#electric car charging cornwall

Explore tagged Tumblr posts

Text

#car charger installation#Electric Vehicle Charger#Home Charging Station#EV Charging Solutions#Electric Vehicle Charger Installer#EV Charger Installation#car charging point installation#electric car charging point installation#ev installer#charging point installation#home car charger installation#electric vehicle charger installation#charge point charger#electric car charging cornwall#cornwall car chargers#electric car charging stations home installation#install home charger for car#electric car chargers for home use#installing electric vehicle charger#solar installation#home solar installation#pv installation#installation of ev charger#solar power and battery#solar panel installation cornwall#solar installation in cornwall#power point installer#solar installers cornwall#ev charging installer#install electric car charger

2 notes

·

View notes

Text

Helston car park to get electric vehicle charging points.

Helston car park to get electric vehicle charging points. Written by Daniel and read to you by Cassidy. Subscribe to Electric Vehicle News Bitesize Podcast for FREE to hear more! Helston car park is one of many in Cornwall where 150 electric car charging points will be installed in the coming months. This was confirmed following work at the Trengrouse Way Extension Car Park, where metal poles…

View On WordPress

0 notes

Text

WHEELS

It Looks Like a Vespa, Rides Like a Vespa, but Doesn’t Smell Like a Vespa

An Irish mechanic in London has developed a kit to transform classic Italian scooters into clean-riding electric machines.

By Nick Czap

April 1, 2021, 6:00 a.m. ET

Among the iconic designs of Italy’s vibrant postwar period, few capture the essence of La Dolce Vita like Vespas and Lambrettas, the free-spirited motor scooters that brought mobility to the masses and became beloved across Italy, and subsequently, the world.

While the two companies still make scooters, those early models — whose whining two-stroke engines spew plumes of aromatic smoke — are by far the most sought by collectors, some commanding up to $30,000.

But just as vintage scooters are reaching a new peak of popularity, a wave of emissions regulations aimed at reducing pollution threatens their access to Europe’s city centers. Within every regulation, though, lies an opportunity, and one lifelong scooter enthusiast has seized it firmly by the tailpipe.

Niall McCart, an Irishman from the city of Armagh, got his first Vespa at 16. De rigueur for a youth swept up in Britain’s early-1980s Mod revival, the Vespa was eminently practical as well.

“A two-stroke is a very simple mechanical structure,” Mr. McCart said, with a modesty common to the mechanically gifted. “I could fix it with a screwdriver and a hammer” — an ability that would eventually serve him well on rallies along the English coast, and on extended tours of Europe and India.

In 1989, at the age of 21, Mr. McCart moved to London, where, after stints in the building trade and delivering packages on a Vespa, he began working as a mechanic at a scooter shop. In 2000, he opened his own concern in a garden shed. Today, his business, Retrospective Scooters, occupies a 3,500-square-foot warehouse in the East End town of Walthamstow.

As Mr. McCart’s business grew, so did restrictions on older vehicles. The European Union’s first Low Emission Zones were established in 1996. By 2018, there were over 260, and still rising.

London has one such zone, as well as an extra-stringent Ultra Low Emission Zone, in the city center. Introduced in April 2019, the more stringent zone will expand substantially this October. To drive inside it, owners of polluting scooters must pay a daily fee of 12.50 pounds (about $17). Failure to pay can result in a hefty fine.

In 2017, with the end of cheap and dirty scootering looming, Mr. McCart posed a question to a friend and fellow scooter enthusiast, John Chubb: “Wouldn’t it be great if we could make our old Vespas electric?”

Mr. Chubb recalled the moment vividly. “We were sitting in a tent in a music festival in Cornwall, and he was saying the future is electric. I said, ‘I reckon I could build one of those.’”

He could also bring a raft of technical competencies to the project. A retired Royal Navy commander with degrees in electrical engineering and rocket science, Mr. Chubb is also an expert in anti-ship missiles, a qualification whose benefit, though perhaps unquantifiable, couldn’t hurt.

Mr. McCart’s brief was explicit. The conversion “was not to interfere in any way with the original design and setup of the scooters,” he said. “You don’t do any cutting or welding or destruction of the original chassis.” And critically important for preserving a scooter’s value, the process had to be reversible.

An encounter with a Chinese manufacturer at a motorcycle show in Milan in 2017 proved instrumental.

“The Chinese have been riding electric scooters for 15 years-plus,” Mr. McCart said. “They’ve done it and made it and perfected it. They had it all laid out.”

Mr. Chubb, meanwhile, hobnobbed with the chief technical officer of QS Motor, a firm in Zhejiang Province that makes motors for electric scooters and e-bikes.

“We had a really good conversation,” Mr. Chubb said. “I’d done a whole load of first-principles calculations about the power of an electric motor and how that would work in an electric scooter. I saw all his equations, and he and I did it exactly the same way.

“Seeing that data was very interesting,” he continued, “because we knew exactly where the sweet spot was in terms of the specifications of what we wanted to run as a motor, and we could run it more or less to optimum efficiency.”

Mr. McCart and Mr. Chubb devised the basic plan: Pull the gas tank and put a lithium-ion battery in its place, and replace the scooter’s original swing arm (which supports the engine and rear wheel) with a custom-made swing arm that holds a wheel with a built-in hub motor.

Mr. Chubb set to work on the prototype, meeting periodically with Mr. McCart, who fine-tuned various components. In June 2018, Mr. McCart unveiled their creation — an electrified 1976 Vespa Primavera — at the Vespa World Days rally in Belfast, Northern Ireland.

The initial reaction was skeptical. “These guys were purists,” Mr. McCart said. “They were against it when they seen it,” he recalled, “but as soon as they drove it to the other end of the car park and back again, they had the biggest grin on their face.”

One rider made a pivotal suggestion: “You’ve got to sell it as a kit.” Mr. McCart, who had planned to offer electric conversions only as a service, embraced the idea. “I thought, ‘He’s right. I’ve got to make it really simple.’ The next step was to try and make a plug-and-play kit.”

Three years later, Retrospective Scooters sells kits for five types of vintage Vespas and Lambrettas. Costing £3,445 (about $4,750), each includes a 64-volt, 28-amp-hour battery that can push a scooter to a top speed of 50 miles an hour and go 30 to 35 miles on a charge.

Certain scooters can accommodate two or three batteries. A Lambretta GP for instance, packed with three lithium-ion units, can go 120 miles between charges. Mr. McCart, though, thinks a single battery is sufficient.

“Let’s not forget what scooters were invented for — traveling in a 20-to-30-mile radius of where you lived,” he said.

To date, Mr. McCart has sold 60 kits — 24 in Britain (20 of them installed at his shop), and 36 to customers overseas, mostly, and somewhat surprisingly to Mr. McCart, in the United States.

“I expected more to go into Europe,” he said, “but there’s quite a lot of bureaucracy and official inspections of any vehicle alterations, so there’s really no incentive for Europeans to buy our kit with all that up against them.

Last summer, Danny Montoya, the owner of a children’s woodworking studio in San Francisco, installed a kit in his 1973 Vespa Rally 180. Mr. Montoya had owned the scooter since 1999, but in recent years had grown uneasy with its pollution, not to mention the constant reek of petroleum.

A capable do-it-yourselfer, he initially considered cobbling together his own electric kit with information gleaned from internet message boards, but when he came across Mr. McCart’s, he said, he thought: “Whoa, this guy has actually done the work.” Although the price gave him pause, after corresponding with Mr. McCart, who promised to assist with any technical issues, Mr. Montoya said, “OK, this is legit.”

Mr. Montoya estimates he spent 20 to 30 hours on the project, the most complex part of which, he said, was ensuring that all of the electrical connections were correct. Mr. McCart acknowledges that at the time, in late 2020, the installation guide was rudimentary. Since then, he explained, the design of the kit and the instructions have been improved so that someone with basic mechanical skills should be able to complete the installation in about 16 hours.

These days, Mr. Montoya seeks any excuse to ride his electrified machine, which performs just as advertised, delivering 30 miles on a charge, even on San Francisco’s hills. Recalling his first ride, Mr. Montoya said: “It was very weird. A normal scooter is so loud, all you hear is the motor. This is so quiet, all you hear is the wind.”

On a recent afternoon, as Mr. Montoya did a few drive-bys, a reporter struggled to discern which was louder — the soft hum of the motor or the sound of the tire treads licking the pavement.

The new incarnation is so stealthy, in fact, Mr. Chubb finds that “when you live in a quiet village, people walk right in front of you.” He’s looking into noise generators that could produce anything from the thrum of a Harley-Davidson to the futuristic racket of a “Star Wars” Podracer.

Mr. McCart, who commutes every day on his electrified Vespa, takes a different approach to unwary pedestrians: “I shout at them. I say, ‘Oi!’”

0 notes

Link

It Looks Like a Vespa, Rides Like a Vespa, but Doesn’t Smell Like a Vespa Among the iconic designs of Italy’s vibrant postwar period, few capture the essence of La Dolce Vita like Vespas and Lambrettas, the free-spirited motor scooters that brought mobility to the masses and became beloved across Italy, and subsequently, the world. While the two companies still make scooters, those early models — whose whining two-stroke engines spew plumes of aromatic smoke — are by far the most sought by collectors, some commanding up to $30,000. But just as vintage scooters are reaching a new peak of popularity, a wave of emissions regulations aimed at reducing pollution threatens their access to Europe’s city centers. Within every regulation, though, lies an opportunity, and one lifelong scooter enthusiast has seized it firmly by the tailpipe. Niall McCart, an Irishman from the city of Armagh, got his first Vespa at 16. De rigueur for a youth swept up in Britain’s early-1980s Mod revival, the Vespa was eminently practical as well. “A two-stroke is a very simple mechanical structure,” Mr. McCart said, with a modesty common to the mechanically gifted. “I could fix it with a screwdriver and a hammer” — an ability that would eventually serve him well on rallies along the English coast, and on extended tours of Europe and India. In 1989, at the age of 21, Mr. McCart moved to London, where, after stints in the building trade and delivering packages on a Vespa, he began working as a mechanic at a scooter shop. In 2000, he opened his own concern in a garden shed. Today, his business, Retrospective Scooters, occupies a 3,500-square-foot warehouse in the East End town of Walthamstow. As Mr. McCart’s business grew, so did restrictions on older vehicles. The European Union’s first Low Emission Zones were established in 1996. By 2018, there were over 260, and still rising. London has one such zone, as well as an extra-stringent Ultra Low Emission Zone, in the city center. Introduced in April 2019, the more stringent zone will expand substantially this October. To drive inside it, owners of polluting scooters must pay a daily fee of 12.50 pounds (about $17). Failure to pay can result in a hefty fine. In 2017, with the end of cheap and dirty scootering looming, Mr. McCart posed a question to a friend and fellow scooter enthusiast, John Chubb: “Wouldn’t it be great if we could make our old Vespas electric?” Mr. Chubb recalled the moment vividly. “We were sitting in a tent in a music festival in Cornwall, and he was saying the future is electric. I said, ‘I reckon I could build one of those.’” He could also bring a raft of technical competencies to the project. A retired Royal Navy commander with degrees in electrical engineering and rocket science, Mr. Chubb is also an expert in anti-ship missiles, a qualification whose benefit, though perhaps unquantifiable, couldn’t hurt. Mr. McCart’s brief was explicit. The conversion “was not to interfere in any way with the original design and setup of the scooters,” he said. “You don’t do any cutting or welding or destruction of the original chassis.” And critically important for preserving a scooter’s value, the process had to be reversible. An encounter with a Chinese manufacturer at a motorcycle show in Milan in 2017 proved instrumental. “The Chinese have been riding electric scooters for 15 years-plus,” Mr. McCart said. “They’ve done it and made it and perfected it. They had it all laid out.” Mr. Chubb, meanwhile, hobnobbed with the chief technical officer of QS Motor, a firm in Zhejiang Province that makes motors for electric scooters and e-bikes. “We had a really good conversation,” Mr. Chubb said. “I’d done a whole load of first-principles calculations about the power of an electric motor and how that would work in an electric scooter. I saw all his equations, and he and I did it exactly the same way. “Seeing that data was very interesting,” he continued, “because we knew exactly where the sweet spot was in terms of the specifications of what we wanted to run as a motor, and we could run it more or less to optimum efficiency.” Mr. McCart and Mr. Chubb devised the basic plan: Pull the gas tank and put a lithium-ion battery in its place, and replace the scooter’s original swing arm (which supports the engine and rear wheel) with a custom-made swing arm that holds a wheel with a built-in hub motor. Mr. Chubb set to work on the prototype, meeting periodically with Mr. McCart, who fine-tuned various components. In June 2018, Mr. McCart unveiled their creation — an electrified 1976 Vespa Primavera — at the Vespa World Days rally in Belfast, Northern Ireland. The initial reaction was skeptical. “These guys were purists,” Mr. McCart said. “They were against it when they seen it,” he recalled, “but as soon as they drove it to the other end of the car park and back again, they had the biggest grin on their face.” One rider made a pivotal suggestion: “You’ve got to sell it as a kit.” Mr. McCart, who had planned to offer electric conversions only as a service, embraced the idea. “I thought, ‘He’s right. I’ve got to make it really simple.’ The next step was to try and make a plug-and-play kit.” Three years later, Retrospective Scooters sells kits for five types of vintage Vespas and Lambrettas. Costing £3,445 (about $4,750), each includes a 64-volt, 28-amp-hour battery that can push a scooter to a top speed of 50 miles an hour and go 30 to 35 miles on a charge. Certain scooters can accommodate two or three batteries. A Lambretta GP for instance, packed with three lithium-ion units, can go 120 miles between charges. Mr. McCart, though, thinks a single battery is sufficient. “Let’s not forget what scooters were invented for — traveling in a 20-to-30-mile radius of where you lived,” he said. To date, Mr. McCart has sold 60 kits — 24 in Britain (20 of them installed at his shop), and 36 to customers overseas, mostly, and somewhat surprisingly to Mr. McCart, in the United States. “I expected more to go into Europe,” he said, “but there’s quite a lot of bureaucracy and official inspections of any vehicle alterations, so there’s really no incentive for Europeans to buy our kit with all that up against them.” Last summer, Danny Montoya, the owner of a children’s woodworking studio in San Francisco, installed a kit in his 1973 Vespa Rally 180. Mr. Montoya had owned the scooter since 1999, but in recent years had grown uneasy with its pollution, not to mention the constant reek of petroleum. A capable do-it-yourselfer, he initially considered cobbling together his own electric kit with information gleaned from internet message boards, but when he came across Mr. McCart’s, he said, he thought: “Whoa, this guy has actually done the work.” Although the price gave him pause, after corresponding with Mr. McCart, who promised to assist with any technical issues, Mr. Montoya said, “OK, this is legit.” Mr. Montoya estimates he spent 20 to 30 hours on the project, the most complex part of which, he said, was ensuring that all of the electrical connections were correct. Mr. McCart acknowledges that at the time, in late 2020, the installation guide was rudimentary. Since then, he explained, the design of the kit and the instructions have been improved so that someone with basic mechanical skills should be able to complete the installation in about 16 hours. These days, Mr. Montoya seeks any excuse to ride his electrified machine, which performs just as advertised, delivering 30 miles on a charge, even on San Francisco’s hills. Recalling his first ride, Mr. Montoya said: “It was very weird. A normal scooter is so loud, all you hear is the motor. This is so quiet, all you hear is the wind.” On a recent afternoon, as Mr. Montoya did a few drive-bys, a reporter struggled to discern which was louder — the soft hum of the motor or the sound of the tire treads licking the pavement. The new incarnation is so stealthy, in fact, Mr. Chubb finds that “when you live in a quiet village, people walk right in front of you.” He’s looking into noise generators that could produce anything from the thrum of a Harley-Davidson to the futuristic racket of a “Star Wars” Podracer. Mr. McCart, who commutes every day on his electrified Vespa, takes a different approach to unwary pedestrians: “I shout at them. I say, ‘Oi!’” Source link Orbem News #doesnt #rides #Smell #Vespa

0 notes

Text

How ‘green’ are electric cars?

With the ban of new petrol and diesel cars in place in the UK by 2030, sales of electric cars are expected to surge. Plug-in hybrid and electric vehicles accounted for more than 1 in 10 vehicle registrations in 2020, up from 1 in 30 in 2019, according to data published by the Society of Motor Manufacturers and Traders.

The International Energy Agency predicts that by 2030, 125 million electric vehicles will be owned around the world and the UK government aims for almost every car and van on the road to be zero emission by 2050.

But just how green are they?

Electric cars are undoubtedly cleaner than fossil fuel run cars. Although more energy is required to make electric vehicles than petrol, you still save more energy in the long run. The deficit is paid off quickly and even, when with no alternative, the electricity used to charge the vehicles is driven by fossil fuels, they are still greener.

However, it is important to address the huge implications for our natural resources not only to produce green technologies like electric cars, but to keep them charged.

Challenges

For every car on our roads to be zero emission by 2050, just under double the current total annual world cobalt production, 75% of the world’s lithium production and at least 50% of the world’s copper production would be required.

Currently, electric cars rely on lithium and cobalt batteries to run, which, whilst undoubtedly better for the environment than carbon, aren’t entirely clean.

Cobalt mining

Cobalt is a key ingredient in the lithium-ion batteries that power electric cars, because it enables the energy density required in batteries intended to last for hundreds of miles per charge.

However, the mining of cobalt is fraught with political issues. 60% of cobalt comes from the Dominican Republic of Congo where children as young as 7 years old are mining it. The mining process also causes terrible pollution in local rivers.

Lithium-ion batteries used in electric cars and other consumer electronics account for about half of all cobalt demand, and the demand for these batteries is projected to more than quadruple over the next decade.

Lithium mining

Lithium is currently produced far from the UK — In 2019, Australia was responsible for more than half of global lithium supply, with the bulk of the rest supplied by Chile, China and Argentina. Lithium deposits are also located near some of the most sensitive ecosystems in the world – The Amur River, on the border of Russia and China, the Andes Mountains (Chile) and the Salt Flats in Bolivia. Deforestation, water shortages and toxic leaks are unfortunately a devastating consequence of lithium mining. Lithium extraction in salt flats in Bolivia uses millions of litres of water. The Sales de Jujuy plant produced 14,000 tonnes of lithium in 2018, using up to 420 million litres of water – the equivalent of 168 olympic sized pools.

Prof. Richard Herrington, Head of Earth Sciences Department, Natural History Museum said: “Society needs to understand that there is a raw material cost of going green and that both new research and investment is urgently needed for us to evaluate new ways to source these. This may include potentially considering sources much closer to where the metals are to be used.”

Recycling

Research in Australia found that only 2% of the country’s 3,300 tonnes of lithium-ion waste was recycled. Because lithium cathodes degrade over time, they can’t simply be placed into new batteries. “That’s the problem with recycling any form of battery that has electrochemistry – you don’t know what point it is at in its life,” says Stephen Voller, CEO and founder of ZapGo. “That’s why recycling most mobile phones is not cost effective. You get this sort of soup.”

At present, there are low volumes of electric-vehicle batteries that require recycling. As these volumes increase dramatically, there are questions concerning the economies (and diseconomies) of scale in relation to recycling operations.

Charging inefficiency

One of the biggest challenges, not just for the UK, but around the world is the installation of charging points. We need more, faster, more reliable charge points for people to be persuaded to take the plunge and purchase electric. Cars also need to be charged at smart times of day to avoid unnecessary costs for energy networks (and ultimately the consumers who pay for them).

Solutions

Sourcing locally

Luckily, lithium is relatively abundant, and could in theory be generated from seawater across the globe in the future.

In Britain, there are exciting developments in the lithium industry. Researchers working on ways to source lithium, a critical component of the batteries used in electric vehicles, have produced a chemical known as lithium carbonate from rocks found in Cornwall and Scotland.

Cornwall has a world-class mineral quality, which has stood idle for decades. The battery revolution provides the opportunity to explore raw materials which are vital to modern technologies such as electric cars. Cornish Lithium believes that the extraction of lithium has the potential to rejuvenate the economy of Cornwall and to provide much needed high value employment.

While the UK may not be a global player, to be able to produce what it needs would place it at a serious advantage over non-lithium- producing countries. It’s an exciting step forward which sets Britain on a good course to create its own EV supply chain in the next five years, which is especially important since the UK left the European Union.

Under the terms of the new free trade agreement with the EU, for goods sold in the EU to qualify as tariff free they must have components produced under localised sourcing. UK-based car makers need to have developed their own local battery supply chain by 2026 in order to avoid these charges.

Alternative resources

As mentioned above, resources like Cobalt aren’t infinite, and the environmental issues associated are prominent. We ideally need to shift to batteries that use less cobalt, or none at all. Elon Musk’s car firm Tesla will make electric vehicle batteries with cobalt-free cathodes, it announced during its Battery Day event in Autumn last year, but there is no set timeline on this yet.

For short-range cars made and sold in China, Reuters says Tesla will instead use lithium-iron-phosphate batteries, which are much cheaper and don’t have the same environmental problems as those needing cobalt. The disadvantage is that these batteries tend to have a lower energy density, reducing how far a car can drive without needing to charge.

Lithium-iron-phosphate batteries are already widely used by other Chinese firms, including BYD, the world’s biggest electric car manufacturer. If other electric car manufacturers follow internationally, we may be able to reduce our dependency on a dwindling mineral resource.

Recycling research

At the University of Birmingham, research funded by the government’s £246m Faraday Challenge for battery research is trying to find new ways of recycling lithium-ion. Researchers, led by the Birmingham Energy Institute are using robotics technology developed for nuclear power plants to find ways to safely remove and dismantle potentially explosive lithium-ion cells from electric vehicles.

A number of improvements could make the recycling processes economically more efficient, such as better sorting technologies, a method for separating electrode materials, greater process flexibility, design for recycling, and greater manufacturer standardization of batteries.

Battery swap shops

China, with electric vehicle sales of more than one million a year, is demonstrating how the charging issues can be addressed with battery ‘swap shops’ in which owners can drive into forecourts and swap batteries quickly. NIO, the Shanghai-based car manufacturer, claims a three-minute swap time at these stations.

This also addresses the high cost of EVs currently. By using the swap concept, the battery could be rented, with part of the swap cost being a fee for rental. This could reduce the purchase cost and incentivise more people to purchase electric. The swap batteries could also be charged using surplus renewable electricity, which is a real plus for the environment.

Electric alternatives

It’s the electric vehicles that have taken off in the world of green automotives. However, there is another player in the field – hydrogen. Hydrogen cars are powered by a chemical reaction. Hydrogen enters the fuel cell from a tank and mixes with oxygen to create H2O, which generates electricity that is used to power the motors that drive the wheels.

Hydrogen tanks are refuelled in a process that’s pretty much the same as with a petrol or diesel car. You could fill your car up just like fossil fuel, but instead of greenhouse gases being emitted, the exhaust would just be pure water vapour. Compared to waiting around for an EV’s battery to recharge, hydrogen appeared to be the much more convenient option.

The challenge is that hydrogen is very energy intensive to create as converting the electricity to hydrogen via electrolysis is only 75% efficient. Then the gas has to be compressed, chilled and transported, which loses another 10%. The fuel cell process of converting hydrogen back to electricity is only 60% efficient, after which you have the same 5% loss from driving the vehicle motor as for a BEV. The grand total is a 62% loss in energy – more than three times as much as an electric car.

Nevertheless, hydrogen still has niches where its main strengths – lightness and quick refuelling – give it a clear advantage. While you can fit your personal driving lifestyle around strategic battery charging stops, this is not ideal for commercial vehicles such as trains that need to run for very long periods and distances with only short waits to refuel. The weight of batteries for eight hours of continual usage would also be prohibitive for these vehicles. Therefore, hydrogen could be a viable option, despite the inefficiency.

The post How ‘green’ are electric cars? appeared first on Renewable Energy World.

from https://ift.tt/3ujBf4C

0 notes

Text

#EV Car Charger cornwall#electric car charging cornwall#cornwall car chargers#solar panel installation cornwall#solar installation in cornwall#power point installer#solar installers cornwall#ev charging installer#commercial ev charger installation#solar cornwall#battery installations#solar panels cornwall#electrician jobs cornwall#ev charging cornwall#Electric Vehicle Charger#Home Car Charging#Electric Vehicle Charger Installer#zappi charger installation#cornwall services ev charging#zappi car charger installation#install electric car charger#electric car charging stations home installation#install home charger for car#electric car chargers for home use#installing electric vehicle charger#solar installation#home solar installation#pv installation#installation of ev charger#charging point installation

1 note

·

View note

Text

Helston car park to get electric vehicle charging points.

Helston car park to get electric vehicle charging points. Written by Daniel and read to you by Cassidy. Subscribe to Electric Vehicle News Bitesize Podcast for FREE to hear more! Helston car park is one of many in Cornwall where 150 electric car charging points will be installed in the coming months. This was confirmed following work at the Trengrouse Way Extension Car Park, where metal poles…

View On WordPress

0 notes

Text

Shadow Chancellor John McDonnell speech to Labour Party Conference

John McDonnell MP, Shadow Chancellor, speaking at the Labour Party Conference in Brighton today, said:

***CHECK AGAINST DELIVERY***

I’d like to thank Ken Loach for that wonderful film and thank Ken for his incredible contribution to our movement. Can I also thank the Shadow Treasury Team: Peter Dowd our Shadow Chief Secretary to the Treasury; Anneliese Dodds; Jonathon Reynolds; Denis Tunnicliffe; Bryan Davies and my brilliant PPS Karen Lee

Only a few months ago we were 24 points behind in the polls. Our opponents and virtually every political commentator = those two groups are often interchangeable by the way - they predicted that we would be wiped out in the general election.

I said then in interview after interview that the polls would narrow and we would shock them all. Not many believed me. And let’s be honest until you saw the exit polls, most of you were pretty on edge too, weren’t you?

Before the election, I said that once we entered the election period and broadcasters were legally obliged to give us some semblance of balanced coverage, we would turn the poll ratings around.

Why? Well, first because people would be given a chance to see Jeremy Corbyn for what he is. The honest, principled and, yes, the strong and determined person and leader that he is. And, second, because people would see in our Manifesto what we really stood for and our vision of hope.

And that is what happened. And it’s also down to you, our members, whose overwhelming enthusiasm inspired people in their millions to come out and vote for us. I want to thank you all.

So yes, we have proved that we are an effective campaigning Party. We now have to prove that we will be an effective governing party. A Government that can set the political agenda for a generation.

If you study the history of our Party, you will see that it’s always been the role of Labour Governments to lead our country into each new era.

It was the Attlee Labour Government that built a new society from the debris of the bomb sites, in the new era after the Second World War. Those men and women who had endured so much throughout the depression of the 1930s and who had sacrificed so much to defeat fascism, placed their trust in our party.

My Dad was a sergeant in the army and my Mum a welder by day, in a munitions factory, and an ARP warden at night. They came out of the war with that spirit of 1945, inspired in them by the election of a Labour Government.

And the Labour Party fulfilled its promise to them and all the other families by creating the welfare state, providing free education for their children, building them a decent home ,investing in an economy based upon full employment. And, of course, creating that jewel in our crown, our NHS.

In the 1960,s when the Tories governed this country from their gentlemen’s clubs on behalf of the privileged few and held this country back from facing the challenges of the modern era, it was the Wilson Labour Government that recognised the potential of a modern Britain, forged, as he said in “the white heat of the scientific revolution.”

For my brother and me, and so many others of our generation, new educational opportunities enabled us to challenge the barriers that had held so many working-class kids back.

And, yes, in 1997, after 18 years of Thatcherism, when whole industries and communities across our country had been destroyed by the Torie,s and our public services were on their knees, it was the Blair/Brown Government that recognised and delivered the scale of public investment that a 21st century society needed.

We should never forget that we are part of that great Labour tradition and we should be so proud of it.

So as we now enter the next, new era, the era of the fourth industrial revolution, I tell you it is a Corbyn Labour Government that will rescue our country from the long years of austerity. And it will be up to us to lay the foundations of the new world that awaits us.

That new world is being shaped already by the beginnings of the fourth industrial revolution. Huge changes are underway in our society and economy. Technological change is accelerating. This year, Chinese scientists used quantum mechanics to teleport data to a satellite.

We can match that, we’ve got a Tory Government teleported from the 18th century. We are determined that Britain embraces the possibilities of technological change – scary though that may be. By the middle of this century, it is possible that up to half of all the jobs we do now could be automated away.

The jobs that remain can, if we let them, be exploitative, dangerous, degrading, and dead-end. Or the jobs we create can provide good, secure employment, in work that is fulfilling and meaningful, in communities where pride and prosperity has been restored.

We have already had a foretaste of what this revolution would look like if it was left to the Tories. It is being used to vastly enrich a tiny elite, whilst creating a life for many workers of long hours, low pay, and insecure employment.

There’s a choice to be made. We can remain a low-wage economy,y specialising in zero hours contracts. Or we can use the state to help shape Britain’s future in this new world. We know it can be done.

As the Tories waste time and energy, alienating our closest trading partners, other countries are using state direction of innovation and investment to carve out vital areas of expertise - in robotics, in electronic cars, in cleantech, in the smart city. Though the technologies are new – the British problem is old. The City is not channelling investment into high value, high productivity businesses. Instead, it’s channelling investment into property speculation.

It’s the rentier economy, where wealth is secured not by what you produce, but by the amount of rent you can charge. So we will change that. We’ll put taxpayers’ money into key research projects; we’ll foster the creation of networks and clusters of expertise. To reconnect the financial sector to the economy of research and development and production, we will transform our financial system.

Labour will establish a Strategic Investment Board, comprising the Chancellor, Secretary of State for Business and Governor of the Bank of England, to co-ordinate the promotion of investment, employment and real wages.

In our investment strategy, we will no longer accept the disparities between investment in London and the Home Counties and the rest of the country.

This Tory Government plans to invest in the north just one-fifth of what it will spend on transport per head in London.

We will legislate for a fair distribution of investment. We’ll devolve decision making through the Regional Development Banks, our Mayors, and regenerate the powers and resources available to local councils.

We’ll build Crossrail for the north, connecting our great northern cities from west coast to east, and extend HS2 into Scotland. We’ll deliver the funding for Midlands Connect, overhauling transport across the Midlands. And we’ll overturn decades of neglect and lack of investment in the South-West. We’ll electrify railway lines from Cornwall right through to London.

The storms and flooding sweeping the world in these last few months are yet another environmental wake up call. This country has huge natural, renewable resources. And we have an immense heritage of scientific and engineering expertise. Yet this Government has slashed the funding, the renewables industry needs to find its feet.

Labour will ensure we become world leaders in decarbonising our economy. With a publicly owned energy supply based on alternative energy sources. Where the Tories have dithered and delayed, to deliver zero-carbon electricity, we will absolutely commit for example to building projects like the Swansea Tidal Lagoon.

Ours will only become an economy for the many, if we significantly broaden ownership. That means supporting entrepreneurs, small businesses, the genuinely self-employed and massively expanding worker control and the co-operative sector.

Building an economy for the many also means bringing ownership and control of the utilities and key services into the hands of people who use and work in them. Rail, water, energy, Royal Mail- we’re taking them back.

We cannot allow this dynamic vision for our economy to be undermined by the combination of belligerence and incompetence, displayed by the Tories in the current EU negotiations. Our aim is to create a Britain for the many, not the few. Our conscience doesn’t end at the English Channel. We also want a Europe for the many, not the few.

That’s why, whilst respecting the referendum decision, we will work with our partners across Europe to create a new European future, based upon collaboration and co-operation.

But we start with addressing the brutal treatment of EU citizens by this Government. We demand that the rights of EU citizens in this country are fully protected, just as we wish to secure the rights of UK citizens in other EU countries.

And I warn the Tories if they try to water down, or undermine protections we have secured on employment, consumer or environmental rights, we will give them the political battle of their lives.

As we go into Government, you know we will have to clear up the mess the Tories will have left us. After their long years of austerity, the Tories are leaving a society steeped in debt and scarred by low pay and insecurity, with our public services in meltdown. We will commission a thorough review of the scale, causes and responses to debt. But action is needed fast.

First, we will do what the Tories have failed to do, and bring the Government’s deficit and debt under effective control. The Tories have borrowed more than any Labour Government ever.

On arrival in office, we will set out plans to eliminate the deficit and reduce debt, based upon our Fiscal Credibility Rule. For each policy in our Manifesto, we are preparing detailed implementation plans. To pay for our public services, we will close the tax loopholes and avoidance scams used by the mega-rich, and we will make sure the rich and the giant corporations pay their way.

Many people are also forced into debt by low wages. It cannot be right that we are the only major developed economy to have grown, while wages are lower than they were before the crash ten years ago. And as inflation hits, many workers are facing yet another real-terms cut in their pay, while the pay of FTSE 100 Chief Executives is 160 times that of the average worker.

In the election campaign Theresa May was asked why nurses were being forced to resort to foodbanks and she replied that the issue was complex. It isn’t complex. It’s simple. They just aren’t being paid enough.

That’s why we insist the pay cap is scrapped once and for all and not just for some, but for everybody. And we demand decent wages for all workers. Britain deserves a pay rise. It’s why we will introduce a real living wage of £10 an hour. We will introduce pay ratios at the top. We will address the gender pay gap that leaves women’s wages still trailing men’s by 14%. And we will ensure every piece of legislation will be measured against its impact on women before implementation.

I am proud to support those brave young people who are campaigning for decent wages now, and those who have joined the Bakers’ Union, to take on the might of McDonalds. Be clear, we will restore basic employment rights, repeal the Tories Trade Union Act, set up a new Ministry of Labour and restore collective bargaining.

As wages have fallen behind, more and more families are being pushed deeper into debt. Household debt in this country stands at the record level of more than £1.8 trillion. We have seen with pay day loans; some companies were making massive profits from people’s financial difficulties.

Under Labour pressure, the Government was forced to cap interest payments on payday loans. But more than 3 million credit card holders are trapped by their debt. They’ve paid more in interest charges and fees than they originally borrowed. The Financial Conduct Authority has argued for action to be taken on credit card debt as on pay day loans.

I am calling upon the Government to act now and apply the same rules on payday loans to credit card debt. It means that no-one will ever pay more in interest than their original loan. If the Tories refuse to act, I can announce today that the next Labour Government will amend the law. Call it the McDonnell amendment.

Some of the heaviest debt burden has fallen on young people.The Tories tripled tuition fees and allowed the Student Loans Company to hike up interest rate charges. Young people are now leaving university with ��57,000 worth of debt. That’s why we put forward our fully-costed commitment to scrap tuition fees.

And we will.

The Tories, with the connivance of the Liberal Democrats, have created a totally unsustainable situation. Three quarters of students will never fully repay their loans. So it’s not just bad for students; it’s a bad deal for the taxpayer too.

As a result of Labour pressure, the Government is now being forced into discussing reducing interest rates or raising repayment thresholds. If they bring forward effective proposals we will support them. But that won’t go nearly far enough. We can’t afford another five years of spiralling student debt.

According to the Institute for Fiscal Studies, and our independent research, writing off the Tories’ student debt now would cost £10bn by 2050. Waiting until 2022 could treble the cost of a write off. I am calling on the Chancellor to act now, before the situation becomes unmanageable.

It’s the Tories who have got young people into this mess, they should take some responsibility for getting them out of it.

It’s not just students and households with credit cards who are being ripped off.The scandal of the Private Finance Initiative, launched by John Major, has resulted in huge, long-term costs for tax payers, whilst handing out enormous profits for some companies. Profits which are coming out of the budgets of our public services.

Over the next few decades, nearly two hundred billion is scheduled to be paid out of public sector budgets in PFI deals. In the NHS alone, £831m in pre-tax profits have been made over the past six years. As early as 2002 this Conference regretted the use of PFI.

Jeremy Corbyn has made it clear that, under his leadership, never again will this waste of taxpayer money be used to subsidise the profits of shareholders, often based in offshore tax havens. The Government could intervene immediately to ensure that companies in tax havens can’t own shares in PFI companies, and their profits aren’t hidden from HMRC.

We’ll put an end to this scandal and reduce the cost to the taxpayers. How? We have already pledged that there will be no new PFI deals signed by us. But we will go further. I can tell you today, it’s what you’ve been calling for.

We’ll bring existing PFI contracts back in-house.

The Tories have tried to change people’s view of what is normal and acceptable in our society. They want us to accept that in the fifth richest country in the world it’s normal and acceptable for people to be saddled with debt; for people to have to work long, often insecure, hours, stressed out, struggling to find time with their family; for people not to have a pay rise for years no matter how dedicated you are or how hard you work; for young people to have no prospect of owning their own home; for disabled people to be pushed to the edge by the benefits system; or for carers to be struggling without support or recognition.

Let’s make it clear - we will never accept that this is normal or acceptable.

Yes we will increase GDP, close the current account deficit and increase productivity. But life is not just about statistics. As Bobby Kennedy said almost 50 years ago:

“The gross national product does not allow for the health of our children, the quality of their education or the joy of their play. It does not include the beauty of our poetry.” (18 March 1968)

The performance of our Government will be measured by the care we show to all our people and the richness of their lives.

We proved in the election, and we will now go on to prove in Government, our belief that:

Hope will always overcome fear.

Kindness and generosity will always overcome greedy self-interest.

And that the flame of solidarity in our society will never be extinguished.

For years we have proclaimed that “Another World is Possible.”

I tell you now, that world is not just possible, it is in sight.

Let’s create it together.

7 notes

·

View notes

Photo

Watch Want to drive your car all the way to the tip of the country on electricity alone? There's an app for that. Of course, what we didn't count on was a hay bale fire in the road, no charger at our destination and doing it all without a mirror. The electric adventure is very much here and now. The plan was to take the all-electric Jaguar I-PACE from London, over 300 miles, to Lands End in Cornwall. Can that be done quickly using fast chargers? Can you just hop in and go without a tap-to-pay electric charging station card? And can the car actually do all that while you stay comfortable? These were a few of the questions that pushed us to test this car to its long range limits. When we got in the car, we thought this electric Jag would banish fuel cars to the past, but we didn't expect to never look back literally. But as we adjusted the rear view mirror it dropped out of the car – no looking back at all then. It spent the rest of the journey in the glove box. While this was a.. video

#Games - #video -

0 notes

Text

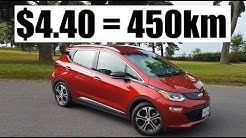

Chevy Bolt Charging Station Cost

Contents

Electric recharging point

Supplies electric energy

240v voltec home

Home charging station

240v charging station cost level 2—home

Public charging: level 2 charging

The JuiceBox Pro 40 will cost $579, while the outdoor version (hardwired) is slightly cheaper. The name Bosch is synonymous with premium grade equipments. The company has their very own EV charging …

The ChargePoint station owned by NPPD cost approximately $6,000 … Change can start with something small, with something like one Chevy Bolt and a single charging station in Columbus, Nebraska. And …

Nissan Electric Charging Stations Springbrook Ia Chevy Dc Fast Charging Stations Cornwall On Hudson Ny On many occasions, I’ve had to leave the Model S at home and take my Chevy Volt on trips to visit friends in upstate New York … the charging rate would slow further.) Still, 15 kW was more than … Obituaries for the last 7 days Leaf Charging Stations An electric vehicle charging station, also called EV charging station, electric recharging point, charging point, charge point, ECS (electronic charging station), and EVSE (electric vehicle supply equipment), is an element in an infrastructure that supplies electric energy for the recharging of electric vehicles, such as plug-in electric vehicles, including electric cars, neighborhood electric … The Cost To Install 240v Charging Station Now, California has ensured that new buildings at least will have electric-car charging in mind from the start. ALSO SEE: In CA, Renters Can Now Install Electric-Car Charging Stations The California . … Sure, the sticker price for the 240v voltec home charging unit designed to quickly and efficiently recharge the Chevrolet Volt is a

General Motors has consistently declined to fund public charging stations that increase the utility … CHECK OUT: More details on fast-charging rate in 2017 Chevy Bolt EV electric car That makes the …

You spend 35,000 on the new chevy bolt and hope you get rebates to bring it down to 30,000. Now add 1500 for a home charging station. Forget going on long trips becasue the chances of finding a charging station glacier national park is zero!

Mar 12, 2017 · Chevrolet Bolt at a dealer in suburban Los Angeles. It’s rated at about 240 miles of battery range.Brooke Crothers

Ev Car Charging Station 240v charging station cost level 2—home and public charging: level 2 charging typically requires a charging unit on a 240V circuit … vehicles during an eight-hour charge. Using a DC fast charger allows for rapid recharging at … Most electric vehicle charging is done at home, but it can be a bit of a daunting

I’ve had my Bolt LT for two weeks shy of a year now. I think Chevy did a wonderful job on it. About the seats, yes they are narrower than usual.

The Tesla Model 3 and the Chevy Bolt are your two main choices if you’re in the market for an all-electric vehicle with a range of at least 200 miles.

This time General Motors selected EVSE-RS as official home charging station for the 2017 Chevrolet Bolt EV, and this is what dealers will recommend you to buy. MONROVIA, Calif., Dec. 6, 2016 – General …

from Charging Chevy Station Cost Bolt https://ift.tt/2FhTSip

0 notes

Text

NEED AN EXPLAINER VIDEO IN THE SOUTH WEST, UK? – GET A 10% DISCOUNT!*

Bandini Videos has recently been relocated to the South West of England and is now based firmly in Somerset, United Kingdom.

Here we plan to produce many more of our excellent animated explainer videos for companies across the globe, as well as our locals in Somerset, Dorset, Devon, Cornwall, Gloucestershire, Wiltshire or Wales.

This means there are great opportunities for local brands to benefit from our expert skills as storytellers and brand builders through the medium of video, which is perfect for entertaining and engaging customers and prospects.

In fact we are so pleased to be here in the South West that we are offering all businesses who are also based here 10% off.

That means that if you are looking for an Explainer Video in Somerset, Dorset, Devon, Cornwall, Gloucestershire, Wiltshire or Wales we can help — and give you a neighbourly rate!

Here are some recent examples of our work:

A video made for a corporate client, which was used on their website and at their Money2020 exhibition in Las Vegas:

A video was prepared for a client who wanted to re-target visitors to their website with an reminder to get a free trial of their app on YouTube:

This video was created to show the benefits of a new mobile charging unit for electric cars:

We made this video for a new dating app company who focus on creating a safe online community of verified users:

It seems fitting for us to be here, because the South West is well known for its creative industries and creative people working hard to make great businesses and a bustling local economy.

Aardman Productions in Bristol, for example, is one of the biggest animation companies in the world, having produced stop motion animation for box office hits such as Chicken Run and Wallace & Gromit.

So whether you are a Cornwall firm making surfboards in Falmouth, a Dorset accountant in Poole, a Devon web developer or a Somerset cider farmer after an animation about the quality of your orchard’s apples, we can help.

And there are a three things that we can guarantee:

1) Our videos convert better than plain text. Yes, our animations will bring in more sales than your best website copy, because people love to watch video content online and be entertained as well as educated.

2) Explainer videos are best for presenting complex information in a simple engaging format. That’s right, explainer videos function like moving diagrams or graphics that present difficult to understand ideas clearly.

3) SEO on your website will be improved thanks to an animated video. With video you can boost the average visit time to your site and drive organic traffic to your site with ‘Video SEO’, which will make your videos rank in Google searches all by themselves.

To find out more about how Explainer Videos can help your business or to discuss our ‘South West Discount’, just get in touch: [email protected] // 0800 0029849.

INTERESTED TO KNOW MORE? CLICK HERE TO VISIT OUR HOME PAGE!

0 notes

Text

Britain looks to ancient mines for electric future

SOUTH CROFTY, England – Britain is banking on a series of ancient mines on its southwestern tip to secure a slice of the global electric car revolution.

FILE PHOTO: The remains of the engine house at the Wheal Prosper copper and tin mine is seen along the Cornish coastline near Porthleven in Cornwall, Britain October 26, 2017. REUTERS/Toby Melville/File Photo

The English county of Cornwall and the surrounding area boast one of the world’s largest tin deposits yet their centuries-old mines have lain abandoned since the 1990s when a collapse in prices for the metal made them unviable.

Now however a rise in demand for tin, along with other metals that can be used in electric vehicles, electronics and renewable energy, has helped create a global deficit and quadruple prices. British officials are supporting reopening of the mines and seeking investment, leading to a mini-rush of mining companies into the area.

Adding to the potential, new research shows the extent to which mines also contain deposits of lithium, the so-called metal of the future.

The first industrial metals mining in Britain for decades represents the country’s best shot at securing a piece of the supply chain for car batteries as well as renewable energy grid connections, officials told Reuters.

“We need to ensure the secure supply of the technology metals and critical minerals,” said government lawmaker Pauline Latham, who heads a parliamentary mining group. “This is necessary with China owning the majority of the market and the potential of a global trade war between China and America.”

It is however early days for the mining projects and there is no guarantee they will produce commercial volumes of metal. Even if they do, Britain is dwarfed by the likes of China, Chile and Australia in terms of battery resources.

The unlikely British mining revival is one example of how countries around the world are scrambling to grab a piece of the electric vehicle action, an area dominated by China, by far the biggest producer of battery metals.

Germany, for instance, is looking to produce lithium at the Zinnwald project in Southern Saxony to help secure supplies for its car industry. In Finland, a nickel mine in Sotkamo in the north aims to start producing material for electric vehicles by 2020, while battery-grade lithium production is planned in Kaustinen, to the west, in 2020.

Serbia, meanwhile, is looking to Rio Tinto to develop a giant mine for jadarite, a newly discovered mineral that contains both boron and lithium, in the west of the country.

Governments, keen to develop future-proof industrial strategies, are seeking to establish their own sources of minerals needed for electrification and electric vehicles to provide supply certainty, as well as revenue and jobs.

The British drive has become more pressing, officials said, because of the country’s upcoming exit from the European Union, the world’s biggest trading bloc.

MINI METALS RUSH

The charge into southwest England is being led by smaller firms, mainly foreign miners with a higher risk appetite. The majors prefer to mine on a vast scale, allowing them to increase margins and cut costs. They prefer to let junior players take the development risk and then buy fully fledged projects.

About half a dozen companies are exploring in the area, with the biggest players being Canada’s Strongbow Exploration, Australia’s New Age Exploration and Wolf Minerals, listed in Sydney and London.

In the largest Cornish project planned so far, Strongbow is seeking to extract tin at the 4 km-long South Crofty mines as a result of the improved tin market economics.

“The timing is better because global capital markets have a much more receptive attitude towards mining projects,” Strongbow CEO Richard Williams said. “This gives us a good chance of delivering on South Crofty.”

FILE PHOTO: A family walk past the remains of the engine house at the Wheal Prosper copper and tin mine, on the Cornish coastline near Porthleven in Cornwall, Britain October 26, 2017. REUTERS/Toby Melville/File Photo

The company needs to raise project financing of about $110 million. To that end, it plans to seek a secondary listing in London this year. It aims to start production in 2021, but first must pump out water that has accumulated over decades of dereliction.

New Age Exploration and its joint venture partner Strategic Minerals said in March they had found tin, tungsten and copper – all useful for electric vehicles – near Plymouth. They have invested about $2.65 million in the project, which is at an earlier stage than South Crofty, and are looking to raise financing.

Just over the English border in Devon, Wolf Minerals has begun operating a mine for tungsten and tin.

One advantage that Britain has, in terms of tin mining and investment, is that it is a stable location compared with big-producing nations such as Democratic Republic of Congo and Myanmar.

LITHIUM PROMISE

A British government-funded research team led by Cristian Rossi analyzed satellite data to find changes in vegetation and temperature that indicate there are some lithium reserves alongside the tin deposits in the area.

The study marked the first time satellite technology has been used to locate lithium – a valuable technique in Cornwall, which is covered in vegetation in contrast to South American prospects in exposed deserts.

“The percentages are small, but that does not mean it’s not relevant,” said Rossi, principal earth observations scientist of not-for-profit research group the Satellite Applications Catapult (SAC), told Reuters at a conference in March at Cornwall’s Camborne School of Mines to present his findings.

The government provided $1.2 million towards the research, which will be available to all explorers.

The SAC findings are currently being used by a British company called Cornish Lithium, which will begin drilling at South Crofty next year. It has an agreement with Strongbow that allows it to explore using Strongbow’s mineral rights, with Strongbow getting royalties from any lithium extracted.

CLIMBING PRICES

In 1998, when South Crofty was the last of hundreds of Cornish tin mines to shut after four centuries of operation, global tin demand was around 200,000 tonnes a year, and the tin price was languishing at around $5,000 per ton.

Now demand has risen to around 350,000 tonnes, buoyed by demand for electronics, where it is used as a replacement for toxic lead in solder. Tin can also be used in lithium-ion batteries, which could have a major impact on a market already in deficit. Tin prices have climbed above $20,000.

Lithium prices, meanwhile, rose by a quarter last year. Spot prices are currently between $22,000 and $24,000 a ton, according to industry sources.

In Britain, officials say the country is well-placed to capitalize on the anticipated boom in demand for electric vehicles in coming years.

“It’s as if we’ve fallen on our feet,” said Darryn Quayle, a mining specialist at government Department for International Trade. “What we have in our own backyard is quite remarkable.”

($1 = 0.7178 pounds)

Reporting by Barbara Lewis; Editing by Pravin Char

The post Britain looks to ancient mines for electric future appeared first on World The News.

from World The News https://ift.tt/2FnJPFg via Breaking News

0 notes

Text

Discover the convenience of EV Charge Points tailored for holiday parks and campsites and manage them with our easy-to-use software and earn extra revenue on every charge. Manta Power makes eco-friendly travel a breeze. Contact us for more information! https://www.mantapower.co.uk

#EV Car Charger cornwall#electric car charging cornwall#cornwall car chargers#solar panel installation cornwall#solar installation in cornwall#power point installer#solar installers cornwall#ev charging installer#commercial ev charger installation#solar cornwall#battery installations#solar panels cornwall#electrician jobs cornwall#ev charging cornwall#Electric Vehicle Charger#Home Car Charging#Electric Vehicle Charger Installer#zappi charger installation#cornwall services ev charging#zappi car charger installation#install electric car charger#electric car charging stations home installation#install home charger for car#electric car chargers for home use#installing electric vehicle charger#solar installation#home solar installation#pv installation#installation of ev charger#charging point installation

1 note

·

View note

Text

Helston car park to get electric vehicle charging points.

Helston car park to get electric vehicle charging points. Written by Daniel and read to you by Cassidy. Subscribe to Electric Vehicle News Bitesize Podcast for FREE to hear more! Helston car park is one of many in Cornwall where 150 electric car charging points will be installed in the coming months. This was confirmed following work at the Trengrouse Way Extension Car Park, where metal poles…

View On WordPress

0 notes

Text

Britain looks to ancient mines for electric future

SOUTH CROFTY, England – Britain is banking on a series of ancient mines on its southwestern tip to secure a slice of the global electric car revolution.

FILE PHOTO: The remains of the engine house at the Wheal Prosper copper and tin mine is seen along the Cornish coastline near Porthleven in Cornwall, Britain October 26, 2017. REUTERS/Toby Melville/File Photo

The English county of Cornwall and the surrounding area boast one of the world’s largest tin deposits yet their centuries-old mines have lain abandoned since the 1990s when a collapse in prices for the metal made them unviable.

Now however a rise in demand for tin, along with other metals that can be used in electric vehicles, electronics and renewable energy, has helped create a global deficit and quadruple prices. British officials are supporting reopening of the mines and seeking investment, leading to a mini-rush of mining companies into the area.

Adding to the potential, new research shows the extent to which mines also contain deposits of lithium, the so-called metal of the future.

The first industrial metals mining in Britain for decades represents the country’s best shot at securing a piece of the supply chain for car batteries as well as renewable energy grid connections, officials told Reuters.

“We need to ensure the secure supply of the technology metals and critical minerals,” said government lawmaker Pauline Latham, who heads a parliamentary mining group. “This is necessary with China owning the majority of the market and the potential of a global trade war between China and America.”

It is however early days for the mining projects and there is no guarantee they will produce commercial volumes of metal. Even if they do, Britain is dwarfed by the likes of China, Chile and Australia in terms of battery resources.

The unlikely British mining revival is one example of how countries around the world are scrambling to grab a piece of the electric vehicle action, an area dominated by China, by far the biggest producer of battery metals.

Germany, for instance, is looking to produce lithium at the Zinnwald project in Southern Saxony to help secure supplies for its car industry. In Finland, a nickel mine in Sotkamo in the north aims to start producing material for electric vehicles by 2020, while battery-grade lithium production is planned in Kaustinen, to the west, in 2020.

Serbia, meanwhile, is looking to Rio Tinto to develop a giant mine for jadarite, a newly discovered mineral that contains both boron and lithium, in the west of the country.

Governments, keen to develop future-proof industrial strategies, are seeking to establish their own sources of minerals needed for electrification and electric vehicles to provide supply certainty, as well as revenue and jobs.

The British drive has become more pressing, officials said, because of the country’s upcoming exit from the European Union, the world’s biggest trading bloc.

MINI METALS RUSH

The charge into southwest England is being led by smaller firms, mainly foreign miners with a higher risk appetite. The majors prefer to mine on a vast scale, allowing them to increase margins and cut costs. They prefer to let junior players take the development risk and then buy fully fledged projects.

About half a dozen companies are exploring in the area, with the biggest players being Canada’s Strongbow Exploration, Australia’s New Age Exploration and Wolf Minerals, listed in Sydney and London.

In the largest Cornish project planned so far, Strongbow is seeking to extract tin at the 4 km-long South Crofty mines as a result of the improved tin market economics.

“The timing is better because global capital markets have a much more receptive attitude towards mining projects,” Strongbow CEO Richard Williams said. “This gives us a good chance of delivering on South Crofty.”

FILE PHOTO: A family walk past the remains of the engine house at the Wheal Prosper copper and tin mine, on the Cornish coastline near Porthleven in Cornwall, Britain October 26, 2017. REUTERS/Toby Melville/File Photo

The company needs to raise project financing of about $110 million. To that end, it plans to seek a secondary listing in London this year. It aims to start production in 2021, but first must pump out water that has accumulated over decades of dereliction.

New Age Exploration and its joint venture partner Strategic Minerals said in March they had found tin, tungsten and copper – all useful for electric vehicles – near Plymouth. They have invested about $2.65 million in the project, which is at an earlier stage than South Crofty, and are looking to raise financing.

Just over the English border in Devon, Wolf Minerals has begun operating a mine for tungsten and tin.

One advantage that Britain has, in terms of tin mining and investment, is that it is a stable location compared with big-producing nations such as Democratic Republic of Congo and Myanmar.

LITHIUM PROMISE

A British government-funded research team led by Cristian Rossi analyzed satellite data to find changes in vegetation and temperature that indicate there are some lithium reserves alongside the tin deposits in the area.

The study marked the first time satellite technology has been used to locate lithium – a valuable technique in Cornwall, which is covered in vegetation in contrast to South American prospects in exposed deserts.

“The percentages are small, but that does not mean it’s not relevant,” said Rossi, principal earth observations scientist of not-for-profit research group the Satellite Applications Catapult (SAC), told Reuters at a conference in March at Cornwall’s Camborne School of Mines to present his findings.

The government provided $1.2 million towards the research, which will be available to all explorers.

The SAC findings are currently being used by a British company called Cornish Lithium, which will begin drilling at South Crofty next year. It has an agreement with Strongbow that allows it to explore using Strongbow’s mineral rights, with Strongbow getting royalties from any lithium extracted.

CLIMBING PRICES

In 1998, when South Crofty was the last of hundreds of Cornish tin mines to shut after four centuries of operation, global tin demand was around 200,000 tonnes a year, and the tin price was languishing at around $5,000 per ton.

Now demand has risen to around 350,000 tonnes, buoyed by demand for electronics, where it is used as a replacement for toxic lead in solder. Tin can also be used in lithium-ion batteries, which could have a major impact on a market already in deficit. Tin prices have climbed above $20,000.

Lithium prices, meanwhile, rose by a quarter last year. Spot prices are currently between $22,000 and $24,000 a ton, according to industry sources.

In Britain, officials say the country is well-placed to capitalize on the anticipated boom in demand for electric vehicles in coming years.

“It’s as if we’ve fallen on our feet,” said Darryn Quayle, a mining specialist at government Department for International Trade. “What we have in our own backyard is quite remarkable.”

($1 = 0.7178 pounds)

Reporting by Barbara Lewis; Editing by Pravin Char

The post Britain looks to ancient mines for electric future appeared first on World The News.

from World The News https://ift.tt/2FnJPFg via Everyday News

0 notes

Text

Britain looks to ancient mines for electric future

SOUTH CROFTY, England – Britain is banking on a series of ancient mines on its southwestern tip to secure a slice of the global electric car revolution.

FILE PHOTO: The remains of the engine house at the Wheal Prosper copper and tin mine is seen along the Cornish coastline near Porthleven in Cornwall, Britain October 26, 2017. REUTERS/Toby Melville/File Photo

The English county of Cornwall and the surrounding area boast one of the world’s largest tin deposits yet their centuries-old mines have lain abandoned since the 1990s when a collapse in prices for the metal made them unviable.

Now however a rise in demand for tin, along with other metals that can be used in electric vehicles, electronics and renewable energy, has helped create a global deficit and quadruple prices. British officials are supporting reopening of the mines and seeking investment, leading to a mini-rush of mining companies into the area.

Adding to the potential, new research shows the extent to which mines also contain deposits of lithium, the so-called metal of the future.

The first industrial metals mining in Britain for decades represents the country’s best shot at securing a piece of the supply chain for car batteries as well as renewable energy grid connections, officials told Reuters.

“We need to ensure the secure supply of the technology metals and critical minerals,” said government lawmaker Pauline Latham, who heads a parliamentary mining group. “This is necessary with China owning the majority of the market and the potential of a global trade war between China and America.”

It is however early days for the mining projects and there is no guarantee they will produce commercial volumes of metal. Even if they do, Britain is dwarfed by the likes of China, Chile and Australia in terms of battery resources.

The unlikely British mining revival is one example of how countries around the world are scrambling to grab a piece of the electric vehicle action, an area dominated by China, by far the biggest producer of battery metals.

Germany, for instance, is looking to produce lithium at the Zinnwald project in Southern Saxony to help secure supplies for its car industry. In Finland, a nickel mine in Sotkamo in the north aims to start producing material for electric vehicles by 2020, while battery-grade lithium production is planned in Kaustinen, to the west, in 2020.

Serbia, meanwhile, is looking to Rio Tinto to develop a giant mine for jadarite, a newly discovered mineral that contains both boron and lithium, in the west of the country.

Governments, keen to develop future-proof industrial strategies, are seeking to establish their own sources of minerals needed for electrification and electric vehicles to provide supply certainty, as well as revenue and jobs.

The British drive has become more pressing, officials said, because of the country’s upcoming exit from the European Union, the world’s biggest trading bloc.

MINI METALS RUSH

The charge into southwest England is being led by smaller firms, mainly foreign miners with a higher risk appetite. The majors prefer to mine on a vast scale, allowing them to increase margins and cut costs. They prefer to let junior players take the development risk and then buy fully fledged projects.

About half a dozen companies are exploring in the area, with the biggest players being Canada’s Strongbow Exploration, Australia’s New Age Exploration and Wolf Minerals, listed in Sydney and London.

In the largest Cornish project planned so far, Strongbow is seeking to extract tin at the 4 km-long South Crofty mines as a result of the improved tin market economics.

“The timing is better because global capital markets have a much more receptive attitude towards mining projects,” Strongbow CEO Richard Williams said. “This gives us a good chance of delivering on South Crofty.”

FILE PHOTO: A family walk past the remains of the engine house at the Wheal Prosper copper and tin mine, on the Cornish coastline near Porthleven in Cornwall, Britain October 26, 2017. REUTERS/Toby Melville/File Photo

The company needs to raise project financing of about $110 million. To that end, it plans to seek a secondary listing in London this year. It aims to start production in 2021, but first must pump out water that has accumulated over decades of dereliction.

New Age Exploration and its joint venture partner Strategic Minerals said in March they had found tin, tungsten and copper – all useful for electric vehicles – near Plymouth. They have invested about $2.65 million in the project, which is at an earlier stage than South Crofty, and are looking to raise financing.

Just over the English border in Devon, Wolf Minerals has begun operating a mine for tungsten and tin.

One advantage that Britain has, in terms of tin mining and investment, is that it is a stable location compared with big-producing nations such as Democratic Republic of Congo and Myanmar.

LITHIUM PROMISE

A British government-funded research team led by Cristian Rossi analyzed satellite data to find changes in vegetation and temperature that indicate there are some lithium reserves alongside the tin deposits in the area.

The study marked the first time satellite technology has been used to locate lithium – a valuable technique in Cornwall, which is covered in vegetation in contrast to South American prospects in exposed deserts.

“The percentages are small, but that does not mean it’s not relevant,” said Rossi, principal earth observations scientist of not-for-profit research group the Satellite Applications Catapult (SAC), told Reuters at a conference in March at Cornwall’s Camborne School of Mines to present his findings.

The government provided $1.2 million towards the research, which will be available to all explorers.

The SAC findings are currently being used by a British company called Cornish Lithium, which will begin drilling at South Crofty next year. It has an agreement with Strongbow that allows it to explore using Strongbow’s mineral rights, with Strongbow getting royalties from any lithium extracted.

CLIMBING PRICES

In 1998, when South Crofty was the last of hundreds of Cornish tin mines to shut after four centuries of operation, global tin demand was around 200,000 tonnes a year, and the tin price was languishing at around $5,000 per ton.

Now demand has risen to around 350,000 tonnes, buoyed by demand for electronics, where it is used as a replacement for toxic lead in solder. Tin can also be used in lithium-ion batteries, which could have a major impact on a market already in deficit. Tin prices have climbed above $20,000.

Lithium prices, meanwhile, rose by a quarter last year. Spot prices are currently between $22,000 and $24,000 a ton, according to industry sources.

In Britain, officials say the country is well-placed to capitalize on the anticipated boom in demand for electric vehicles in coming years.

“It’s as if we’ve fallen on our feet,” said Darryn Quayle, a mining specialist at government Department for International Trade. “What we have in our own backyard is quite remarkable.”

($1 = 0.7178 pounds)

Reporting by Barbara Lewis; Editing by Pravin Char

The post Britain looks to ancient mines for electric future appeared first on World The News.

from World The News https://ift.tt/2FnJPFg via News of World

0 notes