#epoxy shield rebar epoxy shield dowel bars

Explore tagged Tumblr posts

Text

"Sustainability and Innovation: Fusion Bonded Epoxy Coated Dowel Bars in Indonesia"

INTRODUCTION

The construction industry in Indonesia, much like the global market, is undergoing a significant transformation. A growing emphasis on sustainability and innovation has led to the development and use of advanced materials that not only meet the structural demands of modern infrastructure but also adhere to environmental and durability standards. Among these materials, Fusion Bonded Epoxy (FBE) coated dowel bars in Indonesia stand out as an essential component in enhancing the longevity and performance of concrete structures.

In this blog, we will explore the importance of sustainability and innovation in the production and use of Fusion Bonded Epoxy Coated Dowel Bars in Indonesia, their benefits in construction projects, and how they contribute to the country's evolving infrastructure landscape.

1. The Need for Durability in Construction

Indonesia’s growing urbanization and infrastructure projects require durable materials that can withstand harsh environmental conditions. From heavy rainfall to tropical humidity, concrete pavements and structures must endure significant wear and tear. In this context, dowel bars play a critical role in ensuring the structural integrity of concrete joints, absorbing the load and reducing cracking.

Fusion Bonded Epoxy Coated Dowel Bars are designed to enhance the durability of such concrete structures by preventing corrosion. As rebar in concrete is susceptible to rust when exposed to water, especially in coastal or humid environments, an epoxy coating serves as a protective barrier, reducing corrosion risks and extending the lifespan of the structure.

2. What Are Fusion Bonded Epoxy Coated Dowel Bars?

Fusion Bonded Epoxy Coated Dowel Bars are steel bars used in concrete structures, specifically at joints where two sections of pavement meet. The epoxy coating is applied to protect the steel from corrosion and enhance its longevity in harsh environments.

The fusion bonding process involves heating the steel dowel bars and applying the epoxy powder, which melts and forms a continuous protective coating around the bar. This process ensures that the dowel bars are effectively shielded from moisture, chemicals, and other environmental factors that cause corrosion.

3. Sustainability and Eco-Friendly Materials

Sustainability has become a significant focus in construction materials. With the global push toward reducing carbon footprints and using environmentally friendly materials, the use of epoxy-coated dowel bars contributes to green building practices.

The longevity provided by the epoxy coating reduces the need for frequent repairs or replacements, which in turn lowers the demand for new raw materials and energy consumption. Additionally, epoxy coatings themselves are developed using sustainable methods that reduce environmental impact.

The use of Fusion Bonded Epoxy Coated Dowel Bars in Indonesia aligns with the objectives of sustainable construction by minimizing waste and enhancing the overall lifecycle performance of concrete structures. By reducing corrosion, the need for future repairs is minimized, resulting in a smaller environmental footprint and cost savings.

4. Innovation in Fusion Bonded Epoxy Coating Technology

Indonesia’s construction sector is witnessing innovation in the use of advanced materials like Fusion Bonded Epoxy Coated Dowel Bars. Recent advancements in epoxy coating technology have led to the development of coatings that are more resistant to extreme conditions, providing better protection against saltwater exposure, chemical attack, and mechanical abrasion.

Innovations also include faster and more efficient coating methods, making it easier for manufacturers to produce high-quality epoxy-coated dowel bars at a larger scale. The improved performance of these coatings is a direct response to the growing demand for longer-lasting infrastructure solutions in Indonesia’s expanding urban centers.

Incorporating cutting-edge technology in the production of Fusion Bonded Epoxy Coated Dowel Bars demonstrates the country’s commitment to modernizing its construction materials and ensuring that projects can meet both present and future needs.

5. Economic Benefits of Epoxy Coated Dowel Bars

Investing in durable and sustainable materials such as Fusion Bonded Epoxy Coated Dowel Bars can bring significant economic advantages. The initial cost of these materials may be higher compared to uncoated dowel bars, but the long-term savings are substantial. Reduced maintenance costs, fewer repairs, and a longer lifespan for concrete pavements all contribute to lower lifecycle costs for infrastructure projects.

In addition, the use of epoxy-coated dowel bars ensures compliance with international construction standards, making Indonesian infrastructure more competitive and aligned with global best practices. This is particularly relevant in projects such as highways, airports, and large-scale urban developments that require long-lasting and reliable materials.

6. Applications of Fusion Bonded Epoxy Coated Dowel Bars in Indonesia

Fusion Bonded Epoxy Coated Dowel Bars are primarily used in concrete pavements, highways, and other large-scale infrastructure projects that require durable joints. In Indonesia, they are becoming increasingly popular in transportation and urban development projects due to the country’s ongoing efforts to improve its infrastructure.

In major cities, where traffic congestion and heavy loads put pressure on roadways, the use of epoxy-coated dowel bars can significantly improve the performance and longevity of road surfaces. The bars help to evenly distribute the load between concrete slabs, preventing cracking and ensuring smoother, longer-lasting surfaces.

7. Corrosion Resistance: A Key Benefit

Indonesia’s humid climate and coastal geography make corrosion one of the most critical challenges in construction. Steel reinforcement bars, including dowel bars, are particularly vulnerable to rust, which can compromise the strength and durability of the structure.

Fusion Bonded Epoxy Coated Dowel Bars provide superior corrosion resistance, especially in coastal areas where saltwater exposure is a concern. The epoxy coating acts as a barrier that prevents moisture and chlorides from reaching the steel core, thereby mitigating the risk of corrosion and ensuring the long-term stability of the concrete joints.

8. Adherence to Global Construction Standards

To maintain global competitiveness and ensure the quality of its infrastructure, Indonesia follows international standards in construction. Fusion Bonded Epoxy Coated Dowel Bars are produced according to rigorous quality standards that meet global construction requirements, including ASTM (American Society for Testing and Materials) and AASHTO (American Association of State Highway and Transportation Officials) guidelines.

These standards ensure that the dowel bars used in Indonesian projects meet the necessary performance and durability criteria, providing peace of mind to builders and engineers working on long-term infrastructure projects.

9. Future Outlook for Epoxy Coated Dowel Bars in Indonesia

The future of Fusion Bonded Epoxy Coated Dowel Bars in Indonesia looks promising, as the construction industry continues to adopt advanced materials to meet the challenges of urban growth and climate change. With an increasing emphasis on sustainability, the demand for durable and eco-friendly construction materials is likely to grow.

Ongoing innovations in epoxy coating technology will further enhance the performance of dowel bars, making them more resilient to extreme environmental conditions. This will position them as a vital component in Indonesia’s infrastructure development, contributing to the country's long-term economic and environmental sustainability goals.

Conclusion

As Indonesia continues its journey toward modernization, the use of Fusion Bonded Epoxy Coated Dowel Bars in construction is set to become more widespread. These advanced materials offer numerous benefits, including enhanced durability, corrosion resistance, and sustainability, making them an ideal choice for the country's infrastructure projects.

With innovation driving the development of better epoxy coatings and manufacturing processes, the future of construction in Indonesia looks brighter and more sustainable. Fusion Bonded Epoxy Coated Dowel Bars will undoubtedly play a significant role in shaping the nation’s infrastructure landscape, ensuring that buildings, roads, and pavements are built to last for generations.

1 note

·

View note

Text

Zinc coated TMT bars

Galvanization is used for the deposition of zinc on rebars. Zinc is deposited on a metal body through the process of ion transfer. First of all, coating serves like a physical barrier between rebars and the corrosion source. Even in case there is breakage of the layer, the atoms of zinc degenerate around the area to keep the bar protected even more. Zinc coated bars are also advantageous for the fact that there is no loss of flexibility during the process. The bars can be roughly handled or bent easily. Zinc coated TMT bars from top TMT Bar brands in Siliguri are ideal for constructing small structures.

For more information, Visit us at: Hariom Epoxy Shield.

For latest information, visit our Social Media.

#epoxy shield rebar epoxy shield dowel bars#epoxy shield dowel bars manufacturers#manufacturers epoxy coated rebar#manufacturers in india#epoxy coated dowel bar manufacturers#epoxy coated rebar manufacturers in india#dowel bars manufacturers#dowel bars suppliers in india#epoxy coated rebars suppliers in india#epoxy coated tmt bars#fusion bonded epoxy rebars suppliers in india#construction projects#rebars in chennai#coated dowel bars in chennai#fusion bonded epoxy coating companies in india

0 notes

Photo

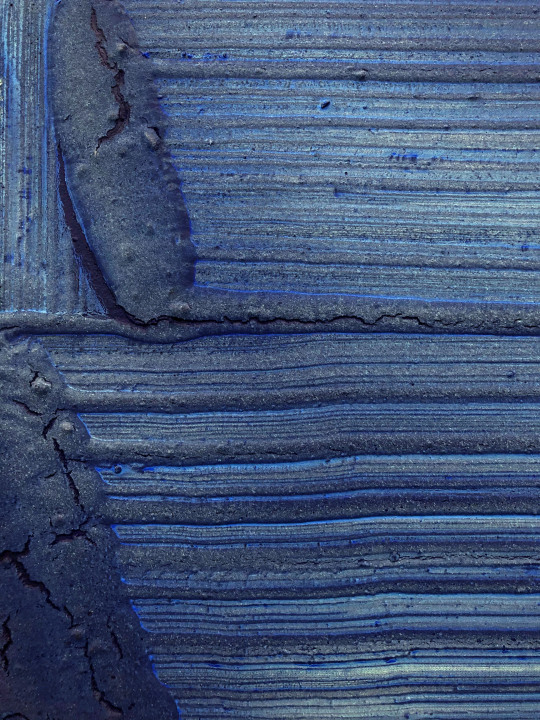

Blum & Poe in Los Angeles is currently showing two very different exhibitions. In the main gallery is a selected survey of work by Harvey Quaytman spanning three decades.

From the press release-

Harvey Quaytman (b. 1937, Rockaway, NY; d. 2002, New York, NY) came of age in the downtown art scene of 1960s New York, living and working in SoHo studios first on Grand Street and later at 231 Bowery, where he would remain through the late ’90s. Long considered an artist’s artist, the painter enjoyed a close-knit and vibrant artistic and social milieu, over the years sharing studio addresses with Brice Marden, Ron Gorchov, and James Rosenquist, among others. Quaytman’s emerging career as a young painter began in the heyday of Ab Ex with a marked allegiance to Gorky and de Kooning. This approach was slowly shed as the decade unfolded, as his work began to lean towards sculpture—compositions with curvilinear shaped canvases and rectilinear U-shaped bases that inhabited a newfound objecthood. This was followed by a forty-year engagement with geometric abstraction, his approach to painting in contradistinction to the prevailing trends of the era—first with Pop Art and later Neo Expressionism. Despite painting being declared “dead” by Minimalist and Conceptual artists of the time, Quaytman maintained a commitment to the medium and to his vision throughout, helping to shape an alternate trajectory for American painting.

The artist’s work in the ‘70s developed into shield-like forms that balance on curved platforms, conjuring a motion that would result in a critic calling them “rocking rectangles”—the body of work later known simply as “rocker” paintings. These eccentrically shaped works were hand-crafted (he would steam and bend the wooden stretchers himself), and inherently related to movement—inspired by Islamic calligraphy, rocking chairs, and the flight patterns of airplanes and birds. His experiments with shape continued in the late ‘70s, and through the manipulation of geometric intersections and overlapping forms that all the while imply motion, a unique group of paintings resembling anchors or pendulums emerged. In the 1980s, Quaytman began his cruciform paintings, investigations of the cross shape not as emblem but as two meeting vectors; Constructivist, perpendicular geometric compositions that focused on the reduced palette of black, white, red, rusted iron, and metallic gold. While these paintings represented a stark departure from his previous work, Quaytman continued to pursue visual movement as he conjured an interplay of symmetry and asymmetry.

Many of the works become even more intriguing up close. His use of different materials to achieve varying tones and textures makes them come alive.

The press release discusses a bit about his process in creating them-

As his paintings evolved in form and shape, variously touching upon Abstract Expressionism, Minimalism, Process Art, and Constructivism, Quaytman simultaneously developed a rigorous practice of experimentation with pigment. He was interested in the history, alchemy, and chromatic effects of color, seeking out unique tonalities at specialty stores at home and abroad, becoming a master of color and texture. He skillfully poured paint, spreading Rhoplex over canvas with broad wallpaper brushes after dusting it with pure pigment that settled in thick, unpredictable strata. He later flecked canvas with glass or iron filings and used additives such as marble dust in paint he always mixed himself. On this subject, he said: “It is very important to me to be reminded that I am not an alchemist but a man engaged in coded, layered conversation with my fellow man on what I hope to be (on another) level than words or music.”

On the second floor are Matt Johnson’s delightful sculptures whose familiar materials seem to defy gravity as they balance on each other in the compositions.

From the press release–

In an ever-expanding practice in search of the peculiar and the sublime, Johnson elevates the mundane to the exceptional. With a new body of work in carved and polychromed wood sculpture, Johnson depicts configurations of raw industrial materials from cinder block, brick, rebar, to traffic cones—permutations of information composed according to gravity, balance, and primitive instinct. A crude horse, a procession of block figures, cantilevered props, and fragile towers make reference to the concept of knowledge with small gestures—a lighter, a match book, a lightbulb, an atlas, and a monograph on Matisse. The doweled joints of glue and/or epoxy between bricks, blocks, and bars exist here not to defy gravity but to freeze balance and preserve delicate moments of experimental groupings. Like a still life, these works are organized information, like subatomic particles, atoms and elements, molecules and compounds, glued by gravity, and magnetic polarity, surfing in a sea of electrical conductivity.

Both of these exhibitions close 1/11/20.

#harvey quaytman#matt johnson#blum and poe#blum and poe los angeles#sculpture#painting#los angeles art shows#culver city art shows#culver city#los angeles#art#art shows

3 notes

·

View notes

Text

Epoxy coating in prevent corrosion

Many environmental factors impact the likelihood of corrosion. It helps to keep metal parts in a clean, dry place when not in use. If you intend to store them for a long time, consider using methods to control the level of sulfur, chloride, or oxygen in the surrounding environment.

Projects Information Initiative by Hariom Epoxy Shield

For latest updates, visit our Social Media

#epoxy shield rebar#epoxy shield rebar epoxy shield dowel bars#manufacturers epoxy coated rebar manufacturers in india#epoxy coated dowel bar manufacturers#epoxy coated rebar manufacturers in india#dowel bars manufacturers#dowel bars suppliers in india#epoxy coated rebars suppliers in india#Epoxy Coated TMT Bars#fusion bonded epoxy rebars suppliers in india#construction projects#coated tmt bars in construction

0 notes

Photo

Previously, the conventional bars were manufactured through the cold twisting process. However, now, the TMT bars are manufactured by the top TMT bar manufacturers using a Tempcore technology where they receive intense cooling when they pass through the water cooling system. This process hardens their outer surface and makes them at least 20% stronger than the bars that are manufactured using cold twisting process.

For more information, Visit us at: Hariom Epoxy Shield.

Source https://hariomtmt.livejournal.com/362.html

#epoxy shield rebar epoxy shield dowel bars#manufacturers epoxy coated rebar manufacturers in india#epoxy coated dowel bar manufacturers#epoxy coated rebar manufacturers in india#dowel bars manufacturers#dowel bars suppliers in india#epoxy coated rebars suppliers in india#epoxy coated tmt bars#fusion bonded epoxy rebars suppliers in india#construction projects#coated tmt bars in construction

0 notes

Photo

The execution errors by the engineer onsite contractor, wrong decisions and supervision lapses of construction head, the stupidity of workers, and the lack of knowledge of standard construction materials and construction processes lead to the low quality of construction work. These deficiencies reduce the load-bearing capacity of the building in terms of strength and also reduce life and durability of the building, which may result in the collapse of building fully or partially due to lack of integrity and homogeneity.

Construction’s Information Initiative by Hariom Epoxy Shield

For more information, visit our Social Media

#Epoxy Coated TMT Bars in Mumbai#Coated TMT Bars in Mumbai#Fusion Bonded Epoxy Coating in Mumbai#Epoxy Shielded TMT Bars in Mumbai#TMT Bars in Mumbai#Construction Business in Mumbai#TMT Rebars in Mumbai#fusion bonded epoxy coatedre bars in chennai#coated dowel bars in chennai#fusion bonded epoxy coating companies in india#epoxy coated tmt bars in Chennai#fusion bonded epoxy coating in chennai#high quality Epoxy Coated Rebars#anti-corrosion coating on the steel#reasons behind the collapse

0 notes

Text

Reasons behind the Collapse of a Building and What Could be the Preventive Measures?

Whenever a building collapses, whether it is old, during or after construction, under repair, or during natural vulnerabilities, such as cyclone or earthquake, it will send waves of shakes in the minds of the public. People start wondering, can such a disaster happen with them and their family. Of course, there is no basis to be scared, as the rate of collapse of new buildings to the existing ones is negligible.

However, you cannot remain neglectful, as it proves lethal and upsetting for you as well as for your whole family. Thus, this is the correct time to know and identify the reasons for the building collapse and to take preventive and corrective measures if it is applicable to you.

1. The Foundations are not Strong Enough

Properly designed foundation resting on well-compacted soil at adequate depth increase the stability of the building for lifetime and reduce the risk of the building collapse. The foundation may also fail when the soil of footing base is not investigated properly, or they are placed in corrosive soil. Foundations of the building are also affected due to soil liquefaction during Earthquake. The error while designing the foundation also leads to the poor stability of the building. It is in this way that the building may collapse due to the failure of the foundation.

2. Use of Inferior Materials

Inferior materials are those construction materials which do not meet the specification i.e. they lack in size or physical properties (weight, density, etc.), lack of chemical properties, or substandard specifications. The use of inferior materials reduces the load-bearing capacity, i.e. the strength of building. In many parts of the world, particularly developing countries the major cause of the collapse of building is due to the use of inferior materials.

3. Repairing or Restoration/Renovation

The building may collapse fully or partially when unthoughtful alteration or unauthorized construction is carried out at the time repairing or restoration/renovation. During repairing or restoration or renovation, you are subjecting the building to additional load or are trying to change load path of the building or making certain elements under repair, redundant, I.e. they do not participate in resisting load). The change in load path causes excessive stress in structural elements which may be a reason for the collapse of building.

4. Lack of Maintenance

Water leakages, structural or non-structural cracks, spalling of concrete or the honeycombed concrete, loose plaster are the damages of the building which deteriorates the structure. Deterioration of concrete or structural components results in the poor stability of the building due to loss of its proportions i.e. strength. If the buildings are not repaired in time or not maintained regularly, the damages will continue to increase and it may be the reason for the collapse of building fully or partially. Poor maintenance invites corrosion of metal item or carbonation of concrete or degradation due to sun’s heat or UV rays, all leading to cascading deterioration.

5. Faulty Execution & Inadequate Supervision

The execution errors by the engineer onsite contractor, wrong decisions and supervision lapses of construction head, the stupidity of workers, and the lack of knowledge of standard construction materials and construction processes lead to the low quality of construction work. These deficiencies reduce the load-bearing capacity of the building in terms of strength and also reduce life and durability of the building, which may result in the collapse of building fully or partially due to lack of integrity and homogeneity.

What Needs to be done?

1. Build Earthquake-Proof Constructions

A seismic zone map released on September 20, 2016 by the National Disaster Management Authority (NDMA) and Building Materials and Technology Promotion Council (BMTPC) states that 59% of households in India are vulnerable to severe and moderate earthquake.

Effective pre-planning carried out by the government and builders and general awareness in this regard has the potential to save thousands of lives. Thus, it will be a wise step to learn from other earthquake-prone countries such as Japan that is several steps ahead from the rest of the world in building earthquake-proof structures. Among the several methods, the most common is installing beams that transfer the sway, dissipation units, and incorporation of flexible material.

2. Avoid Major Alteration

Another major cause of building collapse are the major alternations that are made to the basic exterior and interior arrangement of the structure. For example, removal of one of the beams that provide support to the building could make it susceptible to damage.

Additional and Illegal constructions should be monitored and banned. These add-ons put extra pressure on the weight holding capacity of the building giving rise to cracks on the walls. Also, in the cases of dilapidated establishments, the focus should be on its repair rather on modifications which reduce the longevity.

3. Awareness of the construction area

Look for architectural designs that are common in your area of construction. For example, regions that receive heavy rainfall every year have houses with tiled roofs and effective drainage mechanism to avoid flooding and consequent weakening of the foundation. Similarly, high-rise buildings in zones susceptible to typhoons need to be flexible yet durable enough to withstand high wind velocity, whereas smaller homes in the same region need to have deep set windows.

Construction’s Information Initiative by Hariom Epoxy Shield

For more information, visit our Social Media

#epoxy coated tmt bars in mumbai#Coated TMT Bars in Mumbai#Fusion Bonded Epoxy Coating in Mumbai#Epoxy Shielded TMT Bars in Mumbai#TMT Bars in Mumbai#Construction Business in Mumbai#tmt rebars in mumbai#fusion bonded epoxy coatedre bars in chennai#coated dowel bars in chennai#fusion bonded epoxy coating companies in india#epoxy coated tmt bars in Chennai#fusion bonded epoxy coating in chennai#high quality Epoxy Coated Rebars#anti-corrosion coating on the steel#reasons behind the collapse

0 notes

Text

Things to know before Building a New Home

Building your new home is an exciting and at times overwhelming experience, but for your builder it is very routine, which is why you need to be an active participant in all aspects of the home building process to ensure you end up with "YOUR" dream home.

Building your new home cannot be a passive exercise, because there are so many decisions that "must be" made by you. If you are unable or unwilling to make these decisions, you will force your builder to make them and run the risk that your new home won't turn out the way you envisioned it or cost what you thought. Here are 5 things you must know and take into consideration when building your new home:

1. Think about Every Family Member

For formulating a Project Brief, call every family member together. You should include everyone having interest in the construction – wives, husbands and even the children. Prepare your wish list.

2. Experiment with Different Ideas

For preparing the wish list, you must have some ideas. You should visit a few finished houses or consult architecture books, catalogues, and professional magazines and search the internet to acquire ideas.

3. Take a decision for the Type of House you want

To prepare the wish list, it is important to know the kind of house to be built as every type has its special requirements. It could be a house built for self-use should have comfort, privacy and luxury, with proper finishing and cost-effective materials for rented portion, it could be a house built for renting must have finishing and cost-effective materials and should be suitable for revenue generation.

Not sure about the house type? Design the house in a manner that it can be expanded in future.

4. Work with reputed builder

Many builders are out there, but not all are created equal. Do a little research to find out which builders have the best reputation. Whether you search for information online or get recommendations from your family and friends, find out whether a builder is respected for doing quality work as well as being punctual.

5. Have a Budget Plan

Before you start building your new home, run some numbers to determine whether you can afford to build the home you want. Most house plans offer a cost to build tool (usually for a nominal fee) to give you an accurate estimate of construction costs based on where you're building. The numbers include the costs of construction, tax benefits, funds for the down payment and slush account, and other related calculations.

Once you've determined you can afford to build the house you want — purchase your house plan and head to the bank to arrange for financing. Keep in mind that home construction lending is a little different than regular mortgage financing. First, you'll need a home construction line of credit that will be used to pay subcontractors and suppliers who perform work and provide supplies. Once your house is constructed, you will need a residential mortgage to pay off the construction line.

Be sure you put the money for the completion of your punch list in escrow. This will allow you to move into your new home while still requiring the builder to complete the items on the punch list. The punch list marks an exciting time in the process of building your new home, because your home is almost done! Remember not to get so excited that that you breeze through your punch list, because you don't want regret that you didn't take the time to fix these problems.

Construction’s Information Initiative by Hariom Epoxy Shield

For more information, visit our Social Media

#Epoxy Coated TMT Bars in Mumbai#Coated TMT Bars in Mumbai#Fusion Bonded Epoxy Coating in Mumbai#Epoxy Shielded TMT Bars in Mumbai#TMT Bars in Mumbai#Construction Business in Mumbai#TMT Rebars in Mumbai#fusion bonded epoxy coated rebars in chennai#coated dowel bars in chennai#fusion bonded epoxy coating companies in india#epoxy coated tmt bars in chennai#fusion bonded epoxy coating in chennai#high quality Epoxy Coated Rebars#anti-corrosion coating on the steel

0 notes

Photo

To prepare the wish list, it is important to know the kind of house to be built as every type has its special requirements. It could be a house built for self-use should have comfort, privacy and luxury, with proper finishing and cost-effective materials for rented portion, it could be a house built for renting must have finishing and cost-effective materials and should be suitable for revenue generation.

Construction’s Information Initiative by Hariom Epoxy Shield

For more information, visit our Social Media

#Epoxy Coated TMT Bars in Mumbai#Coated TMT Bars in Mumbai#Fusion Bonded Epoxy Coating in Mumbai#Epoxy Shielded TMT Bars in Mumbai#TMT Bars in Mumbai#Construction Business in Mumbai#TMT Rebars in Mumbai#fusion bonded epoxy coated rebars in chennai#coated dowel bars in chennai#fusion bonded epoxy coating companies in india#epoxy coated tmt bars in Chennai#fusion bonded epoxy coating in chennai#high quality Epoxy Coated Rebars#anti-corrosion coating on the steel

0 notes

Photo

Building material is any material used for construction purpose such as materials for house building. Wood, cement, aggregates, metals, bricks, concrete, clay are the most common type of building material used in construction. The choice of these are based on their cost effectiveness for building projects.

With epoxy coating, we can create structures like no other material when it comes to construction. No other material can match the potency and durability that coating provides. Epoxy Coating is becoming the most preferred choice for construction due to the various benefits it offers. The buildings that are made from steel require various structural frames. Also, constructing with steel requires less time which makes it the most sought-after way of constructing structures.

Construction’s Information Initiative by Hariom Epoxy Shield

For more information, visit our Social Media

#Epoxy Coated TMT Bars in Mumbai#Coated TMT Bars in Mumbai#Fusion Bonded Epoxy Coating in Mumbai#Epoxy Shielded TMT Bars in Mumbai#TMT Bars in Mumbai#Construction Business in Mumbai#TMT Rebars in Mumbai#fusion bonded epoxy coated rebars in chennai#coated dowel bars in chennai#fusion bonded epoxy coating companies in india#epoxy coated tmt bars in Chennai#fusionbonded epoxy coating in chennai#high quality Epoxy Coated Rebars#anti-corrosion coating on the steel

0 notes

Text

Types of Rebars Commonly used in Buildings

Building material is any material used for construction purpose such as materials for house building. Wood, cement, aggregates, metals, bricks, concrete, clay are the most common type of building material used in construction. The choice of these are based on their cost effectiveness for building projects.

With epoxy coating, we can create structures like no other material when it comes to construction. No other material can match the potency and durability that coating provides. Epoxy Coating is becoming the most preferred choice for construction due to the various benefits it offers. The buildings that are made from steel require various structural frames. Also, constructing with steel requires less time which makes it the most sought-after way of constructing structures.

Epoxy Coating constructions have high resistance due to their strength, and they do not cost as much as other materials do, such as concrete for construction purposes. Also, there are various benefits of using steel over other construction materials. These building constructions are environment-friendly, and can withstand natural calamities like earthquakes.

1. Carbon Steel Rebars

This is the most common type of rebar and is sometimes referred to as a "black bar." It's extremely versatile but it corrodes more easily than other types, making it inappropriate in areas that are subject to high humidity or in structures that are frequently exposed to water. Many consider carbon steel rebars to be the best option in all other types of construction, however.

2. Welded Wire Fabric

Welded wire fabric (WWF) is made from a series of steel wires arranged at right angles and electrically welded at all steel wire crossings. It can be used in slab-on-ground slabs where the ground has been well compacted. A heavier fabrication of welded wire fabric can be used in walls and structural floor slabs. This is commonly used in road pavement, box culverts, drainage structures, and in small concrete canals.

3. Sheet-Metal Reinforcing Bars

Sheet-metal reinforcement is commonly used in floor slabs, stairs, and roof construction. Sheet-metal reinforcing is composed of annealed sheet steel pieces bent into corrugations of about one-sixteenth of an inch deep with holes punched at regular spacing.

4. Epoxy-Coated Rebars

Epoxy-coated rebars are expensive and used in areas that will be in contact with salt water or where a corrosion problem is imminent. The only problem is that the coating can be very delicate, so bars should be ordered from a reputable supplier.

5. Stainless Steel Rebars

Stainless steel can be used as an alternative reinforcing steel bar with carbon steel reinforcement. Using stainless steel reinforcing bars will not create galvanic corrosion, and it can be a cost-effective solution in areas subject to corrosion problems or where repair is difficult and expensive. These rebars will cost at least eight times more than epoxy-coated rebars, however.

6. Expanded Metal or Wire Mesh Rebars

Expanded metal or wire mesh reinforcement is another good product for concrete. Expanded metal is made by shearing a sheet of steel into parallel lines that are then expanded to form a diamond shape or a square shape between each cut. Expanded metal is commonly used as reinforcement in areas where a considerable thickness of plaster is required, or to reinforce light concrete construction.

Using Epoxy Coating in the building constructions are gaining popularity across the globe. Almost, all the fields have benefitted with the various advantages of coating. With the growing use in construction, it will soon take over the entire construction field. These building constructions are gaining popularity across the globe. Almost, all the fields have benefitted with the various advantages of epoxy.

Construction’s Information Initiative by Hariom Epoxy Shield

For more information, visit our Social Media

#Epoxy Coated TMT Bars in Mumbai#Coated TMT Bars in Mumbai#Fusion Bonded Epoxy Coating in Mumbai#Epoxy Shielded TMT Bars in Mumbai#TMT Bars in Mumbai#Construction Business in Mumbai#TMT Rebars in Mumbai#fusion bonded epoxy coated rebars in chennai#coated dowel bars in chennai#fusion bonded epoxy coating companies in india#epoxy coated tmt bars in Chennai#fusionbonded epoxy coating in chennai#high quality Epoxy Coated Rebars#anti-corrosion coating on the steel

0 notes

Text

Different Types of TMT Bars offered by Different Brands

TMT bars are extensively used in different kinds of civil construction projects. Therefore, they form the cornerstone of modern city life. They are used for making building, beams, slabs, columns and also other kind of structures that bear the live load of people as well as their belongings. Being the core strength of all kinds of structures, the TMT bars are needed to be capable of withstanding large loads. They should also be able to offer protection to a structure against earthquake and windstorms. Poor quality materials like cheap steel bars generally contain very high levels of different unknown elements that can be quite harmful for construction. In other words, these steel bars lack the requisite physical and chemical properties that would make them appropriate building materials.

These bars can be found in various forms, and you can find one for your needs. Know about the 4 common types of bars that are offered in Coastal Regions specially Mumbai, Chennai, Singapore and more.

1. Fusion bonded epoxy coating (FBEC) rebars

In these types, a hot bar is coated with an epoxy powder with the help of electrostatic charges. Then, the powder melts and is cooled to offer a protective coating that is even and adheres well to the bar. With this layer, the bars can get corrosion resistance. This can offer extremely effective protection from chloride ions. In areas with moderate weather conditions, the surfaces are kept protected even in severe rain. In wet areas, other than in saltwater regions, FBEC rebars can be used with CRS having Corrosion inhibitors.

2. Zinc coated TMT bars

Galvanization is used for the deposition of zinc on rebars. Zinc is deposited on a metal body through the process of ion transfer. First of all, coating serves like a physical barrier between rebars and the corrosion source. Even in case there is breakage of the layer, the atoms of zinc degenerate around the area to keep the bar protected even more. Zinc coated bars are also advantageous for the fact that there is no loss of flexibility during the process. The bars can be roughly handled or bent easily. Zinc coated TMT bars from top TMT Bar brands in Siliguri are ideal for constructing small structures.

3. Corrosion Resistance Steel (CRS) rebars

These rebars are the most powerful, and can offer protection to superstructures from acute weather conditions. There is much higher corrosion resistance in a Cu-Cr TMT rebar, as compared to a standard TMT bar. There is blending of various minerals, such as Phosphorus, Copper and Chromium, during the construction of the bars. Every mineral can be effective in corrosion resistance.

Copper allows prevention of rust, and checks its growth further. Chromium can allow better rust resistance as well. Phosphorus can also inhibit reactions that can lead to the development of rust. CRS bars are recommended in rough regions where construction surfaces can come in contact with harsh solid substances, strong liquid chemicals or corrosive fumes.

4. TMT Re-bars with Admixture that inhibits corrosion

Constructors can use it in the substructures, once the soil is normal and devoid of excessive amount of sulphates and chloride. These bars offered by the best TMT bars in North Bengal can be used in superstructures made of concrete, in a soft ambience other than those located in coastal regions with constant and heavy snow and rains. There is also an addition of Bipolar Corrosion Inhibiting Admixture into the concrete.

It does not serve like a barrier, but can retard the process of corrosion to the maximum possible extent. It should not be directly in contact with the bar steel. It can offer corrosion resistance at a micro level.

Construction Information Initiative by Hariom Epoxy Shield.

For latest information, visit our Social Media.

#epoxy shield rebar#epoxy shield dowel bars#manufacturers epoxy coated rebar#manufacturers in india#epoxy coated dowel bar manufacturers#epoxy coated rebar manufacturers in india#dowel bars manufacturers#dowel bars suppliers in india#epoxy coated rebars suppliers in india#epoxy coated tmt bars#fusion bonded epoxy rebars suppliers in india#construction projects#coated tmt bars in construction#epoxy coated rebars price#epoxy coated tmt bars in mumbai#fusion bonded epoxy coated rebars in chennai#coated dowel bars in chennai#fusion bonded epoxy coating companies in india

0 notes

Photo

Constructors can use it in the substructures, once the soil is normal and devoid of excessive amount of sulphates and chloride. These bars offered by the best TMT bars in North Bengal can be used in superstructures made of concrete, in a soft ambience other than those located in coastal regions with constant and heavy snow and rains. There is also an addition of Bipolar Corrosion Inhibiting Admixture into the concrete.

For more information, Visit us at: hariom epox yshield

For latest update, Visit our social media

#epoxy shield rebar#epoxy shield dowel bars#manufacturers epoxy coated rebar manufacturers in india#epoxy coated dowel bar manufacturers#epoxy coated rebar manufacturers in india#dowel bars manufacturers#dowel bars suppliers in india#epoxy coated rebars suppliers in india#epoxy coated tmt bars#fusion bonded epoxy rebars suppliers in india#construction projects#rebars in chennai#coated dowel bars in chennai#fusion bonded epoxy coating companies in india

0 notes

Text

You must choose right tmt bar for your home

The steel manufacturing business is a very competitive market, and the costs of TMT rods play a huge role in the selection process. The Ultimate Selling Points (USP) of the TMT rods also play a pivotal role in the sales. Customers often purchase rods by comparing the prices and try to acquire rods according to their value for money. Customers are advised to differentiate and compare the USPs of various brands before choosing the right TMT bars according to their requirements.

Construction Information Initiative by Hariom Epoxy Shield

For latest updates, visit our Social Media

#epoxy shield rebar#epoxy shield dowel bars manufacturer#epoxy coated dowel bar manufacturers#dowel bars manufacturers#epoxy coated rebars manufacturers in india#epoxy coated rebars suppliers in india#fusion bonded epoxy rebars suppliers in india#dowel bars suppliers in india#epoxy coated tmt bars#epoxy coated tmt bars in chennai#epoxy coated tmt bars in mumbai#fusion bonded epoxy coating companies in india#fusion bonded epoxy coating in chennai#highquality Epoxy Coated Rebars#anti corrosion coating on the steel

0 notes

Text

5 Point Guide to Choose Right TMT Bars for your Home in Long Run

Building a house is obviously very important and the most important thing is the materials and quality of the material that is being used in the construction process. Very few people have deep knowledge of the materials that they are using for construction.0l

Irrespective of our social standings, we have laid out the blueprint of our dream house thousands of times in our mind. By now, it must be very clear to us that a house is more than just a property; it’s an emotion in which we invest our time, money and energy to build the perfect abode for our family.

The stronger the foundation, the more likely your dream house is going to survive through the natural and man-made disasters. While the importance of a strong foundation has been established, it is crucial to know how this foundation can be achieved. The key to a strong foundation is dependent on choosing the right or coated TMT bars for your house. The structures created out of these bars act as the skeleton of your house and increase its longevity.

Here are a few strong reasons:

1. Strength:

The first and one of the most important things to keep in mind while choosing TMT bars – is the toughness of the rods. The toughness of the rods in-turn will help in increasing the longevity of your constructions. Always go for TMT bars that have effective load-bearing strength. Ideal TMT bars should possess yield stress-bearing capacity of up to 500 N/m2.

2. Corrosion Resistance:

It is understandable that TMT steel rods catch a lot of moisture during construction. So, it is vital to protect the rods from corrosion. Always ensure to check the TMT Bar you are buying comes with corrosion-resistance and a water protection coating.

3. Grades and Certification:

Coated TMT bar is only as good as its grades and certification. If it is manufactured by a certified company and boasts of the right grades, it’s a hallmark of its proven quality. Rods used for the construction of any capacity should possess the ISI grade.

4. Availability:

Transportation plays a crucial role in the availability of TMT bars. A great network of dealers often doesn’t have the transportation to obtain the TMT bars of your choice at your location. This acts as a hindrance while choosing TMT bars and must be taken into consideration. You should be aware of such facilities as an easy availability will help in cutting down the shipping charges and your outside expenses will be minimal.

5. Costs and Ultimate Selling Points:

The steel manufacturing business is a very competitive market, and the costs of TMT rods play a huge role in the selection process. The Ultimate Selling Points (USP) of the TMT rods also play a pivotal role in the sales. Customers often purchase rods by comparing the prices and try to acquire rods according to their value for money. Customers are advised to differentiate and compare the USPs of various brands before choosing the right TMT bars according to their requirements.

6. Safety and weld-ability:

Lastly, you must remember that you have a duty towards your employees and workers and ensuring their safety is thus, your priority. Therefore, the TMT bars you choose should be easily weld-able and should be least hazardous to work with.

Simply pick a TMT Bar and look for the seal of manufacturer in it. Also, ensure that the TMT Bar is without rust and the end of the bundle of TMT Bars is of equal length. Finally, make sure that each TMT Bar in the bundle has the logo of the manufacturing brand of the Coated TMT Bar.

Construction Information Initiative by Hariom Epoxy Shield

For latest updates, visit our Social Media

#epoxy shield rebar#epoxy shield dowel bars manufacturer#epoxy coated dowel bar manufacturers#dowel bars manufacturers#epoxy coated rebars manufacturers in india#epoxy coated rebars suppliers in india#fusion bonded epoxy rebars suppliers in india#dowel bars suppliers in india#epoxy coated tmt bars

0 notes

Photo

The first and one of the most important things to keep in mind while choosing TMT bars – is the toughness of the rods. The toughness of the rods in-turn will help in increasing the longevity of your constructions. Always go for TMT bars that have effective load-bearing strength. Ideal TMT bars should possess yield stress-bearing capacity of up to 500 N/m2.

School Information Initiative by Hariom Epoxy Shield

For latest updates, visit our Social Media

#epoxy shield rebar#epoxy shield dowel bars manufacturer#epoxy coated dowel bar manufacturers#dowel bars manufacturers#epoxy coated rebars manufacturers in india#epoxy coated rebars suppliers in india#fusion bonded epoxy rebars suppliers in india#dowel bars suppliers in india#epoxy coated tmt bars

0 notes