#ferro alloy powder

Explore tagged Tumblr posts

Text

Ferro Alloy Powder | Ferro Alloy Powder Supplier in India

Jayesh Group is a leading ferro alloy powder manufacturer in India, offering a wide range of products including ferro silicon, ferro manganese, and ferro chrome. With a state-of-the-art facility and experienced professionals, they deliver high-quality products for diverse industries. Their commitment to innovation, quality, and customer satisfaction makes them a trusted global supplier. Visit their website to learn more.

1 note

·

View note

Text

Leading Ferro Titanium Suppliers in India for Premium Alloys and Powder!

India has emerged as a significant player in the global metallurgical industry, particularly in the production and supply of ferroalloys such as ferro titanium suppliers. This material is a key component in various industrial applications, including steel manufacturing, aerospace, and chemical processes, owing to its excellent properties like corrosion resistance, high strength-to-weight ratio, and heat resistance. For industries that require premium-quality alloys and powder, identifying the best suppliers is essential for maintaining quality and performance standards.

The Role of Ferro Titanium in Modern Industries

This alloy, composed of titanium and iron, often enriched with small quantities of other elements, is widely used in:

Steel Manufacturing: It acts as a deoxidizer and desulfurizer in steel production, enhancing the mechanical properties of steel and reducing impurities.

Aerospace Industry: Its high strength-to-weight ratio and corrosion resistance make it an ideal choice for aerospace components.

Chemical Processing: The alloy is used in environments that require high corrosion resistance, such as chemical reactors and pipelines.

Additive Manufacturing: The ferro titanium powder form is utilized in 3D printing and advanced manufacturing techniques.

Given these diverse applications, the demand for high-quality alloys and powder continues to grow, particularly in India.

Leading Suppliers of Ferro Titanium in India

Several suppliers in India have established themselves as leaders in this market by offering premium products and reliable services. Below are some of the top suppliers in the country:

1. Indian Metals & Ferro Alloys Limited (IMFA)

IMFA is one of the largest producers of ferroalloys in India, with a strong presence in both domestic and international markets. The company is known for its high-quality alloys, produced using state-of-the-art technology and stringent quality control measures.

Key Highlights:

Advanced manufacturing facilities.

Commitment to sustainability and environmental standards.

A wide range of products catering to multiple industries.

2. Tata Steel

Tata Steel, a global steel manufacturing giant, also produces alloys of exceptional quality. Their expertise in metallurgy and focus on innovation ensure that their products meet the highest industry standards.

Key Highlights:

Strong research and development capabilities.

Focus on delivering customized solutions.

Extensive distribution network for timely delivery.

3. Metkore Alloys & Industries Ltd.

Metkore Alloys specializes in the production of various ferroalloys, including this material. The company emphasizes consistency in product quality and offers tailored solutions to meet specific customer requirements.

Key Highlights:

ISO-certified production processes.

Dedicated customer support services.

Competitive pricing and reliable supply chains.

4. Ferro Alloys Corporation Limited (FACOR)

FACOR is another leading player in India’s ferroalloy industry, offering a range of products, including this alloy. The company leverages its decades of experience to deliver high-quality products that comply with global standards.

Key Highlights:

In-house quality testing laboratories.

Focus on export markets alongside domestic supply.

Expertise in meeting bulk order requirements.

5. FerroTitanium.in

FerroTitanium.in is a specialized supplier dedicated to providinitsg high-quality ferro titanium alloys and powder. Known for their customer-centric approach and extensive industry expertise, the company caters to a wide array of industries, ensuring superior product performance.Key Highlights:Expertise in ferro titanium alloys and powder production.Focused on customer-specific solutions and technical support.Reliable delivery and efficient supply chain management.

Factors to Consider When Choosing a Supplier

When selecting a supplier in India, businesses should consider the following factors to ensure they receive the best products and services:

Product Quality: Ensure the supplier adheres to international quality standards and provides certificates of analysis for their products.

Manufacturing Capabilities: Evaluate the supplier’s production facilities and capacity to meet your specific requirements.

Reputation: Check the supplier’s market reputation, customer reviews, and references.

Technical Support: Opt for suppliers who offer technical support and guidance on product applications.

Cost-effectiveness: Balance quality with competitive pricing to achieve the best value for money.

Logistics and Delivery: Assess the supplier’s ability to deliver products on time and handle bulk orders efficiently.

The Future of Ferro Titanium in India

With the growing demand for high-performance materials in industries like aerospace, automotive, and construction, the Indian market is poised for significant growth. Technological advancements in manufacturing processes, coupled with increasing investments in research and development, are expected to enhance the quality and availability of ferro titanium alloys and powder.

Additionally, government initiatives such as the "Make in India" campaign are encouraging domestic production and exports of ferroalloys. This creates opportunities for Indian suppliers to expand their reach and establish a stronger presence in the global market.

Conclusion

India’s leading suppliers are well-equipped to meet the rising demand for premium alloys and powder, thanks to their advanced manufacturing capabilities, commitment to quality, and customer-centric approaches. Companies like IMFA, Tata Steel, and FACOR are setting benchmarks in the industry, ensuring that businesses across various sectors have access to reliable and high-performance products.

By partnering with trusted suppliers and staying informed about industry trends, businesses can optimize their operations and achieve greater success in their respective fields.

#ferrotitaniumsuppliers #ferrotitanium #ferrotitaniumalloys #ferrotitaniumpowder

#ferro alloys suppliers#ferro titanium powder#ferro titanium#ferro titanium alloys#ferro titanium suppliers#ferro titanium in india#ferro titanium cored wire#ferro titanium manufacturer

0 notes

Text

Ferrochrome Market Size, Share, Demand, Future Growth, Challenges and Competitive Analysis

"Global Ferrochrome Market – Industry Trends and Forecast to 2029

Global Ferrochrome Market, By Type (High Carbon, Medium Carbon, Low Carbon, and Ferro Silico Chrome), Application (Stainless Steel, Cast Iron, Powder Metallurgy, and Others) - Industry Trends and Forecast to 2029.

Access Full 350 Pages PDF Report @

**Segments**

- **Type**: - High Carbon Ferrochrome - Medium Carbon Ferrochrome - Low Carbon Ferrochrome

- **Application**: - Stainless Steel - Engineering Steel - Alloy Steel - Others

- **End-Use Industry**: - Aerospace - Automotive - Construction - Others

The ferrochrome market can be segmented based on type, application, and end-use industry. In terms of type, the market is divided into high carbon ferrochrome, medium carbon ferrochrome, and low carbon ferrochrome. High carbon ferrochrome is primarily used in stainless steel production, while medium and low carbon ferrochrome find applications in engineering steel and alloy steel manufacturing. Regarding applications, ferrochrome is extensively utilized in stainless steel, engineering steel, alloy steel, and other sectors. Moreover, in terms of end-use industries, aerospace, automotive, construction, and other sectors are major consumers of ferrochrome.

**Market Players**

- Glencore - Eurasian Resources Group - Samancor Chrome - Hernic Ferrochrome - IFM (International Ferro Metals)

The ferrochrome market features key players such as Glencore, Eurasian Resources Group, Samancor Chrome, Hernic Ferrochrome, and IFM (International Ferro Metals). These companies are actively involved in the production, distribution, and marketing of ferrochrome products globally. Glencore, a renowned name in the mining and metals industry, has a significant presence in the ferrochrome market. Similarly, Eurasian Resources Group and Samancor Chrome are major players with a strong foothold in the market. Hernic Ferrochrome and IFM (International Ferro Metals) also play crucial roles in shaping the competitive landscape of the ferrochrome industry.

https://www.databridgemarketresearch.com/reports/global-ferrochrome-marketThe ferrochrome market is witnessing significant growth driven by the increasing demand for stainless steel, engineering steel, and alloy steel across various industries. Stainless steel, a key application of ferrochrome, is widely used in sectors such as construction, automotive, and aerospace due to its corrosion resistance and durability. The aerospace industry, in particular, relies on high-quality stainless steel components for aircraft manufacturing, driving the demand for high carbon ferrochrome. Similarly, the automotive sector utilizes ferrochrome in the production of components such as engine parts and exhaust systems, contributing to the market's growth.

Moreover, the construction industry plays a crucial role in the demand for ferrochrome, as stainless steel is extensively used in infrastructure projects, architectural structures, and building materials. The superior strength and aesthetic appeal of stainless steel make it a preferred choice in construction applications, thereby propelling the consumption of ferrochrome in this sector. Additionally, the engineering steel segment benefits from the properties of medium and low carbon ferrochrome, which enhance the mechanical properties and machinability of steel products used in various industrial applications.

In terms of market players, companies such as Glencore, Eurasian Resources Group, Samancor Chrome, Hernic Ferrochrome, and IFM (International Ferro Metals) are key players driving the growth and innovation in the ferrochrome industry. These companies have a strong global presence and invest in research and development to improve product quality and cater to evolving consumer needs. Glencore, known for its expertise in mining and metals, leverages its extensive resources and technological capabilities to maintain a competitive edge in the ferrochrome market.

Furthermore, technological advancements and strategic alliances among market players are expected to shape the future landscape of the ferrochrome market. Collaboration between manufacturers, end-users, and research institutions can lead to the development of advanced ferrochrome products tailored to specific industry requirements. The growing focus on sustainable practices and environmental regulations also drives innovation in ferrochrome production processes, aiming**Global Ferrochrome Market Analysis**

- **Market Trends**: - The ferrochrome market is experiencing growth due to the rising demand for stainless steel across various industries, including automotive, construction, and aerospace. Stainless steel's corrosion resistance and durability make it a preferred material, driving the need for ferrochrome as a key alloying element. - The construction industry is a significant driver of ferrochrome consumption, as stainless steel is widely utilized in infrastructure projects and architectural applications. The strength and aesthetic appeal of stainless steel contribute to its popularity in the construction sector, thereby boosting the demand for ferrochrome. - Technological advancements and strategic collaborations among market players are shaping the future of the ferrochrome market. Companies are investing in research and development to enhance product quality and meet evolving consumer requirements. Additionally, a focus on sustainable practices and environmental regulations is driving innovation in ferrochrome production processes.

- **Market Forecast**: - The global ferrochrome market is projected to witness steady growth in the coming years, driven by an increasing preference for stainless steel in various applications. The aerospace industry's demand for high-quality stainless steel components and the automotive sector's reliance on ferrochrome for engine parts and exhaust systems will further propel market growth. - The construction industry's continued investments in infrastructure development and architectural projects will fuel the consumption of ferrochrome for stainless steel applications. Moreover, the engineering steel segment is expected to benefit from the properties of medium and low carbon fer

Highlights of TOC:

Chapter 1: Market overview

Chapter 2: Global Ferrochrome Market

Chapter 3: Regional analysis of the Global Ferrochrome Market industry

Chapter 4: Ferrochrome Market segmentation based on types and applications

Chapter 5: Revenue analysis based on types and applications

Chapter 6: Market share

Chapter 7: Competitive Landscape

Chapter 8: Drivers, Restraints, Challenges, and Opportunities

Chapter 9: Gross Margin and Price Analysis

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Browse Trending Reports:

Bio Based Succinic Acid Market Baselayer Compression Shirts Market Trauma Devices Market Dairy Flavours Market Immunogenetics Market l Carnitine Market Iv Infusion Bottle Seals And Caps Market Self Storage And Moving Services Market Acute Bronchitis Market Thrombophilia Market Tetracyclines Market Agricultural Biologicals Market Two Part Adhesive Market Labeling Equipment Market Fruit And Herbal Tea Market Air Filter For Automotive Market Organic Feed Market Soy Milk Infant Formula Market Pallet Stretch Wrapping Machine Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

#Global Ferrochrome Market – Industry Trends and Forecast to 2029#Global Ferrochrome Market#By Type (High Carbon#Medium Carbon#Low Carbon#and Ferro Silico Chrome)#Application (Stainless Steel#Cast Iron#Powder Metallurgy#and Others) - Industry Trends and Forecast to 2029.#Access Full 350 Pages PDF Report @#https://www.databridgemarketresearch.com/reports/global-ferrochrome-market#**Segments**#- **Type**:#- High Carbon Ferrochrome#- Medium Carbon Ferrochrome#- Low Carbon Ferrochrome#- **Application**:#- Stainless Steel#- Engineering Steel#- Alloy Steel#- Others#- **End-Use Industry**:#- Aerospace#- Automotive#- Construction#The ferrochrome market can be segmented based on type#application#and end-use industry. In terms of type#the market is divided into high carbon ferrochrome

0 notes

Text

Driving Efficiency: Ferro Silicon Market Soars with Deoxidizer and Inoculants Applications

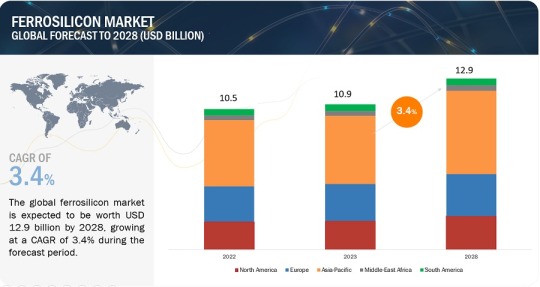

The report “Ferro Silicon Market by Type (Atomized Ferrosilicon, Milled ferrosilicon), Application (Deoxidizer, Inoculants), End-use Industry (Stainless Steel, Cast Iron, Magnesium), and Region (Asia Pacific, Europe, North America, MEA, SA) – Global Forecast to 2028″, is projected to reach USD 12.9 billion by 2028, at a CAGR of 3.4% from USD 10.9 billion in 2023. The ferrosilicon market is…

View On WordPress

#Atomized Ferrosilicon#Deoxidizer#Ferro Silicon#Ferro Silicon Alloy Market#Ferro Silicon Analysis#Ferro Silicon Consumption#Ferro Silicon Demand#Ferro Silicon Export Market#Ferro Silicon Growth#Ferro Silicon Industry#Ferro Silicon Manufacturer#Ferro Silicon Market#Ferro Silicon Market Dynamics#Ferro Silicon Market Forecast#Ferro Silicon Market Graph#Ferro Silicon Market Outlook#Ferro Silicon Market Research#Ferro Silicon Market Segmentations#Ferro Silicon Market Segments#Ferro Silicon Powder Market#Ferro Silicon Pricing#Ferro Silicon Production#Ferro Silicon Regional Growth#Ferro Silicon Supply#Ferro Silicon Trends#Global Ferro Silicon Market#Inoculants#Milled Ferrosilicon

0 notes

Text

Ferro Titanium Scrap Manufacturers, Suppliers in India

We have the lowest prices for Ferro titanium scrap and ferro nickel scrap in India. We offer above price as compared to others in India. Contact us for providing more details on the available product range.Website: http://www.ferrotitanium.in/

0 notes

Text

Optimizing Foundry Operations with Magnesium Cored Wire Feeders for Consistent Mg Recovery!

In the dynamic and demanding world of metallurgy, optimizing foundry operations to achieve consistent Mg recovery and efficient material processing is essential. One of the crucial components in this optimization process, particularly when dealing with ferro alloys like magnesium and its various alloys, is the proper application of wire feeding technology. These systems play a pivotal role in ensuring a smooth and effective process, especially in applications where high purity and precise control of magnesium content are required. As foundries seek to improve their operations, integrating Magnesium cored wire feeders has become an indispensable part of the solution.

The Role of Magnesium in Metallurgy

Magnesium, being a reactive metal with a high strength-to-weight ratio, is widely used in various alloys to enhance the properties of materials, particularly in the automotive and aerospace industries. Ferro alloys, such as ferro silicon magnesium, combine magnesium with other elements like silicon and are essential in the production of high-performance steel and other alloys. The magnesium in these alloys often needs to be added in precise quantities during the casting and steel-making processes to improve the material's strength, ductility, and resistance to corrosion.

However, adding magnesium to molten metal is not without its challenges. Magnesium is highly reactive and can burn off or evaporate if introduced too quickly or in excessive amounts, leading to inefficiency and a loss of the desired alloy properties. Here is where specific wire feeding systems find application. These systems ensure that magnesium is delivered in a controlled manner, improving the quality and efficiency of the overall process.

How Wire Feeders Enhance Foundry Operations

Wire feeders are engineered to introduce magnesium into molten metal in a controlled and precise manner. The core of these wires contains magnesium powder, which is delivered into the melt via a mechanical feeding mechanism. The wires are typically fed into the melt in a manner that ensures optimal dissolution and distribution of magnesium throughout the alloy.

The primary advantage of using wire feeders lies in their ability to deliver magnesium to the molten metal without the risk of excessive oxidation or evaporation. Unlike traditional methods, such as injecting magnesium gas or using larger chunks of magnesium metal, the wire introduces magnesium gradually, which allows the metal to be alloyed efficiently and effectively. This gradual introduction helps maintain the proper chemical composition of the alloy and reduces the potential for unwanted reactions that can compromise the quality of the final product.

By introducing magnesium through cored wire feeders, foundries can achieve a more consistent distribution of magnesium in the alloy, which is critical for meeting the stringent quality standards required in many industries. This consistency not only improves the mechanical properties of the alloy but also leads to greater reliability in the final product, ensuring a more stable process and ultimately improving the recovery rate of magnesium.

Benefits of Using Wire Feeders in Foundry Operations

Increased Precision and Control Wire feeders offer precise control over the amount of magnesium added to the melt. This accuracy ensures that the chemical composition of the alloy remains within the desired specifications, eliminating the risks of excess or insufficient magnesium. Overfeeding or underfeeding can result in suboptimal alloy properties, so being able to regulate the exact quantity of magnesium is crucial for maintaining quality.

Reduced Oxidation and Material Loss One of the challenges when using magnesium in metalworking is that it is highly reactive, particularly with oxygen. Traditional methods of adding magnesium, such as directly introducing magnesium ingots into the melt, can result in significant oxidation and material loss. Wire feeders are designed to minimize exposure to oxygen, which prevents the magnesium from burning off and ensures that the metal is utilized efficiently.

Improved Yield and Cost-Effectiveness With a more controlled and efficient introduction of magnesium into the melt, foundries can see an increase in yield. The improved efficiency also reduces the need for additional adjustments or corrective actions, ultimately leading to cost savings. Less waste material and reduced rework mean that foundries can run more cost-effectively while maintaining high standards of quality.

Enhanced Safety Handling magnesium directly can pose safety risks, particularly in terms of fire hazards. Wire feeding systems offer a safer alternative by minimizing the handling of raw magnesium. The feeder systems can be automated, reducing the need for manual intervention and limiting the exposure of workers to hazardous conditions. This is especially important in large-scale foundries where safety is a top priority.

Versatility and Flexibility Wire feeders are versatile and can be used in various foundry processes, such as steelmaking, cast iron production, and the creation of other ferro alloys. Whether it’s a high-volume industrial operation or a smaller, more specialized production line, these systems can be adapted to meet the specific needs of the foundry, offering flexibility in production capabilities.

Integration of Wire Feeders in Foundry Systems

Integrating wire feeders into existing foundry operations is straightforward but requires proper planning. A well-designed feeding system should align with the overall foundry workflow, from the preparation of molten metal to the final casting of the alloy. The system should be equipped with automated controls that allow operators to adjust the feeding rate, ensuring the proper amount of magnesium is delivered at the right time. Additionally, feeder systems should be regularly maintained to ensure their reliability and efficiency over time.

Furthermore, foundries must take into consideration the quality and specifications of the wire used. The wire must be produced to high standards to ensure uniformity and prevent issues such as wire breakage or clogging, which can disrupt the feeding process.

Conclusion

Magnesium cored wire feeder has emerged as a critical tool for optimizing foundry operations, especially when striving for high levels of recovery and efficiency in ferro alloys such as ferro silicon magnesium. By providing precise control over the introduction of magnesium into molten metal, these systems enhance the quality, consistency, and efficiency of alloy production. They address key challenges, such as oxidation and material loss, while improving safety and reducing costs. As foundries continue to seek ways to enhance their operations, the adoption of wire feeders presents a powerful solution for achieving superior alloy properties and maintaining high standards of quality.

The implementation of these systems is not only a step toward greater operational efficiency but also an investment in the long-term sustainability of the foundry industry. As technology continues to advance, the role of these feeders will likely grow, offering new possibilities for metal production and ensuring that foundries can meet the evolving demands of industries reliant on high-performance alloys.

#FerroSiliconMagnesium #ConsistentMgRecovery #MagnesiumCoredWireFeeder

#ferro silicon magnesium#consistent mg recovery#magnesium cored wire feeder#ferro silicon magnesium in india#bansal brothers#high recovery for ferro silicon magnesium#fesimg#magnesium cored wire injection system

0 notes

Text

What are the applications for niobium products?

Niobium product is dominated by its use as additive to high strength low alloy steel and stainless steel for oil and gas pipelines, car and truck bodies, architectural requirements, tool steels, ships hulls, railroad tracks. However, there are many other applications for niobium metal and compounds.

Niobium product application & technical benefits Niobium oxide - Manufacture lithium niobate for surface acoustic wave filters - Camera lenses - Coating on glass for computer screens - Ceramic capacitors - High index of refraction - High dielectric constant - Increase light transmittance

Niobium carbide -Cutting tool compositions -High temperature deformation, controls grain growth

Niobium powder -Niobium capacitors for electronic circuits -High dielectric constant, stability of oxide dielectric

Niobium metal plates, sheets, wire, rod, tubing

- Sputtering targets - Cathode protection systems for large steel structures - Chemical processing equipment -Corrosion resistance, formation of oxide and nitride films. Increase in high temperature resistance and corrosion resistance, oxidation resistance, improved creep resistance, reduced erosion at high temperatures.

Niobium-titanium alloy Niobium-tin alloy Superconducting magnetic coils in magnetic resonance imagery (MRI), magnetoencephalography, magnetic levitation transport systems, particle physics experiments. Electrical resistance of alloy wire drops to virtually zero at or below temperature of liquid helium (-268.8°C).

Niobium-1% zirconium alloy - Sodium vapor lamps - Chemical processing equipment -Corrosion resistance, fixation of oxygen, resistance to embrittlement. -Vacuum-grade ferro-niobium and nickel-niobium -Superalloy additions for turbine blade applications in jet engines and land-based turbines.

Inconel family of alloys, superalloys. Increase in high temperature resistance and corrosion resistance, oxidation resistance, improved creep resistance, reduced erosion at high temperatures.

https://www.etimaterials.org/niobium/

https://www.edge-techind.com/Products/Refractory-Metals/Niobium/Niobium-Alloys/Niobium-Zirconium-Alloy-179-1.html

0 notes

Text

Ferro Alloy Powder Market to Witness Excellent Revenue Growth Owing to Rapid Increase in Demand

The Ferro Alloy is an alloy of iron that consist of some element other than carbon, which mostly consumed in the aluminum industry as an alloying agents and also in chemical industry. Ferro Alloy market is expected to mark significant growth over forecasted period owing to increasing used for physically introduce or carry that element into molten metal, usually during steel manufacture applications and technological advancement. Ferro Alloy is used to include any alloys that introduce reactive elements or alloy systems, such as nickel and cobalt-based aluminum systems. The major companies are adding more proven technologies systematically and strategically in Asia-Pacific countries as these countries are focused on fastest-growing verticals in the Metallurgical industry.

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/73455-global-ferro-alloy-powder-market?utm_source=Organic&utm_medium=Vinay

Latest released the research study on Global Ferro Alloy Powder Market, offers a detailed overview of the factors influencing the global business scope. Ferro Alloy Powder Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Ferro Alloy Powder The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are Jayesh Group (India), Kamman Group (India), JMC (Japan Metals & Chemicals) (Japan), IFAPA (Seville), Crown Ferro Alloys (India), NISHIT THERMIT ALLOYS PVT LTD (India), MidUral Group (Russia), Titan International (United States), Ecka Granules (Germany), Cheegoole Company (China),

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

Contact Us:

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

0 notes

Text

Ferro Molybdenum: A Critical Alloy In Modern Metallurgy

(Source – Wikipedia).

Ferro molybdenum, an essential alloy in modern metallurgy, combines iron and molybdenum, providing exceptional strength, hardness, and resistance to corrosion. This alloy plays a vital role in the production of high-performance steels and superalloys, making it indispensable in various industrial applications, including construction, automotive, and aerospace. This article explores the production, properties, applications, and significance of ferro molybdenum in contemporary engineering and manufacturing.

Production of Ferro Molybdenum

The production involves several stages, starting from the extraction of molybdenum ore to the final alloying process.

1. Extraction of Molybdenum:

Molybdenum is primarily obtained from molybdenite (MoS₂) ore. The ore is mined through open-pit or underground methods and then processed to extract molybdenum concentrate. The concentrate typically contains around 85-90% molybdenum disulfide.

2. Roasting:

The molybdenum concentrate is roasted in the presence of oxygen to convert molybdenum disulfide into molybdenum trioxide (MoO₃). The chemical reaction is as follows:

This step is crucial as it removes sulfur and produces a more refined molybdenum product.

3. Reduction:

The molybdenum trioxide is then reduced using hydrogen or carbon to produce molybdenum metal powder. The reduction process using hydrogen can be represented by:

4. Alloying:

Finally, the molybdenum metal powder is mixed with iron and subjected to a high-temperature furnace to produce ferro molybdenum. This process involves melting the metals together to form a homogeneous alloy, typically containing 60-75% molybdenum by weight.

Properties of Ferro Molybdenum

It possesses a range of properties that make it highly valuable in metallurgical applications:

1. High Strength and Hardness:

Molybdenum enhances the strength and hardness of steel, making ferromolybdenum an ideal additive for high-strength alloys.

2. Corrosion Resistance:

Molybdenum improves the corrosion resistance of steel, particularly in acidic and chloride-containing environments. This property is critical for applications in chemical processing and marine industries.

3. High Melting Point:

Molybdenum has a high melting point (2,623°C), which contributes to the heat resistance of ferro molybdenum alloys. This makes them suitable for high-temperature applications.

4. Good Weldability:

Ferro molybdenum alloys exhibit excellent weldability, allowing for the production of robust welded joints in construction and manufacturing.

5. Thermal Expansion:

Molybdenum reduces the thermal expansion of steel, enhancing the dimensional stability of components exposed to temperature variations.

Applications of Ferro Molybdenum

The unique properties of ferromolybdenum make it indispensable in various industrial sectors:

1. Steel Production: The primary use of ferromolybdenum is in the production of high-strength and stainless steel. It is added to steel to improve hardenability, strength, toughness, and resistance to wear and corrosion. Common applications include:

Construction: Structural steels used in buildings, bridges, and infrastructure.

Automotive: High-strength steel for car bodies, engine components, and transmission systems.

Oil and Gas: Steels are used in pipelines, drilling equipment, and offshore platforms, where corrosion resistance is crucial.

2. Superalloys: Ferromolybdenum is a key ingredient in the manufacture of superalloys, which are used in demanding environments requiring exceptional mechanical properties and resistance to heat and corrosion. Applications include:

Aerospace: Turbine blades, engine parts, and exhaust systems in aircraft and spacecraft.

Power Generation: Components in gas turbines and power plants.

3. Chemical Processing: In the chemical industry, ferromolybdenum is used to produce corrosion-resistant equipment, such as reactors, heat exchangers, and piping systems, which are exposed to harsh chemicals and high temperatures.

4. Electronics: Molybdenum’s high conductivity and thermal stability make ferromolybdenum alloys suitable for electronic and electrical applications, including semiconductor devices, cathodes, and electrical contacts.

5. Medical Devices: The biocompatibility and corrosion resistance of molybdenum-containing alloys makes them ideal for medical implants and surgical instruments.

Significance in Modern Engineering

Ferromolybdenum’s impact on modern engineering is profound, contributing to advancements in material science and industrial technology. Its ability to enhance the mechanical properties of steel and other alloys has led to the development of stronger, more durable, and more reliable materials. This, in turn, has enabled the creation of innovative structures, vehicles, machinery, and devices that withstand extreme conditions and meet stringent safety standards.

Environmental Impact: While the production of ferromolybdenum involves significant energy consumption and potential environmental concerns, ongoing research and development efforts aim to minimize the ecological footprint. Sustainable practices in mining, refining, and alloy production, along with recycling initiatives, are crucial in mitigating the environmental impact.

Economic Importance: The demand for ferromolybdenum is closely tied to the global steel industry, making it a valuable commodity in international markets. Its importance in critical industries such as construction, automotive, and aerospace underscores its economic significance.

Future Trends: The future of ferromolybdenum looks promising, with advancements in material science and metallurgy driving innovation. Emerging technologies, such as additive manufacturing (3D printing) and the development of new alloys with enhanced properties, will likely expand the applications and demand for ferromolybdenum.

Conclusion

Ferromolybdenum is a cornerstone of modern metallurgy, providing essential properties that enhance the performance and durability of steels and superalloys. Its wide range of applications, from construction and automotive to aerospace and chemical processing, highlights its versatility and importance. As technology advances and new challenges arise, ferro molybdenum will continue to play a critical role in developing high-performance materials that meet the demands of contemporary engineering and manufacturing. Understanding the production processes, properties, and applications of ferro molybdenum is essential for industries aiming to leverage its benefits and drive innovation in material science.

#ModernMetallurgy#FerroMolybdenum#HighPerformanceAlloys#IndustrialApplications#MaterialScienceInnovation

0 notes

Text

Experience Excellence in Metal Powders with G K Min Met Alloys Co.

At G K Min Met Alloys Co., we take pride in being a leading supplier of high-quality metal powders. Located in the industrial hub of Vadodara, Gujarat, we are committed to delivering excellence through our wide range of products, which include Low Carbon Ferro Chrome Powder, Nickel Metal Powder, Chromium Metal Powder, Manganese Metal Powder, and Iron Powder.

Our Products

Low Carbon Ferro Chrome Powder:

Description: Our Low Carbon Ferro Chrome Powder is known for its superior quality and purity. It is extensively used in the production of stainless steel and special alloys, providing excellent corrosion resistance and durability.

Applications: Stainless steel manufacturing, special alloy production, welding electrodes.

Nickel Metal Powder:

Description: We offer premium Nickel Metal Powder with high purity, ideal for various industrial applications. Its excellent thermal and electrical conductivity makes it a preferred choice in the electronics and aerospace industries.

Applications: Electronics, aerospace, battery production, electroplating.

Chromium Metal Powder:

Description: Our Chromium Metal Powder is characterized by its high melting point and corrosion resistance, making it perfect for use in high-performance materials.

Applications: Metallurgical applications, aerospace components, specialty alloys.

Manganese Metal Powder:

Description: Known for its robustness and reliability, our Manganese Metal Powder is essential in steel production, improving the hardness and strength of the final product.

Applications: Steel manufacturing, aluminum alloys, welding consumables.

Iron Powder:

Description: Our Iron Powder is highly versatile and used in a variety of industries. It is crucial in the production of magnetic materials and as a raw material in chemical processes.

Applications: Magnetic materials, chemical industry, powder metallurgy.

Why Choose G K Min Met Alloys Co.?

Quality Assurance: We adhere to stringent quality control measures to ensure that our products meet the highest industry standards.

Customer Focus: Our team is dedicated to understanding and meeting the specific needs of our clients, ensuring complete satisfaction.

Innovation and Sustainability: We are committed to continuous improvement and sustainable practices in our manufacturing processes.

Strategic Location: Based in Vadodara, Gujarat, we leverage our strategic location to efficiently serve clients both locally and internationally.

Our Commitment

At G K Min Met Alloys Co., we believe in building long-term relationships with our clients through trust, quality, and exceptional service. Our expert team is always ready to assist you with your specific requirements and provide tailored solutions to meet your industrial needs.

For more information or to place an order, please contact us at [email protected] or visit our facility in Vadodara, Gujarat. Experience the excellence of G K Min Met Alloys Co., your reliable partner in metal powders.

#Low Carbon Ferro Chrome Powder#Nickel Metal Powder#Chromium Metal Powder#Manganese Metal Powder#Iron Powder

0 notes

Text

G K Min Met Alloys Co.

In the dynamic landscape of the metal powder industry, G K Min Met Alloys Co. is paramount for ensuring product quality, consistency, and reliability. Whether you're in need of nickel metal powder, low carbon ferro chrome powder, chromium metal powder, iron powder, or ferro vanadium powder, identifying trustworthy suppliers is crucial for the success of your projects. In this comprehensive guide, we delve into some of the top suppliers in the industry to help you make informed decisions.

1. Nickel Metal Powder Suppliers:

Nickel metal powder is widely used in various industries, including aerospace, automotive, and electronics, due to its excellent properties such as corrosion resistance and high temperature resistance. When sourcing nickel metal powder, it's essential to partner with suppliers known for their quality products and reliable services. Look for suppliers with a proven track record in delivering high-purity nickel metal powder that meets industry standards.

2. Low Carbon Ferro Chrome Powder Manufacturers:

Low carbon ferro chrome powder is a crucial alloying element in stainless steel production, imparting desirable properties such as corrosion resistance and hardness. When selecting low carbon ferro chrome powder manufacturers, prioritize suppliers with expertise in alloy production and a commitment to quality control. Seek out manufacturers who adhere to stringent manufacturing processes to ensure the consistency and purity of their products.

3. Chromium Metal Powder Manufacturers:

Chromium metal powder finds applications in diverse industries, including metallurgy, coatings, and electronics, owing to its exceptional hardness and corrosion resistance. When sourcing chromium metal powder, opt for manufacturers with advanced production facilities and stringent quality control measures. Consider suppliers who offer customized solutions to meet your specific requirements and provide technical support to assist you in optimizing your applications.

4. Iron Powder Exporters:

Iron powder is a versatile material with applications ranging from metallurgy and automotive to electronics and construction. As a key component in powder metallurgy processes, the quality of iron powder directly impacts the performance of the final products. When choosing iron powder exporters, prioritize suppliers with a comprehensive understanding of powder metallurgy and a commitment to excellence in product quality and customer service.

5. Ferro Vanadium Powder Suppliers:

Ferro vanadium powder is widely used as an alloying agent in the production of high-strength steel and other alloy materials. When sourcing ferro vanadium powder, partner with suppliers renowned for their expertise in metallurgy and alloy production. Look for suppliers who offer high-purity ferro vanadium powder with consistent particle size distribution and excellent metallurgical properties. In conclusion G K Min Met Alloys Co. the metal powder industry is essential for achieving success in your projects. By partnering with reputable suppliers who prioritize quality, consistency, and customer satisfaction, you can ensure the superior performance of your products and drive innovation in your respective fields. Take the time to research and evaluate potential suppliers to make informed decisions that align with your specific requirements and objectives.

0 notes

Text

Innovations in Ferro Alloy Production to Drive Sustainability

Ferro alloys play a vital role in various industries, providing essential properties such as strength, heat resistance, and corrosion resistance. However, traditional methods of ferro alloy production often come with environmental and sustainability challenges. As a result, the industry is undergoing a shift towards more sustainable production practices.

One of the key innovations in ferro alloy production is the adoption of greener technologies and processes. Advancements in technology are enabling Bulk Ferro Alloy Exporters in India and abroad to transition towards cleaner and more sustainable alternatives. For example, the use of electric arc furnaces powered by renewable energy sources can significantly reduce carbon footprint.

Sustainable Practices with Green Technologies

The pursuit of sustainability has spurred the development of green technologies in ferro alloy production. These innovations focus on reducing energy consumption, minimizing emissions, and optimizing resource utilization throughout the production process. The advancements include:

Adoption of energy-efficient furnaces and reactors that utilize advanced heating and cooling systems to reduce energy wastage and improve process efficiency.

Integration of renewable energy sources, such as solar and wind power, into production facilities further reduces carbon footprint and reliance on fossil fuels.

Advancements in process optimization and waste management techniques enable manufacturers to minimize waste generation and maximize resource recovery, contributing to a more sustainable and environmentally friendly ferro alloy industry.

Digitalization and Automation for Efficiency

Digitalization and automation technologies are revolutionizing ferro alloy production, driving improvements in efficiency, quality, and safety. The integration of sensors, data analytics, and artificial intelligence (AI) into production processes enables real-time monitoring and control, optimizing process parameters and reducing variability.

Predictive maintenance algorithms predict equipment failures before they occur, minimizing downtime and maximizing uptime. Furthermore, automated material handling systems and robotics streamline material flow and logistics, reducing manual labor requirements and improving overall productivity.

By harnessing the power of digitalization and automation, manufacturers can achieve higher levels of efficiency and performance while reducing operational costs and environmental impact.

Alloy Design and Product Development to Meet Market Demands

Innovations in alloy design and product development are shaping the future of ferro alloy production, enabling manufacturers to meet the evolving demands of end-users and industries. Advanced alloy formulations and refining techniques allow for the customization of ferro alloys with specific chemical compositions and properties tailored to meet the requirements of various applications.

Additionally, advancements in alloy processing technologies, such as powder metallurgy and additive manufacturing, offer new possibilities for producing complex shapes and components with enhanced performance characteristics. By continually innovating in alloy design and product development, manufacturers can stay ahead of market trends and deliver solutions that meet the needs of their customers.

Innovations in ferro alloy production are driving significant advancements in sustainability and performance, paving the way for a more efficient, environmentally friendly, and economically viable industry. Ferro alloy companies such as Ferro Manganese Manufacturers in India and abroad are adopting green technology to produce ferro alloys in bulk quantities while keeping a check on sustainability.

From green technologies and digitalization to alloy design and product development, these innovations are revolutionizing the way ferro alloys are manufactured, enabling manufacturers to meet the demands of a rapidly evolving market while minimizing their environmental footprint and maximizing their competitiveness. As the industry continues to embrace innovation, the future of ferro alloy production looks brighter than ever.

0 notes

Text

What Sets Top Ferro Alloys Suppliers Apart in the Ferro Titanium Alloy Market

The ferroalloys industry is essential to modern manufacturing, playing a significant role in steelmaking, aerospace, and automotive industries. Suppliers in this space vary in their ability to deliver reliable, high-quality materials, making it important to understand what distinguishes the top players. Several factors set leading ferro titanium suppliers apart and make them preferred partners for industries reliant on ferroalloys.

1. Unwavering Focus on Quality

One of the most defining traits of top suppliers is their commitment to quality. These companies adhere to strict quality control processes, ensuring their products meet international standards. They deliver materials that perform reliably across diverse applications by implementing advanced testing protocols and consistently refining their production methods.

This focus on quality benefits customers by reducing operational risks, minimizing downtime, and ensuring the final products meet desired specifications.

2. Technological Excellence

Innovation is a cornerstone of success in the ferroalloys sector. Leading suppliers invest in advanced technologies that enhance the efficiency and precision of their manufacturing processes. From automated systems to sophisticated refining techniques, these technologies result in materials with consistent properties and reduced impurities.

The use of cutting-edge technology ensures better alloy performance and reduces waste, making it an advantage for industries requiring precision and reliability in their raw materials.

3. Experience and Expertise

Decades of experience and deep industry knowledge are hallmarks of top suppliers. This expertise allows them to understand the unique challenges of various industries and provide tailored solutions. Their ability to offer guidance on material selection and application ensures customers get the most suitable products for their needs.

This knowledge extends to market trends, helping suppliers anticipate customer demands and stay ahead of industry changes.

4. Strong Global Logistics

Reliable suppliers understand the importance of efficient delivery systems. With global demand for ferro titanium alloys, timely delivery is often crucial to avoid production delays. Leading suppliers have robust logistics networks, including strategically located production and distribution hubs.

Their expertise in navigating international trade regulations ensures smooth transactions and minimizes delays in cross-border shipments, making them dependable partners for industries worldwide.

5. Flexibility and Customization

Not all customers have the same requirements. Top suppliers recognize this and offer customized solutions, whether it’s adjusting the composition of alloys or accommodating specific packaging needs.

Flexibility also extends to production volumes, with the ability to fulfill both small-scale and bulk orders. This adaptability makes them valuable to businesses with diverse operational demands.

6. Sustainability Practices

Sustainability has become a key differentiator in many industries, and ferro alloys manufacturing is no exception. Leading suppliers prioritize eco-friendly practices, focusing on energy-efficient processes, waste reduction, and ethical sourcing of raw materials.

By aligning their operations with global sustainability goals, these companies appeal to environmentally conscious clients and contribute to creating a greener supply chain.

7. Customer-Centric Approach

Top suppliers place a high emphasis on customer satisfaction. They provide comprehensive support, from initial consultations to post-sale assistance, ensuring a seamless experience for their clients.

Regular updates, transparent communication, and quick resolution of issues strengthen their relationships with customers. This level of service not only builds trust but also encourages long-term partnerships.

8. Competitive Value Offering

Price is always a consideration, but leading suppliers focus on delivering value rather than just low costs. Their efficient processes and economies of scale enable them to offer competitive pricing while maintaining high-quality standards.

Customers benefit from this balance, knowing they are getting dependable products at fair rates, without compromising on performance or service.

Conclusion

What sets leading suppliers apart in the ferroalloys market is their dedication to quality, innovation, and customer satisfaction. Their ability to deliver consistent products, adapt to customer needs, and operate sustainably ensures they remain at the forefront of the industry.

For businesses relying on ferroalloys, choosing a top supplier is an investment in reliability, efficiency, and long-term success.

#FerrAlloysSuppliers #FerroTitaniumAlloys #FerroTitaniumManufacturerIndia #FerroTitaniumProducersInIndia #FerroTitaniumScrap

#ferro titanium alloys#ferro alloys suppliers#ferro titanium manufacturer in india#ferro titanium in india#ferro titanium cored wire#ferro titanium producers in india#ferro titanium powder#ferro titanium scrap#ferro titanium

0 notes

Text

Premium Ferro Molybdenum Powder Manufacturer - Jayesh Group

Elevate your industrial processes with Jayesh Group's premium Ferro Molybdenum Powder, a powerful alloy of iron and molybdenum. Engineered for exceptional strength and durability, our product enhances steel properties, making it perfect for manufacturing high-performance alloys. Trust Jayesh Group for top-grade Ferro Molybdenum Powder that redefines quality and reliability in every application.

0 notes

Text

0 notes

Text

Why High Recovery of Ferro Silicon Magnesium Relies on Quality Magnesium Cored Wire Feeders.

In modern metallurgy, the demand for high-quality ferroalloys like ferro silicon magnesium (FeSiMg) is essential, especially in producing high-strength, corrosion-resistant alloys. One of the significant factors that enhance the quality and recovery rates of FeSiMg is the use of a high-quality magnesium cored wire feeder. This article explores how magnesium wire feeders contribute to the high recovery for ferro silicon magnesium and why investing in premium feeders is a strategic advantage for manufacturers.

What is Ferro Silicon Magnesium?

Ferro silicon magnesium is an alloy of iron, silicon, and magnesium that plays a vital role in foundry processes, especially in the production of ductile iron. Its inclusion in metal alloys enhances durability, elasticity, and overall strength, making it highly sought after in industries like automotive, construction, and heavy machinery. Achieving optimal recovery of FeSiMg in the alloying process is crucial because it directly impacts the quality and cost-efficiency of the production.

The Role of Magnesium Cored Wire Feeder

A magnesium cored wire feeder is a specialized device used in the alloying process to introduce magnesium into the molten metal. The cored wire, a tube filled with powdered magnesium, is precisely fed into the molten bath, allowing for controlled and efficient dispersion of magnesium. This method ensures that the magnesium does not oxidize quickly, thus optimizing its incorporation and maximizing recovery rates.

Why Quality Cored Wire Feeders Matter

Using a high-quality magnesium cored wire feeder significantly impacts the recovery of FeSiMg in several ways:

1. Consistent Magnesium Insertion

High-quality cored wire feeders are designed for precision. By controlling the feed rate and insertion depth, they allow for a uniform and consistent introduction of magnesium into the molten metal, preventing waste and ensuring optimal recovery rates. Inconsistent or poorly designed feeders may lead to irregular magnesium distribution, affecting the alloy quality and overall recovery.

2. Enhanced Efficiency and Cost-Effectiveness

Premium feeders are engineered for efficiency, meaning less magnesium is required to achieve the desired FeSiMg composition. This not only reduces material costs but also minimizes waste by ensuring that the maximum amount of magnesium is effectively incorporated into the alloy, resulting in higher recovery rates. Low-grade feeders, on the other hand, can result in inefficient magnesium consumption and higher operational costs.

3. Reduction of Oxidation Losses

One of the primary challenges in the alloying process is preventing magnesium oxidation, which can significantly reduce recovery rates. Quality cored wire feeders are designed to minimize oxidation by controlling the introduction of magnesium precisely and swiftly into the molten metal. By reducing exposure to air, high-quality feeders help prevent magnesium from burning off, thus boosting the recovery of FeSiMg.

4. Durability and Reliability

Investing in a high-quality cored wire feeder translates to long-term durability and reliability. These feeders are built with materials and designs that withstand the high temperatures and demanding conditions of foundries. Low-quality feeders are prone to breakdowns and inconsistent performance, which can interrupt production and impact the recovery of FeSiMg.

5. Improved Control Over Alloy Composition

Consistency is key when producing high-quality alloys. Premium cored wire feeders provide operators with better control over the addition of magnesium, allowing them to maintain specific composition standards in FeSiMg production. This precision contributes to consistent high recovery rates, which is especially beneficial for industries that rely on strict material specifications.

Key Features of Quality Magnesium Cored Wire Feeders

To achieve high recovery rates for ferro silicon magnesium, it’s essential to choose feeders that offer:

Precision Feed Control: Allows for accurate and consistent magnesium delivery.

Anti-Oxidation Design: Minimizes air exposure to reduce oxidation losses.

High-Temperature Resistance: Ensures durability and continuous operation in demanding environments.

Easy Adjustability: Allows operators to control feed speed and depth for optimal recovery.

Low Maintenance Requirements: Reduces downtime and keeps costs manageable.

Benefits of High Recovery for FeSiMg Manufacturers

When manufacturers prioritize high recovery for FeSiMg, they benefit in several ways:

Cost Savings: Reduced magnesium consumption translates to lower material costs.

Enhanced Product Quality: High-quality FeSiMg improves the overall properties of alloys, making them more desirable for end-users.

Environmental Impact: Efficient alloy production means less waste and a reduced environmental footprint, which is a growing concern in the industry.

Competitive Advantage: Companies that consistently produce high-quality alloys with optimized recovery rates gain a competitive edge in the marketplace.

Conclusion

Achieving high recovery for ferro silicon magnesium relies heavily on the quality of magnesium cored wire feeders used in the alloying process. Investing in premium feeders offers greater control, efficiency, and reliability, all of which contribute to superior recovery rates and overall product quality. For manufacturers focused on producing high-grade alloys, a quality magnesium cored wire feeder is an invaluable asset that pays off in improved performance, cost savings, and competitive positioning.

#highrecoveryforferrosiliconmagnesium #magnesiumcoredwirefeeder

#high recovery for ferro silicon magnesium#magnesium cored wire feeder#ferro silicon magnesium#ferro silicon magnesium manufacturers#ferro silicon magnesium in india

0 notes