#ethyl propenoate

Explore tagged Tumblr posts

Text

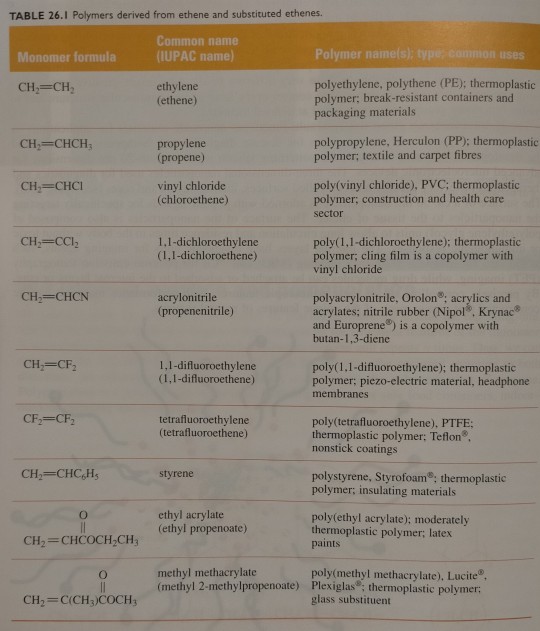

Table 26.1 gives some examples of polymers formed from compounds related to ethene, along with their common names and most important uses.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#polymers#ethene#ethylene#propene#propylene#chloroethene#vinyl chloride#dichloroethene#dichloroethylene#propenenitrile#acrylonitrile#difluoroethene#difluoroethylene#tetrafluoroethene#tetrafluoroethylene#styrene#ethyl propenoate#ethyl acrylate#methyl methylpropenoate#methyl methacrylate

2 notes

·

View notes

Text

코 아래 제상(祭床)도 먹는 것이 제일 ㏛ ETHYL ACRYLATE┝

ETHYL ACRYLATE Molecular Structure Description A chemical structure of a molecule includes the arrangement of atoms and the chemical bonds that hold the atoms together. The ETHYL ACRYLATE molecule contains of 8 Hydrogen atom(s), 5 Carbon atom(s) and 2 Oxygen atom(s) – a total of 15 atom(s). It contains a total of 14 bond(s). There are 6 non-H bond(s), 2 multiple bond(s), 3 rotatable bond(s), 2 double bond(s) and 1 ester(s) (aliphatic). Images of the molecular structure of ETHYL ACRYLATE are given below. An 3-dimensional (3D) Visualization An interactive 3D visualization page provides various features such as rotation, zoom in and out of the molecular model for a more detailed observation of the molecule. Additional visualization such as Van der Waals surfaces and the generation of image files are also available. Go to the 3D visualization page ]The structure data file (SDF) is available for download, which provides the information on the atoms, bonds, connectivity, and coordinates of the molecule. The SDF file is supported by most of the chemistry-related software packages. Go to the SDF download page ] Other names (synonyms) or registry numbers ETHYL ACRYLATE 140-88-5 Acrylic acid ethyl ester Ethyl propenoate ethyl prop-2-enoatemore2-Propenoic acid, ethyl ester Ethyl 2-propenoate Ethylacrylaat Ethylakrylat Etil acrilato Acrylic acid, ethyl ester Acrylate d'ethyle Ethyl acrylate, inhibited Carboset 511 Ethoxycarbonylethylene Aethylacrylat Etilacrilatului Akrylanem etylu RCRA waste number U113 Ethylakrylat [Czech] Ethylacrylaat [Dutch] Aethylacrylat [German] Ethylacrylate Acrylic acid, ethyl ester (inhibited) Etil acrilato [Italian] FEMA Number 2418 Ethyl acrylate (natural) Akrylanem etylu [Polish] Etilacrilatului [Romanian] Ethyl acrylate (inhibited) Ethylester kyseliny akrylove Acrylate d'ethyle [French] 2-Propenoic Acid Ethyl Ester ethyl 2E-propenoate FEMA No. 2418 Acrylsaeureaethylester [German] Ethylester kyseliny akrylove [Czech] RCRA waste no. U113 Ethyl propenoate, inhibited 2-Propenoic acid, ethyl ester, homopolymer ethylacrylat WE(2:0/3:1(2E)) 9003-32-1 Polyethylacrylate Poly(ethyl acrylate) Ethyl acrylate homopolymer Ethylacorate Ethyl 2-propenoate, homopolymer Poly(acrylic acid, ethyl ester) Acrylic acid ethyl Poly(ethylacrylate) Ethyl acrylate polymer Etilacrilatului(roumanian) CH2=CHCOOC2H5 Ethyl ester of 2-propenoic acid Ethyl acrylate, analytical standard 7387AF ANW-42233 LMFA07010505 MFCD00009188 71E6178C9T Cyacetacide; Cyanoacetic acid hydrazide RTR-005296 116404-62-7 CAS-140-88-5 Ethyl acrylate, 99%, stabilized 100ml Ethyl acrylate, purum, >=99.0% (GC) A0143 Ethyl acrylate, >=99.5%, stabilized, FG Ethyl acrylate, SAJ first grade, >=99.0% I04-9136 J-007427 PROPENOIC ACID,ETHYL ESTER (ETHYLACRYLATE) I14-15067 Ethyl acrylate, inhibited [UN1917] [Flammable liquid] Ethyl acrylate, inhibited [UN1917] [Flammable liquid] F1908-0175 Ethyl acrylate, contains 10-20 ppm MEHQ as inhibitor, 99% POLY(ETHYL ACRYLATE),APPROX. 20% SOLUTION IN TOLUENE (M.W. CA. 100,000) 129622-12-4 153313-65-6 163404-78-2 169238-64-6 171022-05-2 182371-81-9 220020-38-2 247179-15-3 37199-30-7 37730-49-7 391860-72-3 ACRYLIC ACID [DIHYDRO-5-(2-HYDROXYETHYL)-2,4,6-TRIOXO-1,3,5-TRIAZINE-1,3(2H,4H)-DIYL]DI-2,1-ETHANEDIYL ESTER 71E6178C9T 140-88-5 Acrylic acid ethyl ester Ethyl propenoate 2-Propenoic acid, ethyl ester ethyl prop-2-enoate Ethyl 2-propenoate Ethylacrylaat Ethylakrylat Etil acrilato Acrylic acid, ethyl ester Acrylate d'ethyle Ethyl acrylate, inhibited Carboset 511 ethylacrylat Ethoxycarbonylethylene Aethylacrylat Etilacrilatului Akrylanem etylu RCRA waste number U113 Ethylakrylat [Czech] Ethylacrylaat [Dutch] Aethylacrylat [German] Ethylacrylate Acrylic acid, ethyl ester (inhibited) Etil acrilato [Italian] FEMA Number 2418 Ethyl acrylate (natural) Akrylanem etylu [Polish] Etilacrilatului [Romanian] Ethyl acrylate (inhibited) Ethylester kyseliny akrylove Acrylate d'ethyle [French] 2-Propenoic Acid Ethyl Ester ethyl 2E-propenoate FEMA No. 2418 Acrylsaeureaethylester [German] Ethylester kyseliny akrylove [Czech] RCRA waste no. U113 Ethyl propenoate, inhibited 2-Propenoic acid, ethyl ester, homopolymer WE(2:0/3:1(2E)) 9003-32-1 Polyethylacrylate Poly(ethyl acrylate) Ethyl acrylate homopolymer Ethylacorate Ethyl 2-propenoate, homopolymer Poly(acrylic acid, ethyl ester) Acrylic acid ethyl Poly(ethylacrylate) Ethyl acrylate polymer Etilacrilatului(roumanian) CH2=CHCOOC2H5 Ethyl ester of 2-propenoic acid Ethyl acrylate, analytical standard 7387AF ANW-42233 AR-1J0598 LMFA07010505 MFCD00009188 Cyacetacide; Cyanoacetic acid hydrazide RTR-005296 116404-62-7 BBV-34551571 CAS-140-88-5 Ethyl acrylate, 99%, stabilized 100ml Ethyl acrylate, purum, >=99.0% (GC) A0143 Ethyl acrylate, >=99.5%, stabilized, FG Ethyl acrylate, SAJ first grade, >=99.0% C-28303 I04-9136 PROPENOIC ACID,ETHYL ESTER (ETHYLACRYLATE) I14-15067 Ethyl acrylate, inhibited [UN1917] [Flammable liquid] Ethyl acrylate, inhibited [UN1917] [Flammable liquid] F1908-0175 Ethyl acrylate, contains 10-20 ppm MEHQ as inhibitor, 99% POLY(ETHYL ACRYLATE),APPROX. 20% SOLUTION IN TOLUENE (M.W. CA. 100,000) 129622-12-4 153313-65-6 163404-78-2 169238-64-6 171022-05-2 182371-81-9 220020-38-2 247179-15-3 37199-30-7 37730-49-7 391860-72-3 코 아래 제상(祭床)도 먹는 것이 제일 제 앞에 아무리 좋은 것이 많이 있다고 해도 실제로 제가 갖게 되어야 가치가 있다는 말.

0 notes

Text

Synthesis and Radical Copolymerization of Novel Phenyl-Disubstituted Propyl Cyanoacrylates- Juniper Publishers

JUNIPER PUBLISHERS- ACADEMIC JOURNAL OF POLYMER SCIENCE

Abstract

Novel phenyl-disubstituted propyl 3-(R-phenyl)-2-cyanoacrylates, RPhCH=C(CN)CO2C3H7 (where R is 2-fluoro-5-methyl, 3-iodo-4-methoxy, 5-iodo-2-methoxy, 3,5-dichloro, 3,4-difluoro, 3,5-difluoro, 2-chloro-4-fluoro, 2-chloro-6-fluoro, 3-chloro-2-fluoro, and 3-chloro-4-fluoro) were prepared using condensation of substituted benzoic aldehydes and propyl ester of cyanoacetic acid. The ethynyl benzene copolymerization of novel cyanoacrylates was conducted in solution with radical initiation at 70 C. Nitrogen analysis, 1H & 13C NMR was used to analyze composition and the structure. Thermal behavior of the copolymers was analyzed by DSC and TGA.

Keywords: Radical copolymerization; Styrene copolymers; Trisubstituted ethylene’s; Cyanoacrylates

Introduction

Ring–functionalized trisubstituted ethylene’s (TSE), esters of 3-phenyl-2-cyanoacrylates, R1PhCH=C(CN) CO2R2 continue to attract attention as compounds with interesting properties and as comonomers for modification of commercial polymers. 3,4-Difluorophenyl substituted methyl 3-phenyl-2-cyanoacrylate was used in synthesis and studies of histamine H2 agonistic activity [1]. Ethyl 3-phenyl-2-cyanoacrylate was used in studies of stereoselective cascade assembling of (1R*,2S*)-1-cyano-5,7-dialkyl-4,6,8-trioxo-2-aryl-5,7-diazaspiro[2.5]octane-1-carboxylates [2] and analgesic activity of 6-fluoroindan-1-carboxylic acid [3]. Alkyl 2-cyanoacrylates are a family of vinyl monomers renowned for their high reactivity, instant adhesive properties, and wide-ranging applications [4].

We have reported synthesis and ethynylbenzene copolymerization of similar ring-substituted methyl [5], ethyl [6], & butyl 3-phenyl-2-cyanoacrylates [7]. With the objective to design novel structures, that could serve as a spring board for further development of novel materials with new properties and applications, we have prepared halogen ring-disubstituted propyl 3-phenyl-2-cyanoacrylate (PPCA), RPhCH=C(CN)CO2C3H7sub>, where R is 2-fluoro-5-methyl, 3-iodo-4-methoxy, 5-iodo-2-methoxy, 3,5-dichloro, 3,4-difluoro, 3,5-difluoro, 2-chloro-4-fluoro, 2-chloro-6-fluoro, 3-chloro-2-fluoro, and 3-chloro-4-fluoro, and copolymerize them with ethynylbenzene. To the best of our knowledge, there have been no reports on either synthesis of these propyl phenyl cyanoacrylates, nor their copolymerization with ethynylbenzene.

Experimental

All benzoic aldehydes, propyl cyanoacetate, piperidine, ethynylbenzene, 1,1’-azobiscyclohexanecarbonitrile, (ABCN), and toluene supplied from Sigma-Aldrich Co., were used as received. The melting points and Tg, were measured with TA Model Q10 DSC. The thermal stability of the copolymers was measured by TGA TA Model Q50 from ambient temperature to 800 ºC at 20 ºC/min. The MW of the copolymers was determined by GPC using an Altech 426 HPLC pump at an elution rate of 1.0mL/min; Phenogel 5μ Linear column at 25 ºC and Viscotek 302 detector. 1H & 13C NMR spectra were obtained on 10–25% (w/v) monomer or polymer solutions in CDCl3sub> at ambient temperature using Avance 300MHz spectrometer. Elemental analyses were performed by Midwest Microlab, LLC (IN).

Results and Discussion

PPCA synthesis

The ring-substituted propyl 3-phenyl-2-cyanoacrylates (PPCA) were synthesized by Knoevenagel condensation [8] of a ring-substituted benzoic aldehyde with propyl cyanoacetate, catalyzed by base, piperidine (1).

Where R is 2-fluoro-5-methyl, 3-iodo-4-methoxy, 5-iodo- 2-methoxy, 3,5-dichloro, 3,4-difluoro, 3,5-difluoro, 2-chloro- 4-fluoro, 2-chloro-6-fluoro, 3-chloro-2-fluoro, & 3-chloro-4- fluoro. The preparation procedure was essentially the same for all the monomers. In a typical synthesis, equimolar amounts of propyl cyanoacetate and an appropriate ring-substituted benzoic aldehyde were mixed in equimolar ratio in a 20mL vial. A few drops of piperidine were added with stirring. The product of the reaction was isolated by filtration and purified by crystallization from 2-propanol. The condensation reaction proceeded smoothly, yielding products, which were purified by conventional techniques.

Copolymerization

The PPCA monomers when mixed with ethynylbenzene, EB at EB/PPCA = 3 (mol) formed copolymers as indicated by white flaky precipitates in high excess of methyl alcohol. The conversion of the EB-PPCA copolymers was maintained 10–20% to decrease compositional drift (Table 1). The PPCA content 8.4- 25.8 mol% in the copolymers indicated relatively high reactivity of the PPCA monomers towards EB radical Figure 1.

The EB-PPCA copolymers were soluble in tetrahydrofuran, ethyl acetate, chloroform and dimethylformamide, and insoluble in methyl alcohol, ethyl and petroleum ethers. GPC analysis the copolymers indicated weight-average molecular masses 10.7- 27.8kD (Table 1). According to elemental analysis, between 18.3 & 42.6 mol% of PPCA monomer is present in the copolymers prepared at EB/PPCA = 3 (mol), which is indicative of relatively high reactivity of the monomers towards EB. Results of DSC and TGA analyses are presented in Table 1.

The FTIR spectra of the monomers were compared with those of copolymers and poly(ethynylbenzene) thus providing evidence that the reaction between the PPCA monomers and EB is a copolymerization. The spectra of the copolymers show overlapping bands in 3200–2820cm-1 region corresponding to C-H stretch vibrations. The bands for the PPCA monomer unit are 2246–2238 (w, CN), 1752–1733 (s, C=O), and 1252–1226cm-1 (m, C-O). Benzene rings of both monomers show ring stretching bands at 1500–1400cm-1 as well as a doublet 824–715cm-1, associated with C-H out of plane deformations. These bands can be readily identified in ethynylbenzene copolymers with TSE monomers containing cyano and carbonyl electron withdrawing groups.

EB-PPCA copolymers microstructure analysis is based on 1H and 13C NMR spectroscopy (DEPT, HETCOR, NOESY and JMODXH) of EB copolymers with 2-phenyl-1,1-dicyanoethene [9] which showed the formation of both head-to-tail and headto- head alternating monomer structures, as well as short EB sequences.

Conclusion

Novel phenyl-disubstituted propyl 2-cyano-3-phenyl-2-propenoates were prepared and copolymerized with ethynylbenzene. The compositions of the copolymers were calculated from nitrogen analysis and the structures were analyzed by IR, H1 & 13C-NMR. The thermal gravimetric analysis indicated that the copolymers decompose in in two steps, first in the 200–500C range with residue (1–3%wt), which then decomposed in the 500–800 ºC range.

For more Open Access Journals in Juniper Publishers please click on: https://juniperpublishers.com

For more articles in Academic Journal of Polymer Science please click on:https://juniperpublishers.com/ajop/index.php

For more Open Access Journals please click on: https://juniperpublishers.com

#polymers#juniper open access journals#Monomers#Polymer Chemistry#Polyelectrolytes#Polymersome#Synthetic rubber#Thermoplastics

0 notes

Text

Tertiary-Butyl Methacrylate Market to Develop Rapidly by 2026

Tertiary-Butyl Methacrylate is defined as a colorless liquid with an ester like odor. It is less dense than water and insoluble in water. It has the molecular formula C8H14O2. Its other chemical names are 85-07-9, tert-butyl 2-methylprop-2-enoate, methacrylic acid, tert-butyl ester, 2-Propenoic acid, etc.

Read Report Overview @

https://www.transparencymarketresearch.com/tertiary-butyl-methacrylate-market.html

Tertiary-butyl methacrylate undergoes a decomposition process where the thermal decomposition of poly (t-butyl methacrylate) results in three distinct reactions: depolymerization to monomer, ester decomposition to isobutene and poly(methacrylic acid), and liberation of water from the resulting acid to give poly(methacrylic anhydride) as the ultimate in volatile residue. Depolymerization occurs rapidly at first but is soon completely inhibited by the products of ester decomposition. Methacrylic acid units, on the other hand, can depropagate quite readily since monomeric methacrylic acid is always found among volatile products in trace amounts. The ester decomposition phase of the reaction exhibits autocatalytic properties, and this is shown to be due to a catalytic effect of acid units on the decomposition of adjacent ester units, for which a mechanism is proposed.

Factors such as rise in demand from end-use industries such as automotive and construction are major drivers of the Tertiary-Butyl Methacrylate market owing to its wide usage. Moreover, the increase in demand for tertiary-butyl methacrylate in LCD and LED flat screens is also propelling the Tertiary-Butyl Methacrylate market. Furthermore, high investments in R&D activities by global manufacturers are anticipated ensure a robust expansion in the Tertiary-Butyl Methacrylate market. However, availability of substitutes is expected to hamper the expansion of the Tertiary-Butyl Methacrylate market.

Request to view Sample Report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=45663

Based on derivative, the Tertiary-Butyl Methacrylate market can be segmented into ethyl methacrylate, butyl methacrylate, methyl methacrylate, and tertiary-butyl methacrylate.

In terms of application, the tertiary-butyl methacrylate market can be classified into acrylic sheets, molding, paints & coatings, additives, and others. The molding segment dominated the tertiary-butyl methacrylate market owing to increase in demand for acrylic resins in end-use products such as tail lights of trucks and cars, instruments, clusters, etc.

Based on end-use industry, the Tertiary-Butyl Methacrylate market can be categorized into architecture & construction, advertisement & communication, electronics, automotive, and others. The automotive segment leads the market owing to widespread use of tertiary-butyl methacrylate in automotive glazing.

In terms of geography, the Tertiary-Butyl Methacrylate market can be segmented into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America. Asia Pacific is expected to lead the Tertiary-Butyl Methacrylate market owing to rise in building & construction activities in the region.

Request For Custom Research @

https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=45663

Key players operating in the Tertiary-Butyl Methacrylate Market include Nippon Shokubai, Mitsubishi Chemical, Sumitomo Chemical, BASF, Eastman Chemical Company, LG Chem, The DOW Chemical Company, Evonik Industries, Arkema, and Hitachi Chemical.

0 notes

Text

Tertiary-Butyl Methacrylate Market Trends, Analysis, Application & Type Forecast to 2026

Global Tertiary-Butyl Methacrylate Market: Overview

Tertiary-Butyl Methacrylate is defined as a colorless liquid with an ester like odor. It is less dense than water and insoluble in water. It has the molecular formula C8H14O2. Its other chemical names are 85-07-9, tert-butyl 2-methylprop-2-enoate, methacrylic acid, tert-butyl ester, 2-Propenoic acid, etc.

Read Report Overview @ https://www.transparencymarketresearch.com/tertiary-butyl-methacrylate-market.html

Tertiary-butyl methacrylate undergoes a decomposition process where the thermal decomposition of poly (t-butyl methacrylate) results in three distinct reactions: depolymerization to monomer, ester decomposition to isobutene and poly(methacrylic acid), and liberation of water from the resulting acid to give poly(methacrylic anhydride) as the ultimate in volatile residue. Depolymerization occurs rapidly at first but is soon completely inhibited by the products of ester decomposition. Methacrylic acid units, on the other hand, can depropagate quite readily since monomeric methacrylic acid is always found among volatile products in trace amounts. The ester decomposition phase of the reaction exhibits autocatalytic properties, and this is shown to be due to a catalytic effect of acid units on the decomposition of adjacent ester units, for which a mechanism is proposed.

Factors such as rise in demand from end-use industries such as automotive and construction are major drivers of the Tertiary-Butyl Methacrylate market owing to its wide usage. Moreover, the increase in demand for tertiary-butyl methacrylate in LCD and LED flat screens is also propelling the Tertiary-Butyl Methacrylate market. Furthermore, high investments in R&D activities by global manufacturers are anticipated ensure a robust expansion in the Tertiary-Butyl Methacrylate market. However, availability of substitutes is expected to hamper the expansion of the Tertiary-Butyl Methacrylate market.

Request Report Brochure @ https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=45663

Global Tertiary-Butyl Methacrylate Market: Key Segmets

Based on derivative, the Tertiary-Butyl Methacrylate market can be segmented into ethyl methacrylate, butyl methacrylate, methyl methacrylate, and tertiary-butyl methacrylate.

In terms of application, the tertiary-butyl methacrylate market can be classified into acrylic sheets, molding, paints & coatings, additives, and others. The molding segment dominated the tertiary-butyl methacrylate market owing to increase in demand for acrylic resins in end-use products such as tail lights of trucks and cars, instruments, clusters, etc.

About Us

Transparency Market Research (TMR) is a global market intelligence company providing business information reports and services. The company’s exclusive blend of quantitative forecasting and trend analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

TMR’s data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With extensive research and analysis capabilities, Transparency Market Research employs rigorous primary and secondary research techniques to develop distinctive data sets and research material for business reports.

Contact

Transparency Market Research

State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Website: http://www.transparencymarketresearch.com

0 notes

Text

Tertiary-Butyl Methacrylate Market Research Report by Geographical Analysis and Forecast up to 2026

Global Tertiary-Butyl Methacrylate Market: Overview

Tertiary-Butyl Methacrylate is defined as a colorless liquid with an ester like odor. It is less dense than water and insoluble in water. It has the molecular formula C8H14O2. Its other chemical names are 85-07-9, tert-butyl 2-methylprop-2-enoate, methacrylic acid, tert-butyl ester, 2-Propenoic acid, etc.

Request Report Brochure @ https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=45663

Tertiary-butyl methacrylate undergoes a decomposition process where the thermal decomposition of poly (t-butyl methacrylate) results in three distinct reactions: depolymerization to monomer, ester decomposition to isobutene and poly(methacrylic acid), and liberation of water from the resulting acid to give poly(methacrylic anhydride) as the ultimate in volatile residue. Depolymerization occurs rapidly at first but is soon completely inhibited by the products of ester decomposition. Methacrylic acid units, on the other hand, can depropagate quite readily since monomeric methacrylic acid is always found among volatile products in trace amounts. The ester decomposition phase of the reaction exhibits autocatalytic properties, and this is shown to be due to a catalytic effect of acid units on the decomposition of adjacent ester units, for which a mechanism is proposed.

Factors such as rise in demand from end-use industries such as automotive and construction are major drivers of the Tertiary-Butyl Methacrylate market owing to its wide usage. Moreover, the increase in demand for tertiary-butyl methacrylate in LCD and LED flat screens is also propelling the Tertiary-Butyl Methacrylate market. Furthermore, high investments in R&D activities by global manufacturers are anticipated ensure a robust expansion in the Tertiary-Butyl Methacrylate market. However, availability of substitutes is expected to hamper the expansion of the Tertiary-Butyl Methacrylate market.

Read Report Overview @ https://www.transparencymarketresearch.com/tertiary-butyl-methacrylate-market.html

Global Tertiary-Butyl Methacrylate Market: Key Segmets

Based on derivative, the Tertiary-Butyl Methacrylate market can be segmented into ethyl methacrylate, butyl methacrylate, methyl methacrylate, and tertiary-butyl methacrylate.

In terms of application, the tertiary-butyl methacrylate market can be classified into acrylic sheets, molding, paints & coatings, additives, and others. The molding segment dominated the tertiary-butyl methacrylate market owing to increase in demand for acrylic resins in end-use products such as tail lights of trucks and cars, instruments, clusters, etc.

About Us

Transparency Market Research (TMR) is a global market intelligence company providing business information reports and services. The company’s exclusive blend of quantitative forecasting and trend analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

TMR’s data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With extensive research and analysis capabilities, Transparency Market Research employs rigorous primary and secondary research techniques to develop distinctive data sets and research material for business reports.

Contact

Transparency Market Research

State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Website: http://www.transparencymarketresearch.com

0 notes