#Fire Retardant Chemical Manufacturer

Explore tagged Tumblr posts

Text

#Flame Retardant Manufacturers in India#Flame Retardant Manufacturers#Fire Retardant Chemical Manufacturer#Flame Retardant Chemical Manufacturer

0 notes

Text

🔥 Ugam Chemicals: Leading Fire Retardant Paint Manufacturer & Supplier in Pune, India! 🔥

Looking for top-quality fire retardant paints that offer maximum protection? Ugam Chemicals provides the best-in-class fire retardant services, trusted by industries across Pune and India. Whether it's for cables or walls, our fire retardant paints are designed to prevent fire from spreading, keeping your assets safe! 🚨

🌐 https://ugamchemicals.com/fire-retardant-paint.html

Key Features of Ugam Chemicals’ Fire Retardant Paints:

Fire Retardant Paints for Cables: Protect your electrical cables with our advanced formulations, designed to resist and contain fire in high-risk environments. 🔌

Fire Retardant Paints for Walls: Ensure the structural integrity of your building’s walls with fireproof coatings that prevent fire from spreading. 🏢

Why Choose Ugam Chemicals? ✔️ We are a trusted manufacturer and supplier of fire retardant paints across Pune and India. ✔️ Our paints meet stringent safety standards and offer long-lasting fire protection. ✔️ Tailored solutions for various applications, from industrial to commercial settings.

Our fire retardant solutions are perfect for any setting where fire safety is a priority. Whether it’s safeguarding electrical systems or fortifying walls, Ugam Chemicals has got you covered. We’re committed to delivering the best fire retardant services to protect lives and assets.

👉 Learn more about our products: https://ugamchemicals.com/fire-retardant-paint.html

#FireRetardantPaint #FireSafety #Fireproofing #IndustrialSafety #CableProtection #WallProtection #Pune #India #FireProtection #UgamChemicals #FireRetardantServices #IndustrialCoatings

#Ugam chemicals#offers best fire retardant services#a manufacturer & supplier in Pune#India. Paints for Cables and for walls that are Fire Retardant.

0 notes

Text

Wearing synthetic clothing sustainably

I have seen a lot of discussion on the Internet about the environmental impact of natural fibers and synthetic fibers used to make clothing. Synthetic fabrics are made from oil, just like plastic is. According to the attached article, “Petrochemical-based synthetics make up 65% of all fibers produced annually, with polyester by far the most widely used synthetic fabric. Despite the serious environmental impacts of cotton production, a T-shirt made from cotton produces 2.1 kg CO2-eqemissions while a polyester T-shirt emits an estimated 5.5 kg CO2-eq.” Synthetic fabrics also contribute to plastic pollution. Washing clothes breaks off microfibers that contribute to microplastic contamination in waterways. Coatings on fibers or clothing contribute to pollution when they wash off and some are made with chemicals that are harmful to us and the planet.

However, sometimes you need the qualities produced by synthetic fabrics and the treatments/coatings applied to the fabric, such as waterproofing. Here are some ideas on how to reduce the environmental impact of clothing made with synthetic fibers.

Buy clothing made from recycled materials when possible. Several manufacturers have begun making clothing using some recycled materials, so look for them.

When evaluating clothing ,whether new or made from recycled materials, look for textile certifications such as Bluesign and Oeko-Tex, which indicate that a product was made with only safer materials and treatments.

You can reduce microfiber pollution by using cooler, faster laundry cycles. Hanging clothes to dry reduces microfiber pollution and also saves energy.

Research microfiber filters that can be installed on your washing machine to capture the microfibers.

Purchase fewer clothing items of higher quality and maintain them carefully. Read the laundering instructions on the label inside the item of clothing. Some clothing requires special detergents or laundry cycles to maintain their waterproof or fire-retardant properties. Clothing that is properly maintained will last much longer, hopefully leading to fewer resources being used to make new clothing.

14 notes

·

View notes

Text

For two decades, researchers worked to solve a mystery in West Coast streams. Why, when it rained, were large numbers of spawning coho salmon dying? As part of an effort to find out, scientists placed fish in water that contained particles of new and old tires. The salmon died, and the researchers then began testing the hundreds of chemicals that had leached into the water.

A 2020 paper revealed the cause of mortality: a chemical called 6PPD that is added to tires to prevent their cracking and degradation. When 6PPD, which occurs in tire dust, is exposed to ground-level ozone, it’s transformed into multiple other chemicals, including 6PPD-quinone, or 6PPD-q. The compound is acutely toxic to four of 11 tested fish species, including coho salmon.

Mystery solved, but not the problem, for the chemical continues to be used by all major tire manufacturers and is found on roads and in waterways around the world. Though no one has studied the impact of 6PPD-q on human health, it’s also been detected in the urine of children, adults, and pregnant women in South China. The pathways and significance of that contamination are, so far, unknown.

Still, there are now calls for regulatory action. Last month, the legal nonprofit Earthjustice, on behalf of the fishing industry, filed a notice of intent to sue tire manufacturers for violating the Endangered Species Act by using 6PPD. And a coalition of Indian tribes recently called on the EPA to ban use of the chemical. “We have witnessed firsthand the devastation to the salmon species we have always relied upon to nourish our people,” the Puyallup Tribal Council said in a statement. “We have watched as the species have declined to the point of almost certain extinction if nothing is done to protect them.”

The painstaking parsing of 6PPD and 6PPD-q was just the beginning of a global campaign to understand the toxic cocktail of organic chemicals, tiny particles, and heavy metals hiding in tires and, to a lesser extent, brakes. While the acute toxicity of 6PPD-q and its source have strong scientific consensus, tire rubber contains more than 400 chemicals and compounds, many of them carcinogenic, and research is only beginning to show how widespread the problems from tire dust may be.

While the rubber rings beneath your car may seem benign — one advertising campaign used to feature babies cradled in tires — they are, experts say, a significant source of air, soil, and water pollution that may affect humans as well as fish, wildlife, and other organisms. That’s a problem because some 2 billion tires globally are sold each year — enough to reach the moon if stacked on their sides — with the market expected to reach 3.4 billion a year by 2030.

(Researchers weigh a salmon that died after four hours in a tank filled with road runoff.)

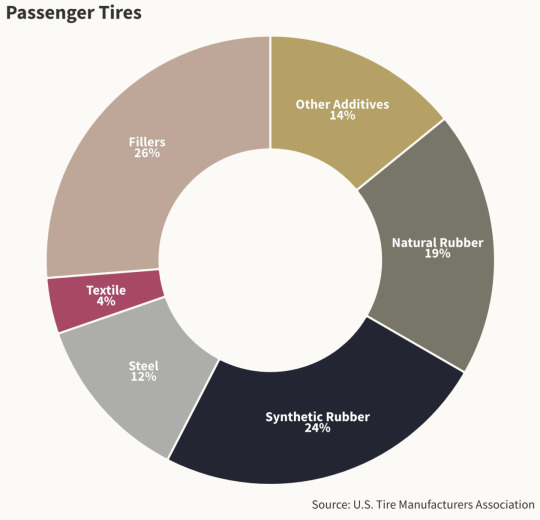

Tires are made from about 20 percent natural rubber and 24 percent synthetic rubber, which requires five gallons of petroleum per tire. Hundreds of other ingredients, including steel, fillers, and heavy metals — including copper, cadmium, lead, and zinc — make up the rest, many of them added to enhance performance, improve durability, and reduce the possibility of fires.

Both natural and synthetic rubber break down in the environment, but synthetic fragments last a lot longer. Seventy-eight percent of ocean microplastics are synthetic tire rubber, according to a report by the Pew Charitable Trust. These fragments are ingested by marine animals — particles have been found in gills and stomachs — and can cause a range of effects, from neurotoxicity to growth retardation and behavioral abnormalities.

“We found extremely high levels of microplastics in our stormwater,” said Rebecca Sutton, an environmental scientist with the San Francisco Estuary Institute who studied runoff. “Our estimated annual discharge of microplastics into San Francisco Bay from stormwater was 7 trillion particles, and half of that was suspected tire particles.”

Tire wear particles, or TWP as they are sometimes known, are emitted continually as vehicles travel. They range in size from visible pieces of rubber or plastic to microparticles, and they comprise one of the products’ most significant environmental impacts, according to the British firm Emissions Analytics, which has spent three years studying tire emissions. The company found that a car’s four tires collectively emit 1 trillion ultrafine particles — of less than 100 nanometers — per kilometer driven. These particles, a growing number of experts say, pose a unique health risk: They are so small they can pass through lung tissue into the bloodstream and cross the blood-brain barrier or be breathed in and travel directly to the brain, causing a range of problems.

According to a recent report issued by researchers at Imperial College London, “There is emerging evidence that tyre wear particles and other particulate matter may contribute to a range of negative health impacts including heart, lung, developmental, reproductive, and cancer outcomes.”

The report says that tires generate 6 million tons of particles a year, globally, of which 200,000 tons end up in oceans. According to Emissions Analytics, cars in the U.S. emit, on average, 5 pounds of tire particles a year, while cars in Europe, where fewer miles are driven, shed 2.5 pounds per year. Moreover, tire emissions from electric vehicles are 20 percent higher than those from fossil-fuel vehicles. EVs weigh more and have greater torque, which wears out tires faster.

Unlike tailpipe exhaust, which has long been studied and regulated, emissions from tires and brakes — which emit significant amounts of metallic particles in addition to organic chemicals — are far harder to measure and control and have therefore escaped regulation. It’s only in the last several years, with the development of new technologies capable of measuring tire emissions and the alarming discovery of 6PPD-q, that the subject is receiving much needed scrutiny.

Recent studies show that the mass of PM 2.5 and PM 10 emissions — which are, along with ozone and ultrafine particles, the world’s primary air pollutants — from tires and brakes far exceeds the mass of emissions from tailpipes, at least in places that have significantly reduced those emissions.

The problem isn’t just rubber in its synthetic and natural form. Government and academic researchers are investigating the transformations produced by tires’ many other ingredients, which could — like 6PPD — form substances more toxic than their parent chemicals as they break down with exposure to sunlight and rain.

“You’ve got a chemical cocktail in these tires that no one really understands and is kept highly confidential by the tire manufacturers,” said Nick Molden, the CEO of Emissions Analytics. “We struggle to think of another consumer product that is so prevalent in the world, and used by virtually everyone, where there is so little known of what is in them.”

“We have known that tires contribute significantly to environmental pollution, but only recently have we begun to uncover the extent of that,” said Cassandra Johannessen, a researcher at Montreal’s Concordia University who is quantifying levels of tire chemicals in urban watersheds and studying how they transform in the environment. The discovery of 6PPD-q has surprised a lot of researchers, she said, because they have learned that “it’s one of the most toxic substances known, and it seems to be everywhere in the world.”

Regulators are playing catch up. In Europe, a standard to be implemented in 2025, known as Euro 7, will regulate not only tailpipe emissions but also emissions from tires and brakes. The California Environmental Protection Agency has passed a rule requiring tire makers to declare an alternative to 6PPD-q by 2024.

(A worker takes apart a tire at a recycling shop in Mit al-Harun, Egypt.)

Tire companies are conducting their own studies of 6PPD, which they have long considered critical for tire safety, and seeking alternatives. In response to new regulations and the emerging research on tire emissions, 10 of the world’s large tire manufacturers have formed the Tire Industry Project to “develop a holistic approach to better understand and promote action on the mitigation” of tire pollution, according to a statement by the project. The group has committed to search for ways to redesign tires to reduce or eliminate emissions.

One critical area of research is how long tire waste, and its breakdown products, persist in the environment. “A five-micron piece of rubber shears off the tire and settles on the soil and sits there a while,” said Molden. “What, over time, is the release of those chemicals, how quickly do they make their way into the water, and are they diluted? At the system level, how big of a problem is this? It is the single biggest knowledge gap.”

Another area of research centers on the impacts of aromatic hydrocarbons — including benzene and naphthalene — off-gassed by synthetic rubber or emitted when discarded tires are burned in incinerators for energy recovery. Even at low concentrations, these compounds are toxic to humans. They also react with sunlight to form ozone, or ground-level smog, which causes respiratory harm. “We have shown that the amount of off-gassing volatile organic compounds is 100 times greater than that coming out of a modern tailpipe,” said Molden. “This is from the tire just sitting there.”

When tires reach their end of life, they’re either sent to landfills, incinerated, burned in an energy-intensive process called pyrolysis, or shredded and repurposed for use in artificial turf or in playgrounds or for other surfaces. But as concern about tire pollutants grows, so do concerns about these recycled products and the hydrocarbons they may off-gas. There is ongoing debate over whether crumb rubber, made from tire scraps, poses a health threat when used to fill gaps in artificial turf. Based on several peer-reviewed studies, the European Union is instituting stricter limits on the use of this material. Other studies, however, have shown no health impact.

Besides California’s requirement to study alternatives to 6PPD, there are a number of efforts worldwide to redesign tires to counter the problems they pose. More than a decade ago, tire makers hoped that dandelions, which produce a form of rubber, and soy oil could provide a steady and sustainable supply of rubber. But tires made from those alternatives didn’t live up to expectations: they still required additives. The Continental Tire Company, based in Hanover, Germany, markets a bicycle tire made of dandelion roots. Tested by Emission Analytics, it emitted 25 percent fewer carcinogenic aromatics than conventionally made bike tires, but the plant-powered tire still contained ingredients of concern.

(Rubber made from dandelions.)

Other companies are searching for ways to address the problem of tire emissions. The Tyre Collective, a clean-tech startup based in the U.K., has developed an electrostatic plate that affixes to each of a car’s tires: The plates remove up to 60 percent of particles emitted by both tires and brakes, storing them in a cartridge attached to the device. The particles can be reused in numerous other applications, including in new tires.

In San Francisco, scientists studying the pollutants in storm runoff found a potential solution: Rain gardens, installed in yards to capture stormwater, were also trapping 96 percent of street litter and 100 percent of black rubbery fragments. In Vancouver, B.C. researchers found that rain gardens could prevent more than 90 percent of 6PPD-q from running off roads and entering salmon-bearing streams.

Tire waste particles, says Molden, of Emissions Analytics, are finally getting the attention they deserve, thanks in part to California’s rule requiring a search for alternatives to 6PPD. The legislation “is groundbreaking,” he says, “because it puts the chemical composition [of tires] on the regulatory agenda.” For the first time, he adds, “Tire manufacturers are being exposed to the same regulatory scrutiny that car manufacturers have been for 50 years.”

8 notes

·

View notes

Text

The Ultimate Lab Coat Buying Guide for Scientists

Past a garment, a sterile jacket fills in as a utilitarian device, a sign of impressive skill, and a boundary against expected risks. Choosing the right lab coat involves considering several factors to ensure it meets your needs in the lab. Here's the ultimate guide to buying the perfect lab coat for scientists.

1. Material Matters

The material of your lab coat significantly affects its functionality and comfort. Common materials include:

Cotton: Breathable and comfortable but can absorb chemicals and stains easily.

Polyester-Cotton Blends: Durable, resistant to wrinkles and shrinkage, and offers a balance between comfort and protection.

Polyester: Highly durable and resistant to chemicals but less breathable.

Consider your working environment when choosing the material. Fire-safe materials, like Nomex, are critical for research centers working with flammable mixtures.

2. Safety Features

Safety is paramount in a lab setting. Look for lab coats with the following features:

Flame Resistance: Crucial for handling flammable materials. Flame-resistant lab coats are made from special fabrics that self-extinguish when exposed to fire.

Chemical Resistance: Coats treated with chemical-resistant finishes offer protection against spills and splashes.

Length: A longer coat provides more coverage, protecting more of your body and clothing.

Cuffs: Knit or elastic cuffs keep sleeves in place firmly and stop them from dragging through potentially dangerous materials.

3. Fit and Comfort

A lab coat should be comfortable for long hours of wear:

Size: Ensure the lab coat fits well without being too tight or too loose. A properly fitting coat allows for easy movement and layering over regular clothing.

Sleeve Length: Sleeves should cover your wrists when your arms are extended but not be so long that they become a hazard.

Breathability: In a warm lab environment, breathable materials prevent overheating and discomfort.

4. Functional Design

The design of a lab coat can enhance its utility:

Pockets: Ample, well-placed pockets are essential for carrying tools, pens, notebooks, and other necessities.

Closure Type: Snap buttons rush to open and close, making them ideal for crises, while customary buttons offer a safer fit.

Back Vent: A vented back can improve ventilation and ease of movement.

5. Professional Appearance

While functionality is key, appearance matters too. A clean, well-fitted lab coat contributes to a professional image:

Color: While white is traditional, other colors like blue or green can be used to designate different departments or levels of contamination risk.

Customization: Adding your name, title, or the institution’s logo can enhance professionalism and prevent mix-ups.

6. Budget Considerations

Investing in a high-quality lab coat can save money in the long run by lasting longer and providing better protection. However, consider your budget and look for coats that offer the best value for your needs.

7. Special Considerations for Different Fields

Different scientific fields have specific requirements for lab coats:

Chemistry Labs: Phenomenal fire retardancy and compound opposition are required.

Biological Labs: Great boundary characteristics are expected for sterile garments to make preparations for organic dangers.

Physics Labs: Often require lab coats that are static-resistant.

8. Care and Maintenance

Proper care extends the life of your lab coat:

Washing Instructions: Follow the manufacturer’s guidelines. Some coats require special cleaning methods to maintain their protective properties.

Regular Inspection: Check regularly for wear and tear, especially in high-risk areas like sleeves and closures.

Conclusion

Choosing the right lab coats involves balancing safety, comfort, functionality, and appearance. By considering the specific needs of your work environment and your personal preferences, you can find a lab coat that not only keeps you safe but also enhances your professional image. Remember, a well-chosen lab coat is an investment in your safety and efficiency in the lab.

2 notes

·

View notes

Video

youtube

For better health and sleeping comfort, go natural Latex mattresses and Sleep Number bed

Latex mattresses are an excellent choice for allergy sufferers. Latex actually contains ingredients known to repel dust mites. Therefore, latex mattresses are guaranteed to remain dust-free at all times. The Comforters bed is just like the Sleep Number learn more bed in many ways. They both use air as the main supporting feature - instead of innersprings, water, memory foam, etc.

As well,For better health and sleeping comfort, go natural Latex mattresses and Sleep Number bed Articles other potential allergens are not able to attach themselves to a latex mattress. Your latex mattress will remain earth and allergy free by simply following a basic cleaning routine. This is a major advantage over synthetic mattresses, which are known to harbor dust and other allergens.

Latex has the unique quality of proving your body with the perfect amount of support and firmness, without being too soft or too hard. If you have never slept on a latex mattress, you will be surprised to see how comfortable it is.

Another benefit of latex is a result of the airy nature of the organic material from which it is made. An important characteristic of latex is its ability to breathe freely. It therefore maintains a proper temperature throughout all seasons. Latex mattresses are noted and appreciated for their ability to stay warm in the winter and cool in the summer.

Latex mattresses are an excellent choice no matter how you look at your mattress purchasing decision. What better solution than to purchase an organic mattress that is comfortable, dust and allergen free and also is manufactured in an environmentally responsible manner.

In addition to lowering cost, mattress manufacturers using blended latex often feel that it adds a plus by combining the elasticity of natural latex with the consistent quality and durability of synthetic latex.

Most higher-quality latex mattresses use pure latex. The same consideration for materials used in the choice of latex for your mattress should also be applied when considering mattress covers. Mattress covers that are fire-retardant as a result of fire-resistant fibers are far superior to covers with topically applied fire-retardants, which often use toxic chemicals.

2 notes

·

View notes

Text

Firefighting Foam Market is Estimated To Witness High Growth Owing To Stringent Safety Regulations

The global Firefighting Foam Market is estimated to be valued at US$ 7.31 billion in 2023 and is expected to exhibit a CAGR of 5.9% over the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights. Market Overview: Firefighting foam is a specialized product used for extinguishing flammable liquid fires. It is highly effective in suppressing fires by forming a thick blanket over the fire, thus preventing oxygen from reaching the fuel and cooling the flames. Firefighting foam offers several advantages such as quick extinguishing capabilities, improved fire retardation, and reduced re-ignition. The increasing need for effective and efficient fire control methods, along with the stringent safety regulations imposed by various government agencies, are driving the demand for firefighting foam in the market. Market Key Trends: One key trend in the firefighting foam market is the growing adoption of environmentally friendly foam solutions. With increasing concerns regarding the environmental impact of firefighting foam, manufacturers are focusing on developing environmentally sustainable foam solutions.

These environmentally friendly foams are biodegradable and possess low toxicity, reducing the potential harm caused to the environment during firefighting activities. This trend is driven by the rising awareness among end-users and government regulations promoting the use of eco-friendly firefighting products. Overall, the global firefighting foam market is expected to witness significant growth due to the increased emphasis on fire safety and the growing demand for environmentally friendly foam solutions. PEST Analysis: Political: The political factors impacting the firefighting foam market include regulations and policies related to fire safety and environmental protection. Governments around the world are increasingly implementing stringent regulations to restrict the use of firefighting foams containing harmful chemicals like PFAS. This has led to the development and adoption of eco-friendly and more sustainable alternatives. Economic: The economic factors affecting the market include the overall economic growth and investments in infrastructure development.

As economies grow, there is an increased demand for fire safety measures and firefighting equipment, including foams. Investments in industries such as oil and gas, aerospace, and construction also contribute to the demand for firefighting foams. Social: The social factors influencing the market include the awareness and concern for fire safety among individuals and organizations. With the increasing number of fire incidents and the potential risks associated with them, there is a greater emphasis on implementing effective firefighting measures. The demand for firefighting foams is driven by the need to protect lives and minimize property damage. Technological: The technological factors impacting the market include advancements in foam formulation and delivery systems. Manufacturers are constantly developing innovative products that are more efficient in suppressing fires. These advancements include the development of fluorine-free foams, improved foam stability, and better compatibility with various fire hazards.

Key Takeaways: The global Firefighting Foam Market Share is expected to witness high growth, exhibiting a CAGR of 5.9% over the forecast period (2023-2030). This growth is driven by several factors, including increasing regulations and policies focused on fire safety and the environment. The shift towards eco-friendly foams is expected to boost market demand. In terms of regional analysis, North America is expected to be the fastest-growing and dominating region in the firefighting foam market. This can be attributed to the stringent regulations in the region, the presence of major key players, and increased awareness and investment in fire safety measures. Key players operating.

1 note

·

View note

Text

Durable, Efficient PVC Conveyor Belts by Arrowcon Conveyors Unlimited

Why Choose Arrowcon Conveyors Unlimited?

With years of expertise in the conveyor industry, Arrowcon Conveyors Unlimited is committed to providing high-quality PVC conveyor belts tailored to meet industry standards. Our belts are manufactured in our Noida-based facility using the latest technology to ensure durability and efficiency.

1. Custom Solutions – We offer customized belt sizes, textures, and coatings to match your specific needs.

2. High-Quality Standards – Our PVC conveyor belts undergo strict quality checks to ensure reliability.

3. Competitive Pricing – Get the best quality at affordable prices.

4. Expert Support – Our team of experts is always ready to assist you with the right conveyor belt solutions.

Maintenance Tips for PVC Conveyor Belts

To increase the lifespan and efficiency of PVC conveyor belts, follow these maintenance tips:

1. Regular Cleaning – Clean the belts regularly to avoid debris, dust, and food particles.

2. Proper Tensioning – Avoid applying too much tension to prevent early wear.

3. Check for Wear & Tear – Always check the belt to make sure it is not broken anywhere.

4. Lubricate Moving Parts – Ensure smooth operation with appropriate lubrication.

5. Use the Right Belt for the Application – Use suitable belts for every task.

How to choose the Right PVC Conveyor Belt?

Choosing the right PVC conveyor belt depends on factors such as:

1. Load Capacity – The loading capacity of PVC conveyor belt is high enough to handle the industry operations.

2. Operating Environment – Consider temperature, humidity, and chemical exposure.

3. Surface Texture – Always select the smooth or patterned belts on the basis of application needs.

4. Industry Requirements – Ensure compliance with safety and hygiene standards.

5. Belt Thickness & Strength – Choose the belt according to the load and the industry operations.

Applications of PVC Conveyor Belts

At Arrowcon Conveyors Unlimited, we supply PVC conveyor belts for various industries, including:

1. Food Industry – Used for transporting bakery products, dairy items, and packaged foods.

2. Pharmaceuticals – Ensures safe handling of tablets, capsules, and medical equipment.

3. Logistics & Warehousing – Ideal for parcel sorting, packaging, and distribution centers.

4. Retail & Supermarkets – Commonly found at checkout counters for automated stock handling.

5. Manufacturing Units – Used in assembly lines, material handling, and quality control processes.

Types of PVC Conveyor Belts

There are many types of PVC conveyor belts on the basis of industry and application:

1. General Purpose PVC Belts – Used in packaging, warehousing, and assembly lines.

2. Food-Grade PVC Belts – Designed for food processing with hygienic coatings.

3. Flame-Retardant PVC Belts – Best for industries where fire resistance is crucial.

4. Oil & Grease Resistant PVC Belts – Used in industries that deal oily or greasy materials.

5. High-Strength PVC Belts – For heavy-duty applications requiring extra durability.

Get in Touch!

If you are looking for reliable PVC conveyor belts, Arrowcon Conveyors Unlimited is your trusted partner. Contact us today for expert advice and the best conveyor solutions for your business.

#PVC Conveyor Belts#PU Conveyor Belts#conveyor belt manufacturers in india#conveyor belts india#conveyor belt manufacturer in india#conveyor belt suppliers#conveyor belt manufacturer#conveyor belt supplier in india#pvc conveyor belt manufacturers in india#conveyor belt in india#conveyor belt company in india

0 notes

Text

How Toy Testing Labs Certify Electronic Toys for Safety Compliance?

Electronic toys have become an integral part of childhood entertainment, offering interactive and educational experiences. However, these toys also pose potential safety risks, including electrical hazards, overheating, and toxic material exposure. To ensure that electronic toys meet safety and regulatory standards, toy testing labs play a crucial role in the certification process. In this blog, we will explore how toys testing lab certify electronic toys for safety compliance and why this process is essential for manufacturers and consumers alike.

Importance of Safety Compliance for Electronic Toys

Electronic toys involve components such as batteries, circuits, and wiring, which can pose risks if not properly tested. Ensuring safety compliance helps:

Prevent electrical shocks and burns

Avoid overheating and fire hazards

Reduce exposure to hazardous substances

Ensure durability and proper functioning

Build consumer trust and meet international safety regulations

Key Safety Standards for Electronic Toys

Toy manufacturers must comply with various safety standards depending on their market. Some of the most recognized standards include:

EN 62115 (Europe): Safety requirements for electric toys

ASTM F963 (USA): Standard consumer safety specification for toy safety

ISO 8124 (International): Safety of toys, including electrical properties

IEC 62115 (Global): Electrical safety requirements for toys

RoHS (Restriction of Hazardous Substances): Limits toxic substances in electronic components

Compliance with these standards ensures that electronic toys are safe for children and meet legal requirements for distribution.

The Certification Process in Toy Testing Labs

Toy testing labs follow a step-by-step certification process to evaluate electronic toys for safety and compliance. Below are the key stages:

1. Electrical Safety Testing

Electronic toys must undergo electrical safety testing to ensure they do not pose a risk of electric shock, overheating, or fire. Tests include:

Short-circuit testing: Ensures the toy does not overheat or catch fire in case of an electrical fault.

Insulation resistance testing: Verifies that electrical insulation prevents accidental shocks.

Battery testing: Evaluates battery performance, leakage risks, and proper installation to avoid overheating.

2. Mechanical and Physical Testing

Mechanical and physical tests assess the durability and structural integrity of electronic toys. Common tests include:

Drop and impact testing: Simulates real-world usage by dropping the toy from different heights.

Sharp edge and small parts testing: Ensures toys do not have sharp edges or small detachable parts that can pose choking hazards.

Tensile strength testing: Evaluates the strength of materials used in the toy’s construction.

3. Chemical Testing

Electronic toys contain various materials that must be free from hazardous substances. Chemical testing ensures compliance with regulations such as RoHS and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals). Tests include:

Heavy metal analysis: Detects toxic metals like lead, cadmium, and mercury.

Phthalate testing: Ensures plastic components are free from harmful plasticizers.

Flame retardant testing: Checks for prohibited flame retardants in plastic materials.

4. EMC (Electromagnetic Compatibility) Testing

Electronic toys emit electromagnetic radiation, which must be within safe limits to prevent interference with other electronic devices. EMC testing evaluates:

Radiated emissions: Measures the electromagnetic energy emitted by the toy.

Conducted emissions: Checks electrical noise transmitted through power sources.

Electrostatic discharge testing: Ensures toys can withstand static electricity discharges without malfunctioning.

5. Environmental Testing

To assess the long-term durability of electronic toys, environmental testing is conducted under various conditions, including:

Temperature and humidity testing: Ensures toys function in extreme temperatures and humidity.

Vibration and shock testing: Simulates rough handling during shipping and use.

UV exposure testing: Tests toys for resistance to sunlight and environmental factors.

6. Labeling and Documentation Review

Proper labeling is a crucial part of compliance. Toy testing labs verify that:

Warning labels are clear and accurate.

Age recommendations align with safety tests.

Instructions for use and battery handling are provided.

CE marking (Europe) or other regulatory labels are correctly displayed.

Challenges in Electronic Toy Testing and Certification

While testing ensures compliance, manufacturers may face challenges in meeting requirements, such as:

Complex toy designs: Advanced electronic features require more rigorous testing.

Rapidly changing regulations: Compliance requirements evolve frequently.

Material sourcing: Ensuring non-toxic materials in all components.

Cost of certification: Comprehensive testing can be expensive but is necessary for legal compliance.

Benefits of Using a Certified Toy Testing Lab

Manufacturers working with accredited toy testing labs gain multiple advantages:

Regulatory compliance: Ensures products meet safety standards.

Market access: Certification is often required for global distribution.

Consumer confidence: Safe toys build brand reputation and trust.

Reduced liability risks: Compliance minimizes the risk of recalls and legal issues.

Conclusion

Toy testing lab play a vital role in certifying electronic toys for safety compliance. Through rigorous testing of electrical, mechanical, chemical, and environmental factors, these labs ensure that toys meet international standards and provide a safe experience for children. For toy manufacturers, working with accredited toy testing labs is not just a regulatory requirement but a key step in building trust, enhancing product quality, and ensuring market success. Whether launching a new toy or expanding into new regions, MOIAT registration and compliance with global safety standards are essential for success in the electronic toy industry.

0 notes

Text

Bromine Derivatives Manufacturers Northern India – Your Trusted Partner for Quality Chemicals

The demand for high-quality bromine-based chemicals is on the rise, and Bromos Organics stands as a leading name among Bromine Derivatives Manufacturers Northern India. With a commitment to innovation, purity, and sustainability, we provide top-tier bromine derivatives that cater to diverse industrial applications.

Understanding Bromine Derivatives

Bromine derivatives are essential chemical compounds derived from bromine, used across multiple industries, including pharmaceuticals, agrochemicals, water treatment, and flame retardants. Their versatility and reactivity make them indispensable for numerous chemical processes.

Key Bromine Derivatives We Manufacture:

Hydrobromic Acid – Used in pharmaceuticals and chemical synthesis

Sodium Bromide – A key component in drilling fluids and water treatment

Potassium Bromide – Commonly used in photography and medicinal applications

Methyl Bromide – Utilized in fumigation and pest control

Other Bromine-Based Specialty Chemicals – Customized solutions for industrial use

Applications of Bromine Derivatives

1. Pharmaceutical & Healthcare Industry

Bromine compounds are widely used in the production of sedatives, anticonvulsants, and other medicinal products. Their effectiveness in chemical synthesis makes them an essential component in drug manufacturing.

2. Flame Retardants

Bromine derivatives play a crucial role in enhancing fire safety. They are used in plastics, textiles, and electronics to prevent the spread of flames, making them vital for consumer and industrial products.

3. Agrochemicals & Pesticides

Bromine-based chemicals contribute significantly to the agricultural sector by serving as key ingredients in pesticides and fumigants that help improve crop yield and protect against pests.

4. Oil & Gas Industry

Sodium Bromide and Calcium Bromide are essential components in drilling fluids, ensuring well stability and efficient extraction processes.

5. Water Treatment

Bromine derivatives are highly effective in disinfecting and treating water, providing safe and sustainable solutions for industrial and municipal water systems.

Why Choose Bromos Organics as Your Bromine Derivatives Supplier?

As a reputed Bromine Derivatives Manufacturer in Northern India, Bromos Organics stands out due to its unwavering commitment to quality, sustainability, and customer satisfaction.

Our Competitive Advantages:

High-Purity Products: Stringent quality control measures ensure top-notch chemical formulations.

Industry Compliance: Our products meet regulatory standards for safety and effectiveness.

Eco-Friendly Practices: We prioritize environmentally sustainable production processes.

Custom Solutions: Tailored formulations to meet specific industrial requirements.

Reliable Supply Chain: Efficient logistics and secure packaging for seamless delivery.

Partner with Bromos Organics Today

For industries seeking premium bromine derivatives, Bromos Organics is the go-to choice in Northern India. Explore our wide range of chemical solutions on our official website and get in touch with us for customized bulk orders.

Choose Bromos Organics—where innovation meets excellence in bromine chemistry.

#BromineDerivativesManufacturersIndia#BromineDerivativesManufacturersNorthernIndia#HYDROBROMICACID48%

0 notes

Text

Why PVC Foam Boards Are Essential for Modern Industrial Applications

Today PVC Foam Board is a revolutionary material to use in any industry. These rigid foam industries with specific properties are not only versatile and strong but also inexpensive and therefore indispensable for a wide range of applications. Supply of high-quality PVC Foam Boards by the company Meghmani Global for a myriad of industries across the globe is keeping pace with this fast-growing demand.

What Are PVC Foam Boards?

PVC Foam Boards are lightweight but rigid sheets made with polyvinyl chloride (PVC) and foaming agents. Their strength, moisture resistance, and easy fabrication are remarkable. In contrast to standard materials such as wood or metal, these boards do not warp or rot and do not corrode, thus making them suitable for an adverse industrial environment.

Advantages of PVC Foam Boards in Industrial Applications

High Durability & Strength:These foam boards for industry endure the real test of conditions outside the walls in which they are produced. PVC Foam Boards are just so different because they are excellent in serving the purpose of high-impact resistance, severe chemicals, temperature, and physical stress. They assure long service life.

Waterproof & Corrosion-Resistant:Industrial materials used in humid or chemical environments require material abuse to moisture and corrosion. PVC Foam Boards, which are completely waterproof and non-soakable, are an excellent choice for a marine, chemical, and construction application.

Lightweight Yet Strong:PVC Foam Boards give strength as Welds do but not as heavy as other forms of metal or wood. It makes it easier to move, place, or handle, reducing labor fitting and improving performance in industrial activities pretty nicely.

Fire-Resistant & Safe:Safety gets into the mind of one industrial use. Fire-retarding PVC foam boards have been specially made by Meghmani Global, which go a long way in helping to reduce fire hazards and also help in meeting safety compliance.

Chemical & UV Resistance:Automotive, healthcare, and signage applications utilize materials resistant to the abrasion of chemicals and UV rays. PVC Foam Board is not prone to degradation of severe chemicals or won't deteriorate through long exposure to sunlight, guaranteeing outdoor durability in heavy chemicals.

Eco-Friendly & Sustainable:The whole world is moving towards sustainability, and introducing PVC Foam Boards gives an environment into the green side. This kind of board is recyclable, as well as reduces dependence on wood-based products, thus guarding industrial practices in favor of eco-awareness.

Discover the Uses and Advantages of PVC Foam Boards in Industries! From construction to advertising, PVC foam boards are transforming multiple sectors with its durability, versatility, and cost-effectiveness.

Industrial Applications of PVC Foam Boards

Construction & Interior Design: Pvc foam boards are being placed as a one-stop solution to aisle cladding, partitions, and ceiling finishes-an easy and aesthetically pleasing alternative to traditional materials combined with high durability.

Signage & Advertising: Smooth surfaces necessitate digital printing, so they turn out to be the most preferable and popular materials for high-quality signage and branding.

Automotive & Transport: They used to be in vehicle interiors and dashboards, as well as in protective panels, for increased durability with weight reductions in vehicles.

Marine & Chemical Industries: Those will be placed internally in boats since they will serve as chemical storage units as well as in industrial work spaces, as they are waterproof and resistant to corrosion.

Choose Meghmani Global for High-Quality PVC Foam Boards

At Meghmani Global, We ensure that our casing foam boards for industry with high durability are manufactured with utmost quality control standards to match the topmost standards using modern technology.

looking for the best solutions for PVC Foam Board, Contact Meghmani Global today! Our specialists are available to assist you with product specifications, customizations, or any questions you may have. Get in touch to know how our state-of-the-art PVC Foam Boards can fulfill your needs.

📞 Call us at +91 7926812827

📧 Email us at [email protected]

🌐 Visit our website: https://www.meghmaniglobal.com/

0 notes

Text

Acrylic-Based Substances and Related Production Technologies

PMMA, commonly referred to as acrylic or organic glass, is a significant early innovation in synthetic polymer materials. This versatile substance exhibits remarkable optical clarity, robust chemical resistance, and exceptional durability against environmental factors. Its characteristics of easy coloration, superior machinability, and aesthetic appeal have led to its extensive adoption in architectural applications. In commercial display applications, Acrylic displays are typically categorized into three primary types: cast panels, extruded sheets, and injection-molded plastic components.

Common sheet types include transparent sheets, dyed transparent sheets, opal white sheets, and colored sheets.

Acrylic sheets can be categorized into cast and extruded sheets by production method. Based on transparency, they are divided into transparent sheets, translucent sheets (including dyed transparent sheets), and colored sheets (including black, white, and colored sheets). Performance-wise, they are classified into impact-resistant sheets, UV-resistant sheets, regular sheets, and special sheets such as high-impact sheets, flame-retardant sheets, frosted sheets, metallic effect sheets, and light guide sheets.

Acrylic is available in sheets, rods, tubes, and various finishes such as glossy, semi-glossy, matte, and frosted, with standard thicknesses of 1.0, 1.5, 2.0, 3.0, 4.0, 5.0, 8.0, 10.0, 12, 15, 20, 25, 30 mm, etc.

Acrylic products include sheets, rods, and tubes (typically round), with surface finishes such as glossy, matte, and frosted, and thicknesses ranging from 1mm to 30mm.

Similar plastics related to acrylic include: Foam PVC (Sintra), PVC, PS, HIPS, PC, PETG

Types of Acrylic

Colorless Transparent Acrylic: Common in everyday life, colorless and transparent acrylic has outstanding light transmission, higher than that of ordinary glass. It is durable and not easily broken, performing better than glass in certain aspects.

Colored Acrylic: This type of acrylic is colored and transparent, with a softer light transmission compared to colorless transparent acrylic. Available in various colors, it is ideal for decorative purposes. Based on light transmission, it can be divided into transparent-colored, translucent-colored, and opaque colored types.

Pearlescent Acrylic: Made by adding pearlescent or fluorescent powder to regular acrylic, it features vivid colors and high gloss. Even after heat-press polishing, it retains embossed patterns, offering unique artistic effects. It can be used for making letters, animal shapes, trademarks, and decorative items.

Characteristics of Acrylic

Its light transmittance is comparable to glass, but it is only half the density.

It is less fragile than glass. Even when damaged, it does not form sharp shards, reducing the risk of injury.

Its wear resistance is close to that of aluminum, and it resists corrosion from various chemicals.

Applications of Acrylic

Acrylic display stands are widely recognized and used in many retail industries for their excellent display performance. Applications include cosmetic display stands, jewelry display stands, digital product display stands, mobile phone display stands, high-end wine display stands, and high-end watch display stands.

Surface Treatments

Transparent Clear/Transparent

Glossy

Frosted

Processing Techniques

Cutting

Engraving/Carving

Drilling

Polishing (diamond polishing, fire polishing)

Bending

Silk-screen printing

UV printing

Injection molding

Acrylic Manufacturing Process

Material Cutting: Use a saw machine to cut acrylic to the required size to avoid material waste.

Engraving: After cutting, engrave various complex patterns, text, or logos as required by the shape of the acrylic product.

Drilling: Acrylic can be drilled directly using a desktop drill press, following the processing drawings.

Edge Finishing: After cutting or engraving, the edges of acrylic sheets are often rough and need further smoothing using a vertical single-shaft woodworking milling machine.

Polishing: After cutting, engraving, and drilling, the edges are still rough and need polishing to prevent injury. Different polishing methods are used depending on the product.

Paper Removal: Acrylic sheets come with a protective paper layer that must be removed before bending and silk-screen printing.

Heat Bending: Acrylic can be shaped into different forms through heat bending, which can be either overall or partial.

Silk-Screen Printing: Use UV printing machines to display brand logos or promotional texts as required.

Bonding: The bonding process is done manually and requires strict control to ensure the product is free of misalignment, bubbles, and weak bonds. Common bonding techniques include butt joints, vertical bonding, 45° angle bonding, and surface bonding.

Assembly: Combine the parts to complete a finished product.

Packaging: After final quality inspection, the product is packaged for shipment.

Related Posts

Which Materials Are Best for Custom POP Displays?

Metal Materials and Corresponding Processing Techniques

Wood Materials and Corresponding Processing Techniques

#acrylic displays#acrylic working#custom acrylic displays#custom pop display#solid displays#retail pop displays#custom display stand#pop displays

0 notes

Text

Maintenance and Care for Fire Retardant Curtains

Fire safety is a top priority in every home, and fire-resistant curtains, including flame retardant drapes and fire retardant curtains, provide essential protection. However, to ensure they continue to function effectively, it’s important to maintain and care for them properly. In this article, we’ll discuss how to care for flame retardant curtains and ensure they remain in optimal condition for years to come.

Understanding the Importance of Proper Maintenance

Flame-retardant curtains are designed to protect your home by reducing the risk of fire spread. But over time, the effectiveness of their fire-resistant properties can diminish if they’re not cared for properly. Whether your curtains are made of treated materials or naturally flame-resistant fabrics, regular maintenance is essential to preserving their fire safety benefits.

How Fire Retardant Curtains Work

Before we dive into care and maintenance, let’s briefly discuss how these curtains work. Fire-resistant curtains are made from materials that are either treated with flame retardant chemicals or inherently resistant to flames, such as fiberglass. The flame retardant properties of these curtains are activated when exposed to heat, preventing the fabric from catching fire easily and slowing down the spread of flames.

However, these properties can be compromised by improper cleaning or handling. Flame retardant chemicals can degrade over time if exposed to harsh detergents, hot water, or frequent washing. Therefore, it’s important to know how to clean and care for your fire-resistant curtains without damaging their flame-retardant abilities.

Tips for Cleaning Flame Retardant Curtains

Read the Manufacturer’s Care Instructions Always start by reading the manufacturer’s care instructions. Each set of flame-retardant curtains may have different cleaning requirements depending on the material and treatment used. Some curtains may be machine washable, while others require dry cleaning. Knowing the right method can help preserve the integrity of the fire-resistant properties.

Spot Cleaning for Light Dirt If your fire-resistant curtains only need minor cleaning, spot cleaning is the best option. Use a mild detergent and a soft cloth to gently dab the affected area. This prevents the fabric from becoming saturated with water or detergent, which could affect its flame-retardant qualities.

Hand Washing or Gentle Machine Wash For curtains that are machine washable, use the delicate cycle and cold water to avoid damaging the fabric. Use a mild detergent and avoid bleach or harsh chemicals, which can degrade the fire-retardant treatment. If hand washing is required, ensure you gently wash the fabric with a non-abrasive detergent.

Dry Cleaning If your curtains are labeled as dry clean only, take them to a professional cleaner who understands how to handle fire-resistant fabrics. Dry cleaning ensures that the fire-retardant properties remain intact, as harsh washing and drying processes can compromise the curtain’s effectiveness.

Avoid Frequent Washing Over-washing fire-resistant curtains can wear down the flame retardant chemicals. If your curtains don’t need frequent cleaning, try to limit washing to once or twice a year, or as needed. Frequent exposure to water and detergent can strip the flame retardant treatment, reducing the fabric’s ability to prevent fire.

How to Maintain the Flame-Resistant Properties

Reapply Fire Retardant Treatments Over time, the flame-retardant treatment applied to curtains may fade. If your curtains have lost their effectiveness, you can reapply flame-retardant spray. This is especially useful for curtains that have been washed several times. There are many flame-retardant sprays available on the market that can be easily applied at home. Be sure to follow the manufacturer’s instructions when applying the spray.

Avoid Direct Heat Sources While flame-retardant curtains can resist flames, they are not immune to heat. Avoid placing them near direct heat sources, such as open flames or heat vents, as prolonged exposure can degrade the fabric and its fire-resistant properties. Keep your curtains away from fireplaces, stovetops, and high-temperature appliances.

Store Properly When not in use, especially if you’re taking down seasonal curtains, store your flame-resistant curtains in a dry, cool place. Avoid folding them tightly or exposing them to sunlight for long periods, as this can weaken the material. Hanging them in a spacious closet or storing them in a breathable fabric bag will help preserve their integrity.

Inspect Regularly Periodically inspect your flame-resistant curtains for any signs of wear or damage. If you notice any holes, tears, or fading in the fabric, it may be time to replace them. Damaged curtains can lose their ability to protect your home from fire, and it’s better to replace them before they pose any risks.

Additional Tips for Extending the Life of Your Curtains

Use Curtain Liners Consider using curtain liners to protect the fabric from dirt and stains. Liners act as a protective layer that absorbs the wear and tear of daily use, reducing the need for frequent washing of the curtains themselves.

Keep Curtains Away from Pets Pets can sometimes scratch or damage curtains, and their claws could tear the fabric, causing it to lose its fire-resistant qualities. Keep your flame-resistant curtains out of reach of pets or use protective coverings to prevent damage.

Regularly Vacuum Dust and dirt buildup on your curtains can affect their appearance and cleanliness. Use a vacuum with an upholstery attachment to regularly clean the fabric. This helps keep your curtains looking fresh and reduces the buildup of allergens.

Conclusion

Fire retardant curtains are an essential part of home fire safety, but they require proper maintenance to continue providing protection. By following the care guidelines and tips provided, you can ensure that your fire-resistant curtains maintain their effectiveness and last for years. Regular cleaning, proper storage, and careful handling will keep your curtains in top shape while preserving their flame-resistant properties, ultimately contributing to a safer home.

#home improvement#custom blackout curtains#home#blackout curtains#blackout curtain#home decor#custom curtain#custom curtains#interior design#curtains

0 notes

Text

How Emulsion Polymers Are Revolutionizing the Textile and Paper Industries

Emulsion polymers have emerged as game-changers in various industries, particularly in textile and paper manufacturing. Their ability to provide superior binding, coating, and finishing properties makes them indispensable in producing high-performance textiles and paper products. Unlike traditional solvent-based polymers, water-based emulsion polymers are more environmentally friendly, cost-effective, and versatile.

In this article, we will explore how emulsion polymers are transforming the textile and paper industries, their key applications, and the benefits they offer in enhancing product quality and sustainability.

What Are Emulsion Polymers?

Emulsion polymers are produced through emulsion polymerization, a process in which monomers are dispersed in water with the help of surfactants and initiators. This results in the formation of polymer particles suspended in a stable emulsion. These water-based polymers are widely used in coatings, adhesives, paints, textiles, and paper products due to their excellent adhesion, flexibility, and film-forming properties.

Unlike solvent-based polymers, which release harmful volatile organic compounds (VOCs), emulsion polymers offer a more sustainable alternative with low toxicity and reduced environmental impact.

The Role of Emulsion Polymers in the Textile Industry

1. Enhancing Fabric Strength and Durability

In textile production, emulsion polymers act as binders that improve the strength, flexibility, and resilience of fabrics. They are widely used in non-woven textiles, technical fabrics, and garment finishing.

Acrylic emulsion polymers provide superior resistance to wear and tear.

Vinyl acetate and styrene-butadiene emulsions improve elasticity and softness.

Waterproof coatings on fabrics are made using polymer emulsions, ensuring durability without compromising breathability.

2. Textile Coatings for Water Resistance and Stain Protection

Emulsion polymers are used in the finishing process of textiles to impart water resistance, stain repellency, and fire retardancy.

Fluoropolymer emulsions create water-repellent coatings for outdoor wear and upholstery.

Silicone-based emulsions enhance the softness and smoothness of textiles.

Polyurethane dispersions provide elasticity and abrasion resistance in sportswear and medical textiles.

3. Eco-Friendly Dyeing and Printing Applications

With growing concerns over toxic dyeing processes, water-based emulsion polymers offer an eco-friendly solution for textile printing and dye fixation.

Pigment printing emulsions ensure long-lasting color retention.

Binder emulsions help pigments adhere to fabrics without heavy metal-based fixatives.

Low-VOC textile finishes enhance product sustainability and regulatory compliance.

By replacing solvent-based dyes and finishes with polymer emulsions, textile manufacturers reduce water pollution, chemical waste, and energy consumption.

Emulsion Polymers in the Paper Industry

1. Improving Paper Strength and Printability

Emulsion polymers play a critical role in paper manufacturing, particularly in enhancing tensile strength, surface smoothness, and ink adhesion.

Styrene-butadiene and vinyl acetate emulsions improve wet and dry strength in paper.

Acrylic emulsions create glossy, smooth surfaces ideal for printing.

Carboxylated polymers enhance ink absorption and color vibrancy.

With these enhancements, paper products such as magazines, labels, posters, and packaging materials achieve superior print clarity and durability.

2. Eco-Friendly Coatings for Paper Packaging

The shift toward sustainable packaging solutions has led to the increased use of emulsion polymer coatings in food packaging, cartons, and paper cups.

Barrier coatings made from polymer emulsions replace plastic laminates, making packaging more biodegradable.

Waterproof paper coatings improve resistance to moisture without affecting recyclability.

Grease-resistant emulsions enhance food-safe paper packaging, reducing reliance on non-biodegradable wax coatings.

As consumers demand sustainable packaging, polymer emulsions offer a cost-effective, recyclable, and eco-friendly alternative to traditional plastic coatings.

3. Enhancing Paper Adhesives and Binding Agents

Emulsion polymers are widely used as adhesives in paper products, ensuring strong binding, laminating, and coating properties.

Polyvinyl acetate (PVA) emulsions are commonly used in bookbinding and envelope adhesives.

Styrene-acrylic emulsions enhance the flexibility and strength of coated papers.

Biodegradable polymer emulsions are replacing petroleum-based adhesives in eco-friendly packaging.

With increased demand for sustainable paper products, manufacturers are adopting biodegradable and recyclable polymer emulsions to meet environmental regulations.

Key Benefits of Emulsion Polymers in Textile and Paper Industries

✅ Eco-Friendly and Low VOC Emissions

Water-based emulsion polymers eliminate the need for harsh solvents, reducing air pollution and health risks in manufacturing.

✅ Improved Product Performance

They enhance durability, water resistance, and adhesion, ensuring higher-quality textiles and paper products.

✅ Cost-Effective and Scalable

Since polymer emulsions require less energy for processing, they reduce production costs and are ideal for large-scale manufacturing.

✅ Sustainability and Biodegradability

With biodegradable formulations, emulsion polymers support eco-friendly alternatives to synthetic coatings and adhesives.

Conclusion

The textile and paper industries are undergoing a major transformation, driven by emulsion polymer innovations. From enhanced fabric coatings to sustainable paper packaging, these water-based polymers offer eco-friendly, high-performance, and cost-effective solutions.

As manufacturers move toward green alternatives, emulsion polymers will continue to play a key role in revolutionizing material quality, sustainability, and regulatory compliance. Whether in fashion textiles, specialty papers, or packaging solutions, emulsion polymers are shaping the future of eco-conscious industries.

0 notes

Text

Non woven Fabric Market 2025: Size, Trends, Regional Outlook, Revenue Analysis & Forecast Till 2032

The Nonwoven Fabrics Market has witnessed robust growth over the past decade, driven by increasing demand across diverse industries such as healthcare, automotive, construction, and personal care. Characterized by its lightweight, durability, and cost-effectiveness, non-woven fabric has emerged as a vital material for both disposable and durable applications. As industries strive for efficiency and sustainability, the non-woven fabric market is poised to expand further, albeit with challenges that require strategic navigation.

Market Overview

Non-woven fabrics are engineered fabrics made from short or long fibers bonded together through chemical, mechanical, heat, or solvent treatment. Unlike traditional woven fabrics, non-woven materials do not require spinning or weaving processes. This production efficiency, combined with the versatility of non-wovens, has propelled their adoption across a wide range of applications.

Nonwoven Fabrics Market Size was valued at USD 57.42 billion in 2023. The Nonwoven fabrics industry is projected to grow from USD 59.32 Billion in 2024 to USD 77.24 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 6.11% during the forecast period (2024 - 2032). The rise in healthcare expenditures, increased use of disposable hygiene products, and advancements in production technologies are key drivers of this growth.

Challenges in the Market

Despite its growth trajectory, the non-woven fabric market faces several challenges:

Environmental Concerns:

Many non-woven fabrics are made from synthetic polymers such as polypropylene and polyester, raising concerns about their environmental impact. The disposal of non-woven products, particularly single-use items, contributes to plastic waste, pushing manufacturers to explore biodegradable and recyclable alternatives.

Fluctuating Raw Material Prices:

The price volatility of raw materials, especially petroleum-based polymers, poses a challenge to manufacturers. Such fluctuations can impact profit margins and increase the cost of end products.

Intense Competition:

The market is highly competitive, with numerous regional and global players. To differentiate, companies need to invest in R&D, improve product offerings, and establish strong distribution networks.

Regulatory Hurdles:

Stringent regulations related to the use of plastics and environmental compliance in several countries necessitate continuous monitoring and adaptation by manufacturers.

Emerging Trends

Sustainability Focus:

The development of biodegradable and eco-friendly non-woven fabrics is gaining traction. Bio-based materials such as polylactic acid (PLA) and cellulose are being explored to create sustainable alternatives.

Smart Non-Wovens:

The integration of smart technologies, such as sensors and conductive materials, into non-woven fabrics is creating innovative products for healthcare and wearable applications.

Asia-Pacific Dominance:

The Asia-Pacific region is emerging as the largest and fastest-growing market for non-woven fabrics, driven by rapid industrialization, population growth, and increasing healthcare spending in countries like China and India.

Customization and Specialty Products:

Demand for customized non-wovens tailored to specific industry needs is rising. Specialty non-wovens, such as fire-retardant and water-repellent fabrics, are finding applications in niche markets.

Opportunities for Growth

Investment in R&D:

Continuous innovation in production techniques and raw materials can help manufacturers meet evolving consumer demands and regulatory requirements.

Expansion in Emerging Markets:

Developing economies offer significant growth potential due to increasing disposable incomes, urbanization, and improving healthcare infrastructure.

Collaborations and Partnerships:

Collaborating with end-users to develop tailored solutions can strengthen market position and open new revenue streams.

Adoption of Circular Economy Models:

Embracing circular economy principles, such as recycling and reusing materials, can reduce environmental impact and align with consumer preferences for sustainable products.

MRFR recognizes the following Non woven Fabric Companies - Dow,DuPont,KCWW,Berry Inc.,Glatfelter,Fitesa,TWE GmbH & Co. KG,Ahlstrom-Munksjö,Kimberly-Clark Corporation,Chevron Corporation,Polymer Group Incorporation,Asahi Kasei Corporation,Fibertex

The non-woven fabric market is at a pivotal juncture, with ample opportunities for growth and innovation. While challenges such as environmental concerns and raw material price volatility persist, the industry’s focus on sustainability and technological advancements is paving the way for a resilient future. As non-woven fabrics continue to gain prominence across industries, stakeholders must embrace innovation and sustainability to harness the market’s full potential.

Related Reports

Fire Resistant Fabrics Market - https://www.marketresearchfuture.com/reports/fire-resistant-fabrics-market-5448 Coated Fabrics Market - https://www.marketresearchfuture.com/reports/coated-fabrics-market-6134 Steel Fabrication Market - https://www.marketresearchfuture.com/reports/steel-fabrication-market-10929

0 notes

Text

The Leading Cable Solutions Provider – Neon Cables Pvt. Ltd.

In today’s fast-paced world, high-quality electrical wiring is essential for ensuring safety, efficiency, and durability in various applications. From homes and industries to automotive and submersible pump systems, selecting the right wires and cables is crucial for optimal performance. Neon Cables Pvt. Ltd. is a renowned name in the industry, known for manufacturing high-quality electrical cables that meet national and international standards. As a leading Submersible Cable Manufacturer, Multi Strand Wire Manufacturer, Automotive Battery Cable Manufacturer, Flexible House Wire Manufacturer, and PVC House Wire Manufacturer, Neon Cables is committed to delivering top-notch products with superior durability, safety, and conductivity.

Submersible Cable Manufacturers – Ensuring Reliability Underwater

Submersible cables are designed to operate efficiently in water-logged environments, making them ideal for borewells, irrigation pumps, and underwater applications. As a top Submersible Cable Manufacturer, Neon Cables offers robust and high-performance cables that are resistant to moisture, chemicals, and abrasion. These cables are insulated with PVC or rubber to withstand extreme underwater conditions, ensuring uninterrupted power supply and long-lasting durability.

Key Features of Neon Cables’ Submersible Cables:

Excellent resistance to water, oil, and chemicals

High insulation properties to prevent short circuits

Superior copper conductors for optimal conductivity

Strong PVC or rubber sheath for enhanced durability

With cutting-edge manufacturing processes and rigorous quality control, Neon Cables’ submersible cables provide reliable performance in challenging environments.

Multi Strand Wire Manufacturers – High Flexibility for Diverse Applications

Multi-strand wires are widely used in residential, commercial, and industrial applications due to their flexibility and ease of installation. As a leading Multi Strand Wire Manufacturer, Neon Cables produces high-quality multi-strand wires that offer excellent electrical conductivity, flexibility, and durability.

Why Choose Neon Cables’ Multi-Strand Wires?

Multiple strands of copper for better conductivity

Enhanced flexibility for easy bending and installation

PVC insulation for fire and shock resistance

Suitable for wiring electrical appliances, panels, and control systems

These wires are essential for modern electrical setups, providing enhanced safety and efficiency in various applications.

Automotive Battery Cable Manufacturers – Powering Your Vehicles Safely

Automotive battery cables play a crucial role in supplying power from the battery to the electrical system of a vehicle. As a premier Automotive Battery Cable Manufacturer, Neon Cables produces top-grade battery cables that ensure seamless power transmission, durability, and high resistance to heat and corrosion.

Key Benefits of Neon Cables’ Automotive Battery Cables:

High conductivity for efficient power flow

Flexible and heat-resistant insulation for automotive applications

Corrosion-resistant material for long-lasting performance

Suitable for cars, trucks, two-wheelers, and heavy-duty vehicles

With a commitment to quality and innovation, Neon Cables provides automotive battery cables that meet global standards for safety and performance.

Flexible House Wire Manufacturers – Enhancing Electrical Safety at Home

House wiring is the backbone of any residential electrical system, and using high-quality flexible house wires is essential for ensuring safety and longevity. Neon Cables, a trusted Flexible House Wire Manufacturer, offers premium house wires that are designed for high performance, flexibility, and fire resistance.

Why Choose Neon Cables’ Flexible House Wires?

High-quality copper conductors for superior conductivity

Flame-retardant insulation for enhanced safety

Flexible design for easy installation in tight spaces

Long lifespan with resistance to wear and tear

Neon Cables’ house wires ensure a secure and efficient electrical connection, making them ideal for homes, offices, and commercial spaces.

PVC House Wire Manufacturers – Durable and Reliable Wiring Solutions

PVC-insulated house wires are among the most widely used electrical wiring solutions due to their durability, affordability, and fire-resistant properties. As a prominent PVC House Wire Manufacturer, Neon Cables produces top-grade PVC house wires that meet stringent safety and quality standards.

Advantages of Neon Cables’ PVC House Wires:

High insulation resistance to prevent electrical leakage

Flame-resistant properties for enhanced safety

Smooth surface for easy installation and handling

Suitable for residential and commercial wiring applications

With a strong emphasis on quality control and customer satisfaction, Neon Cables continues to provide reliable and durable PVC house wires that cater to diverse electrical needs.

Why Choose Neon Cables Pvt. Ltd.?

Neon Cables Pvt. Ltd. has established itself as a leader in the electrical cable industry by consistently delivering top-quality products that meet the highest safety and performance standards. Here’s why Neon Cables is the preferred choice for customers:

✅ Uncompromised Quality – All products undergo rigorous quality testing to ensure reliability and durability.

✅ Advanced Manufacturing Technology – State-of-the-art production facilities equipped with cutting-edge technology.

✅ Industry Compliance – All cables conform to national and international safety standards.

✅ Wide Product Range – From submersible cables to automotive battery cables and house wires, Neon Cables offers a comprehensive range of products.

✅ Customer-Centric Approach – Dedicated customer support and tailored solutions to meet specific requirements.

Conclusion

When it comes to reliable, safe, and high-performance electrical cables, Neon Cables Pvt. Ltd. stands out as a top choice. As a leading Submersible Cable Manufacturer, Multi Strand Wire Manufacturer, Automotive Battery Cable Manufacturer, Flexible House Wire Manufacturer, and PVC House Wire Manufacturer, Neon Cables is committed to delivering superior electrical solutions for homes, industries, and automobiles.

For high-quality electrical cables that ensure safety and efficiency, trust Neon Cables Pvt. Ltd. – your partner in superior electrical wiring solutions!

#SubmersibleCableManufacturers#MultiStrandWireManufacturers#AutomotiveBatteryCableManufacturers#FlexibleHouseWireManufacturers#PVCHouseWireManufacturers#NeonCablesPvtLtd#ElectricalWires#TopCableManufacturers#HighQualityWires#DurableCables#SafeWiringSolutions

0 notes