#epe foam machine

Explore tagged Tumblr posts

Text

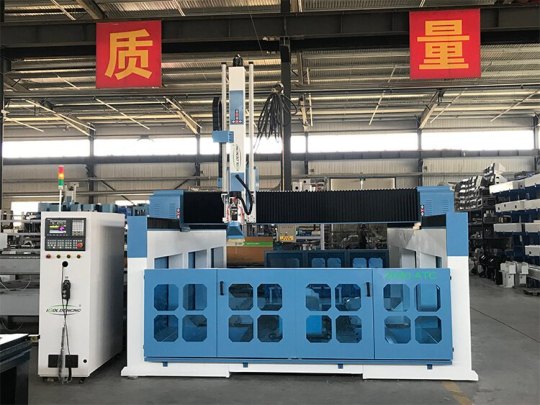

Automatic Tool Change Foam Router EPS CNC Carving Machine

CNC Router Foam Cutting Machine

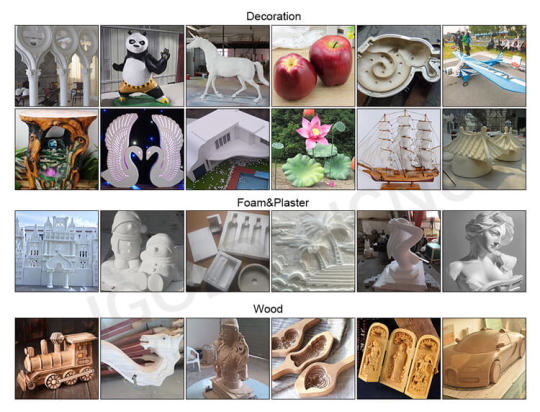

Automatic Tool Change Foam Router, also known as an EPS CNC Carving Machine with Automatic Tool Change, is a specialized computer-controlled machine designed for cutting, carving, and shaping Expanded Polystyrene (EPS) foam materials. These machines are equipped with an automatic tool change system that allows for the seamless swapping of cutting tools during the CNC routing process.The 3d CNC router milling machine can be seamlessly spliced, suitable for various shapes.This CNC router foam machine also can be used in embossing, lettering, hollowing, cutting, vertical carving, round carving, etc.

This 4 axis cnc foam router is a little special when compared with the ordinary four axis machine. The conventional 4-axis construction has two types: one is that the spindle can swing ±90 degrees; the other refers to the rotary axis. Either of the two can be called the ordinary 4-axis cnc machine. What makes this machine special is that it is actually a 2 in 1 cnc foam router as it has the two types 4 axis construction stated above. Based on this design, there is no doubt that it has more possibilities than a normal 4-axis machine. The 4 axis cnc foam router here is perfect for 3D polystyrene shapes making.

4 Axis 3d CNC Router Milling Machine

EPS/foam CNC router usually comes with a big working dimension for carving and cutting large-size workpieces of wood, aluminum, and styrofoam. It can also be equipped with an ATC spindle and a rotary device for complex, heavy-duty, and long-term work. It is widely used to process and carve wood and styrofoam automotive, ship or other molds, and GRG or GRC decorations, and architecture models.

Automatic Tool Change Foam Routers are specifically designed to work with EPS foam materials. EPS foam is commonly used in various industries for insulation, packaging, and creative applications due to its lightweight and easy-to-cut properties.Like other CNC machines, EPS CNC carving machines with automatic tool change offer high precision and accuracy. The CNC technology ensures that complex designs, intricate patterns, and 3D shapes can be executed with precision.

Foam Router EPS CNC Carving Machine

Packaging: Creating custom foam inserts for protecting fragile items during shipping.

Sculpture and Art: Carving intricate sculptures and art pieces from EPS foam.

Architectural Design: Crafting decorative elements and architectural details.

Set Design: Producing props and scenery for theater, film, and events.

Sign Making: Crafting 3D signs, logos, and lettering.

This cnc router foam cutter is designed especially for custom EPS expanded polystyrene foam moldings. The molded foam is usually used for casting & founding. Three-axis construction with 1500x3000mm machining size (5×10 in English); (need 4th rotary? please check out foam milling machine with rotary axis) Dirt guard is designed on X Y Z axes particular for cnc foam machining, which keeps the precise transmission parts away from the machining debris. The table is made of aluminum profiles. It is ideal for EPS EVA foam machining as well as wood machining. CNC router foam cutter for custom EPS EVA molding for sale at a reasonable price now!

Application Scope

How Many Kinds of CNC Foam Router Are There?

Well, this need to see from which perspective. From a motion axis quantity perspective, there are 3 axis, 4 axis and 5 axis cnc foam router; from application point of view, there are cnc foam router for polystyrene, for woods and for aluminum.

0 notes

Video

youtube

compaction system for EPS packaging, eps fish boxes

#youtube#eps compaction#eps compactor#styrofoam compactor#polystyrene compactor#eps recycling machine#eps recycling#styrofoam recycling#polystyrene recycling#foam recycling#eps foam recycling machine#eps foam recycling#styrofoam recycling machine#polystyrene recycling machine#polystyrene foam#foam recycling machine

0 notes

Note

what’s your fave strokes album and song (or top few of it’s too hard to choose)? who are your other favorite musicians?

OMG im gonna answer under a cut cause i cant answer this question without yapping

ROOM ON FIRE! is my hand on the bible favorite but every couple of months i cycle between which one is my favorite..

ppl r gonna get my ass for this but im a comedown machine freeak that might be my number 2 🙈

its all SO closely tied it depends on the month

ima say my favorite strokes songs tho R

meet me in the bathroom

hard to explain

youre so right

fast/slow animals

one way trigger

new york city cops

ize of the world

the ENTIRE future present past EP.. bro

ODE TO THE METS

life is simple in the moonlight

i like the night demo has me foaming at the mouth enuf to add it to this list LOL id give any thing for them to put this out

other stuff i listen to a lot

excluding all the non-strokes but still related stuff like the voidz + solo projects:

the breeders, grimes, sufjan stevens, joy division+new order, lou reed+the velvet underground, daniel johnston, drug store romeos, yo la tengo, the eels, lana, pedro the lion, massive attack, guided by voices, fukinnnn weezer LOL

anddd this playlist has a lot of my favorite shit on iT

thank u for this queschin i love music

8 notes

·

View notes

Text

Chicago Fire Season 4 Ep. 21 "Kind of a Crazy Idea"

Dawson saves a boy from a fire; Kidd's Molly's idea fails; Severide hits a wall while advocating for new fire masks; Cruz and Brett use a secret weapon to get Otis to see Halstead take a blood test.

If you want to watch the series for yourself, stop reading! This post contains spoilers to the storyline.

Dawson and Casey are in bed together. After sex, Dawson wants him to get pancakes with her. Casey has to leave. He has a meeting about a youth center.

Later, a call comes in for a structure fire. They arrive at an apartment building and Boden tells them to clear the floors before the ceilings cave in. Herrmann and Dawson find a woman passed out in a building with hardly any smoke. It's not smoke inhalation. They find a needle in her arm. She overdosed. Herrmann carries the woman out. Dawson finds a toddler hiding under a table. She coaxes him out as the building collapses. Herrmann gets the woman outside and puts her on a stretcher. Dawson gets the boy out just in time. She carries him to the back of Sylvie's ambulance, but he won't let go, so she rides with him to the hospital.

Back in the break room, Stella is taking her bar management seriously and wants Herrmann to get an Artisan ice machine. Cruz finds Otis. Will tells him about the blood tests he never got done. Will is worried about the big bruises on Otis's back. Otis laughs it off and says the bruises went away. He says it's not that serious.

At the hospital, Dawson learns the woman who overdosed was not his mother - she was a foster mother. Child Protective Services arrives. She says they were investigating her and planning to move Louie. Dawson is upset, but lets Cantrell take Louie away. She says he is going to a group home.

After the fire, Severide finds Boden. They need thermal imaging masks. Severide and Otis nearly died trying to save a Star Wars toy. If they had the masks, they would have known it wasn't a person. Boden says Chief Barr won't order them because they're over budget. Severide visits Chief Barr and they argue. Barr says there is not enough money.

Dawons gets back to the firehouse. She tells them Louie went to the group home. Dawson feels bad because Louie kept asking for a blanket. Dawson goes back to the burnt apartment and finds the blanket. She gives it to Cantrell at her office. Cantrell says Louie has no family, but they're trying to find him a new foster family.

Cruz doesn't think Otis is okay. He wants him to get tested. He calls baba and asks her to come to the fire station to talk to Otis. After she yells at him, Otis is upset but says he'll go to the hospital after work to get blood work done.

Sylvie rushes to the scene after a call for an ambulance. A kid meets them outside and says Damon is acting like he has rabies. They rush inside and find him foaming at the mouth and gasping for air. Damon's friends say they made him drink soy sauce. Sylvie says he's having a sodium overdose. Sylvie goes back to the firehouse. She thinks Damon won't make it. He was in a coma by the time they got him to the hospital. She tells Cruz they did the right thing by calling Baba. Damon's friends waited too long to call for help.

Otis goes in for blood work with Cruz and Sylvie. Will tells Otis he doesn't have leukemia. He has a blood platelet disorder and his blood isn't clotting. He's lucky he didn't bleed to death. He needs treatment fast to stop is brain bleeding. Otis is upset when Will says he can't go back to work until they get the platelets under control.

Casey gets home late from the youth center meeting, and Dawson is waiting. She wants them to foster Louie. She can't stop thinking about him, and he has no family. Dawson says it's fate. Casey agrees Louie deserves a family, but they're too busy. They can't take care of him. Dawson is upset. She makes up an excuse to leave and leaves.

The next day, Dawson talks to Casey at work. She says it's not right for Casey to take in a child. It's the right time for her. Dawson says she'll take care of Louie by herself. She's already met with Cantrell to become a foster parent.

There's a fire call at Molly's, Herrmann's bar. They put out the fire before it spreads. An electrical fire started by the ice maker Stella got for Herrmann.

Back at the firehouse, they get good news. Casey used his position to get the money for the firehouse to get the thermal gear Severide wanted. Boden thanks him for his help. It seems politics is his calling.

In the locker room, Dawson asks Herrmann if she'll make a good him. He doesn't think so, but he knows she'll be a good mother. Cruz checks on Otis and finds him throwing out junk food. Cruz is proud of him and says they'll beat this together.

Dawson meets with Cantrell. She is upset that it takes over a month to become a foster parent. Cantrell says they'll put Louie in another home by then. They can't keep him at the group home until Dawson is approved. Dawson is upset, but Cantrell lets her visit with Louie and they read a book.

Stella is trying to fix the wall at Molly's that was ruined by her ice machine. Severide shows up and offers to help. She is clearly struggling. They end up hooking up.

3 notes

·

View notes

Text

Sustainable Polystyrene Recycling: Australia Adopts GREENMAX Polystyrene Compactor

🌟 GREENMAX is thrilled to announce our partnership with the Melbourne Market, where our Polystyrene Compactor A-C200 is hard at work! This incredible machine compactly processes various plastic foams – EPS, XPS, PSP – reducing waste volume by up to 50 times. That means Melbourne Market can handle more waste with less impact, optimizing their space and minimizing transportation needs. 💪

Our mission at GREENMAX is to help businesses achieve a sustainable impact through advanced recycling technology. With the Polystyrene compactor, the Melbourne Market can now turn what was once a difficult waste material into manageable, recyclable blocks that are ready for further use. This solution is paving the way for a future where waste management aligns with environmental care. 🌍

Hats off to the Melbourne Market for being a leader in sustainable practices! We’re excited to see more businesses joining the green journey and are proud to provide innovative solutions that make it possible. Together, let’s embrace a circular economy that benefits everyone! 🌿🌱

0 notes

Text

Application of STMMA copolymer sheets

STMMA casting-specific sheets have attracted widespread attention and great interest from theautomobile mold industry and machine tool casting industry since its launch. We have applied STMMA copolymer sheets produced by a mold casting company of Anhui Province and a mold casting company ofHebei Province, the most famous domestic companies in batches, with a very significant effect.

(1) A company in Anhui Province mainly produces automobile covering molds and provides them to well-known domestic automobile companies. The casting blank has a maximum weight of about 30T EPS sheets that have been used for foam pattern making. Problems of easy deformation, numerous carbon defects, large machining allowances, high cutting costs, high repair costs, long lead time, and high mold scrap rate are mainly found.

Test plan: Use Castchem STMMA copolymer sheets with a pre-foaming density of 22± 1kg/m³. The pattern-making and coating processes remain unchanged, and the casting rate in the black area remains unchanged. The casting temperature is between 1,450~1,500'c and the negative pressure increases accordingly. No reverse squish is found during the casting process. Test results: The casting results show that on an area of 12m2, there are only 3 carbon defects in the processing area of 3-5mm, 2 of which are minor, The machined surface is very smooth and beautiful, and the overall casting quality has been greatly improved. Compared with EPS sheets, carbon defects have been greatly increased. The machining allowance can be controlled at about 10mm, half that of EPS. It can greatly save cutting and repair costs, shorten the lead time, and reduce the scrap rate, as shown in Figure 1.6:

(2) A company of Hebei Province mainly produces automobile covering molds and is a direct subsidiary of a famous domestic automobile brand and a well-known domestic automobile covering mold casting company. The casting blank has a maximum weight of about 30T, and EPS sheets have been used for foam pattern making. Problems of easy deformation, numerous carbon defects, large machining allowances high cutting costs, high repair costs, long lead time, and high mold scrap rate are mainly found. Test plan: Use Castchem STMMA copolymer sheets with a pre-foaming density of 18±l KG/m3. The full mold manufacturing and coating processes remain unchanged, and the casting speed in the black areas remains unchanged. The casting temperature is between 1,450~1,500'c, and negative pressure is increased accordingly, No reverse squish is found during the casting process.

0 notes

Text

Is it possible to recycle EPS dust using an EPS densifier to efficiently reduce pollution?

Expanded polystyrene, or EPS for short, is a polymer that is frequently used in construction, packaging, and disposable dinnerware. Because EPS degrades slowly in nature, recycling material has become more crucial. Large foam blocks are typically disposed of as part of the primary EPS recycling process, but EPS dust—fine EPS particles produced during production or breakage—also has to be recycled effectively. Recycling EPS dust with an EPS densifier is a useful technique.

EPS densifiers typically recycle dust in this way. EPS dust is being recycled using the GREENMAX EPS densifier; typically, EPS dust is recycled in conjunction with EPS blocs. Both are simultaneously added to the feeding bin, where they are heated, melted, and formed into dense ingots. In certain cases, crushing EPS dust is not necessary if you wish to recycle it separately; instead, you can pour it directly into the silo for hot melting. The two primary recycling status quos are as follows. Dense ingots are created when the amount of trash processed with GREENMAX EPS densifier is reduced to one-90th of its initial size.

Recycling EPS dust with a hot melt machine is a cost-effective and efficient way to treat trash. Hot melt technology can be intelligently applied to minimize the volume of EPS, increase recycling efficiency, and reuse resources. Reducing environmental impact and promoting sustainable development can be achieved through the use of effective recycling procedures and equipment management. A significant volume of EPS dust can be processed effectively and turned into recyclable products using the hot melt equipment. This lessens the environmental impact and increases recycling efficiency. Resource recycling is achieved by using recycled EPS that has undergone hot melt processing to create new goods or find other uses. This preserves raw materials while also lowering the amount of waste produced. Efficient recycling can lessen EPS dust's negative environmental effects. The environmental issues associated with landfilling and incineration can be lessened by turning garbage into reusable resources.

0 notes

Video

youtube

XPE Foam cnc hot wire cutting machine, styrofoam cnc hot wire cutter, ep...

0 notes

Text

What Commonly Used Injection Molding Materials Have: An Insight into Their Properties and Applications.

Injection molding is a widely utilized manufacturing process that involves injecting molten material into a mold to create a wide array of products. The choice of material is crucial as it influences the properties, cost, and applications of the final product.

Here, we delve into some of the most used injection molding materials, exploring their characteristics and common applications.

1. Polypropylene (PP)

Characteristics:

Polypropylene is a type of plastic that is very versatile. It is lightweight, resists chemicals well, and can handle repeated stress without breaking. This makes it perfect for uses that need to be durable.

Applications:

PP is often used in packaging, car parts, everyday products, and medical devices. Repeated bending makes it great for items like living hinges that need to bend a lot.

2.Acrylonitrile Butadiene Styrene (ABS)

Characteristics:

ABS is a type of plastic made by mixing styrene and acrylonitrile with polybutadiene. This makes it very strong, tough, and keeps its shape well.

Applications:

ABS is commonly used in car parts, electronic cases, everyday items, and toys. Its strength and easy shaping also make it popular for 3D printing.

3. Polyethylene (PE)

Characteristics:

Polyethylene comes in different types like HDPE and LDPE. It resists chemicals, insulates electricity, and is flexible. HDPE is harder and more rigid, while LDPE is softer, more flexible, and melts at a lower temperature.

Applications:

PE is used for many items like containers, bottles, plastic bags, and toys. It is also great for medical and food packaging because it is safe and non-reactive.

4. Polycarbonate (PC)

Characteristics:

Polycarbonate is a strong type of plastic known for being tough and clear. It can be shaped easily and is used in many ways.

Applications:

Polycarbonate is often used in eyeglass lenses, medical tools, car parts, and electronics. Its clearness and strength make it perfect for things that need to be strong and easy to see through.

5. Polystyrene (PS)

Characteristics:

Polystyrene is a type of man-made plastic that comes in two types: solid and foam. It is light, stiff, and cheap to make.

Applications:

PS is used in things like disposable utensils, plastic models, CD cases, and foam packaging. The foam kind, called expanded polystyrene (EPS), is common in insulation and packing materials.

6. Nylon (Polyamide - PA)

Characteristics:

Nylon is a man-made material that is strong and flexible. It can handle being pulled hard, resist wear and tear, and is good with heat and chemicals.

Applications:

Nylon is used in cars, machines, everyday items, and clothes. It is tough and strong, perfect for parts that get a lot of use and pressure.

7.Polyethylene Terephthalate (PET)

Characteristics:

PET is a thermoplastic polymer resin of the polyester family. It is known for its strength, thermostability, and resistance to moisture.

Applications:

PET is widely used in beverage bottles, food packaging, and synthetic fibers. Its recyclability makes it a popular choice for environmentally conscious manufacturers.

Different materials used in injection molding have special qualities that suit various needs. For example, polypropylene is versatile and tough, while polycarbonate is strong and clear. Knowing these traits helps manufacturers pick the best material for their specific use, ensuring good performance, cost-efficiency, and eco-friendliness. As technology and materials improve, more options for injection molding become available, opening new possibilities for innovation in manufacturing.

There are 7 Most Common Injection Moulding Gate Types - Choosing a Gate for Your Project

An injection molding gate is a specially designed opening that controls how molten plastic flows into the mold. Its main job is to manage the amount and direction of the plastic as it fills the mold. There are different kinds of gates, such as edge gates, sub gates, and direct sprue gates, each with its own unique features and uses. We will look at these types more closely below.

Most common types of injection moulding gate:

Edge Gates

Tunnel / Submarine (Sub) Gates

Cashew Gates

Sprue or Direct Gates

Fan Gates

Diaphragm Gates

Pin Gates

Inject moulding is a prototyping tool made by HLH Rapid. Before beginning production, our engineers choose the ideal gate for your design and build bespoke moulds and parts based on your CAD drawings. Simply use our site contact form to send us your CAD designs and project specifics, including quantity, material, and any surface finishing. In a span of 24 to 48 hours, our staff will furnish an estimate.

Do you want to learn about Injection Molding or need a Free Quote? Submit your CAD drawings and project details, including quantity, material, and surface finish, through our site contact form. Our team will send you a quote within 24-48 hours.

0 notes

Video

youtube

eps compacting line/eps compactor with hydraulic/eps compactor/eps foam ...

#youtube#eps compactor#foam compactor#eps foam compactor#polystyrene compactor#styrofoam compactor#eps densifier#foam densifier#hydraulic compactor#oil hydraulic compactor#eps recycling#eps recycling machine#eps foam recycling#foam recycling#foam recycling machine#eps foam recycling machine

0 notes

Text

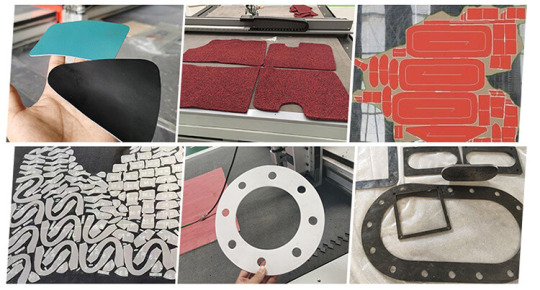

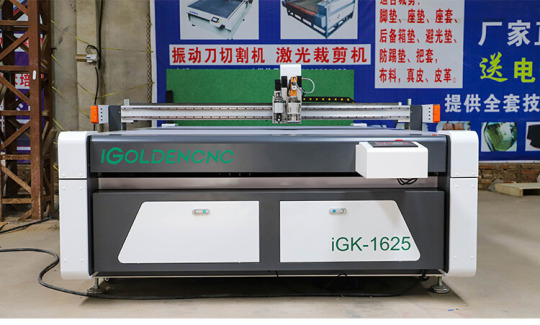

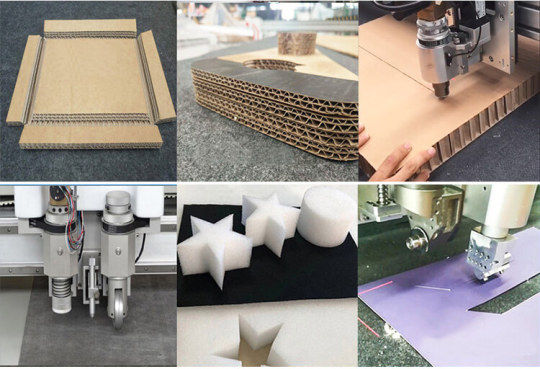

CNC Knife Cutter Machine for PE and EVA Foams

CNC knife cutter machines are widely used in industries such as packaging, textile, automotive, aerospace, and signage. They offer precise and efficient cutting capabilities, enabling the production of intricate shapes and patterns with minimal material waste.

Affordable cnc oscillating knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

CNC Knife Cutter Machine

A CNC knife cutter machine, also known as a CNC cutting machine or a CNC oscillating knife cutter, is a computer-controlled cutting system specifically designed for precision cutting of various materials. It utilizes a vibrating or oscillating knife, which moves rapidly up and down to cut through the material.

Affordable cnc oscillating knife machine have two types: ① CNC Router machine add oscillating knife cutting knife head (Knife together with spindle independent work, compatible with cnc router cotrol system, and running perfectly, Solve the processing needs of soft materials); ② Professional oscillating knife cutting machine ( Professional and efficient ). Accordding to functions: can be divided into oscillating knife cutting , round knife cutting, pneumatic knife cutting. you need to accordding to different material shapes cutting, choose different knives.

CNC can provide all kinds CNC Knife Cutter Machine for sale:

CCD camera series: automatic edge finding, automatic scanning, automatic imaging system.

CNC knife cutter machine table size:

CNC oscillating knife cutting machine for sale have model: 6090, 1390, 1410, 1610, 1325, 1530, 2030, and working table size 600*900mm, 900*1300mm, 1000*1400mm, 1000*1600mm, 1300*2500mm, 1500*3000mm, 2000*3000mm etc, maybe some regions describe cnc knife cutter machine table size with feet: 3*4, 3*5, 4*8, 5*10 etc. We also accept custom table sizes,to meet customer needs.

CNC Knife Cutter Machine Processing advantages

With the continuous development of numerical control technology, more and more customers choose to use smart cutting equipment instead of workers. It uses advanced oscillating knife cutting technology to select different tools according to material thickness and hardness. It can meet a variety of foam material cutting, such as EVA, EPE, sponge, EPS styrofoam and so on.

There are 6 advantages to using the CNC Knife Cutter Machine to cut the foam:

1. More flexible; EVA foam automatic cutting machine does not need a mold, just process the processing data (PLT, DXF, AI format) into the system to cut, and can modify the size and shape of the processing graphics arbitrarily;

2. Save materials; automatic nesting software can complete typesetting quickly and accurately without manual nesting. After actual testing, using an automatic cutting machine can save more than 10% of material compared to manual cutting;

3. Meet different foam cutting; can cut foam of different width, thickness, and material. High cutting precision and flat cutting to meet the cutting requirements of complex graphics.

4. The processing site is more humanized; AMOR EVA foam cutting machine adopts high-frequency oscillating knife cutting technology. Compared with laser cutting technology, the processing site has no soot, and the cutting speed is 3-4 times that of the laser. More environmentally friendly processing methods.

5. Different types of tools can be configured; customers can configure different processing tools according to the processing materials – round knife, pneumatic knife, punching knife, vibrating knife, and other cutter heads to configure freely to cut other materials except for foam;

6. Achieve higher cutting efficiency; AMOR EVA foam cutting machine adopts Japanese Mitsubishi servo motor with cutting speed of up to 2000mm/s. Customers can also choose dual-oscillating tools to cut at the same time, which doubles the processing efficiency.

CNC Knife cutter machine application

Affordable cnc Digital knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

Oscillating Knife Details

Cutting Capabilities

CNC knife cutter machine are versatile and can cut a wide range of materials, including but not limited to:

Soft materials: Foam, rubber, gaskets, textiles, carpets, felt, leather, etc.

Rigid materials: Cardboard, corrugated board, honeycomb board, thin plastics, composite materials, etc.

Other materials: Vinyl, paper, cork, magnetic sheets, adhesive-backed materials, and more.

The oscillating knife’s high-frequency motion allows for clean and precise cuts, even in intricate designs or complex patterns.

Additional Tool Option

In addition to the oscillating knife, CNC knife cutter machines can often accommodate other cutting tools or attachments, expanding their capabilities. Some common additional tools include:

Creasing wheels: Used for creating creases or scoring lines in materials like cardboard or paper, enabling easier folding or bending.

Perforation wheels: Used to create perforated lines for tear-off sections in materials like paper or cardboard.

Routing attachments: Used for cutting harder materials like acrylic or wood, where an oscillating knife may not be suitable.

The ability to interchange tools allows for more versatility in the types of materials and applications that can be handled by the machine.

High Precision and Repeatability

CNC knife cutter machines offer excellent precision and repeatability in cutting. The computer-controlled nature of the machine ensures accurate cutting paths, resulting in consistent and high-quality finished products. This is especially beneficial for industries that require precise fitting, such as packaging or automotive interior components.

Design Flexibility

With the help of specialized software, CNC knife cutter machines can process various design file formats, allowing for flexibility in design creation. Designs can be imported from computer-aided design (CAD) software or created directly within the cutting software. This flexibility enables customization, prototyping, and small-batch production with ease.

Production Efficiency

CNC knife cutter machines streamline the cutting process, reducing manual labor and increasing production efficiency. Once the cutting program is set up, the machine can autonomously execute the cutting tasks, optimizing material usage and minimizing waste. This automation also allows for faster turnaround times, enabling manufacturers to meet tight deadlines and handle larger production volumes.

Integration with Workflow

CNC knife cutter machine can be integrated into a larger production workflow, connecting with other equipment or systems. This integration facilitates seamless material handling, automated nesting (arranging shapes to minimize material waste), and data exchange, enhancing overall productivity and efficiency.

0 notes

Text

Plastic foam pelletizer is a device used to convert used or discarded plastic foam materials into granular form. It processes the foam material into reusable granules through a series of heating, extruding and cutting processes, providing convenience and efficiency for plastic recycling.

If you are interested in plastic foam granulator or other related products, please feel free to contact us through the following ways: WhatsApp/Tel/Wechat: +86 17303831295 Website: https://plasticsl.com/ Email: [email protected]

To know more about our products and services, please visit our website: https://plasticsl.com/epe-foam-pelletizing-machine/

#plastic recycling#plastic pelletizing machine#plastic granulating#plastic pelletizing#plasticgranulator

0 notes

Text

How to Choose the Best Foam Cutting Machine for Your Business in India

In today's era of sustainability and innovation, businesses across various industries in India are increasingly turning towards foam cutting machines to streamline their operations. Whether you're in the packaging, furniture manufacturing, or construction industry, investing in the right foam cutting machine can significantly enhance productivity and efficiency while reducing costs. However, with a plethora of options available in the market, choosing the best foam cutting machine for your business can be a daunting task. To help you navigate through this decision-making process, we've compiled a comprehensive guide outlining key factors to consider when selecting a foam cutting machine tailored to your specific business needs.

Understand Your Business Requirements: Before diving into the selection process, it's crucial to assess your business requirements thoroughly. Determine the type and volume of foam materials you'll be working with, the desired cutting precision, production capacity, and budget constraints. Understanding these factors will provide clarity on the type of foam cutting machine that best suits your business operations.

Types of Foam Cutting Machines: Foam cutting machines come in various types, each designed for specific cutting applications. The commonly used types include:

Hot Wire Foam Cutters: Ideal for cutting through expanded polystyrene (EPS) foam with precision and smooth edges. Suitable for intricate shapes and designs.

CNC Foam Cutting Machines: Computer Numerical Control (CNC) machines offer unparalleled precision and versatility in cutting foam materials. They are programmable and can produce complex shapes with high accuracy.

Vertical Foam Cutting Machines: Suited for cutting large foam blocks into sheets or custom sizes. They are efficient for bulk production and are commonly used in the furniture and mattress manufacturing industries.

Horizontal Foam Cutting Machines: Designed for cutting foam blocks horizontally into uniform sheets. They are suitable for applications requiring consistent thickness, such as packaging and insulation materials.

Cutting Capacity and Efficiency: Consider the cutting capacity and efficiency of the foam cutting machine in relation to your business requirements. Assess factors such as cutting speed, throughput, and the ability to handle different foam densities and thicknesses. Opt for a machine that offers optimal performance and can meet your production demands without compromising on quality.

Precision and Cutting Quality: The precision and cutting quality of the foam cutting machine are paramount, especially for industries requiring intricate designs or high-quality finished products. Look for machines equipped with advanced cutting technologies, such as servo motors and precision guides, to ensure accurate and consistent cuts.

Ease of Operation and Maintenance: Choose a foam cutting machine that is user-friendly and easy to operate, minimizing training time and operational complexities. Additionally, consider the maintenance requirements of the machine, including access to spare parts and technical support. A reliable after-sales service network is essential to ensure smooth operation and timely troubleshooting.

Safety Features: Prioritize safety features when selecting a foam cutting machine to protect your workers and maintain a safe working environment. Look for features such as emergency stop buttons, safety guards, and automatic shutdown mechanisms to mitigate the risk of accidents and injuries.

Cost and Return on Investment (ROI): While cost is a significant factor, it's essential to evaluate the overall return on investment (ROI) of the foam cutting machine. Consider factors such as long-term operational costs, energy efficiency, and potential savings in material wastage. Investing in a quality foam cutting machine may entail a higher initial cost but can yield substantial returns through improved productivity and product quality over time.

Reputation and Customer Reviews: Research the reputation of the foam cutting machine manufacturer or supplier in the industry. Look for reviews and testimonials from other businesses who have used their products. A reputable manufacturer with positive customer feedback is more likely to deliver reliable and high-quality machines that meet your expectations.

Customization and Additional Features: Evaluate whether the foam cutting machine offers customization options or additional features that align with your business requirements. Some machines may come with optional accessories or software upgrades that enhance functionality and expand cutting capabilities.

Future Expansion and Scalability: Anticipate your future business growth and consider whether the chosen foam cutting machine can accommodate expansion or scalability. Selecting a machine with modular design or upgradeable features allows you to adapt to changing market demands and increase production capacity as needed.

In conclusion, choosing the best foam cutting machine for your business in India requires careful consideration of various factors, including your specific requirements, cutting applications, efficiency, precision, safety, and overall cost-effectiveness. By thoroughly evaluating these factors and conducting thorough research, you can select a foam cutting machine that maximizes productivity, enhances product quality, and drives long-term success for your business.

#Foam Cutting#Foam Cutting Machines#Santech Foam Machines#Vertical Foam Cutting Machines#Horizontal Foam Cutting Machines#Best Foam Cutting Machines in India

0 notes

Text

Characteristics of copolymer sheet

The copolymer sheets include STMMA and STMMA-FD copolymer sheets (FD sheets for short). STMMA copolymer sheets are mainly used for the casting of ductile iron and steel castings, and the FD sheets are mainly used for the casting of gray cast iron. The copolymer sheets do not contain any flame-retardant ingredients and have the characteristics of low carbon and fewer slags, sufficient combustion, high gas evolution rate, and easy decomposition. Recarburization and carbon defects can be significantly reduced. Compared with EPS sheets, STMMA casting-specific sheets have the following advantages:

(1)Low carbon content, easy decomposition and less recarbonization EPS has a relatively high carbon content (92%), and its molecular structure is a relatively stable benzene ring structure (as shown in Figure 1.3(a)). It is not easy to decompose when heated, EPS is broken and decomposed in a disordered manner, it is not easy to gasify instantly, and residues that are not easy to decompose are generated. STMMA has a small carbon-to-hydrogen ratio (shown in Figure 1.3(b)) and low carbon content (63%)and is broken and decomposed in a zipper-like manner at high temperatures, having more honeycombs inside, which increases the contact area between the material and the air and accelerates the burning rate of the material. The molecular structure contains oxygen atoms. During heating and combustion, oxygen atoms react with carbon atoms to generate gas, so few residues are generated.

(2)Good gasification, few residues, and fewer carbon defects STMMA casting-specific sheets are well gasified, and most foam models are decomposed into products such as CO, CO2, water, and carbides during the casting process. Low molecular gases can escape through the coating layer, so few residues are generated in the foam pattern, Experimental data shows that for EPS and STMMA copolymer sheets of the same density, the residues on the STMMA copolymer sheets under high-temperature casting conditions are about one-tenth of that of the EPS sheets.

(3) Reducing the amount of patching, eliminating secondary processing of castings, and improving the quality of castings. Since STMMA casting-specific sheets have excellent casting properties such as low carbon content, easy decomposition, less recarbonization, good gasification, and fewer residues and carbon defects, castings made of STMMA casting-specific sheets have a high surface finish and less recarbonization and carbon defects, and the machined surface is smooth and flat, and the quality of castings is greatly improved. Only then can casting companies reduce the amount of patching, eliminate secondary processing of castings, and thereby reduce the total production costs of castings. Moreover, the production cycle of castings has also been shortened, thereby achieving the goals of rapid production and delivery. The appearance of the sheets is shown in Figure 1.4, and the sheet production site is shown in Figure 1.5.

1 note

·

View note

Text

0 notes