#ethylene oxide sterilizer

Explore tagged Tumblr posts

Text

Choosing the Right Ethylene Oxide Sterilizer for Your Industry Needs

Sterilization is a critical process in various industries, from healthcare to pharmaceuticals, ensuring that medical devices and sensitive equipment remain free from harmful microorganisms. Ethylene oxide (EO) sterilization is one of the most effective methods for sterilizing heat- and moisture-sensitive materials. However, selecting the right ethylene oxide sterilizer for your industry needs requires careful consideration of several factors, including size, functionality, safety features, and compliance with industry regulations. This guide will help you navigate the key aspects to consider when choosing an EO sterilization machine to meet your specific requirements.

Understanding Ethylene Oxide Sterilization

Ethylene oxide sterilization is widely used to eliminate bacteria, viruses, and other pathogens from medical instruments, surgical tools, and laboratory equipment. Unlike other sterilization methods such as steam or dry heat, EO sterilization is suitable for delicate items made from plastic, rubber, and electronics that cannot withstand high temperatures. The process involves exposing products to ethylene oxide gas under controlled conditions, ensuring complete sterilization while maintaining the integrity of the materials.

Key Factors to Consider When Choosing an Ethylene Oxide Sterilizer

1. Industry Requirements and Compliance

Each industry has specific sterilization requirements and regulatory standards that must be met. Healthcare facilities, pharmaceutical companies, and medical device manufacturers need EO sterilization machines that comply with global standards such as the FDA, ISO 11135, and EPA regulations. Ensuring that your ethylene oxide sterilizer meets these guidelines is crucial for safety and legal compliance.

2. Capacity and Throughput

The size and capacity of an ethylene oxide sterilization machine should match your industry’s production needs. Small clinics may require compact tabletop sterilizers, while large-scale medical manufacturers may need industrial-sized units capable of handling high-volume sterilization cycles. Assessing your daily or monthly sterilization demands will help you determine the right capacity for optimal efficiency.

3. Safety Features and Operator Protection

Since ethylene oxide is a hazardous gas, safety is a top priority when selecting a sterilizer. Look for models equipped with advanced safety features, including:

Gas leak detection systems to monitor EO levels and prevent exposure risks.

Automated aeration cycles to remove residual gas before handling sterilized items.

Pressure and temperature controls for precise sterilization settings.

Sealed chamber design to prevent gas leaks and ensure operator safety. Investing in a sterilizer with enhanced safety features not only protects employees but also ensures compliance with workplace safety regulations.

4. Efficiency and Cycle Time

The efficiency of an EO sterilizer plays a crucial role in maintaining workflow productivity. Advanced ethylene oxide sterilization machines are designed with optimized cycle times, reducing downtime while ensuring complete sterilization. Some modern units offer pre-programmed sterilization cycles, allowing users to customize settings based on the type of materials being processed. Faster cycle times translate to increased productivity and cost savings for businesses.

5. Energy and Resource Consumption

With the growing focus on sustainability, selecting an ethylene oxide sterilizer that minimizes energy and resource consumption is beneficial. Some models are designed to use less EO gas while maintaining high sterilization efficacy. Features such as vacuum sealing, gas recapture systems, and energy-efficient heating elements can help reduce operational costs and environmental impact.

6. Maintenance and After-Sales Support

Like any industrial equipment, EO sterilization machines require regular maintenance to ensure long-term performance. Before making a purchase, consider the availability of spare parts, technical support, and warranty coverage. Companies like Equilateral Solutions provide reliable after-sales support, ensuring that your sterilizer remains in optimal working condition for years to come.

Popular Applications of Ethylene Oxide Sterilization

EO sterilization is commonly used in multiple industries, including:

Medical and Healthcare: Sterilizing surgical instruments, catheters, and syringes.

Pharmaceuticals: Ensuring the sterility of drug packaging and lab equipment.

Biotechnology and Laboratories: Sterilizing research tools and sensitive components.

Veterinary Clinics: Disinfecting surgical tools and animal care equipment.

Cosmetics and Personal Care: Sterilizing beauty instruments and packaging materials.

Making the Right Choice for Your Business

Investing in the right ethylene oxide sterilizer is essential for ensuring effective sterilization, safety, and compliance with industry standards. When selecting an EO sterilization machine, consider your industry’s specific needs, production volume, safety features, and long-term operational efficiency. Partnering with a trusted supplier that offers high-quality sterilization solutions and reliable customer support can help you achieve optimal results.

By carefully evaluating these factors, you can choose an EO sterilizer that enhances your sterilization processes while maintaining the highest standards of safety and efficiency. Whether you run a hospital, pharmaceutical company, or research facility, having the right sterilization equipment ensures that your products remain contamination-free and safe for use.

For businesses looking for high-quality EO sterilization solutions, companies like Equilateral Solutions offer cutting-edge sterilization machines designed for efficiency and compliance with industry standards. Selecting the right ethylene oxide sterilizer will not only improve your sterilization workflow but also ensure the safety and reliability of your products for years to come.

#Ethylene oxide#ethylene oxide sterilization machine#ethylene oxide sterilizer#Pune#India#Industrial#medical instruments manufacturers

0 notes

Text

Labtron Ethylene Oxide Sterilizer is a vertical, 80L capacity unit with a constant 50°C temperature and -60 kPa work pressure. It features a manual door, 304 stainless steel chamber, LCD display, built-in printer, explosion-proof heating, over-voltage/temp protection, and automatic residual air processing for reliability.

#Autoclaves#Ethylene Oxide Sterilizer#Ethylene Oxide Sterilizer supplier#Buy Ethylene Oxide Sterilizer

0 notes

Text

Ethylene Oxide Sterilizer

Labtron Ethylene Oxide Sterilizer is a vertical, constant temperature heating box type sterilizer cabinet with manual door opening offers 80 L of capacity,This process uses ethylene oxide gas to sterilize items at a relatively low temperature. pen_spark it has Working pressure-60 kPa an Maximum pressure 140 kPa in ethylene oxide; 1g/L-This concentration is effective for sterilization.

0 notes

Text

Type=vertical-constant-temperature-heating-box-type; Door opening=manual; Capacity=80-l; Sterilization temperature=50-plusmn-3; Work pressure=60-kpa. Shop Online at Labtron.us

0 notes

Text

Ethylene Oxide Sterilizer

Discover the industry-leading ethylene oxide Sterilizers with various types, capacities, sterilization temperatures, ventilation, and vacuum systems. Visit Labtron.org!

#Ethylene Oxide Sterilizer#autoclave machine#autoclave sterilization#autoclave pressure#autoclave vertical#horizontal autoclave

0 notes

Text

3 good things

Compounded some chemotherapy drugs today *O * the paclitaxel and docetaxel were really fun to inject into the bag because they're really viscous. Also looks cool

Cleaned up a bit more

Used a nice scented soap on my hands

#3 good things#personal#I feel like pushing that little bit of air out of a new sterile syringe#is such a good texture#one of my profs taught me that ethylene oxide can be used to sterilize syringes#and that's why there's always extra air in a new syringe#it's just kind of satisfying

2 notes

·

View notes

Text

#ETO Sterilizer#ETO Sterilizer Exporter#ETO Sterilizer Manufacture#Ethylene oxide sterilizers Exporter#Ethylene oxide gas sterilizers#Ethylene oxide sterilizers#ETO Sterilizer India#Maharashtra#Manufacture#Exporter#India

0 notes

Text

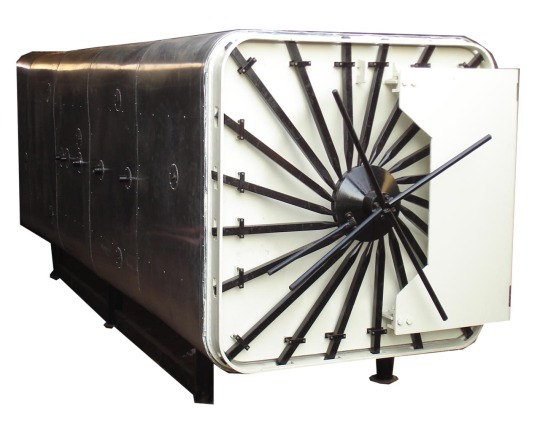

Production Scale ETO Sterilizer

Production Scale ETO Sterilizer or industrial eo gas sterilizer has been specially designed for sterilization of products sensitive to high temperature and to humidity (Syringes, DE fluxers, Catheters, Cartridges for Dialysis, Plastic articles, Bandages, Sutures etc.). Sterilizer can be uses even for sterilization of powders which deteriorate by heating exposure. For the wide range of product that can be treated, such sterilizer find application in Disposable Surgical Products, Para Pharmaceutical and Pharmaceutical Industry, Laboratories, Hospital and Food Processing Industries.

Adinath Ethylene Oxide Gas Sterilizer Manufacturer can be realized in to satisfy different requirements working under pressure (1.5 kg/cm² + vacuum) with mixtures of Ethylene Oxide and Carbon Oxide (usual composition 10% ETO + 90% CO₂, 20% ETO + 80% CO₂)

Ethylene Oxide gas infiltrates packages as well as products themselves to kill microorganisms that are left during production or packaging processes. This gas, mixed with air at a ratio of at least 3% ETO gas, forms an explosive mixture. Pure ETO gas boiling point is 10.73 ºC at atmospheric pressure. Most of the time, it is mixed with Nitrogen or CO2. EO Gas Sterilizers uses to sterilize to surgical instruments and medical disposables.

The system has been designed to operate on eto+co2 combination gas cylinders. The chamber and all contact parts shall be made from S.S 304. The chamber has been provided with a single door, easy locking arrangement and silicon gasket for leak proof operation. Electronically controlled heating system to ensure uniform heating of the chamber at 50 degrees centigrade. The chamber is provided with a adequate capacity rotary vacuum pump enclosed in sturdy cabinet duly powder coated for durability. We provide four of control switches with built in indicator light to regulate evacuation, feeding of gas, fresh air inlet through filter and aeration facility. Ethylene Oxide Gas Sterilization Unit is compact stand-alone sterilizer chamber.

0 notes

Text

Ethylene Oxide Sterilizer LX720EOS

Labdex ethylene oxide sterilizer holds a 120 L capacity with a durable 304 stainless steel inner chamber and a carbon steel exterior. It integrates built-in sensors, automatic control, an LCD display, and a printer. The explosion-proof heating system, air replacement, and temperature alarms ensure safe and efficient sterilization.

#Ethylene Oxide Sterilizer Companies#Ethylene Oxide Sterilizer Supplier#Ethylene Oxide Sterilizer Manufacturers

0 notes

Text

Ethylene Oxide Sterilizer/Weight-196 kg/

Labtron Ethylene Oxide Sterilizer is a 120-L vertical unit with a manual door opening, operating at 50 °C sterilization temperature and maximum pressure -60 kPa. It features a 304 stainless steel chamber, automatic 3-cycle ventilation, digital LCD control, built-in sensors, an oil-free vacuum pump, explosion-proof heating, high and low temperature alarms, casters, and a user-friendly design.

0 notes

Text

Seamless Sterilization Assurance: Auto Ethylene Oxide Gas Sterilizer Crafting by Industry Experts

Discover the pinnacle of convenience and safety with Auto Ethylene Oxide Gas Sterilizer from industry leaders. Experience the artistry of sterilization as we blend cutting-edge automation with precise Ethylene Oxide gas application. Trust in our expertise to safeguard your products and elevate your sterilization processes to unmatched levels of efficiency and excellence.

0 notes

Text

Excerpt from this story from Grist:

Cardinal Health uses that warehouse, and another one across town, to store medical devices that have been sterilized with ethylene oxide. Among the thousands of compounds released every day from polluting facilities, it’s among the most toxic, responsible for more than half of all excess cancer risk from industrial operations nationwide. Long-term exposure to the chemical has been linked to cancers of the breast and lymph nodes, and short-term exposure can cause irritation of the nasal cavity, shortness of breath, wheezing, and bronchial constriction. Dominguez’s family would go on to experience some of these symptoms, but only years later would they tie it to ethylene oxide exposure.

Warehouses like the ones in El Paso are ubiquitous throughout the country. Through records requests and on-the-ground reporting, Grist has identified at least 30 warehouses across the country that definitely emit some amount of ethylene oxide. They are used by companies such as Boston Scientific, ConMed, and Becton Dickinson, as well as Cardinal Health. And they are not restricted to industrial parts of towns — they are near schools and playgrounds, gyms and apartment complexes. From the outside, the warehouses do not attract attention. They look like any other distribution center. Many occupy hundreds of thousands of square feet, and dozens of trucks pull in and out every day. But when these facilities load, unload, and move medical products, they belch ethylene oxide into the air. Most residents nearby have no idea that the nondescript buildings are a source of toxic pollution. Neither do most truck drivers, who are often hired on a contract basis, or many of the workers employed at the warehouses.

Grist identified the country’s top medical device manufacturers and distributors, including Cardinal Health, Medline, Becton Dickinson, and Owens & Minor, and collated a list of the more than 100 known warehouses that they own or use. Some of these companies have reported to state or federal regulators that they operate at least one distribution center that stores products sterilized with ethylene oxide. Others were identified in person by Grist reporters as recipients of products from sterilization facilities. But since companies use multiple sterilization methods, it’s unclear whether each of these emits ethylene oxide. However, Grist still chose to publish the information to demonstrate the scale of the potential problem: There are almost certainly dozens, if not hundreds, more warehouses than the 30 we are certain about — and thousands more workers unknowingly exposed to ethylene oxide.

Identifying these warehouses and the 30 or so that emit some amount of ethylene oxide was a laborious process, in part because information about these facilities isn’t readily available. Grist reporters staked out sterilization facilities, spoke to truck drivers and warehouse workers, and combed through property databases.

The problem is “much bigger than we all assume,” said Rick Peltier, a professor of environmental health sciences at the University of Massachusetts. “The lack of transparency of where these products go makes us worried.”

16 notes

·

View notes

Text

i mean i’ve heard of ethylene oxide but GAMMA RADIATION? you’re telling me Bruce Banner sterilized these blades? (to the tune of a shrimp fried this rice?)

13 notes

·

View notes

Text

It's foolish to think that Putin isn't orgasmic over what the Trump administration has been doing to screw America.

Trump and his co-president Elon Musk have now targeted the EPA for revenge and retribution.

Trump, Musk move to oust EPA staff in the Great Lakes region, including dozens responsible for protecting drinking water for 30 million in U.S. and Canada

Trump purged dozens of career officials in the Chicago office during his first term. His latest attempt to cull the workforce is led by billionaire Elon Musk, whose companies Tesla and SpaceX have been fined by the EPA for multiple violations of environmental laws. “Elon Musk wants to turn EPA into every polluter’s ally,” U.S. Sen. Edward Markey, a Massachusetts Democrat, said Thursday at a rally in front of the agency’s headquarters. “He wants to take environmental cops off the beat.” History suggests Musk and scores of other polluters are going to catch a break during the next four years. Water pollution cases filed by the EPA in the Great Lakes region declined during each of the first three years Trump was president, according to an analysis of agency records by the nonprofit Environmental Law and Policy Center. Meanwhile, the number of chronic violators of the Clean Water Act in the heavily industrialized states skyrocketed under Trump, who as a candidate in 2016 vowed to abolish the EPA. [ ... ] More than 8 million people in Illinois get their drinking water from a utility where at least one PFAS has been detected, a 2022 Chicago Tribune investigation found. The discovery of high levels of ethylene oxide pollution led to the closure of a sterilization plant in southwest suburban Willowbrook and prompted a state law requiring another facility in north suburban Waukegan to dramatically reduce emissions.

Trump feels it's his right to make life easy for polluters who have given him and other far right Republicans huge campaign contributions.

States like Illinois can step up enforcement. But they don't have the reach and resources of the federal government. Be prepared to get sicker over the next few years.

#epa#the environment#water pollution#pfas#illinois#the great lakes#donald trump#elon musk#maga#republicans#make america sick again#vladimir putin#trump is a russian asset#traitor trump#владимир путин#путин хуйло#путлер#трамп - путинский пудель#дональд трамп#трамп хуйло

12 notes

·

View notes

Text

How does ETO Sterilization work?

What is ETO Sterilization?

Ethylene oxide (ETO) sterilization is a process used to sterilize medical and pharmaceutical products that cannot withstand traditional high-temperature steam sterilization methods. ETO is a gas that effectively kills microorganisms such as bacteria, viruses, and fungi by disrupting their DNA and cellular proteins.

How Does ETO Sterilization Work?

Preparation: Items to be sterilized are placed in a sealed chamber.

Exposure: ETO gas is introduced into the chamber, reaching all surfaces of the items.

Conditioning: The gas is held at specific temperature, humidity, and pressure levels for a predetermined time to ensure effective sterilization.

Aeration: Post-sterilization, the chamber is aerated to remove residual ETO gas, as ETO is toxic and potentially carcinogenic.

Monitoring: Throughout the process, parameters such as gas concentration, temperature, and exposure time are closely monitored to ensure efficacy and safety.

Applications of ETO Sterilizers

ETO sterilization is particularly suitable for:

Medical Devices: Such as surgical instruments, implants, and catheters.

Pharmaceuticals: Including drugs, ointments, and powders that are sensitive to heat and moisture.

Packaging Materials: Like plastic pouches and tubes that cannot withstand high temperatures.

Its ability to penetrate porous materials and complex devices makes ETO sterilization indispensable in many healthcare and pharmaceutical settings where other methods might be impractical or ineffective.

Considerations and Safety

While highly effective, ETO sterilization poses certain safety challenges:

Toxicity: ETO is hazardous to human health and requires careful handling. Workers must be trained in its safe use, and facilities must have adequate ventilation and monitoring systems.

Residuals: Proper aeration is crucial to remove ETO residues, which can otherwise compromise product safety.

Regulatory Compliance: Due to its potential health risks, ETO sterilization is heavily regulated by health authorities and environmental agencies worldwide.

Future Trends and Innovations

As technology advances, efforts are underway to improve the efficiency and safety of ETO sterilization processes. This includes developments in gas monitoring systems, aeration techniques, and automation to minimize human exposure.

Conclusion

ETO sterilization plays a critical role in ensuring the safety and efficacy of medical and pharmaceutical products that are sensitive to heat and moisture. While it requires careful handling due to its toxicity, advancements in technology continue to enhance its reliability and safety. As healthcare and pharmaceutical industries evolve, ETO sterilization remains a cornerstone in the arsenal of sterilization methods, ensuring that healthcare providers and patients alike can trust in the sterility of essential medical products.

Top ETO Sterilizer Manufacturer in India

If you are looking for Best ETO Sterilizer Manufacturer in India, look no further than Instech Sytems, we are a leading manufacturer and supplier of ETO Sterilizer in India.

For more details, please contact us!

Website :- www.cssdtechnologies.com

Contact No. :- +91–8896456000 , +91–9873069138

Email :- [email protected]

#ETO Sterilizer manufacturer#ETO Sterilizer manufacturer in India#Top ETO Sterilizer supplier in India#Best ETO Sterilizer manufacturer in India#Instech Systems

2 notes

·

View notes