#deck sheet manufacturer in India

Text

instagram

Take your construction projects to the next level with SteelDECK52 - the cost-effective, speedy, and superior solution for streamlined construction. Connect with us to explore how we can support your specific project requirements and goals.

.

Visit Us: www.steeldeckingsheets.com

Contact Us: [email protected]| 8550995556

#steeldeck #steeldecks #deckingsheet #highwayconstruction #industrialcontractor #roadcontractors #roadconstruction #deckdepth

#deck profile sheet#deck sheet#decking steel#decking profile sheet manufacturer#decking sheets#decking sheet price#metal deck sheet#steel decking sheet#gi decking sheet#deck sheet profile#jsw deck sheet#metal deck sheet price#deck sheet manufacturer in india#decking sheet for bridges#Instagram

0 notes

Text

Deck Sheet Manufacturer in India

As a prominent deck sheet manufacturer in India, Perfect Metal Structure offers top-notch solutions for various construction projects. With their expertise and cutting-edge technology, they produce high-quality deck sheets that are widely used in flooring and roofing applications. These sheets are made from superior-grade materials, ensuring durability and strength. Perfect Metal Structure's deck sheets are known for their excellent load-bearing capacity and resistance to corrosion, making them ideal for both commercial and residential projects. Their precision-engineered sheets provide a stable and safe platform, enhancing the structural integrity of buildings. With a commitment to customer satisfaction, Perfect Metal Structure delivers reliable and cost-effective deck sheet solutions across India.

0 notes

Text

Best WPC and HPL Suppliers in Bangalore

Materials selection remains a crucial factor in building outside which is durable, attractive, and easy to maintain. WPC (Wood-Plastic Composite) and HPL (High-Pressure Laminate) are two materials that have gained immense popularity in Bangalore given their outdoor applications. Being uniquely advantageous for exterior cladding, decking, or any other outdoor projects WPC and HPL are considered ideal materials. At Makmore we provide a variety of WPC and HPL products that suit different purposes ensuring your investment yields high quality and good value for your investment.

#louvers for exterior wall#wpc exterior wall cladding#wpc outdoor wall panel#wpc decking manufacturers in india#wpc supplier in bangalore#wpc decking suppliers in india#wpc deck flooring near me#HPL cladding sheets in Bangalore#HPL sheet installation in Bangalore#HPL Sheet distributor in Bangalore#hpl sheet manufacturer near bangalore#hpl sheet work in bangalore#hpl cladding sheet works#hpl cladding works

0 notes

Text

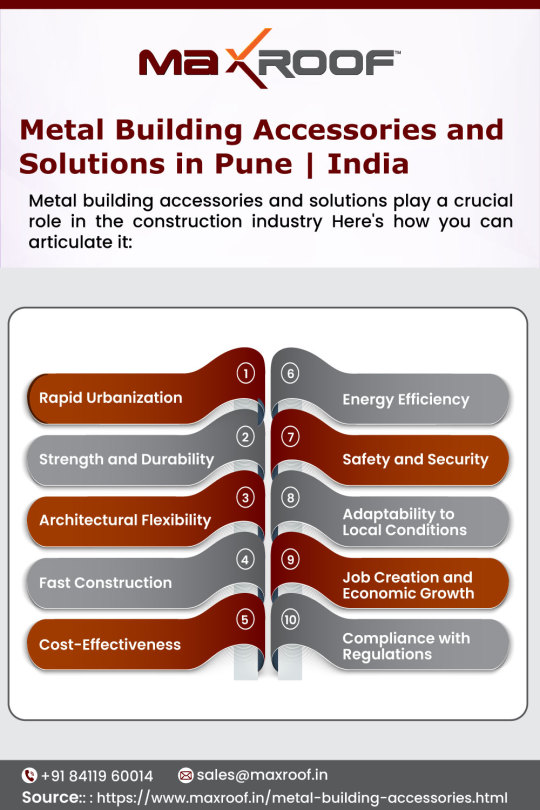

Our superior-quality steel and aluminum products are designed to satisfy the needs of functionality, safety, and simplicity of installation. Based on the dimensions of the wall and roof panels, our experts will determine the total number of accessories. You can make sure that everything will go according to plan when you have access to our wide selection of accessories for building.

#complete metal building solutions#steel wall cladding#roofing services and solution providers#metal deck manufacturers#roofing sheet suppliers#metal building accessories and solutions in india#metal roofing manufacturers#structural roof decking#roofing sheets#standing seam roof manufacturers and suppliers

0 notes

Text

Decking Sheet Manufacturers in India

PM Impex is a Decking Sheet Manufacturers that specializes in providing high-quality, durable, and long-lasting decking sheets. They offer a variety of sizes, colors, and styles, all designed to fit the requirements of any building project. Their products are made from durable materials that are designed to withstand harsh weather conditions, making them ideal for outdoor projects. They also offer a range of customization options, ensuring that customers get the exact product they need.

#Decking Sheet#PM Impex#India#Decking Sheet Manufacturers#Deck Slab Manufacturers in India#Deck Slab Suppliers in India

1 note

·

View note

Text

Decking Sheet Manufacturers

Gupta Iron Steel is India's Leading Decking Sheet Manufacturers. These Decking Sheets are made of Galvanized/PPGI/PPGL materials. The thickness of these sheets is 0.80mm to 2.00mm. The main features of the Decking Sheet are its Water Proof nature. We are using high-quality materials to make these sheets. Our aim is to provide the best quality products to our clients because customer satisfaction is our first priority. For more details, you can contact us.

Address : X-9 Loha Mandi, Naraina, New Delhi

Email Id : [email protected]

contact No : +91-9999740008

Website : https://www.guptaironsteel.com/decking-sheet.html

2 notes

·

View notes

Text

𝐄𝐱𝐜𝐢𝐭𝐢𝐧𝐠 𝐃𝐞𝐚𝐥𝐞𝐫𝐬𝐡𝐢𝐩 𝐎𝐩𝐩𝐨𝐫𝐭𝐮𝐧𝐢𝐭𝐲 𝐰𝐢𝐭𝐡 𝐕𝐞𝐫𝐦𝐚 𝐋𝐚𝐦𝐢𝐧𝐚𝐭𝐞 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐞𝐬!

Don’t miss out on this exclusive dealership opportunity with India's leading manufacturer of HPL Sheets, WPC Louvers, and WPC Decking. Join us and be a part of the future of stylish, durable, and innovative building materials.

Call or WhatsApp Us : +91-9899005395

#verma laminate industries#verma laminate#architecture#home decor#wpclouvers#hpl sheet#wpc louvers#wpc decking

0 notes

Text

The Growing Industry of WPC Panels : Innovations and Opportunities

Introduction

In recent years, the construction and interior design sectors in India have witnessed a significant transformation, largely due to advancements in materials technology. Among these innovations, Wood-Plastic Composite (WPC) panels have emerged as a game-changer. These panels, which combine the durability of plastics with the aesthetic appeal of wood, have quickly become a popular choice for architects, designers, and homeowners alike. In this article, we will delve into the WPC panels industry in India, exploring the technology behind these products, their benefits, the key Wpc pannel Price in Ahmedabad, and the future outlook for this burgeoning market.

What Are WPC Panels?

Wood-Plastic Composite (WPC) panels are engineered materials made from a blend of wood fibers and plastic polymers. The combination results in a product that leverages the strengths of both materials—offering the natural look and feel of wood with the resilience and low maintenance of plastic. The typical composition includes:

Wood Fibers: Sourced from sawdust, wood shavings, and other wood by-products.

Plastic Polymers: Usually recycled plastics or virgin polymers, such as polyethylene or polypropylene.

Additives: Various chemicals are added to enhance durability, color, and resistance to environmental factors.

The production process involves mixing these components, molding them into panels, and then curing them to create a finished product that is both durable and versatile.

Advantages of WPC Panels

Durability and Longevity: WPC panels are resistant to moisture, termites, and rot, making them suitable for both indoor and outdoor applications. They do not warp or crack easily, which enhances their longevity compared to traditional wood.

Low Maintenance: Unlike natural wood, WPC panels do not require regular sealing or painting. They can be cleaned with a simple wipe-down and are less susceptible to stains and discoloration.

Eco-Friendly: Many WPC panels are made using recycled plastics and wood fibers, contributing to sustainability and reducing waste. The production process also typically involves fewer emissions compared to traditional wood processing.

Aesthetic Flexibility: WPC panels come in a variety of finishes and colors that mimic the appearance of different types of wood, allowing for a broad range of design options.

Cost-Effectiveness: While the initial investment in WPC panels might be higher than some traditional materials, their durability and low maintenance costs often result in lower overall expenses over time.

Key Manufacturers of WPC Panels in India

India has seen a surge in companies specializing in WPC panels, driven by increasing demand from both the residential and commercial sectors. Here are some notable manufacturers:

Greenply Industries Ltd.: One of India's largest plywood and panel manufacturers, Greenply has diversified into WPC panels under its brand, GreenPanel. The company offers a range of WPC products designed for various applications, including wall panels and flooring.

Acrylics India Ltd.: Known for its high-quality acrylic sheets, Acrylics India has ventured into the WPC market. Their panels are designed for both indoor and outdoor use, emphasizing durability and aesthetic appeal.

Everwood WPC: Specializing exclusively in WPC products, Everwood offers a wide range of panels for applications such as decking, cladding, and fencing. Their focus on innovation and quality has made them a prominent player in the Indian market.

Kushal Ltd.: Kushal Ltd. produces a variety of WPC panels, including those for architectural and interior applications. The company is known for its emphasis on sustainability and eco-friendly production practices.

NCL Industries Ltd.: NCL Industries, with its long-standing reputation in the building materials sector, has entered the WPC panel market, offering products that cater to diverse design and structural needs.

Market Trends and Opportunities

The Wpc panels manufacturer in India is experiencing robust growth due to several factors:

Urbanization and Infrastructure Development: As India continues to urbanize, the demand for innovative building materials, including WPC panels, is on the rise. Infrastructure projects, residential complexes, and commercial spaces are increasingly incorporating these materials for their aesthetic and functional benefits.

Sustainability and Green Building Practices: With growing awareness about environmental issues, there is a shift towards sustainable building materials. WPC panels, with their eco-friendly attributes, are gaining traction in green building projects and certifications.

Technological Advancements: Continuous improvements in manufacturing technology are enhancing the quality and performance of WPC panels. Innovations such as better moisture resistance and advanced finishing techniques are expanding their application range.

Customization and Design Flexibility: The ability to customize WPC panels for specific design requirements is appealing to architects and designers. This flexibility allows for unique and personalized interior and exterior designs.

Challenges and Future Outlook

Despite the positive trends, the WPC panel industry in India faces several challenges:

Price Sensitivity: The initial cost of WPC panels can be higher than traditional materials, which may deter some consumers, especially in price-sensitive segments.

Quality Variability: The quality of WPC panels can vary between manufacturers. Ensuring consistent quality and performance is crucial for maintaining consumer trust and satisfaction.

Awareness and Education: There is still a need for greater awareness about the benefits and applications of WPC panels among architects, builders, and homeowners.

Looking ahead, the Wpc panels for exterior walls in India is poised for significant growth. Continued innovation, coupled with rising demand for sustainable and low-maintenance materials, will likely drive further expansion. Manufacturers who focus on quality, customization, and environmental sustainability will be well-positioned to capitalize on these opportunities.

Conclusion

WPC panels represent a promising segment of the building materials market in India, offering a blend of durability, aesthetic appeal, and environmental benefits. As the industry evolves, advancements in technology and growing awareness about sustainable construction practices will likely further boost the adoption of WPC panels. For manufacturers, staying at the forefront of innovation and addressing market challenges will be key to sustaining growth and meeting the diverse needs of the Indian market.

Frequently Asked Questions (FAQ)

1. What are WPC Panels?

WPC (Wood Plastic Composite) panels are engineered wood alternatives made from a combination of wood fibers and thermoplastics. These panels are durable, weather-resistant, and eco-friendly, making them an ideal choice for various applications such as wall cladding, decking, flooring, and furniture.

2. Are WPC Panels suitable for outdoor use?

Yes, WPC panels are highly suitable for outdoor applications due to their resistance to moisture, UV radiation, and varying weather conditions. They are commonly used in decking, fencing, and outdoor furniture.

3. How do WPC Panels compare with traditional wood?

WPC panels offer superior durability, require less maintenance, and are more resistant to environmental factors than traditional wood. Additionally, they are eco-friendly, as they are made from recycled materials, and do not contribute to deforestation.

4. Can WPC Panels be customized?

Yes, WPC panels can be customized in terms of size, color, texture, and finish according to your specific requirements. We offer a range of customization options to match your design needs.

5. How should WPC Panels be installed?

WPC panels can be installed using standard woodworking tools. For best results, follow our installation guide or consult a professional installer. We also provide technical support for installation if required.

6. What is the lifespan of WPC Panels?

WPC panels have a long lifespan, often exceeding 20-25 years, depending on the application and maintenance. They are highly resistant to wear and tear, making them a durable choice for both indoor and outdoor uses.

7. Are WPC Panels eco-friendly?

Yes, WPC panels are environmentally friendly. They are made from recycled wood and plastic materials, reducing the need for natural wood and contributing to sustainable building practices.

1 note

·

View note

Text

Decking Sheet Manufacturer in India

LCP FORMDEK®60 is an outstanding structural steel formwork system from LCP Building Products.

Main features:

Composite Structural Decking: Acts as permanent formwork during concrete pouring, supporting wet concrete, reinforcement bars, and construction loads without propping.

60mm Crest Height: Provides robust support and efficiently handles heavy loads and wet concrete.

Versatility: Ideal for commercial buildings, infrastructure projects, and residential developments.

Seamless Integration: FORMDEK®60 integrates seamlessly into diverse structures, enhancing both quality and efficiency.

Contact the LCP Building Products Pvt. Ltd. team for more technical information about this product.

Website: https://lcpindia.com/decking-sheet-formdek-60

0 notes

Text

Why is Stainless Steel pipe a First choice for marine manufacture?

Advantages of Stainless Steel Pipes in Marine Applications

The great expanse of the sea gives a unique set of demanding situations for materials used in shipbuilding and marine creation. Constant exposure to saltwater, intense weather conditions, and the ever-present hazard of corrosion necessitate strong and dependable substances. Among these substances, stainless-steel pipes reign ideal, providing an unmatched mixture of power, corrosion resistance, and durability. This weblog delves into the reasons why chrome steel pipes are the go-to desire for marine manufacturing, exploring special pipe sorts and highlighting legitimate suppliers.

Unveiling the Advantages of Stainless Steel Pipes in Marine Applications

Stainless metallic’s excellent residences make it a perfect cloth for pipes in marine environments:

Superior Corrosion Resistance: The presence of chromium in stainless-steel bureaucracy is a passive oxide layer that protects against saltwater corrosion, a vital thing for structures constantly scuffling with the ocean’s harshness.

High Strength and Durability: Stainless steel offers a wonderful energy-to-weight ratio, making pipes perfect for load-bearing packages at the same time as preserving a lightweight gain. This translates to improved gas performance for vessels and more desirable structural integrity for offshore platforms.

Low Maintenance: Stainless metal’s inherent corrosion resistance minimizes renovation needs, lowering expenses and downtime for marine devices and structures.

Fire Resistance: Many grades of stainless steel possess exceptional hearth resistance, a crucial safety function for ships and offshore installations.

Hygienic Properties: Certain chrome steel grades show off terrific hygiene properties, making them appropriate for applications regarding food and water transportation on ships.

Types of Stainless Steel Pipes for Marine Use

There are two number one forms of stainless steel pipes utilized in marine manufacturing:

Seamless Stainless Steel Pipes: These pipes are fashioned by piercing a solid billet of stainless steel, resulting in a non-stop, uniform structure with exceptional energy and pressure resistance. They are the favored choice for crucial applications like excessive-stress piping structures and boiler tubes.

Welded Stainless Steel Pipes: These pipes are created by rolling a flat sheet of stainless steel right into a cylindrical form and welding the seam. They offer a fee-powerful opportunity to seamless stainless steel pipe tube manufacturers for programs with much less worrying strain requirements, such as ventilation systems and deck railings.

Finding Reliable Suppliers: Stainless Steel Pipe Suppliers, Exporters, and Manufacturers

Selecting the right provider for your stainless-steel pipe wishes in marine applications is crucial. Here are some elements to not forget:

Product Quality: Ensure the provider adheres to identified standards like ASTM or ASME, making sure the pipes meet the vital electricity and corrosion resistance necessities for marine environments.

Product Availability: Choose a dealer presenting a wide variety of sizes, thicknesses, and grades of stainless-steel pipes to cater on your precise venture wishes. Look for suppliers with seamless and welded pipe alternatives.

Experience and Expertise: Partnering with a dealer with revel within the marine industry ensures they understand the precise demands of such applications and can provide technical guidance on pipe selection and setup.

Certifications: Look for suppliers with relevant certifications like ISO 9001, indicating their commitment to first-class control structures.

Manilaxmi Industrial Corporation: Your Trusted Partner for Marine-Grade Stainless Steel Pipes

At Manilaxmi Industrial Corporation, we’re India’s leading stainless steel and welded pipes supplier, producer, and exporter of great chrome steel pipes. We understand the critical position stainless steel performs in marine packages and are devoted to providing merchandise that meets the stringent demands of the maritime enterprise.

Our extensive inventory contains a wide range of:

Seamless Stainless Steel Pipes: We offer various sizes, thicknesses, and grades of seamless pipes, making sure you find an appropriate answer in your excessive-strain marine applications.

Welded Stainless Steel Pipes: Our welded pipes offer a powerful option for applications wherein stress necessities are less stressful.

Additional Marine-Grade Products: We provide a comprehensive selection of stainless-steel products mainly ideal for marine environments, inclusive of sheets, plates, and fasteners.

We prioritize outstanding customer service and offer technical guides to assist you in selecting the maximum suitable chrome steel pipes for your marine challenge.

#Pipes#Tubes#Flanges#Buttwelded Pipe Fittings#Forged Fittings#Tube Fittings#Sheets#Plates & Coils#Bars#Fasteners

1 note

·

View note

Text

instagram

#decking steel#deck sheet#decking profile sheet manufacturer#decking sheets#decking sheet price#metal deck sheet#deck sheet profile#jsw deck sheet#deck sheet manufacturer in india#decking sheet for bridges#decking sheet for flyover#decking sheet for sealink#Instagram

0 notes

Text

WPC Boards in Green Building Certification: Meeting Sustainability Standards

In recent years, the construction industry has increasingly embraced sustainable building practices to mitigate environmental impacts and enhance energy efficiency. One significant contributor to these efforts is the adoption of WPC (Wood-Plastic Composite) boards, renowned for their eco-friendly attributes and versatile applications in modern architecture.

Understanding WPC Boards and Their Eco-Friendly Features

What are WPC Boards?

WPC boards are composite materials made from a blend of wood fibers or sawdust and recycled plastic polymers. This combination results in a durable, low-maintenance product that mimics the appearance of natural wood while offering superior performance in various environmental conditions.

Sustainability Benefits of WPC Boards

Use of Recycled Materials: WPC boards typically incorporate recycled plastics, diverting waste from landfills and reducing the demand for virgin plastic production.

Reduced Environmental Footprint: Compared to traditional building materials like solid wood or PVC, WPC boards require fewer natural resources and emit fewer greenhouse gases during production.

Longevity and Durability: WPC boards have a longer lifespan than traditional wood products, reducing the frequency of replacements and associated environmental impacts.

Floresta: Leading the Way in Sustainable WPC Solutions

Floresta, a prominent manufacturer of WPC boards and sheets, exemplifies the commitment to sustainability in their product offerings. By integrating recycled materials and employing efficient manufacturing processes, Floresta ensures that their WPC sheets meet stringent environmental standards.

WPC Boards and Green Building Certifications

LEED (Leadership in Energy and Environmental Design)

LEED is a widely recognized green building certification program that promotes sustainable building and development practices. WPC boards contribute to LEED certification in several ways:

Materials & Resources: Using WPC boards with recycled content contributes to MR credits, specifically MRc4 (Recycled Content) and MRc5 (Regional Materials).

Energy Efficiency: The durability and thermal properties of WPC boards can contribute to improved energy performance and indoor environmental quality, supporting Energy & Atmosphere (EA) credits.

Innovation: Innovations in material design and sustainable practices in manufacturing may qualify for Innovation in Design (ID) credits under LEED.

Advantages of Choosing Floresta's WPC Boards for Green Buildings

Certified Sustainability: Floresta ensures that their WPC boards adhere to rigorous environmental standards, making them a reliable choice for architects and builders pursuing green building certifications.

Versatility in Applications: From interior finishes to exterior cladding and decking, Floresta's WPC boards offer versatile solutions that align with sustainable design principles.

Conclusion: Embracing Sustainability with Floresta's WPC Boards

As the construction industry continues to prioritize sustainability, WPC boards from Floresta emerge as a pivotal solution for achieving green building certifications like LEED. With their commitment to using recycled materials and reducing environmental impact, Floresta not only meets but exceeds the expectations of eco-conscious architects, developers, and homeowners. By integrating Floresta's sustainable WPC sheets into building projects, stakeholders contribute to a more sustainable built environment while enjoying the aesthetic and functional benefits of these innovative materials.

Also, Read:

Innovations and Technologies Driving the Success of Leading WPC Companies in India

Understanding the Environmental Impact of Waterproof Plywood and its Alternatives

Originally published at https://florestaproducts.blogspot.com

0 notes

Text

Coil Coating Market: Navigating Regulatory Challenges for Growth

Coil coatings are coating materials that are applied as a thin layer protective film onto metal coils and sheets. They help protect the underlying substrate from corrosion and other environmental damages. Coil coatings provide excellent gloss retention and color stability. They find applications in construction, appliances, automobiles and other general industrial applications.

The global coil coatings market size is estimated to be valued at US$ 1,510.97 billion in 2024 and is expected to exhibit a CAGR of 4.3% over the forecast period from 2023 to 2030.

Key Takeways

Key players operating in the coil coatings market are Beckers Group., Akzo Nobel N.V., PPG Industries, Inc., The Sherwin-Williams Company, Nippon Paint Holdings Co., Ltd. Key players are focusing on developing bio-based and sustainable coil coating products to capitalize on the growing environmental consciousness. For instance, Beckers Group offers Beckryl waterborne and sustainably certified coil coatings.

The growing construction industry across the globe is driving the demand for coil coatings. Coil coatings find widespread application in roofing, siding, decking, and other building components in the construction of commercial and residential buildings. Rapid urbanization and infrastructure development are augmenting the growth of the global construction industry.

Geographic expansion into emerging economies is another key trend observed in the coil coatings market. Leading manufacturers are focusing on setting up production facilities or acquiring regional players in high growth markets like Asia Pacific, Middle East & Africa and South America. This allows them to better serve the local demand and leverage growth opportunities. For example, AkzoNobel has production sites across 20 countries to serve customers globally.

Market key trends

Sustainable product innovation is a major trend in the coil coatings market. Customers are increasingly preferring eco-friendly coatings manufactured using bio-based resins and low or zero VOCs. To cater to this demand, manufacturers are investing in R&D to develop novel and greener coating formulations. For instance, Beckers Group offers Xyladecor coil coating made from wood extracts and Nippon Paint provides Novacq water-based coil coating with very low environmental footprint. Such innovations will drive further revenue growth of the market over the coming years.

Porter’s Analysis

Threat of new entrants: New entrants face high capital requirements to enter the mature coil coatings market.

Bargaining power of buyers: Large buyers in the automotive and construction industries can negotiate lower prices from suppliers due to their purchasing power.

Bargaining power of suppliers: The presence of many suppliers ensures that no individual supplier has significant influence over prices.

Threat of new substitutes: There exists a threat from substitute materials like powder coatings and galvanizing for end-use applications.

Competitive rivalry: The rivalry among existing players is very high as they compete on the basis of product quality, price and service.

Geographical Regions

North America accounted for the largest share of the global coil coatings market in terms of value in historical year. This is attributed to the presence of well-established construction and automotive industries in the region. Asia Pacific is expected to be the fastest growing geographical market for coil coatings between the forecast period. This growth can be attributed to increasing automobile production and construction activities in developing countries like China and India.

0 notes

Text

Floor decking sheet manufacturers in Pune | India

Roof Decking Sheets offer an extraordinarily strong base and a sturdy structural structure, which enables the roof's components to be sustained. We provide decking sheets in a wide range of bespoke sizes and weight bearing capacities to satisfy the needs of our clients. Our sheets' excellent dimensional stability and remarkable durability have been demonstrated.

#Metal Deck Manufacturers#Structural Roof Decking#Standing Seam Roof Manufacturers and Suppliers#Steel wall Cladding#Roofing Services and Solution Providers#Complete Metal Building Solutions#Roofing sheet suppliers#roofing sheets

0 notes

Text

A Comparative Analysis of Bolts, Screws, and Nails: Understanding Their Differences and Applications

Fasteners Manufacturers in India

Introduction:

In construction and manufacturing, the selection of fasteners plays a crucial role in ensuring structural integrity and reliability. Among the most commonly used fasteners are bolts, screws, and nails. While they may appear similar, each serves distinct purposes and possesses unique characteristics. This case study aims to provide a comprehensive analysis of bolts, screws, and nails, highlighting their differences and respective applications.

Objective:

The primary objective of this case study is to elucidate the key differences between bolts, screws, and nails, and to elucidate their optimal applications in various industries. By understanding the distinctive features of each fastener type, professionals can make informed decisions when selecting the appropriate fastening solution for their projects.

Bolt Manufacturers in India

Brief:

Bolts, screws, and nails are all fasteners used in construction, manufacturing, and various other industries. However, they differ significantly in terms of design, function, and application.

Bolts:

Bolts are threaded fasteners characterized by a head on one end and a threaded shaft on the other. They require a nut to secure two or more components together. Bolts are commonly used in applications where a strong, durable connection is needed, such as construction, automotive, and aerospace industries. They provide high tensile strength and are suitable for heavy-duty applications where disassembly may be required.

Screws:

Screws are similar to bolts but differ in that they typically have a tapered, pointed end and may or may not require a nut. Screws create their own internal threads when driven into a material, providing a secure grip. They are versatile fasteners used in woodworking, furniture assembly, electronics, and general construction. Screws come in various types, including wood screws, machine screws, and self-tapping screws, each designed for specific applications.

Nails:

Nails are non-threaded fasteners with a sharp point on one end and a head on the other. They are driven into materials using a hammer or nail gun and rely on friction to maintain their grip. Nails are commonly used in woodworking, carpentry, framing, and general construction applications. They provide quick and easy installation and are ideal for temporary or non-load-bearing connections.

High Tensile Fasteners

Applications:

- Bolts:

- Structural steel construction

- Machinery assembly

- Automotive manufacturing

- Bridge building

- Screws:

- Woodworking and furniture assembly

- Electrical and electronic equipment

- Sheet metal fabrication

- Drywall installation

- Nails:

- Framing and carpentry

- Roofing and siding installation

- Flooring and decking

- Pallet and crate assembly

ASME Fastener Standards

Conclusion:

In conclusion, bolts, screws, and nails are fundamental fasteners with distinct characteristics and applications. Bolts offer high strength and reliability for heavy-duty connections, screws provide versatility and ease of installation in various materials, and nails offer quick and cost-effective solutions for light-duty applications. Understanding the differences between these fasteners is essential for selecting the most suitable option for specific project requirements, ultimately ensuring optimal performance and durability.

0 notes

Text

PVC Batch Mixer in Ahmedabad

Invoit Plast Machinery Pvt. Ltd.

Invoit Plast Machinery Pvt. Ltd. is a reputed manufacturer, supplier, and exporter of plastic processing machines based in India, known for its dependable solutions in plastic processing.

Specializes in the production and supply of top-quality PVC Batch Mixer in Ahmedabad, Gujarat, India, essential equipment for various PVC product manufacturing processes.

PVC Batch Mixers, also referred to as high-speed mixers, efficiently blend PVC resin with additives, ensuring a homogeneous compound suitable for further processing.

They play a pivotal role in maintaining consistent quality throughout PVC production processes.

Types of PVC Batch Mixer:

High-speed mixers: Operate at approximately 40 meters per second, ensuring rapid mixing and shorter processing times.

Low-speed mixers: Suitable for mixing heat-sensitive additives or when a gentler mixing action is required.

Advantages of PVC Batch Mixer:

Ensures efficient and thorough mixing, maintaining consistent compound quality.

Short mixing cycles contribute to high production capacity.

Versatility in handling various PVC formulations and additives.

Robust and reliable equipment designed for long-term operation.

Applications:

PVC compounds produced by batch mixers are utilized across industries for:

Pipes and fittings in plumbing, drainage, and construction.

Profiles like window and door profiles, siding, and decking.

Sheets and films for flooring, membranes, and packaging.

Wire and cable insulation offering excellent electrical insulation.

Toys and sporting goods requiring durable and flexible PVC.

Service Coverage:

Invoit Plast Machinery Pvt. Ltd Provide PVC Batch Mixer in Ahmedabad, Gujarat, India, and surrounding areas, including Sanand, Vani, Kathawada, Odhav, Vatva, Rakhial, Singarva, Bakrol, Kadi, Kalol, Kanbha, Kujad, Changodar, Naroda, Dhandhuka, Dholka, Viramgam, Kerala, and Vatva.

For detailed information and inquiries, please feel free to contact us.

Read the full article

#Ahmedabad#Bakrol#Changodar#Dhandhuka#Dholka#Exporter#ExporterofPVCBatchMixer#Gujarat#India#Kadi#Kalol#Kanbha#Kathawada#Kerala#Kujad#Manufacturer#ManufacturerofPVCBatchMixerinAhmedabad#Naroda#Odhav#PVCBatchMixerinAhmedabad#PVCBatchMixerinGujarat#PVCBatchMixerinIndia#Rakhial#Sanand#Singarva#Supplier#SupplierofPVCBatchMixer#Vani#Vatva#Viramgam

0 notes