#cyanamid

Explore tagged Tumblr posts

Text

So I am considering making calcium cyanamide at some point in the future. An important ingredient is urea. Urea is available readily at hardware stores for like $2 a pound. I could also make it from my own piss, but this is really inefficient, and possibly more expensive depending on how I go about it

27 notes

·

View notes

Text

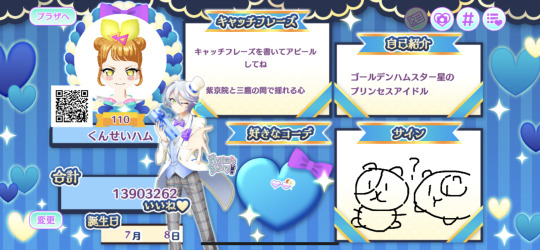

Hi! I'm adpara player from Japan🗾 I'm sorry for my broken English📛

I may not be great at English, but I've decided to give it a shot here because there seem to be a lot of English speakers around hehe

I'm writing this, but I'm not an OC – her name is Kunsei-ham🐹 She can't use a computer, so she tells me to make collages & input text usually...

Even though I'm a beginner at Tumblr, I'm enjoying it! Ham is having fun with it too🐹

~~~~~~~~🧡~~~~~~~~

Hiya pals!ヾ(´Y`)ノ” I'm Kunsei-ham, the super cool hamster plushie idol from Planet Golden Hamster!🐹💨 I love to enjoy 'promise', mix coord, and sing song on stage with friends♫

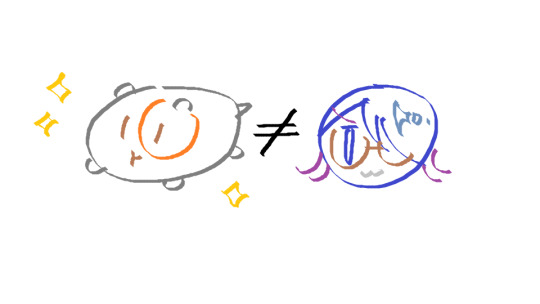

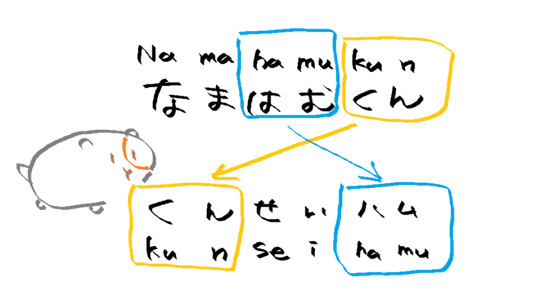

In English, my name 'Kunsei ham' means smoked ham🍖😋 I'm not really smoked ham; 'Kunsei ham' is more like a stage name, I made up that sounds like my real name but with a silly twist💫

My favorite outfit is the Golden Military ensemble – it's just so fabulous💛✨ Wearing it makes me feel like a 'Brilliant Prince' because it's super cool!!!ヾ(*´Y`*)ノ” What are some of your favorite?🌟✨

My theme colors are white, yellow, orange, and gold, because I'm a golden hamster🐹🤍💛🧡👑 Pretty sure these suit me, don't you think?

I've got many items in Pretty series... I wish I could wear that to adpara~ Ugh, My heart yearns for things I can never have( í Y ì )💘

⇧I would like to see 'My☆Dress design' implemented in adpara💭 ⇩If possible, I'd also like to create 'My☆CR' *1

This feature can allow players to create their own custom outfits by selecting from a variety of design elements...! I really enjoyed it!!!😭

I think it would be a great addition to game...🥺 I want to play as long as possible

\ Let's enjoy together🐹😉 /

Temporary addition : pls translation as necessary⇩🙏

【2024年5月6日追記】 暫定的な英語の自己紹介でした。もうちょい推敲させたいけど、人間の腕も英語力も限界だって( í Y ì ) でもせっかく書かせたし、いっそ放流することに(´Y`).oO(少しでもぼくのことが伝わると嬉しいな~)

マイキャラをOC(Original Character?)と呼んだり、アドパラをadparaと書くのは他ユーザーの投稿で知った! 「他の言語で書かれた投稿はとても興味深いです、勝手に感謝してます!」って、人間が……

絵文字ってなんと��く世界共通の用途かな~って思うけど、聞いたと��ろによると 🙏ハイタッチ/手を合わせて謝る 📛燃やされる豆腐(!?)/幼稚園児の名札バッヂ とか、ぜんぜん違う意味で受け取られちゃうらしいね( í Y ì ) でも日本のノリ(英語ができない幼稚園児とか)も織り交ぜたいような気も…… ちなみに(´Y`)は普段のぼく、( í Y ì )は泣いてるぼくを表した顔文字(さすがに伝わるか……?)

自然な英訳がわからなくてとりあえず音の響きをそのまま書かせたところもあるよ。 日本語って意味より雰囲気重視で雑にカタカナを使ったり略したりするのでよく混乱させられる…… Engrishなんかはきっと有名な話。

たぶんいろいろ変なところはあるだろうけど許してやってね🐹💨 あるいは指摘してくれたら勉強になって嬉しいってさ🐹💨

人間がもうちょっとマシな英語ができるようになって腕も治ったら改めて自己紹介させたいよ~(´Y`) ではまた!

*1 【2024年10月30日追記】

"glowing coord" とか "LED coord" とか色々考えたけど、検索したところ普通にCRで通用しているっぽいので変更しました。 正しい綴りは "cyalume" 。同じカタカナ表記「サイリウム」になる "psyllium" では、増粘剤やお通じ改善に使われがちな植物になってしまうとか。わー!🤤日本の「オオバコ」とは別の品種らしい。

「サイリューム」はケミカルライトの商標名。開発社サイアナミッド (Cyanamid) とルミネッセンス (luminescence : 発光) の合成語だそうな。商標権に一応は引っかからない「サイリウム」が広まった結果が今。

この時はわからない言葉は日本語でググっていたので、そこから来た勘違いだと思う。 「なんでサイリウムコーデの植物が由来なんだ?」という引っかかりはあったけど、 「このCRという書き方、実は日本人のよくやる変な英語シリーズなのか?」から先に行けなくて、とりあえずそう書いた覚えがある。変な英語を書いたのは私だった😂 多分こういう���違いは気づいていないだけでいっぱいあると思う、面白いよね。

19 notes

·

View notes

Note

Can you explain your blog title? Is it a reference to something?

oh man I love talking about this

short version: Trichloroethylene is a carcinogenic industrial pollutant that happened to be one of the primary water pollutants at a Superfund site near where I grew up.

long version: I have a long-running fascination with New Jersey's Superfund sites. Despite not being a very large state, NJ has more EPA designated toxic waste sites than any other US state. (Not per-person or per-area: just the most in general). Probably just due to being a densely populated industrial area back when environmental regulations were often even worse than they are today.

the topic features a lot in my short stories (Groundwater Classification Exception, Cyanamid)

also heres me wearing the shirt i designed with all of new jersey's superfund sites on the back :)

but why trichloroethylene specifically? why "knight in trichloroethylene armor"?

well. it is clear and colorless with a cyanide-like sweet smell. it has a history of being used as an anaesthetic, up until the 1960s. so, it feels fitting to use as a cultural signifier: the grease of our postindustrial sins, the cost of progress. (certainly I am not against progress in any sense of the word. i am probably more for the nebulous idea of "progress" than I should be.)

the history of large-scale industrial pollution haunts the Rust Belt. over decades, billions of dollars have been spent on remediation, but we're still not "done": like Lady Macbeth washing the blood off her hands, we never really will be.

because the symptoms of relatively low-level, long term exposure to many of these pollutants is hard to clearly identify, it can be hard to determine what was truly "caused" by the exposure. (don't get me wrong-- there have definitely been lawsuits won over the high cancer rates caused by these pollutants, including trichloroethylene specifically. but in many cases it's impossible to separate a specific person's cancer, autoimmune condition, Parkinson's disease, or other harms from the background noise.)

that's why. trichloroethylene queen... maybe as some sort of weird coping mechanism for my sometimes very difficult to cope with chronic GI pain, I blame things that I am 99% certain are unrelated, but at least give me something to point the finger at other than random chance.

If nothing else, there are certainly many other people who are more clearly affected by the health affects of exposure to certain industrial chemicals. including arguably my own family members.

(not trichloroethylene in particular in that case, but who could blame me for choosing the one with the catchy six-syllable name?)

16 notes

·

View notes

Text

https://github.com/anushka224473/Market-insight-group/blob/main/North America Calcium Cyanamide (CAS 156-62-7) Market Drivers And Trends.md

0 notes

Text

What Is Melamine Particle Board? Comparison with Plywood and MDF

How Are Melamine Particle Board Manufactured?

Melamine particle board are crafted through a process involving melamine resin, initially an organic compound that undergoes polymerization to become a robust and durable plastic material. Essentially, melamine is a chemical compound derived from an organic base and acts as a trimer of cyanamide.

Melamine Laminate is typically resistant to stain, heat, and fire. It’s moisture and scratch-resistant and can be found in many colors, patterns, sizes, and thicknesses making it ideal for particleboard, plywood, or MDF applications. Melamine is more like small pieces of wood (particleboard) glued and pressed together and covered with a plasticized coating.

Uses of Melamine

The term "melamine" finds extensive application not only in cabinet construction but also in various other industrial sectors unrelated to construction.

For instance, melamine laminate serves as a key material not only in crafting woodworks such as shelves and cabinets but also in the resin utilized for Formica and other laminated countertops commonly found in kitchens.

Moreover, melamine is widely employed in the manufacture of floor tiles. Melamine tile floors offer enhanced glossiness, scratch resistance, reduced susceptibility to staining, and easier maintenance compared to porcelain or stone alternatives. Importantly, they also tend to be more cost-effective.

Given the glossy finish of melamine-coated boards and their ability to resist surface scratches, melamine proves to be an excellent material for the production of whiteboards.

Advantages of Melamine Wood

Melamine engineered products are often more budget-friendly while maintaining reliability.

Melamine boards boast a consistent surface that is highly durable and resistant to scratches, stains, heat, and fire.

The waterproof nature of typical melamine surfaces allows for easy cleaning with soap and water.

Many prefer the absence of wood grain in melamine boards, especially those seeking solid-colored cabinets, as melamine is readily available pre-finished in various colors.

It offers a smooth finish, ready for use with minimal construction waste.

Cutting melamine is relatively straightforward with the right equipment, such as a saw with a scoring unit or CNC routers, which help prevent chipping. Proper material support during cutting reduces the risk of breakage.

Disadvantages of Melamine Board

Melamine boards are prone to bending and warping under heavier loads.

Due to its composite composition, melamine material tends to be heavy.

Melamine boards are manufactured using glues that can emit Volatile Organic Compounds (VOCs), which, according to the United States Environmental Protection Agency, may have adverse health effects in both the short and long term.

Comparing Melamine with Plywood

Melamine board offers distinct advantages when compared to plywood. While plywood board is known for its strength and natural wood grain appearance, melamine board provides a cost-effective alternative with increased durability and moisture resistance. It offers a wide range of attractive finishes, allowing for diverse design options.

Moreover, melamine board demands minimal upkeep and exhibits lower susceptibility to warping or delamination when contrasted with plywood. These attributes have propelled melamine board to become a preferred option in furniture production, especially when factors like durability, cost-effectiveness, and aesthetic appeal are pivotal. Although plywood possesses its own strengths, the benefits of melamine board render it an enticing choice for furniture designers and manufacturers aiming for a versatile and pragmatic material.

Comparing Melamine with MDF

Fiberboards, particularly MDF board (Medium Density Fiberboard), offer a cost-effective option for those looking to outfit modern kitchens, bathrooms, and interior furniture.

This material is composed of numerous wood fibers mixed with wax and resin under high pressure and temperature conditions.

Fiberboards available in the market are classified based on their densities, which are determined by the levels of temperature and pressure during manufacturing. Consequently, HDF (High Density Fiberboard) requires higher levels of pressure and temperature compared to MDF.

In summary, MDF falls in between HDF and particleboard in terms of density, with particleboard having the lowest density and exhibiting larger wood grains.

Comparing Melamine with solid wood, plywood, or fiberboards is a complex task.

Melamine is a popular plastic material widely used by modern cabinet builders. It can be applied as a laminate onto substrates such as plywood or particleboard, or it can be incorporated into the construction of kitchen cabinets, particularly when combined with MDF or particleboard. These substrates, made from wood chips, are used to form High Pressure Laminate (HPL) or Thermally Fused Laminate (TFL). Consequently, direct comparisons between melamine and MDF or particleboard can be challenging.

One of the key advantages of melamine is its durability and high resistance to scratches, along with its extensive range of colors and patterns. This versatility makes melamine fused with plywood arguably one of the most sustainable options for cabinetry.

Previous:The Benefits and Safety of LVL Scaffold Planks in Construction

Next:LVL vs. Solid Wood Window Frames: Choosing the Right

0 notes

Text

Calcium Carbide Prices Trend | Pricing | News | Database | Chart

Calcium Carbide a crucial chemical compound, plays a significant role in numerous industrial applications, including the production of acetylene gas, calcium cyanamide, and as a desulfurization agent in steel manufacturing. The price of calcium carbide is influenced by a combination of factors, including raw material costs, production capacity, regulatory frameworks, energy prices, and market demand across various sectors. In recent years, the global calcium carbide market has experienced fluctuations in pricing due to shifts in these driving elements, reflecting broader economic and industrial trends.

The raw materials for calcium carbide production, primarily limestone and coke, are key contributors to its pricing structure. Variations in the availability and cost of these resources have a direct impact on the overall market price. For example, disruptions in the mining sector or changes in the cost of coal can lead to an increase in production costs, subsequently raising market prices. Furthermore, energy costs significantly influence the pricing of calcium carbide. As the production process requires high energy inputs, fluctuations in electricity prices or fuel availability can contribute to cost volatility. Energy-intensive processes in calcium carbide manufacturing mean that producers in regions with abundant and cost-effective energy sources often maintain a competitive edge.

Get Real time Prices for Calcium Carbide: https://www.chemanalyst.com/Pricing-data/calcium-carbide-1145

The demand for calcium carbide is closely tied to its end-use industries, including construction, agriculture, and chemicals. The acetylene gas market, a major application area for calcium carbide, significantly drives demand. Acetylene is widely used in metal cutting and welding, which sees robust demand during periods of industrial growth or large-scale infrastructure projects. The agriculture sector also contributes to the demand, particularly through the use of calcium cyanamide as a fertilizer. Market dynamics, such as the pace of urbanization and industrialization in emerging economies, further amplify these trends, as developing countries increasingly rely on calcium carbide-based products to support growth initiatives.

Regional dynamics also play a pivotal role in shaping calcium carbide prices. Countries such as China and India are dominant producers and consumers of calcium carbide, driven by their expansive industrial bases and significant investments in infrastructure. China, in particular, is a major global player, with a well-established production capacity and government policies that influence market trends. However, stringent environmental regulations in China aimed at reducing emissions have sometimes led to temporary shutdowns of production facilities, thereby constraining supply and pushing up prices. Similarly, India's reliance on domestic production and occasional import needs creates a dynamic pricing environment influenced by both local and global factors.

Trade policies and international market dynamics further influence calcium carbide prices. Tariffs, import-export regulations, and geopolitical developments can create additional price fluctuations. For instance, disruptions in global trade routes or heightened tensions between major trading partners may lead to supply chain bottlenecks, impacting the availability and cost of calcium carbide. Additionally, exchange rate fluctuations can affect import costs for countries that rely on external suppliers, introducing another layer of complexity to pricing.

Technological advancements and production efficiencies have also started to shape the market for calcium carbide. Companies investing in modern technologies to optimize production processes can potentially reduce costs and enhance competitiveness. However, the adoption of advanced technology often requires significant capital investment, which can initially increase production costs before long-term benefits are realized. Moreover, advancements in alternative methods of acetylene production, such as natural gas-based technologies, have created competitive pressures, influencing the demand and pricing of calcium carbide.

Environmental concerns and sustainability trends are increasingly influencing the calcium carbide market. As governments and industries worldwide place greater emphasis on reducing carbon footprints and adopting environmentally friendly practices, producers are under pressure to comply with stringent regulations. This has led to additional costs associated with upgrading facilities and implementing greener production methods. While these measures aim to create a more sustainable industry, they can also contribute to short-term price increases.

Looking ahead, the calcium carbide market is expected to remain influenced by global economic conditions, technological innovations, and regulatory developments. The growing emphasis on renewable energy and sustainability may lead to shifts in production practices and demand patterns. Additionally, the expansion of emerging economies and increased investment in infrastructure projects are likely to sustain demand for calcium carbide in the foreseeable future. However, producers will need to navigate challenges such as energy cost volatility, raw material availability, and environmental compliance to maintain competitiveness.

In conclusion, the calcium carbide market presents a dynamic landscape shaped by a multitude of factors, including raw material costs, energy prices, industrial demand, and regulatory pressures. While short-term fluctuations in pricing are expected due to supply chain dynamics and geopolitical influences, long-term trends suggest steady demand driven by industrial growth and infrastructure development. As the market evolves, stakeholders across the supply chain will need to adapt to emerging trends and challenges to ensure sustainable growth and profitability in the years to come.

Get Real time Prices for Calcium Carbide: https://www.chemanalyst.com/Pricing-data/calcium-carbide-1145

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Calcium Carbide#Calcium Carbide Price#Calcium Carbide Prices#Calcium Carbide Pricing#Calcium Carbide News#Calcium Carbide Price Monitor

0 notes

Text

Aging October 27, 2024

Songs about aging and the aged like Aunt Lotte here! (image from Stranger Than Paradise)

listen to the show

The Undertones - When Saturday Comes Unit 4 - Growing Up

DJ speaks over Shelly Manne - Past My Prime

Come On - Old People David Bowie - Where Have All the Good Times Gone Collate - Adults

The Weavers - Get Up and Go John Cale - Please Cyanamid - Older People Neighbourhood Watch - Vicious Circle Inu - おっさんとおばはん Abyecta - Nacer, Crecer, Morir Blutsturz - Vom Erwachsenwerden

The Byrds - My Back Pages Pookie and the Poodlez - Young Adult The Tammys - Part of Growing Up Grit - Nineteen The Red Crayola With Art And Language - An Old Man's Dream

The Jam - Burning Sky Rudimentary Peni - Defined by Age Catalogue - Ageing (As time goes by) Poison Girls - Old Tart's Song Benjamin Carry Ltd - Old Man Game Theory - 24 Bärchen und die Milchbubis - Ich will nicht älter warden

Los Violadores - Viejos Pateticos Los Crudos - Viejos Patéticos The Magnetic Fields - When You're Old and Lonely The Joyce McKinney Experience - Older The Bureaucrats - Grown Up Age Deseos Primitivos - Crecer Billy Bragg - Brickbat

X-Ray Spex - Age The Clean - Getting Older The Assassinators - Nar Voksne Leger Total Fury - You're Too Old

Oi Polloi - Skinheads of Tomorrow

#radio#community radio#punk#music#playlist#post punk#wprb#new wave#hardcore punk#garage rock#aging#older people#anarcho punk#growing up#mod punk

1 note

·

View note

Text

0 notes

Text

Working principle of Fertilizer Granules Compaction Machine:

Fertilizer Granules Compaction Machine is the use of pressure to directly squeeze the material into the finished product granulation process, especially suitable for the granulation of thermal sensitive materials. There are usually two types of extrusion machinery: one is the push type granulator; The other is Fertilizer Granules Compaction Machine. The two types have various forms due to their different structures. The water content of the feed of the push and press type extrusion granulator is usually 5% ~ 8%, and the cylindrical product is obtained after extrusion, and the compound fertilizer product with water content less than 5% is obtained by cooling. The water content of the feed of the pelleting Fertilizer Granules Compaction Machine can be lower, foreign reports can be between 0.5% and 1.5%, the belt material obtained by extrusion is broken by the Chain Crusher, and the double screen is screened to get the bulk or compound fertilizer products with edges and angles. The fine powder after crushing is returned to the extrusion machine for pelleting. Coarse blocks are then returned to the Chain Crusher for crushing. Because the product contains low moisture, it does not need to be dried. The granulation rate is usually about 85%.

The extrusion granulation process of compound Fertilizer with an annual output of 10,000 to 20,000 tons is shown in the figure below (NPK Fertilizer Production Line) :

Due to the precipitation of water during the reaction process, the material becomes thin, wet and sticky. At the same time, the decomposition rate of urea increases, making granulation impossible. Therefore, in the formulation must be equipped with human calcium magnesium phosphate fertilizer or other fertilizers, such as potassium sulfate and potassium chloride.

In the extrusion granulation process, two basic fertilizers, calcium superphosphate and urea, cannot be used alone for production, because calcium superphosphate contains free acid, which chemically reacts with urea during extrusion as follows: H3PO4+CO (NH2) 2→CO (NH2) 2·H3PO4

Process analysis of Fertilizer Granules Compaction Machine production line

Selection of appropriate raw materials and preparation of mixtures are important factors in the production of qualified extruded fertilizers. Some raw materials can be mixed and extruded according to their respective characteristics. Such as potassium chloride, ammonium sulfate and urea are raw materials with good extrusion properties. Super phosphate, lime nitrogen [calcium cyanamide (CaCN2)], hard boron calcium stone and phosphate rock can be extruded, but they do not have as good extruding performance as the above raw materials. However, some fertilizers, such as super phosphate, can be pre-dried or extended its ripening period to improve its extruding performance. In terms of raw materials, other factors that affect the extrusion performance of products include: particle size distribution, moisture content, temperature, plasticity and hardness. Extrusion operation conditions include pressure, roller diameter and speed, roller surface and spacing between two rollers, etc. The PRACTICE SHOWS THAT USING ammonium sulfate, diam monium phosphate, super PHOSPHATE, potassium CHLORIDE and UREA (MOISTURE ≤1.5%) as raw materials, THE PRODUCTION of 13-13-21 and 15-15-15 compound fertilizers has obtained satisfactory results.

The materials that have been used for extrusion granulation are as follows:

Ammonium chloride urea monoammonium phosphate ammonium sulfate + dicyandiamide (cyanoguanidine)

Ammonium sulfate urinary aldehyde diammonium sulfate lime nitrogen [cyanamide calcium (CaCN2)]

Calcium sulfate phosphate ore vanadium sulfate gypsum (CaSO4·2H2O) peat mixture

Limestone heavy ore potassium chloride potassium chloride + trace element fertilizer

Organic fertilizer potassium sulfate NPK magnesium mixed fertilizer

Slow-acting fertilizer Port Gate phosphate fertilizer (acid slag)

Fertilizer Granules Compaction Machine has a wide range of applications and can graninate a variety of raw materials. So it is also known as ammonium sulfate compound fertilizer dry extrusion granulator, Fertilizer Granules Compaction Machine, potassium magnesium fertilizer Fertilizer Granules Compaction Machine, calcium chloride Fertilizer Granules Compaction Machine, dry ammonium sulfate roller granulator, compound fertilizer roller granulator, ammonium sulfate granulator, compound fertilizer extrusion granulator.

0 notes

Text

Artificial Cornea and Corneal Implant Market: Dissecting the Factors Steering Growth and Potential Risks

Artificial Cornea and Corneal Implant Market provides in-depth analysis of the market state of Artificial Cornea and Corneal Implant manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Artificial Cornea and Corneal Implant in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Artificial Cornea and Corneal Implant Market Report:

The report offers a comprehensive and broad perspective on the global Artificial Cornea and Corneal Implant Market.

The market statistics represented in different Artificial Cornea and Corneal Implant segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Artificial Cornea and Corneal Implant are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Artificial Cornea and Corneal Implant.

Major stakeholders, key companies Artificial Cornea and Corneal Implant, investment feasibility and new market entrants study is offered.

Development scope of Artificial Cornea and Corneal Implant in each market segment is covered in this report. The macro and micro-economic factors affecting the Artificial Cornea and Corneal Implant Market

Advancement is elaborated in this report. The upstream and downstream components of Artificial Cornea and Corneal Implant and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/artificial-cornea-and-corneal-implant-market-100558

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Global Dehumidifier MarketMarket Size

Tumbler MarketMarket Growth

Composite Decking & Railing MarketMarket Analysis

Vinyl Acetate-Ethylene Emulsions (VAE Emulsion) MarketMarket Size

Global In-Memory Computing MarketMarket Share

Global Selective Laser Sintering MarketMarket Growth

Depaneling Machine MarketMarket

Fleece Knitting Yarn MarketMarket Share

Construction Software MarketMarket Growth Rate

Wellness Tourism MarketMarket Forecast

Global Sickle Cell Anemia Therapeutics MarketMarket Size

Video On Demand MarketMarket Growth

Cloth Diapers MarketMarket Analysis

Nano Positioning Systems MarketMarket Size

Global Software Asset Management MarketMarket Share

Global Safety Motion Control MarketMarket Growth

Silica Analyzer MarketMarket

Carbon Accounting Software MarketMarket Share

Spectrometer MarketMarket Growth Rate

Healthcare AI MarketMarket Forecast

Global Blockchain Technology in Healthcare MarketMarket Size

Urokinase MarketMarket Growth

Fixed-Route Autonomous Vehicle MarketMarket Analysis

Contract Management Solutions MarketMarket Size

Global Solar Modules MarketMarket Share

Global Slurry Separator MarketMarket Growth

Zinc Aluminum Magnesium Coated Steel MarketMarket

Artificial Intelligence in Manufacturing and Supply Chain MarketMarket Share

1,3-butylene Glycol (CAS 107-88-0) MarketMarket Growth Rate

Calcium Cyanamide MarketMarket Forecast

Global Seismic Isolation Systems MarketMarket Size

Container Screening MarketMarket Growth

Accounts Payable Software MarketMarket Analysis

Butterfly Valves MarketMarket Size

Global Helicopter Tail Boom MarketMarket Share

Global Bezel-less Screen MarketMarket Growth

Frequency Conversion Heat Pump Drye MarketMarket

Nano Indentation Tester MarketMarket Share

Mutton MarketMarket Growth Rate

0 notes

Link

0 notes

Text

Analyzing the Calcium Carbide Price Trend

Calcium carbide, a chemical compound primarily used in the production of acetylene gas and various chemical reactions, serves as a vital raw material in industries such as metallurgy, chemical synthesis, and agriculture. Understanding the price trend of calcium carbide is crucial for manufacturers, suppliers, and stakeholders to make informed decisions regarding procurement, production, and pricing strategies. In this analysis, we delve into the historical Price Trends of Calcium Carbide, factors influencing its fluctuations, and future projections for the calcium carbide market.

Historical Price Trends

Past Performance

Historically, the price of calcium carbide has exhibited moderate to high volatility, influenced by factors such as raw material costs, energy prices, production capacity, market demand, and regulatory changes. Over the past decade, fluctuations in calcium carbide prices have been notable, with periods of stability interspersed with significant increases or decreases. These fluctuations are attributed to changes in the prices of raw materials, shifts in demand from end-user industries, and global economic conditions.

Recent Trends

In recent years, calcium carbide prices have shown resilience amidst changing market conditions. Despite occasional volatility, the overall trend has been moderate to high price stability. The increasing demand for acetylene gas, calcium cyanamide, and other downstream products has driven demand for calcium carbide, leading to steady growth in prices. Additionally, advancements in calcium carbide production technologies and quality control measures have contributed to price stability and market growth.

Enquire For Regular Prices: https://www.procurementresource.com/resource-center/calcium-carbide-price-trends/pricerequest

Factors Influencing Price Fluctuations

Raw Material Costs

The price of calcium carbide is closely linked to the costs of its primary raw materials, namely coke and limestone. Fluctuations in the prices of these raw materials, influenced by factors such as energy prices, supply-demand dynamics, and environmental regulations, impact the overall cost structure of calcium carbide production. Changes in raw material availability, geopolitical events, and trade policies also influence raw material costs and, consequently, calcium carbide prices.

Energy Prices

Energy prices, particularly electricity and coal prices, significantly affect the production costs of calcium carbide, as the electric arc furnace process used for calcium carbide production is energy-intensive. Fluctuations in energy prices, driven by factors such as fuel costs, government policies, and renewable energy investments, directly impact the operating expenses of calcium carbide manufacturers. Changes in energy prices influence production costs and, consequently, calcium carbide prices.

Market Demand

Market demand for calcium carbide is driven by factors such as growth in industrial sectors, infrastructure development, and agricultural activities. Increasing demand for acetylene gas in welding, cutting, and metal fabrication industries, as well as the use of calcium cyanamide in fertilizer production, stimulates the demand for calcium carbide. Additionally, calcium carbide finds applications in chemical synthesis, steelmaking, and environmental remediation, contributing to market demand and pricing trends.

Future Outlook

Technological Innovations

Technological advancements in calcium carbide production processes, such as improved furnace designs, energy efficiency measures, and process optimization techniques, are expected to drive cost reductions and sustainability improvements in the future. Research efforts towards alternative feedstocks, carbon capture technologies, and waste heat recovery systems offer potential solutions to enhance resource efficiency and reduce environmental impacts in calcium carbide production.

Technological innovations refer to the development and implementation of new or improved technologies aimed at solving existing problems, improving efficiency, and driving progress across various industries. These innovations encompass a wide range of advancements, including new materials, processes, systems, and tools, as well as advancements in digital technologies, artificial intelligence, and automation. Technological innovations play a crucial role in driving economic growth, enhancing productivity, and fostering competitiveness in the global marketplace. They enable businesses to streamline operations, create new products and services, and adapt to changing market demands. Additionally, technological innovations contribute to addressing societal challenges, promoting sustainability, and improving quality of life. Embracing technological innovations empowers organizations to stay ahead of the curve, seize new opportunities, and drive positive change in the world.

Market Expansion

The future outlook for calcium carbide is characterized by market expansion opportunities in various industries, including metal fabrication, chemical manufacturing, and agriculture. Increasing infrastructure investments, urbanization trends, and industrialization in emerging economies drive demand for acetylene gas and calcium carbide-based products. Moreover, advancements in environmental regulations, safety standards, and product innovations present new opportunities for market growth and diversification.

Market expansion refers to the process of increasing the presence and penetration of a product or service in existing or new markets. It involves identifying and capitalizing on growth opportunities to reach a wider audience, generate more sales, and enhance profitability. Market expansion strategies can vary depending on factors such as industry dynamics, consumer preferences, competitive landscape, and regulatory environment. Common approaches to market expansion include geographical expansion, product diversification, strategic partnerships, and innovation. By expanding into new markets or segments, businesses can tap into unmet needs, gain market share, and sustain long-term growth.

Conclusion

In conclusion, the price trend of calcium carbide is influenced by various factors, including raw material costs, energy prices, market demand, and technological innovations. While historical data provides insights into past performance and volatility, future trends will be shaped by evolving market dynamics, regulatory developments, and sustainability considerations. Proactive risk management, strategic investments, and collaboration across the value chain are essential for stakeholders to navigate price fluctuations and capitalize on emerging opportunities in the dynamic calcium carbide market.

Contact Us:

Company Name: Procurement Resource Contact Person: Leo Frank Email: [email protected] Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537 132103 | Asia-Pacific (APAC) - Phone no: +91 1203185500 Address: 30 North Gould Street, Sheridan, WY 82801, USA

0 notes

Text

Cyanamide-inducible expression of homing nuclease I-SceI for iterative genome engineering and parallel promoter characterisation in Saccharomyces cerevisiae

BioRxiv: http://dlvr.it/T4jzc4

0 notes

Text

0 notes

Text

Calcium Carbide Prices | Pricing | Trend | News | Database | Chart | Forecast

Calcium carbide is a chemical compound primarily used in the production of acetylene gas, which is crucial for various industrial applications. The demand for calcium carbide has steadily increased due to its significant role in the chemical industry, particularly in producing plastics, synthetic rubber, and various other organic chemicals. The prices of calcium carbide are influenced by several factors, including raw material costs, production capacity, and market demand fluctuations. As a result, understanding the dynamics of calcium carbide prices is essential for businesses that rely on this compound.

One of the primary factors affecting calcium carbide prices is the cost of its raw materials. Calcium carbide is produced by heating limestone and carbon in an electric arc furnace. The prices of limestone, petroleum coke, and other feedstocks can fluctuate based on market conditions, impacting the production costs of calcium carbide. Additionally, environmental regulations and energy prices play a critical role in determining overall production expenses. When energy costs rise, manufacturers may pass these expenses on to consumers, leading to increased calcium carbide prices. Therefore, businesses must keep a close watch on energy markets and raw material availability to understand potential price movements.

Get Real Time Prices for Calcium Carbide : https://www.chemanalyst.com/Pricing-data/calcium-carbide-1145

Market demand significantly influences calcium carbide prices, particularly in key industries like steel manufacturing, welding, and the production of chemicals. The growing demand for acetylene, derived from calcium carbide, has resulted from its widespread use in various applications such as welding and cutting. With the resurgence of construction and manufacturing activities globally, especially in emerging economies, the demand for calcium carbide is projected to rise. Consequently, when demand outpaces supply, it can lead to price increases, making it essential for industry stakeholders to forecast market trends effectively.

Additionally, the global calcium carbide market is impacted by trade policies and tariffs. Countries that are major producers and consumers of calcium carbide may impose tariffs that can significantly affect pricing. For instance, if a leading producer faces trade barriers in exporting calcium carbide, the resulting scarcity can lead to higher prices in the affected regions. Conversely, when trade barriers are lifted, and imports increase, prices may stabilize or decline, offering opportunities for buyers to acquire calcium carbide at more favorable rates. Thus, monitoring global trade developments is vital for understanding price dynamics.

Seasonal factors can also influence calcium carbide prices. For example, in regions where calcium carbide is used primarily for agricultural purposes, such as producing calcium cyanamide fertilizer, demand may spike during planting seasons. This seasonal variation can lead to temporary price increases, impacting overall market stability. Companies need to factor in these seasonal trends when planning their procurement strategies to ensure they can secure sufficient supplies at reasonable prices throughout the year.

Another critical aspect to consider is the competitive landscape of the calcium carbide market. The presence of numerous manufacturers contributes to price fluctuations. If new players enter the market or existing companies expand their production capacity, it may lead to an oversupply situation, causing prices to drop. Conversely, if major manufacturers consolidate or reduce output, prices could rise due to limited availability. Therefore, companies must analyze competitive dynamics and production capabilities to predict pricing trends effectively.

Technological advancements in production processes can also play a significant role in shaping calcium carbide prices. Innovations that increase production efficiency or reduce raw material consumption can lead to lower production costs, allowing manufacturers to offer more competitive pricing. As companies invest in advanced technologies, they may gain a market advantage, impacting overall pricing strategies within the industry. Keeping abreast of these technological developments can provide businesses with insights into potential price shifts and market opportunities.

In recent years, sustainability concerns have gained prominence, influencing not only production methods but also pricing strategies in the calcium carbide market. Manufacturers are increasingly pressured to adopt environmentally friendly practices, which may lead to higher production costs. As a result, businesses may need to consider these factors when assessing calcium carbide prices. Consumers are becoming more conscious of the environmental impact of their purchases, prompting manufacturers to balance profitability with sustainability. This shift may ultimately lead to higher prices for products that do not meet environmental standards, influencing overall market pricing.

The geopolitical landscape also plays a critical role in calcium carbide pricing. Political instability in key producing regions can disrupt supply chains, leading to shortages and price volatility. Companies must remain vigilant regarding geopolitical developments that may affect their supply sources and pricing structures. Establishing diversified sourcing strategies can mitigate the risks associated with geopolitical fluctuations, ensuring a stable supply of calcium carbide at competitive prices.

In conclusion, the pricing of calcium carbide is a complex interplay of various factors, including raw material costs, market demand, trade policies, seasonal variations, competitive dynamics, technological advancements, sustainability initiatives, and geopolitical influences. For businesses relying on calcium carbide, understanding these elements is crucial for effective procurement and cost management strategies. As the market evolves, stakeholders must stay informed about industry trends and developments to navigate the challenges and opportunities presented by calcium carbide prices effectively. By doing so, they can make informed decisions that align with their operational needs and market conditions, ensuring long-term success in this vital sector.

Get Real Time Prices for Calcium Carbide : https://www.chemanalyst.com/Pricing-data/calcium-carbide-1145

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Calcium Carbide#Calcium Carbide Price#Calcium Carbide Prices#Calcium Carbide Pricing#Calcium Carbide News

0 notes

Text

Contact Lens Market Overview 2023 with Stastical data and Forecast till 2031

[LATEST] Contact Lens Market Report 2023: (Report Pages: 114)

CAGR and Revenue: “Contact Lens market was estimated at USD 9160.65 million, and it’s anticipated to reach USD 13690.66 million in 2031, with a CAGR of 6.93% during the forecast years.”

Years considered for this report: -

Historical Years: 2018-2021

Base Year: 2022

Estimated Year: 2023

Forecast Period: 2023-2031

Contact Lens Market Report offers an Complete view about the cutthroat scene of the Contact Lens market and incorporates a profound picture of execution by a portion of the key global players finishing on the lookout. Besides, the report offers a full data about the position, extent of development, and possibilities of new members or players on the viewpoint.

Browse full Report: https://www.globalgrowthinsights.com/market-reports/contact-lens-market-100425

The Major Players in the Industrial Contact Lens Market include:

Incorporated; ZEISS International

Abbott Medical Optics, Inc.

STAAR Surgical Company

Bausch and Lomb

Contamac

Valeant Pharmaceutical International Inc.

Hoya Corporation

Alcon Laboratories, Inc.

Essilor International S.A.

Johnson & Johnson Services, Inc.

SynergEyes, Inc.

X-Cel Specialty Contacts

Medennium; Seed Co., Ltd.

Cooper Vision

Classification Based on Types and applications & Region:

By Product Types:

Silicone hydrogel Soft Contact Lens

Methacrylate hydrogel Soft Contact Lens

Gas-Permeable Contact Lens

Others

By Applications:

Corrective Lens

Cosmetic & Lifestyle oriented Lens

Others

By Region:

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

Browse full Report: https://www.globalgrowthinsights.com/market-reports/contact-lens-market-100425

For More Related Reports Click Here :

Frozen Food Industry Growth Report

Capillary Blood Collection Tubes Market Forecast

Prescription Pet Food Industry Forecast

RH (Wet Strength Resin) Polyaminoamide-epichlorohydrin (PAE) Industry Revenue

Medical Device Contract Manufacturing Market Size

Phonocardiography Instrument Market Size

Crude Tall Oil Market Size and Share Estimation

Sucrose Monolaurate (CAS 25339-99-5) Market Size

Blockchain Software Market

Intelligent Cash Counter Market Size and Share Estimation

Protein Characterization And Identification Market Trends

Smart Rice Cooker Market Trends

Digital Experience Platform (DXP) Market Statistics

Indocyanine Green Market Statistics

Commercial Heavy-Duty Laundry Machinery Market

Laser Treatment Devices of Varicose Veins Market Forecast

Tact Switch Market Size

Viscose Fiber Market Size

Methyl Tert-Butyl Ether(Mtbe) Industry Growth Report

Calcium Cyanamide Market Size and Share Estimation

0 notes