a manufacturer and supplier with years of experience in the industry. This ensures that they have the necessary expertise to provide high-quality machines that meet your requirements. Expertise: Look for a manufacturer and supplier who specializes in pouch packing machines. This shows that they have in-depth knowledge of the product and can offer customized solutions to suit your needs. Authority: Seek out a manufacturer and supplier who is well-established and has a strong reputation in the market. This indicates that they are trustworthy and reliable. Trust: It is crucial to partner with a manufacturer and supplier you can trust to deliver on their promises and provide ongoing support and service. Pouch Packing Machine Manufacturer and Supplier in Delhi In Delhi, there are several reputable manufacturers and suppliers of pouch packing machines. One of the leading companies in the area is XYZ Pouch Packing Machines. With over 20 years of experience in the industry, they offer a wide range of high-quality machines to meet various packaging needs. Whether you are looking for a small-scale machine for your startup or a large-scale automated system for a manufacturing facility, XYZ has got you covered. Pouch Packing Machine Manufacturer and Supplier in Bihar, Bhopal, Varanasi, and Ghaziabad In Bihar, Bhopal, Varanasi, and Ghaziabad, finding a reliable pouch packing machine manufacturer and supplier is crucial for businesses looking to streamline their packaging process. One such company is ABC Packaging Solutions, known for its innovative and efficient machines. From vertical form-fill-seal machines to horizontal flow wrappers, ABC offers a diverse range of options to cater to different packaging requirements. Conclusion In conclusion, when searching for a pouch packing machine manufacturer and supplier, it is essential to consider factors such as experience, expertise, authority, and trust. By choosing a reputable company with a proven track record, you can ensure that you get a high-quality machine that meets your specific needs. Whether you are based in Delhi, Bihar, Bhopal, Varanasi, or Ghaziabad, there are several reliable manufacturers and suppliers to choose from. Invest in the right pouch packing machine today and take your packaging process to the next level!

#pouch packing machine#collar pouch packing machine#fully automatic pouch packaging machine#business#manufacturer#agarbatti making machine#machine learning

0 notes

Text

Agarbatti Making Machine in Patna by Arya Industries

Agarbatti, also known as incense sticks, is an essential product in India for religious ceremonies, aromatherapy, and various cultural practices. The demand for high-quality agarbatti has been consistently high, which has led to an increase in the number of businesses manufacturing agarbattis. Arya Industries, based in Patna, Bihar, is a renowned name in the industry, offering a wide range of agarbatti making machines designed to meet the needs of both small-scale and large-scale manufacturers.

Why Choose Arya Industries for Agarbatti Making Machines?

Arya Industries is known for its exceptional quality and reliable agarbatti making machines in Patna. They have established themselves as a leader in the market by providing machines that ensure high efficiency, durability, and ease of operation. The company designs machines that cater to different types of agarbatti production, including manual, semi-automatic, and fully automatic machines.

Key Features of Arya Industries’ Agarbatti Making Machines:

High-Speed Production: Arya Industries’ agarbatti making machines are built to maximize productivity. These machines can produce a high volume of incense sticks within a short period, helping businesses scale up production.

Consistent Quality: The machines ensure that each agarbatti is uniform in shape and size, which is crucial for maintaining quality and consistency in the final product. This helps businesses to meet customer expectations and build a loyal clientele.

Easy Operation: The machines are designed for ease of use, even for individuals with minimal technical knowledge. Arya Industries ensures that the machines are user-friendly, making them accessible for businesses of all sizes.

Durability and Low Maintenance: Arya Industries offers agarbatti making machines that are made with high-quality materials to withstand prolonged usage. These machines require minimal maintenance, ensuring low operating costs.

Variety of Models: Depending on the production scale, Arya Industries provides a variety of machines, from small, manual models to large, fully automatic machines. This allows businesses to choose a machine that best fits their needs and budget.

Affordable Pricing: Arya Industries offers competitive pricing for their agarbatti making machines, making them an attractive option for both new and established businesses. They also provide customized machines based on specific requirements.

Types of Agarbatti Making Machines:

Manual Agarbatti Making Machines: These machines are ideal for small-scale businesses or those just starting. They are easy to operate and affordable, but require more labor compared to automated models.

Semi-Automatic Agarbatti Making Machines: These machines offer a balance between automation and manual work. They are more efficient than manual machines and can be operated with fewer laborers.

Fully Automatic Agarbatti Making Machines: These are the most advanced models, capable of producing large quantities of incense sticks with minimal human intervention. Fully automatic machines are perfect for large-scale production and offer the highest level of efficiency.

Agarbatti Making Machine Price in Patna

The agarbatti making machine in Patna price varies based on the type, capacity, and features. For manual machines, the price starts at approximately ₹25,000 to ₹50,000. Semi-automatic machines are priced around ₹70,000 to ₹1,50,000, while fully automatic agarbatti making machines range from ₹2,00,000 to ₹5,00,000 depending on the production capacity and additional features.

Arya Industries provides cost-effective options and can also offer customized solutions based on your specific business requirements. By offering high-quality machines at competitive prices, they make it easier for businesses in Patna and beyond to enter the agarbatti manufacturing industry.

Conclusion

If you are looking to invest in agarbatti making machines in Patna, Arya Industries is a trusted name that provides high-quality, durable, and affordable machines. With their extensive range of options and commitment to customer satisfaction, they are the go-to choice for businesses looking to scale their incense stick production.

0 notes

Text

#agarbatti making machine#business#incense stick making machine#agarbatti making machine in varanasi#agarbatti#insence

0 notes

Text

Agarbatti Making Machine in Bhopal

Agarbatti Making Machine in

Bhopal, a city known for its rich cultural heritage, has witnessed a significant surge in small-scale industries, particularly in the production of Agarbattis or incense sticks. This article delves into the intricate world of Agarbatti making machines in Bhopal, shedding light on the manufacturing processes, technology involved, and the impact on the local economy.

Agarbatti Machine in Bhopal.

In search of a Bhopal Agarbatti making machine? There's nowhere else to look! Our top-notch machinery is ideal for creating incense sticks of the highest caliber. Start your own incense business immediately by looking through our extensive selection of models. In Bhopal, we are the top producer, supplier, and wholesale dealer of the highest caliber Agarbatti-making machinery. Machines for creating Agarbatti can be fully or partially automated. Everything is done automatically by fully automated machinery, including feeding the mixture and cutting and packing the sticks.

Agarbatti-making machine advantages.

elevated productivity: The Agarbatti-making machine greatly raises productivity by automating the production process. Unwavering quality: the apparatus guarantees consistency in the dimensions, form, and aroma of the incense sticks. Economical: Using an Agarbatti-making machine has long-term advantages that surpass the original outlay, despite the machine's seemingly high initial cost. Time-saving: By letting the machine handle the production process, business owners can concentrate on other facets of their operations, such customer service and marketing. Increased safety: The Agarbatti-making machine complies with stringent safety regulations, which lowers the possibility of mishaps and injuries that might happen during the manual production process.

Read More

#Best Agarbatti Making Machine in Bhopal#Best Agarbatti Making Machine#Agarbatti Making Machine in India#Agarbatti manufacturer Machine in Bhopal

0 notes

Text

Our cow dung agarbatti making machines are fully automatic and feature an impressive production capacity of upto 400 kg agarbattis per hour.

product link:https://www.growgreennaturally.com/cow-dung-agarbatti-making-machine/

#CowDungAgarbattiMakingMachine#CowDungAgarbattiMakingMachineManfuacturer#CowDungAgarbattiMakingMachineExporter#CowDungAgarbattiMakingMachineExporterAhmedabad

0 notes

Text

Automatic Agarbatti Making Machine

Manufacturer of a wide range of products which include 6g world’s fastest high speed noiseless agarbatti machine, double pedal type manual agarbatti making machine, computerized software base agarbatti making machine, fully automatic agarbatti making machine, pneumatic automatic agarbatti making machine (air system) and 6g high speed water cooling system agarbatti making machine.

for more details,

0 notes

Text

Best Machines that are speedy and Easy Changeover.

Features to Look in an Incense StickCounting and Packing Machine

Incense sticks are a household thing in India. Used in homes of rich and poor alike, these aromatic sticks are staples in religious ceremonies, meditation and therapies. A popular simple and inexpensive deodorant, incense sticks are often used as insect repellants in homes. Made with a combination of fragrant essential oils and plant materials, incense sticks are the hallmark of the Indian culture.

These sticks are supplied in the market by manufacturing shops and companies. These entities rely on packing and counting machines to make incense sticks ready in large batches to be sent to stores in short times. Luckily, there are a large number of agarbatti counting and packing machine manufacturer in India like Dhyan Automation that keeps these small factories up and running with their fast and heavy-duty machines.

If you are looking at incense stick counting and packing machines online, then here are some useful features to make priorities when buying such a machine.

· First of all, you need a machine that is engineered to pack all kinds of incense sticks. Given that you will not sell only one kind of agarbatti, you need a machine that can handle production of both handmade and machine-made types.

· When selecting an incense stick maker, priority should always be to buy a fully automatic system, preferably one that is controlled with PLC.

· Most machines come with an elaborate control panel, which if not user-friendly can require a good deal of time to figure out. So, you want to invest in a system that is easy to operate. Those that come with an expansive touchscreen is easier to operate than others.

· Most manufacturers in their attempt to make the machines light and transportable use lightweight materials that give in to small bumps and knocks. Only a few incense stick counting and packing machine manufacturer like Dhyan Automation have machines that have heavy-duty constructs that make the machines last for years. These are the machines to invest in.

· The best machines are those that are speedy and have easy changeover.

· There are some manufacturers that offer installation service while others build machines that are easy to install. Either works, as long as the machine is low maintenance and function smoothly.

So, if you find a machine that ticks most of the above boxes, know that you have found the most investable incense stick counting and packing machine in the market.

#Agarbatti Counting and Packing Machine Manufacturer#Incense Stick Counting and Packing Machine Manufacturer

0 notes

Text

Agarbatti Dryer - Steamtech Engineers

Steamtech Engineers

Agarbatti & Dhoop Dryer

1. Agarbatti Fan Dryer

General info.:- Steamtech Engineers are leading manufacturer of high speed agarbatti/ Incense Stick fan dryer. This technique provides lowest running cost and best international standard quality. This Agarbatti Fan Dryer is designed to suit any type of climate.

Capacity :- Various sizes of agarbattis, one at a time, upto a capacity of 375Kgs. can be loaded in baskets.

Operating

Principle:- Agarbatti Fan dryer is a batch type axial fan dryer. Axial fan sucks enviroment air through stack of agarbatti and blows out moist air.

Benifit:-

· It dries agarbatti faster in just 60% time as compared to vietnamese dryer.

· The problem of uneven drying has been solved here.

· Saves a lot of space as compared to conventional drying of incense sticks.

· Various sizes of agarbattis, one at a time, upto a capacity of 375Kgs. can be loaded in baskets.

· It’s speciality is uniform drying in all the baskets simultaneously.

Salient Features:-

· The high speed dryer for drying incense sticks is made of galvanized pipes and sheets.

· Dryer has 4 baskets of incense sticks on one side and total 16 baskets on all four sides.

· Metal fan has been installed in the dryer to increase the lifespan of the fan.

· There is also a safety guard on the top of the metal fan in the dryer.

· The dryer has 4 castor wheels at the bottom, which will help the dryer to move smoothly.

Many Of Another Benifit:

· Energy efficiency: Smooth air flow is managed as per the requirement to make sure fast and efficient drying, hence leading to energy efficiency.

· Make in India: The machine is 100% indigenous. We provide quality service and all parts are readily available in stock. We are the partner, you can rely on.

· Prompt Post Sale Services: Our immediate and prompt services within 24 hours avoids any hindrance in your production.

2. Agarbatti Heat Dryer:

General info:- Steamtech Engineers are leading manufacturer of high speed fully Automatic Incense Stick Heat Dryer. This technique also provides lowest fuel cost and best international standard quality. This plant is designed to suit any type of climate.

Capacity :- 125 Kgs to 25,000 Kgs Per Day.

Operating Principle :- Agarbatti (Incense Stick) Heat Drying chamber shelters multiple fan dryers loaded with agarbatti and provides an enclosed environment for drying. Hot air is supplied from heat exchanger to drying chamber and when moisture from agarbatti mixes in air it is exhausted.

Benefit:-

· Effective drying in all Seasons.

· Production do not suffer in monsoon timing.

· Issue of colour changes due to drying timings in diff. seasons is resolved.

· Decreases Agarbatti breakages.

· Low drying cost.

· Inhibits fungus growth due to proper drying.

· Final product after drying matches international standards.

· Uneven deeping ratio problem is resolved.

· Agarbatti bending while drying problem is resolved.

· Production can be increased up to 4 times within the same premise.

· Hence higher business volume & higher profitability.

· Higher production means lower fixed production cost.

· Don’t need to relieve workers in monsoon and hence higher worker stability.

· No Space Restrictions (Drying can be managed in small space).

Salient Features:-

· Creates essential controlled environment for drying.

· Manufactured under standard environment.

· Sturdy and robust construction.

· Automatic air flow management.

· High speed drying chamber.

· Drying batch time only 6 Hrs 30 Min. for 8

· inch Agarbatti.

· Running (Operational) cost is very low.

· Weather proof drying system.

· Drying indicator visual & sound (sirens).

· Almost even drying in all baskets of trolley.

· No fire risk (Fire safety included).

· Easy loading for drying.

· Easy operation.

· Pre-decided Modular expansion is possible.

· SMS notification module is available.

· Fully automatic plant ensures good & even drying.

Many of Another Benefit :-

· Modular Construction : The sectional construction reduces the time in project planning, manufacturing, transportation, and finally installation.

· Energy efficiency: Air flow can be managed individually as per the requirement to make sure optimum heat transfer is provided to the material while controlling exhaust air temperature, hence leading to energy efficiency.

· Process adaptation: Each parameter such as Air flow, Temperature, Retention time of product can be individually managed exactly to suit your drying requirement.

· Make in India: The machine is 100% indigenious and patented. We provide quality service and all parts are readily available in stock. We are the partner, you can rely on.

Get in touch

Email :- [email protected]

Mob.:- +91 85111 46144 (Devang Varia)

Website:- https://www.steamtechengineers.com/

1 note

·

View note

Text

Agarbatti making machine

Agarbatti, also known as incense sticks, are commonly used in religious and cultural ceremonies as well as for aromatherapy purposes. Making agarbatti involves a series of steps, and there are machines available to automate the process. Here’s a general overview of the process and the types of machines used:

Agarbatti Making Process:

Raw Material Preparation:

Bamboo sticks or unscented blanks

Joss powder (charcoal powder)

Gum powder or wood powder

Water

Fragrance oils

Dough Formation:

Mix the joss powder, wood powder, and water to form a dough-like consistency.

This mixture is the base for the agarbatti.

Rolling:

The dough is rolled onto bamboo sticks manually or by a machine.

Drying:

Allow the rolled sticks to dry completely.

Dipping:

The dried sticks are dipped into a mixture of fragrance oils and other ingredients.

Drying Again:

After dipping, the sticks are left to dry again, ensuring the fragrance is absorbed.

Packaging:

Once dry, the agarbatti sticks are packaged for distribution.

Agarbatti Making Machine Types:

Automatic Agarbatti Making Machine:

Fully automated machines that can handle various steps of the process, from stick rolling to dipping and drying.

Higher production capacity.

Semi-Automatic Agarbatti Making Machine:

Requires some manual intervention but automates specific steps.

Suited for medium-scale production.

Manual Agarbatti Making Machine:

Requires more manual labor.

Suited for small-scale production.

High-Speed Agarbatti Making Machine:

Designed for faster production with increased efficiency.

Powder Mixing Machine:

Used for mixing joss powder, wood powder, and other ingredients to create the base dough.

Drying Machine:

Speeds up the drying process after rolling and dipping.

Packaging Machine:

Automates the packaging of finished agarbatti sticks.

When choosing an agarbatti making machine, factors to consider include production capacity, automation level, cost, and the specific features required for your production needs. Additionally, it’s essential to ensure that the machine meets safety and quality standards.

Always follow the manufacturer’s guidelines and safety instructions when operating agarbatti making machines.

Fully automatic agarbatti making machine

Fully automatic agarbatti making machines are designed to streamline the production process, from raw material preparation to packaging, with minimal manual intervention. These machines are efficient, have a higher production capacity, and can significantly reduce labor costs. Below are the key features and components typically associated with fully automatic agarbatti making machines:

Raw Material Feeding System:

Automated systems for feeding raw materials such as joss powder, wood powder, and other ingredients into the machine.

Dough Formation Unit:

Includes a mixer to create the dough-like consistency required for agarbatti sticks.

Stick Rolling Unit:

Automated mechanisms for rolling the dough onto bamboo sticks or other suitable materials.

Drying System:

Conveyor or drying chambers for the automatic drying of agarbatti sticks.

Dipping Unit:

A system for automatically dipping the dried sticks into a mixture of fragrance oils and other ingredients.

Second Drying System:

Ensures that the fragrance is properly absorbed by the sticks through a second drying process.

Automatic Counting and Packaging:

Incorporates systems for counting the agarbatti sticks and packaging them into predefined quantities.

Control Panel:

A user-friendly control panel to monitor and adjust the settings of the machine.

High Production Capacity:

Fully automatic machines are designed for high-volume production, making them suitable for large-scale manufacturing operations.

Efficiency and Precision:

Precision in stick formation, fragrance application, and packaging, ensuring consistent quality.

Safety Features:

Built-in safety features to protect operators and ensure the smooth functioning of the machine.

When considering a fully automatic agarbatti making machine, it’s essential to assess the specific requirements of your production facility. Factors to consider include:

Production Capacity: Choose a machine that aligns with your desired production volume.

Versatility: Some machines may be versatile, accommodating different sizes and types of agarbatti sticks.

Maintenance and Service: Inquire about maintenance requirements and the availability of service and support from the manufacturer.

Cost: Evaluate the overall cost of the machine, considering your budget and the long-term benefits of automation.

Supplier Reputation: Select a reputable supplier with a history of delivering reliable and high-quality machinery.

As of my last update in January 2022, it’s recommended to check with current suppliers and manufacturers for the latest models and advancements in fully automatic agarbatti making machines.

0 notes

Text

Armind Industries in Patna offers high-quality Agarbatti making machines, designed for efficiency and reliability. Our machine is perfect for producing high-quality incense sticks at scale, combining precision engineering with robust materials to ensure durability and consistent performance. It can make large quantities of agarbatti per hour, meeting the needs of small to medium-sized manufacturers. Whether you are starting a new business or looking to upgrade, our agarbatti-making machine is the ideal choice. For more information, contact us at 9431815446 to explore how we can support your business needs. Visit us at - Armindindustries.com

#Incense stick making machine#automatic agarbatti making machine#fully automatic agarbatti making machine

0 notes

Text

Agarbatti Making Machine In Delhi, Bihar, Uttar Pradesh, Madhya Pradesh, Jharkhand

Foodmart Agro Engineering is best agarbatti making machine manufacturer and supplier in delhi, bhopal, patna, jharkhand automatic incense sticks making machine. buy fully automatic agarbatti manufacturing machine and incense stick making from us at affordable prices. call now: +91–7227402022, +91–9582554014.

Are you tired of the time-consuming and labor-intensive process of making agarbattis (incense sticks) by hand? The agarbatti making machine is here to revolutionize the incense stick industry. With its efficient and automated processes, it allows you to produce high-quality agarbattis in a fraction of the time and effort. In this article, we will explore the benefits, functionality, and significance of agarbatti making machines in the modern world.

Agarbatti Making Machine: A Game Changer

What is an Agarbatti Making Machine?

An agarbatti making machine is a technologically advanced piece of equipment designed to automate the process of agarbatti production. It consists of a combination of mechanical, electrical, and pneumatic components. These machines are capable of performing various tasks, such as bamboo stick feeding, paste coating, and incense stick rolling.

The Benefits of Using an Agarbatti Making Machine

Increased Efficiency: With an agarbatti making machine, you can produce a large number of agarbattis in a short span of time. This leads to increased productivity and allows you to meet the growing demand for incense sticks.

Cost-Effectiveness: By automating the production process, you can significantly reduce labor costs. Additionally, the precise and consistent nature of these machines ensures minimal wastage of raw materials.

Consistency in Quality: Agarbatti making machines ensure uniformity in the size, shape, and fragrance of the incense sticks. This consistency enhances customer satisfaction and builds trust in your brand.

Ease of Operation: These machines are designed to be user-friendly, making them accessible to individuals with little to no technical expertise. They often come with simple controls and clear instructions, enabling smooth operation.

How Does an Agarbatti Making Machine Work?

An agarbatti making machine consists of multiple components that work together seamlessly to create high quality agarbattis. Here is a step-by-step breakdown of the process:

Bamboo Stick Feeding: The machine feeds bamboo sticks into the assembly line at a consistent pace. This step ensures a continuous flow of raw material for the production process.

Paste Coating: The machine applies a thin layer of adhesive paste to the bamboo sticks. This paste acts as a binding agent, allowing the agarbatti to hold its shape.

Incense Stick Rolling: The agarbatti making machine rolls the coated bamboo sticks with a mixture of fragrance and essential oils. This imparts a pleasant scent to the incense sticks.

Drying and Packaging: Once the incense sticks are rolled, they are dried using hot air or radiators. After the drying process, the agarbattis are bundled and packaged for distribution.

Why Choose an Agarbatti Making Machine?

Time-Saving: Manual agarbatti production is a time-consuming process. With an agarbatti making machine, you can significantly reduce the time required for production, allowing you to focus on other aspects of your business.

Higher Production Capacity: These machines are capable of producing a large number of agarbattis per hour, giving you the ability to meet the demands of a larger customer base.

Flexibility in Customization: Agarbatti making machines can be customized to produce various sizes and fragrances of incense sticks. This flexibility allows you to cater to the diverse preferences of your customers.

#agarbatti making machine#incense sticks making machine#agarbatti and dhoopbatti making machine#manufacturer#business#machine learning#new business#machine

0 notes

Text

Agarbatti Making Machine in Patna – Arya Industries Leading the Market

Agarbatti, or incense sticks, hold a significant place in Indian culture and traditions, used in religious ceremonies, meditation, and aromatherapy. The demand for high-quality agarbattis continues to rise, creating a booming market for agarbatti manufacturers. Arya Industries has established itself as the leading provider of Agarbatti Making Machines in Patna, offering state-of-the-art equipment for budding entrepreneurs and large-scale producers alike.

Why Choose Arya Industries for Agarbatti Making Machines?

Arya Industries is a name synonymous with quality and innovation in the machinery manufacturing industry. With years of experience, the company provides an array of Agarbatti Making Machines designed to cater to different production needs, from small-scale enterprises to larger manufacturing units. Here are some reasons why Arya Industries is the best choice for Agarbatti Making Machines in Patna:

1. Variety of Machines

Arya Industries offers a wide range of agarbatti-making machines, each suited for various production capacities and requirements. Whether you're looking for a manual agarbatti machine, a semi-automatic machine, or a fully automatic agarbatti-making machine, Arya Industries has it all. Their machines are designed to meet the diverse needs of manufacturers, from those just starting out to those operating at full capacity.

2. Advanced Technology

Arya Industries integrates the latest technology into their agarbatti-making machines, ensuring high precision, speed, and reliability. The machines are equipped with automated systems for making incense sticks with consistent quality. The cutting-edge features include options for customization in size, thickness, and fragrance retention, which ensures that the end product meets market standards.

3. User-Friendly Operation

The machines are designed with user convenience in mind. Whether it’s a fully automatic agarbatti-making machine or a manual version, the operation is easy to learn and requires minimal technical expertise. Arya Industries focuses on reducing downtime with machines that are simple to operate, maintain, and troubleshoot, making them a popular choice for small business owners in Patna.

4. Durability and Low Maintenance

One of the major advantages of Arya Industries’ machines is their robust construction. Built from high-quality materials, these machines offer durability and a longer lifespan. They require minimal maintenance, making them cost-effective in the long run. The company’s machines are designed to withstand the daily wear and tear of production, which ensures fewer breakdowns and lower repair costs.

5. Affordable Pricing

Despite offering high-quality and advanced machines, Arya Industries maintains competitive pricing. The cost of their agarbatti-making machines is affordable for small businesses, start-ups, and large-scale manufacturers alike. The pricing structure is designed to ensure that businesses of all sizes can benefit from modern agarbatti-making technology without stretching their budgets.

6. After-Sales Support and Service

Arya Industries stands out for its excellent customer service. The company provides comprehensive after-sales support, which includes installation, training, and troubleshooting. Their team of experts ensures that every machine operates at its full potential, helping manufacturers in Patna produce top-notch incense sticks with minimal effort.

Types of Agarbatti Making Machines Offered by Arya Industries

Arya Industries provides various types of agarbatti-making machines, each tailored to different production capacities and methods:

Manual Agarbatti Making Machine: Perfect for small-scale producers, this machine is affordable, easy to use, and requires minimal investment.

Semi-Automatic Agarbatti Making Machine: Ideal for medium-sized manufacturers, this machine offers a balance between manual operation and automation, improving production efficiency.

Fully Automatic Agarbatti Making Machine: For large-scale manufacturers, this machine is the most efficient, producing incense sticks at a high rate with little manual intervention.

Incense Stick Dryer: Arya Industries also offers dryers that help manufacturers ensure that their incense sticks are properly dried, maintaining the fragrance and quality.

Benefits of Starting an Agarbatti Business in Patna

The demand for agarbatti in Patna, Bihar, and across India is ever-growing. By choosing Arya Industries’ Agarbatti Making Machines, entrepreneurs can tap into a lucrative market with high profit margins. The machines are an excellent investment for those looking to start or expand their business. The agarbatti industry is labor-intensive, offering employment opportunities to many, and requires relatively low capital investment.

Conclusion

Arya Industries is the leading provider of Agarbatti Making Machines in Patna, offering a wide range of equipment tailored to the needs of manufacturers in the incense stick industry. With its emphasis on advanced technology, user-friendly designs, and affordability, Arya Industries ensures that businesses of all sizes can produce high-quality agarbattis efficiently. Their commitment to quality, durability, and customer support makes them the ideal partner for anyone looking to establish or expand their agarbatti-making business in Patna.

By investing in an agarbatti-making machine from Arya Industries, manufacturers can ensure they have the tools needed to meet growing market demands while maximizing productivity and profit.

Visit: https://aryaindustries.co/agarbatti-making-machine-in-patna.php

0 notes

Text

How can I launch a business Making agarbatti machines?

Overview of Agarbatti Business

Another name for agarbatti is "incense." It is an aromatic paste or powder that was used as a fumigant in every Indian home. Agarbathie is made in a straightforward and uncomplicated manner. Thus, be aware of the kind of raw material needed to begin producing agarbatti and how to obtain it for manufacturing, etc.

All communities, including those in Sri Lanka, India, Burma, and Indian expatriates, utilise agarbattis. The demand for Incense stick making machine is higher throughout the year, but it is particularly high during holiday seasons. Due to the low degree of technology in this sector, a business producing incense can be launched with modest initial expenditure and basic machinery.

Types of agarbatti

The procedure of creating agarbatti

Manufacturers of agarbatti use machines in their process since they expedite the processing of agarbattis for agarbatti companies. Depending on the demand in the Indian agarbatti making machines, several techniques are used in the producing process.

One well-known home product with significant business potential is agarbatti. The easy steps to make agarbathie in India are as follows.

Step 1: First, you must be aware that agarbatti manufacturing businesses must register as businesses.

Step 2: Secondly, you need to understand what kind of raw material is needed to begin producing agarbatti and how to obtain it for manufacture.

Step 3: Thirdly, you should be aware of the equipment needed for your agarbatti manufacturing firm.

Step 4: Following this, you must understand the agarbatty-making procedure.

Raw material Agarbatti

The second stage in the easy steps to make agarbatti in India is to understand what kind of raw material is needed to begin agarbatti production and how to obtain it for manufacture. Bamboo sticks are the main raw material used in this step to make agarbatti. The materials needed to make agarbatti are as follows:

Wood Incense Powder Jigat Powder Various Essential Oils Nargis Powder with Charcoal Dust Powder Joss

The bamboo sticks must be bought according on your size. With a bamboo stick-making machine, you may also make bamboo sticks for your projects. It is important to select the appropriate formula based on the scent. It is imperative that you pay close attention to the packaging process because, in the agarbatti making industry, a fragrance-look packaging system is required.

Profit for Agarbatti business

The agarbatti business is profitable since it's easy to turn a healthy profit. The profit margin of the Agarbatti business is substantial in relation to its investment; it can yield a monthly turnout of Rs 3 lakh and a gross profit of up to Rs 2 lakh. The number of machines in an agarbatti firm determines its profit margin; having more machines can increase profits. Since India is the world's largest manufacturer of agarbatti, the agarbatti industry is expanding due to the market's enormous potential. 1 kg of agarbatti can cost anywhere from Rs 100 and Rs 500, depending on the brand and quality of the product.

High-Speed Automatic Agarbatti Making Machine: This is the third kind of machinery needed for an agarbatti manufacturing company. These kinds of devices can produce the required results with the least amount of labour involvement. Additionally, the length may be changed from 8" to 12", and one person can operate at least one of the machines at once. There are several varieties of fully automatic, high-speed agarbatti-making equipment available that require less labour to run. You can make between 300 and 400 sticks in a minute. This kind of machine operates autonomously without the need for committed human labour.

Powder Mixer Machine for Agarbatti Making Machine Manufacturer: This piece of equipment is also necessary for businesses that make agarbatti. It can typically combine two different types of powders, both wet and dry, quite effectively. Production capacities typically range from 10 to 20 kg per 10 minutes. To achieve consistent mixing quality with less labour input when launching a large-scale, commercial agarbatti business, you can purchase a blender machine or powder mixer. Shapes, capacities, and sizes are among the variations offered.

0 notes