#dtf vectores

Text

CORALINE CAT VECTOR EDITABLE EPS PDF

#coraline#diseño vectorial#disney#dtf vectores#editable#eps#pack de vectores#pdf#svg#vector#vectores dtf

0 notes

Text

www.rkdesigning3.com is for Quality DTF Designs, DTF Transfers, Embroidery Digitizing, Vector Design.

#DTF # DTF Designs # DTF Transfers # Embroidery Digitizing #Vector Design

1 note

·

View note

Photo

Valentine stickers, part 3!

DHL/DTF!

<3

#stickers#sticker#heart#love#valentines#valentines day#dhl#dtf#graphic#illustration#parody#cartoon#vector

1 note

·

View note

Text

Wholesale DTF Transfer by Size - DTF Illinois

Do you have a READY TO DTF PRINT image/design in VECTOR format?

Our various-sized transfer options are tailored just for you! Simply upload each of your designs, select the quantity, and then add them to your cart! If you have any questions, feel free to chat with us!

Features

We print using the highest quality inks, film, and TPU powder to ensure the brightest whites and colors on any type, material, color, or level of stretchiness of garment.

Our process and materials offer increased durability, and stretchability, and withstand the toughest wash tests.

Every order is meticulously reviewed by one of our professional designers to ensure proper and optimized printing.

Each order is printed with the utmost care and attention to detail.

0 notes

Link

Premium Itachi Uchiha Naruto Anime Vector T-shirt Design Template

THE DIGITAL DOWNLOAD WILL INCLUDE:

✅ 📂 AI

✅ 📂 EPS

✅ 📂 PNG

✅ 📂 SVG

✅ 📂 Layered & Grouped by Color

✅ 📂 Ready to Print

THESE FILES ARE PERFECT FOR

✓ DTF

✓ DTG

✓ Sublimation

✓ Transfer

✓ Vinyl

✓ Serigraphy

✓ Posters

✓ Masks

✓ Stickers

✓ And Other Merchandise

0 notes

Text

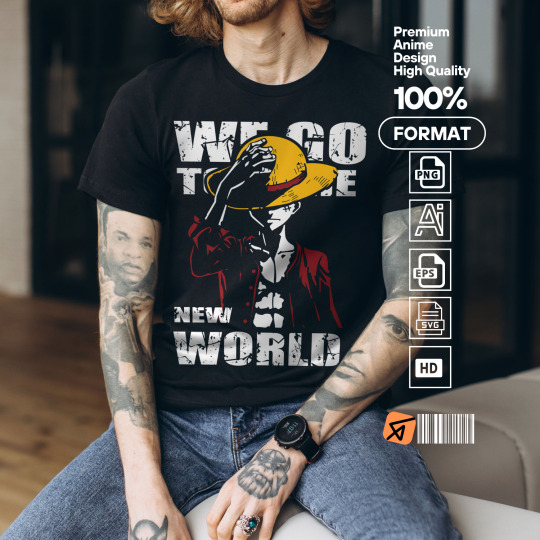

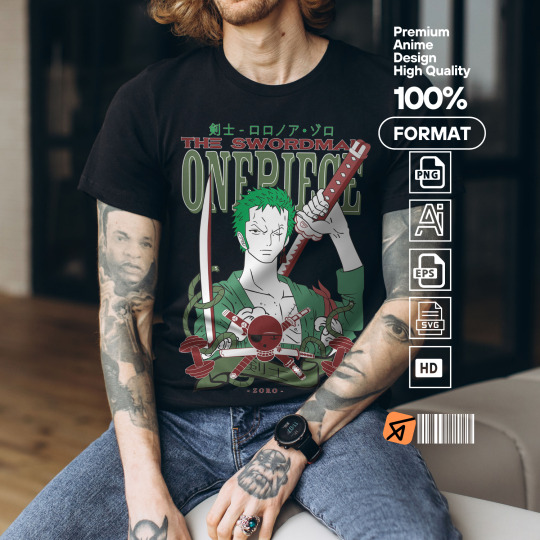

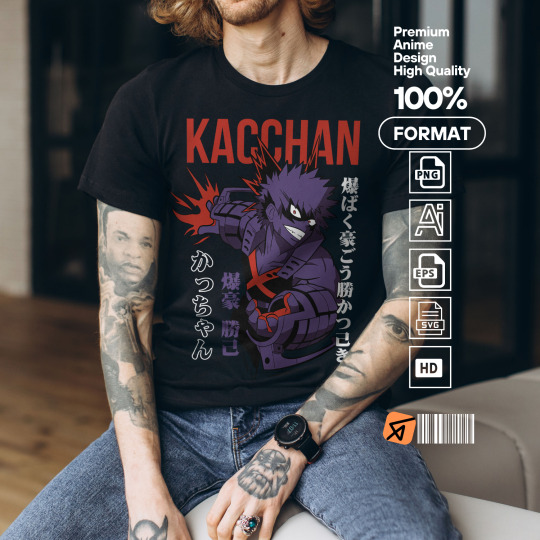

Anime Vector Premium High Quality Files, Ready for DTF, DTG, Sublimation Printing, Anime png for shirts, SVG, AI, EPS, PNG HD

WHAT'S INCLUDED?

✓ 1 top-tier, high-quality t-shirt vector graphic

✓ Diverse file formats, including AI, EPS, SVG, and PNG

✓ Organized and grouped by color for easy editing

✓ Scalable to suit your needs

✓ Print-ready

✓ Versatile for use across different media

This vector is a must-have – don't let it slip through your fingers!

BUY ON ETSY

THESE FILES ARE IDEAL FOR :

✓ DTF

✓ DTG

✓ Sublimation

✓ Transfer

✓ Vinyl

✓ Serigraphy

✓ Posters

✓ Masks

✓ Stickers

✓ And Other Merchandise

0 notes

Text

The Ultimate Guide to DTF Printing for T-Shirts

Direct-to-film (DTF) DTF Printing for T-shirts printing has emerged as a game-changing technology for T-shirt printing businesses and designers looking to create high-quality custom apparel. This innovative technique delivers unparalleled photorealistic prints with stunning vibrancy and durability.

In this comprehensive guide, we’ll explore everything you need to know about DTF printing for t-shirts and showcase the immense benefits it offers for digital printers and designers.

What is DTF Printing?

DTF printing, also known as direct-to-film printing, is a digital printing process that involves transferring photorealistic designs onto t-shirts, fabrics, and a wide range of other products.

The DTF printing process starts with printing full-color graphics onto a specially coated transfer film using a digital production printer loaded with speciality DTF inks. Once printed, the film is coated with a polymer powder adhesive and then heat-pressed onto the t-shirt or textile, allowing the print to effectively transfer.

The end result is a soft, stretchy print that looks and feels embedded into the fabric for stunning photorealistic quality. DTF Printing for T-shirts can accurately reproduce gradients, photographs, illustrations, vector art, and complex multilayered designs with impressive vibrancy.

Some key advantages of DTF printing include:

Photorealistic print quality

Vibrant colors and image accuracy

Soft hand feel without thickness on the fabric

Stretchable and durable prints

High washability without fading or cracking

Compatibility with cotton, polyester, blends and other fabrics

Ability to print on colored shirts

Simple transfer process with heat press

Cost-effective digital printing process

For these reasons, DTF printing has quickly gained traction in the t-shirt printing industry as it enables unparalleled prints for apparel decorators and brands.

The DTF Printing Process

To achieve flawless DTF-printed t-shirts, it’s important to fully understand the direct-to-film printing process from start to finish. Here are the key steps we take at QUICKTRANSFERS.com:

1. DTF Printing for T-Shirts Design Creation

The process begins with creating designs intended for DTF printing. Vector art and high-resolution images containing gradients or photorealistic elements are well-suited for utilizing the capabilities of DTF printing.

Here at QUICKTRANSFERS.com, we recommend that designers create artwork in programs like Adobe Illustrator, Photoshop, or InDesign in the proper print-ready format. The design can incorporate as many colors, layers and effects as desired.

2. Print onto Transfer Film

Next, here at QUICKTRANSFERS.com, the designs get printed onto specialized DTF transfer film using a DTF-specific digital printer loaded with DTF inks and white ink.

We use Inks formulated explicitly for DTF printing that contains binders, carriers and pigments optimized to properly release from the film and bond to polyester and polymer fibres. The white ink acts as a base layer, allowing colored images to appear vibrant on darker shirt fabrics.

3. Apply Polymer Powder

After printing the design, the inked film gets sent through a conveyorized powder coater that applies a fine layer of polymer adhesive powder evenly across the surface. This powder will trigger the release of the inks from the film and bond it to the fabric during pressing.

4. Heat Press the Film onto the Shirt

Our specially trained staff at QUICKTRANSFERS.com then positioned the print onto the shirt and pressed using an industrial heat press at 350-375°F for 10-20 seconds. The heat activates the polymer powder adhesive, which forms a bond between the film ink and shirt fibers causing the image to effectively release onto the fabric.

5. Remove Film

Finally, once cooled, the printed film gets peeled away, leaving only the printed design perfectly embedded into the shirt. The result is a soft, stretchy, photorealistic print ready to be worn and washed.

Now that you understand how we at QUICKTRANSFERS.com complete the DTF printing process for t-shirts, let’s delve into the many benefits this application method provides over other decoration options.

Benefits of DTF Printing for T-Shirts

here at QUICKTRANSFERS.com, we appreciate that DTF printing offers immense advantages for t-shirt decorators compared to traditional decoration techniques like screen printing, vinyl heat transfer, sublimation, and direct-to-garment printing.

Here are the top benefits of using DTF for t-shirt printing and custom apparel:

Photorealistic Print Quality

Arguably the biggest advantage of DTF printing we have at QUICKTRANSFERS.com is the ability to produce the photographic image quality and color accuracy when printing complex designs.

DTF printing expands the depth of photorealism achievable in apparel printing using speciality-formulated inks applied in a digital process. The white ink base combined with CMYK color inks creates opacity and vibrancy that brings designs to life in incredible detail and dimension.

The physical bonding process as the release of the ink from the PET film and fusing with the fabric creates sprints with stunning definition and clarity. Even fine details and small text come out crisp and sharp.

For t-shirt brands and designers looking to feature photorealistic designs, illustrations, vector art, or photographs, DTF printing delivers exceptional reproduction quality bringing images to life.

Vibrant, Opaque Colors

Along with photorealistic detailing, DTF prints stand out with their rich, vibrant and opaque color reproduction.

The proprietary DTF ink formulas combined with an under-base white ink layer as the canvas allow for precise color matching and intense hues. The white ink foundation prevents any color dilution on darker-coloured fabrics.

DTF printing can accurately match Pantone colors and CMYK values for spot-on color reproduction. Prints exhibit pronounced vibrancy with solid color consistency across the entire image. Even gradients contain seamless color transitions.

For t-shirt brands that want accurate color representation or use artwork with colorful graphics and photography, DTF Printing for T-Shirts produces bold, vivid and opaque colors that make designs pop.

Soft Hand Feel

DTF prints have a soft “hand” or feel that matches the native texture and draping of the fabric. Unlike many other decorating methods, DTF Printing for T-Shirts does not leave prints feeling “plasticky” or noticeably different from unprinted areas of the garment.

The DTF process embeds inks directly into fabric fibers rather than sitting on the surface. This allows the prints to stretch and move with the natural drape of the apparel, maintaining a soft natural feel.

Even with multiple layers of ink, DTF prints avoid the heavy rubbery feeling that some processes create. The result is custom t-shirts with stunning photorealistic graphics that remain soft, supple, breathable and comfortable to wear.

High Durability and Stretch

Durability is a major concern when evaluating decoration methods. DTF prints achieve excellent durability and wash permanence for long-lasting wearability.

The bonding process as the ink fuses into fabric fibers creates prints capable of withstanding repeated wash and wear cycles without deteriorating. DTF prints show impressive resistance to fading, cracking, peeling or degrading over time.

Along with durability, DTF prints maintain stretch and flexibility to move with fabrics. Even on elastic performance fabrics intended for athletic apparel, DTF prints stretch and flex along with the material without compromising the range of motion.

For custom t-shirt businesses, exceptional durability and stretch ensure customer satisfaction with end products that provide long lifespans of vibrant image quality.

Compatibility with Polyester and Synthetic Fabrics

One of the greatest assets of QUICKTRANSFERS.com and DTF printing is its ability to effectively print on performance polyester and synthetic fabric blends.

Many t-shirt decorators hesitate to print photos or complex graphics on moisture-wicking poly shirts because inkjet and screen printing have difficulties adhering to the slick polyester fibers. This often leads to poor print quality with ink washing out and a “faded” look over time.

The chemical bonding mechanism of DTF inks allows them to properly fuse with polyester fibers where other ink processes struggle. This makes it ideal for directly printing onto performance tees, athletic jerseys, dri-fit shirts and other synthetics.

For poly-blend fabrics, DTF printing achieves the same photorealistic quality and vibrancy as on cotton garments. The prints remain vivid even through repeated wash and wear because the inks turn into part of the fabric itself.

Ability to Print on Colored Fabric

An added benefit of DTF printing is the ability to print full-color images onto colored fabric without compromising vibrancy or clarity.

The white ink under the base acts as a “primer” layer that allows colored inks to properly show atop darker garment colors. Essentially, DTF printing creates a new printable layer onto the apparel.

This versatility makes it possible to produce stunning full-color prints even on black t-shirts or other colored garments. Photographs and graphics will not take on a faded or washed-out appearance as the white ink prevents the fabric shade from muting the colors.

For t-shirt companies offering products in a variety of colors, DTF empowers photorealistic prints on any color garment.

Simple Transfer Process

From an operational standpoint, QUICKTRANSFERS.com DTF printing offers a simplified transfer process compared to other decoration options.

To apply DTF prints, decorators only need a commercial heat press – no messy screen printing or pretreatment equipment is required. The ability to quickly heat press DTF film transfers makes on-demand fulfilment of single orders convenient and efficient.

The simplicity also allows new entrants to offer DTF printing with a reasonably short learning curve. The plug-and-print workflow and minimal equipment provide accessibility for small businesses.

With just a DTF printer and heat press combo, companies can provide high-quality custom apparel without intensive labor or complex transfer steps. The simplified process improves productivity.

Cost-Effective Short Run Printing

For businesses focused on short runs and customized orders, DTF printing we at QUICKTRANSFERS.com have discovered that this method provides an extremely cost-effective printing solution for us and our clients.

Because DTF utilizes a digital inkjet print method, it avoids the cumbersome setup and laundry list of variables with screen printing that increases per unit costs on small quantity orders.

The ability to print and store transfer film reduces waste from minimum orders and screen charges. And the straightforward heat press transfer allows profitability in single print jobs.

DTF digitally prints only the designs needed for an order. This on-demand printing model is far more economical for short runs than analogue methods requiring films and set-up for each job.

For t-shirt companies fulfilling high-mix low-volume orders, DTF printing optimizes the cost per print while maintaining photorealistic quality.

Fast Turnaround Time

The combination of digital on-demand printing and heat press transfers makes DTF printing exceptionally fast. Transfer film can be printed and pressed in about 30 minutes from start to finish.

Here at QUICKTRANSFERS.com we have found that Rapid fulfilment is a huge advantage for businesses focused on quick-turn custom apparel and rush orders. Event shirts, local band merchandise, school spiritwear and other single orders can be completed in hours, not days.

Because DTF film transfers can also be pre-printed and stocked for popular designs, decorators keep their best-sellers on hand for instant pressing. This allows same-day fulfilment in many cases.

The ability to rapidly go from art to printed garments makes DTF perfect for small businesses and print-on-demand models.

How to Get Started With DTF Printing for T-shirts

For t-shirt companies and apparel decorators interested in bringing DTF printing into their operations, the startup process is relatively straightforward. Here is an overview of getting set up with this profitable service:

1. Choose a DTF Printing for T-shirts Package

First, you’ll need to invest in a commercial DTF printing system which includes a digital production printer and DTF inks/films formulated specifically for direct-to-film printing.

When researching for DTF printer packages QUICKTRANSFERS.com, looked for models that:

Are optimized for high-volume DTF printing

Offer precise color management and print algorithms

Use flexible printable transfer films resistant to heat/stretch

Have a conveyorized inline powder system for efficiency

Provide proprietary DTF ink formulations

Reputable vendors like ColDesi, Kornit Digital and Polyprint DTF offer excellent turnkey DTF printer bundles to simplify getting started.

2. Purchase a Commercial Heat Press

In addition to the DTF printer system, you, like QUICKTRANSFERS.com will need an industrial-grade heat press to apply printed transfer film onto garments. Look for an automatic “clamshell” style press with digital controls and even platens.

Heat presses for DTF film should have:

Digital LED temperature/time displays

Capacity of at least 16×20” platens

Maximum temperature of 400°F+

Programmable pressure settings

Even heat distribution across the platen

Automatic open/close mechanism

Quality presses from Geo Knight, Stahls’ Hotronix and TransPro ensure optimal film adhesion.

3. Set Up Shop Workflow and Space

When laying out your production workspace, QUICKTRANSFERS.com made sure to allow room for efficient workflow from printing the transfer film to heat pressing the garments. Your shop layout should have space for:

Feeder/take-up reels for transfer film rolls

Conveyorized inline powder coating system

DTF printer with exhaust venting

Work tables for sorting/inspection of prints

Heat press station(s) with adjacent workspace

Completed product packaging/storage

Computer station for order intake and design workflow

Optimizing the operational flow from order intake through fulfilled products is key for an efficient DTF t-shirt printing operation.

4. Learn Application Tips and Techniques

While DTF printing is quite straightforward, QUICKTRANSFERS.com we learned that there are application techniques that help ensure flawless results. Take time to learn:

Correct time, temperature and pressure settings based on fabric

Film smoothing techniques to prevent bubbles or creases

Proper alignment/placement before pressing

Peeling process to avoid pulling color from the fabric

Small batch workflow tips

How to finish and package final products

With a little practice, you’ll quickly master DTF printing for stunning photorealistic custom t-shirt printing.

5. Market Your DTF Printing Services

Once everything is ready to print, it’s time to get the word out! Promote your DTF printing services through:

A website showcasing DTF capabilities and products

Search ads for terms like “DTF printing” or “custom t-shirts”

Social media photo galleries displaying your prints

In-person sales calls to local businesses and brands

T-shirt products featuring DTF prints as physical examples

Attending trade shows and networking events

By leveraging both digital and in-person marketing, you can attract new clients excited about DTF’s capabilities for eyebrow-raising custom t-shirt printing.

DTF Printing for T-Shirts Applications and Products

One of the most compelling advantages of DTF printing is its versatility for producing stunning graphics on a wide spectrum of products beyond just t-shirts.

Thanks to DTF’s ability to print onto synthetic fabrics and stretchy materials, decorators can expand profits by offering photorealistic printing on all kinds of apparel, accessories and beyond.

DTF Printing for T-Shirts Apparel Opportunities

For businesses focused on apparel, DTF opened up new possibilities for QUICKTRANSFERS.com to move beyond basic t-shirt printing into other specialized markets.

Athletic Wear – Print neon graphics and team logos onto performance fabrics for sports jerseys, activewear and team uniforms.

Corporate Uniforms – Add photorealism to polos, button-downs, jackets and other professional apparel.

Swimwear/Lycra – Produce vibrant beach-ready fashions with photo prints on swimsuits, rash guards and cover-ups.

Intimate Apparel – Offer personalization like bridal garter printing or graphics for special occasions.

Leggings & Yoga Pants – Print eye-catching motif leggings or vibrant patterns onto stretch fabrics.

Scarves & Ties – Add fashionable flair with printed wraps, shawls, ties and sarongs.

Socks & Undergarments – Print your own brand of stylish printed socks, underwear and lingerie for boutique fashions.

DTF Printing for T-Shirts Accessory and Lifestyle Goods

Applying DTF transfer film offers alternatives to printed apparel as well. Entrepreneurial decorators can deliver photorealistic images onto all kinds of accessories and non-apparel products.

Hats & Caps – Use DTF as an alternative to embroidery for sharp logo printing onto curved brims and adjustable hats.

Bags – Totes, purses, backpacks and carryalls become walking billboards for photo prints.

Shoes – Add printed flair to sneakers, slip-ons or sandals by printing directly onto canvas or synthetic uppers.

Phone Cases – Produce custom photorealistic phone and tablet sleeves on demand in any design.

Skateboards – Print directly onto the bottom deck for custom-tailored graphics on each board.

Laptop Sleeves – Enable customers to showcase unique digital artwork on protective laptop and tablet carriers.

Home Décor – Blankets, pillows and curtains are canvasses for photo prints and artistic graphics.

DTF Printing for T-shirts Equipment Overview

When exploring DTF printing equipment, you’ll encounter two essential machines:

DTF Printers – These specialized digital production printers include proprietary DTF inks for printing transfer film.

Heat Presses – These industrial heat applicators enable heat transferring DTF film onto apparel and other products.

Here’s an overview of key considerations when selecting equipment for your DTF printing operation:

DTF Printer Options

A commercial DTF Printing for T-Shirts customized for direct-to-film printing is the foundation of your production capabilities. When comparing DTF printers, we at QUICKTRANSFERS.com used the following factors to evaluate include:

Print Technology – Look for advanced digital inkjet printheads capable of photorealistic image quality. Single-pass printing is preferred for higher throughput.

Ink Configuration – Printers should use CMYK inks plus White ink specifically designed for DTF printing. The inks must release cleanly from the transfer film and properly bind to fabrics.

Print Width – Wider print carriages allow larger print areas and multi-up transfers for increased efficiency. Standard widths are 17” and 64”.

**Print

Resolution** – Higher DPI delivers sharper detail and smoothness. Standard resolutions range from 600 x 600 dpi up to 1200 x 1200 dpi.

RIP Software – Look for bundled RIP and color management software tuned for accurate DTF print and film handling profiles.

Capacity – Printers with higher hourly output and more robust duty cycles allow increased production capabilities. Standard output ranges from 350 ft2/hr to over 1,000 ft2/hr.

Inline Powder – Built-in conveyorized powder systems provide even polymer coating without the extra step of offline powder application.

Company Support – Choose an established DTF equipment company that provides service, support and supplies to optimize uptime.

Popular dedicated DTF printer models include:

ColDesi Mammoth DTF – A fast 17” single-pass printer with inline powder coating and exceptional color accuracy perfect for high-volume apparel decoration.

Kornit Vulcan DTF – A heavy-duty industrial 64” printer leveraging Kornit’s expertise in digital textile printing for mass customization capabilities.

Polyprint TexJet Echo2 – A 17” DTF printer focused on cost-effectiveness and easy usability for startup decorators.

Heat Press Options

Alongside the printer, an industrial heat press transfers the printed film onto garments or products. Key considerations for DTF heat presses:

Platen Size – To handle larger transfers, look for clamshell style presses with 16” x 20” platens or larger. Swing-away presses offer multiple platen sizes.

Digital Displays – Presses with digital displays for setting time, temperature and pressure variables help reproduce the ideal application settings.

Pressure Adjust – Variable pressure settings ensure even contact across textured fabrics or uneven product surfaces like hats or shoes.

Low platen operating temperatures** – Presses should achieve as low as 225-250°F to avoid scorching fabrics during film application. Look for max temps over 400°F.

Digital Timers and Alerts – Programmable timers with countdown displays and alerts prevent under or over-curing film transfers.

Auto Clamshell – Presses with automated opening and closing of the heated platens increase efficiency in high-volume production.

Warranty – choose presses with generous 1- to 3-year warranty protection on parts and labor.

Well-known commercial heat press brands include Geo Knight, Hotronix by Stahls, TransPro and Hix among others. These companies offer presses designed specifically for DTF printing.

Choosing equipment optimized for DTF production is the best way to achieve photorealistic results and maximize shop productivity. By investing in dedicated DTF printers and professional heat presses, apparel decorators can bring this profitable service into their business.

How to Price DTF Printing for T-Shirts Printing Services

For t-shirt printing companies adding DTF printing, determining the right pricing for this high-value service is an important factor for profitability. When calculating DTF pricing, there are a few key variables to factor:

1. Printer Operation Costs

Consider the base costs for running and maintaining your DTF printer system including:

Ink and transfer film

Printhead replacement and maintenance

Electricity and shop overhead

Labor for production and finishing

Machine servicing and tech support

2. Heat Press Expenses

Account for the additional small costs associated with heat press operations:

Electricity

Equipment maintenance

Parchment paper and application consumables

3. Order Size

Larger quantity orders allow spreading fixed printer setup and labor costs over more items to achieve a lower cost per print.

4. Design Complexity

More complex or multicolor designs require more ink and print time thus increasing the production cost per transfer.

5. Market Rate for DTF Printing for T-shirts

Research current market pricing in your region for DTF printing services to align with customer expectations.

With these factors in mind, decorators typically price DTF prints between $8-$15 per transfer depending on quantity. As you dial in your unique operating costs and margins, establishing value-based pricing allows profitability.

DTF Printing for T-shirts vs. Screen Printing

For t-shirt decorators accustomed to manual screen printing, adopting digital DTF printing offers game-changing advantages.

Here’s how DTF printing compares to traditional screen printing:

Photorealism

DTF printing can reproduce photorealistic imagery and detail that exceeds screen printing capabilities. The CMYK ink layers combined with a white under base provide stunning image accuracy.

Colors

The digital CMYK process allows DTF printing to produce millions of colors compared to screen printing where each color requires a separate screen. DTF achieves photo-quality color vibrancy.

Feel

DTF prints exhibit a softer hand versus the thicker ink layer left by screen printing that can stiffen fabrics. DTF inks bond into the fibres rather than sitting on the surface.

Setup

DTF bypasses the extensive setup of screens, emulsion, ink mixing and curing required in screen printing. The digital workflow is far more streamlined.

Short Runs

Low minimum orders make DTF ideal for fast custom one-offs. Screen printing has high labor costs for short runs that limit profitability on small orders.

Applications

DTF printing accommodates more fabrics like 100% polyester without bleeding or dye migration issues common in screen printing.

Efficiency

The average DTF printer outputs up to 500 prints per hour compared to ~100/hr average for manual screen printing. DTF allows faster order fulfilment.

For forward-thinking apparel decorators, adopting DTF printing alongside screen printing empowers new capabilities in custom photorealistic prints, polyester printing, short runs, and improved order turnaround.

DTF Printing Troubleshooting Guide

While DTF printing provides stunning results, decorators may occasionally encounter print defects or quality issues. Here are some common DTF printing problems and potential solutions:

Problem: Whites have a yellow or discoloured tint

Solution: Purge and clean printheads to prevent misfiring nozzles. Ensure proper color profiles and ink limits are set.

Problem: The image appears faded without bold colors

Solution: Check white ink supply and printhead health. Make sure ink limits and printer settings match the media being used.

Problem: Print is blurry and lacks sharpness

Solution: Confirm designs are high-resolution 300+ DPI images. Clean printheads and check for alignment or calibration issues.

Problem: Colors look different than on the screen

Solution: Review color management settings and make sure proper ICC profiles and color spaces are configured for print vs. display.

Problem: The film won’t release cleanly from shirt after pressing

Solution: Adjust the time, temp and pressure so inks fully release. Ensure the shirt surface is clean and lint/residue-free before pressing.

Problem: Print cracks or peels after washing

Solution: Validate time/temp/pressure settings match fabric type. Insufficient bonding can reduce durability. Check printheads for full ink coverage.

Problem: Polyester shirt prints bleeding or dye migration

Solution: Use inks formulated specifically for polyester fabrics. Adjust print profiles and increase ink bonding temp/dwell.

Carefully evaluating each step of the DTF process helps identify where breakdowns may be occurring. Contact your equipment provider for specific advice tailored to your printer model and media.

The Future of DTF Printing for T-shirts

As more apparel decorators realize the immense benefits of DTF Printing for T-Shirts, the adoption of direct-to-film transfer technology is poised for rapid growth.

The future possibilities of DTF expand far beyond just t-shirt printing into all sectors of textile and product decoration.

Several innovations on the horizon will further improve DTF Printing for T-Shirts including:

Hybrid DTF Machines – Combination DTG and DTF Printing for T-Shirts systems allowing decorators to offer both print technologies from one setup.

White Ink Technologies – Next-gen white inks with increased opacity and adhesion for even more vibrant and durable light or dark fabric printing.

Specialty Transfer Films – New films like metallic foils or heat-reactive adhesives that enable printing onto challenging products like leather, ceramics and plastics.

Direct Printers – DTF Printing for T-Shirts engines that bypass the film transfer step and directly print graphics onto final materials using inline heat and bonding processes.

Expanded Print Sizes – Industrial DTF Printing for T-Shirts enable larger-scale graphics like an all-over shirt and poster printing.

Print-on-Demand Integration – Automated workflows combining digital design ordering, DTF printing, and fulfilment for streamlined customization.

Apparel decorators that embrace DTF printing now will be well-poised in the future as direct-to-film transfer technology unlocks new avenues in digital textile printing.

Conclusion of DTF Printing for T-shirts

DTF printing provides t-shirt companies and apparel decorators with a powerful method for decorating garments and products with photorealistic quality and versatility.

Some key takeaways:

DTF utilizes digital printing of CMYK and white inks onto transfer film that heat presses onto apparel.

DTF printing achieves photographic image reproduction far exceeding screen printing.

Vibrant opaque colors, crisp details, and soft hand feel are benefits over other print methods.

DTF Printing for T-Shirts works on both light and dark garments including polyester athletic apparel.

The print process only requires a DTF printer system and heat press for easy low startup.

On-demand DTF Printing for T-Shirts film printing makes low minimum orders profitable.

Decors can expand offerings with unique photorealistic prints on apparel, accessories, and beyond.

As an innovative print technology, DTF empowers t-shirt companies with new revenue opportunities through capabilities impossible only a few years ago.

For DTF Printing for T-Shirts and Clothing Printers eager to push the boundaries of custom apparel printing, it’s time to start exploring everything DTF Printing for T-Shirts can make possible! Call Phone: 404-400-5420 Today

Read more here https://marketing-tutor.com/blog/the-ultimate-guide-to-dtf-printing-for-t-shirts/

0 notes

Text

The Ultimate Guide to DTF Printing for T-Shirts

Direct-to-film (DTF) DTF Printing for T-shirts printing has emerged as a game-changing technology for T-shirt printing businesses and designers looking to create high-quality custom apparel. This innovative technique delivers unparalleled photorealistic prints with stunning vibrancy and durability.

In this comprehensive guide, we’ll explore everything you need to know about DTF printing for t-shirts and showcase the immense benefits it offers for digital printers and designers.

What is DTF Printing?

DTF printing, also known as direct-to-film printing, is a digital printing process that involves transferring photorealistic designs onto t-shirts, fabrics, and a wide range of other products.

The DTF printing process starts with printing full-color graphics onto a specially coated transfer film using a digital production printer loaded with speciality DTF inks. Once printed, the film is coated with a polymer powder adhesive and then heat-pressed onto the t-shirt or textile, allowing the print to effectively transfer.

The end result is a soft, stretchy print that looks and feels embedded into the fabric for stunning photorealistic quality. DTF Printing for T-shirts can accurately reproduce gradients, photographs, illustrations, vector art, and complex multilayered designs with impressive vibrancy.

Some key advantages of DTF printing include:

Photorealistic print quality

Vibrant colors and image accuracy

Soft hand feel without thickness on the fabric

Stretchable and durable prints

High washability without fading or cracking

Compatibility with cotton, polyester, blends and other fabrics

Ability to print on colored shirts

Simple transfer process with heat press

Cost-effective digital printing process

For these reasons, DTF printing has quickly gained traction in the t-shirt printing industry as it enables unparalleled prints for apparel decorators and brands.

The DTF Printing Process

To achieve flawless DTF-printed t-shirts, it’s important to fully understand the direct-to-film printing process from start to finish. Here are the key steps we take at QUICKTRANSFERS.com:

1. DTF Printing for T-Shirts Design Creation

The process begins with creating designs intended for DTF printing. Vector art and high-resolution images containing gradients or photorealistic elements are well-suited for utilizing the capabilities of DTF printing.

Here at QUICKTRANSFERS.com, we recommend that designers create artwork in programs like Adobe Illustrator, Photoshop, or InDesign in the proper print-ready format. The design can incorporate as many colors, layers and effects as desired.

2. Print onto Transfer Film

Next, here at QUICKTRANSFERS.com, the designs get printed onto specialized DTF transfer film using a DTF-specific digital printer loaded with DTF inks and white ink.

We use Inks formulated explicitly for DTF printing that contains binders, carriers and pigments optimized to properly release from the film and bond to polyester and polymer fibres. The white ink acts as a base layer, allowing colored images to appear vibrant on darker shirt fabrics.

3. Apply Polymer Powder

After printing the design, the inked film gets sent through a conveyorized powder coater that applies a fine layer of polymer adhesive powder evenly across the surface. This powder will trigger the release of the inks from the film and bond it to the fabric during pressing.

4. Heat Press the Film onto the Shirt

Our specially trained staff at QUICKTRANSFERS.com then positioned the print onto the shirt and pressed using an industrial heat press at 350-375°F for 10-20 seconds. The heat activates the polymer powder adhesive, which forms a bond between the film ink and shirt fibers causing the image to effectively release onto the fabric.

5. Remove Film

Finally, once cooled, the printed film gets peeled away, leaving only the printed design perfectly embedded into the shirt. The result is a soft, stretchy, photorealistic print ready to be worn and washed.

Now that you understand how we at QUICKTRANSFERS.com complete the DTF printing process for t-shirts, let’s delve into the many benefits this application method provides over other decoration options.

Benefits of DTF Printing for T-Shirts

here at QUICKTRANSFERS.com, we appreciate that DTF printing offers immense advantages for t-shirt decorators compared to traditional decoration techniques like screen printing, vinyl heat transfer, sublimation, and direct-to-garment printing.

Here are the top benefits of using DTF for t-shirt printing and custom apparel:

Photorealistic Print Quality

Arguably the biggest advantage of DTF printing we have at QUICKTRANSFERS.com is the ability to produce the photographic image quality and color accuracy when printing complex designs.

DTF printing expands the depth of photorealism achievable in apparel printing using speciality-formulated inks applied in a digital process. The white ink base combined with CMYK color inks creates opacity and vibrancy that brings designs to life in incredible detail and dimension.

The physical bonding process as the release of the ink from the PET film and fusing with the fabric creates sprints with stunning definition and clarity. Even fine details and small text come out crisp and sharp.

For t-shirt brands and designers looking to feature photorealistic designs, illustrations, vector art, or photographs, DTF printing delivers exceptional reproduction quality bringing images to life.

Vibrant, Opaque Colors

Along with photorealistic detailing, DTF prints stand out with their rich, vibrant and opaque color reproduction.

The proprietary DTF ink formulas combined with an under-base white ink layer as the canvas allow for precise color matching and intense hues. The white ink foundation prevents any color dilution on darker-coloured fabrics.

DTF printing can accurately match Pantone colors and CMYK values for spot-on color reproduction. Prints exhibit pronounced vibrancy with solid color consistency across the entire image. Even gradients contain seamless color transitions.

For t-shirt brands that want accurate color representation or use artwork with colorful graphics and photography, DTF Printing for T-Shirts produces bold, vivid and opaque colors that make designs pop.

Soft Hand Feel

DTF prints have a soft “hand” or feel that matches the native texture and draping of the fabric. Unlike many other decorating methods, DTF Printing for T-Shirts does not leave prints feeling “plasticky” or noticeably different from unprinted areas of the garment.

The DTF process embeds inks directly into fabric fibers rather than sitting on the surface. This allows the prints to stretch and move with the natural drape of the apparel, maintaining a soft natural feel.

Even with multiple layers of ink, DTF prints avoid the heavy rubbery feeling that some processes create. The result is custom t-shirts with stunning photorealistic graphics that remain soft, supple, breathable and comfortable to wear.

High Durability and Stretch

Durability is a major concern when evaluating decoration methods. DTF prints achieve excellent durability and wash permanence for long-lasting wearability.

The bonding process as the ink fuses into fabric fibers creates prints capable of withstanding repeated wash and wear cycles without deteriorating. DTF prints show impressive resistance to fading, cracking, peeling or degrading over time.

Along with durability, DTF prints maintain stretch and flexibility to move with fabrics. Even on elastic performance fabrics intended for athletic apparel, DTF prints stretch and flex along with the material without compromising the range of motion.

For custom t-shirt businesses, exceptional durability and stretch ensure customer satisfaction with end products that provide long lifespans of vibrant image quality.

Compatibility with Polyester and Synthetic Fabrics

One of the greatest assets of QUICKTRANSFERS.com and DTF printing is its ability to effectively print on performance polyester and synthetic fabric blends.

Many t-shirt decorators hesitate to print photos or complex graphics on moisture-wicking poly shirts because inkjet and screen printing have difficulties adhering to the slick polyester fibers. This often leads to poor print quality with ink washing out and a “faded” look over time.

The chemical bonding mechanism of DTF inks allows them to properly fuse with polyester fibers where other ink processes struggle. This makes it ideal for directly printing onto performance tees, athletic jerseys, dri-fit shirts and other synthetics.

For poly-blend fabrics, DTF printing achieves the same photorealistic quality and vibrancy as on cotton garments. The prints remain vivid even through repeated wash and wear because the inks turn into part of the fabric itself.

Ability to Print on Colored Fabric

An added benefit of DTF printing is the ability to print full-color images onto colored fabric without compromising vibrancy or clarity.

The white ink under the base acts as a “primer” layer that allows colored inks to properly show atop darker garment colors. Essentially, DTF printing creates a new printable layer onto the apparel.

This versatility makes it possible to produce stunning full-color prints even on black t-shirts or other colored garments. Photographs and graphics will not take on a faded or washed-out appearance as the white ink prevents the fabric shade from muting the colors.

For t-shirt companies offering products in a variety of colors, DTF empowers photorealistic prints on any color garment.

Simple Transfer Process

From an operational standpoint, QUICKTRANSFERS.com DTF printing offers a simplified transfer process compared to other decoration options.

To apply DTF prints, decorators only need a commercial heat press – no messy screen printing or pretreatment equipment is required. The ability to quickly heat press DTF film transfers makes on-demand fulfilment of single orders convenient and efficient.

The simplicity also allows new entrants to offer DTF printing with a reasonably short learning curve. The plug-and-print workflow and minimal equipment provide accessibility for small businesses.

With just a DTF printer and heat press combo, companies can provide high-quality custom apparel without intensive labor or complex transfer steps. The simplified process improves productivity.

Cost-Effective Short Run Printing

For businesses focused on short runs and customized orders, DTF printing we at QUICKTRANSFERS.com have discovered that this method provides an extremely cost-effective printing solution for us and our clients.

Because DTF utilizes a digital inkjet print method, it avoids the cumbersome setup and laundry list of variables with screen printing that increases per unit costs on small quantity orders.

The ability to print and store transfer film reduces waste from minimum orders and screen charges. And the straightforward heat press transfer allows profitability in single print jobs.

DTF digitally prints only the designs needed for an order. This on-demand printing model is far more economical for short runs than analogue methods requiring films and set-up for each job.

For t-shirt companies fulfilling high-mix low-volume orders, DTF printing optimizes the cost per print while maintaining photorealistic quality.

Fast Turnaround Time

The combination of digital on-demand printing and heat press transfers makes DTF printing exceptionally fast. Transfer film can be printed and pressed in about 30 minutes from start to finish.

Here at QUICKTRANSFERS.com we have found that Rapid fulfilment is a huge advantage for businesses focused on quick-turn custom apparel and rush orders. Event shirts, local band merchandise, school spiritwear and other single orders can be completed in hours, not days.

Because DTF film transfers can also be pre-printed and stocked for popular designs, decorators keep their best-sellers on hand for instant pressing. This allows same-day fulfilment in many cases.

The ability to rapidly go from art to printed garments makes DTF perfect for small businesses and print-on-demand models.

How to Get Started With DTF Printing for T-shirts

For t-shirt companies and apparel decorators interested in bringing DTF printing into their operations, the startup process is relatively straightforward. Here is an overview of getting set up with this profitable service:

1. Choose a DTF Printing for T-shirts Package

First, you’ll need to invest in a commercial DTF printing system which includes a digital production printer and DTF inks/films formulated specifically for direct-to-film printing.

When researching for DTF printer packages QUICKTRANSFERS.com, looked for models that:

Are optimized for high-volume DTF printing

Offer precise color management and print algorithms

Use flexible printable transfer films resistant to heat/stretch

Have a conveyorized inline powder system for efficiency

Provide proprietary DTF ink formulations

Reputable vendors like ColDesi, Kornit Digital and Polyprint DTF offer excellent turnkey DTF printer bundles to simplify getting started.

2. Purchase a Commercial Heat Press

In addition to the DTF printer system, you, like QUICKTRANSFERS.com will need an industrial-grade heat press to apply printed transfer film onto garments. Look for an automatic “clamshell” style press with digital controls and even platens.

Heat presses for DTF film should have:

Digital LED temperature/time displays

Capacity of at least 16×20” platens

Maximum temperature of 400°F+

Programmable pressure settings

Even heat distribution across the platen

Automatic open/close mechanism

Quality presses from Geo Knight, Stahls’ Hotronix and TransPro ensure optimal film adhesion.

3. Set Up Shop Workflow and Space

When laying out your production workspace, QUICKTRANSFERS.com made sure to allow room for efficient workflow from printing the transfer film to heat pressing the garments. Your shop layout should have space for:

Feeder/take-up reels for transfer film rolls

Conveyorized inline powder coating system

DTF printer with exhaust venting

Work tables for sorting/inspection of prints

Heat press station(s) with adjacent workspace

Completed product packaging/storage

Computer station for order intake and design workflow

Optimizing the operational flow from order intake through fulfilled products is key for an efficient DTF t-shirt printing operation.

4. Learn Application Tips and Techniques

While DTF printing is quite straightforward, QUICKTRANSFERS.com we learned that there are application techniques that help ensure flawless results. Take time to learn:

Correct time, temperature and pressure settings based on fabric

Film smoothing techniques to prevent bubbles or creases

Proper alignment/placement before pressing

Peeling process to avoid pulling color from the fabric

Small batch workflow tips

How to finish and package final products

With a little practice, you’ll quickly master DTF printing for stunning photorealistic custom t-shirt printing.

5. Market Your DTF Printing Services

Once everything is ready to print, it’s time to get the word out! Promote your DTF printing services through:

A website showcasing DTF capabilities and products

Search ads for terms like “DTF printing” or “custom t-shirts”

Social media photo galleries displaying your prints

In-person sales calls to local businesses and brands

T-shirt products featuring DTF prints as physical examples

Attending trade shows and networking events

By leveraging both digital and in-person marketing, you can attract new clients excited about DTF’s capabilities for eyebrow-raising custom t-shirt printing.

DTF Printing for T-Shirts Applications and Products

One of the most compelling advantages of DTF printing is its versatility for producing stunning graphics on a wide spectrum of products beyond just t-shirts.

Thanks to DTF’s ability to print onto synthetic fabrics and stretchy materials, decorators can expand profits by offering photorealistic printing on all kinds of apparel, accessories and beyond.

DTF Printing for T-Shirts Apparel Opportunities

For businesses focused on apparel, DTF opened up new possibilities for QUICKTRANSFERS.com to move beyond basic t-shirt printing into other specialized markets.

Athletic Wear – Print neon graphics and team logos onto performance fabrics for sports jerseys, activewear and team uniforms.

Corporate Uniforms – Add photorealism to polos, button-downs, jackets and other professional apparel.

Swimwear/Lycra – Produce vibrant beach-ready fashions with photo prints on swimsuits, rash guards and cover-ups.

Intimate Apparel – Offer personalization like bridal garter printing or graphics for special occasions.

Leggings & Yoga Pants – Print eye-catching motif leggings or vibrant patterns onto stretch fabrics.

Scarves & Ties – Add fashionable flair with printed wraps, shawls, ties and sarongs.

Socks & Undergarments – Print your own brand of stylish printed socks, underwear and lingerie for boutique fashions.

DTF Printing for T-Shirts Accessory and Lifestyle Goods

Applying DTF transfer film offers alternatives to printed apparel as well. Entrepreneurial decorators can deliver photorealistic images onto all kinds of accessories and non-apparel products.

Hats & Caps – Use DTF as an alternative to embroidery for sharp logo printing onto curved brims and adjustable hats.

Bags – Totes, purses, backpacks and carryalls become walking billboards for photo prints.

Shoes – Add printed flair to sneakers, slip-ons or sandals by printing directly onto canvas or synthetic uppers.

Phone Cases – Produce custom photorealistic phone and tablet sleeves on demand in any design.

Skateboards – Print directly onto the bottom deck for custom-tailored graphics on each board.

Laptop Sleeves – Enable customers to showcase unique digital artwork on protective laptop and tablet carriers.

Home Décor – Blankets, pillows and curtains are canvasses for photo prints and artistic graphics.

DTF Printing for T-shirts Equipment Overview

When exploring DTF printing equipment, you’ll encounter two essential machines:

DTF Printers – These specialized digital production printers include proprietary DTF inks for printing transfer film.

Heat Presses – These industrial heat applicators enable heat transferring DTF film onto apparel and other products.

Here’s an overview of key considerations when selecting equipment for your DTF printing operation:

DTF Printer Options

A commercial DTF Printing for T-Shirts customized for direct-to-film printing is the foundation of your production capabilities. When comparing DTF printers, we at QUICKTRANSFERS.com used the following factors to evaluate include:

Print Technology – Look for advanced digital inkjet printheads capable of photorealistic image quality. Single-pass printing is preferred for higher throughput.

Ink Configuration – Printers should use CMYK inks plus White ink specifically designed for DTF printing. The inks must release cleanly from the transfer film and properly bind to fabrics.

Print Width – Wider print carriages allow larger print areas and multi-up transfers for increased efficiency. Standard widths are 17” and 64”.

**Print

Resolution** – Higher DPI delivers sharper detail and smoothness. Standard resolutions range from 600 x 600 dpi up to 1200 x 1200 dpi.

RIP Software – Look for bundled RIP and color management software tuned for accurate DTF print and film handling profiles.

Capacity – Printers with higher hourly output and more robust duty cycles allow increased production capabilities. Standard output ranges from 350 ft2/hr to over 1,000 ft2/hr.

Inline Powder – Built-in conveyorized powder systems provide even polymer coating without the extra step of offline powder application.

Company Support – Choose an established DTF equipment company that provides service, support and supplies to optimize uptime.

Popular dedicated DTF printer models include:

ColDesi Mammoth DTF – A fast 17” single-pass printer with inline powder coating and exceptional color accuracy perfect for high-volume apparel decoration.

Kornit Vulcan DTF – A heavy-duty industrial 64” printer leveraging Kornit’s expertise in digital textile printing for mass customization capabilities.

Polyprint TexJet Echo2 – A 17” DTF printer focused on cost-effectiveness and easy usability for startup decorators.

Heat Press Options

Alongside the printer, an industrial heat press transfers the printed film onto garments or products. Key considerations for DTF heat presses:

Platen Size – To handle larger transfers, look for clamshell style presses with 16” x 20” platens or larger. Swing-away presses offer multiple platen sizes.

Digital Displays – Presses with digital displays for setting time, temperature and pressure variables help reproduce the ideal application settings.

Pressure Adjust – Variable pressure settings ensure even contact across textured fabrics or uneven product surfaces like hats or shoes.

Low platen operating temperatures** – Presses should achieve as low as 225-250°F to avoid scorching fabrics during film application. Look for max temps over 400°F.

Digital Timers and Alerts – Programmable timers with countdown displays and alerts prevent under or over-curing film transfers.

Auto Clamshell – Presses with automated opening and closing of the heated platens increase efficiency in high-volume production.

Warranty – choose presses with generous 1- to 3-year warranty protection on parts and labor.

Well-known commercial heat press brands include Geo Knight, Hotronix by Stahls, TransPro and Hix among others. These companies offer presses designed specifically for DTF printing.

Choosing equipment optimized for DTF production is the best way to achieve photorealistic results and maximize shop productivity. By investing in dedicated DTF printers and professional heat presses, apparel decorators can bring this profitable service into their business.

How to Price DTF Printing for T-Shirts Printing Services

For t-shirt printing companies adding DTF printing, determining the right pricing for this high-value service is an important factor for profitability. When calculating DTF pricing, there are a few key variables to factor:

1. Printer Operation Costs

Consider the base costs for running and maintaining your DTF printer system including:

Ink and transfer film

Printhead replacement and maintenance

Electricity and shop overhead

Labor for production and finishing

Machine servicing and tech support

2. Heat Press Expenses

Account for the additional small costs associated with heat press operations:

Electricity

Equipment maintenance

Parchment paper and application consumables

3. Order Size

Larger quantity orders allow spreading fixed printer setup and labor costs over more items to achieve a lower cost per print.

4. Design Complexity

More complex or multicolor designs require more ink and print time thus increasing the production cost per transfer.

5. Market Rate for DTF Printing for T-shirts

Research current market pricing in your region for DTF printing services to align with customer expectations.

With these factors in mind, decorators typically price DTF prints between $8-$15 per transfer depending on quantity. As you dial in your unique operating costs and margins, establishing value-based pricing allows profitability.

DTF Printing for T-shirts vs. Screen Printing

For t-shirt decorators accustomed to manual screen printing, adopting digital DTF printing offers game-changing advantages.

Here’s how DTF printing compares to traditional screen printing:

Photorealism

DTF printing can reproduce photorealistic imagery and detail that exceeds screen printing capabilities. The CMYK ink layers combined with a white under base provide stunning image accuracy.

Colors

The digital CMYK process allows DTF printing to produce millions of colors compared to screen printing where each color requires a separate screen. DTF achieves photo-quality color vibrancy.

Feel

DTF prints exhibit a softer hand versus the thicker ink layer left by screen printing that can stiffen fabrics. DTF inks bond into the fibres rather than sitting on the surface.

Setup

DTF bypasses the extensive setup of screens, emulsion, ink mixing and curing required in screen printing. The digital workflow is far more streamlined.

Short Runs

Low minimum orders make DTF ideal for fast custom one-offs. Screen printing has high labor costs for short runs that limit profitability on small orders.

Applications

DTF printing accommodates more fabrics like 100% polyester without bleeding or dye migration issues common in screen printing.

Efficiency

The average DTF printer outputs up to 500 prints per hour compared to ~100/hr average for manual screen printing. DTF allows faster order fulfilment.

For forward-thinking apparel decorators, adopting DTF printing alongside screen printing empowers new capabilities in custom photorealistic prints, polyester printing, short runs, and improved order turnaround.

DTF Printing Troubleshooting Guide

While DTF printing provides stunning results, decorators may occasionally encounter print defects or quality issues. Here are some common DTF printing problems and potential solutions:

Problem: Whites have a yellow or discoloured tint

Solution: Purge and clean printheads to prevent misfiring nozzles. Ensure proper color profiles and ink limits are set.

Problem: The image appears faded without bold colors

Solution: Check white ink supply and printhead health. Make sure ink limits and printer settings match the media being used.

Problem: Print is blurry and lacks sharpness

Solution: Confirm designs are high-resolution 300+ DPI images. Clean printheads and check for alignment or calibration issues.

Problem: Colors look different than on the screen

Solution: Review color management settings and make sure proper ICC profiles and color spaces are configured for print vs. display.

Problem: The film won’t release cleanly from shirt after pressing

Solution: Adjust the time, temp and pressure so inks fully release. Ensure the shirt surface is clean and lint/residue-free before pressing.

Problem: Print cracks or peels after washing

Solution: Validate time/temp/pressure settings match fabric type. Insufficient bonding can reduce durability. Check printheads for full ink coverage.

Problem: Polyester shirt prints bleeding or dye migration

Solution: Use inks formulated specifically for polyester fabrics. Adjust print profiles and increase ink bonding temp/dwell.

Carefully evaluating each step of the DTF process helps identify where breakdowns may be occurring. Contact your equipment provider for specific advice tailored to your printer model and media.

The Future of DTF Printing for T-shirts

As more apparel decorators realize the immense benefits of DTF Printing for T-Shirts, the adoption of direct-to-film transfer technology is poised for rapid growth.

The future possibilities of DTF expand far beyond just t-shirt printing into all sectors of textile and product decoration.

Several innovations on the horizon will further improve DTF Printing for T-Shirts including:

Hybrid DTF Machines – Combination DTG and DTF Printing for T-Shirts systems allowing decorators to offer both print technologies from one setup.

White Ink Technologies – Next-gen white inks with increased opacity and adhesion for even more vibrant and durable light or dark fabric printing.

Specialty Transfer Films – New films like metallic foils or heat-reactive adhesives that enable printing onto challenging products like leather, ceramics and plastics.

Direct Printers – DTF Printing for T-Shirts engines that bypass the film transfer step and directly print graphics onto final materials using inline heat and bonding processes.

Expanded Print Sizes – Industrial DTF Printing for T-Shirts enable larger-scale graphics like an all-over shirt and poster printing.

Print-on-Demand Integration – Automated workflows combining digital design ordering, DTF printing, and fulfilment for streamlined customization.

Apparel decorators that embrace DTF printing now will be well-poised in the future as direct-to-film transfer technology unlocks new avenues in digital textile printing.

Conclusion of DTF Printing for T-shirts

DTF printing provides t-shirt companies and apparel decorators with a powerful method for decorating garments and products with photorealistic quality and versatility.

Some key takeaways:

DTF utilizes digital printing of CMYK and white inks onto transfer film that heat presses onto apparel.

DTF printing achieves photographic image reproduction far exceeding screen printing.

Vibrant opaque colors, crisp details, and soft hand feel are benefits over other print methods.

DTF Printing for T-Shirts works on both light and dark garments including polyester athletic apparel.

The print process only requires a DTF printer system and heat press for easy low startup.

On-demand DTF Printing for T-Shirts film printing makes low minimum orders profitable.

Decors can expand offerings with unique photorealistic prints on apparel, accessories, and beyond.

As an innovative print technology, DTF empowers t-shirt companies with new revenue opportunities through capabilities impossible only a few years ago.

For DTF Printing for T-Shirts and Clothing Printers eager to push the boundaries of custom apparel printing, it’s time to start exploring everything DTF Printing for T-Shirts can make possible! Call Phone: 404-400-5420 Today

Read more here https://marketing-tutor.com/blog/the-ultimate-guide-to-dtf-printing-for-t-shirts/

0 notes

Text

The Ultimate Guide to DTF Printing for T-Shirts

Direct-to-film (DTF) DTF Printing for T-shirts printing has emerged as a game-changing technology for T-shirt printing businesses and designers looking to create high-quality custom apparel. This innovative technique delivers unparalleled photorealistic prints with stunning vibrancy and durability.

In this comprehensive guide, we’ll explore everything you need to know about DTF printing for t-shirts and showcase the immense benefits it offers for digital printers and designers.

What is DTF Printing?

DTF printing, also known as direct-to-film printing, is a digital printing process that involves transferring photorealistic designs onto t-shirts, fabrics, and a wide range of other products.

The DTF printing process starts with printing full-color graphics onto a specially coated transfer film using a digital production printer loaded with speciality DTF inks. Once printed, the film is coated with a polymer powder adhesive and then heat-pressed onto the t-shirt or textile, allowing the print to effectively transfer.

The end result is a soft, stretchy print that looks and feels embedded into the fabric for stunning photorealistic quality. DTF Printing for T-shirts can accurately reproduce gradients, photographs, illustrations, vector art, and complex multilayered designs with impressive vibrancy.

Some key advantages of DTF printing include:

Photorealistic print quality

Vibrant colors and image accuracy

Soft hand feel without thickness on the fabric

Stretchable and durable prints

High washability without fading or cracking

Compatibility with cotton, polyester, blends and other fabrics

Ability to print on colored shirts

Simple transfer process with heat press

Cost-effective digital printing process

For these reasons, DTF printing has quickly gained traction in the t-shirt printing industry as it enables unparalleled prints for apparel decorators and brands.

The DTF Printing Process

To achieve flawless DTF-printed t-shirts, it’s important to fully understand the direct-to-film printing process from start to finish. Here are the key steps we take at QUICKTRANSFERS.com:

1. DTF Printing for T-Shirts Design Creation

The process begins with creating designs intended for DTF printing. Vector art and high-resolution images containing gradients or photorealistic elements are well-suited for utilizing the capabilities of DTF printing.

Here at QUICKTRANSFERS.com, we recommend that designers create artwork in programs like Adobe Illustrator, Photoshop, or InDesign in the proper print-ready format. The design can incorporate as many colors, layers and effects as desired.

2. Print onto Transfer Film

Next, here at QUICKTRANSFERS.com, the designs get printed onto specialized DTF transfer film using a DTF-specific digital printer loaded with DTF inks and white ink.

We use Inks formulated explicitly for DTF printing that contains binders, carriers and pigments optimized to properly release from the film and bond to polyester and polymer fibres. The white ink acts as a base layer, allowing colored images to appear vibrant on darker shirt fabrics.

3. Apply Polymer Powder

After printing the design, the inked film gets sent through a conveyorized powder coater that applies a fine layer of polymer adhesive powder evenly across the surface. This powder will trigger the release of the inks from the film and bond it to the fabric during pressing.

4. Heat Press the Film onto the Shirt

Our specially trained staff at QUICKTRANSFERS.com then positioned the print onto the shirt and pressed using an industrial heat press at 350-375°F for 10-20 seconds. The heat activates the polymer powder adhesive, which forms a bond between the film ink and shirt fibers causing the image to effectively release onto the fabric.

5. Remove Film

Finally, once cooled, the printed film gets peeled away, leaving only the printed design perfectly embedded into the shirt. The result is a soft, stretchy, photorealistic print ready to be worn and washed.

Now that you understand how we at QUICKTRANSFERS.com complete the DTF printing process for t-shirts, let’s delve into the many benefits this application method provides over other decoration options.

Benefits of DTF Printing for T-Shirts

here at QUICKTRANSFERS.com, we appreciate that DTF printing offers immense advantages for t-shirt decorators compared to traditional decoration techniques like screen printing, vinyl heat transfer, sublimation, and direct-to-garment printing.

Here are the top benefits of using DTF for t-shirt printing and custom apparel:

Photorealistic Print Quality

Arguably the biggest advantage of DTF printing we have at QUICKTRANSFERS.com is the ability to produce the photographic image quality and color accuracy when printing complex designs.

DTF printing expands the depth of photorealism achievable in apparel printing using speciality-formulated inks applied in a digital process. The white ink base combined with CMYK color inks creates opacity and vibrancy that brings designs to life in incredible detail and dimension.

The physical bonding process as the release of the ink from the PET film and fusing with the fabric creates sprints with stunning definition and clarity. Even fine details and small text come out crisp and sharp.

For t-shirt brands and designers looking to feature photorealistic designs, illustrations, vector art, or photographs, DTF printing delivers exceptional reproduction quality bringing images to life.

Vibrant, Opaque Colors

Along with photorealistic detailing, DTF prints stand out with their rich, vibrant and opaque color reproduction.

The proprietary DTF ink formulas combined with an under-base white ink layer as the canvas allow for precise color matching and intense hues. The white ink foundation prevents any color dilution on darker-coloured fabrics.

DTF printing can accurately match Pantone colors and CMYK values for spot-on color reproduction. Prints exhibit pronounced vibrancy with solid color consistency across the entire image. Even gradients contain seamless color transitions.

For t-shirt brands that want accurate color representation or use artwork with colorful graphics and photography, DTF Printing for T-Shirts produces bold, vivid and opaque colors that make designs pop.

Soft Hand Feel

DTF prints have a soft “hand” or feel that matches the native texture and draping of the fabric. Unlike many other decorating methods, DTF Printing for T-Shirts does not leave prints feeling “plasticky” or noticeably different from unprinted areas of the garment.

The DTF process embeds inks directly into fabric fibers rather than sitting on the surface. This allows the prints to stretch and move with the natural drape of the apparel, maintaining a soft natural feel.

Even with multiple layers of ink, DTF prints avoid the heavy rubbery feeling that some processes create. The result is custom t-shirts with stunning photorealistic graphics that remain soft, supple, breathable and comfortable to wear.

High Durability and Stretch

Durability is a major concern when evaluating decoration methods. DTF prints achieve excellent durability and wash permanence for long-lasting wearability.

The bonding process as the ink fuses into fabric fibers creates prints capable of withstanding repeated wash and wear cycles without deteriorating. DTF prints show impressive resistance to fading, cracking, peeling or degrading over time.

Along with durability, DTF prints maintain stretch and flexibility to move with fabrics. Even on elastic performance fabrics intended for athletic apparel, DTF prints stretch and flex along with the material without compromising the range of motion.

For custom t-shirt businesses, exceptional durability and stretch ensure customer satisfaction with end products that provide long lifespans of vibrant image quality.

Compatibility with Polyester and Synthetic Fabrics

One of the greatest assets of QUICKTRANSFERS.com and DTF printing is its ability to effectively print on performance polyester and synthetic fabric blends.

Many t-shirt decorators hesitate to print photos or complex graphics on moisture-wicking poly shirts because inkjet and screen printing have difficulties adhering to the slick polyester fibers. This often leads to poor print quality with ink washing out and a “faded” look over time.

The chemical bonding mechanism of DTF inks allows them to properly fuse with polyester fibers where other ink processes struggle. This makes it ideal for directly printing onto performance tees, athletic jerseys, dri-fit shirts and other synthetics.

For poly-blend fabrics, DTF printing achieves the same photorealistic quality and vibrancy as on cotton garments. The prints remain vivid even through repeated wash and wear because the inks turn into part of the fabric itself.

Ability to Print on Colored Fabric

An added benefit of DTF printing is the ability to print full-color images onto colored fabric without compromising vibrancy or clarity.

The white ink under the base acts as a “primer” layer that allows colored inks to properly show atop darker garment colors. Essentially, DTF printing creates a new printable layer onto the apparel.

This versatility makes it possible to produce stunning full-color prints even on black t-shirts or other colored garments. Photographs and graphics will not take on a faded or washed-out appearance as the white ink prevents the fabric shade from muting the colors.

For t-shirt companies offering products in a variety of colors, DTF empowers photorealistic prints on any color garment.

Simple Transfer Process

From an operational standpoint, QUICKTRANSFERS.com DTF printing offers a simplified transfer process compared to other decoration options.

To apply DTF prints, decorators only need a commercial heat press – no messy screen printing or pretreatment equipment is required. The ability to quickly heat press DTF film transfers makes on-demand fulfilment of single orders convenient and efficient.

The simplicity also allows new entrants to offer DTF printing with a reasonably short learning curve. The plug-and-print workflow and minimal equipment provide accessibility for small businesses.

With just a DTF printer and heat press combo, companies can provide high-quality custom apparel without intensive labor or complex transfer steps. The simplified process improves productivity.

Cost-Effective Short Run Printing

For businesses focused on short runs and customized orders, DTF printing we at QUICKTRANSFERS.com have discovered that this method provides an extremely cost-effective printing solution for us and our clients.

Because DTF utilizes a digital inkjet print method, it avoids the cumbersome setup and laundry list of variables with screen printing that increases per unit costs on small quantity orders.

The ability to print and store transfer film reduces waste from minimum orders and screen charges. And the straightforward heat press transfer allows profitability in single print jobs.

DTF digitally prints only the designs needed for an order. This on-demand printing model is far more economical for short runs than analogue methods requiring films and set-up for each job.

For t-shirt companies fulfilling high-mix low-volume orders, DTF printing optimizes the cost per print while maintaining photorealistic quality.

Fast Turnaround Time

The combination of digital on-demand printing and heat press transfers makes DTF printing exceptionally fast. Transfer film can be printed and pressed in about 30 minutes from start to finish.

Here at QUICKTRANSFERS.com we have found that Rapid fulfilment is a huge advantage for businesses focused on quick-turn custom apparel and rush orders. Event shirts, local band merchandise, school spiritwear and other single orders can be completed in hours, not days.

Because DTF film transfers can also be pre-printed and stocked for popular designs, decorators keep their best-sellers on hand for instant pressing. This allows same-day fulfilment in many cases.

The ability to rapidly go from art to printed garments makes DTF perfect for small businesses and print-on-demand models.

How to Get Started With DTF Printing for T-shirts

For t-shirt companies and apparel decorators interested in bringing DTF printing into their operations, the startup process is relatively straightforward. Here is an overview of getting set up with this profitable service:

1. Choose a DTF Printing for T-shirts Package

First, you’ll need to invest in a commercial DTF printing system which includes a digital production printer and DTF inks/films formulated specifically for direct-to-film printing.

When researching for DTF printer packages QUICKTRANSFERS.com, looked for models that:

Are optimized for high-volume DTF printing

Offer precise color management and print algorithms

Use flexible printable transfer films resistant to heat/stretch

Have a conveyorized inline powder system for efficiency

Provide proprietary DTF ink formulations

Reputable vendors like ColDesi, Kornit Digital and Polyprint DTF offer excellent turnkey DTF printer bundles to simplify getting started.

2. Purchase a Commercial Heat Press

In addition to the DTF printer system, you, like QUICKTRANSFERS.com will need an industrial-grade heat press to apply printed transfer film onto garments. Look for an automatic “clamshell” style press with digital controls and even platens.

Heat presses for DTF film should have:

Digital LED temperature/time displays

Capacity of at least 16×20” platens

Maximum temperature of 400°F+

Programmable pressure settings

Even heat distribution across the platen

Automatic open/close mechanism

Quality presses from Geo Knight, Stahls’ Hotronix and TransPro ensure optimal film adhesion.

3. Set Up Shop Workflow and Space

When laying out your production workspace, QUICKTRANSFERS.com made sure to allow room for efficient workflow from printing the transfer film to heat pressing the garments. Your shop layout should have space for:

Feeder/take-up reels for transfer film rolls

Conveyorized inline powder coating system

DTF printer with exhaust venting

Work tables for sorting/inspection of prints

Heat press station(s) with adjacent workspace

Completed product packaging/storage

Computer station for order intake and design workflow

Optimizing the operational flow from order intake through fulfilled products is key for an efficient DTF t-shirt printing operation.