#electroplating-grade ABS

Explore tagged Tumblr posts

Text

Introduction, characteristics, application, injection molding process of ABS plastic raw materials

01 Introduction of ABS plastic raw materials ABS resin is acrylonitrile-butadiene-styrene copolymer. ABS plastic raw material is light yellow granular or beaded opaque resin, which is a bulk general-purpose resin. ABS is an engineering plastic after being modified (adding additives or alloys) to improve its performance. ABS alloy has a large output, a variety of types and a wide range of…

View On WordPress

#ABS manufacturers#ABS plastic#ABS resin#Electrical properties#electroplating-grade ABS#engineering plastic#household appliances#injection molding process#injection pressure#injection speed#Mechanical Properties#Mold temperature#screw speed#Thermal properties

0 notes

Text

The ABCs of ABS: Unraveling the Characteristics and Uses of Acrylonitrile Butadiene Styrene (2023-2034)

This blog will focus on Acrylonitrile Butadiene Styrene (ABS). ABS is comprised of three monomers: Acrylonitrile, Butadiene, and Styrene. In this article, we'll look at how the polymer's unique properties work together to give ABS its exceptional strength, toughness, as well as the manufacturing process. The global Acrylonitrile Butadiene Styrene (ABS) market is likely to flourish at a moderate CAGR of 5.90% by the year 2034.

Introduction

Styrene Acrylonitrile has existed since the 1940s. While they improved toughness over pure styrene, their limits necessitated the addition of rubber (butadiene) as a third monomer. ABS consists of three major monomers: acrylonitrile, butadiene, and styrene.

Acrylonitrile contributes to ABS's chemical resistance and heat stability.

Butadiene enhances the toughness and impact strength of ABS.

Styrene provides ABS with rigidity and facilitates its processability.

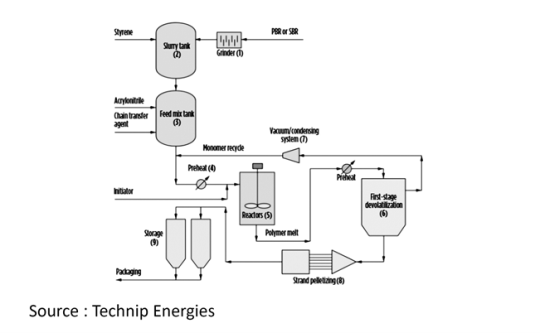

Manufacturing Process

ABS copolymers exhibit notable toughness, superior thermal resistance, and properties that surpass those of polystyrene plastics. ABS is produced through three distinct polymerization techniques: emulsion, suspension, and mass processes.

In the Mass Process, ABS is produced by the continuous copolymerization of styrene and acrylonitrile monomers with Polybutadiene Rubber (PBR) or Styrene-Butadiene Rubber (SBR) using a series of reactors, aided by organic peroxide. In a sequential process, chopped PBR or SBR is added to a slurry tank containing styrene monomer. The resultant mixture is then transferred to the ABS feed batch tank for complete rubber dissolution. This concentrated rubber solution is diluted with acrylonitrile, recycled monomer, and a chain transfer agent according to product requirements before preheating prior to entering the polymerization reactors.

Polymerization Section

The polymerization section employs a unique combination of plug flow and boiling stirred tank reactors arranged in series. Organic peroxide is introduced to initiate polymerization. This reactor setup allows precise control over various parameters such as rubber grafting, phase inversion, and molecular weight. Monomer conversion increases progressively throughout the reactor system, reaching final levels between 60% to 75%. Devolatilization is achieved through either extrusion or flash chamber methods.

Devolatization

In the extrusion devolatilization approach, the product from the last reactor undergoes stripping of unreacted monomers and byproducts in an extruder devolatilization system. Alternatively, the reactor product is subjected to volatile removal in a multistage flash devolatilization system operating under vacuum. Vapors are condensed, and the resulting mixture is recycled. The devolatilized polymer melts and then pelletizes and then dried.

Applications of Acrylonitrile Butadiene Styrene (ABS):

ABS (Acrylonitrile Butadiene Styrene) finds numerous applications across various industries. High impact grades are utilized in the production of travelling bags, helmets, furniture, sports goods, and automotive components, while medium impact grades are employed in radiator and air conditioner grills, heavy-duty domestic appliances, and control panels. Electroplating grades find their place in TV and radio knobs, bathroom fittings, refrigerator handles, and nameplates. High flow grades are ideal for housing domestic appliances, office equipment, and cabinets of electronic devices. High heat-resistant grades are utilized in automobile components and housing for electrical heaters and dryers. Transparent grades are sought after for areas requiring high transparency and impact strength, while impact modifier grades serve as modifiers for PVC compounding across various formulations. Glass-filled grades cater to applications demanding high flexural strength and stiffness, maintaining impact and tensile properties, while extrusion grades are used in refrigerator linings and luggage production.

Automotive

The automotive industry demands stringent standards from its materials. They must remain dimensionally stable and resist warping even when subjected to extreme stresses and significant temperature fluctuations.

Electronics & Electricals

ABS stands out in this regard due to its outstanding antistatic properties, providing a distinct advantage in meeting these requirements.

Appliances

ABS finds extensive applications in appliances, encompassing appliance control panels, housings for various devices such as shavers, vacuum cleaners, and food processors, as well as refrigerator liners, among others. Household and consumer goods represent the primary domains where ABS is widely utilized. Additionally, ABS is commonly employed in the manufacturing of keyboard keycaps.

Pipes & Fittings

ABS pipes and fittings are highly liked due to their ease of installation and rust resistance, making them a popular choice in a variety of applications.

Market Outlook:

ABS is an invariable thermoplastic polymer made up of three distinct monomers: acrylonitrile, butadiene, and styrene, which can change in proportion. They are also referred to as engineering plastics. Acrylonitrile provides chemical and thermal stability, styrene gives the plastic a glossy sheen, and butadiene provides strength and durability. These materials are widely used in the electronic appliance and automobile industries for vehicle and auto components production. The rapid growth of the medical business has increased demand for medical equipment, which is driving market growth. Furthermore, the growing construction and aerospace industries are predicted to significantly boost the ABS sector during the projection period. The global Acrylonitrile Butadiene Styrene (ABS) market is anticipated to reach approximately 15.7 million tonnes by 2034.

Acrylonitrile Butadiene Styrene (ABS) Major Manufacturers

Significant companies in the Global Acrylonitrile Butadiene Styrene (ABS) market are Formosa Chemicals and Fiber Corporation, LG Chem, LOTTE Chemical Corporation, Jilin Petrochemical Company, Toray Industries, CHIMEI Corporation, Tianjin Dagu Chemical Co., Ltd., and Others.

Challenges and Opportunities

While ABS possesses numerous advantageous properties, there are several restraining factors that could impact its market growth:

Environmental Concerns: ABS is derived from petrochemical sources, and its production and disposal can contribute to environmental pollution. Increasing environmental consciousness, combined with strict laws on plastic waste management and recycling, may present difficulties to the ABS market.

Competition from Alternative Materials: ABS faces competition from other engineering thermoplastics, such as polycarbonate (PC) and polypropylene (PP), which offer similar or enhanced properties in certain applications.

Conclusion:

Acrylonitrile Butadiene Styrene (ABS) is a versatile polymer with numerous useful applications. It is an essential in automotives and Electrical & Electronics industries owing to its unique set of properties. The surging demand for Acrylonitrile Butadiene Styrene (ABS) from Automotive, Home Appliances, Electrical & Electronics, and Building & Construction end-use industries, is anticipated to play a role in the demand-supply dynamics of the Acrylonitrile Butadiene Styrene (ABS) market.

0 notes

Text

Latin America Slide Rails for Home Appliances In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Latin America Slide Rails Market for Home Appliances — Outlook 2027

The Latin America slide rails market size for home appliances is expected to reach $1,734.4 million in 2027, from $1,307.0 million in 2019, growing at a CAGR of 3.6% from 2020 to 2027. Slide rails are used to provide linear motion to drawers in furniture, electronic appliances, industrial devices, and medical devices. In the home appliances market, slide rails are used for refrigerators, ovens, dishwashers, and washing machines, and are available in various load bearing capacities to assist in smooth linear operations. Slide rails are classified into light-, medium-, and heavy-duty rails, depending on the drawer loads in different appliances. They are mainly manufactured with steel or aluminum and are electroplated using zinc or other metals to prevent corrosion. In addition, slide rails majorly utilize ball bearing sliding movement or telescopic movement, which is greased using food grade lubricants to avoid contamination of food inside the appliance.

Rise in focus on public-private partnerships (PPPs) by various governments in Latin America to develop infrastructure and improve living conditions of people helps in increasing the consumption of home appliances. The development in infrastructure improves the standard of living of population and boosts the consumption of appliances, electronics, automotive, and other products, which propels adoption of home appliances, thereby driving the Latin America slide rails market growth. In addition, surge in urbanization in various Latin American countries majorly boosts the home appliances industry. Increase in manufacturing facilities in Latin America has led to the development in living standards of the population in the region. This leads to development of urban cities, thereby driving the demand for home appliances, which, in turn, boosts the Latin America slide rails industry growth. Moreover, many manufacturers of home appliances in Latin America are focused on taking initiatives related to business expansion with an objective to enhance their product portfolio and increase their presence in the region. In addition, various government programs and tax reforms have resulted in foreign investments, a factor that subsequently boosts the demand for slide rails in the home appliance segment in Latin America.

The Latin America slide rails market for home appliances is divided on the basis of product type, end-user, and country. By product type, the market is segmented into light-, medium-, and heavy-duty slide rails. By end-user, the market is classified into refrigerators, ovens, dishwashers, and others. The others segment is further classified into cloth washers and laundry dryers.

The Latin America slide rails market analysis for home appliances is conducted across the Brazil, Argentina, Chile, and rest of Latin America. Brazil holds the largest market share during 2019 and Chile is expected to grow at the fastest rate.

Competition Analysis

The key market players profiled in the report include AB Electrolux, Elesa+Ganter, Midea Group Co., Ltd., Hettich Holding GmbH & Co. oHG, Whirlpool Corporation, THK Co., Ltd. LG Corp., Qingdao Haier Co., Ltd., Robert Bosch GmbH (Bosch Rexroth AG), and ASKO Appliances.

Many competitors in the Latin America slide rails market for home appliances adopted product launch as their key developmental strategy to expand their product portfolio for the technological upgradations. For instance, in February 2019, Hettich launched new user-friendly movement devices for home appliances including dishwashers, refrigerators, and ovens. The new launched product includes Quadro Compact full extension runner system for refrigerators, which provides maximum stability, smooth running performance, and quiet closing action with the integration of silent system technology. In addition, it also launched Quadro runner system for dishwashers, which features over-extension opening of the dishwasher rack. Similarly, in July 2017, Elesa+Ganter launched 13 new variants of telescopic slides to its current product portfolio. The slide can carry loads between 28 and 310 kg. Furthermore, the slides can be used for any application and features dampening systems, latches, detach function, and self-retracting mechanisms.

Full Report With TOC:-https://www.alliedmarketresearch.com/latin-america-slide-rails-market-A06294

0 notes

Text

Stainless Steel Coffee Tumbler

https://www.novfeel.com/products/stainless-steel-coffee-tumbler/

This stainless steel coffee tumbler has a standard cylindrical appearance and is low in height. It has a straight through design with a multi-functional transparent plastic lid, which prevents beverage spills due to shaking and is easy to clean.

It is made of vacuum technology and double wall structure, with good cold insulation and heat insulation function.

Features of Stainless Steel Coffee Tumbler

1

Vacuum insulated.

2

100% BPA Free.

3

Durable and strong.

4

Suitable for home use or car cup holder.

5

Transparent cover and prevent spillage.

6

Easy to clean.

7

Sustainable and healthy materials.

Specifications of Stainless Steel Coffee Tumbler

Product Description:

Stainless Steel Coffee Tumbler

Drinkware Type:

Tumbler

Model:

NFT01T

Capacity:

8/10/12/14/16 Oz or customized

Body Shape:

Straight

Bottom Diameter:

72 mm

Mouth Diameter:

87 mm

Body Height:

175 mm

Body Material:

18/8 food-grade stainless steel (Grade 304 Stainless Steel)

Lid Material:

ABS/Silica gel

Design Style:

Modern

Wholesaler Type:

Department Stores, Super Markets, retail shop, company, organization, etc

Applicable People:

All

Season:

All

Function of Insulation:

Keep cold up to 6 hours/ keep hot up to 3 hours

ECO Friendly:

Yes

BPA Free:

Yes

Phthalate-Free:

Yes

Sweat Free Design:

Yes

Certificate:

FDA / LFGB / CE / EU

Place of Origin:

Zhe Jiang, China

MOQ:

1 PCS

Sample:

About $30 per style, depending on requirements

Customizing Options of Stainless Steel Coffee Tumbler

Surface Finish:

No coating( brushed stainless steel),spray painting, powder coating,UV coating,water transfer printing,gas transfer print,electroplating process,sublimation transfer,grind arenaceous,etc.

Logo:

Customized LOGO accepted.Include silkscreen print,heat transfer printing,laser engraved,steel seal,3D print,4D print,water decals,sublimation transfer, etc.

Pattern:

Customized pattern accepted.Include silkscreen printing, laser engraved,heat transfer printing,water transfer printing,etc.

Packaging Box:

Egg crate,horizontal and vertical separation,PE bag and white box,custom colour/printed box,cylinder box,display box, bubble bag, etc.

0 notes

Text

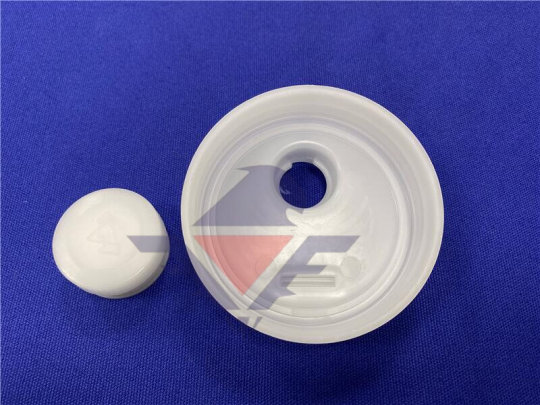

Plastic Machining

https://www.ljzcncmachining.com/plastic-machining/

In industrial design, in addition to commonly used metals, engineers also favor engineering-grade plastics. These plastic machined parts have favorite characteristics such as optical transparency, wear resistance, and corrosion resistance. LJZ has been providing professional plastic machining, surface finishes, and assembly services for a long time, our CNC plastic parts not only ensure performance but also attract customers in perfect appearance.

Surface Finishes In Machined Plastic Parts

We are not only good at surface treatment of metal products but also professional in surface finishes of CNC plastic machined parts: painting, silk screen printing, powder coating, electroplating, laser engraving, polished transparent, fumigated transparent, dyeing, etc.

Engineering Grade Plastics That We Mostly Work With

The most commonly machined engineering plastics are ABS, POM, PTFE, PEEK, Nylon, Acrylic, polycarbonate etc. These CNC plastics have long been used in electronics, instrument & equipment, precision machinery, aerospace, medical and other fields.

Here are some of these engineering plastics for your reference, but NOT limited.

Plastic

Color

Characteristics

Application

ABS

Natural Black Transparent

High mechanical strength High rigidity High surface hardness High dimensional stability

Quick prototype Electronics, electrical appliances, Plastic housings and components

PMMA (Acrylic)

Transparent

High mechanical strength Can be polished and transparent Good insulation

Aviation Electronics Optics manifold Medical components

POM

Black White

High mechanical strength High compressive strength Wear resistance Good machinability

Precision mechanical parts Water-resistant parts Bearings, gears, impellers, bushing, gaskets

PTFE

White

High-temperature resistance Wear and corrosion resistant Good flame retardancy

Oil & gas Instruments Mechanical components

PEEK

Yellow Black Natural

High rigidity and hardness preservative High-temperature resistance UV and radiation resistance

Aerospace Medical treatment Electronic Mechanical

0 notes

Text

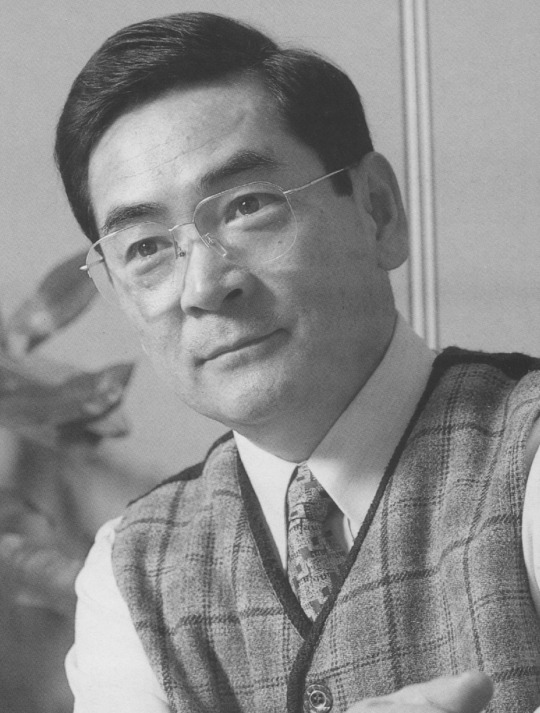

1999 Interview with Iwakichi Ogawa, Creator of Microman

The following interview was translated from the fantastic 1999 Tokuma Shoten publication, Roman Album Hyper Mook 6: Henshin Cyborg and Microman Victory Project

President and Representative Director of Russell, Ltd. Iwakichi Ogawa

From here on [in this section of the book], we’ll introduce the inventors behind the history of creating the Takara original SF toys. Iwakichi Ogawa, having been involved in the development of Henshin Cyborg and production of Microman himself, is a living witness to the history of the Takara SF toys. His eyes shone like a young boy’s as he shared with us the behind the scenes story of these two major heroes.

--Ogawa-san, you handled making prototypes, right?

That’s right. I was originally in my college’s economics department, with a focus on marketing, and nothing to do with development work, one might say. But you know, I loved doing it and learning everything after joining Takara, so that by the time of Cyborg and Microman, I had begun to sculpt my own prototypes by hand.

--You only started creating models after you had joined Takara?

Precisely. I had a subordinate, a nice guy who had been in his university’s art club who I told, “teach me, too.” (laughs)

--That must have been nice, getting to paid to learn on the job. (laughs)

You mean playing every day from morning to night, and getting paid for it, right? (laughs) Oh, I played, all right. When establishing the (Japanese localized) rules for “The Game of Life”--adapting this thing which came from America--it couldn’t be anything but fun coming up with the “directions for each space”. If someone complained at the time, “oh, all you’re doing is goofing off,” I would answer, “no, this is work, you see,” but that was a lie. (laughs)

--Well then, please tell us about the time Henshin Cyborg was created.

As you are aware, the forerunner to Henshin Cyborg was Hasbro’s GI Joe, which began around the time I was on “The Game of Life”, so I was not directly responsible for that. “GI Joe will do well” was Takara president Yasuta Satou’s insight. So soon we were all on GI Joe. It was at a point when sales had declined a bit that I remember one fellow suggested, “let’s make a transparent one”. So the molding section at the factory followed up and produced one. Once it was assembled, the reaction was “hey, this looks pretty cool.” It had thick areas where the screws were inside it, right? From the side, it had a really amazing look to it. Though parts of the joints were made out of nylon, I could work with that.

The young guy responsible (he was around 24-25?) had incredibly good sense. Being transparent was just how it started, with it being plain and hollow, of course we needed to make the insides. But at the time, Takara was focused mostly on producing games and Licca-chan dolls, so there was no separate department yet for boys’ toys. Therefore, I wound up taking some kits of motorbikes that the model companies Tamiya and Arii were making at the time which had chrome-plated parts, and put those bits inside. So the first Cyborg we previewed at an industry trade show had a motorcycle engine for his innards.

At that time we stated the head was still under development, and just used a metal spring inside it. When the actual design was made, it was created by Dan Kobayashi (known since for creating Gaiking and Danguard Ace among others). He did all the prototyping for the head and the finer detailing. Though the prototype was made in wax, I noticed quickly that it was green. Normally the wax is brown but when I asked him about it, he said, “sorry, that’s my secret.” It was a custom mix of waxes that was extraordinarily fine and easy to texture and tailor. I managed to get some and started using it in my own prototypes. Kobayashi-san worked with me on the prototypes for Microman as well. The prototypes for the Microman breastplates were made from a kind of plaster. Kobayashi used this plaster because silicon was expensive in those days.

Well, it’s actually called “rebase”, and it’s what dentists use to repair crowns in their work. It hardens quickly, making it easy to work with. Come to think of it, when we were doing Microman Command’s capsule later on, I forgot how it happened, but the mold wound up with a small “Ogawa” (小川) inside it, and I believe you can find it in there. (laughs)

--Well that’s… (laughs) I’ll check later when I get a chance (later on I confirmed that it can be seen molded into Command 3’s capsule). So, speaking of Microman, can you talk about how that began?

In fact, it started with GI Joe. GI Joe sold incredibly well at first, but eventually not so well, which was when my superior Wakase-san said “we should make these smaller.” He had worked in steel manufacturing, a very talented man. “You can’t produce vehicles when they are this big, so make them smaller,” was the advice of my boss from back then. We were still producing the original flesh-colored GI Joe at that time. Yet at that point it was totally undoable, with joints already smaller than you’d find on your own pinky finger. So, after trying anyway using insect mounting pins, I said “this isn’t viable (for production)”, to which Wakase-san answered, “ah, well”. Later, Cyborg became extremely popular. But both GI Joe and Cyborg were still too big to make vehicles for them to drive. So once again I confronted making the “miniature poseable figure” with the desire to make it possible at whatever cost. In any case, we needed to solve the joint problem, so I tried many different methods; using a beaded key chain to try making small ball and sockets, and other such ideas. But these would come apart after repeated use by a child. This was the biggest issue Microman would face. Then, with a portable folding ruler I found something—a tiny rivet, only 2mm wide. I began to hunt for it. It came from the shop making Licca-chan backpacks. I learned they had a machine that could install 2mm rivets automatically, so I checked, but while the rivets were 2mm in diameter, they were much too long. There’s no choice but to make the rivets shorter. After confirming it was possible, I asked Kobayashi-san for about 3 test sample bodies. With that, we assembled them with the fresh rivets, and the heads of the rivets looked quite cool. “This is good,” I thought as I could now put a request in with the boss which would only require a single mold casting. Nikkou Toys (a tin toy maker at the time) or such ought to be able to take the order. When I thought about the potential to use it with translucent parts, I was dumbstruck. Well, once I put these connections together in private, I actually cried. It had been over a year since I had first embarked on this project.

--That’s quite a while, isn’t it? How was it received in the end?

In those days of labor guilds, in spite that there were some who would think heavier was best, others felt “No, lightweight is good”. And with the oil shock of the following year, with the rise of the era of energy conservation, this was a potential selling point (laughs). And see, you could put a Microman on a matchbox, and now it’s a vehicle, right? Or an ashtray can be a flying saucer. When I showed it to sales, they too were, “Yeah, that’s good”. Then, for a company evaluation meeting, we took an electroplated frying pan and put a clock inside it so just the second hand axle was exposed and affixed a Microman to it. That way each time the hand ticked, the Microman would move. This had an incredible effect. “That’s it!” they said (laughs). Not much later this would become the counter display.

(Earliest known discernable photo of Microman prototypes being displayed, via Minoru Sashida.)

--For Microman, the play mechanics were quite novel, weren’t they?

Indeed they were. I put a lot of thought into how to make the series stand out as unique. This was “Episode 2” of Microman’s creation for me (laughs). At that time, Lego blocks were becoming the next big thing, and I had bought a set for my daughter, too. However, living in an apartment housing complex back then, things turned when neighboring children from the third and fourth grade came to play. “So, this is what I got.” “I wouldn’t buy that, it’s like a baby toy.” “But aren’t you playing with it too?” “Sure, it’s fun, but we’re elementary schoolers now.” I felt that they were the target. So the block was shaved down into the form of a wing. These days, blocks come in all forms, but back then they were only in the square form of bricks. And when we manufactured Jaguar, we used 3mm joints of ABS plastic for attachments. Blocks are fun, but for babies. So you have to make it in a form that is clearly not for babies. And if you make them into a science-fiction form, it begins to become interesting. (laughs) So while the figures were ready, the release schedule was repeatedly pushed back to “It will be available when it’s ready”. (laughs) Honestly, I already had something kind of like Robotman worked out by then. But nothing like vehicles yet, on the other hand. So for that I came up with the term “Material Block”. Since the 3mm pegs seemed to break easily, I figured, okay, let’s go with 5mm. From that point onward, Takara has used the 5mm gauge for all their product’s molds ever since. When we went on to create “Steel Jeeg”, we were able to incorporate the 5mm parts with magnets, too. So you could say that 5mm interchangeability started out as the basis for playing with Microman.

--That was profound, wasn’t it? It even became a hit abroad.

At first, when the president and department manager went to try to sell it in America, their efforts failed. Around then, a certain agent in California asked for “a percentage of the royalties if successful”. A half-year later, it became an explosive hit in Japan. When that happened, the company “Mego” was approached. When we showed them, they were interested and agreed. Then it became a huge hit there and his share turned into hundreds of millions. (laughs) When I visited his home after that, even though it was still back in the day, he had a giant projection TV, a home theater. A pool, too. Yet I was still some kind of salaryman. (laughs)

--Even though you’re the real father! (laughs)

The suspension that holds the hips would have broken were it not made from metal. I tooled it on a drill press and welded a hook onto it. It was fully my idea. (The book’s editor suggests comparing with a replica Microman figure release for reference here.) But I didn’t patent it. Back around the turn of the century, a similar design was filed to make wooden artist’s mannequins, so it wouldn’t have passed.

If the owner of that patent challenged us, even if they were wrong, it would have ended everything. But even today, GI Joe is using the same structure as Microman. Yet I was the one who designed it…

--By the way, how did it become called Microman?

It was originally codenamed internally as Microman --it was micro-sized, thus Microman—but it became the brand name in the end. The same for Acroyear which was “’akudoi yarou’ (‘vicious brute’), so we went with “Akuroiya”, or such (laughs).

--Was the story yours, too?

Yes. To sell them individually, we wanted to present them in a clear box. And, I started to think about how we could make the clear box itself a desirable feature. So I had read and researched a lot of science fiction by that point. I didn’t really agree with the theory of evolution. My own fancy was that living things could spontaneously change overnight. I hadn’t seen any fossils of transitional forms. So, I came up with the idea that the alpha H7 gas drifting in the galaxy would cause evolutionary change whenever it came into contact with life, and when MicroEarth exploded, it had a different effect by chance. Back then, there was the notion that Atlantis used crystal energy which I found interesting. Crystals that return the same frequency when exposed to electromagnetic waves. So the setting was created by combining these ideas. That’s what I recorded to a mini-cassette when it hit me in the middle of the night. (laughs) I contacted Design Mate, and gave it as the pitch. Suguwara from Design Mate (see page 80 [of this book]) then edited it and it turned out quite good. I spent a couple extra hours that night on the telephone. “Am I ever going home?” I thought (laughs). I’m sure I was annoying them too (laughs).

--I would imagine you always carried a Microman with you?

I always did. I made a ring for myself, you see. I placed the head of a Microman inside clear acrylic. I really wore it. However, as I gained weight, I had to shave out the center over time. (laughs) It was a lot of trouble to keep shaving down that acrylic.

--Still, it seems like you could put that on the market, now.

You think so? I guess I’ll take it to Takara and find out (laughs). But lately Microman has been getting a good reception from a lot of respectable folks these days, hasn’t it? However, I had gotten rid of most of mine. Such a waste, isn’t it? When it came about, I was “Ah, so that’s how it goes, huh?” (laughs) But, seeing the resurgence in popularity has been fun, you know? Seeing everyone joining in and putting them up on their home pages and such. Sometimes I wonder if I should drop in and introduce myself. (laughs) Ah, well…

--What kind of work are you doing next?

As a person who lived in the toy industry, you could say I wish to make a new “toy launch”. Without an anime launch, a toy that is a hit, becomes a game, then becomes an anime. Right now, I’m planning toward that goal. I’m about 60% there. This is a toy’s true essence! –is what I want to be able to express. That would be something like a new Microman for me. So now, I’m really fired up! (laughs) What’s it about? ….that’s a secret (laughs).

Iwakichi Ogawa, born August 24, 1942 in Fukushima Prefecture Former head of boy’s product development division at Takara. Current President and Representative Director of toy development company Russell, Ltd.

33 notes

·

View notes

Text

Copper Sulfate Market Inclination Highpoints Contribution of Prosperous Economies to Push Growth between 2020-2024

The Global Copper Sulfate Market 2020 report delivers a fundamental overview of the copper sulfate industry, including definitions, segmentation, applications and industry chain structure analysis. The copper sulfate market report provides competitive landscape analysis, major trends, and key regional development status. It also offers a competitive framework for major revenue-contributing firms covering company market shares with comprehensive profiles. The report provides a key overview of the market status of copper sulfate market manufacturers with market size, share, growth, market expansion, and technological innovations, as well as the industry cost structure.

It provides the impact and recovery of Covid-19 pandemic on the copper sulfate Market. Relevant statistical data is also provided in the report to recognize the challenges caused by the outbreak of Covid-19 and strategies to cope up with the current scenario.

GET FREE SAMPLE REPORT@ https://www.factomarketinsights.com/sample/128

The Following are the Key Features of Copper Sulfate Market Report:

Market Overview, Industry Development, Market Maturity, PESTLE Analysis, Value Chain Analysis

Growth Drivers and Barriers, Market Trends & Market Opportunities

Porter’s Five Forces Analysis & Trade Analysis

Market Forecast Analysis for 2020-2024

Market Segments by Geographies and Countries

Market Segment Trend and Forecast

Market Analysis and Recommendations

Price Analysis

Key Market Driving Factors

Copper Sulfate market Company Analysis: Company Market Share & Market Positioning, Company Profiling, Recent Industry Developments etc.

Market Segmentation:

The segmentation of copper sulfate market is as follows By Product Type, By Application Type. Both developed and developing regions are extensively studied in the report.

By Product Type

- Food Grade Copper Sulfate - Technical Grade Copper Sulfate - Feed Grade Copper Sulfate

By Application Type

- Agriculture - Animal Nutrient - Electroplate - Mining - Chemical Intermediates - Textile & Leather

By Geography

The regional segmentation of the market covers following regions: North America (U.S. & Canada), Europe (Germany, United Kingdom, France, Italy, Spain, Russia, and Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Indonesia, Taiwan, Australia, New Zealand, and Rest of Asia Pacific), Latin America (Brazil, Mexico, and Rest of Latin America), Middle East & Africa (GCC, North Africa, South Africa, and Rest of Middle East & Africa).

GET FULL REPORT@ https://www.factomarketinsights.com/report/128/copper-sulfate-market-outlook-2019-2024-amr

Fundamental Coverage of the Copper Sulfate Market:

Covid-19 impact and strategies to recover.

Valuable information about the copper sulfate Market

Identification of growth in various segments and sub segments of the studied market.

Strategic ideas for investment opportunities

Key statistical data along with products, price analysis, applications, levels of production and consumption, supply and demand.

Emerging developments in the existing market segment and research to help investors devise new business strategies

Accelerates decision-making by drivers and constraints

Competitive Analysis

The key players of the market are listed in this section of the study. It helps to understand the tactics and alliances that players concentrate on fighting market rivalry. An essential microscopic look at the market is given in the detailed study. The major players operating in the copper sulfate market are:

- Anhui Tongling Jinhao Chemical Co., Ltd. - Anshan Xinxingda Mineral Substance Co., Ltd. - Aurubis AG - Boliden AB - Cuprichem Limited - Jiangxi Copper Co., Ltd. - Jinchuan Group Ltd. - JX Nippon Mining & Metals Corporation - KGHM Polska Miedź S.A. - Kimleigh Chemicals SA - Manica S.p.a. - MCM Industrial - Meltex Inc. - NEKK OJSC - Old Bridge Chemicals, Inc.

HAVE ANY QUERY BEFORE BUYING THIS REPORT @ https://www.factomarketinsights.com/enquiry/128

About Us:

Facto Market Insights is one of the leading providers of market intelligence products and services. We offer reports on over 10+ industries and update our collection daily which helps our clients to access database of expert market insights on industries, companies, products, and trends.

Our in-house research experts have a wealth of knowledge in their respective domains. With Facto Market Research, you always have the choice of getting customized report free of cost (up to 10%). Our support team will help you customize the report and scope as per your business needs. This ensures that you are making the right purchase decision.

Our clients list includes various Fortune 500 companies and leading advisory firms.

Contact Us:

Facto Market Insights

90 State Street, Albany,

New York, USA 12207

+1 (518) 250-1215

Email:[email protected]

Website: www.factomarketinsights.com

0 notes

Text

Acrylonitrile Butadiene Styrene Plastic Market Global Driving Factors & Technology Advancements Forecast 2024

Market.Biz focuses on providing the users or readers with a descriptive assessment of the industry and the valuable analyzed information of several markets. The latest research report on the global Acrylonitrile Butadiene Styrene Plastic market is completely concentrated on satisfying the requirements of the users by offering them with all insights into the industry. The Entire data Structured in the report is collected by Professional researchers and experts.

Market Scope of the Acrylonitrile Butadiene Styrene Plastic report:

Each segment included in the research report is detailed and well-examined based on various crucial factors such as market share, revenue, Production, Region, Usage of the Acrylonitrile Butadiene Styrene Plastic, Regional overview, Types, and Manufacturer. The report on Acrylonitrile Butadiene Styrene Plastic market supports the competitors to focus on key regions of the Industry. It also provides an independent assessment of each segment as per future opportunities.

"Global Acrylonitrile Butadiene Styrene Plastic Market 2019 Sample Pdf"

The Competitive Manufacturers of the Acrylonitrile Butadiene Styrene Plastic Market:

Trinseo LG Chemical Huajin Chemical JSR CNPC (Jilin) Toray Dagu Chemical Lejin Chemical Styrolution CNPC (Daqing) UMG ABS CHIMEI SABIC Formosa Gaoqiao Samsung SDI Chemical CNPC (Lanzhou) KKPC

Some Advantages of the Global Acrylonitrile Butadiene Styrene Plastic Market Report:

1. This Report is a precise document that provides basic guidance to the User of the Acrylonitrile Butadiene Styrene Plastic market.

2. The information collected in the Report is derived for true sources such as Press releases, Personal Interviews, Industry expert reviews, Government documents, Financial Reports, and investor information.

3. The Evolution of market dynamics, market trends and also the changing supply and demand conditions are framed in the report.

4. It Quantifies market opportunities and threats with the help of market sizing and market forecasting.

5. Competitive insights included in this report helps in Tracking current trends which leads to a forecast of upcoming changes in current business ideas.

Key Type of Acrylonitrile Butadiene Styrene Plastic:

General Grade High Flow Grade Extrusion Grade Fire Retardant Grade High Heat Grade Product Electroplating Grade High Gloss Grade Low Gloss Grade Other grade

Main Applications of Acrylonitrile Butadiene Styrene Plastic:

Transportation industry Building and construction Consumer goods Healthcare Large and small appliances

Global Acrylonitrile Butadiene Styrene Plastic Market Key Geographical Segments:

North America Europe China Japan The Middle East & Africa India South America

"Ask Your Query Here"

In Addition, the Acrylonitrile Butadiene Styrene Plastic Market report gives a strong Foundation for gathering a bunch of insights that potential customers can refer to reduce costs and enhance the revenues. The Report is the outcome of various analyses such as Pestle analysis and Porter's 5 force analysis etc. The reference and facts in the report are put forth to give the reader a clear thought of the market.

Also, Visit this Interesting Article:

Global Multilayer Ceramic Capacitor (Mlcc) Industry Market Research Report

0 notes

Text

Latin America Slide Rails for Home Appliances Forecast to 2031 with Key Companies Profile, Supply, Demand and SWOT Analysis

Latin America Slide Rails Market for Home Appliances — Outlook 2027

The Latin America slide rails market size for home appliances is expected to reach $1,734.4 million in 2027, from $1,307.0 million in 2019, growing at a CAGR of 3.6% from 2020 to 2027. Slide rails are used to provide linear motion to drawers in furniture, electronic appliances, industrial devices, and medical devices. In the home appliances market, slide rails are used for refrigerators, ovens, dishwashers, and washing machines, and are available in various load bearing capacities to assist in smooth linear operations. Slide rails are classified into light-, medium-, and heavy-duty rails, depending on the drawer loads in different appliances. They are mainly manufactured with steel or aluminum and are electroplated using zinc or other metals to prevent corrosion. In addition, slide rails majorly utilize ball bearing sliding movement or telescopic movement, which is greased using food grade lubricants to avoid contamination of food inside the appliance.

Rise in focus on public-private partnerships (PPPs) by various governments in Latin America to develop infrastructure and improve living conditions of people helps in increasing the consumption of home appliances. The development in infrastructure improves the standard of living of population and boosts the consumption of appliances, electronics, automotive, and other products, which propels adoption of home appliances, thereby driving the Latin America slide rails market growth. In addition, surge in urbanization in various Latin American countries majorly boosts the home appliances industry. Increase in manufacturing facilities in Latin America has led to the development in living standards of the population in the region. This leads to development of urban cities, thereby driving the demand for home appliances, which, in turn, boosts the Latin America slide rails industry growth. Moreover, many manufacturers of home appliances in Latin America are focused on taking initiatives related to business expansion with an objective to enhance their product portfolio and increase their presence in the region. In addition, various government programs and tax reforms have resulted in foreign investments, a factor that subsequently boosts the demand for slide rails in the home appliance segment in Latin America.

The Latin America slide rails market for home appliances is divided on the basis of product type, end-user, and country. By product type, the market is segmented into light-, medium-, and heavy-duty slide rails. By end-user, the market is classified into refrigerators, ovens, dishwashers, and others. The others segment is further classified into cloth washers and laundry dryers. The Latin America slide rails market analysis for home appliances is conducted across the Brazil, Argentina, Chile, and rest of Latin America. Brazil holds the largest market share during 2019 and Chile is expected to grow at the fastest rate.

Competition Analysis

The key market players profiled in the report include AB Electrolux, Elesa+Ganter, Midea Group Co., Ltd., Hettich Holding GmbH & Co. oHG, Whirlpool Corporation, THK Co., Ltd. LG Corp., Qingdao Haier Co., Ltd., Robert Bosch GmbH (Bosch Rexroth AG), and ASKO Appliances.

Many competitors in the Latin America slide rails market for home appliances adopted product launch as their key developmental strategy to expand their product portfolio for the technological upgradations. For instance, in February 2019, Hettich launched new user-friendly movement devices for home appliances including dishwashers, refrigerators, and ovens. The new launched product includes Quadro Compact full extension runner system for refrigerators, which provides maximum stability, smooth running performance, and quiet closing action with the integration of silent system technology. In addition, it also launched Quadro runner system for dishwashers, which features over-extension opening of the dishwasher rack. Similarly, in July 2017, Elesa+Ganter launched 13 new variants of telescopic slides to its current product portfolio. The slide can carry loads between 28 and 310 kg. Furthermore, the slides can be used for any application and features dampening systems, latches, detach function, and self-retracting mechanisms.

Full Report With TOC:-https://www.alliedmarketresearch.com/latin-america-slide-rails-market-A06294

0 notes

Photo

Electroplated Quartz, AB clear Quartz, Rough Quartz Beads, Nugget Rough, center drilled, AB clear, Grade AA, 15inches, 12-18x22-30mm

0 notes

Text

Electroplating Grade ABS Market To, 2025 Focus on Top Manufacturers, Trends, Growth Opportunities and Regions

DecisionDatabases recommend a most recent report on the Electroplating Grade ABS Marketbased on industry analysis and forecast until 2025 with the estimated the year 2020. This report delivering key insights and offering an economical advantage to the client thought a comprehensive report. The report also covering the latest outbreak of COVID-19 impact analysis on the market. This pandemic has…

View On WordPress

#Electroplating Grade ABS#Electroplating Grade ABS Industry Report#Electroplating Grade ABS Market#Electroplating Grade ABS Market Forecast#Electroplating Grade ABS Market Growth#Electroplating Grade ABS Market Report#Electroplating Grade ABS Market Share#Electroplating Grade ABS Market Size#Electroplating Grade ABS Market Trends#Global Electroplating Grade ABS Industry

0 notes

Text

Stainless Steel Beer Tumbler

https://www.novfeel.com/products/stainless-steel-beer-tumbler/

This stainless steel tumbler is in the shape of a long thin cylinder with a straight-through design. Plastic lid with transparent multi-functional, and stainless steel straw can be inserted to prevent the drink from sloshing out.

Using vacuum process and double wall structure, excellent insulation function, can avoid condensation phenomenon, easy to clean.

Features of Stainless Steel Beer Tumbler

1

Vacuum insulated.

2

100% BPA Free.

3

Durable and strong.

4

Suitable for home use or car cup holder.

5

Transparent cover and prevent spillage.

6

Easy to clean.

7

Sustainable and healthy materials.

Specifications of Stainless Steel Beer Tumbler

Product Description:

Stainless Steel Beer Tumbler

Drinkware Type:

Tumbler

Model:

NFT03T

Capacity:

8/10/12/14/16/20/30 Oz or customized

Body Shape:

Straight

Bottom Diameter:

72 mm

Mouth Diameter:

87 mm

Body Height:

175 mm

Body Material:

18/8 food-grade stainless steel (Grade 304 Stainless Steel)

Lid Material:

ABS/Silica gel

Design Style:

Modern

Wholesaler Type:

Department Stores, Super Markets, retail shop, company, organization, etc

Applicable People:

All

Season:

All

Function of Insulation:

Keep cold up to 6 hours/ keep hot up to 3 hours

ECO Friendly:

Yes

BPA Free:

Yes

Phthalate-Free:

Yes

Sweat Free Design:

Yes

Certificate:

FDA / LFGB / CE / EU

Place of Origin:

Zhe Jiang, China

MOQ:

1 PCS

Sample:

About $30 per style, depending on requirements

Customizing Options of Stainless Steel Beer Tumbler

Surface Finish:

No coating( brushed stainless steel),spray painting, powder coating,UV coating,water transfer printing,gas transfer print,electroplating process,sublimation transfer,grind arenaceous,etc.

Logo:

Customized LOGO accepted.Include silkscreen print,heat transfer printing,laser engraved,steel seal,3D print,4D print,water decals,sublimation transfer, etc.

Pattern:

Customized pattern accepted.Include silkscreen printing, laser engraved,heat transfer printing,water transfer printing,etc.

Packaging Box:

Egg crate,horizontal and vertical separation,PE bag and white box,custom colour/printed box,cylinder box,display box, bubble bag, etc.

1 note

·

View note

Link

Industry Insights

The Global Electroplating Grade ABS Market is expected to grow at a CAGR of XX % during the forecast period 2018-2025.

The Global Electroplating Grade ABS Market is segmented on the basis of Type and Application. The Global Electroplating Grade ABS Market is segmented based on the basis of type General Grade, Other,. By Application, it is classified as Automobile, Appliance, Other,. The regional outlook on the Global Electroplating Grade ABS Market covers regions, such as North America, Europe, Asia-Pacific, and Rest of the World. Global Electroplating Grade ABS Market for each region is further bifurcated for major countries including the U.S., Canada, Germany, the U.K., France, Italy, China, India, Japan, Brazil, South Africa, and others.

To get a free sample report: https://www.supplydemandmarketresearch.com/home/contact/773746?ref=Sample-and-Brochure&toccode=SDMRCH773746

To get a detailed report: https://www.supplydemandmarketresearch.com/global-electroplating-grade-abs-market-773746

#Electroplating Grade ABS Market#Electroplating Grade ABS Market Industry#Electroplating Grade ABS Market Analysis#Electroplating Grade ABS Market Forecasts#Electroplating Grade ABS Market research report

0 notes

Text

Electroplating Grade ABSMarket – Current Trends, Opportunities &Challenges by 2024

According to Acquire Market Research this study,over the next five years the Electroplating Grade ABS market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2017. In particular, this report presents the global market share (sales and revenue) of key companies in Electroplating Grade ABS business.

This report presents a comprehensive overview, market shares, and growth opportunities of Electroplating Grade ABS market by product type, application, key manufacturers and key regions and countries.

This study considers the Electroplating Grade ABS value and volume generated from the sales of the following segments:

Request Sample Report@https://www.acquiremarketresearch.com/sample-request/3

Segmentation by product type

General Grade

Other

Segmentation by application

Automobile

Appliance

Other

This report also splits the market by region

Americas

APAC

Europe

Middle East & Africa

More Info and TOC @ https://www.acquiremarketresearch.com/industry-reports/global-electroplating-grade-abs-market-growth-2019-2024/3/

The report also presents the market competition landscape and a corresponding detailed analysis of the major vendor/manufacturers in the market.

The key manufacturers covered in this report

BASF

Chi Mei

IRPC

Toray

LG Chem

INEOS Styrolution

...

In addition, this report discusses the key drivers influencing market growth, opportunities, the challenges and the risks faced by key manufacturers and the market as a whole. It also analyzes key emerging trends and their impact on present and future development.

Request for Discount@ https://www.acquiremarketresearch.com/discount-request/3

Research objectives

To study and analyze the global Electroplating Grade ABS consumption (value & volume) by key regions/countries, product type and application, history data from 2013 to 2017, and forecast to 2024.

To understand the structure of Electroplating Grade ABS market by identifying its various sub segments.

Focuses on the key global Electroplating Grade ABS manufacturers, to define, describe and analyze the sales volume, value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Electroplating Grade ABS with respect to individual growth trends, future prospects, and their contribution to the total market.

To share detailed information about the key factors influencing the growth of the market (growth potential, opportunities, drivers, industry-specific challenges and risks).

To project the consumption of Electroplating Grade ABS submarkets, with respect to key regions (along with their respective key countries).

To analyze competitive developments such as expansions, agreements, new product launches, and acquisitions in the market.

To strategically profile the key players and comprehensively analyze their growth strategies.

Enquiry before Buying @ https://www.acquiremarketresearch.com/enquire-before/3

Table of Contents

1Scope of the Report

1.1 Market Introduction

1.2 Research Objectives

1.3 Years Considered

1.4 Market Research Methodology

1.5 Economic Indicators

1.6 Currency Considered

2 Executive Summary

2.1 World Market Overview

2.1.1 Global Electroplating Grade ABS Consumption 2013-2023

2.1.2 Electroplating Grade ABS Consumption CAGR by Region

2.2 Electroplating Grade ABS Segment by Type

2.2.1 General Grade

2.2.2 Other

2.3 Electroplating Grade ABS Consumption by Type

2.3.1 Global Electroplating Grade ABS Consumption Market Share by Type (2013-2018)

2.3.2 Global Electroplating Grade ABS Revenue and Market Share by Type (2013-2018)

2.3.3 Global Electroplating Grade ABS Sale Price by Type (2013-2018)

2.4 Electroplating Grade ABS Segment by Application

2.4.1 Automobile

2.4.2 Appliance

2.4.3 Other

2.5 Electroplating Grade ABS Consumption by Application

2.5.1 Global Electroplating Grade ABS Consumption Market Share by Application (2013-2018)

2.5.2 Global Electroplating Grade ABS Value and Market Share by Application (2013-2018)

2.5.3 Global Electroplating Grade ABS Sale Price by Application (2013-2018)

3 Global Electroplating Grade ABS by Players

3.1 Global Electroplating Grade ABS Sales Market Share by Players

3.1.1 Global Electroplating Grade ABS Sales by Players (2016-2018)

3.1.2 Global Electroplating Grade ABS Sales Market Share by Players (2016-2018)

3.2 Global Electroplating Grade ABS Revenue Market Share by Players

About Acquire Market Research: Acquire Market Research is a shrine of world-class research reports from around the world and we offer you only the best in the Industry when it comes to research. At Acquire, every data need will be catered to and met with a powerful world of choices. "We understand the integral role data plays in the growth of Business empires." Contact Us: 555 Madison Avenue, 5th Floor, Manhattan, New York, 10022 USA Phone No.: +1 (800) 663-5579 Email ID:[email protected]

0 notes

Text

Acrylonitrile Butadiene Styrene Plastic Market Growth, Forecast and Application to 2024

This research report categorizes the 'Global Acrylonitrile Butadiene Styrene Plastic Market' by region players/brands, type and application. This report examines the market status, competition, market share, growth speed, prospective trends, market drivers, sales channels, chances and challenges and distributors.

Acrylonitrile Butadiene Styrene Plastic market report has been an up to date analysis of the present market including the most effective organizations, industrial chain, consumption sourcing strategy, research methodology.

The report covers the growth prospects of this Acrylonitrile Butadiene Styrene Plastic market and the present scenario. To compute the industry size, the report believes that the revenue generated across the globe from the selling of all Acrylonitrile Butadiene Styrene Plastic.

Futuristic's sample reports comprise portions like prediction and industry size, drivers, challenges, trends, and much more and have been totally free.

Get Free Sample Report PDF Of The Report @ https://futuristicreports.com/request-sample/5105

Acrylonitrile Butadiene Styrene Plastic market Segmentations:

Leading Top company Profiles Covered in This Report:

Samsung SDI Chemical, UMG ABS, CNPC (Lanzhou), Formosa, SABIC, Gaoqiao, LG Chemical, JSR, Dagu Chemical, Styrolution, CNPC (Daqing), Toray, Trinseo, Huajin Chemical, CNPC (Jilin), Lejin Chemical, CHIMEI, KKPC

Global Acrylonitrile Butadiene Styrene Plastic Market, By Type

General Grade

High Flow Grade

Extrusion Grade

Fire Retardant Grade

High Heat Grade

Product Electroplating Grade

High Gloss Grade

Low Gloss Grade

Other grade

Global Acrylonitrile Butadiene Styrene Plastic Market, By End Users/Applications:

Transportation industry

Building and construction

Consumer goods

Healthcare

Large and small appliances

Others

Leading Regions and Countries included in the Report: North America, Europe, China, Japan, The Middle East & Africa, India, South America, Others

Inquire/Speak To Expert Regarding Acrylonitrile Butadiene Styrene Plastic Report for Detailed Info: https://futuristicreports.com/send-an-enquiry/5105

Key Questions Answered in the report:

- What was the growth rate in the past 5 years and also the market size from 2014-2018, and what the growth rate and the market size is likely to be from 2019-2024?

- Which would be the critical factors in the market?

- Which will be the challenges to advertise development?

- What will be the chances for players?

- Which are Acrylonitrile Butadiene Styrene Plastic earnings, revenue, and price analysis through regions?

Acrylonitrile Butadiene Styrene Plastic market 2019-2024, the report, was prepared based on a comprehensive market investigation with inputs from industry pros. The report covers the industry landscape and its own growth prospects over the next few years. The report also includes a discussion of the main vendors operating within this market.

View Full Report at: https://futuristicreports.com/insights/5105/global-acrylonitrile-butadiene-styrene-plastic-industry-market-research-report

About Futuristic Reports

We believe growth is the fundamental aim of any company, which makes businesses imperative to stay ahead of the market curve, abreast of expansions. Targeting different industries challenges, we help our clients, from various companies globally, and reach their development targets together with our market intelligence and consulting solutions. At Futuristic Reports rely on delivering strategic patterns of succeeding which help our client’s success by experiencing market knowledge that inspires strategies.

Media Contact:

Company Name: Futuristic Reports

Contact Person: Ross Williams

Email: [email protected]

Visit our website: https://futuristicreports.com

Phone: +1 (408) 520 9037

Address:2066 N. Capitol Ave, Suite 3041, City: San Jose, CA 95132 State: California

Country:United States

0 notes

Text

Copper Sulfate Market Trends, Share, Industry Size, Growth 2020 to 2024

Facto Market Insights published a title on “COPPER SULFATE MARKET – 2020-2024”, to its collection. The study on the global copper sulfate market defines the analysis of all the segments, along with the market sizing, year-over-year growth analysis and structure of the industry. The research report also includes the analysis of geographical manufacturers & new market players, covering all the data & information suitable for the clients to make strategic business decisions.

The market research report provides detailed analysis of market drivers, challenges, opportunity analysis, and trends, along with various key insights into the global copper sulfate market research report. The study on global copper sulfate market demonstrates the important aspects that are envisioned to shape the growth of the global market over the forecast period. In addition, the report also covers the facts & figures related to the macroeconomic trends that are anticipated to impact the growth of the market.

Get Free Sample Report at https://www.factomarketinsights.com/sample/128

Additionally, the study covers the pestle analysis and porter’s five forces analysis which demonstrates the five forces including buyers bargaining power, suppliers bargaining power, the threat of new entrants, the threat of substitutes, and degree of competition in the global copper sulfate market. The market research report represents the framework of porter's five forces analysis explains the method for examining the competition of the business covering the structure of industry & the level of competition in the market.

Moreover, the study also covers the section of competitive landscape of the global copper sulfate market including the market share & positioning of all the major & prominent players in the market. The competitive landscape analysis provides in-depth analysis of the company’s business and performance including company overview, recent investments by top players, financial information of market players, business strategy, revenue breakup by segment and by geography, SWOT Analysis, key product offering, marketing and distribution strategies, new product development. The section of recent news & development has been added to the market research report which covers the latest information that are related with the market covering the product launch, innovation, acquisition, expansion, technology development, research & development activities, and other market activities.

For Full Report with TOC Visit at https://www.factomarketinsights.com/report/128/copper-sulfate-market-outlook-2019-2024-amr

Impact of COVID-19 Disease on Global COPPER SULFATEMarket:

The research report on global copper sulfate market explains the impact of corona virus disease (COVID-19), covering the following points:

- How the corona virus pandemic is going to impact the overall copper sulfate market in the upcoming years.

- Identifying the issues & disruptions caused by COVID-19on the basis of region & countries on the market

- What strategies are being adopted by the manufacturers to survive such pandemic in the near future?

Segmentation:

By Product Type:

- Food Grade Copper Sulfate - Technical Grade Copper Sulfate - Feed Grade Copper Sulfate

By Application Type:

- Agriculture - Animal Nutrient - Electroplate - Mining - Chemical Intermediates - Textile & Leather

By Region Type:

The geographies are fragmented into the country and regional groupings:

- North America (U.S. & Canada)

- Latin America (Brazil, Mexico, Colombia, Argentina, Peru, Chile, Cuba, and Rest of Latin America)

- Europe (Germany, United Kingdom, France, Italy, Spain, Russia, Belgium, Netherlands, Luxembourg, Poland, Romania, Czech Republic, Portugal, Switzerland, Denmark, Finland, Sweden, and Rest of Europe)

- Asia Pacific (China, India, Japan, South Korea, Indonesia, Taiwan, Australia, New Zealand, Philippines, Thailand, Malaysia, Cambodia, Hong Kong, Singapore, Laos, and Rest of Asia Pacific)

- Middle East & Africa (GCC (Saudi Arabia, UAE, Bahrain, Kuwait, Qatar, Oman), North Africa, South Africa, and Rest of Middle East & Africa)

Competitive Landscape:

The market research report covers the section of competitive landscape in the global copper sulfate market, including profiles of various major & niche key market players:

- Anhui Tongling Jinhao Chemical Co., Ltd. - Anshan Xinxingda Mineral Substance Co., Ltd. - Aurubis AG - Boliden AB - Cuprichem Limited - Jiangxi Copper Co., Ltd. - Jinchuan Group Ltd. - JX Nippon Mining & Metals Corporation - KGHM Polska Miedź S.A. - Kimleigh Chemicals SA - Manica S.p.a. - MCM Industrial - Meltex Inc. - NEKK OJSC - Old Bridge Chemicals, Inc.

For any Inquiry before buying this report visit at https://www.factomarketinsights.com/enquiry/128

About Us:

Facto Market Insights is one of the leading providers of market intelligence products and services. We offer reports on over 10+ industries and update our collection daily which helps our clients to access database of expert market insights on global industries, companies, products, and trends.

Our in-house research experts have a wealth of knowledge in their respective domains. With Facto Market Research, you always have the choice of getting customized report free of cost (up to 10%). Our support team will help you customize the report and scope as per your business needs. This ensures that you are making the right purchase decision.

Our clients list includes various Fortune 500 companies and leading advisory firms.

Contact Us:

Facto Market Insights

90 State Street, Albany,

New York, USA 12207

+1 (518) 300-1215

Email:[email protected]

Website: www.factomarketinsights.com

0 notes