#flame retardants manufacturers

Explore tagged Tumblr posts

Text

Lifeline Technologies offer Halogenated and non-halogenated Flame Retardant Additive Masterbatch and Compound based on the end application. Contact us for pricing and other details.

0 notes

Text

Top 15 Market Players in Global Halogen-Free Flame Retardants for Electric Vehicles Market

Top 15 Market Players in Global Halogen-Free Flame Retardants for Electric Vehicles Market

The transition to electric vehicles (EVs) has created a booming demand for halogen-free flame retardants to ensure safety and sustainability. The global market features numerous key players driving innovation and addressing the specific needs of EV manufacturers. Below are the top 15 companies in this domain:

Clariant AG Clariant is a pioneer in sustainable solutions, offering advanced halogen-free flame retardants designed for EV components like batteries and cables.

BASF SE BASF stands out with its comprehensive portfolio of eco-friendly flame retardants tailored for EV applications, ensuring high safety standards.

DuPont DuPont leverages its expertise in high-performance materials to produce flame retardants that enhance the safety and durability of EV parts.

Lanxess AG Lanxess is a prominent supplier of halogen-free flame retardants, providing innovative solutions for critical EV components such as battery enclosures and charging systems.

Huntsman Corporation Huntsman focuses on sustainable chemistry, offering non-halogenated flame retardants for EV interior and exterior applications.

ICL Group ICL is a global leader in flame retardant solutions, developing halogen-free options that meet the growing demand for safer EV components.

Solvay Solvay provides advanced flame retardant technologies that are lightweight, durable, and tailored for EV battery packs and structural materials.

Albemarle Corporation Albemarle delivers state-of-the-art halogen-free flame retardants that meet stringent thermal stability and fire safety requirements in EVs.

DSM Engineering Materials DSM is renowned for its sustainable solutions, offering non-halogenated flame retardants for use in EV cables, connectors, and battery systems.

FRX Polymers FRX Polymers specializes in non-halogenated, environmentally friendly flame retardants that enhance the fire safety of EV applications.

Italmatch Chemicals Italmatch provides halogen-free flame retardants designed for high-performance polymers used in electric vehicle manufacturing.

Nabaltec AG Nabaltec offers aluminum-based flame retardants, which are particularly effective in EV battery safety systems.

ADEKA Corporation ADEKA produces halogen-free flame retardants that deliver exceptional fire resistance and thermal stability for EV applications.

Huber Engineered Materials Huber provides sustainable flame retardants for EV components, focusing on reduced smoke emission and environmental impact.

Jiangsu Yoke Technology Co., Ltd. Jiangsu Yoke is a major player in the market, offering halogen-free flame retardants for EV insulation and structural parts.

Request report sample at https://datavagyanik.com/reports/global-halogen-free-flame-retardants-for-electric-vehicles-market-size-production-sales-average-product-price-market-share/

Top Winning Strategies in Halogen-Free Flame Retardants for Electric Vehicles Market

The halogen-free flame retardants market for EVs is highly competitive, with companies adopting innovative strategies to enhance their market presence and cater to the growing demand. Below are the top strategies employed by industry leaders:

Prioritizing R&D for EV-Specific Applications Companies are investing heavily in research and development to create flame retardants that address the unique challenges posed by EV batteries, charging systems, and high-voltage components.

Collaboration with EV Manufacturers Close partnerships with EV manufacturers enable companies to co-develop customized solutions that align with safety and performance requirements.

Focus on Lightweight Materials To support the demand for energy efficiency in EVs, companies are developing lightweight, halogen-free flame retardants that do not compromise fire safety.

Adherence to Regulatory Standards Ensuring compliance with international safety and environmental standards, such as UL94 V-0 and RoHS, is critical for market success.

Expansion into Emerging Markets With rapid growth in EV adoption in Asia-Pacific and Latin America, companies are targeting these regions to capitalize on the increasing demand.

Sustainability as a Core Principle Firms are prioritizing eco-friendly formulations to meet the rising demand for sustainable and non-toxic flame retardants.

Development of Multifunctional Materials Combining flame retardancy with additional properties such as thermal conductivity and electrical insulation provides added value for EV manufacturers.

Strategic Mergers and Acquisitions Leading players are acquiring smaller companies with specialized expertise to expand their portfolios and gain a competitive edge.

Enhancing Manufacturing Capabilities Scaling up production facilities and adopting advanced manufacturing techniques helps meet the growing demand for EV-related flame retardants.

Customizing Solutions for Battery Safety Given the criticality of battery safety in EVs, companies are tailoring flame retardants to ensure superior thermal stability and fire resistance.

Marketing and Branding Initiatives Strong branding and targeted marketing campaigns are helping companies position themselves as leaders in halogen-free flame retardants for EVs.

Digital Tools and Analytics Companies are leveraging digital platforms and predictive analytics to optimize supply chains and better understand customer needs.

Fostering Innovation through Alliances Partnerships with universities, research institutions, and technology providers foster innovation in flame retardant technologies.

Enhancing Product Transparency Providing detailed product information, including lifecycle analysis, reassures customers about the safety and sustainability of flame retardant solutions.

Customer-Centric Approach Engaging directly with EV manufacturers and addressing their pain points ensures a steady demand for customized, high-performance products.

Request a free sample copy at https://datavagyanik.com/reports/global-halogen-free-flame-retardants-for-electric-vehicles-market-size-production-sales-average-product-price-market-share/

#Halogen-Free Flame Retardants for Electric Vehicles Market#Halogen-Free Flame Retardants for Electric Vehicles Production#market players#revenue#average price#top trends#Manufacturing Capabilities

0 notes

Text

Specialized Masterbatches and Compounds for the White Goods Industry!

As a trusted master batch company in India, We listed Our Product Range for White Goods Industry, with Key Benefits of Our Masterbatches. Like, colour masterbatches, Special Effect Masterbatches, Additive Masterbatches, Black Masterbatches, White Masterbatches, etc. Checkout blog now!

#master batch company in India#colour masterbatches#Special Effect Masterbatches#Additive Masterbatches#Black Masterbatches#White Masterbatches#Conductive Masterbatches#Long Glass Fibre Reinforced Compounds#Flame Retardant Compounds#Key Benefits of Our Masterbatches#masterbatch manufacturer in India

0 notes

Text

Electrical Cables Fireproof Coatings services in pune | Ugam Chemicals

For all your fireproofing and heat-resistant coating needs, look no further than Ugam Chemicals, the trusted supplier and manufacturer of high-quality protective coatings in Pune and across India. 🛡️🔥

Our Product Range:

🔹 Electrical Cables Fireproof Coatings suppliers in Pune: Protect your electrical systems with advanced fireproof coatings.

🔹 Flame Retardant Coatings manufacturer in Pune: High-performance coatings to minimize fire risks in industrial and commercial setups.

🔹 Fire Protective Epoxy Intumescent Coatings manufacturer in Pune: Enhance fire resistance for critical structures with durable epoxy solutions.

🔹 Fireproof Vermiculite Coating suppliers in Pune: Ideal for structural fireproofing needs. 🔸 Fireproof Vermiculite Coating services in India: Nationwide application services to ensure optimal fire safety.

Heat-Resistant and Thermal Insulation Paints:

✅ For 100°C: Trusted suppliers in Pune for medium-temperature applications. ✅ For 400°C: High-performance thermal insulation coatings for industrial usage. ✅ For 600°C (EPSI services in Pune): Perfect for extreme conditions in industrial environments. ✅ For 1200°C-WB: Specialized water-based coatings designed for ultra-high temperatures.

Elastomeric Heat Resistant Coatings

Our cutting-edge elastomeric coatings are ideal for a variety of surfaces, combining flexibility and thermal resistance to withstand harsh environments.

Why Choose Ugam Chemicals?

We are known for: ✔️ Top-notch quality products tailored for durability. ✔️ Expertise in fireproofing and heat-resistant coatings. ✔️ Reliable service with nationwide coverage. ✔️ On-time delivery for all your projects.

Whether you're looking for fireproof coatings for cables, heat-resistant paint for high temperatures, or thermal insulation solutions, Ugam Chemicals is your one-stop destination. Visit our website today to learn more! 🌟

📌 #FireproofCoatings #HeatResistantPaint #ThermalInsulationSolutions #UgamChemicals

#Electrical Cables Fireproof Coatings suppliers in pune#Flame Retardant Coatings manufacturer in pune#Fire Protective Epoxy Intumescent Coatings manufacturer in pune#fireproof vermiculite coating suppliers in pune#fireproof vermiculite coating services in india#Heat Resistant & Thermal Insulation Paint For 100 Deg C suppliers in pune#Heat Resistant & Thermal Insulation Paint For 400 Deg C suppliers in pune#Heat Resistant & Thermal Insulation Paint For 600 Deg C EPSI services in pune#Heat Resistant & Thermal Insulation Paint For 1200 Deg C- WB suppliers in pune#Elastomeric Heat Resistant Coatings suppliers in pune.

0 notes

Text

https://vibgyorworkwear.com/the-importance-of-ifr-coveralls-for-safety-in-high-risk-jobs/

#industrial fr coverall#flame resistant safety coveralls#safety coverall ifr#ifr cotton coveralls#fire retardant coverall manufacturer in india#gujarat manufacturer of cotton coveralls#vibgyor workwear#importance of ifr coveralls#protective workwear#arc & flame resistant coveralls#fr coverall#fr inherent coverall

0 notes

Text

Fireproof: Ceresana Publishes New Market Report on Flame Retardants

Practically nothing works without electricity. However, electricity is also the most common cause of fire, ahead of forgotten cigarettes or botched welding jobs. Almost half of all flame retardants are therefore used for cables, electrical engineering, and electronics. Ceresana has investigated the global market for these chemicals, which prevent plastics and other flammable materials from igniting or at least slow down fires. A total of around 2.3 million tonnes of flame retardants are currently used every year: Phosphorus, aluminum (ATH), or antimony (ATO) compounds, brominated and chlorinated flame retardants, increasingly also bio-based additives.

Further information on the new, already 8th edition of the market study “Flame Retardants – World Report”: https://ceresana.com/en/produkt/flame-retardants-market-report

#flame retardants#additives#chemcials#fire protection#manufacturers#producers#markets#plastics#market size#market study#market data

0 notes

Text

High-quality Flame Retardant Coveralls Manufacturers for complete Protection

Our world class flame retardant coveralls manufacturers offer the superior quality and comfortable coveralls. Our coveralls, made for experts working in hazardous settings, provide unmatched protection from heat and fire.

0 notes

Text

#Flame Retardant Manufacturers in India#Flame Retardant Manufacturers#Fire Retardant Chemical Manufacturer#Flame Retardant Chemical Manufacturer

0 notes

Link

Boiler insulation materials are mainly used for boiler shells and insulation layers to improve the thermal efficiency of the boiler and reduce energy consumption. Thermal insulation materials can effectively reduce the energy loss and heat loss of the boiler, improve the thermal efficiency of the boiler, reduce energy consumption, and are of great significance to environmental protection and resource utilization.

#thermal insulation materials#Melamine foam#thermal insulation#boiler thermal insulation#sound absorption#flame retardant#melamine foam manufacturer#basotect foam supplier

0 notes

Text

The Key Role of an FR Fabric Supplier in Ensuring Safety and Compliance

FR Levitex

In the realm of safety-conscious industries, the significance of flame-resistant (FR) fabrics cannot be overstated. These specialized textiles play a vital role in protecting workers from potential fire hazards, making them an indispensable component of personal protective equipment (PPE). At the heart of this safety-driven endeavor is the FR fabric supplier, whose expertise and commitment are pivotal in ensuring the well-being of workers and compliance with safety regulations.

What is an FR Fabric Supplier?

An FR fabric supplier is a crucial link in the chain that connects manufacturers, employers, and end-users in industries where exposure to flames or intense heat is a constant concern. These suppliers are responsible for providing high-quality, durable, and certified flame-resistant fabrics that meet stringent safety standards. Their role extends beyond mere material provision; they are partners in safeguarding lives and fostering a culture of safety.

Ensuring Compliance and Quality

Compliance with industry regulations and standards is paramount when it comes to FR fabrics. An experienced supplier understands the intricate requirements set forth by organizations such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA). From selecting the appropriate materials to adhering to manufacturing processes that guarantee the fabric's flame-resistant properties, these suppliers ensure that their products meet or exceed the necessary benchmarks.

Expertise in Material Selection

The choice of materials is a critical aspect of FR fabric manufacturing. A reputable supplier possesses an in-depth understanding of the characteristics of various fibers, blends, and treatments that contribute to flame resistance. They leverage this knowledge to recommend fabrics that align with the specific needs of different industries, whether it's oil and gas, manufacturing, or firefighting.

Customization for Varied Applications

No two industries are exactly alike, and neither are their safety requirements. An accomplished FR fabric supplier recognizes this and offers customization options to cater to diverse applications. Whether it's designing fabrics with enhanced breathability for hot environments or incorporating additional protective properties, such as arc flash resistance, these suppliers tailor their offerings to suit the unique demands of each sector.

Collaboration and Education

Beyond supplying FR fabrics, a dedicated supplier acts as a partner in education and collaboration. They engage with manufacturers and end-users to provide insights into proper garment construction, care, and usage. Training programs and seminars offered by suppliers empower workers to make informed decisions about their safety, fostering a culture of awareness and responsibility.

Research and Innovation

In a rapidly evolving world, innovation is a driving force behind safety enhancements. Accomplished FR fabric suppliers invest in research and development to push the boundaries of flame-resistant technology. From advanced fabric treatments that enhance durability to exploring sustainable materials, these suppliers are at the forefront of ensuring that FR fabrics remain effective, efficient, and environmentally responsible.

Conclusion

The role of an FR fabric supplier transcends that of a mere vendor; it is a pivotal partnership that safeguards lives and promotes safety. By adhering to stringent regulations, providing high-quality materials, and fostering collaboration, these suppliers play a central role in ensuring that workers across various industries are adequately protected from potential fire hazards. As technology and safety standards continue to advance, the contributions of FR fabric suppliers remain essential in upholding the highest standards of workplace safety and well-being.

#flame retardant fabric#LEVITEX flame resistant fabric#LEVITEX fr fabric#fr fabric manufacturer#fr fabric supplier#LEVITEX

0 notes

Link

#Flame Retardant Wires Manufacturers#Fire Retardant House Wire In India#Fire Retardant House Wires#Best House Wires Suppliers In India#Best Electrical Wires For House Wiring#House Wires Manufacturers

0 notes

Text

When we set off on a car ride, we might not think about the chances of an accident, or any other risks – including the potentially dangerous materials that researchers have found in 99 percent of cabins tested in vehicles manufactured in the US since 2015. These materials are fitted to meet flame retardant safety standards, but according to the US and Canadian team behind the new study, their inclusion may be causing more harm than good. They're now asking for a rethink on the inclusion of these substances. "Our research found that interior materials release harmful chemicals into the cabin air of our cars," says environmental scientist Rebecca Hoehn from Duke University. "Considering the average driver spends about an hour in the car every day, this is a significant public health issue."

Continue Reading.

#Science#Health#Biology#Enviromental Science#Flame Retardants#Cars#Cancer#TCIPP#Tris (1-Chloro-Isopropyl) Phosphate

88 notes

·

View notes

Text

The phone or computer you’re reading this on may not be long for this world. Maybe you’ll drop it in water, or your dog will make a chew toy of it, or it’ll reach obsolescence. If you can’t repair it and have to discard it, the device will become e-waste, joining an alarmingly large mountain of defunct TVs, refrigerators, washing machines, cameras, routers, electric toothbrushes, headphones. This is “electrical and electronic equipment,” aka EEE—anything with a plug or battery. It’s increasingly out of control.

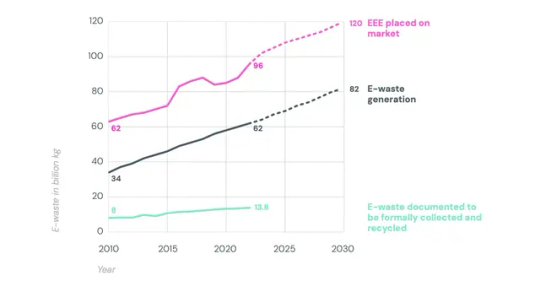

As economies develop and the consumerist lifestyle spreads around the world, e-waste has turned into a full-blown environmental crisis. People living in high-income countries own, on average, 109 EEE devices per capita, while those in low-income nations have just four. A new UN report finds that in 2022, humanity churned out 137 billion pounds of e-waste—more than 17 pounds for every person on Earth—and recycled less than a quarter of it.

That also represents about $62 billion worth of recoverable materials, like iron, copper, and gold, hitting e-waste landfills each year. At this pace, e-waste will grow by 33 percent by 2030, while the recycling rate could decline to 20 percent. (You can see this growth in the graph below: purple is EEE on the market, black is e-waste, and green is what gets recycled.)

“What was really alarming to me is that the speed at which this is growing is much quicker than the speed that e-waste is properly collected and recycled,” says Kees Baldé, a senior scientific specialist at the United Nations Institute for Training and Research and lead author of the report. “We just consume way too much, and we dispose of things way too quickly. We buy things we may not even need, because it's just very cheap. And also these products are not designed to be repaired.”

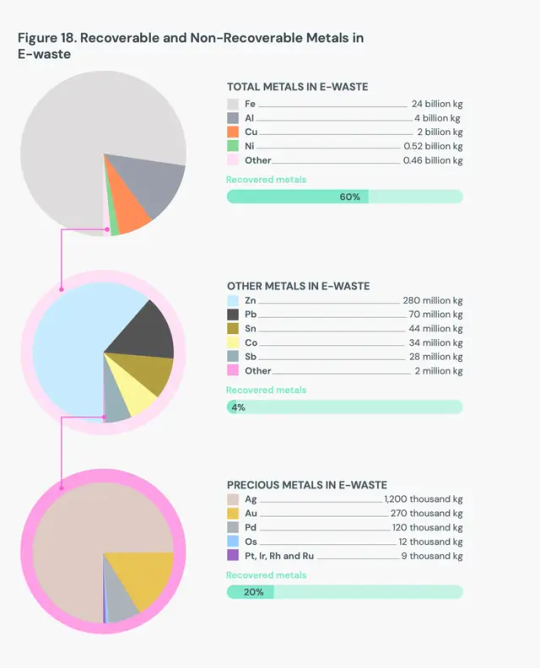

Humanity has to quickly bump up those recycling rates, the report stresses. In the first pie chart below, you can see the significant amount of metals we could be saving, mostly iron (chemical symbol Fe, in light gray), along with aluminum (Al, in dark gray), copper (Cu), and nickel (Ni). Other EEE metals include zinc, tin, and antimony. Overall, the report found that in 2022, generated e-waste contained 68 billion pounds of metal.

E-waste is a complex thing to break down: A washing machine is made of totally different components than a TV. And even for product categories, not only do different brands use different manufacturing processes, but even different models within those brands vary significantly. A new washing machine has way more sensors and other electronics than one built 30 years ago.

Complicating matters even further, e-waste can contain hazardous materials, like cobalt, flame retardants, and lead. The report found that each year, improperly processed e-waste releases more than 125,000 pounds of mercury alone, imperiling the health of humans and other animals. “Electronic waste is an extremely complex waste stream,” says Vanessa Gray, head of the Environment and Emergency Telecommunications Division at the UN’s International Telecommunication Union and an author of the report. “You have a lot of value in electronic waste, but you also have a lot of toxic materials that are dangerous to the environment.”

That makes recycling e-waste a dangerous occupation. In low- and middle-income countries, informal e-waste recyclers might go door-to-door collecting the stuff. To extract valuable metals, they melt down components without proper safety equipment, poisoning themselves and the environment. The new report notes that in total, 7.3 billion pounds of e-waste is shipped uncontrolled globally, meaning its ultimate management is unknown and likely not done in an environmentally friendly way. Of that, high-income countries shipped 1.8 billion pounds to low- and middle-income countries in 2022, swamping them with dangerous materials.

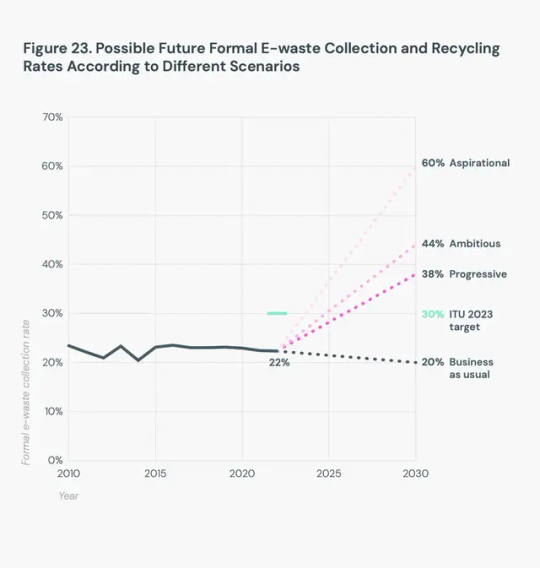

High-income countries have some of this informal recycling, but they also have formal facilities where e-waste is sorted and safely broken down. Europe, for example, has fairly high formal e-waste recycling rates, at about 43 percent. But globally, recycling is happening nowhere near enough to keep up with the year-over-year growth of the waste. Instead of properly mining EEE for metals, humanity keeps mining more ore out of the ground.

Still, the report found that even the small amount of e-waste that currently gets recycled avoided the mining of 2 trillion pounds of ore for virgin metal in 2022. (It takes a lot of ore to produce a little bit of metal.) The more metals we can recycle from e-waste, the less mining we’ll need to support the proliferation of gadgets. That would in turn avoid the greenhouse gases from such mining operations, plus losses of biodiversity.

The complexity of e-waste, though, makes it expensive to process. As the chart above shows, even an ambitious scenario of a formal e-waste collection rate in 2030 is 44 percent. “There is no business case for companies to just collect e-waste and to make a profit out of this in a sustainable manner,” says Baldé. “They can only survive if there is legislation in place which is also compensating them.”

The report notes that 81 countries have e-waste policies on the books, and of those, 67 have provisions regarding extended producer responsibility, or EPR. This involves fees paid by manufacturers of EEE that would go toward e-waste management.

Of course, people could also stop throwing so many devices away in the first place, something right-to-repair advocates have spent years fighting for. Batteries, for instance, lose capacity after a certain number of charge cycles. If a phone can’t hold a charge all day anymore, customers should be able to swap in a new battery. “Manufacturers shouldn't be able to put artificial limitations on that ability,” says Elizabeth Chamberlain, director of sustainability at iFixit, which provides repair guides and tools. That includes limiting access to parts and documentation. “Repair is a harm-reduction strategy. It's not the be-all-end-all solution, but it's one of many things we need to do as a global society to slow down the rate at which we're demanding things of the planet.”

At the core of the e-waste crisis is the demand: A growing human population needs phones to communicate and fridges to keep food safe and heat pumps to stay comfortable indoors. So first and foremost we need high-quality products that don’t immediately break down, but also the right to repair when they do. And what absolutely can’t be fixed needs to move through a safe, robust e-waste recycling system. “We are consuming so much,” says Baldé, “we cannot really recycle our way out of the problem.”

26 notes

·

View notes

Text

#Electrical Cables Fireproof Coatings suppliers in pune#Flame Retardant Coatings manufacturer in pune#Fire Protective Epoxy Intumescent Coatings manufacturer in pune#fireproof vermiculite coating suppliers in pune#fireproof vermiculite coating services in india#Heat Resistant & Thermal Insulation Paint For 100 Deg C suppliers in pune#Heat Resistant & Thermal Insulation Paint For 400 Deg C suppliers in pune#Heat Resistant & Thermal Insulation Paint For 600 Deg C EPSI services in pune#Heat Resistant & Thermal Insulation Paint For 1200 Deg C- WB suppliers in pune#Elastomeric Heat Resistant Coatings suppliers in pune.

0 notes

Text

https://vibgyorworkwear.com/ifr-winter-coveralls-tips-for-longevity/

#vibgyor workwear#industrial fr coverall#ifr cotton coverall#ifr winter coveralls#gujarat manufacturer of cotton coveralls#safety coverall ifr#ifr cotton coveralls#flame resistant safety coveralls#fire retardant coverall manufacturer in india#winter coveralls tips#fr coveral

0 notes

Text

A novel flame-retardant, smoke-suppressing and superhydrophobic transparent bamboo for future glasses

Professors Yiqiang Wu and Caichao Wan, along with their team from Central South University of Forestry and Technology (CSUFT), have pioneered a transparent material derived from natural bamboo. This material features a three-layered flame-retardant barrier, effectively reducing heat release, slowing flame spread, and restraining the emission of combustible volatiles, toxic smoke, and CO. Their findings have been documented in the journal Research. Silica glass, a widely used transparent material in the construction industry, has seen increased adoption as an essential building material over the past 50 years. Its versatility is reflected in the global glass production reaching approximately 130 million tons in 2020. According to C. Wan, a full professor at the College of Materials Science and Engineering at CSUFT and a corresponding author of the paper, "Despite its numerous advantages such as high transparency and the availability of raw materials, traditional silica glass still grapples with challenges including brittleness, high density, and substantial CO2 emissions and greenhouse gases during the manufacturing process."

Read more.

#Materials Science#Science#Flame retardants#Flames#Bamboo#Plants#Biomaterials#Superhydrophobic#Glass#Silica#Transparency

16 notes

·

View notes