#epoxy comparison

Explore tagged Tumblr posts

Text

Comparative Benefits of Epoxy vs. Other Flooring Materials

Index

1. Introduction

2. Cost Comparison: Epoxy vs. Carpet, Tile, Hardwood, Laminate, and LVP

3. Customization Options

4. Durability and Longevity

5. Benefits for Landlords

6. Maintenance and Upkeep

7. Flexibility for Future Changes

8. Aesthetic Appeal

9. Suitability for All Rooms

10. Conclusion

Introduction

Welcome to Darling Flooring’s blog! As the owner of Darling Flooring, I’m thrilled to share why epoxy flooring stands out as a superior choice compared to other common flooring options such as carpet, tile, hardwood, laminate, and luxury vinyl plank (LVP). Whether you’re a homeowner looking to enhance your space or a landlord seeking a practical solution for rental properties, understanding the benefits of epoxy flooring can help you make an informed decision. Let’s dive into the reasons why epoxy might be the perfect choice for your needs.

Cost Comparison: Epoxy vs. Carpet, Tile, Hardwood, Laminate, and LVP

When evaluating flooring options, cost is a crucial factor. Epoxy flooring is often more cost-effective compared to high-end materials like hardwood and extensive tile installations. Carpet may appear cheaper initially, but it requires frequent replacement and cleaning. Laminate and LVP are more affordable but can still fall short in durability compared to epoxy. Overall, while the upfront cost of epoxy may be slightly higher than budget-friendly options, its long-term durability and minimal maintenance needs offer excellent value.

Customization Options

Epoxy flooring offers unparalleled customization compared to traditional flooring systems. With epoxy, you can choose from a variety of colors, finishes, and textures to match your interior design perfectly. Whether you prefer a sleek, modern look or a more textured surface, epoxy can be tailored to fit your style. In contrast, carpet and laminate offer limited design choices, and tile patterns can be restrictive. Epoxy’s flexibility allows for a personalized touch that can enhance the aesthetic appeal of any space.

Durability and Longevity

Durability is one of the standout benefits of epoxy flooring. Unlike carpet, which wears out and stains easily, or hardwood, which can scratch and dent, epoxy provides a tough, long-lasting surface. It’s highly resistant to moisture, stains, and heavy impacts, making it ideal for high-traffic areas and environments prone to spills or heavy use. This level of durability means that epoxy can outlast most other flooring types, making it a wise investment for both residential and commercial spaces.

Benefits for Landlords

For landlords, epoxy flooring offers several advantages. Its durability and ease of maintenance make it a practical choice for rental properties. Epoxy floors are less likely to be damaged by tenants, and they are simple to clean between rentals. Additionally, the low maintenance requirements reduce the frequency of costly repairs and replacements. The long-lasting nature of epoxy ensures that landlords won’t need to replace flooring as often, making it a cost-effective option in the long run.

Maintenance and Upkeep

Epoxy flooring shines when it comes to maintenance. Unlike carpet, which traps dirt and requires regular cleaning, or tile, which can be difficult to grout and clean thoroughly, epoxy floors are incredibly easy to maintain. Regular sweeping and occasional mopping are typically sufficient to keep epoxy floors looking their best. This ease of upkeep contrasts sharply with the more demanding maintenance needs of hardwood and the grouting issues associated with tile.

Flexibility for Future Changes

One of the unique advantages of epoxy flooring is its ability to be covered with other flooring materials if you decide to change your home’s aesthetic. If you choose to install carpet, tile, or any other type of flooring over epoxy, it provides a solid, stable base. This flexibility allows homeowners to update their flooring style without having to remove the existing epoxy, saving money, time and effort.

Aesthetic Appeal

Epoxy flooring is known for its sleek, modern appeal. It can instantly elevate the look of any room with its shiny, smooth finish and customizable designs. Unlike traditional carpet or laminate, which may show wear and tear over time, epoxy maintains its new appearance for years. The reflective nature of epoxy can also brighten up spaces, adding a touch of contemporary elegance.

Suitability for All Rooms

Epoxy flooring excels in various environments, including high-moisture areas like kitchens, bathrooms, and garages. Its resistance to water and stains makes it ideal for these spaces, where other flooring options might struggle. Whether it’s dealing with spills in the kitchen or the demands of a busy bathroom, epoxy stands up to the challenge, offering both functionality and style.

Conclusion

In summary, epoxy flooring offers numerous benefits over traditional options like carpet, tile, hardwood, laminate, and LVP. From cost-effectiveness and customization to durability and low maintenance, epoxy is a versatile and practical choice for both homeowners and landlords. If you’re considering upgrading your flooring, I invite you to reach out to Darling Flooring. Let us help you explore how epoxy can enhance your space and meet your specific needs. Contact us today to see if epoxy flooring is the right fit for you!

#darling flooring#epoxy flooring#epoxy comparison#flooring options#pros and cons#inland empire#epoxy vs.#flooring installation#concrete coating#home improvement#interior design#landlord#Jacob darling#bathroom#garage floor#metallic epoxy

2 notes

·

View notes

Text

oh btw i got the second version of the mario and luigi keychain, i think it needs to be 4 inches wide tbh (it's 3.5 here) the new background art looks a lot better though! i think it turned out great. however, the REST of it was too saturated- luckily i only got this one for size comparison. hopefully wherever i order them from when preorders go up they'll look like it's supposed to, like the first one i had made (that one looked very accurate to the raw art). epoxy will still be added, but there wasnt an option for the listing i ordered from and it was also just cheaper to get it without it. overall im really happy with how it turned out and im excited to start selling them when i finally get to it!

#acrylic keychain#mario and luigi superstar saga#mario and luigi#nintendo#alphadream#mario and luigi rpg

213 notes

·

View notes

Note

the main thing im struggling with in regards to AI art is if the person using AI can even call it their art. is the creator the person who put in the prompt(s)? is it the person who made the AI? is it all the artists that the AI created 0.01% of its patterns from? is it the AI itself? does the question even matter? i don't know if it's comparable to something like scrapbooking, moodboarding or interior design (see: using things You Didn't Make (magazine images, gifs, furniture) to then create your own art. the comparison just feels...off. there is a general understanding that scrapbookers/moodboarders/interior designers probably didn't create the things they're using, and people generally have a different view on it than say painting or drawing because of those differences in fundamentals. i understand that a lot of AI artists can take a lot of time, effort and skill into narrowing down prompts to get very unique and specific outputs but it feels more comparable to a commission to me. i do think there is an amount of creativity that goes into prompt-making, visualising the end product and figuring out how to get there, but i struggle to see where the line sits of "AI did this" vs "I used AI to do this". i also don't find generative AI to be very similar to other technology 'shortcuts' like digital art tools such as layering, blending and line stabilization -- generative AI is on a whole other level to that. i'd love to know your thoughts on this

I think AI generation is a tool that's the logical progression from a lot of already-existing digital art tools. We don't question whether a digital artist gets to call their work their own even though they couldn't have done it without the hundreds of people who program and maintain Photoshop and we don't question whether a traditional painter gets to call their work their own even though they didn't grind their own paints or build their own paintbrushes. For that matter, we don't call digital artists lazy hacks because they use a computer to generate colors instead of buying and mixing their own paints, because we understand it's a different medium that requires different skills - or at least, we don't anymore, because I'm pretty sure we went through all this same discourse when digital art started being a thing.

There's already plenty of art forms out there that rely on some level of randomness or automation - plenty of digital artists use custom brushes to do the grunt work of filling in foliage so they don't have to individually place every leaf, splatter artists let paint fall where it will instead of deliberately placing every dot, epoxy artists let physics and gravity pull resin across the canvas with relatively little human input. They're still artists, they're just using art styles and tools that don't rely on intention in every aspect of the art the way traditional artists might.

Overall I think if you say "sure, this person has an artistic vision they are trying to express with a tool that requires skill and practice to use effectively, but can we really call them an artist?" you're getting lost in the weeds. But I also think we've had this argument with every single advancement in art technology since we moved on from cave paintings, so I kind of wish we could just skip this one.

And because I think there's a disconnect here that people are getting tripped up on - am I saying that every person who throws a prompt into DALL-E is an artist? No, in the same way I don't call myself a photographer because I took a picture with my cellphone. But that doesn't mean the nature photographer who spends hours laboring over getting the perfect shot isn't an artist either, y'know?

36 notes

·

View notes

Text

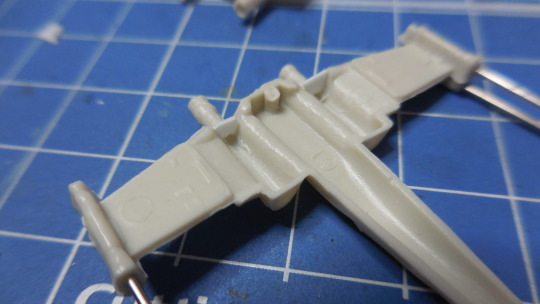

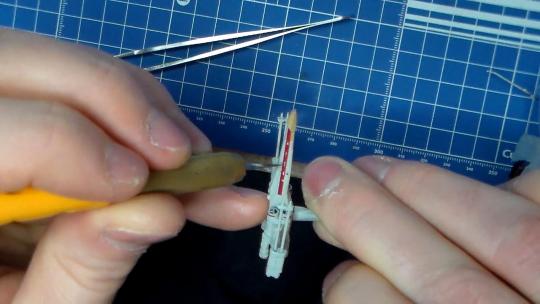

MPC Empire Strikes Back Hoth Rebel Base build update August 4th, 2023

Here I'll post updates on what I have done to incorporate the X-Wings included with this kit into the diorama I'm working on. Unfortunately, the Y-Wings are just too goofy looking, and they were sculpted without proper reference material. After a discouraging setback with trying to use fiber optics to light the X-Wings' engines, I decided to go all out and use red 0402 SMDs for the engines.

Channeling out the engine cans was not too difficult of a task. the X-Wings come sculpted with only one laser cannon per side so in order to give them four laser cannons, I used sewing pins, capped with Wave 2mm semi-circular plastic sticks cut into segments to represent the flash suppressors at the tip of each. I just needed to drill a hole into the center of each of these segments.

Once the SMDs were fastened into position using 2 part Wave epoxy glue (which smells really badly). Once the X-wings' top and bottom halves were glued together, I added back plates that I had invented on my own to sort of represent the detail that's supposed to go there. I used masking circles by HiQ Parts to protect the SMDs.

The next step was to add detail to the tips of the engine nacelles. The way the kit comes, they look rather featureless. I used Wave plastic pipe cut into segments for the nacelle tips and plastic plate to create the T-sections. They look nice! Check out this comparison before/after picture:

I airbrushed these X-Wings with Model Master Camouflage Gray acrylic paint.

I had scanned the excellent Fine Molds decals for this kit, mathematically sized it down to the proper scale, and printed them out on Fine Molds clear decal paper.

I distressed the decals with my hobby knife as I saw fit, in order to create paint chips. That's it for this update. I'm nearly done!

46 notes

·

View notes

Text

Like i am a for real an artist actually I know I'm like EVERYTHING IS ART EVERYTHING IS ART THERE IS NO WAY TO BE UNDERQUALIFIED TO BE AN ARTIST LET'S ALL TOYS FOREVER But Ive been hanging with irl artisans and kind of being shy of my obsessive interest art in comparison to theirs but no I am an artist too I'm also just neuro divergent. And I'm making bottle cup epoxy resin pins

4 notes

·

View notes

Text

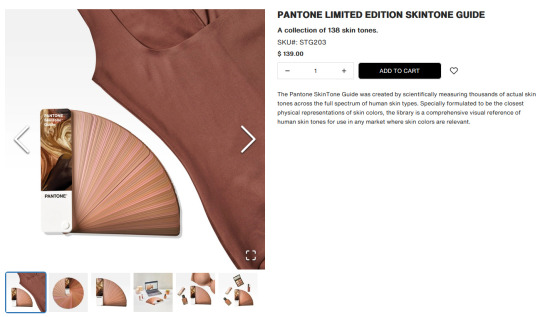

I am a doll collector with BJD and buying parts or making hybrids can be a pain to color match. Just like playline dolls there’s not much consistency between brands. Some resins age differently, too.

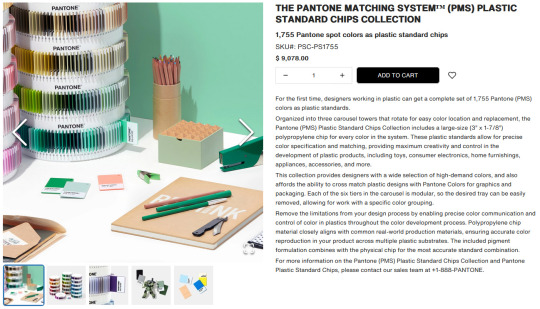

The most reliable color matching source would probably be something like Pantone color cards, but those are FREAKING EXPENSIVE and it’s not reasonable to expect everyone to have them.

BJD collecting is an expensive luxury hobby and there are some of us that do need to keep our spending as minimal as possible.

This skintone chips set (https://www.pantone.com/products/fashion-home-interiors/skintone-guide-limited-edition) has an excellent range of skin tones, but seems to be lacking the pasty pale practically white colors a lot of Asian BJD come in and costs as much as a lower-priced BJD.

This set (https://www.pantone.com/products/plastics/the-pantone-matching-system-plastic-standard-chips-collection) seems ideal for color matching plastics, which resin is, at first but it’s polypropylene chips which will degrade in a few years, and not all colors of urethane or epoxy resins can be replicated in polypropylene. It’s also NINE THOUSAND FREAKING DOLLARS.

We all know I’m always looking for something functional and accessible and $9k that’s going to discolor and maybe even crumble in a decade is not my idea of accessible.

-

@maleficentmrsofallevil suggested a digital resource (https://redketchup.io/color-picker) which is free and accessible to most collectors that have an internet connection and using HEX codes is consistent across devices, however there are a few problems that we might run into.

Everyone’s monitors/phone screens and cameras would have to be calibrated exactly the same, and everyone’s lighting when making comparisons would have to be identical for this to be a viable resource. The hex chart being backlit could also skew the way it looks compared to a tangible resin sample.

That’s frustrating. Free and easy for most people to get a hold of is the ideal.

The main benefit of a physical vs digital resource for color matching is that the color sample and the doll are both subjected to the same lighting conditions, monitor settings, and camera settings so even if those factors vary between users, the comparison will still be relatively accurate.

-

A bunch of us sat around discussing different options. International hobby paint brands like Vallejo or Mr. Color, international makeup foundation color cards, etc. etc.

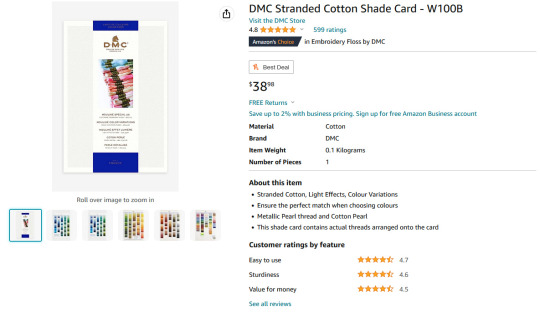

I’ve decided to give DMC embroidery floss color cards a try.

There are two versions.

One has samples of the actual floss in the book and costs about $40.

https://amzn.to/3Oq8G2f

The other has printed color blocks that presumably match the floss colors and costs about $10.

https://amzn.to/3Q2H8Bb

DMC are sticklers for their colors being the same across dye lots. Sometimes they change the numbers on colors and sometimes they discontinue colors all together, so we do still run into the issue of whether everyone’s looking at the same color cards or different versions.

At $10, needing to replace or update the color card every few years isn’t nearly as daunting as a $9k plastic samples set falling apart in your hands once a decade.

(Can you tell I hate polypropylene when used in conjunction with dolls?)

Other variables that will affect the efficacy of using DMC color cards are the conditions under which the color cards are kept like sun exposure, temperature, humidity etc. affecting either the color of the thread samples or the quality of the printed samples.

Another factor is consistency between printed samples.

I have not received these, yet, but my plan is to first compare them to each other to see how well the printed samples match the swatched samples, and then proceed from there.

21 notes

·

View notes

Text

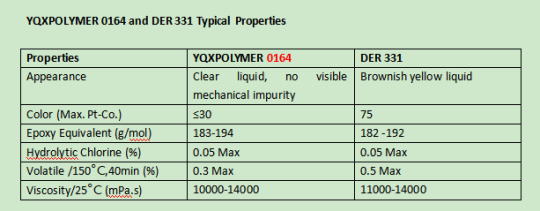

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes

Text

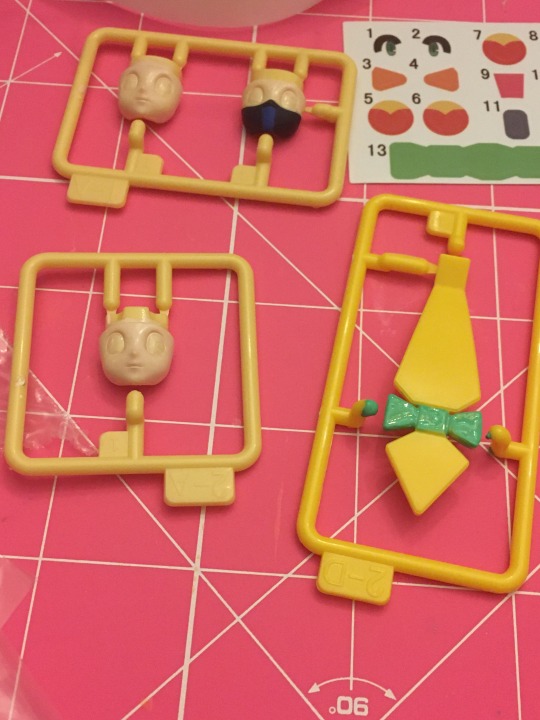

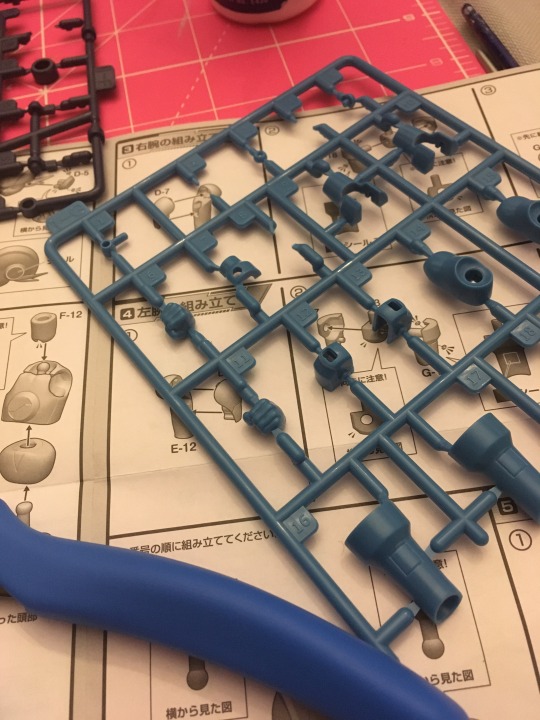

scenegraph reviews: smp kit makes pose rockman.exe (part one: assemblé)

i thought i wasn’t going to type up one of these for rockman. he’s basically the same as roll, right? he’s going to have similar pain points on assembly, right?

lolno. well, lolsorta.

so! as you might recall from the roll review, ‘skin’ tone for these kits is a bright shade of simpsons yellow, which i painted over at the same time as painting the roll parts to arrive at a more attractive pale peach:

these look like they’re going to be faceplates, and on the side of the box they’re displayed like they’re option parts like roll’s hand attachments are, but they slide (with a lot of resistance) into place the same way roll’s face did. so they’re really more like choose your adventure options. just select the one that suits the way you tend to display your figures; because i like to make my figures do doofy shit all the time rather than just fight, i went with the maskless one.

now, the good news is, there are way less load-bearing decals on rockman! things that should arrive painted in, like his bodysuit stripes, are painted in! noice!

at first i thought this was Main Character Privilege. then i realized that rockman has no open hands. just these fists.

that’s all he gets! he cannot do the ‘guess ill die’ shrug like roll can because lol no open hands, though he can flex his wrists to do the jealousy pose which no rockmans or megamans i’ve owned before could do so... equality at last??

roll’s open hands are so expressive and she can do so much between them and the fists, it’s a shame rockman doesn’t have the same. presumably you can fix this by buying the style change set, since that comes with a kusamura seed and presumably they’d give you an extra set of open hands so that base rockman can hold it too, but that’s another one hundred and fifty dollars when i don’t want no style changes, give me more navis instead and don’t make me buy whole other kits just so i can get the option parts rockman deserves. u actin’ like these are nine-dollar barbies i can just yoink a head or an outfit from instead of full-blown model kits with collector price points, i don’t appreciate it, bandai.

(also on the subject of rockman’s hands, there is an absolutely massive sprue to cut in the meat of rockman’s thumb that looks like booty even after sanding. grr.)

however, i can say that this is still way cooler than 66 action rockman’s lack of a second hand at all. either you displayed him with a sword made of bendy plastic or a buster. here, rockman has a nice non-bendy sword, a buster, and a regular arm. putting the sword together is quite painful, because it doesn’t slide together smoothly, but it’s a tiny model, it happens.

in addition, while that one finicky bit in roll’s upper arm that required boiling water and pliers is gone, instead they have introduced a new pain point:

this popped out and went sailing across the room the first time i tried assembling it. on roll, this upper arm and shoulder joint is a single piece. once the arm is assembled, it even plugs into rockman’s torso the exact same way it did on roll. why is it different at all

the same “at this small size, invisible variances in the casting will make bits of this hard to jam together or not fit on at all” disclaimer from roll applies to rockman as well, so his wrist is very tetchy and he can’t wear his backpack until i sit there and epoxy it to his back, buuut that can wait for another day. for now, both rock and roll are assembled, and nothing has outright broken so i don’t think i need to buy another set of these. mission accomplished!

...aaaand i’ll do more pictures, comparisons, etcetc in a part two tomorrow or sunday.

#rockman.exe#rockman exe#mmbn#megaman nt warrior#megaman battle network#mega man battle network#smp kit makes pose#smp#bandai namco#plamo#plamodel#Shokugan Modeling Project

4 notes

·

View notes

Text

The "Three Kingdoms" of LED Display: DIP, SMD, and COB Technologies

In the LED display industry, three packaging technologies dominate: DIP, SMD, and COB. Among them, COB (Chip on Board) stands out for outdoor fine-pitch applications due to its revolutionary design.

1. Technology Comparison

DIP: Early through-hole packaging, simple but bulky, gradually being phased out.

SMD: Surface-mount technology, integrates RGB chips but relies on solder joints and lead frames, limiting reliability.

COB: Direct chip-on-board bonding, eliminating lead frames and reflow soldering for a more streamlined process.

2. Key Advantages of COB

2.1 Superior Reliability

Dead pixel rate below 0.005% (vs. industry standard 0.03%), thanks to fewer solder joints (e.g., eliminates 4 million joints in a P1.0 display).

Full epoxy encapsulation resists moisture, corrosion, and harsh outdoor conditions.

2.2 Cost & Efficiency

Removes lead frames, sorting, and SMT processes, reducing material and labor costs.

Lightweight (50% lighter than SMD) cuts logistics expenses.

2.3 Fine-Pitch Breakthrough

No lead frame constraints enable sub-P1.7 pitch, with potential for <P1.0 using flip-chip tech.

2.4 Enhanced Performance

180° wide viewing angle and flexible bendable designs.

High impact resistance and easy-to-clean surface.

3. Industry Outlook

COB’s simplified supply chain (chip-to-module integration) and unmatched reliability make it ideal for outdoor fine-pitch displays. Meanwhile, SMD struggles with solder joint aging and waterproofing challenges in high-end markets.

4. Conclusion: COB’s lead frame-free design delivers a technological edge, poised to end the "Three Kingdoms" era and dominate future LED displays.

0 notes

Text

Polyurea vs Epoxy: Load-Bearing Comparison

Polyurea and epoxy coatings are both popular for load-bearing applications, but they excel in different ways. Here’s what you need to know: Polyurea: Highly flexible, absorbs dynamic loads, resists impacts, and lasts up to 4x longer than epoxy. Ideal for high-impact areas like industrial floors, parking garages, and loading docks. Epoxy: Rigid, handles static loads well, and bonds strongly to…

0 notes

Text

PTFE Lined Gate Valves vs. Conventional Gate Valves: Which One is Right for Your Industry?

Selecting the right valve for industrial applications is critical to ensuring safety, reliability, and efficiency. PTFE (Polytetrafluoroethylene) lined gate valves and conventional metal-seated gate valves are two widely used options, each with its own set of advantages and limitations. PTFE lined gate valves are preferred in industries dealing with highly corrosive fluids, while conventional gate valves remain dominant in high-pressure and high-temperature applications.

This article provides a comprehensive comparison between PTFE lined gate valves and conventional gate valves, discussing their design, performance, maintenance requirements, cost-effectiveness, and suitability for different industries.

Design and Material Composition

PTFE Lined Gate Valves

Designed with an internal PTFE lining that protects the valve’s metallic body from corrosive fluids.

Typically constructed with materials like cast iron, ductile iron, or stainless steel to ensure structural integrity while benefiting from PTFE’s corrosion resistance.

The non-stick and low-friction properties of PTFE provide smooth valve operation and prevent buildup of deposits.

Conventional Gate Valves

Made entirely of metal, including stainless steel, carbon steel, or bronze.

Available in different designs such as wedge gate, slab gate, and parallel slide gate valves.

Require additional coatings or internal linings (like epoxy or rubber) for corrosion protection, which may degrade over time.

Performance & Durability

Corrosion Resistance

PTFE Lined Gate Valves: Offer excellent chemical resistance to acids, alkalis, and solvents, making them ideal for highly aggressive environments.

Conventional Gate Valves: More susceptible to corrosion, requiring special coatings or higher-grade alloys for resistance, which increases cost.

Temperature and Pressure Handling

PTFE Lined Gate Valves: Typically designed for moderate pressure applications (ANSI Class 150-300) and temperatures between -50°C to 200°C.

Conventional Gate Valves: Can withstand extreme high-pressure (ANSI Class 600-2500) and high-temperature conditions (up to 600°C), making them suitable for steam and power plants.

Sealing Efficiency

PTFE Lined Gate Valves: Provide superior zero-leakage sealing, ensuring tight shutoff and preventing fluid loss.

Conventional Gate Valves: Offer effective sealing but may experience wear over time, leading to potential leakage if not maintained properly.

Cost & Maintenance Considerations

Initial Investment

PTFE Lined Gate Valves: Higher upfront cost due to PTFE lining and specialized construction.

Conventional Gate Valves: Lower initial cost, but potential expenses arise due to frequent maintenance in corrosive applications.

Maintenance and Service Life

PTFE Lined Gate Valves: Require minimal maintenance since PTFE lining prevents scaling, deposits, and corrosion.

Conventional Gate Valves: More prone to corrosion, erosion, and mechanical wear, requiring frequent servicing and part replacements.

Industry Suitability

PTFE Lined Gate Valves: Best for Corrosive Environments

Chemical Processing: Handles strong acids and corrosive fluids safely.

Pharmaceutical Industry: Maintains sterility and prevents contamination.

Water & Wastewater Treatment: Resistant to scaling and harsh treatment chemicals.

Food & Beverage: Hygienic and resistant to cleaning agents.

Conventional Gate Valves: Best for High-Pressure and High-Temperature Applications

Oil & Gas Industry: Withstands extreme pressure in refineries and pipelines.

Power Plants: Handles steam at high temperatures and pressures.

Mining & Metallurgy: Robust design for handling abrasive slurries and solids.

Long-Term Cost Analysis

Although PTFE lined gate valves have a higher initial investment, their low maintenance costs and extended lifespan make them more cost-effective in corrosive industries. Conventional gate valves, while more affordable upfront, may lead to higher operational costs due to frequent repairs and material degradation in chemical environments.

Final Verdict: Which One Should You Choose?

Choose PTFE Lined Gate Valves if: You require excellent corrosion resistance, low maintenance, and contamination-free operation in industries like chemical processing and pharmaceuticals.

Choose Conventional Gate Valves if: You need to handle high-pressure and high-temperature conditions in power plants, steam applications, or the oil & gas industry.

Both PTFE lined gate valves and conventional gate valves serve critical roles in industrial applications. The choice depends on operational conditions, fluid compatibility, and long-term maintenance considerations. Investing in the right valve ensures safety, efficiency, and cost savings, making it essential to evaluate your industry’s specific requirements before making a selection.

0 notes

Text

Foundation Repair vs. Replacement: Key Factors to Consider

The foundation provides stability and ensures the safety of a building. However, over time, foundations can develop issues due to soil movement, moisture, and other environmental factors. Homeowners often face the challenge of deciding between foundation repair and foundation replacement. Both options have advantages and drawbacks, making it essential to understand which solution is best for a particular situation. This blog explores the key factors to consider when choosing between repairing or replacing a foundation.

Assessing the extent of foundation damage

The severity of foundation damage plays a crucial role in determining whether repair or replacement is necessary. Minor cracks, uneven floors, or slight settling can often be fixed with foundation crack repair techniques however, if the foundation has significant structural issues, such as deep cracks, bowing walls, or extensive deterioration, a complete replacement may be required. A professional foundation inspection can help determine the extent of the damage and the best course of action.

Cost comparison between repair and replacement

Foundation repair is typically more cost-effective than foundation replacement. Repair solutions such as piering, slab jacking, or sealing cracks can restore stability without requiring extensive labor or materials. On the other hand, foundation replacement involves demolishing the existing foundation, excavating, and building a new one, which can be a costly and time-consuming process. Homeowners should obtain multiple estimates and consider long-term expenses before making a decision.

Time and disruption involved in the process

Repairing a foundation is usually a quicker and less disruptive process compared to replacement. Techniques such as underpinning or epoxy injections can often be completed within a few days. In contrast, foundation replacement requires extensive excavation, which can take weeks and may temporarily displace residents. If minimal disruption is a priority, opting for repair is often the preferred choice.

Longevity and effectiveness of each solution

The durability of foundation repair depends on the method used and the extent of the damage being addressed. If done correctly, foundation crack repair can provide a long-lasting solution for minor structural problems. However, in cases of severe foundation failure, repair solutions may only serve as temporary fixes. A full replacement provides a brand-new foundation, ensuring structural integrity for decades. Homeowners must consider the long-term effectiveness of each option when making their decision.

Soil conditions and environmental factors

The condition of the soil beneath a structure significantly impacts the foundation. Expansive clay soils, poor drainage, or excessive moisture can cause ongoing foundation problems. In some cases, foundation waterproofing can help prevent moisture-related issues and extend the life of a repaired foundation. However, if soil instability is severe, simply repairing the foundation may not be enough, making a complete replacement necessary.

Choosing the right option for your home

Every foundation issue is unique, and the right solution depends on multiple factors, including budget, severity of damage, and long-term stability. A professional assessment can provide valuable insights into whether foundation waterproofing and repairs are sufficient or if a complete foundation replacement is the best choice. Homeowners should consider the overall investment and potential risks before proceeding with any foundation work.

A stable foundation is essential for a safe and secure home. Whether opting for repair or replacement, taking the right steps ensures the longevity and value of the property. Seeking expert guidance can help homeowners make an informed decision and protect their investment for years to come.

0 notes

Text

Garage Epoxy Floors: Just How Durable and Chemical Resistant Are They?

Garage floors endure constant wear and tear from heavy vehicles, tools, and chemical spills. Many homeowners struggle with cracking concrete, oil stains, and surface damage, making their garages look worn out. Epoxy flooring protects and enhances garage floors, providing exceptional durability and chemical resistance that surpasses traditional concrete and paint coatings.

If you're considering an upgrade, here's a closer look at the durability and chemical resistance of epoxy garage floors.

How Durable is an Epoxy Garage Floor?

Epoxy flooring is known for its strength and longevity, making it an ideal solution for high-traffic areas like garages. Unlike bare concrete, which can crack, chip, and wear down over time, epoxy forms a rigid, impact-resistant surface that can handle:

Heavy vehicle weight – Supports the pressure of parked cars, trucks, and motorcycles without cracking.

Dropped tools and equipment – Resists damage from impact, reducing dents and chips.

Abrasion from foot traffic and machinery – Withstands constant movement without wearing down.

Extreme temperatures – Performs well in hot and cold climates without expanding or contracting.

Because of their durability, epoxy garage floors last significantly longer than other flooring types, making them a cost-effective long-term investment. If you're looking for a garage flooring solution that won’t break down under pressure, check out epoxy garage floors in Las Vegas for high-performance options.

Chemical Resistance: How Epoxy Protects Against Spills and Stains

One of the biggest challenges for garage floors is exposure to harsh chemicals. Whether oil, gasoline, antifreeze, or cleaning solvents, traditional concrete floors absorb liquids, leading to permanent stains, weakening of the material, and lingering odors. Epoxy flooring, on the other hand, is entirely non-porous, forming a protective barrier that resists chemical damage.

What Substances Can Epoxy Flooring Resist?

Motor oil and gasoline – Prevents staining and repels petroleum-based fluids.

Brake fluid and antifreeze – Won’t seep into the floor or cause surface deterioration.

Household cleaners and solvents – Safe against spills from detergents, degreasers, and other chemicals.

Battery acid and automotive chemicals – Resistant to corrosion and surface breakdown.

Thanks to its chemical-resistant properties, epoxy flooring is perfect for homeowners who use their garages for automotive work, home projects, or industrial storage. If you want to protect your floors from spills and stains, explore epoxy floors in Las Vegas for the best protective coatings.

Epoxy vs. Traditional Garage Flooring: A Durability Comparison

To understand why epoxy outperforms other garage flooring options, let's compare it to standard alternatives.

Bare concrete is prone to cracks, stains, and dust accumulation and requires sealing or resurfacing over time.

Garage floor paint – Provides a temporary improvement, but peels and chips are under heavy use.

Tile or interlocking mats – Looks tremendous but can shift, crack, or trap dirt between seams.

Epoxy flooring – Offers a seamless, impact-resistant, and chemical-proof surface that lasts years.

Because epoxy is a long-term solution, many homeowners find it more cost-effective than repeatedly repairing or refinishing other flooring materials. If you're considering a garage floor upgrade, Las Vegas epoxy flooring offers customized options for durability and style.

Does Epoxy Flooring Crack or Peel Over Time?

One of the biggest concerns for homeowners investing in new garage floors is whether epoxy will crack, peel, or degrade over time. Unlike low-quality coatings like paint, epoxy flooring is engineered to withstand:

Daily wear and tear without peeling or flaking.

Temperature fluctuations without expanding or contracting.

Moisture exposure without soaking up water or developing mold.

Long-term use with minimal maintenance requirements.

When installed correctly, epoxy flooring lasts decades, making it one of the most durable garage flooring options. To ensure a high-quality, long-lasting installation, visit Epoxy Flooring Las Vegas to find expert solutions tailored to your space.

Low Maintenance and Easy Cleaning

Epoxy flooring is not only durable—it’s also incredibly easy to maintain. Unlike concrete, which absorbs dirt and requires frequent scrubbing, epoxy’s sealed surface makes cleaning a breeze.

Dust and dirt won’t stick – A simple broom or mop keeps the floor looking new.

Oil and grease wipe away easily – No need for special degreasers or pressure washing.

No cracks or crevices – Unlike tile, epoxy doesn’t have grout lines that collect dirt and bacteria.

Minimal upkeep required – Epoxy floors maintain their durability and shine with little effort.

For a garage floor that’s easy to clean and built to last, consider Las Vegas epoxy flooring for a low-maintenance flooring upgrade.

Final Thoughts: Is Epoxy the Best Garage Flooring Option?

If you want a garage floor that lasts for years, resists chemical spills, and requires minimal maintenance, epoxy flooring is one of the best investments you can make. Its impact resistance, non-porous surface, and long lifespan make it far superior to traditional concrete, paint, or tile.

For homeowners looking to upgrade their garage flooring, check out Epoxy Garage Floor Las Vegas to explore customized epoxy solutions that match their style and durability needs.

0 notes

Text

Pipes for Oil & Gas Industry

Introduction

Pipes play a crucial role in the oil and gas industry, ensuring the safe and efficient transportation of crude oil, natural gas, and refined products. Selecting the right type of pipe is essential for performance, safety, and durability.

Importance of Pipes in Oil & Gas Industry

Essential for exploration, extraction, and transportation of oil and gas

Must withstand high pressure, temperature, and corrosive environments

Compliance with international standards ensures reliability

Types of Pipes Used in Oil & Gas Industry

1. Seamless Pipes

Manufactured without a welded seam

High strength and resistance to extreme conditions

Ideal for high-pressure applications

2. ERW (Electric Resistance Welded) Pipes

Used in low to medium-pressure applications

Cost-effective and widely available

Preferred for onshore applications

3. LSAW (Longitudinal Submerged Arc Welded) Pipes

High strength and durability

Suitable for large-diameter pipelines

Common in offshore and long-distance transportation

4. DSAW (Double Submerged Arc Welded) Pipes

Enhanced durability due to double-welding

Used in deepwater and high-pressure environments

Preferred for subsea pipelines

5. API 5L Pipes

Standard pipes used in the oil and gas industry

Available in various grades like X42, X52, X60, and X80

Designed for high-performance and long service life

Pipe Coatings & Linings

Fusion Bonded Epoxy (FBE): Prevents corrosion

3LPE Coating: Protects from harsh environments

Concrete Weight Coating (CWC): Adds stability for subsea applications

Polyethylene & Polypropylene Linings: Increases longevity

Comparison Table of Oil & Gas Pipes

Pipe TypeStrengthCorrosion ResistanceApplicationsSeamless PipesHighExcellentHigh-pressure & offshore useERW PipesMediumModerateOnshore & low-pressure applicationsLSAW PipesVery HighHighLong-distance & offshore transportationDSAW PipesVery HighHighDeepwater & subsea pipelinesAPI 5L PipesHighExcellentOil & gas transportation pipelines

Factors to Consider When Choosing Oil & Gas Pipes

Pressure & Temperature Resistance – Ensure pipes can handle extreme conditions.

Corrosion Protection – Coated pipes enhance longevity.

Material & Grade – Choose appropriate steel grade (API 5L, ASTM standards, etc.).

Pipe Diameter & Thickness – Depends on application and industry standards.

Compliance & Certification – Pipes must meet international standards (API, ASTM, ISO, etc.).

FAQs

What is the best type of pipe for oil and gas transportation?

Seamless and API 5L pipes are ideal due to their high strength and corrosion resistance.

Why is corrosion protection necessary for oil & gas pipes?

Corrosion can lead to leaks, failures, and costly repairs; coatings like FBE and 3LPE prevent damage.

What standards apply to oil and gas industry pipes?

Pipes must meet API 5L, ASTM, ASME, and ISO standards for quality and performance.

How are pipelines protected from extreme temperatures?

Pipes are coated with special linings and insulated to withstand extreme temperatures.

Which pipe material is best for offshore applications?

DSAW and LSAW pipes with corrosion-resistant coatings are preferred for offshore use

0 notes

Text

Flooring Contractor Texas

Elevate Your Space: How To Pick A Flooring Contractor For Your Luxury Car Space

A luxury car deserves more than just a parking spot—a space reflecting elegance and value. A well-designed garage with premium flooring can elevate your car's home, providing durability, style, and functionality.

Choosing the right flooring contractor Texas for this important upgrade is essential to ensure your luxury car space looks its best and serves its purpose.

Understanding Your Flooring Needs

Before you start searching for a contractor, it's important to understand your specific needs. Luxury car spaces require flooring that can withstand the weight of vehicles, resist stains from oil or chemicals, and remain visually appealing. Epoxy and polyaspartic coatings are popular choices due to their durability and sleek finish.

Knowing what you want in terms of material, color, and texture will help you find a contractor who specializes in these options.

Researching Local Contractors

Finding a reputable flooring contractor in Texas, especially in cities like Austin, can be overwhelming, given the options. Start by looking for contractors who have experience with garage floor coatings and replacements.

Explore their websites, read customer reviews, and look at their portfolio of completed projects. A good contractor will proudly showcase their work and have positive feedback from satisfied clients.

Checking Credentials and Experience

A professional flooring contractor should be licensed, insured, and experienced in working with high-end garage spaces. Credentials ensure that the contractor meets industry standards and is qualified to handle your project.

Additionally, experience matters when it comes to luxury spaces. Contractors who specialize in garage floor replacement and coatings will have the expertise needed to deliver a flawless finish that complements your car's aesthetic.

Requesting an In-Person Consultation

A reputable contractor will offer an in-person consultation to assess your garage space and discuss your vision. During this visit, they should take measurements, evaluate the condition of your existing flooring, and provide recommendations tailored to your needs.

This step also allows you to ask questions about the process, timeline, and materials they plan to use.

Comparing Estimates and Services

Once you've consulted with a few contractors, compare their estimates and the services they offer. Look beyond the price and consider what's included in the quote.

Some contractors may offer additional services like moisture testing, surface preparation, or warranty coverage.

Remember, the cheapest option isn't always the best. Quality materials and skilled craftsmanship are worth investing in for a long-lasting, luxurious result.

Reviewing Warranties and Guarantees

Garage flooring is a significant investment, and you want to ensure it will last. Check whether the contractor offers warranties for their work and guarantees on the materials they use.

A contractor confident in their quality will provide warranties that give you peace of mind and protect your investment.

Evaluating Communication and Professionalism

The contractor's communication and professionalism throughout the process can also indicate the quality of their work.

Are they responsive to your inquiries? Do they explain the details clearly and address your concerns? A professional contractor will prioritize customer satisfaction and work to build trust.

Finalizing Your Decision

After thorough research, consultations, and comparisons, you'll be ready to choose a flooring contractor. Pick one that aligns with your vision, offers top-quality materials, and has a track record of excellence in garage flooring.

A skilled contractor will transform your luxury car space into a showcase-worthy environment that complements your prized vehicle.

Conclusion

Upgrading your garage flooring is more than just a functional improvement; it's a way to elevate your space and enhance the experience of owning a luxury car.

By carefully selecting the right contractor, you can achieve a durable, stylish, and high-performance floor that reflects the sophistication of your vehicle. Visit MyGarageFloors.com for more solution about garage floor replacement.

Look at our homepage to get more information about Garage Floor Coating Austin Texas!

0 notes

Text

Boat Wraps vs. Repainting: Which Option is Right for Your Vessel?

When it comes to updating or refreshing the look of your boat, two primary options come to mind: boat wraps and repainting. Both methods can provide a stunning new appearance for your vessel, but they differ significantly in terms of cost, maintenance, longevity, and ease of application. The choice between these two options depends on a variety of factors, including your budget, how long you plan to keep your boat, and the level of customization you desire. In this article, we’ll compare boat wraps and repainting to help you decide which option is the best for your vessel.

1. Cost Comparison: Boat Wraps vs. Repainting

One of the first things most boat owners consider is the cost of the project. Both boat wraps and repainting can be expensive, but the pricing can vary based on the size of the boat, the complexity of the design, and whether you're choosing a high-quality paint or wrap.

Boat Wraps: The cost of boat wraps typically ranges from $2,000 to $5,000 depending on the size of the vessel and the design complexity. Custom wraps can increase the price, especially if you opt for intricate designs or full coverage. However, the labor costs for applying a boat wrap are generally lower than for repainting because the application process is quicker and less labor-intensive.

Repainting: Repainting your boat can cost significantly more, especially for a high-quality job. Expect to pay between $3,000 and $10,000 or more, depending on the boat size, type of paint used, and the extent of prep work needed. The repainting process involves sanding, priming, painting, and multiple coats, all of which contribute to higher labor and material costs. Additionally, more time is required to ensure that the finish is smooth and durable.

Overall, boat wraps are usually the more affordable option, particularly for owners on a tighter budget or those who want a quick, cost-effective makeover.

2. Durability and Maintenance: Boat Wraps vs. Repainting

Durability is a key factor when considering any boat aesthetic upgrade. Your boat is exposed to a variety of elements, including saltwater, UV rays, and constant wear and tear. Both wraps and paint have their pros and cons when it comes to longevity.

Boat Wraps: Boat wraps are generally made from durable vinyl materials designed to withstand harsh marine environments. High-quality wraps can last anywhere from 3 to 7 years with proper care. However, their lifespan can be shortened by constant exposure to the sun, frequent washing, or aggressive cleaning techniques. The vinyl material can also become scratched or damaged, but it’s often easier and cheaper to repair a wrap than to repaint a whole boat.

Maintenance for wraps is relatively simple: regular cleaning with a mild detergent, avoiding harsh chemicals, and making sure the wrap doesn’t suffer from UV degradation or physical damage. Repairs are also relatively straightforward, as a damaged section of the wrap can often be replaced without redoing the entire boat.

Repainting: Repainting a boat with high-quality marine-grade paint can last 5 to 10 years or even longer, depending on the conditions the boat is exposed to and how well it is maintained. Painted surfaces, particularly when using premium products like polyurethane or epoxy paints, can withstand saltwater, UV rays, and physical abrasion better than wraps.

However, repainting requires more attention and care over the years. You will need to inspect and maintain the paintwork regularly to avoid peeling, fading, or chipping. If the paint starts to degrade, it can be more costly and time-consuming to repair compared to a wrap.

In terms of durability, both options are fairly reliable, but repainting can provide a longer-lasting solution if properly maintained.

3. Customization and Design: Boat Wraps vs. Repainting

When it comes to design flexibility and the level of customization, boat wraps are generally the clear winner. Whether you’re looking to add logos, graphics, complex patterns, or even high-resolution images, boat wraps offer an unmatched level of design versatility.

Boat Wraps: Vinyl wraps can be custom-designed in any way you choose. From intricate graphics and logos to stunning, full-color photographic prints, the possibilities are endless. Wraps can cover every inch of your boat, including curves and irregular surfaces, which is often harder to achieve with paint. Additionally, wraps can be removed and replaced easily without damaging the boat’s underlying surface.

For boat owners who want something unique or temporary, wraps allow for endless customization. This is why wraps are commonly used for promotional boats, racing yachts, or anyone who wants a personalized, eye-catching design. Furthermore, if you get bored with the design or want to change it, replacing a wrap is much easier and less costly than repainting.

Repainting: Repainting offers a more classic and durable finish, but the customization options can be limited compared to wraps. Custom colors, patterns, and artwork can be applied, but the level of detail and flexibility may not match that of a vinyl wrap. For boats with intricate curves or unique shapes, achieving a flawless finish can be a time-consuming and challenging process. Additionally, repainting typically involves more labor-intensive techniques, especially when trying to replicate detailed designs or layered colors.

If you’re looking for a clean, glossy, traditional look or prefer a more permanent design, repainting is a great option. However, the design options can be more restrictive and might not offer the same range of creative freedom as wraps.

4. Time and Convenience: Boat Wraps vs. Repainting

If time is a crucial factor for you, then boat wraps offer a significant advantage over repainting. The installation process for a wrap is much faster and more convenient than the painting process.

Boat Wraps: The installation of a boat wrap typically takes 1 to 5 days depending on the size and complexity of the design. The process involves preparing the boat’s surface, cutting the vinyl to fit the contours of the boat, and carefully applying the wrap. The wrap adheres directly to the boat's surface, and no drying time is necessary. Once applied, the boat is immediately ready to use.

This quick turnaround is ideal for boat owners who need their vessels to be back on the water quickly or who want to avoid long periods of downtime.

Repainting: The repainting process is more involved and can take anywhere from 1 week to several weeks depending on the size of the boat and the number of coats required. This process includes sanding, priming, painting, drying, and curing, and often involves waiting for optimal weather conditions to apply the paint. The drying times between coats are critical, and delays can occur if the weather is humid or rainy.

5. Resale Value and Aesthetics: Boat Wraps vs. Repainting

Finally, it's important to consider the impact that a boat wrap or repaint may have on the resale value of your vessel.

Boat Wraps: While a well-maintained boat wrap can significantly improve the aesthetics and appeal of your vessel, it’s important to note that wraps are often considered temporary compared to paint. Some prospective buyers may be wary of a boat with a wrap because they perceive it as a superficial upgrade or may worry about potential issues when removing the wrap. However, if the wrap is in great condition, it can make the boat stand out and appear more modern and well-maintained.

When selling a boat with a wrap, you’ll need to consider whether potential buyers will want to keep the wrap or remove it, which could impact the sale price. For some buyers, a wrap is a selling point, while for others, it may detract from the boat's perceived value.

Repainting: A freshly repainted boat with a high-quality finish can significantly increase the resale value of the boat, particularly if the paint job is well-maintained and looks pristine. A boat with a solid, high-end paint job conveys to potential buyers that the vessel has been cared for and is in good condition. Repainting may also be seen as a more permanent and lasting improvement, making it an attractive feature for buyers who want a long-term solution.

Conclusion

Deciding between boat wraps and repainting ultimately depends on your priorities, budget, and preferences. If you’re looking for an affordable, quick, and customizable option, a boat wrap might be the best choice for you. It’s ideal if you want a temporary, eye-catching design or if you plan to frequently update the boat’s look. On the other hand, if you’re seeking a long-lasting, durable solution and are willing to invest more time and money, repainting could be the way to go. It offers a timeless, polished finish that can withstand the test of time.

0 notes