#environmental testing

Explore tagged Tumblr posts

Text

Benefits of Consumer Product Testing

Discover how consumer product testing plays a critical role in ensuring product success. From minimizing failure risks to boosting quality and customer satisfaction, this infographic highlights key benefits of Consumer Product Testing.

#battery testing#environmental testing#refrigerator appliances#battery testing services#lab testing services#cell testing

0 notes

Text

Environmental Testing Lab | +971 554747210

0 notes

Text

Environmental Testing Labs and Their Role in ISO 14001 Certification

As businesses worldwide increasingly focus on sustainable practices, achieving ISO 14001 certification has become a key objective for companies committed to environmental responsibility. ISO 14001 is an internationally recognized standard for Environmental Management Systems (EMS), guiding organizations to minimize their environmental impact while complying with regulations and improving efficiency.

One of the most crucial partners in this journey is the Environmental Testing Lab. These labs provide the scientific data and analysis necessary to evaluate environmental performance, identify risks, and verify compliance with ISO 14001 standards. This blog explores the essential role that environmental testing labs play in helping organizations achieve and maintain ISO 14001 certification.

What is ISO 14001 Certification?

ISO 14001 is a globally accepted standard that provides a framework for organizations to develop an effective EMS. It emphasizes continual improvement, pollution prevention, and compliance with environmental laws.

Key components of ISO 14001 include:

Environmental policy development

Planning and identifying environmental aspects and impacts

Setting objectives and targets

Implementing operational controls

Monitoring and measurement

Internal audits and management reviews

By adopting ISO 14001, organizations demonstrate a proactive commitment to environmental stewardship, which can enhance reputation, reduce costs, and improve regulatory compliance.

Why Are Environmental Testing Labs Crucial for ISO 14001 Certification?

ISO 14001 requires organizations to measure and monitor environmental performance accurately. This is where environmental testing labs come in:

1. Objective Measurement of Environmental Impact

Environmental testing labs provide precise measurement of air, water, soil, and waste samples. These objective data points allow organizations to understand their environmental footprint accurately and identify areas for improvement.

2. Identifying Environmental Aspects and Impacts

The ISO 14001 framework mandates identifying environmental aspects (elements of an organization’s activities that can interact with the environment) and their impacts. Testing labs analyze emissions, effluents, and waste to quantify these impacts scientifically.

3. Regulatory Compliance Monitoring

ISO 14001 requires organizations to comply with relevant environmental laws. Environmental labs verify whether pollutant levels meet local, national, and international regulations, helping companies avoid legal penalties and fines.

4. Baseline Establishment and Continuous Improvement

Testing labs help establish baseline environmental performance data at the start of the EMS implementation. Continuous monitoring and retesting allow organizations to track improvements and adjust strategies for better environmental outcomes.

Key Environmental Parameters Tested for ISO 14001 Compliance

Environmental testing labs conduct a range of tests essential for ISO 14001 certification, including:

Air Quality Testing

Measurement of pollutants such as sulfur dioxide (SO2), nitrogen oxides (NOx), particulate matter (PM), and volatile organic compounds (VOCs)

Ensuring emissions meet regulatory thresholds to protect air quality

Water Quality Testing

Analyzing wastewater for chemical oxygen demand (COD), biological oxygen demand (BOD), heavy metals, pH, and microbial contamination

Verifying treated effluents meet discharge standards to protect water bodies

Soil Testing

Assessing soil contamination levels from industrial activities

Identifying heavy metals, hydrocarbons, and pesticide residues impacting soil health

Waste Characterization

Testing hazardous and non-hazardous waste streams to determine appropriate disposal or recycling methods

Ensuring compliance with waste management regulations

How Environmental Testing Labs Support the ISO 14001 EMS Cycle

The ISO 14001 EMS operates on a Plan-Do-Check-Act (PDCA) cycle. Environmental testing labs play a critical role throughout this process:

Plan

During planning, organizations identify significant environmental aspects and legal requirements. Labs provide baseline data to support risk assessments and objective setting.

Do

Operational controls and procedures are implemented to manage environmental impacts. Labs assist by validating pollution control systems and monitoring emissions.

Check

Environmental testing labs conduct regular monitoring and testing to measure performance against objectives and regulatory limits. This stage ensures transparency and accountability.

Act

Based on lab results, management can review performance, identify non-conformities, and implement corrective actions to improve environmental outcomes continuously.

Benefits of Partnering with Accredited Environmental Testing Labs

Choosing the right environmental testing lab is vital for credible ISO 14001 certification. Accredited labs, certified to standards such as ISO/IEC 17025, offer several advantages:

Reliable and Accurate Data: Accredited labs use validated methods and calibrated equipment to ensure trustworthy results.

Regulatory Acceptance: Results from accredited labs are widely accepted by certification bodies and regulators.

Comprehensive Reporting: Detailed, transparent reports facilitate management reviews and audits.

Expert Consultation: Labs often provide guidance on sampling protocols, data interpretation, and compliance strategies.

Wide Range of Testing Services: Accredited labs cover chemical, microbiological, physical, and toxicological analyses needed for thorough EMS monitoring.

Common Challenges and How Testing Labs Help Overcome Them

Organizations pursuing ISO 14001 certification often encounter challenges, including:

Complex Regulatory Environment

With evolving environmental laws, it can be difficult to stay updated and compliant. Environmental labs help by providing testing aligned with current regulations and alerting companies to changes.

Technical Expertise Gaps

Many companies lack in-house expertise for environmental sampling and testing. Labs fill this gap with specialized knowledge and equipment.

Data Accuracy and Consistency

Inconsistent data can undermine certification efforts. Accredited labs maintain stringent quality control to deliver precise, reproducible results.

Case Example: Environmental Testing Labs in Action for ISO 14001

Consider a manufacturing plant aiming for ISO 14001 certification. The plant partners with an environmental testing lab to:

Conduct baseline air and water quality testing

Monitor emissions from smokestacks and effluent discharge points

Analyze soil samples near the facility to detect contamination

Characterize waste streams for proper disposal

Using the lab’s data, the company identifies high nitrogen oxide emissions, prompting upgrades to air filtration systems. Continuous testing shows improvements, supporting successful ISO 14001 certification and compliance with local environmental laws.

Conclusion

Achieving ISO 14001 certification is a strategic step for organizations committed to environmental sustainability. However, success hinges on reliable data and compliance verification, which only Environmental Testing Labs can provide.

From baseline assessments to ongoing monitoring, these labs offer critical scientific support to measure environmental impacts, ensure regulatory compliance, and drive continual improvement. Partnering with an accredited environmental testing lab is not just beneficial—it is essential for organizations seeking to demonstrate genuine environmental responsibility and achieve ISO 14001 certification.

0 notes

Text

Environmental Testing Lab – EKO Testing Labs

EKO Testing Labs is a trusted Environmental Testing Lab serving Ghaziabad, Noida, and Delhi. We specialize in providing accurate and reliable environmental testing services to ensure safety, compliance, and quality. Our lab is equipped with advanced technology and operated by experienced professionals, delivering results you can trust.

Our Services Include:

Air Quality Testing

Water & Wastewater Testing

Soil Testing

Noise & Vibration Monitoring

Environmental Compliance & Reporting

Whether you’re an industry, construction site, or government organization, EKO Testing Labs ensures all environmental standards are met. We deliver fast turnaround times, competitive pricing, and expert consultation.

Service Areas: Ghaziabad, Noida, Delhi

Call Us: 9810240678

Business Name: EKO Testing Labs

Contact us today for comprehensive environmental testing solutions.

0 notes

Text

NABL Accreditation: Ensuring Excellence in Laboratory Testing.

In today's rapidly advancing scientific and medical fields, the accuracy and reliability of laboratory results are paramount. Whether it's a medical diagnosis, environmental testing, or product quality assurance, the credibility of test results can significantly impact health, safety, and regulatory compliance. This is where NABL accreditation plays a crucial role.

What is NABL Accreditation?

The National Accreditation Board for Testing and Calibration Laboratories (NABL) is an autonomous body under the Quality Council of India (QCI), established by the Department of Science and Technology, Government of India. NABL provides accreditation to laboratories based on international standards, ensuring their competence and reliability in producing accurate and precise test results.

NABL accreditation is granted to laboratories that meet the requirements of various standards, including:

ISO/IEC 17025: General requirements for the competence of testing and calibration laboratories.

ISO 15189: Medical laboratories – Requirements for quality and competence.

ISO/IEC 17043: Conformity assessment – General requirements for proficiency testing.

ISO/IEC 17034: General requirements for the competence of reference material producers.

Importance of NABL Accreditation

1. Assurance of Quality and Reliability

NABL accreditation laboratory signifies that a laboratory has undergone a rigorous evaluation process, assessing its technical competence, quality management systems, and adherence to international standards. This ensures that the laboratory consistently produces accurate and reliable results, instilling confidence in clients and stakeholders.

2. Compliance with Regulatory Requirements

Many industries and sectors are governed by stringent regulatory standards that mandate the use of accredited laboratories for testing and calibration. NABL accreditation helps laboratories comply with these regulations, facilitating smoother operations and reducing the risk of legal issues.

3. Enhanced Customer Confidence

Clients seeking laboratory services often prioritize quality and reliability. NABL-accredited laboratories demonstrate their commitment to excellence, building trust and long-term relationships with clients. The accreditation serves as a mark of credibility, assuring clients that the laboratory meets high standards of quality and competence.

4. Access to Global Markets

NABL is a signatory to international mutual recognition arrangements, such as the International Laboratory Accreditation Cooperation (ILAC) and the Asia Pacific Laboratory Accreditation Cooperation (APLAC). This recognition allows NABL-accredited laboratories to have their test results accepted globally, facilitating international trade and cooperation.

5. Continuous Improvement and Operational Efficiency

The process of obtaining and maintaining NABL accreditation encourages laboratories to establish robust quality management systems, implement standard operating procedures, and engage in regular internal audits. This fosters a culture of continuous improvement, leading to enhanced operational efficiency and reduced errors.

NABL Accreditation Process

The journey to NABL accreditation involves several key steps:

Application Submission: Laboratories interested in accreditation submit an application to NABL, providing details about their scope of services, facilities, and quality management systems.

Document Review: NABL reviews the laboratory's documentation, including quality manuals, standard operating procedures, and records, to ensure compliance with relevant standards.

On-Site Assessment: A team of NABL assessors conducts an on-site evaluation of the laboratory's facilities, equipment, and personnel competence. This includes witnessing testing procedures and reviewing records.

Corrective Actions: If any non-conformities are identified during the assessment, the laboratory is required to implement corrective actions and provide evidence of their resolution.

Accreditation Decision: Based on the assessment findings and corrective actions taken, NABL makes an accreditation decision. If granted, the laboratory receives a certificate outlining the scope of its accreditation.

Surveillance and Reassessment: To maintain accreditation, laboratories undergo periodic surveillance visits and reassessments to ensure ongoing compliance with NABL requirements.

Benefits of NABL Accreditation

International Recognition: NABL-accredited laboratories are recognized globally, facilitating acceptance of their test results in international markets.

Improved Marketability: Accreditation enhances the laboratory's reputation, making it more attractive to potential clients and partners.

Risk Mitigation: By adhering to established standards and procedures, laboratories reduce the risk of errors, rework, and non-compliance.

Operational Excellence: The accreditation process promotes the implementation of best practices, leading to improved efficiency and effectiveness.

Competitive Advantage: Laboratories with NABL accreditation can differentiate themselves in the marketplace, gaining a competitive edge over non-accredited counterparts.

Conclusion

NABL accreditation laboratory is a testament to a laboratory's commitment to quality, competence, and continuous improvement. It provides assurance to clients and stakeholders that the laboratory's test results are accurate, reliable, and compliant with international standards. For laboratories, obtaining and maintaining NABL accreditation not only enhances their credibility but also opens doors to global markets and fosters operational excellence. In an era where precision and reliability are paramount, NABL accreditation serves as a cornerstone for laboratories striving to meet the highest standards of quality and performance.

In today's rapidly advancing scientific and medical fields, the accuracy and reliability of laboratory results are paramount. Whether it's a medical diagnosis, environmental testing, or product quality assurance, the credibility of test results can significantly impact health, safety, and regulatory compliance. This is where NABL accreditation plays a crucial role.

What is NABL Accreditation?

The National Accreditation Board for Testing and Calibration Laboratories (NABL) is an autonomous body under the Quality Council of India (QCI), established by the Department of Science and Technology, Government of India. NABL provides accreditation to laboratories based on international standards, ensuring their competence and reliability in producing accurate and precise test results.

NABL accreditation is granted to laboratories that meet the requirements of various standards, including:

ISO/IEC 17025: General requirements for the competence of testing and calibration laboratories.

ISO 15189: Medical laboratories – Requirements for quality and competence.

ISO/IEC 17043: Conformity assessment – General requirements for proficiency testing.

ISO/IEC 17034: General requirements for the competence of reference material producers.

Importance of NABL Accreditation

1. Assurance of Quality and Reliability

NABL accreditation laboratory signifies that a laboratory has undergone a rigorous evaluation process, assessing its technical competence, quality management systems, and adherence to international standards. This ensures that the laboratory consistently produces accurate and reliable results, instilling confidence in clients and stakeholders.

2. Compliance with Regulatory Requirements

Many industries and sectors are governed by stringent regulatory standards that mandate the use of accredited laboratories for testing and calibration. NABL accreditation helps laboratories comply with these regulations, facilitating smoother operations and reducing the risk of legal issues.

3. Enhanced Customer Confidence

Clients seeking laboratory services often prioritize quality and reliability. NABL-accredited laboratories demonstrate their commitment to excellence, building trust and long-term relationships with clients. The accreditation serves as a mark of credibility, assuring clients that the laboratory meets high standards of quality and competence.

4. Access to Global Markets

NABL is a signatory to international mutual recognition arrangements, such as the International Laboratory Accreditation Cooperation (ILAC) and the Asia Pacific Laboratory Accreditation Cooperation (APLAC). This recognition allows NABL-accredited laboratories to have their test results accepted globally, facilitating international trade and cooperation.

5. Continuous Improvement and Operational Efficiency

The process of obtaining and maintaining NABL accreditation encourages laboratories to establish robust quality management systems, implement standard operating procedures, and engage in regular internal audits. This fosters a culture of continuous improvement, leading to enhanced operational efficiency and reduced errors.

NABL Accreditation Process

The journey to NABL accreditation involves several key steps:

Application Submission: Laboratories interested in accreditation submit an application to NABL, providing details about their scope of services, facilities, and quality management systems.

Document Review: NABL reviews the laboratory's documentation, including quality manuals, standard operating procedures, and records, to ensure compliance with relevant standards.

On-Site Assessment: A team of NABL assessors conducts an on-site evaluation of the laboratory's facilities, equipment, and personnel competence. This includes witnessing testing procedures and reviewing records.

Corrective Actions: If any non-conformities are identified during the assessment, the laboratory is required to implement corrective actions and provide evidence of their resolution.

Accreditation Decision: Based on the assessment findings and corrective actions taken, NABL makes an accreditation decision. If granted, the laboratory receives a certificate outlining the scope of its accreditation.

Surveillance and Reassessment: To maintain accreditation, laboratories undergo periodic surveillance visits and reassessments to ensure ongoing compliance with NABL requirements.

Benefits of NABL Accreditation

International Recognition: NABL-accredited laboratories are recognized globally, facilitating acceptance of their test results in international markets.

Improved Marketability: Accreditation enhances the laboratory's reputation, making it more attractive to potential clients and partners.

Risk Mitigation: By adhering to established standards and procedures, laboratories reduce the risk of errors, rework, and non-compliance.

Operational Excellence: The accreditation process promotes the implementation of best practices, leading to improved efficiency and effectiveness.

Competitive Advantage: Laboratories with NABL accreditation can differentiate themselves in the marketplace, gaining a competitive edge over non-accredited counterparts.

Conclusion

NABL accreditation laboratory is a testament to a laboratory's commitment to quality, competence, and continuous improvement. It provides assurance to clients and stakeholders that the laboratory's test results are accurate, reliable, and compliant with international standards. For laboratories, obtaining and maintaining NABL accreditation not only enhances their credibility but also opens doors to global markets and fosters operational excellence. In an era where precision and reliability are paramount, NABL accreditation serves as a cornerstone for laboratories striving to meet the highest standards of quality and performance.

0 notes

Text

The global environment testing market is expected to grow from USD 7.43 billion in 2025 to USD 9.32 billion by 2030, at a CAGR of 4.6%. This growth is driven by increasing regulatory compliance, rising environmental concerns, and advancements in testing technologies.

#Environmental Testing Market#Environmental Testing#Environmental Testing Market Size#Environmental Testing Market Share#Environmental Testing Market Growth#Environmental Testing Market Trends#Environmental Testing Market Forecast#Environmental Testing Market Analysis#Environmental Testing Market Report#Environmental Testing Market Scope#Environmental Testing Market Overview#Environmental Testing Market Outlook#Environmental Testing Market Drivers#Environmental Testing Industry#Environmental Testing Companies

0 notes

Text

NexorTest Technologies | Expert EMI Testing Services in Bengaluru

NexorTest Technologies is a leading provider of EMI Testing Services in Bengaluru, offering ISO/IEC 17025 accredited testing and expert regulatory consultation. We cater to industries such as aerospace, defense, automotive, and more, ensuring your products meet global compliance standards, including CE, BIS, FCC, and USFDA-MDR certifications. To learn more about our EMI testing services, visit

#EMI testing services in bengaluru#emi testing services#nexortest technologies#nexortest#emi emc testing in bengaluru#environmental testing

0 notes

Text

#emctestlabs#EMC#ESDTEST#electromagnetic compatibility#Transient Immunity#Impulse Noise Test#climatic test#environmental testing#Radiated immunity#Radiated Emission#Conducted Immunity#Conducted Emission#Magnetic Immunity#Magnetic Emission#Automotive ECU Testing#ESD Test#EMC Test#emc testing#Transient Test#Pulse 1#Pulse 2a#Pulse 2b#Pulse 3a#Pulse 3b#Pulse 4#Pulse A1A2#Pulse B1B2#Load Dump#Starting Profile#Reset Behavior

1 note

·

View note

Text

Asbestos Construction Augusta

0 notes

Text

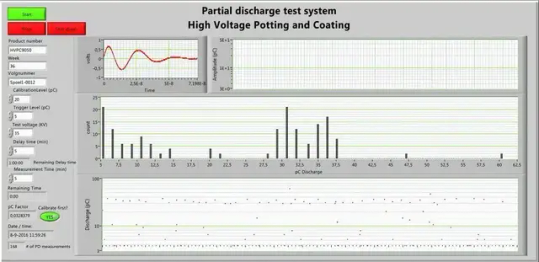

Boost Your Reliability Of HV Electronics With Partial Discharge Test | HV Products, GmbH

Monitoring partial discharge is essential for assessing the reliability of high-voltage electronics in important applications such as flexible layers.

We provide design services for auxiliary circuits, environmental testing, and product specifications. Our testing facility supports high-voltage testing up to 100 kV.

Know more!

#Partial Discharge Test#high-voltage electronics#auxiliary circuits#environmental testing#HV Products#high voltage products#high voltage#hvp#HV test & measurement

0 notes

Text

0 notes

Text

All You Need To Know About Energy Efficiency Testing

Today, competition is so much higher in the market. If you are a manufacturer of products like refrigerators or air conditioners, your items must undergo thorough energy efficiency testing. This ensures your products are of high quality, work efficiently, and last longer. In this post, we will explore energy efficiency testing, including its types and why it’s important for you. Let’s dive in!

What is energy efficiency testing?

Energy efficiency testing checks if a product saves energy and works properly without wasting power. A trained team of professionals performs many evaluations to check the overall power consumption of your appliance. This helps you to build products that reduce energy bills, protect the environment, and comply with safety regulations as well. Various categories, such as consumer electronics, home appliances, commercial kitchen equipment, office electronics, heating equipment, cooling equipment, lighting products, industrial machines, and water heating systems, are required to undergo this test to ensure that they are energy efficient.

Why Energy Efficiency Testing is Required?

Today, manufacturers need to do efficiency testing to make their products work better and last longer. This inspection method ensures that the product you build uses less electricity and still functions properly. With a thorough energy efficiency test, you can ensure that your home appliances save energy and reduce your electricity bills. This evaluation method makes your product more sustainable for the environment.

Energy efficiency testing is necessary to align your product with local and global authorities, which set rules and regulations for all manufacturers. Therefore, you need to contact a testing laboratory to get expert help and use their expertise to meet the standards. For example, if you accidentally build a fan that consumes too much power, environmental testing can help fix the problem. This testing is important for companies to offer better and cost-saving products.

Types of Energy Efficiency Testing

There are many types of energy efficiency testing that you can use based on your specific needs and purpose. Each type focuses on a distinct part or feature of the product. For example, standby power testing is dedicated to checking how much power a refrigerator uses when it is running or in standby mode. Let’s talk about the types of energy efficiency testing you should know about:

Power Consumption Testing

Power consumption testing is a crucial method because it checks how much electricity a product uses during operation. This evaluation methodology helps manufacturers identify and reduce the excess energy use of their products. A team of testers uses equipment such as power meters and watt-hour meters to ensure efficient operations. Products such as refrigerators, fans, televisions, and computers have to undergo this mechanical testing.

This step helps product manufacturers know the electricity their product uses. In television testing, trained experts can turn on your TV and connect it to an electricity meter to measure its energy consumption. This approach helps you know its power consumption. You can make the products more energy-efficient and cost-saving for users.

Standby Power Testing

Standby power testing is another type of energy efficiency testing to check how much electricity a product uses when it is off but still plugged in. Testers use tools like a power meter or wattmeter to measure standby energy use. Products like TVs, microwaves, chargers, and set-top boxes are required for this testing. For example, in household appliances testing, a team of testers check your commercial kitchen equipment. They can plug the product in and turn it off. The meter shows its power consumption. This helps create appliances that save energy even when not in use.

Load Testing

Load testing in energy efficiency is a crucial method to check how a product uses electricity under different working loads. For example, if you are a manufacturer of air conditioners and you connect with a testing laboratory. Their team can test your AC at full and half cooling levels. Tools like power meters, load simulators, and data loggers are used. You can test your fans, heaters, pumps, and other products. Load testing enables manufacturers to measure energy usage in high and low settings. This ensures that the product remains efficient in all working conditions.

Thermal Efficiency Testing

Thermal efficiency testing is an important type of energy efficiency testing that checks how well a product converts energy into heat without wasting it. Experts use equipment such as thermal sensors, data loggers, and infrared cameras. That helps them get accurate results with minimal errors.

Electric water heater testing is essential to check how well your product converts heat into energy without wasting it. For example, a geyser is tested to see how quickly it heats water and how much energy it wastes as heat. This helps manufacturers to produce reliable and quality water heaters for their target consumers.

Efficiency Rating Testing

Efficiency rating testing involves checking how much energy a product uses and giving it a star rating (from 1 star to 5 stars). This device is designed for use with devices such as electricity meters, load testers, and energy analyzers. Many products like refrigerators, air conditioners, fans, and washing machines must go through this test.

For example, a refrigerator is periodically tested for its electricity usage, and based on the results, it is given a rating. This is how it is made efficient and efficient in using electricity. A 1-star electrical product means that it consumes high electricity while working poorly. On the other hand, 5-star electrical products offer perfect functioning, minimal power usage, and high performance.

Bottom Line

Energy efficiency tests are designed to develop high-quality and energy-efficient products. This supports the efforts of manufacturers, importers, and even retailers. Energy efficiency testing detects any problems or defects in your product and lets you rework them before selling it in the market. This evaluation method is ideal for small and large manufacturers who build electric products. They can meet local and global compliance with regulations. Connecting with a testing laboratory provides you with a comprehensive report after in-depth testing. Their support helps you establish a reputation and trust in the market.

0 notes

Text

Environmental Testing Lab | +971 554747210

0 notes

Text

How Manufacturing Plants Benefit from Environmental Lab Testing?

In today's industrial landscape, sustainability, environmental compliance, and public health are critical priorities for manufacturing companies. With growing regulations and rising public concern over pollution and climate change, manufacturing plants are under pressure to monitor and mitigate their environmental impact. This is where an Environmental Testing Lab becomes a vital partner.

These labs offer scientific testing and analysis of air, water, soil, and waste materials to ensure that manufacturing processes remain compliant, efficient, and environmentally responsible. In this blog, we’ll explore how manufacturing plants benefit from environmental lab testing, and why it's a strategic investment for long-term success.

What is an Environmental Testing Lab?

An Environmental Testing Lab is a certified facility equipped to assess environmental samples using advanced instrumentation and analytical methods. These labs help identify pollutants, evaluate risks, and ensure compliance with national and international environmental standards.

They perform a range of tests, including:

Air quality and emissions testing

Wastewater analysis

Soil contamination assessments

Hazardous waste characterization

Noise and vibration monitoring

Indoor air and occupational safety testing

For manufacturing plants, these services are critical to maintaining operational compliance and avoiding environmental damage.

1. Regulatory Compliance and Legal Protection

One of the foremost reasons manufacturing plants rely on environmental testing is to comply with environmental regulations. Governments enforce strict rules on emissions, wastewater discharge, and hazardous waste management.

Environmental Testing Labs help manufacturers:

Monitor compliance with local and international laws (e.g., EPA, ISO 14001, REACH, UAE EAD, GCC regulations)

Prepare data for environmental audits and reporting

Obtain necessary permits and certifications

Avoid legal penalties, fines, and shutdowns

Without accurate testing data, manufacturers risk breaching regulations, which could damage their finances and reputation.

2. Improved Environmental Performance

Environmental testing identifies inefficiencies and environmental risks in manufacturing operations. By analyzing emissions, waste streams, and water usage, labs provide actionable data that can lead to:

Reduced pollutant output

Optimized waste disposal methods

More efficient resource use

Safer chemical handling practices

This results in cleaner production, lower environmental impact, and alignment with sustainability goals.

3. Protection of Worker and Community Health

Manufacturing plants often use chemicals, release emissions, and generate waste that can pose health risks. Environmental Testing Labs help assess these risks and recommend mitigation strategies.

Testing can detect:

Volatile organic compounds (VOCs)

Heavy metals in water or soil

Hazardous airborne particles

Chemical spills or leaks

Indoor air pollutants

Protecting workers and nearby communities from exposure not only demonstrates corporate responsibility but also improves workplace safety and community relations.

4. Support for ISO and Environmental Certifications

Many manufacturers pursue ISO 14001 certification and other environmental management system standards. Testing data is essential to this process.

An Environmental Testing Lab supports:

Documentation and monitoring for ISO audits

Tracking of environmental Key Performance Indicators (KPIs)

Compliance with ESG (Environmental, Social, Governance) reporting

Third-party verification of sustainability efforts

Certifications help manufacturers win contracts, attract investors, and enhance brand reputation.

5. Waste Management Optimization

Improper waste disposal is a major environmental and regulatory risk. Environmental labs test and classify waste materials to help manufacturers:

Identify hazardous vs. non-hazardous waste

Comply with waste disposal and transport laws

Reduce overall waste volume

Identify opportunities for recycling and reuse

Accurate waste classification saves money and reduces environmental liability.

6. Air Emissions Monitoring

Manufacturing processes often release pollutants into the atmosphere. Air quality testing is crucial for maintaining safe levels of emissions and meeting clean air regulations.

Labs test for:

Particulate matter (PM2.5, PM10)

Nitrogen oxides (NOx)

Sulfur dioxide (SO₂)

Carbon monoxide (CO)

VOCs and greenhouse gases

Continuous monitoring ensures that air pollution is minimized, helping manufacturers reduce their carbon footprint and meet climate targets.

7. Water and Wastewater Analysis

Manufacturing plants use significant volumes of water and produce wastewater that may contain harmful contaminants. An Environmental Testing Lab evaluates:

Water quality for operational use

Industrial effluent characteristics

Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD)

Heavy metals, pH, and other chemical parameters

This helps ensure safe water discharge, reduce treatment costs, and meet environmental discharge standards.

8. Soil Testing for Site Safety

For manufacturers operating on large industrial sites or expanding facilities, soil testing is essential to assess contamination and suitability for use.

Labs test for:

Heavy metals (lead, arsenic, mercury)

Hydrocarbons and petroleum products

Pesticide residues

Soil acidity and composition

This information is vital during site development, remediation, or sale, protecting the business from future liabilities.

9. Noise and Vibration Monitoring

Industrial equipment and operations often generate high levels of noise and vibration. These may affect workers and surrounding communities.

Environmental Testing Labs can:

Measure occupational and environmental noise

Evaluate compliance with noise control regulations

Recommend engineering or administrative controls

Help prevent worker hearing loss and neighborhood complaints

Monitoring ensures a safer and more compliant work environment.

10. Reputation and Market Advantage

Environmental responsibility is increasingly tied to business success. Consumers, investors, and partners prefer to engage with manufacturers that demonstrate sustainable practices.

Testing by an accredited Environmental Testing Lab builds trust and provides:

Credible environmental reporting

Proof of green initiatives for marketing

Competitive advantage in eco-conscious markets

Better access to green financing or ESG-aligned investment funds

A good environmental record can be a powerful asset in the marketplace.

Conclusion

As sustainability and environmental regulations become central to business strategy, manufacturing plants must invest in reliable testing and monitoring. Partnering with an Environmental Testing Lab offers manufacturers scientific insight into their operations, helping them stay compliant, efficient, and environmentally responsible.

From regulatory compliance and risk reduction to brand enhancement and operational savings, the benefits of environmental lab testing are far-reaching. In a competitive global economy, taking a proactive approach to environmental monitoring is not just good for the planet—it's good for business.

0 notes

Text

Ensuring a Safer Future with Environmental Testing

Ensure environmental safety and regulatory compliance with EKO Testing Labs. We provide accurate, reliable, and certified testing services for air, water, soil, and industrial waste.

✅ Air Quality Testing — Monitor pollutants & ensure clean air ✅ Water & Wastewater Analysis — Check purity & contamination levels ✅ Soil & Sediment Testing — Evaluate soil health for agricultural & industrial use ✅ Industrial Waste Testing — Ensure proper disposal & compliance ✅ Noise & Vibration Testing — Maintain environmental safety standards

Why Choose EKO Testing Labs?

✔ ISO-Certified Testing Facility ✔ Advanced Equipment & Expert Analysis ✔ Fast & Accurate Reports ✔ Compliance with Environmental Regulations

📍 Business Name: EKO Testing Labs 📞 Call Now: +91–9810240678 🌐 Visit Us: EKO Testing Labs — Environmental Testing

🔍 Ensure a Cleaner & Safer Environment with EKO Testing Labs!

0 notes

Text

Ensure the safety and sustainability of your projects with ITC Labs’ environmental impact assessment services. Our comprehensive environmental testing solutions include process water testing, testing of drinking water, and hazardous waste testing. We also offer compliance monitoring to help you meet regulatory standards. Our services extend to illumination testing and compressed air testing, including compressed air quality testing services. With over 36 years of expertise, ITC Labs is your trusted partner for reliable and accurate environmental testing. Contact us today to ensure your project meets all environmental and safety standards.

0 notes