#europe automotive paints and coatings market trends

Explore tagged Tumblr posts

Text

Europe Automotive Paints and Coatings Industry: A Spectrum of Innovation and Sustainability

The European automotive paints and coatings market is experiencing significant growth as it adapts to evolving environmental regulations and consumer demands. The Europe automotive paints and coatings market size is projected to be valued at USD 4.96 billion in 2024 and is anticipated to reach USD 5.76 billion by 2029, with a compound annual growth rate (CAGR) of 3% over the forecast period (2024-2029).

Market Overview:

The European automotive paints and coatings industry is highly advanced, driven by the region’s strong automotive manufacturing sector and strict environmental regulations. From luxury cars to commercial vehicles, manufacturers rely on high-performance coatings to ensure durability and maintain the vehicle’s aesthetic over time.

Key Drivers of Growth:

Environmental Regulations: The push for sustainability is driving the adoption of eco-friendly coatings, such as water-based and powder coatings. Regulations focused on reducing volatile organic compounds (VOCs) are influencing manufacturers to invest in green technologies.

Automotive Industry Growth: Europe, being a hub for luxury car manufacturers, is witnessing increasing demand for premium-quality finishes, driving innovations in the automotive paints and coatings sector.

Technological Advancements: The market is benefiting from innovations in coating materials, such as nano-coatings, which offer enhanced durability and scratch resistance, and self-healing coatings that can repair minor surface damage.

Electric Vehicle (EV) Boom: As Europe accelerates its transition to electric vehicles, the demand for specialized coatings that address the unique thermal and electrical needs of EVs is on the rise.

Emerging Trends in the European Market:

Sustainability and Eco-Friendly Solutions: Automotive paint manufacturers are increasingly focused on developing low-VOC and solvent-free coatings to meet stringent environmental standards in Europe. Green coatings are gaining traction as they reduce emissions and pollution without compromising performance.

Customization and Aesthetics: Consumers are showing a growing interest in personalized and high-quality vehicle finishes. As a result, the demand for custom colors, metallic finishes, and smart coatings that change colors is increasing.

Increased Focus on Lightweighting: With automakers looking to reduce vehicle weight to improve fuel efficiency, the demand for lightweight, durable coatings that can adhere to modern lightweight materials such as aluminum and carbon fiber is rising.

Corrosion Protection: Advanced coatings that provide long-lasting corrosion resistance, especially in harsh climates, are seeing high demand from automotive manufacturers.

Future Outlook:

As the European automotive market continues to evolve, the paints and coatings industry is expected to see robust growth. The shift toward electric vehicles, coupled with increasing consumer demand for sustainable and high-performance products, will be key drivers for market expansion. Furthermore, the ongoing innovation in nano-technology and smart coatings will shape the future of automotive paint applications in the region.

Conclusion:

The European automotive paints and coatings industry is undergoing significant transformation, driven by technological innovations, environmental concerns, and evolving consumer preferences. As the industry continues to focus on sustainability, aesthetics, and functionality, it is set to play a pivotal role in shaping the future of the automotive sector.

For a detailed overview and more insights, you can refer to the full market research report by Mordor Intelligence https://www.mordorintelligence.com/industry-reports/europe-automotive-paints-and-coatings-market

#europe automotive paints and coatings market#europe automotive paints and coatings market size#europe automotive paints and coatings market share#europe automotive paints and coatings market trends#europe automotive paints and coatings market analysis#europe automotive paints and coatings market forecast

0 notes

Text

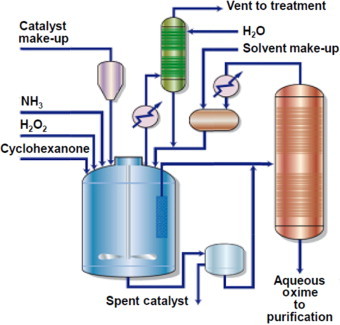

𝐄𝐮𝐫𝐨𝐩𝐞 𝐂𝐲𝐜𝐥𝐨𝐡𝐞𝐱𝐚𝐧𝐨𝐧𝐞 𝐌𝐚𝐫𝐤𝐞𝐭: 𝐊𝐞𝐲 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 & 𝐓𝐫𝐞𝐧𝐝𝐬-IndustryARC™

The Europe Cyclohexanone Market size is forecasted to reach US$1.2 billion by 2027, after growing at a CAGR of 4.5% during the forecast period 2022-2027.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞

Cyclohexanone (C₆H₁₁O) is a key industrial solvent and chemical intermediate with a wide range of applications in various industries. It is classified as a ketone due to its molecular structure, which consists of a six-carbon chain with a carbonyl group (C=O) attached to one of the carbons. Cyclohexanone is highly valued for its ability to dissolve a variety of substances and its role in the synthesis of key chemicals.

𝐊𝐞𝐲 𝐓𝐫𝐞𝐧𝐝𝐬

𝐑𝐢𝐬𝐢𝐧𝐠 𝐃𝐞𝐦𝐚𝐧𝐝 𝐢𝐧 𝐍𝐲𝐥𝐨𝐧 𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧:

The Europe Cyclohexanone market is experiencing sustained growth, driven primarily by the increasing demand for nylon and its derivatives. As industries like automotive and textiles expand, the need for nylon-6 and nylon-6,6 is pushing up cyclohexanone consumption, especially in countries like Germany and France.

𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲 𝐚𝐧𝐝 𝐆𝐫𝐞𝐞𝐧 𝐂𝐡𝐞𝐦𝐢𝐬𝐭𝐫𝐲:

Environmental concerns are pushing manufacturers to adopt more sustainable practices. Bio-based cyclohexanone production is gaining traction as an eco-friendly alternative to traditional petroleum-based methods.

𝐈𝐧𝐜𝐫𝐞𝐚𝐬𝐞𝐝 𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧 𝐢𝐧 𝐂𝐨𝐚𝐭𝐢𝐧𝐠𝐬 𝐚𝐧𝐝 𝐀𝐝𝐡𝐞𝐬𝐢𝐯𝐞𝐬:

Cyclohexanone's role as a solvent in paints, coatings, and adhesives is expanding due to its excellent ability to dissolve a variety of resins. With the growth of the construction and automotive industries, demand for high-performance coatings and adhesives continues to rise.

𝐒𝐡𝐢𝐟𝐭 𝐓𝐨𝐰𝐚𝐫𝐝𝐬 𝐀𝐮𝐭𝐨𝐦𝐚𝐭𝐢𝐨𝐧 𝐚𝐧𝐝 𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠:

The Europe Cyclohexanone market is seeing a shift toward advanced manufacturing technologies and automation. This trend is improving production efficiency, reducing costs, and meeting the growing demand for high-quality cyclohexanone in various industrial sectors.

𝐄𝐱𝐩𝐚𝐧𝐝𝐢𝐧𝐠 𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬 𝐢𝐧 𝐏𝐡𝐚𝐫𝐦𝐚𝐜𝐞𝐮𝐭𝐢𝐜𝐚𝐥𝐬 𝐚𝐧𝐝 𝐂𝐨𝐬𝐦𝐞𝐭𝐢𝐜𝐬:

Cyclohexanone's use in pharmaceuticals and cosmetics is increasing as demand for active ingredients and specialty fragrances grows. The compound is being utilized more in the formulation of certain pharmaceuticals and cosmetic products, which is opening new markets within the chemical industry.

0 notes

Text

Printing Inks Market: Key Applications in Packaging, Commercial & Digital Printing 2021 - 2028

The global printing inks market size is expected to reach USD 23.8 billion by 2028, registering a CAGR of 2.8% over the forecast period, according to a new report by Grand View Research, Inc. Growing demand from end-use applications including flexible packaging & labels, corrugated cardboards, commercial letterpress, and folding cartons are the main factors expected to drive the market over the forecast period. Rise in consumer spending in Asia Pacific and North American regions, increasing demand for superior quality flexible packaging are some of the main parameters influencing the overall demand for printing inks globally.

Product innovations, technological progressions, new raw material sourcing models and expansion strategies are some of the major drifts the companies are focusing on to cater to the specific consumer requirements. The recent trends witnessed by this industry include rising significance of flexographic and digital toners, food-safe printing inks and a shift in consumer preference towards environment-friendly products.

Gather more insights about the market drivers, restrains and growth of the Printing Inks Market

The regulatory framework also plays a crucial role in this industry dynamics. Stringent regulations regarding toxic metals in solvents & volatile organic compound (VOC) emissions in these inks are expected to hamper the growth of the overall market. This rationale has led to increased usage of cellulose and rosin derivatives as resins for manufacturing energy-efficient inks.

Digital ink is expected to be the fastest growing product segment owing to its superior properties and specific demands from textile, ceramic and 3D printing application sectors. The digital toners have observed a lower label costs as compared to conventional inks and its potential of switching among labels instantly have resulted in this product to be the fastest growing.

Browse through Grand View Research's Paints, Coatings & Printing Inks Industry Research Reports.

The Central and South America automotive wrap films market size was valued at USD 165.7 million in 2024 and is projected to register a CAGR of 3.8% from 2025 to 2030.

The global thermal insulation coating market sizewas estimated at USD 10.45 billion in 2024 and is projected to grow at a CAGR of 6.6% from 2025 to 2030.

Printing Inks Market Segmentation

Grand View Research has segmented the global printing inks market on the basis of product, resins and application:

Printing Inks Product Outlook (USD Million, 2016 - 2028)

Gravure

Flexographic

Lithographic

Digital

Others

Printing Inks Resin Outlook (USD Million, 2016 - 2028)

Modified rosin

Modified cellulose

Acrylic

Polyurethane

Others

Printing Inks Application Outlook (USD Million, 2016 - 2028)

Packaging & labels

Corrugated cardboards

Commercial printing/Publishing

Others

Printing Inks Regional Outlook (Revenue, USD Million, 2016 - 2028)

North America

US

Canada

Mexico

Europe

Germany

Italy

UK

Asia Pacific

China

Japan

India

Central & South America (CSA)

Brazil

Middle East & Africa

Key Companies profiled:

Flint Group

DIC Corporation

Siegwerk Druckfarben AG & Co. KGaA

Sakata Inx Corporation

T&K TOKA Corporation

Dainichiseika Color & Chemicals Mfg. Co., Ltd.

DEERS I CO., Ltd.

Epple Druckfarben AG

TOYO INK SC HOLDINGS CO., LTD.

Hubergroup

TOKYO PRINTING INK MFG CO., LTD.

Order a free sample PDF of the Printing Inks Market Intelligence Study, published by Grand View Research.

0 notes

Text

2-Ethylhexanoic Acid Prices Trend | Pricing | News | Database | Chart

2-Ethylhexanoic acid (2-EHA) is a versatile and essential chemical compound widely used in the production of various industrial products, such as plasticizers, lubricants, coatings, and as a precursor for manufacturing other chemicals. Over the years, 2-EHA has gained significant demand across multiple sectors, contributing to its price fluctuations. Understanding the pricing dynamics of 2-EHA is crucial for businesses and consumers involved in its supply chain. The price of 2-EHA is influenced by several factors, including raw material costs, demand and supply imbalances, geopolitical factors, and shifts in the global economy. In recent years, 2-EHA prices have experienced considerable volatility, driven by global market conditions and local production capabilities.

The cost of raw materials plays a pivotal role in determining the price of 2-EHA. One of the primary feedstocks for 2-EHA production is n-butene, which is derived from natural gas and petroleum. Fluctuations in the prices of crude oil and natural gas directly impact the production costs of 2-EHA. When crude oil prices rise, the cost of producing n-butene increases, which subsequently pushes up the price of 2-EHA. Conversely, when oil prices decline, production costs decrease, resulting in lower 2-EHA prices. Therefore, market participants closely monitor crude oil price trends to forecast 2-EHA price movements.

Get Real Time Prices for 2-Ethylhexanoic acid (2-EHA): https://www.chemanalyst.com/Pricing-data/2-ethylhexanoic-acid-2-eha-1192

The demand for 2-EHA across various industries has also been a major driver of price fluctuations. The plasticizer industry, which accounts for a significant portion of 2-EHA consumption, is highly sensitive to changes in the construction, automotive, and consumer goods sectors. For instance, increased demand for polyvinyl chloride (PVC) in construction and automotive applications leads to higher demand for plasticizers, driving up 2-EHA prices. Similarly, a surge in the production of personal care products, paints, and coatings also contributes to higher demand for 2-EHA. As global economies grow, the demand for 2-EHA tends to increase, supporting higher prices. Conversely, economic slowdowns or recessions can reduce demand, leading to price declines.

Another key factor influencing 2-EHA prices is the supply side of the equation. The production of 2-EHA is concentrated in a few regions, with major manufacturers located in Asia, Europe, and North America. Any disruptions in the production process, whether due to labor strikes, natural disasters, or political instability, can lead to supply shortages and subsequently increase prices. Furthermore, limited production capacities in some regions can cause supply-demand imbalances, resulting in higher prices for 2-EHA. As production expands in emerging markets or new production technologies are introduced, the price may stabilize or decrease, depending on the availability of supply.

Geopolitical factors also play a significant role in the pricing of 2-EHA. Trade policies, tariffs, and sanctions can disrupt the global supply chain, affecting the cost of raw materials and finished products. For example, the imposition of tariffs on chemical imports or exports can increase the cost of 2-EHA in certain regions. Similarly, tensions in key oil-producing countries can lead to supply chain disruptions, pushing crude oil prices higher and impacting the cost of 2-EHA production. Political instability in regions where major 2-EHA manufacturers are located may also result in production delays or supply shortages, further driving up prices.

Additionally, environmental regulations and sustainability trends are becoming increasingly important factors influencing 2-EHA prices. As global industries face stricter environmental standards, the production of chemicals like 2-EHA must comply with more stringent emission controls and sustainability practices. Manufacturers may need to invest in cleaner technologies or pay for carbon offset credits, raising production costs and, consequently, the price of 2-EHA. Furthermore, the shift toward more sustainable and bio-based alternatives to traditional chemicals is gradually affecting demand for conventional products like 2-EHA. If bio-based alternatives gain widespread acceptance, it could put downward pressure on the price of traditional 2-EHA.

Over the past few years, the price of 2-EHA has been subject to significant fluctuations, reflecting these multiple factors. In 2020, the COVID-19 pandemic caused a sharp decline in demand for many industrial chemicals, leading to lower prices for 2-EHA. However, as economies began to recover in 2021 and 2022, 2-EHA prices rebounded, driven by increased demand from sectors like construction, automotive, and coatings. In addition to recovering demand, supply chain disruptions caused by the pandemic further contributed to higher prices. The rising cost of raw materials, particularly petroleum and natural gas, also played a significant role in the price increase during this period.

Looking ahead, the pricing of 2-EHA is likely to remain volatile as global market conditions continue to evolve. The ongoing impact of the COVID-19 pandemic, geopolitical tensions, and fluctuations in raw material prices will continue to affect 2-EHA prices. Additionally, the growing focus on sustainability and green chemistry will influence the demand for traditional chemicals like 2-EHA, potentially leading to price adjustments over time. For businesses and consumers in the 2-EHA supply chain, staying informed about market trends, raw material costs, and geopolitical developments is essential to understanding price movements and managing risk.

In conclusion, the price of 2-Ethylhexanoic acid (2-EHA) is determined by a complex interplay of factors, including raw material costs, demand from key industries, production capacity, geopolitical factors, and environmental regulations. As these factors continue to evolve, businesses and consumers must remain agile and informed to navigate the fluctuations in 2-EHA pricing. By understanding the key drivers of price movements, stakeholders can better anticipate future trends and make more informed decisions in their procurement strategies.

Welcome to ChemAnalyst App: https://www.chemanalyst.com/ChemAnalyst/ChemAnalystApp

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#2-Ethylhexanoic Acid#2 EHA#2-Ethylhexanoic Acid Price#2-Ethylhexanoic Acid Price Monitor#2-Ethylhexanoic Acid Pricing

0 notes

Text

Automotive Paints Market Business Strategies, Revenue Global Technology, Application, and Growth Rate up to 2031

Automotive Paints Market Size was valued at US$ 18.61 billion in 2023 and is projected to reach US$ 26.16 billion by 2031, growing at a CAGR of 4.47% from 2024 to 2031.

Kings Research™ presents this information in its report titled, Automotive Paints Market Size, Share & Industry Analysis, By Vehicle Type (Light Commercial Vehicle, Heavy Commercial Vehicle, Passenger Vehicle), By Technology (Waterborne Coatings, Solvent Borne Coatings, Powder Coatings), By Coating (Primer Base Coat, Base Coat, Clear Coat, Electrocoat), and Regional Forecast, 2024 – 2031”

One major trend in the market is the growing emphasis on vehicle aesthetics and customization. Consumers, especially in mature markets, are seeking high-quality paints that offer both protection and visual appeal, prompting a demand for advanced paint formulations and finishes. Technological advancements in paint formulations, such as improved durability, scratch resistance, and environmental sustainability, are key drivers of this market growth. The adoption of eco-friendly coatings like waterborne and powder coatings is increasing due to their lower VOC emissions and compliance with stringent environmental regulations.

Browe Full Report Details @ https://www.kingsresearch.com/automotive-paints-market-472

List of Key Companies in Automotive Paints Market

3M

Axalta Coating Systems, LLC

AkzoNobel N.V.

BASF SE

Berger Paints India Limited

Henkel Corporation

Nippon Paint Holdings Co., Ltd.

PPG Industries, Inc.

RPM International Inc.

Sika AG

Regionally, the automotive paints market is diverse. North America and Europe continue to see high demand for premium coatings with advanced properties, while emerging economies in Asia Pacific and Latin America offer significant growth opportunities. Rapid industrialization, urbanization, and infrastructural developments in these regions are driving the demand for automobiles and consequently, automotive paints.

In particular, Asia-Pacific holds a significant share of the market, accounting for 35.48% in 2023. The region's dominance is attributed to its booming automotive industry, driven by countries like China, India, and Japan. Europe, the second-largest region in the market, accounted for $4.28 billion in 2023 and is expected to grow at a CAGR of 4.476%. The region's growth is supported by a mature automotive industry, technological advancements, and stringent environmental regulations promoting eco-friendly coatings.

The shift towards electric vehicles (EVs) presents additional opportunities for the automotive paints market. EV manufacturers are prioritizing lightweight materials and advanced coatings to enhance vehicle performance and range. This transition is spurring innovation in specialized coatings that offer thermal management, corrosion resistance, and aesthetic differentiation for EVs.

Leading companies in the market, such as 3M, Axalta Coating Systems, AkzoNobel, BASF SE, and PPG Industries, are employing strategic measures like acquisitions, mergers, partnerships, and product innovations to strengthen their market positions. For instance, NIPSEA Group's subsidiary NP Auto Refinishes completed the acquisition of D-Act Co., Ltd., reinforcing its market share in Asia-Pacific.

Moreover, regulatory initiatives aimed at reducing vehicle emissions and enhancing safety standards are pushing manufacturers towards eco-friendly paint formulations. Water-based paints have gained prominence due to their lower environmental impact and compliance with these regulations.

Overall, the automotive paints market is poised for robust growth, driven by technological advancements, rising consumer demand for customized and high-quality finishes, and the expanding automotive sector in emerging economies

Contact Us:

Kings Research

Website: https://www.kingsresearch.com

E-mail: [email protected]

Phone: (+1) 888 328 2189

1 note

·

View note

Text

UV Curable Coatings Market Challenges and Opportunities in 2024

UV Curable Coatings Market Growth Strategic Market Overview and Growth Projections

The global UV curable coatings market size was valued at USD 7.76 billion in 2022. It is estimated to reach USD 15.76 billion by 2031, growing at a CAGR of 8.20% during the forecast period (2023–2031).

The latest Global UV Curable Coatings Market by straits research provides an in-depth analysis of the UV Curable Coatings Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global UV Curable Coatings Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the UV Curable Coatings Market are

DSM

AkzoNobel

BASF

PPG Industries

Sherwin-Williams

DYMAX

Nippon Paint

Cardinal Paint

Axalta Coating Systems

Jainco Industry Chemicals

Get Free Request Sample Report @ https://straitsresearch.com/report/uv-curable-coatings-market/request-sample

The UV Curable Coatings Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global UV Curable Coatings Market: Segmentation

The UV Curable Coatings Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

By Component

Monomer

Photoinitiator

Oligomers

Pigments

Fillers

Additive

By End-User

Wood

Electronics

Automotive

Printing/Graphic Art

Paper and Packaging

Other

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/uv-curable-coatings-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the UV Curable Coatings Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the UV Curable Coatings Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the UV Curable Coatings Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the UV Curable Coatings Market market over the next several years?

How do regulatory and legal frameworks influence the market?

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#UV Curable Coatings Market Market#UV Curable Coatings Market Market Share#UV Curable Coatings Market Market Size#UV Curable Coatings Market Market Research#UV Curable Coatings Market Industry#What is UV Curable Coatings Market?

0 notes

Text

How Market Trends Present Opportunities in the Maleic Anhydride Market

The global maleic anhydride market is projected to reach a size of USD 4,386.1 million in 2023, with expectations of expanding at a compound annual growth rate (CAGR) of 4.2% from 2024 to 2030. This growth can be largely attributed to the increasing demand for unsaturated polyester resins (UPR), which are a primary component in the production of fiberglass-reinforced resins. These resins find extensive applications in various industries, including automotive and marine sectors, as well as in construction products like sinks, countertops, and bathtubs.

In North America, the United States stands out as the largest consumer of maleic anhydride, commanding a revenue share of 82.9% in 2023. This dominance is linked to the rapid expansion of key industries such as agriculture, automotive, and construction. According to TST Europe, total construction spending in the U.S. reached approximately $1.98 trillion in 2023, marking a 7.4% increase from the previous year. This growth was particularly pronounced in nonresidential construction, which saw a significant 17.6% year-over-year increase, while residential construction spending experienced a decline of 3% due to rising interest rates and inflationary pressures. Additionally, the U.S. consistently constructs structures valued at over USD 1.8 trillion annually, which is expected to further bolster the maleic anhydride market in the country.

Gather more insights about the market drivers, restrains and growth of the Maleic Anhydride Market

Drivers, Opportunities, and Restraints

Unsaturated polyester resins play a critical role in the automotive sector, serving as body fillers that facilitate rapid reconstruction and repair of damaged vehicle components. They are also used as putty in car painting processes, ensuring a smooth finish by masking any imperfections. UPRs provide excellent adhesion for paint, which enhances the durability of the coating applied. Specifically, these resins are commonly utilized in the repair of bumpers, doors, roofs, and interior components affected by accidents. As global car accident rates continue to rise, the demand for UPR is anticipated to increase, subsequently driving up the need for maleic anhydride.

Moreover, maleic anhydride is integral to a variety of industries, including automotive, building and construction, pharmaceuticals, and personal care and cosmetics. The rising demand for unsaturated polyester resins in automotive and construction applications is poised to significantly boost the market for maleic anhydride. Additionally, the incorporation of additives in the automotive sector aimed at improving fuel efficiency and reducing emissions is likely to further fuel the demand for this chemical compound.

The production of maleic anhydride primarily relies on feedstocks such as n-butane and benzene. The global prices of these feedstocks are closely tied to the trends in crude oil and naphtha prices. The volatility of crude oil has been a significant factor contributing to the fluctuations in benzene prices. Consequently, the pricing of crude oil and the downstream demand from various industries have a considerable impact on the global petroleum derivatives market, influencing the availability and cost of maleic anhydride.

The maleic anhydride market is positioned for growth driven by robust demand from multiple industries, particularly in applications utilizing unsaturated polyester resins. As the automotive and construction sectors expand, and as new regulations drive the need for more efficient materials, the outlook for maleic anhydride remains positive, with ample opportunities for development and innovation.

Order a free sample PDF of the Maleic Anhydride Market Intelligence Study, published by Grand View Research.

#Maleic Anhydride Market#Maleic Anhydride Market Analysis#Maleic Anhydride Market Report#Maleic Anhydride Industry#Maleic Anhydride Market Opportunities#Maleic Anhydride Market Drivers

0 notes

Text

Revenue Forecast and Competitive Landscape for the Nitrocellulose Market

The Nitrocellulose Market Report for 2024 provides a comprehensive overview of the Nitrocellulose Market industry, presenting crucial data and insights into market dynamics, including growth drivers, challenges, and future potential. The report evaluates the Nitrocellulose Market Components, focusing on significant opportunities and trends that could shape the industry's trajectory. Key stakeholders such as CEOs, global managers, traders, and analysts will find value in the SWOT analysis, which assesses the competitive strengths, vulnerabilities, opportunities, and threats impacting market players.

According to Straits Research, the global Nitrocellulose Market market size was valued at USD 0.86 Billion in 2021. It is projected to reach from USD XX Billion in 2022 to USD 1.39 Billion by 2030, growing at a CAGR of 5.5% during the forecast period (2022–2030).

Get a Sample PDF/Excel of report starting from USD 995 :https://straitsresearch.com/report/nitrocellulose-market/request-sample

Top Key Players of Nitrocellulose Market :

EURENCO

GRN Cellulose Pvt. Ltd.

Hagedorn Nc

Hengshui Orient Chemical Co. Ltd.

Nitrex Chemicals India Pvt. Ltd

Nitrocellulose Group

Nitro Quimica

North Sichuan Nitrocellulose Corporation

Synthesia A.S

TNC Industrial Co. Ltd.

and more....

Key Insights from the Nitrocellulose Market Report

Market Size Overview: The report provides comprehensive estimates of the Nitrocellulose Marketsize, including value and sales volume, for the period.

Market Trends and Dynamics: An analysis of the key drivers, opportunities, challenges, and risks shaping the Nitrocellulose Market.

Global Economic and Regional Impact: Evaluation of the effects of global inflation and the Russia-Ukraine conflict on the Nitrocellulose Market.

Trade Flow Analysis: Detailed examination of import and export volumes of Nitrocellulose Marketacross major regions.

Industry Value Chain: Insight into the Nitrocellulose Marketvalue chain, covering raw materials, suppliers, manufacturing processes, distributors, and downstream customers.

Industry News, Policies, and Regulations: Coverage of the latest developments, policies, and regulations impacting the Nitrocellulose Market.

Regional Analysis for Nitrocellulose Market:

The regional analysis section of the report offers a thorough examination of the global Nitrocellulose Market market, detailing the sales growth of various regional and country-level markets. It includes precise volume analysis by country and market size analysis by region for both past and future periods. The report provides an in-depth evaluation of the growth trends and other factors impacting the Nitrocellulose Market market in key countries, such as the United States, Canada, Mexico, Germany, France, the United Kingdom, Russia, Italy, China, Japan, Korea, India, Southeast Asia, Australia, Brazil, and Saudi Arabia. Moreover, it explores the progress of significant regional markets, including North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

Nitrocellulose Market Segmentations:

By Applications

Printing ink

Automotive paint

Wood coating

Leather finish

Nail varnish

By Product

M-grade cellulose

E-grade cellulose

Get Detail Market Segmentation :https://straitsresearch.com/report/nitrocellulose-market/segmentation

Unit Economics must be known by C-suite professionals:

Cost of Goods Sold (COGS): Includes material, labor, and overhead costs in manufacturing.

R&D Costs: Investment in innovation and compliance with regulations.

Engineering and Design Costs: Resources for design, prototyping, and meeting technical standards.

Production Costs: Specialized manufacturing and quality control expenses.

Supply Chain Costs: Managing procurement and logistics for specialized components.

Testing and Quality Assurance: Costs for ensuring product safety and reliability.

SG&A Costs: Marketing, sales, and administrative expenses.

Revenue per Unit: Income from contracts, services, and licensing.

Gross Margin: Revenue minus COGS, showing unit profitability.

Break-even Analysis: Units or contracts needed to cover total costs.

Customer Acquisition Cost (CAC): Costs to secure new contracts.

Lifetime Value (LTV): Total revenue from a customer over time.

Capital Expenditure (CapEx): Investments in facilities and technology.

Economies of Scale: Cost reductions in larger production runs.

Profit Margin: Final profit after all expenses.

Top Reasons to Choose This Report

Access to Comprehensive Insights: Gain access to extensive analysis, research, and data that are often challenging to gather independently. This report provides valuable information, saving you significant time and effort.

Support for Informed Decisions: Enhance your decision-making process with in-depth insights into market trends, consumer behavior, and key industry factors. This report is essential for strategic planning, including investments, product development, and marketing strategies.

Gain a Competitive Edge: Stay competitive by understanding market dynamics and competitor strategies. The report provides detailed insights into competitor performance and market trends, helping you craft effective business strategies.

Cost-Effective Research Solution: Save on research costs by investing in this report, which offers a detailed and comprehensive analysis of the market. This cost-effective option eliminates the need for extensive independent research.

COVID-19 Aftermath and Geopolitical Influences: Russia-Ukraine Conflict and Middle East Crisis

The report explores the multifaceted impact of COVID-19 on the Nitrocellulose Market market, covering both direct and indirect effects across global and local levels. It discusses market size, trends, and growth trajectories in the Nitrocellulose Market , classified by type, application, and customer sector. Additionally, it provides a detailed evaluation of market development components before and after the pandemic, supported by a PESTEL analysis to assess key influencers and barriers to market entry. We offer the flexibility to customize the report based on specific regions, applications, or any other statistical details. Our goal is to align our analysis with your specific needs, ensuring a more complete market study. The final report will also examine the impact of the Russia-Ukraine War on the Nitrocellulose Market market, assessing how these geopolitical events are influencing current market conditions and future opportunities.

This Report is available for purchase on :https://straitsresearch.com/buy-now/nitrocellulose-market

About Us:

Straits Research is a leading research and intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & research reports.

Contact Us: email: [email protected] Address: 825 3rd Avenue, New York, NY, USA, 10022 Tel: +1 646 905 0080 (U.S.) +91 8087085354 (India) +44 203 695 0070 (U.K.)

#Nitrocellulose Market#Nitrocellulose Market Share#Nitrocellulose Market Size#Nitrocellulose Market Research#Nitrocellulose Industry#What is Nitrocellulose?

0 notes

Text

Automotive Specialty Coatings Market to Hit $4.08 Billion by 2032

The global Automotive Specialty Coatings Market was valued at USD 3.10 Billion in 2024 and it is estimated to garner USD 4.08 Billion by 2032 with a registered CAGR of 6.5% during the forecast period 2024 to 2032.

Global Automotive Specialty Coatings Market Research Report 2024, Growth Rate, Market Segmentation, Automotive Specialty Coatings Market. It affords qualitative and quantitative insights in phrases of market size, destiny trends, and nearby outlook Automotive Specialty Coatings Market. Contemporary possibilities projected to influence the destiny capability of the market are analyzed in the report. Additionally, the document affords special insights into the opposition in particular industries and diverse businesses. This document in addition examines and evaluates the contemporary outlook for the ever-evolving commercial enterprise area and the prevailing and future outcomes of the market.

Get Sample Copy of Report @ https://www.vantagemarketresearch.com/automotive-specialty-coatings-market-1173/request-sample

** Note: You Must Use A Corporate Email Address OR Business Details.

The Major Players Profiled in the Market Report are:-

KCC (South Korea), Nippon Paint (Japan), PPG (US), Axalta (US), BASF (Germany), AkzoNobel (Netherlands), Kansai (Japan), Sherwin Williams (US), Covestro (Germany), DOW Chemical (US), and Solvay (Belgium)

Automotive Specialty Coatings Market 2024 covers powerful research on global industry size, share, and growth which will allow clients to view possible requirements and forecasts. Opportunities and drivers are assembled after in-depth research by the expertise of the construction robot market. The Automotive Specialty Coatings Market report provides an analysis of future development strategies, key players, competitive potential, and key challenges in the industry.

Global Automotive Specialty Coatings Market Report 2024 reveals all critical factors related to diverse boom factors inclusive of contemporary trends and traits withinside the worldwide enterprise. It affords a complete review of the top manufacturers, present-day enterprise status, boom sectors, and commercial enterprise improvement plans for the destiny scope.

The Automotive Specialty Coatings Market document objectives to offer nearby improvement to the market using elements inclusive of income revenue, destiny market boom rate. It gives special observation and analysis of key aspects with quite a few studies strategies consisting of frenzy and pestle evaluation, highlighting present-day market conditions. to be. Additionally, the document affords insightful records approximately the destiny techniques and opportunities of worldwide players.

You Can Buy This Report From Here: https://www.vantagemarketresearch.com/buy-now/automotive-specialty-coatings-market-1173/0

Global Automotive Specialty Coatings Market, By Region

1) North America- (United States, Canada, Mexico, Cuba, Guatemala, Panama, Barbados, and many others)

2) Europe- (Germany, France, UK, Italy, Russia, Spain, Netherlands, Switzerland, Belgium, and many others)

3) the Asia Pacific- (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Vietnam, and many others)

4) the Middle East & Africa- (Turkey, Saudi Arabia, United Arab Emirates, South Africa, Israel, Egypt, Nigeria, and many others)

5) Latin America- (Brazil, Argentina, Colombia, Chile, Peru, and many others)

This Automotive Specialty Coatings Market Research/analysis Report Contains Answers to your following Questions

What trends, challenges, and barriers will impact the development and sizing of the global market?

What is the Automotive Specialty Coatings Market growth accelerator during the forecast period?

SWOT Analysis of key players along with its profile and Porter’s five forces analysis to supplement the same.

How much is the Automotive Specialty Coatings Market industry worth in 2019? and estimated size by 2024?

How large is the Automotive Specialty Coatings Market? How long will it keep growing and at what rate?

Which section or location will force the market and why?

What is the important thing current tendencies witnessed in the Automotive Specialty Coatings Market?

Who are the top players in the market?

What and How many patents are filed by the leading players?

What is our Offering for a bright industry future?

The Research Objectives of this Report are to:-

Company, key regions/countries, merchandise and applications, historical records from 2018 to 2022, and global Automotive Specialty Coatings Market till 2032. Study and analyze the market length (cost and volume).

To recognize the structure of Automotive Specialty Coatings Market via way of means of figuring out its numerous subsegments.

Automotive Specialty Coatings Market on the subject of the primary regions (with every essential country). Predict the cost and length of submarkets.

To examine the Automotive Specialty Coatings Markets with appreciation to person boom trends, destiny prospects, and their contribution to the general market.

To examine aggressive trends consisting of expansions, contracts, new product launches, and acquisitions withinside the market.

Strategic profiling of key gamers and complete evaluation of growth strategies.

Read Full Research Report with [TOC] @ https://www.vantagemarketresearch.com/industry-report/automotive-specialty-coatings-market-1173

Reasons to Buy Market Report

The market record presents a qualitative and quantitative analysis of the market based on segmentation that includes each economic and non-economic element.

Automotive Specialty Coatings Market through the region. The market evaluation highlights the consumption of products/services in areas and well-known shows elements influencing the market in every region.

Automotive Specialty Coatings Market. It consists of an in-depth analysis of the market from specific views via Market Porter's Five Forces Analysis and provides insights into the market via the Value Chain.

The Automotive Specialty Coatings Market file provides an outline of market fee (USD) information for every segment and sub-segment.

It consists of an in-depth analysis of the market from distinct views via a 5 forces analysis of the Automotive Specialty Coatings Market and offers insights into the market through the fee chain.

Check Out More Reports

Global Pest Control Market : Report Forecast by 2032

Global Foam Tape Market: Report Forecast by 2032

Global Waterproof Coating For Roof Covering Market: Report Forecast by 2032

Global Automotive Brake Fluid Market: Report Forecast by 2032

Global Nanomaterials Market: Report Forecast by 2032

#Automotive Specialty Coatings Market#Automotive Specialty Coatings Market 2024#Global Automotive Specialty Coatings Market#Automotive Specialty Coatings Market outlook#Automotive Specialty Coatings Market Trend#Automotive Specialty Coatings Market Size & Share#Automotive Specialty Coatings Market Forecast#Automotive Specialty Coatings Market Demand#Automotive Specialty Coatings Market sales & price

0 notes

Text

Drivers and Restraints in the Wollastonite Powder Market: A Comprehensive Overview

The Wollastonite Powder market is gaining traction due to its wide array of applications in several industries, including construction, ceramics, plastics, and paints. Wollastonite, a naturally occurring calcium silicate mineral, is prized for its reinforcement capabilities, low moisture absorption, and chemical inertness. These properties make it an ideal choice for manufacturers seeking high-performance materials. As industries increasingly turn to sustainable and high-quality materials, wollastonite powder is becoming a preferred option in many verticals.

The global wollastonite powder industry, valued at US$ 405.4 million in 2022, is projected to grow at a CAGR of 7.8% from 2023 to 2031, reaching US$ 797.8 million by the end of 2031.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/wollastonite-powder-market.html

Market Segmentation:

The Wollastonite Powder market can be segmented into various categories based on service type, sourcing type, application, industry vertical, and region.

By Service Type: Raw wollastonite powder, modified wollastonite powder.

By Sourcing Type: Natural wollastonite, synthetic wollastonite.

By Application: Ceramics, plastics, paints & coatings, construction materials, metallurgy, friction products, and others.

By Industry Vertical: Construction, automotive, ceramics, paints & coatings, metallurgy, and polymers.

By Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa.

Regional Analysis:

North America: The demand for wollastonite powder is high in this region, primarily driven by the growing construction and ceramics industries. The U.S. is the key contributor to market growth.

Europe: European countries such as Germany, Italy, and the UK are notable markets for wollastonite powder due to the strong presence of automotive and manufacturing industries.

Asia-Pacific: This region is expected to witness the highest growth due to the rapidly expanding construction and automotive sectors, especially in China and India. The increasing use of wollastonite powder in plastics and paints is also contributing to the market's growth.

Latin America and Middle East & Africa: These regions are gradually emerging markets as infrastructure development projects and industrial activities rise.

Market Drivers and Challenges:

Drivers:

Growing Construction Industry: The increasing urbanization and infrastructure projects globally are driving the demand for construction materials, which in turn is boosting the demand for wollastonite powder.

Sustainability and Lightweight Materials: Manufacturers across various industries are shifting towards sustainable and lightweight materials, which wollastonite powder effectively provides due to its reinforcing properties.

Wollastonite as a Substitute: Wollastonite is used as a substitute for other reinforcing agents, such as asbestos, which is banned in many countries due to health hazards.

Challenges:

Price Fluctuations: The availability of raw wollastonite and synthetic alternatives may lead to price volatility, which could impact the market’s profitability.

Limited Awareness: Some end-use industries remain unaware of the benefits of wollastonite powder, which may hinder market growth.

Market Trends:

Technological Innovations: Advanced processing technologies are enhancing the quality and properties of wollastonite powder, increasing its adoption in high-end applications such as automotive components and electronic devices.

Eco-friendly Materials: With the rise of green building materials, wollastonite powder is increasingly used as a natural, eco-friendly material in construction and industrial applications.

Future Outlook:

The Wollastonite Powder market is poised for robust growth through 2031 as industries continue to prioritize high-performance, sustainable materials. The expansion of end-use industries, especially in developing regions, will play a critical role in the market's growth trajectory. Additionally, innovations in synthetic wollastonite and the development of new applications will create new opportunities in the market.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=48768<ype=S

Key Market Study Points:

Rapid growth in construction and automotive sectors.

Increasing demand for high-performance materials in manufacturing.

Strong potential for synthetic wollastonite development.

Competitive Landscape:

The Wollastonite Powder market is characterized by the presence of several key players competing to gain market share through innovations and strategic expansions. Some of the major players include:

NYCO Minerals

Imerys S.A.

R.T. Vanderbilt Holding Company, Inc.

Nordkalk Corporation

Anhui Pioneer Mining Co., Ltd.

These companies are focusing on product innovation, mergers & acquisitions, and expanding their production capacities to stay competitive.

Recent Developments:

Imerys announced the expansion of its wollastonite production capacity in 2022 to meet the growing demand from the ceramics and plastics industries.

NYCO Minerals has been developing advanced processing technologies to enhance the application scope of wollastonite powder in various industries, particularly automotive and electronics.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Electronic Adhesives Market - Forecast (2024-2030)

Electronic Adhesives Market Overview

Electronic Adhesives Market Size is forecast to reach $ 6,820 Million by 2030, at a CAGR of 6.50% during forecast period 2024-2030. Electronic adhesives are used for circuit protection and electronic assembly applications such as bonding components, wire tacking, and encapsulating electronic components. The use of electronic adhesives in manufacturing components for electric vehicles such as printed circuit boards, lithium-ion batteries, and battery pack assemblies are facilitating growth of the market. Growing adoption of surface mounting technology to replace welding and soldering is one of the prominent trends in the electronics industry, shaping the demand for electronics adhesives.

Report Coverage

The report: “Electronic Adhesives Market – Forecast (2024-2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Electronic Adhesives Industry.

By Type: Thermal Conductive, Electrically Conductive, Ultraviolet-Curing and Others.

By Resin Type: Epoxy, Cyanoacrylates, Polyamides, Phenolic, Silicones, and Others (Acrylics, and Polyurethane)

By Application: PCB’s, Semiconductor, and Others

By End-User Industry: Consumer Electronic (Wearable Devices, LEDs & TVs, Smart Phones & Tablets, Computers, Laptops, and Others), Healthcare, Energy & Power (Solar, Wind, and Others), Telecom Industry, Transportation (Automotive (Passenger Vehicles, Light Commercial and Heavy Commercial Vehicles), Marine, Locomotive, and Aerospace), Oil & Gas, Chemical, Pulp & Paper, and Others.

By Geography: North America, South America, Europe, APAC, and RoW

Request Sample

Key Take away

In 2020, North America held the largest share after APAC. Due to growing demand for electronic adhesives in electronics and telecommunication industry. The US hold the largest share in the region over the forecast period.

Growing adoption of electric vehicles is expected to provide a major growth opportunity for the market.

Emission of Volatile Organic Compounds (VOC’s) may deter the market's growth during the forecasted period.

COVID-19 has hindered the market growth owing to the disruption of supply chain and worldwide lockdown.

Electronic Adhesives Market Segment Analysis - By Type

Electrically Conductive segment held the largest share of more than 30% in the electronics adhesives market in 2020. Electrically Conductive are used in various industry verticals such as aerospace, automotive, medical, and telecom products. Electrically conductive is an excellent solution for making electrical contacts on PCBs and other temperature-sensitive substrates, as their curing temperature is below the soldering temperature. An increase in demand for Anisotropic Conductive Adhesives (ACA) in LCD connections, PCBs, and bonding antenna structures further boost the demand for the market. Electric conductive are also used in the LED industry for their capacity to serve as stable electrical contacts by absorbing mismatches, which will likely boost the market's growth for the forecasted period.

Inquiry Before Buying

Electronic Adhesives Market Segment Analysis - By Resin Type

Epoxy segments held the largest share of more than 25% in the market in 2020. Epoxy is widely used in electronic applications, either in two-part or single-part heat cure products. Epoxy has good resilience against environmental and media influences, it has a dry and non-tacky surface which is perfect to be used as a protective coating and is widely used in adhesives, plastics, paints, coatings, primers and sealers, flooring, and other. Curing epoxy adhesives can take place either at room or elevated temperature or through photoinitiators and UV light. Modern photoinitiators also react to the special UV spectrum of LED light sources, so that newly developed epoxide resin adhesives can be cured with both UV and UV LED light. Some epoxies exhibit optical properties and diffraction indexes, making them useful for applications in precision optics, lens bonding, and information technology, which will further boost the market's growth.

Electronic Adhesives Market Segment Analysis - By Application

Printed Circuit Boards (PCBs) segment held the largest share of more than 35% in the market in 2020. Electronic adhesives are used as a conformal coating in PCBs. Adhesive is used in wire tracking, potting & encapsulation of components, conformal coatings of circuit boards, and bonding of surface mount components. PCBs are highly reliable, cheap, less chance of short circuit, easily repairable, and are compact in size. The growing uses of laptops, smartphones, and household appliances coupled with developing living standards further drive the growth of PCB. Whereas, the growing uses of PCB’s in automotive, industrial & power equipment, control & navigation systems, and aerospace monitoring also contribute to the market growth. According to Aerospace Industries Association (AIA) report, in 2018, aerospace and defense exports amounted to $151 billion, an increase of 5.81% from the previous year, and civil aerospace accounted for the majority of exports with $131.5 billion.

Schedule a Call

Electronic Adhesives Market Segment Analysis - By End-User Industry

Consumer Electronics segment held the largest share of more than 30% in the Electronic Adhesives Market in 2020. Rapid urbanization and increase in the development of new technology have propelled the demand for consumer electronics. As per the United Nations, 55% of the world’s population lives in urban areas, which propel the demand for consumer electronics. The growing demand for lightweight and portable equipment such as smartphones, laptops, and digital cameras are playing a significant role in boosting the demand for the market. As per a report released by Nexdigm Private Limited, a private company, the global electronics industry is expected to reach $7.3 trillion by 2025, which will significantly propel the demand for the market during the forecasted period.

Electronic Adhesives Market Segment Analysis - By Geography

Asia-Pacific held the largest share of more than 45% in the Electronic Adhesives Market in 2020. China, India, and Japan are the major contributors to the growth of Electronic Adhesives Market in APAC. The large consumer base, developing manufacturing sector, and increase in middle-class population along with smart city projects are major factors for the market growth. As per the Indian Brand Equity Foundation (IBEF) report released in 2020, electronics manufacturing in India is expected to reach $163.14 billion by 2025, and demand for electronics hardware in India is expected to reach US$ 400 billion by 2024. The shifting of production lines to the APAC region for the low cost of production and the ability to serve the local emerging market is another factor for the growth of the market in the region.

Buy Now

Electronic Adhesive Market Drivers

Growing Need for Miniaturized Electronic Products

Growing demand for low-cost, reliable, and miniaturized electronic devices from consumers propel the market's growth. The increasing demand for miniaturized products has led to the development of smaller electrical components, which occupy less area. The need for smaller and thinner consumer electronics devices is a new trend among consumers. The surface mount technology helps in using and assembling much smaller components, thus facilitating a smaller, portable, and lightweight electronic device. Pocket calculators, smartwatches & other wearable devices are some of the examples. Such miniature devices will further drive the demand for electronic devices and in return will boost the demand for the Electronic Adhesives Market as they are used in manufacturing these devices.

Introduction of 5G Network

Introduction 5G networks are planned to increase mobile broadband speeds and added capability for 4K/8K video streaming, virtual reality (VR) or augmented reality (AR), Internet of Things (IoT), and mission-critical applications. Introduction of 5G will boost the telecommunication industry, with better coverage, and internet speed, which also create a demand for Electronic Adhesives Market as they are used in manufacturing telecom devices. 5G will transmit data ten times faster than 4G and is set to take hold in 2020. This will spark a revolution in many industries such as electronic, energy, medical, automotive, defense, aerospace and others, which will boost the market's growth. 5G will impact the viewing experience for consumer, with its VR & AR which will further boost the demand for consumer electronic industry, which in return will boost the demand for electronic adhesive market.

Electronic Adhesive Market Challenges

Technological Changes & VOC Emission

The market is facing challenges due to technological changes. Shorter leads can damage temperature-delicate components in several applications and to overcome such obstacles electrical components should be assembled after soldering. However, this hampers productivity due to higher costs of production and time consumed in the manufacturing process. Growing concern over the emission of volatile organic compounds (VOCs) is expected to hamper the market growth over the coming years. During the manufacturing of electronics adhesives, VOC is discharged that may pose health and environmental concerns. VOCs are the major contributors to smog and ozone formation at low atmospheric levels.

Emergence of COVID 19

The COVID-19 pandemic continues to unfold everyday with severe impact on people, communities, and businesses. And the Electronic Adhesives Market was no exceptional, as the global production facilities of the electronics, parts have been reduced due to the logistics slowdown and unavailability of the workers. Furthermore, various e-commerce sites had discontinued the delivery of non-essential items which included electronics devices, which affected the electronic industry.

Electronic Adhesive Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the Electronic Adhesives Market. In 2020, the market of electronic adhesives has been consolidated by the top 10 players accounting for xx% of the share. Major players in the Electronic Adhesives Market are BASF SE, Panacol-Elosol GmbH, 3M Co., H.B. Fuller Co., Henkel AG & Co. KGaA, Hitachi, Ltd., Mitsui & Co., Ltd., Bostik, Inc., Chemence Inc., tesa SE, Parker Hannifin Corp., Meridian Adhesives Group, among others.

Acquisitions/Technology Launches

In November 2019, Bostik, Inc., announced it has launched a new range of innovative engineering adhesives Born2Bond™, for bonding applications in automotive, electronics, luxury packaging, and medical devices. With this new launch Bostik will not only expand its product portfolio but also expand it offering to various industries, which will further drive the market's growth.

In September 2020, Meridian Adhesives Group, a leading manufacturer of high-value adhesives technologies has announced that the “Company” would be serving the Electric Vehicles Market and provide its adhesive solution, with this announcement Meridian Adhesives would expand its product offering in automobile industry, which will further derive the market's growth.

Key Market Players:

The Top 5 companies in Electronic Adhesives Market are:

Panacol-Elosol GmbH

3M

H.B. Fuller Company

Henkel AG & Co.KGaA

Parker Hannifin Corp.

#Electronic Adhesives Market Size#Electronic Adhesives Market Trends#Electronic Adhesives Market Growth#Electronic Adhesives Market Forecast#Electronic Adhesives Market Revenue#Electronic Adhesives Market Vendors#Electronic Adhesives Market Share#Electronic Adhesives Market

0 notes

Text

Retro-Reflective Materials Market Innovations in Technology and Product Development

Retro-Reflective Materials Market Growth Strategic Market Overview and Growth Projections

The global retro-reflective materials market size was valued at USD 59.1 billion in 2022 and is projected to reach a value of USD 153.6 billion by 2031, registering a CAGR of 11.2 % during the forecast period (2023-2031).

The latest Global Retro-Reflective Materials Market by straits research provides an in-depth analysis of the Retro-Reflective Materials Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global Retro-Reflective Materials Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the Retro-Reflective Materials Market are

3M

American, and Efird

Asian Paints

Avery Dennison

Changzhou Hua R Sheng Reflective Material

Coats Group

Nippon Carbide Industries

ORAFOL Europe

Paiho Group

REFLOMAX.

Get Free Request Sample Report @ https://straitsresearch.com/report/retro-reflective-materials-market/request-sample

The Retro-Reflective Materials Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global Retro-Reflective Materials Market: Segmentation

The Retro-Reflective Materials Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

By Technology Type

Ceramic Beads

Glass Beads

Micro-Prismatic

By Product Type

Films, Sheets and Tapes

Paints and Coatings

Others

By Application

Traffic Control and Work Zone

Safety Apparel

Automotive

Industrial

Others

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/retro-reflective-materials-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the Retro-Reflective Materials Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the Retro-Reflective Materials Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the Retro-Reflective Materials Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the Retro-Reflective Materials Market market over the next several years?

How do regulatory and legal frameworks influence the market?

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Retro-Reflective Materials Market Market#Retro-Reflective Materials Market Market Share#Retro-Reflective Materials Market Market Size#Retro-Reflective Materials Market Market Research#Retro-Reflective Materials Market Industry#What is Retro-Reflective Materials Market?

0 notes

Text

Collaborative Robots Market Size, Share, Growth and Industry Trends, 2030

The global collaborative robots market size is anticipated to reach USD 11.04 billion by 2030, exhibiting a CAGR of 32.0% over the forecast period, according to a new report published by Grand View Research, Inc. The growth can be credited to the growing inclination of industries toward collaborative robots or cobots to automate manufacturing processes.

Over the past few years, the growing interest in robot technology across various industries has positively impacted the collaborative robots industry. Unlike conventional industrial robots, cobots are developed to operate at par with their human counterparts. They are mobile and can be easily moved from one area of a manufacturing facility to another. Moreover, they can be programmed with ease, are more cost-effective than their fixed counterparts, and can be used in a wide range of low-speed, repetitive applications.

The increasing need for highly efficient and user-friendly robots that do not require highly skilled experts for deployment and functioning has created a significant demand for software platforms. These platforms allow the integration of robots, motion control, and the generation of an interface that enables the programming of such robots. For instance, Mitsubishi Electric Corporation has launched a cobot named MELFA ASSISTA equipped with RT VisualBox, the company’s engineering software. This software allows the intuitive creation of operating sequences by connecting block diagrams in a chain of events, including linking with other devices, such as cameras and the hands of the robot.

Gather more insights about the market drivers, restrains and growth of the Collaborative Robots Market

Detailed Segmentation:

Application Insights

The gluing & welding segment is expected to witness the highest CAGR over the forecast period, which can be attributed to various benefits offered by cobots such as reduced waste, increased consistency, quality, and output product gaining attention from marketers. The assembly application segment captured a sizeable revenue share of around 23.0% across the collaborative robots market in 2022, owing to the increased usage of cobots for combining easy and repetitive tasks and supporting complex assembly processes.

Payload Capacity Insights

The up to 5kg payload capacity segment held a revenue share of more than 44% in 2022 and is anticipated to show remarkable growth in the future owing to its wide range of attributes. They are light in weight and offer flexibility while optimizing low-weight collaborative processes such as picking, placing, and testing. The launch of advanced cobots in this payload capacity range is opening new growth opportunities for the market. For instance, in March 2021, Comau S.p.A. launched a cost-effective cobot named Racer-5 suitable for packaging and warehousing. This advanced cobot works at an industrial speed of up to 6 m/s and has a 5kg payload capacity which facilitates seamless operations.

Vertical Insights

The automotive segment accounted for a revenue share of more than 24% in 2022 and is expected to grow substantially over the forecast period. The growth can be largely attributed to the increased adoption of collaborative robots owing to their ability to reduce floor space and the cost of production downtime. In addition to this, they find important usage in spot and arc welding, assembling parts, painting, coating, etc. Furthermore, the implementation of collaborative robots helps the automotive industry to increase productivity, resulting in increased demand over the forecast period.

Regional Insights

Europe is a remunerative hub for collaborative robots and captured a significant revenue share of more than 30.0% in 2022. This can be chiefly credited to the enormous application of collaborative robots across various verticals, including logistics, electronics, and inspection. Moreover, various advantages such as efficient manufacturing optimization solutions and increased collaboration offered by automation at the workplace are also expected to support the market expansion.

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

• The global robotic platform market size was estimated at USD 9.97 billion in 2023 and is projected to grow at a CAGR of 5.9% from 2024 to 2030.

• The global drone charging station market size was estimated at USD 0.43 billion in 2023 and is expected to grow at a CAGR of 6.5% from 2024 to 2030.

Key Companies & Market Share Insights

The major companies operating in the collaborative robots industry are inclined to introduce innovative offerings to gain a competitive edge in the market. For instance, in February 2021, ABB Group expanded its collaborative robot portfolio with the introduction of the SWIFTI and GoFa cobot range, delivering higher speeds and payloads. This new range complements ABB’s cobot line-up of YuMi and Single Arm YuMi and is faster, stronger, and more capable.

It has been designed to support high-growth segments such as consumer goods, electronics, healthcare, logistics, food, and beverage, etc. Additionally, in November 2022, Epson America, Inc. announced the expansion of the VT6L-Series through the launch of the VT6L-DC All-in-One 6-Axis Robot. The newly launched product is ideal for mobile solutions and delivers next-level technology that helps to improve operational efficiency.

Some prominent players in the global collaborative robots market include:

• ABB Group

• DENSO Robotics

• Epson Robots

• Energid Technologies Corporation

• F&P Robotics AG

• Fanuc Corporation

• KUKA AG

• MRK-Systeme GmbH

• Precise Automation, Inc

• Rethink Robotics, Inc

• Robert Bosch GmbH

• Universal Robots A/S

• Yaskawa Electric Corporation

• MABI Robotic AG

• Techman Robot Inc.

• Franks Emika Gmbh

• AUBO Robotics

• Comau S.p.A.

Collaborative Robots Market Segmentation

Grand View Research has segmented the global collaborative robots market based on payload capacity, application, vertical, and region:

Collaborative Robots Payload Capacity Outlook (Revenue, USD Billion, 2018 - 2030)

• Upto 5kg

• Upto 10kg

• Above 10kg

Collaborative Robots Application Outlook (Revenue, USD Billion, 2018 - 2030)

• Assembly

• Pick & Place

• Handling

• Packaging

• Quality Testing

• Machine Tending

• Gluing & Welding

• Others

Collaborative Robots Vertical Outlook (Revenue, USD Billion, 2018 - 2030)

• Automotive

• Food & Beverage

• Furniture & Equipment

• Plastic & Polymers

• Metal & Machinery

• Electronics

• Pharma

• Others

Collaborative Robots Regional Scope (Revenue, USD Billion, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o U.K.

o France

• Asia Pacific

o China

o Japan

o India

• South America

o Brazil

• Middle East and Africa

Order a free sample PDF of the Collaborative Robots Market Intelligence Study, published by Grand View Research.

#Collaborative Robots Market#Collaborative Robots Market size#Collaborative Robots Market share#Collaborative Robots Market analysis#Collaborative Robots Industry

0 notes

Text

A Coat of Perfection: The Future of Automotive Paints

According to the report, the global automotive paints and coatings market is projected to grow at a compound annual growth rate (CAGR) of about 5.50% during the forecast period of 2022-2028. In 2022, the market was valued at nearly USD 16 billion and is expected to exceed USD 22 billion by 2028, driven by increasing vehicle production and demand for enhanced aesthetics and protection.

What Are Automotive Paints and Coatings?

Automotive paints and coatings are specialized materials applied to vehicle surfaces for both aesthetic appeal and protection against environmental factors. These coatings not only provide color and shine but also safeguard vehicles from corrosion, UV radiation, and wear and tear.

Get Sample pages of Report: https://www.infiniumglobalresearch.com/reports/sample-request/1154

Market Dynamics and Growth Drivers

The global automotive paints and coatings market is experiencing growth due to several key factors: