#dealkalization

Explore tagged Tumblr posts

Text

एफ्लुएंट ट्रीटमेन्ट प्लान्ट सप्लायर्स, जल प्रदूषण और वेस्ट वॉटर मैनेजमेंट के क्षेत्र में अद्भुत सफलता

लार्को इंडीया प्रा.लि. कंपनी साॅलीड एण्ड लिक्वीड वेस्ट पोल्युशन कंन्ट्रोल सिस्टम में विशेषज्ञ हैं और वे बोहोत बड़े एफ्लुएंट ट्रीटमेन्ट प्लान्ट के सप्लायर्स हैं।

जल प्रदूषण और वेस्ट वॉटर मैनेजमेंट और एफ्लुएंट ट्रीटमेन्ट प्लान्ट के सप्लायर्स

लार्को इंड��या प्राइवेट लिमिटेड एक ऐसी कंपनी है जो पानी और पर्यावरण को स्वच्छ रखने में लोगों की मदद करती है। उन्होंने 1998 में श्री माणिकराव एम येले की मदद से शुरुआत की, जो कचरे से होने वाले प्रदूषण को नियंत्रित करने के बारे में बहुत कुछ जानते हैं। वे ठोस और तरल अपशिष्ट प्रबंधन दोनों में मदद करने में विशेषज्ञ हैं। यह कंपनी विभिन्न स्थानों जैसे चीनी कारखानों, दूध डेयरियों और अस्पतालों को उनकी पानी और अपशिष्ट आवश्यकताओं में मदद करती है। उनके पास ऐसे लोगों की एक टीम भी है जो अच्छी सेवा देने और यह सुनिश्चित करने के लिए प्रशिक्षित हैं कि ग्राहक खुश हैं।

माणिकराव जी ने बहुत समय पहले क्राउन केमिकल्स नाम से एक कंपनी शुरू की थी। सबसे पहले, उन्होंने कारों के लिए फ्रिज बनाए, लेकिन बाद में उन्होंने गंदे पानी को साफ करने और कचरे के प्रबंधन में मदद करने के लिए रसायन बनाना शुरू कर दिया। उन्होंने काफी शोध किया और पानी और कचरे के प्रबंधन के लिए कंपनी का एक नया हिस्सा बनाया। उन्होंने ठोस कचरे के प्रबंधन और पुनर्चक्रण के तरीकों पर भी गौर करना शुरू कर दिया।

कंपनी गंदे पानी को साफ करके उसे दोबारा इस्तेमाल लायक बनाने में मदद करती है। उनके पास विशेष मशीनें और प्रौद्योगिकियां हैं जो पानी को स्वच्छ और सुरक्षित बनाने में मदद कर सकती हैं और वह महाराष्ट्र में जाने पहचाने एफ्लुएंट ट्रीटमेन्ट प्लान्ट के सप्लायर्स हैं। यह महत्वपूर्ण है क्योंकि यह पर्यावरण की रक्षा करने में मदद करता है और व्यवसायों के लिए पैसा बचा सकता है। लार्को इंडिया प्राइवेट लिमिटेड पुणे एक कंपनी है जो पानी साफ करने के लिए उपकरण बनाती है और वे पुणे और अन्य स्थानों में विभिन्न प्रकार की परियोजनाओं में मदद कर सकते हैं।

लार्को इंडीया प्रा.लि. इन्डस्ट्रीज जिसमे हम काम कर चुके है

ईटीपीए कारखानों से गंदे पानी को साफ करने के लिए महत्वपूर्ण हैं, और हमारी कंपनी इस बारे में बहुत कुछ जानती है कि वे कैसे काम करते हैं। हम सुनिश्चित करते हैं कि हमारी उपचार प्रणालियाँ नियमों का पालन करें और विभिन्न प्रकार की फ़ैक्टरियों को उनकी विशिष्ट आवश्यकताओं में मदद करें।

हमारी कंपनी में 50 से 100 के बीच लोग काम करते हैं, और वे जो करते हैं उसमें वास्तव में अच्छे हैं। हमारी योजना विकास करने और जनता से धन जुटाने की भी है। अभी हम पानी साफ करने के लिए दूसरे देशों से विशेष फिल्टर खरीदते हैं, जो काफी महंगा होता है। हम भारत में अपना फ़िल्टर बनाना चाहते हैं, इसलिए वे सस्ते होंगे। हम ऐसा करने के लिए एक बड़ी सुविधा के निर्माण पर काम कर रहे हैं, और इससे हमें बहुत सारे पानी का पुनर्चक्रण करने में मदद मिलेगी।

हमेशा अच्छी गुणवत्ता वाली और उचित कीमतों पर चीजें बनाना महत्वपूर्ण है, भले ही इसका मतलब यह है कि हमें उतने ऑर्डर नहीं मिलते हैं या उतना पैसा नहीं मिलता है। जब हम किसी ऐसे क्षेत्र में काम करते हैं जो हमें पसंद है, तो हमें पर्यावरण का भी ध्यान रखना होता है और चीजों को फेंकने के बजाय दोबारा इस्तेमाल करने के तरीके खोजने होते हैं। ऐसा करने के लिए नए विचारों और तरीकों के साथ आना हमारा काम है। हमें उम्मीद है कि इस रीसाइक्लिंग को करने वाली कंपनी अच्छा काम करेगी और हम उन्हें रीसाइक्लिंग की ओर से शुभकामनाएं देते हैं। अगर आपको अपने प्लान्ट में कुछ दिक्कते है और आप उसको समझ नहीं पा रहे तो आप हमसे कांटेक्ट कर सकते है। हम महाराष्ट्र के जाने माने इटीपी मनुफक्चरर्स और सप्लायर्स हैं।

#water treatment plant#water filter#watertreatmentsolutions#etp#sewagetreatmentplant#dealkalization#water purification

0 notes

Text

Industrial Resins

Indion Resins, a division of Ion Exchange, offers a comprehensive range of industrial resins designed for various applications. These resins are produced in an advanced, ISO 9001 and 14001 certified facility, ensuring high quality and consistency. Indion's portfolio includes ion exchange resins for conventional water treatment processes like softening, deionization, and dealkalization. These resins are noted for their lower rinse volumes, high capacity, and superior lifecycle, making them a preferred choice in the industry (Ion Exchange) (Indion Resins).

Additionally, Indion Resins cater to specialized industrial needs across sectors such as pharmaceuticals, food and beverages, nuclear, chemical processing, biodiesel production, and more. These resins come in various forms with different particle sizes, surface areas, porosities, and matrices, suitable for a wide range of applications (Ion Exchange) (Ion Exchange Oman).

For more details, you can visit our website:https://ionresins.com/

0 notes

Text

Pem Electrolysis: Harnessing Renewable Energy Sources to Produce Hydrogen

PEM electrolysis of water is a technology that produces hydrogen from renewable energy sources through the corruption of water motes into hydrogen and oxygen using an electrochemical process. It's one of the three main specialized routes for hydrogen product, along with alkaline electrolysis and solid oxide electrolysis.

Compared to the other two specialized routes, PEM electrolysis has a advanced effectiveness of hydrogen product and is suitable for the volatility of renewable energy power generation. It's presently the mainstream and promising electrolysis of water hydrogen product technology.

The structure of a typical PEM electrolytic cell consists of an anode and cathode end plate, a cathode and anode prolixity subcaste, an anode and cathode catalytic subcaste, and a proton exchange membrane. The end plates fix the factors of the electrolytic cell, guide current transfer, and distribute water and gas, while the prolixity subcaste collects current and promotes gas-liquid transfer. The catalytic subcaste is composed of a catalyst, electron conduction medium, and proton conduction medium and is the core point for electrochemical responses.

The advantages of PEM electrolysis water technology include the use of a proton exchange membrane solid electrolyte, which eliminates the need for dealkalization of the gas generated, advanced effectiveness compared to the alkaline electrolytic cell, quick launch and stop, good responsiveness, and the capability to acclimatize to the volatility of renewable energy power generation.

still, the current PEM water electrolysis technology has a disadvantage in its high cost due to the use of precious essence platinum as a catalyst. Reducing the platinum lading of the catalyst or chancing a new low- cost volition material is a crucial specialized issue to be studied and overcome.

PEM electrolysis of water is a technology that produces hydrogen from renewable energy sources through the corruption of water motes into hydrogen and oxygen using an electrochemical process. It's one of the three main specialized routes for hydrogen product, along with alkaline electrolysis and solid oxide electrolysis.

Compared to the other two specialized routes, PEM electrolysis has a advanced effectiveness of hydrogen product and is suitable for the volatility of renewable energy power generation. It's presently the mainstream and promising electrolysis of water hydrogen product technology.

The structure of a typical PEM electrolytic cell consists of an anode and cathode end plate, a cathode and anode prolixity subcaste, an anode and cathode catalytic subcaste, and a proton exchange membrane. The end plates fix the factors of the electrolytic cell, guide current transfer, and distribute water and gas, while the prolixity subcaste collects current and promotes gas-liquid transfer. The catalytic subcaste is composed of a catalyst, electron conduction medium, and proton conduction medium and is the core point for electrochemical responses.

The advantages of PEM electrolysis water technology include the use of a proton exchange membrane solid electrolyte, which eliminates the need for dealkalization of the gas generated, advanced effectiveness compared to the alkaline electrolytic cell, quick launch and stop, good responsiveness, and the capability to acclimatize to the volatility of renewable energy power generation.

still, the current PEM water electrolysis technology has a disadvantage in its high cost due to the use of precious essence platinum as a catalyst. Reducing the platinum lading of the catalyst or chancing a new low- cost volition material is a crucial specialized issue to be studied and overcome.

1 note

·

View note

Text

Ion Exchange Resins Market Growth - Global Industry In Depth Study And Huge Demand In Future 2023-2030

Ion exchange resins are a type of solid polymer material that can selectively exchange ions with a surrounding solution. They are widely used in various industrial and scientific applications, including water treatment, chemical processing, pharmaceuticals, food and beverage production, and more. Ion exchange resins are typically composed of small beads or particles made of a cross-linked polymer matrix, which provides a porous structure with a large surface area for ion exchange to occur. The polymer matrix is usually functionalized with specific chemical groups that determine the type of ions that can be exchanged. Common functional groups include sulfonic acid (-SO3H) for cation exchange resins that exchange positively charged ions (cations), and quaternary ammonium (-NR4+) for anion exchange resins that exchange negatively charged ions (anions).

The ion exchange process occurs when ions in a solution come into contact with the resin beads. The ions that have a higher affinity for the resin's functional groups will replace the ions originally attached to the resin, resulting in an exchange of ions between the resin and the solution. This allows for selective removal or recovery of specific ions from a solution.

The global ion exchange resins market is a growing industry that is driven by various factors, including increasing demand for clean water, growing awareness about water pollution and the need for water treatment, and the expanding industrial and manufacturing sectors. The ion exchange resins market is also influenced by factors such as regulatory requirements for water quality, advancements in technology, and increasing applications in diverse industries.

The market for ion exchange resins is segmented based on type, application, end-use industry, and geography. The most common types of ion exchange resins include cation exchange resins, anion exchange resins, and mixed bed resins. Cation exchange resins are used for cation exchange processes, anion exchange resins are used for anion exchange processes, and mixed bed resins are used for both cation and anion exchange processes.

Ion exchange resins find applications in various industries, including water treatment, chemical processing, pharmaceuticals, food and beverages, power generation, and others. In the water treatment industry, ion exchange resins are used for water softening, demineralization, dealkalization, and removal of heavy metals and other contaminants. In the chemical processing industry, they are used for purification, separation, and recovery of chemicals and compounds. In pharmaceuticals, they are used for drug purification and formulation. In food and beverages, they are used for juice and wine clarification, sugar decolorization, and other applications. In power generation, they are used for water treatment in boilers and condensers to prevent scale formation.

Geographically, the ion exchange resins market is segmented into regions such as North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Asia-Pacific is expected to be the fastest-growing region due to increasing industrialization, urbanization, and growing awareness about water pollution and the need for water treatment. North America and Europe are also significant markets for ion exchange resins due to strict water quality regulations and increasing demand for clean water.

Major players operating in the global ion exchange resins market include The Dow Chemical Company, Lanxess Ag, Purolite Corporation, Thermax Limited, Ion Exchange India Ltd., Samyang Holdings Corporation, Mitsubishi Chemical Holdings Corporation, Sunresin New Materials Co. Ltd., ResinTech Inc., Novasep Holding, Samyang Corporation, Bio-Rad Laboratories Inc. and Jiangsu Suqing Water Treatment Engineering Group Co., Ltd

Ion exchange resins find diverse applications across various industries due to their ability to selectively remove ions from solutions based on their functional groups. Some of the common applications of ion exchange resins are:

➢ Water treatment and purification: Ion exchange resins are widely used in water treatment and purification processes to remove contaminants such as dissolved salts, heavy metals, nitrates, and other pollutants from drinking water, industrial process water, and wastewater. These resins are used in both municipal and industrial water treatment plants to improve water quality, meet regulatory standards, and ensure safe and clean water supply.

➢ Chemical processing: Ion exchange resins are used in the chemical industry for various applications, such as purification of process streams, recovery of valuable compounds, and removal of impurities. They are used in processes such as demineralization, decolorization, deionization, and catalysis in chemical reactions, contributing to the production of high-quality chemicals and intermediates.

➢ Pharmaceuticals: Ion exchange resins are used in the pharmaceutical industry for purification of Active Pharmaceutical Ingredients (APIs) and other chemicals, as well as for drug formulation and drug delivery systems. These resins help in removing impurities, such as salts, organic compounds, and heavy metals, from pharmaceutical products to ensure their quality, safety, and efficacy.

➢ Food and beverages: Ion exchange resins are used in the food and beverage industry for water purification, as well as for removal of impurities, such as color, taste, and odor, from process streams. These resins help in improving the quality of drinking water, soft drinks, fruit juices, brewing water, and other food and beverage products.

➢ Power generation: Ion exchange resins are used in the power generation industry for water treatment in steam generation systems, such as boilers and condensers. These resins help in removing impurities from water, such as dissolved salts and heavy metals, to prevent scaling, corrosion, and fouling in the steam generation equipment, which can improve their efficiency and extend their lifespan.

➢ Electronics: Ion exchange resins are used in the electronics industry for purification of ultrapure water used in semiconductor manufacturing processes. These resins help in removing trace impurities from water, such as ions, organic compounds, and particulate matter, which can impact the quality and reliability of electronic devices.

➢ Mining and metallurgy: Ion exchange resins are used in the mining and metallurgy industry for recovery of valuable metals, such as gold, silver, uranium, and rare earth elements, from process streams and waste streams. These resins help in selectively adsorbing and recovering specific metal ions from complex mixtures, providing an efficient and cost-effective method for metal recovery.

➢ Environmental remediation: Ion exchange resins are used in environmental remediation processes for removal of contaminants from soil, groundwater, and other environmental matrices. These resins can selectively adsorb contaminants, such as heavy metals, radioactive ions, and organic pollutants, from environmental media, contributing to the cleanup of contaminated sites and protection of the environment.

➢ Other applications: Ion exchange resins are also used in various other applications, such as sugar refining, biotechnology, cosmetics, and personal care products, where purification, separation, and recovery of specific ions or compounds are required.

The ion exchange resins market offers several benefits, which contribute to its growing demand across various industries. Some of the key benefits of ion exchange resins are:

✦ Water purification ✦ Selective ion removal ✦ Process efficiency ✦ Wide range of applications ✦ Compliance with environmental regulations ✦ Improved product quality ✦ Cost-effective solution

In summary, the benefits of ion exchange resins include water purification, selective ion removal, process efficiency, wide range of applications, compliance with environmental regulations, improved product quality, and cost-effective solutions, which contribute to their growing demand in the market.

0 notes

Text

Weak Acid Cation Exchange Resin Market - Forecast (2022 - 2027)

Weak acid cation exchange resin market size is estimated to reach US$0.7 billion by 2027 after growing at a CAGR of 3.5% from 2022-2027. Weak acid cation exchange resin is a type of ion exchange resin which have a functional group of carboxylic acid and is used in dealkalization, demineralization, and other water purification applications. Such ion resin consists of two types i.e., an acrylic acid type which is used in water processing with high carbonates, and methacrylic acid type which is used for purification of anti-biotics and amino acid. The drivers for the weak acid cation exchange resin market are the growing initiatives of a government organization for improving water quality, innovations in wastewater treatment, an increase in global demand for electricity, and rapid development in the power sector. However, the waste water treatment process is expensive due to high investments made in technology, equipment, and multistage facilities. Such high cost has caused inadequacy in water treatment plants in the least developed nations which have negatively affected the demand for weak acid cation exchange resin in such nations for water treatment.

0 notes

Photo

Pretreatment Process… Filtration, Activated carbon usage, Softening, Dealkalization, Reverse osmosis, Demineralization…. BIMAKS, Quality never lies. [email protected] www.bimakskimya.com.tr/en/ #suarıtma #su #temizsu #tersosmoz #kimya #watertreatment #water #cleanwater #reverseosmosis #waterfilter #filtres #eau #eaupropre #osmoseinverse #filtreàeau #вода #чистаявода #осмос #обратныйосмос #мембраны #tratamientodelagua #agua #agualimpia #remosmosis #filtrodeagua #ماء #مياه_نقية #تناضح_عكسي #تصفية #مياه_شرب (Bimaks Water Treatment Chemicals) https://www.instagram.com/p/B72v-oPFfgU/?igshid=18uj2i6f2qhpy

#suarıtma#su#temizsu#tersosmoz#kimya#watertreatment#water#cleanwater#reverseosmosis#waterfilter#filtres#eau#eaupropre#osmoseinverse#filtreàeau#вода#чистаявода#осмос#обратныйосмос#мембраны#tratamientodelagua#agua#agualimpia#remosmosis#filtrodeagua#ماء#مياه_نقية#تناضح_عكسي#تصفية#مياه_شرب

0 notes

Photo

The Best Natural Deodorant Ever: Consonant Skincare Dealkalizing Deodorant | Gli… http://bit.ly/30tFGvz

0 notes

Text

feedwater treatment chemicals

ChemSystems, Inc. Conversely, if your plant rarely has hardness and iron upsets and you are still running a phosphate based scale inhibitor program, then you are almost certainly losing money every year in fuel and water by not optimizing the cycles you can run in your best water treatment plant . These treatment methods help to reduce the accumulation of mineral deposits, minimize boiler blowdown and improve steam purity. SUEZ's comprehensive boiler water treatment programs will successfully offer both online and offline protection throughout the steam system, namely the areas of feedwater treatment chemicals, internal boiler treatment chemicals,and steam condensate chemicals. Distributor of boiler water treatment including water softeners & chemical tanks. Precise blowdown control may improve boiler cycles of concentration as well, saving water and chemicals. Fortunately, it's easy to keep the boiler in your facility in the Tampa Bay area operating at peak performance while also significantly extending its service life - simply contact R2J to implement a custom boiler water treatment program. Sulfite is inexpensive, safe, easily fed and monitored, reacts quickly with oxygen, and is compatible with most other boiler treatment chemicals. ISO 9002 certified distributor of industrial boiler water treatment chemicals. Western Group know the most efficient ways to combat the key problems found in boiler systems, as well as providing custom made solutions which will ensure that the health and efficiency of your system is maintained to the highest level, as well as keeping you compliant with BS2486. This conservative approach insures that our feedwater treatments are effective and environmentally sound. NuChem has extensive experience in the chemical treatment of water systems for more than 50 years. Process water and rinse water, used in a variety of industries, that has become contaminated with chemicals and metals must be properly filtered through a process water filtration system prior to discharge. Cetamine® : Innovative and comprehensive technology based on film-forming amines to prevent corrosion and deposits in boiler systems. Galvanized steel cooling towers are particularly susceptible to white rust” corrosion, which is prevented during equipment start-up by metal passivation. The concept is developed to reduce the blowdown rate in steam boilers and will therefore significantly save water, fuel and chemicals for the end-user. To control boiler scale formation it is therefore important to pre-treat the feed water, removing as effectively as possible any hardness salts before they enter the boiler system. The Certified Water Technologist (CWT) program represents the highest professional credential in the industrial and commercial water treatment field. Both solids and non-solids varieties, these products prevent oxygen-induced corrosion in steam generating system equipment (boilers, economizers, pumps and feedwater lines), by chemically removing the last traces of oxygen from the feedwater. All our treatment chemicals are manufactured in house to ISO 9001 standards. The metallurgy in steam boilers today is very different from the past. The problems associated with poor boiler water treatment and system maintenance can include scaling, corrosion and deposition. SINCE 1998, BOND WATER TECHNOLOGIES has treated high and low-pressure steam boilers. The two main functions of a boiler are to transfer heat to water to produce steam under pressure and to separate steam from the water in the boiler. They may also be fed through a separate line discharging in the feed-water drum of the boiler. Products include boil outs, dispersants, chelants, amine based products, oxygen scavenging products and lay-ups. Water treatment and specialty chemical programs are critical to ensuring maximum recovery and throughput while helping minimize downtime and mitigate environmental, health, and safety risks. The Global Boiler Water Treatment Chemicals Market research report provides an exhaustive research report that includes an executive summary, definition, and scope of the market.

Based on our experience and with the help of our experts, we develop tailored solutions to meet your individual requirements for your boiler water treatment. The most common of these being oxygen associated corrosion which is caused by oxygen dissolved in the feed water entering the boiler system. In the case of low to medium pressure steam boilers, many of the corrosion and tube failure are deposit related. The SUEZ boiler water treatment process includes injection, monitoring and control solutions for optimal and efficient protection based on the system's operating variables. Global Boiler Water Treatment Chemicals Market 2019-2024, has been prepared based on an in-depth market analysis with inputs from industry experts. Types of boiler water treatment chemicals include acid neutralizers, algaecides, corrosion inhibitor, fuel treatments, and steam sludge removers. Treatment is typically using a steam volatile Amine which either neutralises the steam pH or uses a filming amine to coat the surface of the tube with a corrosion resistant film. Offers internal scale, corrosion, water sludge, dispersant, and return line treatments; oxygen scavengers; antifoams; and descaling chemicals. When steam is produced from water containing dissolved solids, the solids remain and concentrate in the boiler water. With significant experience gained from large industrial and utility operations, we have applied many technical achievements in water treatment to our programs involving both cooling towers and boiler operations. Boiler water is treated to prevent scaling, corrosion , foaming, and priming. If left untreated, boiler water oxygen will corrode boiler components leading to increased maintenance costs and reduced boiler operating efficiency. As members of the Association of Water Technologist and the National Association of Power Engineers, we can provide in depth training on all water related equipment and issues. Scale, corrosion, fouling, microbiological contamination and other water treatment problems can be costly. A study of the influence of chloride ion concentration on the corrosion behavior of carbon steel in phosphate high-temperature boiler water chemistries. Founded in 1993, Lenntech is an international water treatment and filtrations solution company based in the Netherlands. Scale is caused by the accumulation of minerals in the boiler water which, if not removed, can cause localized overheating, reduced heat transfer efficiency, and in severe situations tube failure. Their Hydrex 1000 series of additive chemicals include scale inhibitors, dispersants, oxygen scavengers, and steam line treatments. Our field engineers have decades of wastewater treatment experience and are supported by a team of highly regarded scientists and engineers based in Newton, Massachusetts. The following list of reagents are for use in various water testing applications including Potable, Process, Industrial Boilers & Cooling Systems, Swimming Pool and Waste Water treatment. SAMCO has over 40 years of experience helping our customers design and custom-engineer boiler feed water treatment systems. Correctly treating the water cycle within the boiler system is critical to ensure the boilers provide optimum performance over their service life in order to increase plant efficiency,” explained Kgomotso Khomo, Project Engineer, Veolia Water Technologies South Africa. While extensive planning goes into designing, installing and maintaining your facility's systems, often little thought goes into the water treatment of that system. Such systems use water (steam) at elevated temperatures which is a highly efficient means of energy transfer. When corrosion is controlled by ULF treatment the colour of chilled water changes from brown to clear, after a period. GCM Water is a proudly South African company that provides sustainable total water management services to industry. No two systems are alike and we will develop a water treatment solution to meet your facility's individual requirements. Chemical treatment of water inside the boiler is usually essential and complements external treatment by taking care of any impurities entering the boiler with the feed water (hardness, oxygen , silica , etc.). In many cases external treatment of the water supply is not necessary and the water can be treated only by internal methods.

We offer a wide range of water maintenance programs for Cooling Towers, Water Softeners, Boilers, and Closed-loop systems. Using scale inhibitors, corrosion inhibitors and polymers, we can help maintain your steam boiler plant, preventing the need for expensive repairs such as boiler tube replacement. In addition, we have expertise in the design of makeup water pretreatment systems including water filtration and softening systems, demineralizers, dealkalizers, reverse osmosis systems, and condensate polishers. According to the report, the global boiler water treatment market is projected to grow moderately during the forecast period. Most typical failures are due to oxygen pitting of the steel and therefore chemical treatment of the feed water is essential to prevent such corrosion occurring. Industrial water systems typically consist of four sections, designed for the particular current and predicted future industrial requirements of the facility. We offer boiler water treatment services and chemistries depending on your specific system and operational needs. ChemTreat has the field expertise and innovative solutions necessary for our clients to not only meet those goals but enjoy a competitive advantage in the marketplace, even for the most complex chemical processing systems. Maintain the conductivity of your boiler water in the range determined by your Chardon Service Technician. GE Water and Process Technologies offers an assortment of technologies that solve common boiler feed water issues, such as corrosion, deposition, and scaling. Suitable pre-treatment of the boiler feed water, this may include commercial water softeners and industrial reverse osmosis units. Visit our Boiler Treatment Chemicals Page to find out more and order online today. The most appropriate boiler feed water treatment system will help the facility avoid costly plant downtime, expensive maintenance fees, and boiler failure as a result of scaling, corrosion, and fouling of the boiler and downstream equipment. Electric heaters can be added to smaller steam boiler feedwater systems that operate in the same way. Boiler water treatment; Industrial boilers and steam raising plant are used extensively in many commercial, manufacturing and industrial processes. Only pure water leaves the boiler as steam is produced; any dissolved solids are left behind. Services and commitments needed to protect you from the risks of poor water quality. The best solution is to have the water needs of the facility properly evaluated and necessary upgrades directed by the industrial water treatment experts at Culligan Industrial Water. By investing in the proper industrial water treatment services, businesses can avoid expensive repair problems and mitigate downtime. 2-5 years of experience in water treatment, chemical or hydrocarbon industries. Economizers recover heat from combustion gases leaving the boiler, and transfer it to feedwater. Coagulation, flocculation, lamella clarification, sand filtration, disinfection and reverse osmosis are all standard processes in these off-the-shelf plants, while this specific boiler water applications required an additional Activated Carbon Filter in the pre-treatment phase to protect the RO membranes. Steam boilers should treated for lay-up conditions any time the boiler will be off-line for more than two weeks. With us, you can count on a reliable service from an experienced water treatment provider. Barclay's feedwater treatment programs are designed to maintain the waterside integrity of boilers and related heat exchange equipment including economizers, air preheaters, as well as steam turbines and auxiliaries. Advanced Water Technologies engineers will consider these factors in the preparation of a treatment proposal after close discussion with the client. Remember, pitted boiler tubes are inevitable without some mechanism to preheat the feedwater to at least 190° F. Treatment plans are based on your actual operational details, production requirements and the results of comprehensive water analyses performed by our state-of-the-art testing laboratory.

A well-managed boiler water treatment programme will help to optimise costs and operational efficiencies, reduce downtime, achieve water and energy savings, maintain steam quality, and increase plant reliability and safety. In 1928, Nalco was formed with the merger of two Chicago-based companies selling sodium aluminate to treat water for steam locomotives, municipalities, and boiler feed water for industrial plants. The STEAM-CO Drumless” Delivery System offers the safest method of delivery for water treatment products. Full service renting of boilers for short or extended periods. Equipment failure and defective products can be directly linked to incorrectly processed industrial water. We also use different external services like Google Webfonts, Google Maps, and external Video providers. The equipment is carefully selected to allow for periodic maintenance, and the right monitoring apparatus is added to allow for the carefully supervised operation of all industrial water systems. For more complex steam systems such as high steam pressure or turbine boilers, more advanced boiler chemicals are used. We are always looking to add to our growing number of locally based distributors working within the water treatment and related service sectors around the world. Advanced Water Technologies engineers, in making any particular recommendations, will always provide a balanced financial overview of the capital cost of any particular plant versus the ongoing savings in operational costs. Pre-treatment equipment can be properly sized, and arranged to accomplish the essential job of effectively removing larger particulates, and modifying the chemical profile of the source water. We also make use of various boiler water treatment products that effectively disperse particulates and precipitated crystals. Boiler water must be treated in order to be proficient in producing steam. To maintain the quality of any generated steam or hot water, appropriate to the application. Traditionally, water treatment services have been supplied by a third party, independent of the equipment manufacturer. Kurita ultimately plans to expand coverage provided under the TELEMAC® NEO service to include cooling water and to provide a full range of water treatment services that meet customer requirements for safety and security. Over time, the concentration of dissolved solids from the make-up water increases in the boiler as pure water is removed as steam. In many cases for an industrial steam boiler, a duplex softener is required as there is a need for no interruption to soft water supply to the hotwell, if you are unsure about what system is best for your application then contact Accepta today. Properly treating your boiler feedwater is a critical practice that will minimize or prevent unscheduled downtime, prolong equipment life, maximize energy efficiency, reduce maintenance costs, and ensure the best possible ROI for your system. Based out of the suburbs of Paris, France, Veolia Water Technologies is foremost a worldwide water treatment equipment, service, and maintenance company. When it is time to clean and passivate, the boiler is filled with water and an appropriate amount of chemicals and biocide to the header valve. For industrial companies using a boiler for its facility, some type of boiler feed water treatment system is usually necessary to ensure an efficient process and quality steam generation. This process starts off with an assortment of mixing reactors, typically one or two reactors that add specific chemicals to take out all the finer particles in the water by combining them into heavier particles that settle out. Technologies for optimising boiler feed water and cooling tower feed to minimise chemical usage. Our boiler water treatment product line is at the forefront of innovation through sustained investment in research and development. STEAM-CO specializes in Quality Water Treatment Products and Services. Scale formation is prevented by firstly removing as much hardness from the make-up water as possible (normally with a boiler water softener), and then secondly by dosing boiler water chemicals such as alkalinity builders, phosphate treatments and polymer sludge conditioners.

These chemical products, equipment and control systems are produced for treatment of high, medium and low pressure boilers as well as for hot water heating boilers. Water Purification Systems and Equipment. ChemTreat provides boiler water treatment chemicals , and testing and control equipment. If you are interested in becoming an international distributor of Accepta - The Water Treatment Products Company please click here to learn more. While many types of corrosion can occur in the steam boiler environment, oxygen-related corrosion is by far the most common. Water Energy offers the opportunity to do in site purification of water, thanks to its multiple solutions of plants and equipments that allows re-using the treated water. Accurate chemical water treatment and skillful maintenance are key elements to attain optimal boiler operation. Water treatment chemicals are vital in preventing this scale deposits. SUEZ's boiler services include a range of solutions that combine chemistry, equipment, data analytics, and field services to address boiler water performance. Another way in which we treat boiler feed water is by adding chemicals to the water. Our highly trained water treatment consultants operate across the UK and Ireland and use our industry leading electronic reporting system which provides trend graphs, traffic light warnings, automatic calculations and cost-saving recommendations to provide exceptional service. Carbon dioxide corrosion, which leads to uniform metal loss below the water line caused by acid attack, can be controlled either by pre-treatment techniques such as de-alkalisation and reverse osmosis, or by the addition of special steam volatile chemicals such as neutralising and filming amines. The boiler water treatment companies near the region of Denver, Colorado are also looking for- reverse engineering, and in-house product testing as secondary services in addition to the boiler water treatments plants in the nearby region. Customized cooling water treatment systems are typically utilized in conjunction with other water treatment methods, such as boiler water pretreatment. Kroff has the expertise and experience to provide advanced boiler and cooling tower water treatment solutions tailored to your systems. Many boilers have a limiting factor of alkalinity caused by the amount of carbonate in the make-up water used by the boiler. This can be achieved using a commercial water softener and specialist chemical scale inhibitors. Chemicals are put into boiler water through the chemical feed tank to keep the water within chemical range. Ecospec's ULF treatment system effectively controls scaling and corrosion in the boiler without utilizing any chemicals. Industrial steam boilers and generating systems are an essential component in many commercial, industrial and process applications where their primary purpose is to transfer energy from one part of the system to another. We clean and maintain cooling towers, closed loops, process loops, air washers, scrubbers, and pretreatment systems to ensure their effectiveness. In addition to ensuring energy savings, this reduces costs and contributes to water savings by reducing the amount of water wasted during the boiler blowdown process. Wisconsin Mechanical Co can supply you with water treatment chemicals, pot feeders, complete test kits or reagents for test kits, laboratory analysis of your systems, metering pumps and electronic controls. This procedure is for cleaning carbonate based mineral scale from the waterside of steam boilers. As steam is generated in a boiler system water naturally evaporates and is lost to the atmosphere. For this reason dosing arrangements where the oxygen scavenger is dosed into the feed-line just before the boiler or directly into the boiler shell should be avoided. Initially this is beneficial since it allows the treatment chemicals to become more concentrated and offer better protection to the boiler but eventually, if unchecked, the water would become so concentrated that its surface tension increases and steam bubbles can no longer escape freely, resulting in foaming and carryover.

0 notes

Text

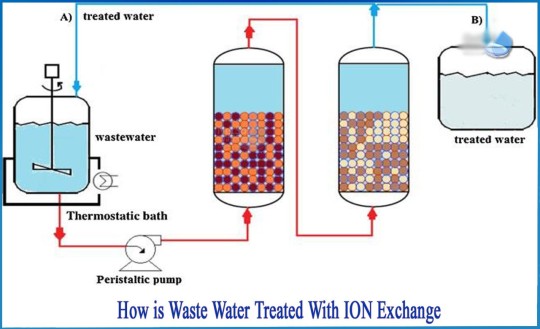

WHAT IS THE PH OF DEALKALIZER WATER?

Welcome to Larco India Pvt Ltd, Pune! We are a leading provider of comprehensive water treatment solutions, and we are excited to delve into the fascinating topics of dealkalization, the pH of dealkalizer water, and the alkalinity of RO water. Our aim is to provide you with detailed insights into these subjects, enabling you to make informed decisions for your specific water treatment needs. Let’s explore each topic in depth.

WHAT IS THE PURPOSE OF DEALKALIZATION?

The dealkalization unit, a crucial step in water treatment, concentrates on removing alkaline minerals. Calcium and magnesium carbonates are the main alkaline minerals. Reducing the alkalinity of water is de- alkalization’s main goal. Alkalinity, which will correspond to the presence of alkaline ions such as hydroxide, carbonate, and bicarbonate, can cause a number of issues in industrial and commercial applications.

Scale formation is a major issue brought on by high alkalinity. When heated, water with a high alkalinity level has the propensity to deposit scale on heat transfer surfaces. This scale of building decreases the effectiveness of heat transfer, increases energy use, and can cause equipment failure. Dealkalization helps in preventing the buildup of scale, extending the useful life, and enhancing the general effectiveness of heat exchange equipment, including boilers, cooling towers, and other systems that make use of heat transfer processes.

High alkalinity can also contribute to corrosion in equipment and pipelines made of metal. Dealkalization helps to decrease corrosion hazards by lowering alkalinity, thereby defending your infrastructure and saving money on maintenance. In order to ensure effective and efficient operation throughout your industrial or commercial site, the procedure is also essential for optimizing various water treatment processes.

What is the pH of dealkalizer water?

The pH is below 3.0 when hydrogen is present. Water with no carbonate or hydroxide alkalinity has a pH lower than 4.3.

The exact dealkalization procedure used and the properties of the influent water are two elements that have an impact on the pH of dealkalizer water. Strong base anion exchange resins or weak acid cation exchange resins are commonly used in dealkalization. These resins make it easier for alkaline ions to swap places with other ions in the resin, which lowers alkalinity.

Depending on the make-up of the influent water and the particulars of the deacidification system, the pH of the treated water can change. Dealkalizer water typically has a pH that is slightly acidic or close to neutral.

It is crucial to remember that the pH level may change depending on the design and modifications made to best suit your particular water quality requirements during the dealkalization process.

We at Larco India Pvt Ltd are aware of the importance of preserving the proper pH range for your particular application. To build and execute a dealkalization system that assures ideal pH levels and thereby maximizes the effectiveness and longevity of your equipment, our qualified staff will work directly with you.

Is RO water high in alkalinity?

Reverse osmosis (RO) is a very efficient method of water filtration that eliminates dissolved salts and minerals as well as other contaminants. Although RO is effective at lowering total dissolved solids, it is not intended to precisely address alkalinity. The amount of alkalinity in the source water that enters the RO system has a significant impact on the alkalinity of the RO water.

Lower amounts of alkalinity will be present in the RO water if the source water has high alkalinity because the RO system will also remove a considerable amount of the alkalinity. However, the RO process may not have a substantial impact on the alkalinity levels in the treated water if the source water contains low alkalinity.

RO plant

It is important to keep in mind that additional elements, such as the RO system’s design, the characteristics of the membrane, and any later changes or treatments given to the water after the RO process, may affect the pH and alkalinity of the finished RO water.

If your intended usage has specific alkalinity requirements, it will urge you to measure and monitor the levels frequently in order to accurately analyze the alkalinity of RO water. To make sure that your RO water system complies with the required quality standards, Larco India Pvt Ltd Pune offers cutting-edge water testing and monitoring systems.

Conclusion

Larco India Pvt Ltd, based in Pune, takes great satisfaction in providing complete water treatment solutions that meet your unique requirements. Dealkalization is an essential procedure that efficiently lowers alkalinity, avoiding the development of the scale, corrosion, and other related problems in industrial and commercial applications. While the alkalinity of RO water depends on the levels of alkalinity present in the source water, dealkalizer water normally has a pH that is somewhere between neutral and slightly acidic.

Modern technologies and customized dealkalization solutions are what our team of professionals will dedicate themselves to offering you. Explore our selection of water treatment services today, and get in touch with us to find out how Larco India Pvt Ltd can help you get the best performance, effectiveness, and lifespan out of your water systems.

#ro plant#water treatment#wastewatertreatment#dealkalization#wastewatertreatmentplant#watertreatmentsolutions

0 notes

Text

DM Plants And Softeners

Memtec Engineering product range include all types of ion exchange systems such as Demineralization Plants, Softeners, De Alkalizers and Split Stream Dealkalizers using reputed ion exchange resins of Indion, Tusion, Rohm and Hass (DOW) and Purolite.

0 notes

Text

Lengthen Reverse Osmosis Technique Lifespans: Silica & Calcium Phosphate Scale Manage

Lengthen Reverse Osmosis Technique Lifespans: Silica & Calcium Phosphate Scale Manage

Posted January 12, 2018by AXEON Water Systems

A big use of reverse osmosis methods is to management h2o hardness by lessening the concentration of magnesium and calcium compounds, as well as other minerals that contribute to hardness, this sort of as silicon dioxide or silica. Regrettably, processing hard h2o on a day-to-day foundation contributes to scaling, or mineral deposits that in the end cause problems to the procedure and have to have additional intensive maintenance and repairs. Technique operators can optimize their RO system’s lifespan by performing scale management maintenance on a common foundation.

Some alternatives for scale management consist of:

Acids for Scale Manage

When carbonates are exposed to acids, the resulting reaction triggers their kind to develop into unstable. In its place of accumulating and sticking to the insides of pipes and membranes, they continue to be in a dissolved point out, and clean away easily with the use of a cleanse-in-position cycle. Acids are an effective approach of scale management for carbonate scaling only.

The appropriate sort of acid to use for scale management relies upon on availability and chemical properties. Sulfuric acid is the least difficult to get and the the very least pricey in numerous areas, but with the use of sulfuric acid will come the addition of sulfates to the feed h2o, which is undesirable and demands subsequent treatment method. Hydrochloric acid is a desired different, though food grade acid need to be made use of.

Scale Inhibitors

Scale inhibitors are a broader alternative than acids, properly managing scaling from carbonate, sulfate, and calcium fluoride resources. The 3 big types of scale inhibitors consist of sodium hexametaphosphate (SHMP), organophosphonates, and polyacrylates.

SHMP is low-cost and broadly offered, and when made use of in modest amounts, it inhibits crystal progress of carbonate, sulfate, and fluoride salts. When made use of in excess of extensive intervals of time, SHMP can cause calcium phosphate scaling to accumulate, so it need to be made use of minimally.

Organophosphonates are an effective choice that cuts down scaling and simultaneously acts as an antifoulant for insoluble iron and aluminum. Finally, polyacrylates are a remarkably precise scale inhibitor that is effective specially for silica scaling.

Softening Resins

A powerful acid cation trade resin cuts down h2o hardness by taking away carbonate ions, barium ions, and strontium ions, and replacing them with sodium ions that can be cleanly taken off in the future steps of the RO procedure. Some ion trade resins operate with an efficacy of up to 99.5 %, which can do away with the hazard of scale buildup when made use of as portion of the common maintenance procedure.

Dealkalizing Resins

Weak acid cation trade resins are made use of for partial h2o softening when planning to procedure batches of brackish feed h2o. These resins focus on bicarbonate alkalinity ions that lead to non permanent spikes in h2o hardness. This procedure is remarkably effective with the right feed h2o resource, but it qualified prospects to carbon dioxide as a byproduct in the permeate, and demands degassing just after processing. It also stops doing work when the pH drops outside of 4.2, so it is most useful in h2o that starts at a pH of 5 or better.

Lime Softening

For h2o that’s only impacted by carbonate hardness, lime softening is an low-cost different. Hydrated lime additional to the feed h2o resource targets carbonate ions, and sodium carbonate can be additional to focus on silica scaling, as well. Lime softening also cuts down the existence of barium, strontium, and natural and organic substances.

For the finest constant procedure, common preventative cleansing need to be carried out in addition to getting steps to lessen silica and calcium scaling. A periodic ahead flush at small stress is effective well at limited intervals, e.g. 30 seconds of cleansing per 30 minutes of procedure. With the right tactic and care, hard feed h2o does not have to be a resource of problems to your RO procedure.

Concerns about h2o softening alternatives for reverse osmosis methods? AXEON Water Systems is in this article to help.

Rationalization of the internet site: Filtration-Products and solutions.com internet site discloses the most recent tales, summaries and filter products from the filtrations arena. Filtration-Products and solutions keeps you up on separation and all the principal professional products such as string wound filter cartridges, pleated filters, meltblown depth aspects, bag filters, reverse osmosis filters, from makes this sort of as Pall made for h2o recylcling, and just about anything else the filter company has to advise.

The post Lengthen Reverse Osmosis Technique Lifespans: Silica & Calcium Phosphate Scale Manage appeared first on Filtration Products.

from Filtration Products http://ift.tt/2mwOMoQ

0 notes

Photo

PK Water Technologies is a Pakistan based manufacturer of advanced, innovative and sustainable treatment solutions for applications in process water, drinking water, water reuse and waste water. Our company is focused on providing solutions to the following sectors: Energy (Oil/Gas, Mining, Petrochemical, Power Generation) Food/Beverage (Agriculture, Aquaculture, Food/Beverage Processing) Industrial (Pharmaceutical, Textile, Pulp & Paper) Municipal Infrastructure (Drinking Water, Desalination, Waste Water, Humanitarian) Buildings & Hotels (Drinking Water, Grey Water Reuse, Domestic Waste Water) Services Include: Portable Deionized Water Services Reverse Osmosis Maintenance Membrane Cleaning Preventive Maintenance, Break/Fix and Troubleshooting Media and Resin Rebed Services System Equipment Design and Build Capabilities Include: Softeners Reverse Osmosis Filters Dealkalizers Condensate Polishers Ion Exchange Systems Replacement Parts and Media for Most Water Treatment Equipment PK Water Technologies is dedicated to providing superior customer service, high quality solutions and system consumables to our valued clients and collaboration partners across the world. (at Pk Water Technologies)

0 notes

Link

Backed by our team of dexterous professionals, we have emerged as a successful Manufacturer, Supplier and Exporter of Ion Exchange plant. Our range is inclusive of Water Softener Plant, Demineralization Plants, Dealkalizer Plant and many more. The plants are available in different specifications in order to meet the diverse requirements of the buyers.

0 notes

Text

WHAT IS THE DIFFERENCE BETWEEN A DEALKALIZER AND A SOFTENER?

There are many techniques for treating water that will raise its quality and convert it for use in a variety of applications. Dealkalization and softening are two frequently employed strategies. Both approaches attempt to improve water quality, but they work in different ways and with different goals. This essay will examine the difference between a dealkalizer and a softener. illuminating their functions and uses.

Understanding Dealkalization of Water :

Reduced alkalinity in water is the goal of the procedure known as the dealkalization of water. Alkalinity is the water’s ability to neutralize acids, which is mainly because bicarbonates, carbonates, and hydroxides are present. High amounts of alkalinity can cause problems like scale, corrosion, and decreased productivity in industrial processes.

To remove alkaline substances from water, a dealkalizer system will use ion exchange technology. It typically consists of a bed of strong base anion resin, which converts carbonate and bicarbonate ions into chloride ions by exchanging their negative charges. The water that results has less alkalinity and is better suited for some uses.

Unveiling Water Softening:

The main goal of water softening is the elimination of calcium and magnesium ions, also known as “hardness” minerals. High concentrations of hardness minerals in water can result in the creation of soap scum, scale accumulation in pipes and appliances, and reduced efficacy of soaps and detergents.

Ion exchange is a method that softeners employ to get rid of hardness minerals. The system includes a bed of cation exchange resin, which draws calcium and magnesium ions and swaps them out for sodium ions. By removing these hard minerals, the water will turn “soft,” which has several advantages for cleanliness, less maintenance, and higher productivity.

Key Differences:

difference between a dealkalizer and a softener utilize ion exchange technology and contributes to overall water quality, their distinctions lie in the specific ions they target and their intended outcomes. Here are some key differentiating factors:

Ions Targeted:

Dealkalizer: Mainly focused on eliminating carbonate and bicarbonate ions to reduce alkalinity.

Softener: It mainly targets calcium and magnesium ions, which are hardness minerals.

Purpose:

Dealkalizer: Designed to handle alkalinity-related severe problems such as scaling, corrosion, and decreased productivity in industrial processes.

Softener: The main purpose of a softener is to reduce the negative impacts of hard minerals, such as scale buildup, soap inefficiency, and appliance maintenance.

Water Quality:

Dealkalizer: Decreases water’s alkalinity, making it suitable for applications requiring lower alkaline levels.

Softener: Reduces water hardness, which improves lathering, soap performance, and scale buildup.

Applications:

Dealkalizers and softeners are used in a wide variety of companies and residences. Here are a few examples of how they are typically used:

Applications of Dealkalizer:

The company will use dealkalizer in industrial processes that involve boilers and cooling towers.

The manufacturing of beverages

Food and pharmaceutical product manufacturing

Applications of Softener:

Providing water to households

Providing laundry services

Facilities and offerings

Car washing

Watering procedures

Conclusion:

In conclusion, the difference between a dealkalizer and a softener are separate water treatment processes with different goals. Dealkalizers address problems associated with high-alkalinity water by concentrating on lowering alkalinity levels in the water. Softeners, on the other hand, primarily target hardness minerals, enhancing water quality and avoiding scale formation. It is crucial to comprehend how these two approaches differ to select the best option for a given set of water quality standards. You can guarantee optimum performance, efficiency, and longevity for varied applications by choosing the appropriate treatment solution. Remember, whether you’re seeking a dealkalizer or a softener, consulting with water treatment professionals can provide valuable insights tailored to your specific needs. Make informed decisions to enjoy the benefits of high-quality water in your daily life or industrial operations. Larco India Pvt Ltd offers dependable and efficient water treatment solutions.

#water filter#water treatment#wastewatertreatment#water softener#dealkalization#water purification#water treatment plant#watertreatmentsolutions

0 notes

Text

What is the difference between a dealkalizer and a softener?

There are many techniques for treating water that will raise its quality and convert it for use in a variety of applications. Dealkalization and softening are two frequently employed strategies. Both approaches attempt to improve water quality, but they work in different ways and with different goals. This essay will examine the difference between a dealkalizer and a softener. illuminating their functions and uses.

Understanding Dealkalization of Water :

Reduced alkalinity in water is the goal of the procedure known as the dealkalization of water. Alkalinity is the water's ability to neutralize acids, which is mainly because bicarbonates, carbonates, and hydroxides are present. High amounts of alkalinity can cause problems like scale, corrosion, and decreased productivity in industrial processes.

To remove alkaline substances from water, a dealkalizer system will use ion exchange technology. It typically consists of a bed of strong base anion resin, which converts carbonate and bicarbonate ions into chloride ions by exchanging their negative charges. The water that results has less alkalinity and is better suited for some uses.

Unveiling Water Softening:

The main goal of water softening is the elimination of calcium and magnesium ions, also known as "hardness" minerals. High concentrations of hardness minerals in water can result in the creation of soap scum, scale accumulation in pipes and appliances, and reduced efficacy of soaps and detergents.

Ion exchange is a method that softeners employ to get rid of hardness minerals. The system includes a bed of cation exchange resin, which draws calcium and magnesium ions and swaps them out for sodium ions. By removing these hard minerals, the water will turn "soft," which has several advantages for cleanliness, less maintenance, and higher productivity.

Key Differences:

difference between a dealkalizer and a softener utilize ion exchange technology and contributes to overall water quality, their distinctions lie in the specific ions they target and their intended outcomes. Here are some key differentiating factors:

Ions Targeted:

Dealkalizer: Mainly focused on eliminating carbonate and bicarbonate ions to reduce alkalinity.

Softener: It mainly targets calcium and magnesium ions, which are hardness minerals.

Purpose:

Dealkalizer: Designed to handle alkalinity-related severe problems such as scaling, corrosion, and decreased productivity in industrial processes.

Softener: The main purpose of a softener is to reduce the negative impacts of hard minerals, such as scale buildup, soap inefficiency, and appliance maintenance.

Water Quality:

Dealkalizer: Decreases water's alkalinity, making it suitable for applications requiring lower alkaline levels.

Softener: Reduces water hardness, which improves lathering, soap performance, and scale buildup.

Applications:

Dealkalizers and softeners are used in a wide variety of companies and residences. Here are a few examples of how they are typically used:

Applications of Dealkalizer:

The company will use dealkalizer in industrial processes that involve boilers and cooling towers.

the manufacturing of beverages

Food and pharmaceutical product manufacturing

Applications of Softener:

providing water to households

providing laundry services

Facilities and offerings

car washing

Watering procedures

Conclusion:

In conclusion, the difference between a dealkalizer and a softener are separate water treatment processes with different goals. Dealkalizers address problems associated with high-alkalinity water by concentrating on lowering alkalinity levels in the water. Softeners, on the other hand, primarily target hardness minerals, enhancing water quality and avoiding scale formation. It is crucial to comprehend how these two approaches differ to select the best option for a given set of water quality standards. You can guarantee optimum performance, efficiency, and longevity for varied applications by choosing the appropriate treatment solution. Remember, whether you're seeking a dealkalizer or a softener, consulting with water treatment professionals can provide valuable insights tailored to your specific needs. Make informed decisions to enjoy the benefits of high-quality water in your daily life or industrial operations. Larco India Pvt Ltd offers dependable and efficient water treatment solutions.

#water filter#water softener#dealkalization#water treatment plant#RO system#RO plant#ETP#STP#sewage treatment system

0 notes

Photo

The Best Natural Deodorant Ever: Consonant Skincare Dealkalizing Deodorant… http://bit.ly/2DttvVB

0 notes