#f304l

Text

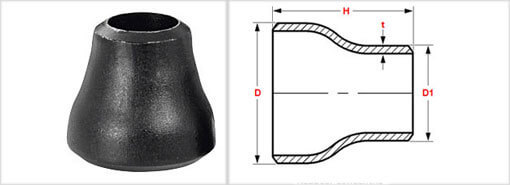

Concentric Reducers Exporters in India

CONCENTRIC REDUCERS

The Concentric Reducers are accessible in assortment of shapes and measurements to suit real pipeline establishment necessities in commercial ventures. This is a standout amongst the most generally utilized modern funnel fitting for adjusting distinctive channel sizes in a pipeline framework. It is fundamentally used to associate two funnels with various widths.

Produced using best grades of stainless steel, these reducers are accessible in an extensive variety of sizes, divider thicknesses and weight evaluations to look over as indicated by the pipeline. Guaranteeing an in-line funnel shaped move between various widths of pressurized channels, these concentric reducers join the pipelines on the same axis.The development of these reducers is finished by joining the little breadths and expansive distances across on inverse closures of cone formed move area. Discover application in petrochemicals, sugar factories and refineries, steel plants and bond and development commercial ventures, the reducer has separate gulf and outlet closes.TECHNICAL SPECIFICATIONSSTANDARD MATERIAL GRADES OF BUTTWELD SS REDUCER

Stainless steel grades:

ASTM A403 Grade WP304, WP304L, WP304H, WP304N, WP304LN, WP309, WP310S, WPS31254, WP316, WP316L, WP316H, WP316N, WP316LN, WP317, WP317L, WP321H, WP321, ASTM A815 S31803, S32750, S32760, S32205

Standard material grades in stainless steel:

ASTM A182 F304, F304H, F304L, F304N, F304LN, F309H, F310, F310H, F316, F316H, F316L, F316N, F316LN, F317, F317L, F347, F347H, F321, F321H, FXM-19, F50, F51, F53, F55, F60, F904L

Application Areas:

Oil and gas industry

Petrochemical industry

Power stations

Shipbuilding industry

10 notes

·

View notes

Text

Trunnion Ball Valve Manufacturers

Speciality Valve is distinguished as the leading Trunnion Ball Valve Manufacturers in India, catering to regions like Karnataka, Uttar Pradesh, and Andhra Pradesh.

What are Trunnion Ball Valves and How They Work?

Trunnion ball valves hold significant importance in fluid control systems, facilitating the regulation of various fluids such as steam, gas, or oil within pipelines. It is a quarter-turn device with a ball that can rotate 90 degrees on its axis to either block or allow fluid flow. The main body of these valves has a spherical disk design that revolves to control the start-stop flow cycle. The disk, also known as the ball, has a little extending shaft at the top and bottom that is mechanically supported.

The flow within a trunnion ball valve is regulated by the position of an opening located in the center of the ball. The trunnion ball valve has an additional shaft that holds the ball from under. The Trunnion is a simple shaft. Its purpose is to keep the ball securely attached. In some cases, the Trunnion is an extension of the spherical ball, and in others, it is joined to the spherical ball disk by welded joints.

Key Components:

Body: The main housing of the valve, providing structural support.

Ball: Spherical disk within the valve body, rotates to control fluid flow.

Trunnion: Shaft supporting the ball from below, ensuring secure attachment.

Seat: Machined surface where the ball makes contact to regulate flow.

Stem: Connects the actuator to the ball, facilitating its rotation.

Disk: Another term for the ball, referring to its spherical shape.

Actuator: Mechanism for operating the valve, such as handwheel or gear.

Injection: Feature allowing for the introduction of sealant or lubricant into the valve.

Trunnion-mounted ball valves offer advantages in industries requiring precise shut-off action due to their inherent flexibility and reliability.

We are Trunnion Ball Valve Manufacturers in India our valve give following advantages:

Long Service Life: Built to withstand wear and tear, ensuring durability.

High Pressure and Temperature Handling: Capable of operating in demanding conditions.

Wide Range of Materials: Available in various materials to suit diverse applications.

Tight Shutoff: Ensures minimal leakage for precise flow control.

Easy Operation: User-friendly design for seamless valve operation.

Customizable: Can be tailored to specific requirements for optimal performance.

Corrosion Resistance: Resistant to corrosion, extending valve lifespan.

Industries:

Oil and Gas Industry: Used in upstream, midstream, and downstream operations.

Petrochemical Industry: Essential for handling chemicals and petrochemical products.

Chemical Industry: Suitable for controlling the flow of various chemicals and solvents.

Power Generation Industry: Employed in power plants for fluid control applications.

Water and Wastewater Treatment Plants: Ensures efficient management of water resources.

Mining Industry: Used in mining operations for slurry and fluid control.

Hydrocarbon Industry: Critical for handling hydrocarbons and related fluids.

Product Description:

Available Materials: F304L, A105, A182 F304, F316, F51, F316L, F53, A350 LF2, LF3, Inconel, Monel, Hastelloy (Forging), A351 CF3, A351 CF8, A216 WCB, A351 CF3M, A351 CF8M, A890 4A/5A, A352 LCC/LCB (Casting)

Class: 150-2500, PN25 – PN450.

Size: 2” to 48”.

Ends: Buttweld, Socket weld, Threaded, Flanged

Operations: Handwheel Operated, Gear Operated, Electric Actuated, Pneumatic Operated.

For more details, visit our website: https://www.specialityvalve.com/product-category/trunnion-ball-valve/

Address:- Corporate Office, Specialityvalve, 37 NGR Street, P.N Palayam, Coimbatore, Tamil Nadu – 641037

0 notes

Text

Forged Steel Gate Valve Manufacturer in USA

SVR Global is the top Forged steel gate valve manufacturer in USA servicing mining, chemical, and oil and gas industries with valves of the highest quality. An industrial valve used to control fluid flow in pipelines is a forged steel gate valve. It has a gate mechanism that may be raised or lowered to control the flow of fluid through the valve and is composed of forged steel, which is a strong and long-lasting material. They are appropriate for businesses that must distinguish between thick fluids and liquids. These valves have a rising stem attached to a yolk, as well as an outside screw.

SVR Global, the Forged steel gate valve manufacturer in USA offers valves with a strong body that can withstand harsh conditions. These valves provide a safe and secure shutdown either in horizontal or vertical positions to process the mediums in pipes.

PARTS

Valve body

Seat and Gate

Stem

Bonnet

Operator

INDUSTRIES

Water industry

Sewage industry

Power production industry

Oil and Gas Industry

Chemical Industry

Petrochemical Industry

Mining Industry

Marine Industry

Textile industry

APPLICATIONS

Oil and Gas Industry: Forged steel gate valves are commonly used in the oil and gas industry for various applications such as upstream, midstream, and downstream processes, including drilling, extraction, transportation, and refining.

Petrochemical Industry: Forged steel gate valves are widely used in the petrochemical industry for controlling the flow of various fluids and gases in chemical processing plants, refineries, and other related facilities.

Power Generation: Forged steel gate valves are used in power generation plants to control the flow of water, steam, and other fluids in boilers, turbines, and other equipment.

Water Treatment: Forged steel gate valves are also used in water treatment plants to regulate the flow of water and other fluids in various stages of the treatment process.

ADVANTAGES

Reliable and durable construction

Can withstand high pressure and high temperature

Suitable for corrosive fluids and gases

Minimal flow resistance

Provides tight shut-off capability

Low maintenance requirements

Flexibility in installation orientation (horizontal or vertical)

Can be operated manually or automated with actuators

Long service life and reduced replacement costs

Good for throttling applications due to ability to partially open

Wide range of sizes and materials available to suit different needs and requirements

Resistance to wear and erosion

DESCRIPTION:

Material: A105, F11, F22, F51, LF2, F304, F304L, F316, F316, F91, ASTM A 105 – Forged Carbon Steel, ASTM A 182 F 304/304L/316/316L – Forged Stainless Steel 304/304L/316/316L, ASTM A 182 F 11/22

Sizes– 1/2″ to 2″

Class: 150 to 2500, PN25 to PN450

End Connections: Buttweld, Socket weld, Flanged, Threaded

Operations: Hand Wheel Gate valve, Gear operated Gate valve, Electric actuated Gate valve and Pneumatic Actuated Gate valve

Visit our website for more information-

1 note

·

View note

Text

Trunnion Ball Valve Manufacturer in India

Speciality Valve is distinguished as the leading Trunnion Ball Valve Manufacturer in India, catering to regions like Karnataka, Uttar Pradesh, and Andhra Pradesh.

What are Trunnion Ball Valve and working?

Trunnion ball valves hold significant importance in fluid control systems, facilitating the regulation of various fluids such as steam, gas, or oil within pipelines. It is a quarter-turn device with a ball that can rotate 90 degrees on its axis to either block or allow fluid flow. The main body of these valves has a spherical disk design that revolves to control the start-stop flow cycle. The disk, also known as the ball, has a little extending shaft at the top and bottom that is mechanically supported.

The flow within a trunnion ball valve is regulated by the position of an opening located in the center of the ball. The trunnion ball valve has an additional shaft that holds the ball from under. The Trunnion is a simple shaft. Its purpose is to keep the ball securely attached. In some cases, the Trunnion is an extension of the spherical ball, and in others, it is joined to the spherical ball disk by welded joints.

Trunnion-mounted ball valves offer advantages in industries requiring precise shut-off action due to their inherent flexibility and reliability.

Key Components:

Body: The main housing of the valve, providing structural support.

Ball: Spherical disk within the valve body, rotates to control fluid flow.

Trunnion: Shaft supporting the ball from below, ensuring secure attachment.

Seat: Machined surface where the ball makes contact to regulate flow.

Stem: Connects the actuator to the ball, facilitating its rotation.

Disk: Another term for the ball, referring to its spherical shape.

Actuator: Mechanism for operating the valve, such as handwheel or gear.

Injection: Feature allowing for the introduction of sealant or lubricant into the valve.

Advantages of Our Trunnion Ball Valves

Long Service Life: Built to withstand wear and tear, ensuring durability.

High Pressure and Temperature Handling: Capable of operating in demanding conditions.

Wide Range of Materials: Available in various materials to suit diverse applications.

Tight Shutoff: Ensures minimal leakage for precise flow control.

Easy Operation: User-friendly design for seamless valve operation.

Customizable: Can be tailored to specific requirements for optimal performance.

Corrosion Resistance: Resistant to corrosion, extending valve lifespan.

Industries:

Oil and Gas Industry

Petrochemical Industry

Chemical Industry

Power Generation Industry

Water and Wastewater Treatment Plants

Mining Industry

Description :

Available Materials: F304L, A105, A182 F304, F316, F51, F316L, F53, A350 LF2, LF3, Inconel, Monel, Hastelloy(Forging), A351 CF3, A351 CF8, A216 WCB, A351 CF3M, A351 CF8M, A890 4A/ 5A, A352 LCC/ LCB (Casting)

Class: 150-2500, PN25 – PN450.

Size: 2” to 48”.

Ends: Buttweld, Socket weld, Threaded, Flanged

Operations: Handwheel Operated, Gear Operated, Electric Actuated, Pneumatic Operated.

For more details, visit our website: https://www.specialityvalve.com/product-category/trunnion-ball-valve/

0 notes

Text

Forged Steel Gate Valve Manufacturer in Norway

Forged Steel Gate Valve Manufacturer in Norway

Valvesonly Europe is the top Forged steel gate valve manufacturer in Norway servicing mining, chemical, and oil and gas industries with valves of the highest quality. An industrial valve used to control fluid flow in pipelines is a forged steel gate valve. It has a gate mechanism that may be raised or lowered to control the flow of fluid through the valve and is composed of forged steel, which is a strong and long-lasting material. They are appropriate for businesses that must distinguish between thick fluids and liquids. These valves have a rising stem attached to a yolk, as well as an outside screw.

Valvesonly Europe, the Forged steel gate valve manufacturer in Norway offers valves with a strong body that can withstand harsh conditions. These valves provide a safe and secure shutdown either in horizontal or vertical positions to process the mediums in pipes.

PARTS

Valve body

Seat and Gate

Stem

Bonnet

Operator

INDUSTRIES

Water industry

Sewage industry

Power production industry

Oil and Gas Industry

Chemical Industry

Petrochemical Industry

Mining Industry

Marine Industry

Textile industry

APPLICATIONS

Oil and Gas Industry: Forged steel gate valves are commonly used in the oil and gas industry for various applications such as upstream, midstream, and downstream processes, including drilling, extraction, transportation, and refining.

Petrochemical Industry: Forged steel gate valves are widely used in the petrochemical industry for controlling the flow of various fluids and gases in chemical processing plants, refineries, and other related facilities.

Power Generation: Forged steel gate valves are used in power generation plants to control the flow of water, steam, and other fluids in boilers, turbines, and other equipment.

Water Treatment: Forged steel gate valves are also used in water treatment plants to regulate the flow of water and other fluids in various stages of the treatment process.

ADVANTAGES

Reliable and durable construction

Can withstand high pressure and high temperature

Suitable for corrosive fluids and gases

Minimal flow resistance

Provides tight shut-off capability

Low maintenance requirements

Flexibility in installation orientation (horizontal or vertical)

Can be operated manually or automated with actuators

Long service life and reduced replacement costs

Good for throttling applications due to ability to partially open

Wide range of sizes and materials available to suit different needs and requirements

Resistance to wear and erosion

DESCRIPTION:

Material: A105, F11, F22, F51, LF2, F304, F304L, F316, F316, F91, ASTM A 105 – Forged Carbon Steel, ASTM A 182 F 304/304L/316/316L – Forged Stainless Steel 304/304L/316/316L, ASTM A 182 F 11/22

Sizes– 1/2″ to 2″

Class: 150 to 2500, PN25 to PN450

End Connections: Buttweld, Socket weld, Flanged, Threaded

Operations: Hand Wheel Gate valve, Gear operated Gate valve, Electric actuated Gate valve and Pneumatic Actuated Gate valve

Visit our website for more information-

0 notes

Text

Korean Flanges Stockists in India

Korean flanges are use check, real and solid. While meandering we pick something explicit number furthermore remarkable covering shade to isolate steel grades. We mark Korean flanges moving with the most fitting and clear meandering structure. Korean Standard Flanges are changed by the necessities of our clients. Nickel 200 Korean Flanges can be made so the thickness of the divider could have near evaluations as that of the straightening out Pipes & Tubes.

korean flanges manufacturers in India. We are controlling Incoloy korean flanges, 254 Smo korean Flanges and Carbon Steel korean flanges, most very smart arrangement, cost considering sensible expert hours in India and best wellspring of five star Metal korean flanges, most ideal condition, cost open in Mumbai, India.

korean flanges manufacturers in India. We are controlling Incoloy korean flanges, 254 Smo korean Flanges and Carbon Steel korean flanges, most very smart arrangement, cost contemplating sensible expert hours in India and best wellspring of five star Metal korean Flanges, most ideal condition, cost open in Mumbai, India.

Korean Flanges Manufacturers, Korean Flanges Suppliers, Korean Flanges Stockists, Korean Flanges Exporters

Nutech Overseas is Manufacturers of korean standard Flanges remained mindful of by Saudi Aramco. We keep up most obvious satisfactorily of Stainless Steel korean Flanges.Nutech Overseas has firm degree of Korean standard Flanges, Monel korean Flanges in Stock in different sizes.

Talk with us to purchase Carbon Steel korean Flanges, most ideal condition, cost in India, check our most recent cost of ASME SA 182 F304l Flanges including Korean flanges, Titanium korean flanges and Alloy Steel Korean Flanges. Copper korean flanges to UAE, Sweden,Canada, Kuwait, Oman, Indonesia, USA, Germany, Thailand, France, Australia, UK, Egypt, Qatar, Russia, Turkey, Italy, Iran, Singapore, Bahrain, Malaysia, Israel, Sri Lanka and Saudi Arabia.

We are suppliers of korean flanges, most very smart arrangement, cost as we are a legend among other suppliers. We have our stocking wholesalers in Delhi, Bangalore, Surat, (Gujarat), Hyderabad, Pune (Maharashtra) and Chennai in Tamil Nadu. Actually take a look immediately our expense going preceding purchasing Hastelloy korean flanges and Nickel korean Flanges from India or China. likewise mail for our live deftly of korean standard Flanges to check types and sizes with our set up stock we can give you best cost of korean flanges.

0 notes

Text

Pneumatic Actuated Ball Valve manufacturer in USA

SVR Global is the top Pneumatic actuated ball valve manufacturer in USA supplying good quality valves to chemical industries, petroleum industries and oil and gas industries in Alabama, Nashville and Miami. The Pneumatic Ball Valve, which regulates the flow of liquid or gas through a ball with a bore, is a robust valve that shuts off perfectly. Its exceptional safety features ensure quick and secure shutdown, making it a popular choice in various industrial applications. Its efficient performance makes it even more appealing.

Parts

Valve body: The valve body is the main housing that contains the ball and the ports through which the fluid flows.

Ball: The ball is a spherical component inside the valve body that rotates to open and close the valve.

Seat: The seat is a ring-shaped component that fits around the ball and provides a seal when the valve is closed.

Stem: The stem is a component that connects the ball to the actuator and is used to rotate the ball.

Actuator: The actuator is the device that converts compressed air into mechanical force to rotate the ball.

Mounting bracket or coupling: The mounting bracket or coupling is used to connect the actuator to the valve body.

Control system: The control system is a set of components that allow the valve to be operated remotely, such as a solenoid valve or control panel.

Accessories: Additional components may include limit switches, positioners, or other accessories that provide additional control or feedback for the valve.

TYPES

Pneumatic Actuated two-piece ball valve

Pneumatic Actuated Three-piece ball valve

Pneumatic Actuated Flanged ball valve

Pneumatic Actuated Three-way ball valve

Industry

Oil and Gas Industry

Chemical Industry

Textile industry

Petrochemical Industry

Mining Industry

Marine Industry

Features of Pneumatic Actuated Ball Valve:

• Provides tight and safe shutoff.

•It has a quick opening and shutting capabilities.

•It is compact and simple to use.

Applications:

Chemical processing: Pneumatic actuated ball valves are commonly used in chemical processing applications to control the flow of chemicals and other fluids.

Water treatment: used in water treatment applications to control the flow of water and other liquids.

Oil and gas industry: used in the oil and gas industry to control the flow of oil and gas through pipelines and other equipment.

Advantages:

Fast operation: Pneumatic actuated ball valves are capable of fast and efficient operation, making them suitable for applications that require quick response times.

Reliable: These valves are known for their high reliability and durability, which makes them suitable for use in a wide range of industrial applications.

Easy to maintain: Pneumatic actuated ball valves are relatively simple to maintain, which can help to reduce downtime and maintenance costs.

Versatile: These valves can be used with a wide range of fluids, including gases, liquids, and slurries.

Good flow control: The design of the ball valve allows for good flow control, which can help to improve the efficiency of a system.

SVR Global is thepremium Pneumatic actuated ball valve manufacturer in USA is used in throttling applications for smooth flow of mediums.

Body: cast iron, cast steel (WCB, WCC, WC6, LCC, LCB), carbon steel (CF8, CF8M), titanium, stainless steel (SS304, SS316, A105, F304, F304L, F316, F316L).

Class: 150-2500, PN 10 – PN450.

Size: ½” to 48”

Ends: socket weld, butt weld, flanged, threaded

Operation: pneumatic actuated

Visit our website for more information-https://svrglobal.net/products/pneumatic-actuated-ball-valve/

0 notes

Text

3000LB high pressure socket welded elbow 90D, ASTM A182 F304L materials produced by ANSI B16.11 standard.

We have same product quality like bothwell. We have more competitive discount than him. I believe we will have a good market in the world.

Welcome to order it from us.

#fittings #welded #socketed #elbow #pressure #3000LB #hardware #manufacturer #factory #export #China #pipes #feidingtrade #feiding #hbfeiding #FLANGES

Tommy

Hebei Feiding Trade Co.,Ltd

WhatsApp 0086-13231170855

Email: [email protected]

Web: www.hbfeiding.com

0 notes

Text

Grades of material used for pipes, fittings, flanges according to various Astm standards

What are ASTM Grades..

ASTM standards define the specific manufacturing process of the material and determine the exact chemical composition of pipes, fittings and flanges, through percentages of the permitted quantities of carbon, magnesium, nickel, etc., and are indicated by “Grade”. Cortensteeltube.com is one of the leading corten steel suppliers in Mumbai.

For example, a carbon steel pipe can be identified with Grade A or B, a stainless-steel pipe with Grade TP304 or Grade TP321, a carbon steel fitting with Grade WPB etc.

Below you will find as an example 3 tables with chemical requirements for..

Flanges ASTM A182 Grade F304, F304L F316L

Pipes ASTM A312 Grade TP304, TP304L, TP3016L

Fittings ASTM A403 Grade WP304, WP304L, WP316L

Pipes

A106▸ This specification covers carbon steel pipe for high-temperature service.

A335▸ This specification covers seamless ferritic alloy-steel pipe for high-temperature service.

A333▸ This specification covers wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures.

A312▸ Standard specification for seamless, straight-seam welded, and cold worked welded austenitic stainless steel pipe intended for high-temperature and general corrosive service.

Fittings

A234▸ This specification covers wrought carbon steel and alloy steel fittings of seamless and welded construction.

A420▸ Standard specification for piping fittings of wrought carbon steel and alloy steel for low-temperature service.

A403▸ Standard specification for wrought austenitic stainless steel piping fittings.

Flanges

A105▸ This specification covers standards for forged carbon steel piping components, that is, flanges, fittings, valves, and similar parts, for use in pressure systems at ambient and higher-temperature service conditions.

A182▸ This specification covers forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves and parts for high-temperature service.

A350▸ This specification covers several grades of carbon and low alloy steel forged or ring-rolled flanges, forged fittings and valves for low-temperature service.

Valves

A216▸ This specification covers carbon steel castings for valves, flanges, fittings, or other pressure-containing parts for high-temperature service and of quality suitable for assembly with other castings or wrought-steel parts by fusion welding.

A217▸ This specification covers steel castings, martensitic stainless steel and alloys steel castings for valves, flanges, fittings, and other pressure-containing parts intended primarily for high-temperature and corrosive service.

A352▸ This specification covers steel castings for valves, flanges, fittings, and other pressure-containing parts intended primarily for low-temperature service.

A182▸ This specification covers forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves and parts for high-temperature service.

Bolts and Nuts

A193▸ This specification covers alloy and stainless steel bolting material for pressure vessels, valves, flanges, and fittings for high temperature or high pressure service, or other special purpose applications.

A320▸ Standard Specification for Alloy-Steel and Stainless Steel Bolting Materials for Low-Temperature Service.

A194▸ Standard specification for nuts in many different material types.

Tap here to read more about this article:

0 notes

Text

Threadolets Manufacturers

We supply Threadolets (3000#, 6000 #) in pressure grade of 3000LBSCH40, SCH80, STD, XS, 6000LBSCH160, XXS etc., and carbon steel of A182 A105 and in stainless steel of A182 F304, A182 F304L, A182 F316, A182 F316L, A182 F321 respectively. These Threadolet Fittings are available in sizes ranging from 1/8" ~ 20".

0 notes

Text

Pneumatic Actuated Ball Valve manufacturer in USA

SVR Global is the top Pneumatic actuated ball valve manufacturer in USA. We make high quality products as per international standards with our team of experts.

The Pneumatic Actuated Ball Valve Actuator is a double-piston actuator, specifically designed for operating ball valves and flaps. This actuator comes in two versions, namely the double-acting and single-acting models. The Pneumatic Ball Valve, which regulates the flow of liquid or gas through a ball with a bore, is a robust valve that shuts off perfectly. Its exceptional safety features ensure quick and secure shutdown, making it a popular choice in various industrial applications. Its efficient performance makes it even more appealing.

SVR Global is thepremium Pneumatic actuated ball valve manufacturer in USA and is used in throttling applications for smooth flow of mediums.

Parts

Valve body: The valve body is the main housing that contains the ball and the ports through which the fluid flows.

Ball: The ball is a spherical component inside the valve body that rotates to open and close the valve.

Seat: The seat is a ring-shaped component that fits around the ball and provides a seal when the valve is closed.

Stem: The stem is a component that connects the ball to the actuator and is used to rotate the ball.

Actuator: The actuator is the device that converts compressed air into mechanical force to rotate the ball.

Mounting bracket or coupling: The mounting bracket or coupling is used to connect the actuator to the valve body.

Control system: The control system is a set of components that allow the valve to be operated remotely, such as a solenoid valve or control panel.

Accessories: Additional components may include limit switches, positioners, or other accessories that provide additional control or feedback for the valve.

TYPES

Pneumatic Actuated two-piece ball valve

Pneumatic Actuated Three-piece ball valve

Pneumatic Actuated Flanged ball valve

Pneumatic Actuated Three-way ball valve

Industry

Oil and Gas Industry

Chemical Industry

Textile industry

Petrochemical Industry

Mining Industry

Marine Industry

Features of Pneumatic Actuated Ball Valve:

• Provides tight and safe shutoff.

•It has a quick opening and shutting capabilities.

•It is compact and simple to use.

Applications:

Chemical processing: Pneumatic actuated ball valves are commonly used in chemical processing applications to control the flow of chemicals and other fluids.

Water treatment: used in water treatment applications to control the flow of water and other liquids.

Oil and gas industry: used in the oil and gas industry to control the flow of oil and gas through pipelines and other equipment.

Advantages:

Fast operation: Pneumatic actuated ball valves are capable of fast and efficient operation, making them suitable for applications that require quick response times.

Reliable: These valves are known for their high reliability and durability, which makes them suitable for use in a wide range of industrial applications.

Easy to maintain: Pneumatic actuated ball valves are relatively simple to maintain, which can help to reduce downtime and maintenance costs.

Versatile: These valves can be used with a wide range of fluids, including gases, liquids, and slurries.

Good flow control: The design of the ball valve allows for good flow control, which can help to improve the efficiency of a system.

Body: cast iron, cast steel (WCB, WCC, WC6, LCC, LCB), carbon steel (CF8, CF8M), titanium, stainless steel (SS304, SS316, A105, F304, F304L, F316, F316L).

Class: 150-2500, PN 10 – PN450.

Size: ½” to 48”

Ends: socket weld, butt weld, flanged, threaded

Operation: pneumatic actuated

Visit our website for more information-

https://svrglobal.net/products/pneumatic-actuated-ball-valve/

0 notes

Text

Pneumatic Actuated Ball Valve Manufacturer in USA

Valvesonly is the best Pneumatic Actuated Ball Valve Manufacturer in USA. The flow of the medium is controlled and regulated by a pneumatically operated ball valve, which uses compressed air as its actuator. These valves have the capacity to sustain pressure. Because Pneumatic Actuators fully automate every process, less labour is needed. This valve's durable construction enables it to function well in gas, water, and oil. Numerous industries, including the generation of power, textile, metallurgy, water, sewage, and construction, employ these valves extensively. The amount of media that flows via a ball valve is controlled by its hollow ball. The stem to which the ball is fastened pivots both upward to open and downward to close. This kind of valve is made to operate in conditions of high pressure and heat.

Features of Pneumatic Actuated Ball Valve:

· Increased flow

· It has a quick opening and quick shutting characteristic; • Both seals on the sides are covered with balls and may provide a tight shutdown even after years of use.

Configuration of a Pneumatic Actuator:

· 4-20 Mamp

· Pneumatic single acting actuators

· Pneumatic double acting actuators

· Pneumatic rotary actuators

· Pneumatic Scotch and Yoke actuators

· Pressure: 228 bar

Temperature:

Standard -4°F to 200°F (-20°C to 93°C)

Low -40°F to 176°F (-40°C to 80°C)

High 0°F to 300°F (-18°C to 149°C)

The secret to Valvesonly's success in the valves industry is our well-integrated work environment. Valvesonly is a top Pneumatic Actuated Ball Valve Manufacturer in USA. For expansion, our infrastructure is scattered throughout a broad geographic area. In any industrial application, our valves are dependable and long-lasting.

Description:

· Body: Cast Iron, Cast steel (WCB, WCC, WC6, LCC, LCB), Carbon steel (CF8, CF8M), Titanium, Stainless steel (SS304, SS316, A105, F304, F304L, F316, F316L).

· Class: 150-2500,

PN 10 - PN450.

· Size: ½” to 48”.

· Ends: Socket weld pneumatic actuated ball valve,

Butt weld pneumatic actuated ball valve,

Flanged pneumatic actuated ball valve,

Threaded pneumatic actuated ball valve.

· Operation: Pneumatic actuated Ball Valve.

Visit here for more details: https://valvesonly.com/product-category/pneumatic-actuated-ball-valve/

0 notes

Text

✅✅✅Hongji-Stainless steel Needle/ Bleed Type Saddle Root Valve Welding

👉Body Material:A105, F304, F304L, F316, F316L

👉Type of Connection:Welding/Flange

👉Seal Type:Hard Sealing:

👉Manufacturing:Forging and CNC

👉Application:Nontoxic Liquid or Gas, Steam, Oil

👉Pressure Range:Class 2500/33.4Mpa/4844Psi

Inquiry Whatsapp: wa.me/8618226669977

#needlevalves #rootvalve #ballvalve #valves #Oilfieldservices

0 notes

Text

Floating Ball Valve Manufacturer in USA

SVR Global is a valuable Floating Ball Valve Manufacturer in USA that offers a wide range of product solutions, satisfying even the most demanding operating conditions, ensuring more flexibility, more capacity and therefore more excellent economy.

Definition of a Floating Ball Valve:

A floating ball valve features a ball, a valve, and a stem. The stem is connected to a slot at the top of the ball which allows the ball to rotate a quarter turn (90 degrees). The ball is free to float inside the valve body. The ball is held in the position by the compression of the two elastomeric seats against the ball.

Once pressure is applied, the flow will push the ball against the seat creating a bubble-tight seal. This type of valve design is capable of bi-directional shut-off. The floating valve is very difficult to operate when upstream pressure is high.

Advantages of a Floating Ball Valve:

Compact in design.

Fast shut off, only a 90-degree turn is required to close the valve.

Flow pressure will not be reduced when the valve is fully open.

No possibility of leakage.

The open or closed state of the valve can be easily detected by the position of the handle.

Industries that use a Floating Ball Valve:

SVR Global is a valuable Floating Ball Valve Manufacturer in USA having a presence in

Chemical Industry

Drilling Platform

Gas Industry

Oil Industry

Petrochemical Industry

Power Industry

Water Supply Industry

Definition of a Ball Valve:

A ball valve is a quarter-turn on/off valve with a rotational motion that controls the flow of a liquid or gas. Ball valves are referred to as quarter-turn valves because the ball rotates 90 degrees between the fully open and fully closed positions. On/off valves either allow flow (on) or obstruct it completely (off). These valves are also known as isolation valves, because they can effectively shut down flow into a segment of a system, often for maintenance to be performed. A ball valve comprises a valve housing, which is often a metal casting and a perforated ball. The flow is restricted by turning the ball 90 degrees around its axis using a stem.

Advantages of a Ball Valve:

Compact in size

Corrosive environments aren’t an issue

Do not require lubrication

Easy to use

Fast-acting

Flexibility in design

Great shut on/off capability

Long life expectancy

Low-pressure drop (flow is almost unrestricted)

Minimal leakage through wear & tear if properly used.

Low maintenance cost

Requires little maintenance

Suitable for emergency power outages

Suitable for use in high-pressure environments

Time effective to operate

Disadvantages of a Ball Valve:

Body cavity filled with fluid

Not suitable for high temperature

Not suitable for throttling

Not suitable for thicker media as sedimentation could occur and damage the valve disc & seat.

Surge pressure could occur due to rapid closing and opening.

The partially exposed seat erodes quickly in a throttling position due to the impact of high-velocity flow.

Should be positioned upright and cannot be used for throttling because the valve handle has been rotated.

Industries that use Ball Valves:

Automotive

Chemical

Cryogenic

Oil & Gas

Petrochemical

Power Processing

Vacuum

Water Treatment

Description of a Floating Ball Valve:

Body Material: Stainless steel, brass, or other metals, Cast Steel (WCB, WCC, WC6, WC9), Cast Iron, SS316, SS304, Forged Steel (F22, F51, LF2, F304, F304L, F316, F316L)

Class: 150-2500; PN 10-PN 450

Ends: Buttweld, Flanged, Socketweld, Threaded

Operation: Gear operated, Electric actuated, Lever-operated, Pneumatic actuated

Size:1/4’’ to 48’’

About various valves provided by SVR Global - https://svrglobal.net/products/floating-ball-valve/

0 notes

Text

ASTM Grades of Alloy steel buttweld pipe fittings: What are they?

Pipes, fittings, and flanges manufactured according to ASTM standards have a chemical composition determined by percentages of the permitted quantities of carbon, magnesium, nickel, etc., as shown by “Grade”.

It is possible to identify carbon steel pipes by Grade A or B, stainless steel pipes by Grade TP304 or Grade TP321, and carbon steel fittings by Grade WPB, for example.

As one of the leading manufacturers of Alloy Steel Pipe Fittings in India, Aesteiron Steels LLP is an excellent choice. Our company manufactures pipe fittings including reducers, caps, elbows, tees, bends, couplings, unions, and nipples.

Welding Buttweld Fittings in Alloy Steel:

These types of metal fittings pipe allow the direction of flow to be changed, the pipe size to be reduced or auxiliary equipment to be attached. The fittings are permanently leak proof because of its many inherent advantages. This system is reinforced by the continuous metal structure that forms between the fitting and pipe. Corrosion and erosion are minimized through smooth inner surfaces and gradual direction changes, which reduce pressure losses and turbulence. Despite being ferrous, it is still susceptible to rust when exposed to the elements.

Alloy Steel Weld Fittings:

It refers to the process of inserting a pipe into recessed areas of valves, fittings, or flanges. For piping with a nominal diameter of NPS 2 or smaller, it is primarily used for small pipe diameters. Stainless steel has a tensile strength of 758-1882 MPa, whereas carbon steel has a strength of 758-1882 MPa.

Low Alloy Steel Fittings

In general, alloys with a total content of 1.5% to 5% are considered to be alloys. It is alloyed with chromium, manganese, silicon, molybdenum, nickel, vanadium, and molybdenum. Heating elements are manufactured with it.

Elbows made of alloy steel

Flow direction is changed by this component in a piping system. The pipe can be turned in a 45-degree or 90-degree angle by connecting two pipes with different or same nominal diameters.

Tee made from alloy steel

Fluid can be changed direction by three branches. Liquids and gases are commonly conveyed through pipe networks. There are two outlets in T-shape, at 90° to this line’s connection. A lateral outlet is located at the end of a short pipe piece. A wide variety of elbow seamless pipe fittings are made from it.

The following are three tables with chemical requirements for

Flanges ASTM A182 Grade F304, F304L F316L

Pipes ASTM A312 Grade TP304, TP304L, TP3016L

Fittings ASTM A403 Grade WP304, WP304L, WP316L

Moreover, there is a table that shows the most commonly used ASTM grades for a234 Pipes, Fittings, Flanges, Valve, Bolt, and Nuts that are all related.

You may have noticed that ASTM A105 does not have a grade in the table below. It is sometimes described as ASTM A105N;

N stands for normalized, not grade. In view of the fact that normalizing is a type of heat treatment, it is important to note that it can only be applied to ferrous metals. Normalizing an object, as the term implies, is the process of removing the internal stresses that have been produced by heat treatment, casting, forming, etc., in order to make the object as normal as possible.

What is Steel pipe fittings

A steel pipe fitting material like, plate, profile, or device made of carbon or alloy fitting steel that is shaped in a way that could change the flow direction or rate of fluid in a pipeline system. Most of these fittings include steel elbows for pipe (45or 90-degree bends), tees, reducers (concentric or eccentric reducers), caps, nipples, flanges, gaskets, and studs.

For industrial applications, pipeline systems require changes in transmission direction, fluid flow rate adjustment, opening and closing of pipelines, etc. This will be accomplished by using steel pipe fittings.

What is ASTM A234 WPB

This standard is an ASTM A234 which specifies the 3r elbow dimensions and a234 materials of steel elbow for pipe fittings for moderate and high-temperature applications ranging from mild steel to alloy steel. The scope of the document covers both seamless and welded steel fittings. There are many uses for steel pipe fittings, including pressure pipelines and pressure vessels that are fabricated from steel. The material that makes up these fittings is comprised of steel, forgings, bars, plates, seamless or HFW (fusion welded) pipe products, as well as filler metal that has been added to them.

Among the fittings covered by ASTM A234 are wrought carbon steel fittings of seamless and welded construction, that meet ASTM B16.9, B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, and MSS-SP-97. etc.

In pressure piping and pressure vessel fabrication, ASTM A234 steel pipe fittings are used for moderate and elevated temperatures. This standard specifies materials for fittings such as killed steel, forgings, bars, plates, and seamless or fusion-welded tubular products.

There are specifications for elbows, tees, reducers, caps, and crosses in this standard. The ends are usually butt welded.

Tap Here to Read More About This Article: https://thesteelexporter.com/astm-grades-of-alloy-steel-buttweld-pipe-fittings-what-are-they/

#Steel #steelexports #steelsuplier #dineshtube #stainlesssteel #cupronickel #nickel

0 notes

Photo

Nufit Piping Solutions - Manufacturer, exporter & supplier of Stainless Steel Flanges, Carbon Steel Flanges, Alloy Steel Flanges, Duplex Steel Flanges according to ASME B16.5. Stainless Steel Flanges - ASTM A182 / ASME SA182 F304, F304L, F310, F310S, F316, F316L, F316Ti, F317L, F321, F347, F20 (N08020), F904L (N08904) Carbon Steel Flanges - ASTM A105 / ASME SA105, ASTM A350 / ASME SA350 LF2, LF3, ASTM A516 / ASME SA516 Grade 60, 70 Alloy Steel Flanges - ASTM A182 / ASME SA182 F1, F5, F9, F11, F12, F22, F91 Duplex Steel Flanges - ASTM A182 / ASME SA182 F44 (S31254), F51 (S31803), F52 (S32950), F53 (S32750), F55 (S32760), F60 (S32205) Flange types: Slip-on, Socketweld, Weld Neck, Blind, Threaded, Long Weld Neck Flange Face: Flat Face, Raised Face, Ring Type Joint Face, Male/Female Face, Tongue and Groove Face For more details, visit us at Https://flanges-manufacturer.com For your requirement, mail us at [email protected] #ssflange #csflange#sliponflange #socketweldflange #weldneckflange #blindflange #threadedflange #longweldneckflange #forgedflange #nace #flange #rtjflange #texas #rotterdam #miami #milan #canada #manufacturer #exporter #flangemanufacturer #flangeexporter #astmflange #asmeflange #nufit #nufitpipingsolutions #india #instagood #instadaily #instalike #newpost (at Berkel en Rodenrijs, Zuid-Holland, Netherlands) https://www.instagram.com/p/Cj3dilfLEul/?igshid=NGJjMDIxMWI=

#ssflange#csflange#sliponflange#socketweldflange#weldneckflange#blindflange#threadedflange#longweldneckflange#forgedflange#nace#flange#rtjflange#texas#rotterdam#miami#milan#canada#manufacturer#exporter#flangemanufacturer#flangeexporter#astmflange#asmeflange#nufit#nufitpipingsolutions#india#instagood#instadaily#instalike#newpost

0 notes