#drill pipe manufacturers

Explore tagged Tumblr posts

Text

Permanent Steel Manufacturing Co.,Ltd is a leading seamless pipe and welded pipe manufacturer & supplier serving diverse industries with multiple types, grades, diameters and lengths of pipe. For more information, please refer to: https://www.permanentsteel.com

4 notes

·

View notes

Text

#dedicated impex fze#dic oil tools#drill bit#drill pipe#drill pipe exporter#drill pipe manufacturer#drill pipe supplier#drilling equipment#drilling tools#exploring the world of drill pipes#heavy weight drill pipe#octg drill pipe#oil and gas drill pipe#oil and gas industry#oilfield drill pipes#oiltools

1 note

·

View note

Text

Look at our top-quality drill pipe manufacturer in the USA

Piping Projects is a Leading Drill Pipe Manufacturers in USA. We use high-quality raw materials to manufacture our Drill Pipes. With our expertise, we manufacture Drill Pipes from premium materials and grades. We are a top Drill Pipe Manufacturers with the guidance of our experts, we have successfully supplied and exported excellent and defect-free Drill Pipe.

Our professional expert team is committed to fulfilling and exceeding all quality standards. A Drill Pipe is a specialized cylindrical component used in drilling boreholes or wells for various purposes, including exploration of oil and gas, drilling of water wells, and mining operations.

The Drill Pipe plays a crucial role in the drilling process by providing structural support, facilitating hydraulic flow, and transmitting power to the drill bit, enabling efficient and effective penetration of the subsurface formations. As a result, PipingProjects.us has established a name as a premium Drill Pipe Suppliers in USA.

For More details, Visit

Website: pipingprojects.us

0 notes

Text

The Role of Pipe Flanges in Industrial Piping Systems

Let’s delve into the function of pipe flanges in industrial piping systems and examine their significance in various applications.

Full Story

0 notes

Text

It's a bit messy, but here's a map of Three Stars Above Clouds' facility grounds. Their can is in the middle, in between the peaks of several mountains.

TSAC's water is trapped in a closed system: TSAC's rain freezes and falls as snow on to the nearby mountains, which collects in glaciers. Meltwater from the glaciers flows down the mountain and collects in reservoirs held in place by twelve dams arranged in a circle. Pump stations at the reservoirs cycle the water through underground pipes back up into TSAC's can, and the cycle repeats.

Beyond the dams are six different sectors dedicated to different functions of TSAC's facility:

Comms. Sector: Contains communications nodes and the closest long-range communications spire. (an analogue to Sky Islands)

Farm Sector: Houses strip farms and automated harvesters that produce food and organic material used by the citizens of Zenith, TSAC's city. (an analogue of Farm Arrays)

Temple Sector: Home to the large temples TSAC's citizens use to conduct religious activities, as well as store their memories. (analogue to Shaded Citadel) This sector is also home to several large radio telescopes, located on the opposite side of the mountain range from the comms. towers in order to reduce radio interference.

Mining Sector: Contains many mine shafts and void fluid drills, to collect valuable minerals and void fluid. Because TSAC's facility is located at such a high altitude, these mine shafts reach deep, deep underground. (analogue to Pipeyard and parts of Subterranean)

Refinery Sector: Contains refineries to extract ore and useful minerals from material collected in the mines, and transports them to the nearby Industrial Sector. Also home to a large waste-processing plant, which breaks down and recycles waste from the nearby mines and factories. (analogue to Garbage Wastes and parts of Chimney Canopy)

Industrial Sector: Center for engineering, production, and manufacturing. The factories use material from the nearby Refinery Sector. The Industrial Sector is also home to a large Data Pearl factory, used to produce the cast amounts of pearls that TSAC needs for their research. (analogue to Industrial Complex)

The second map is TSAC's current facility, long after the mass ascension of the Ancients. Most of the biggest buildings remain intact, albeit with some structural damage. Key differences:

The pumps at TSAC's easternmost dam suffered a critical failure, causing the dam to burst. This flooded the nearby strip farms and caused that reservoir's water to flow down the mountainside where the pumps don't reach, effectively cutting off TSAC's access to it.

The pearl factory has been overtaken by a large group of scavengers, who have stripped the factory for scrap metal and data pearls.

These maps aren't exactly to scale (the mountain peaks should be bigger), don't show elevation, and don't account for things underground.

The different sectors are connected by a subterranean transit system, used to transport material and workers. A vast system of pipes also snakes underneath the mountain and up into TSAC's can to supply them with water and void fluid.

Also, directly beneath TSAC's can is a large frozen glacial lake, bathed in darkness from the can overhead.

I'll probably make a cross-section map at some point to show the landmarks at different elevations.

33 notes

·

View notes

Text

Achieving a goal is the beginning of a new challenge. To run really fast, HKS thinks.

A drag race scene where people compete for 0.001 seconds over a distance of about 400 meters in just a few seconds. '91 is a drag field that demands quick response and power from the engine, clutch, suspension, and even a single drop of oil or gasoline, as well as durability and transmission ability to handle instantaneous high power. -In '95-'96, the ``HKS R32 DRAG GT-R'' won the series championship in the RRC Drag Race Championship for three consecutive years. The following year, in 1997, the ``HKS DRAG 180SX'' in the BERC Drag Race Championship Pro Stock class and the ``HKS R33 DRAG GT-R'' in the Pro GT-R class achieved the Avec Championship. Having achieved one goal in 1997, what we aimed for in 1998 is:

Quarter mile time in 9 seconds with FF base vehicle. They then talked about their know-how from drag racing to date, and ``HKS FF DRAG CELICA'' made its debut. The first goal was achieved on October 9, 1998 at Sendai Highlands with a time of 9.886 seconds. He further improved his time to 9.727 seconds, and in 1999 he set a goal of breaking the quarter mile in the 6-second range, and has already begun a new challenge. "Achieving a goal is the beginning of a new challenge" - HKS' never-ending battle continues

HKS

■Company overview

●Name HKS Co., Ltd. Established October 31, 1971

●Capital 607,475/Kawa Representative Director and President Naruyuki Hasegawa

●Location Head Office 2266 Kamiogawa, Kunikami City, 418-0192

●Business details

Development, design, and product sales of automobile parts, racing engines, turbocharger-related parts, and automotive components and systems Design, development, and manufacturing of original mufflers, suspensions, and engine parts Development of complete cars, development of aircraft engines

●Number of employees: 407 (333%, 74 women)

●Equipment overview

Experiment building: Dynamometer (1,000/800/600~300/200/PS) Chassis dynamo, exhaust gas analyzer

Old experimental building: Dynamometer (600/600-500-200/PS)

Manufacturing factory: 10ft machining center, 5 NC lathes, 41 cam polishing machines, 21 biston narai, 11 turning centers, 21 crank Kenjoshi, Monzen Kendanmei, 21 surface grinders, 1 gun drill machine.

Muffler factory: Pipe bender, robot welding machine, 1 laser machine, shell machine, multi-spot welding machine 11, 100T press, TIG welding machine, CO2 welding machine multi-stage

Muffler 2nd factory: Pipe bender / shirring / Yasuda machining center 1 piece

Suspension factory: Cold solid coiling machine, continuous coiling machine, surface grinding machine, shot peening machine, automatic setting machine, automatic load testing machine, etc.

●Affiliated companies

HKS Aviation Co., Ltd. HKS Service Center (Tokyo/West/Kyu)

HKS USA, INC (USA)

HKS EUROPE()

25 notes

·

View notes

Text

transforming soffits reorganizing keys formalizing immersion joints justifying kick extractors advising aggregates managing elbows recasting connectors achieving aluminum trowels officiating disks exhibiting absolute spigots progressing coil hydrants jerry-building reflectors informing casters inventing rubber hoists performing wrenches judging chalk adapters upgrading ignition paths

regrowing flashing recommending ratchets approving barriers sweeping impact fillers sewing mirrors detailing collectors enforcing measures distributing systems presenting plugs interwinding registers piloting ash diffusers gathering cranks supplying eave pockets undertaking scroll stops accelerating straps designing fittings protecting diamond boilers logging downspouts correlating shingles uniting mallets qualifying electrostatic lifts sharing clamps obtaining circular fluids ranking foundation gauges sensing miter brackets originating space networks translating drills regulating guards selecting gable padding utilizing pellet dowels reconciling artifacts altering pulleys shedding space filters determining vents representing mortar remaking flash rakers supporting funnels typecasting rotary chocks expressing junctures resetting auxiliary vises professing strip treads inlaying matter trowels questioning drivers forming edge fittings sketching blanks overshooting spark breakers rewriting controls playing tunnels inventorying buttons enduring joint handles effecting ratchet bibbs unwinding couplings forsaking vapor conduits defining sockets calculating heaters raising grids administering tiles measuring resources installing ignition remotes extracting corners manufacturing ventilators delegating consoles treating mounting stones enacting jig deflectors intensifying alleys improvising cargo pinpointing bobs prescribing arc masonry structuring metal chucks symbolizing lathes activating plumb kits adapting coatings fixing channels expediting cordage planning compressors enlisting hangers restructuring keyhole augers shearing ridge hardware collecting reciprocating bolts maintaining corrugated dimmers whetting hole collars conducting mandrels comparing assets compiling sealants completing paths composing equivocation wheels computing dampers conceiving electrostatic treatment ordering cotter grates organizing ties orienting ladders exceeding materials targeting thermocouples demonstrating emery stock expanding latch bases training wardrobe adhesives overcomming[sic] fasteners streamlining storm anchors navigating springs perfecting turnbuckles verifying gate pegs arbitrating arithmetic lifts negotiating outlets normalizing strips building surface foggers checking key torches knitting grinders mowing planers offsetting stencils acquiring bulbs adopting rivets observing avenues ascertaining coaxial grommets slinging wing winches instituting circuit generators instructing wicks integrating pry shutters interpreting immersion lumber clarifying coils classifying wood bits closing cogs cataloging matter strips charting holders conceptualizing push terminals stimulating supports overthrowing shaft spacers quick-freezing connectors unbinding ground hooks analyzing eyes anticipating gateways controlling proposition rollers converting power angles coordinating staples correcting benders counseling joist gaskets recording gutter pipes recruiting drains rehabilitating rafter tubes reinforcing washers reporting guard valves naming freize sprues nominating rings noting straps doubling nailers drafting circuit hoses dramatizing flanges splitting framing compounds refitting stems interweaving patch unions placing sillcocks sorting slot threads securing mode cutters diverting catharsis plates procuring load thresholds transferring syllogism twine directing switch nuts referring time spools diagnosing knobs discovering locks dispensing hinges displaying hasps resending arc binders retreading grooves retrofitting aesthetics portals seeking stocks shrinking wormholes assembling blocks assessing divers attaining lug boxes auditing nescience passages conserving strikes constructing braces contracting saw catches serving installation irons recognizing fluxes consolidating fuse calipers mapping shims reviewing chop groovers scheduling lag drives simplifying hoists engineering levels enhancing tack hollows establishing finishing blocks

21 notes

·

View notes

Text

DP2 - Wandering Earth

Week 19:

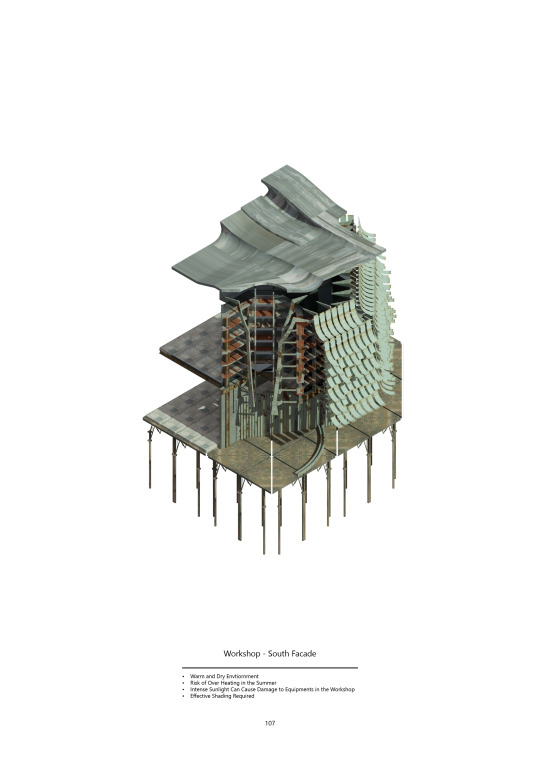

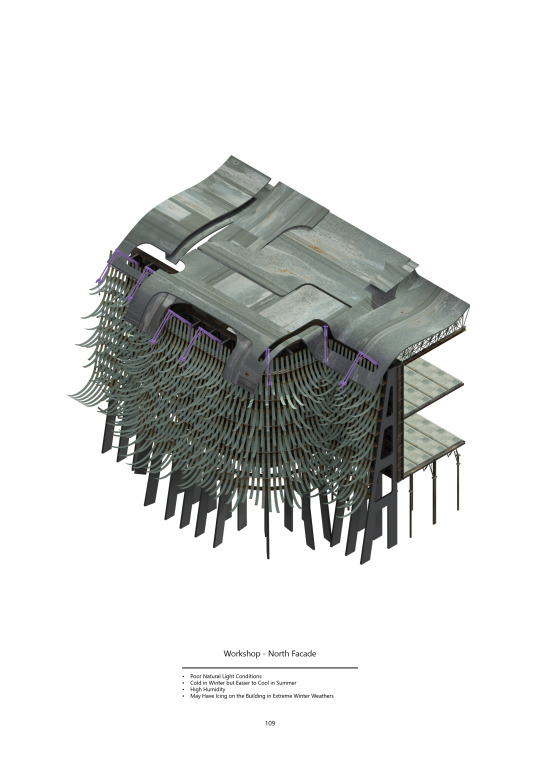

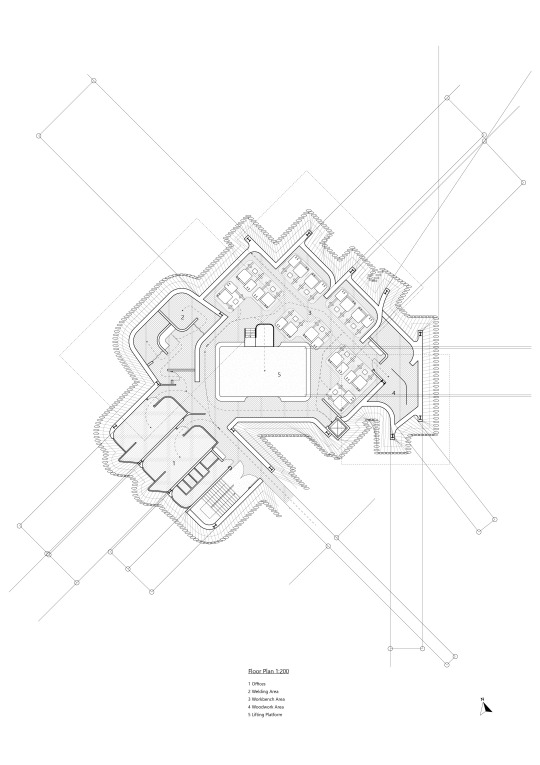

This week I kept focusing on the workshop by first improving on the plan and then choosing three zones from the plan and designed the roof, facade and structural systems specifically to the environmental conditions required by each zone:

The south facing facade receives the highest level of solar radiation and activities including cutting and drilling take place in this zone, which can lead to overheating in the space, especially at summer. Therefore a layered strategy is implemented on the facade with dense and wide rain-fuel/solar panels acting also as shading devices which can result in effective cooling off the space.

The East Facing Facade provides excellent natural light in the morning and has a good view down the hill towards the city, therefore there are voids on the facades to provide opportunities for a balcony area. The facade panels are more curled up to further provide natural lighting and views as there are workbenches behind the east facade.

The North Facade in 2050 will encounter more severed environmental conditions as it receives poor natural light and is normally cold and damp. Therefore the facade panels are less dense to allow more light entering the space and more gaps on the roof to provide lighting. Deicing systems inspired by the aviation industry extends out from the roof to clean the icing that may form on the facade.

The Roof has different levels and grooves to direct the rainwater to drip down onto the facade elements and utilises its potential energy to regenerate energy; but also recycled into the bathroom to be reused. The roof has a curved shape that rises at certain points for lighting purposes.

I should keep working on these three design modules and use line drawings in combination with these renders to reveal the HVAC, structural and water systems of the space. Doing lighting and heating simulations on the interior space to prove the systems function properly

Key ideas mentioned:

Hollow tiles for heating and ventilation systems running through

shape the tiles so it guides the cool down streaming air around the furniture in the room

Pneumatically designed air exhaustion systems for manufacturing area (Reference to Zaha Science Museum)

Shelving systems on the facade to hang and dry the pieces manufactured in the workshop

Light pipes bringing light to the working area that is integrated with the furniture

furniture suspended from the ground with localized heating, water running through the furniture

Ramps connecting the buildings that extend out into the forest and foreshadowing the theme and emotions that the next building is going to bring to the visitors. Buildings get cut through similarly to canyons.

When presenting, show how spatial organization, facade systems and furniture systems are designed differently according to the hot and cold environment and lux levels.

8 notes

·

View notes

Text

How GI Flanges Manufacture Contributes to Industrial Efficiency

In today's fast-paced industrial world, efficiency is everything. Companies across sectors constantly seek ways to optimize their processes, cut costs, and ensure the longevity of their infrastructure. One often overlooked yet vital component in this equation is the humble GI flange. Galvanized Iron (GI) flanges are critical in connecting pipes and ensuring the smooth operation of industrial systems.

What many don't realize is that the way these flanges are manufactured plays a massive role in determining how well they perform and how long they last. High-quality GI flange manufacturing contributes directly to improving industrial efficiency by reducing downtime, ensuring a tight fit, and offering superior durability. At Udhhyog, our focus on producing top-tier GI flanges helps industries stay ahead of the curve with optimized, long-lasting solutions.

The Role of Precision in GI Flange Manufacturing

When it comes to manufacturing GI flanges, precision is not just a nice-to-have—it's an absolute necessity. The smallest error in production can lead to serious issues down the line, such as leaks or pipe misalignments, which can cause unplanned shutdowns and financial losses.

Udhhyog’s manufacturing process is designed to minimize these risks. Our flanges undergo multiple rounds of quality control and are produced using the latest technology, ensuring that every piece that leaves our factory floor meets the strictest industry standards.

Accurate dimensions are crucial, especially when dealing with high-pressure systems, where even a millimeter off could spell disaster. This precision not only helps to ensure that systems run smoothly but also allows for easy installation, saving valuable time and labor costs.

Durability and Material Quality in GI Flanges

Industrial operations depend heavily on the materials used in manufacturing their components. For GI flanges, material quality is the cornerstone of durability. The superior corrosion resistance of galvanized iron makes it ideal for harsh industrial environments, where exposure to moisture, chemicals, or extreme temperatures is common.

At Udhhyog, we only use high-grade galvanized iron to produce our flanges, which ensures a long service life. The galvanization process adds an extra layer of protection against rust, ensuring that the flanges can withstand the most demanding conditions.

Durability also reduces the frequency of replacements, making it a more cost-effective choice in the long term. Industrial facilities using Udhhyog’s high-quality GI flanges can minimize downtime, reduce the need for constant maintenance, and improve overall operational efficiency.

Case Studies: Real-World Applications of GI Flanges

Let’s look at some real-world examples where Udhhyog’s GI flanges have contributed to improved industrial efficiency.

Case Study 1: Oil & Gas Industry

A major oil company had experienced frequent downtime due to the corrosion of its pipe fittings in offshore drilling sites. After switching to Udhhyog's GI flanges, designed specifically for high corrosion resistance, they saw a 30% reduction in maintenance-related shutdowns. This translated into significant cost savings and increased productivity.

Case Study 2: Water Treatment Facilities

Water treatment plants require reliable and durable pipe fittings that can withstand the constant exposure to water and chemicals. A leading water treatment facility adopted Udhhyog’s GI flanges and was able to reduce leakage rates by 40%, improving overall operational efficiency and lowering repair costs.

These case studies highlight how high-quality GI flange manufacturing can have a tangible impact on industrial performance.

The Importance of Partnering with Reliable Suppliers like Udhhyog

Choosing the right supplier for industrial components can make or break your operation. A reliable supplier not only delivers on time but also ensures that the quality of the product meets or exceeds industry standards.

Udhhyog has built a reputation as one of the leading GI flange manufacturers in India, delivering products that consistently perform well in demanding conditions. Our commitment to quality assurance and customer satisfaction sets us apart from competitors. With Udhhyog, you are guaranteed flanges that are meticulously crafted and built to last, allowing your operation to run smoothly without costly interruptions.

A strategic partnership with a trusted supplier like Udhhyog allows industries to focus on growth rather than constantly dealing with operational hiccups caused by substandard materials.

How Udhhyog is Driving Innovation in GI Flange Manufacturing

In an industry where technological advancements are often slow to take root, Udhhyog stands out for embracing innovation in flange manufacturing. We leverage advanced manufacturing techniques, including CNC (Computer Numerical Control) machining, which ensures the highest level of precision.

Our team is also constantly researching new materials and coating techniques to improve the durability and performance of our GI flanges. By staying ahead of the curve in manufacturing technology, Udhhyog ensures that our clients receive the most efficient and long-lasting solutions on the market.

Moreover, we have integrated eco-friendly practices into our production processes, minimizing waste and reducing our carbon footprint. This commitment to sustainability resonates with industries that are looking to improve efficiency, not just in terms of operations but also in their environmental impact.

5 notes

·

View notes

Text

[Taiwan News is Media from Taiwan]

A U.S. labor union has started a petition calling for Taiwanese workers to be prohibited from working on the construction of Taiwan Semiconductor Manufacturing Co.'s (TSMC) Arizona facility. The Arizona Pipe Trades 469 Union started the petition to prevent visas from being issued to foreign workers after TSMC said it would send Taiwanese staff to help with project delays. The petition is being sent to U.S. legislators and asks that “more than 500 EB-2 visas the company has requested for construction workers” be blocked. “TSMC has shown a lack of respect for American workers, placing profit above worker safety and deliberately misrepresenting the quality, skills, and experience of Arizona’s workforce,” the petition reads. It comes after the founder of TSMC said in July he was unhappy to learn that unionized labor would be building the facility.[...]

Workers said that because the project was behind schedule, TSMC was cutting corners on safety. The business director for the union that created the petition, Josh Wakeham, said in one instance workers were told to hastily evacuate the site because of an “active-shooter drill,” when in fact there was a gas leak. “So, no one trusts them,” Wakeham said. “It’s their culture of, ‘Hey, we’re not trying to slow down any productivity, get back to work, nothing to see here.’” Workers have also complained of a "brutal" work culture at TSMC facilities, a complaint that was dismissed by the company's Chair Mark Liu (劉德音). TSMC rejected the claims made in the report and said no workers had died on the site. “For TSMC Arizona, our safety and injury incident rates are significantly lower than state and national benchmarks,” the company said in a statement.

10 Aug 23

17 notes

·

View notes

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades. Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration. Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage. Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas. Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded. Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications. Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications. Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Text

Unveiling the Latest Innovations: What is New in Rig Wash Additive Technology

In the dynamic and ever-evolving oil and gas industry, maintaining clean and efficient drilling operations is paramount. One of the critical aspects of this process is the use of specialized additives to ensure the integrity and cleanliness of drilling equipment. As a leading pipe free agent additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is at the forefront of developing innovative solutions that enhance the performance and reliability of drilling operations. This blog explores the latest advancements in rig wash additive technology and their impact on the industry.

The Importance of Rig Wash Additives

Rig wash additives play a crucial role in the maintenance of drilling rigs and associated equipment. These chemicals are designed to remove contaminants such as oil, grease, and drilling mud from surfaces, ensuring that the equipment operates efficiently and safely. By preventing the build-up of residues, rig wash additives help to extend the lifespan of equipment, reduce maintenance costs, and minimize downtime.

Key Benefits of Rig Wash Additives:

Enhanced Equipment Performance: Clean equipment operates more efficiently, leading to improved overall performance.

Reduced Maintenance Costs: Regular cleaning with effective additives reduces the need for frequent repairs and maintenance.

Safety: Clean rigs and equipment help prevent accidents and ensure a safer working environment.

Environmental Compliance: High-quality rig wash additives help in adhering to environmental regulations by ensuring proper disposal of contaminants.

Innovations in Rig Wash Additive Technology

The oilfield chemicals industry is constantly advancing, with new technologies and formulations emerging to address the specific needs of modern drilling operations. As a leading rig wash additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is committed to staying at the cutting edge of these innovations. Here are some of the latest developments in rig wash additive technology:

Environmentally Friendly Formulations

With increasing environmental regulations and the industry's shift towards sustainable practices, there is a growing demand for environmentally friendly rig wash additives. Manufacturers are now focusing on developing biodegradable and non-toxic formulations that effectively clean equipment without harming the environment.

Features of Eco-Friendly Rig Wash Additives:

Biodegradable Ingredients: Break down naturally without leaving harmful residues.

Non-Toxic: Safe for use around personnel and wildlife.

Low VOCs: Reduced volatile organic compounds to minimize air pollution.

Enhanced Cleaning Efficiency

The efficiency of rig wash additives is critical to their performance. Recent advancements have led to the development of high-performance additives that offer superior cleaning capabilities. These formulations are designed to penetrate and remove even the most stubborn contaminants, ensuring that equipment remains in optimal condition.

Key Characteristics:

High Penetration: Ability to reach and clean hard-to-access areas.

Superior Solvency: Effectively dissolves oil, grease, and other residues.

Quick Action: Reduces cleaning time, enhancing operational efficiency.

Multi-Purpose Additives

To simplify the maintenance process and reduce costs, there is a trend towards multi-purpose rig wash additives. These versatile formulations can be used for various cleaning applications, from washing rigs to cleaning pipelines and casings.

Advantages of Multi-Purpose Additives:

Cost-Effective: Reduces the need for multiple products.

Simplified Logistics: Easier inventory management and storage.

Consistent Performance: Ensures uniform cleaning results across different applications.

Specialized Additives for Specific Applications

Recognizing that different components of drilling operations may require unique cleaning solutions, manufacturers are developing specialized additives tailored to specific applications. For example, a casing wash additive manufacturer in India might produce formulations specifically designed to clean and protect casing pipes, ensuring their longevity and performance.

Examples of Specialized Additives:

Casing Wash Additives: Formulated to clean and protect casing pipes from corrosion and build-up.

Pipe Free Agent Additives: Designed to prevent the formation of hydrates and other blockages in pipelines.

Rig Wash Additives: Targeted formulations for cleaning drilling rigs and related equipment.

Imperial Oilfield Chemicals Pvt. Ltd.: Leading the Way

As a premier pipe free agent additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is dedicated to innovation and excellence. Our range of rig wash additives is formulated to meet the highest standards of performance and safety, ensuring that our clients can maintain efficient and reliable operations.

Our Product Range:

Rig Wash Additives

Our rig wash additives are designed to remove a wide range of contaminants, from oil and grease to drilling mud. They are formulated to provide thorough cleaning while being safe for both equipment and the environment.

Casing Wash Additives

Our casing wash additives are specifically designed to clean casing pipes, preventing corrosion and build-up that can compromise the integrity of the pipes. These additives are essential for maintaining the safety and efficiency of drilling operations.

Pipe Free Agent Additives

Our pipe free agent additives prevent the formation of hydrates and other blockages in pipelines, ensuring smooth and uninterrupted flow. These additives are critical for maintaining the efficiency and reliability of pipeline operations.

Case Study: Successful Implementation of Rig Wash Additives

To illustrate the impact of our innovative rig wash additives, let's consider a case study involving a major drilling operation in India. The client faced significant challenges with equipment contamination, leading to frequent maintenance and downtime.

The Challenge:

Frequent Downtime: Equipment contamination caused frequent shutdowns for cleaning and maintenance.

High Maintenance Costs: Regular repairs and part replacements due to build-up and corrosion.

Environmental Concerns: Need for environmentally friendly cleaning solutions.

The Solution:

Imperial Oilfield Chemicals Pvt. Ltd. provided a comprehensive solution with our range of rig wash and casing wash additives. The implementation involved:

Regular Cleaning Schedule: Establishing a routine cleaning schedule using our high-performance additives.

Training and Support: Providing training to the client's staff on the proper use of the additives and best cleaning practices.

Environmental Compliance: Ensuring that the products used were environmentally friendly and compliant with local regulations.

The Results:

Reduced Downtime: The client experienced a significant reduction in equipment downtime, leading to uninterrupted operations.

Lower Maintenance Costs: The effective cleaning reduced the need for frequent repairs and part replacements, resulting in cost savings.

Enhanced Safety and Compliance: The use of eco-friendly additives ensured a safer working environment and compliance with environmental regulations.

Future Trends in Rig Wash Additive Technology

The future of rig wash additive technology looks promising, with ongoing research and development aimed at addressing the evolving needs of the oil and gas industry. Here are some trends to watch:

Smart Additives

The integration of smart technologies into rig wash additives is an exciting development. These additives can be designed to change their properties in response to specific conditions, enhancing their effectiveness and efficiency.

Nano-Technology

Nano-technology is set to revolutionize rig wash additives by enabling the development of formulations with enhanced penetration and cleaning capabilities. Nano-particles can reach and clean areas that traditional additives cannot, ensuring thorough cleaning.

Sustainability Focus

As environmental concerns continue to grow, there will be an increased focus on developing sustainable rig wash additives. This includes not only biodegradable and non-toxic formulations but also products that require less water and energy for their application.

Conclusion

The advancements in rig wash additive technology are transforming the oil and gas industry, making drilling operations more efficient, safe, and environmentally friendly. As a leading rig wash additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. is proud to be at the forefront of these innovations. Our commitment to quality, performance, and sustainability ensures that our clients receive the best possible solutions for their cleaning needs.

Whether you are looking for a pipe free agent additive manufacturer in India or a casing wash additive manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. has the expertise and products to meet your requirements. Stay ahead of the curve with our innovative rig wash additives and experience the difference they can make in your operations.

#Pipe free agent additive manufacturer in India#Rig wash additive manufacturer in India#Casing wash additive manufacturer in India#petrochemical products#petrochemical companies#petrochemical industries#petrochemical solutions#oil and gas industry#oil and gas companies#chemical product#chemical industry#chemical companies#oil & gas supply chain#India#Upstream activities#exploration and production#upstream oil and gas segment#upstream oil and gas industry

4 notes

·

View notes

Text

#casing thread protectors#composite thread protector#dedicated impex fze#dic oil tools#drill pipe thread protectors#importance of thread protectors#oilfield thread protectors#plastic thread protectors#thread protector#thread protectors#how thread protectors prevent damage and downtime on projects#thread protectors exporters#thread protectors in saudi arabia#thread protectors in usa#thread protectors manufactures#thread protectors suppliers

0 notes

Text

Big Ben - Sovereign

Big Ben is a renowned pipe manufacturer from the Netherlands. As part of the Gubbels Group, the company has been producing a wide range of pipes since the 1940s, from classic to modern, made from high-quality materials such as briar and olive wood. The pipes are characterised by precise workmanship and careful drilling.

3 notes

·

View notes

Text

The Vital Role of Pipe Fittings in Industrial Piping Systems

In this blog post, we’ll break down the crucial function of pipe fittings in industrial piping systems.

#pipe fittings#stainless steel pipe#best pipe threading services#stainless steel pipe manufacturer#drill pipes

1 note

·

View note

Text

To all my peeps who need hardware/home improvement/DIY stuff but don’t know how to go about getting it, here’s a little guide on how to navigate the hardware store:

If you know exactly what item you need

Bring as many visual aids are you can. Bring a picture of the item, a link to the store you found it on, even better, a link to the hardware store’s website showing the item, heck even a drawing of the item would help

What we want most from you is the brand name, the size, the UPC or manufacturer number or SKU if you have it, and the name of the item if you know it.

We also want the purpose you’re using the item for in a general sense. Hardware stores tend to be laid out by general area of work and being able to say, I need a light for a car is going to get you a different location than I need a light for a standing lamp in my house

If you know what purpose you want the item to serve but don’t know what item you need

Tell us about your project and what role the item plays in it. Use words like connect or bend or secure. We want to know the limits of what you need the item to do.

We also want to know the materials the item is interacting with. Drill bits for wood differ greatly from drill bits for cement and drill bits for sheet metal.

Do you need raw material? What items will probably be interacting with it? Ex: you’re putting up a shelf. Important info: the shelf must be made of wood and you plan to use screws and brackets to connect it to drywall.

If you know any unusual stressors the item will have to put up with, say them. Ex: I’m going to leave this item outside in all seasons, I plan to put heavy things on top of this item, I need this item to secure a delicate object

If you know what type of item you’re looking for but not which one you need

Stressors, again. How strong do you need the item to be? Some hooks can hold 10lbs, some can hold 50lbs, what are you planning on hanging from the hook?

Do you know the color or material you’re looking for? Does the pipe fitting have to be bronze or stainless steel?

Ask for the pluses and minuses of objects we present you, hopefully usually we’ll know and we work for the store not the supplier so we’ll give it to you straight if something’s of higher quality

I’m gonna give some quick examples here that sound more like natural conversation to show you how to convey this information

Ex: first bullet point

Hi I’m looking for some chains (name of item) for my trailer hitch (purpose of item, role item plays). The trailer is pretty heavy (strength needed) and I drive with it a lot (possible stressor). I’ll need about six feet of them (size) and they’ll have to be thick (size and appearance). I noticed you had them listed on your website here *shows phone* (visual aid)

Ex: second bullet point

Hi I need to join (type of connection) two pieces of wood (materials interacting with item, role item plays) together for a bookshelf (purpose of item, identifiable stressor). I don’t really know what’s best for that (asking for advice).

Ex: third bullet point

Hi I’m looking for a paint primer (type of item). It’s going on drywall that already has painter’s paint on it (material it’s interacting with, strength of item needed) I’ve heard there are some types that include paint and primer (mentioning options you want to consider)?

All of these will help you get the hobby or project item you need as quickly and efficiently as possible, best of luck!

2 notes

·

View notes