#copper flat bar suppliers

Explore tagged Tumblr posts

Text

Shaping Excellence: Exploring the World of Copper Flat Bar Suppliers

In the world of metal fabrication and construction, copper flat bars play a crucial role in various applications, from electrical wiring to architectural accents. As a versatile and highly conductive material, copper offers a multitude of benefits, making it a preferred choice for many industries. However, finding reliable copper flat bar suppliers can be a daunting task. In this blog post, we'll delve into the importance of copper flat bars, the qualities to look for in suppliers, and where to find reputable sources for your copper needs.

The Significance of Copper Flat Bars

Copper flat bars are essential components in a wide range of industries due to their unique properties and versatility. As one of the most conductive metals available, copper is widely used in electrical applications, including wiring, circuit boards, and electrical contacts. Additionally, copper flat bars are valued for their corrosion resistance, making them ideal for use in marine environments and outdoor structures. In architectural design, copper flat bars are prized for their aesthetic appeal, lending a timeless elegance to building facades, roofing, and decorative elements.

Qualities to Look for in Suppliers

When sourcing copper flat bars, it's essential to partner with reputable suppliers who can provide quality materials and reliable service. Here are some key qualities to consider when evaluating potential suppliers:

Quality Assurance: Look for suppliers who adhere to strict quality control standards and provide certifications to guarantee the purity and consistency of their copper products.

Variety of Sizes and Grades: Choose suppliers who offer a diverse range of copper flat bar sizes and grades to meet your specific project requirements.

Customization Options: Opt for suppliers who can accommodate custom orders and provide machining or fabrication services to tailor copper flat bars to your exact specifications.

Reliability and Timeliness: Select suppliers with a track record of timely deliveries and responsive customer service to ensure smooth transactions and project timelines.

Sustainability Practices: Consider suppliers who prioritize sustainable sourcing and manufacturing practices to minimize environmental impact and promote responsible stewardship of resources.

Where to Find Reliable Copper Flat Bar Suppliers

Finding reliable copper flat bar suppliers may require some research and due diligence, but there are several avenues to explore:

Online Marketplaces: Platforms like Alibaba, Thomasnet, and Global Sources offer a vast selection of copper flat bars from suppliers worldwide. Be sure to read reviews and verify credentials before making a purchase.

Industry Associations: Trade organizations such as the Copper Development Association (CDA) or the International Copper Association (ICA) can provide resources and recommendations for reputable copper suppliers.

Local Metal Suppliers: Many cities have local metal suppliers or distributors that carry copper flat bars in stock or can order them from trusted manufacturers.

Referrals and Recommendations: Reach out to colleagues, industry contacts, or fellow professionals for referrals to reputable copper flat bar suppliers they have worked with successfully.

Direct Contact with Manufacturers: Some copper producers and mills may sell directly to consumers or provide a list of authorized distributors where their products are available.

Conclusion

In conclusion, sourcing copper flat bars from reliable suppliers is essential for ensuring the success of your projects and the longevity of your installations. By prioritizing quality, reliability, and sustainability, you can find trusted suppliers who offer high-quality copper flat bars that meet your specific needs and specifications. Whether you're working on electrical systems, architectural designs, or industrial applications, partnering with reputable copper flat bar suppliers is the first step toward achieving excellence in your projects.

Contact Us More Information

Emai: [email protected] Contact number :(02) 9624 2355 Website : https://brassandcopper.com.au/

#copper flat bar#copper bar#copper flat bar suppliers#copper metal bar#copper flat bar brisbane#copper flat bar sydney

0 notes

Text

Copper Flat Bars are accessible in manufactured or hot/cool moved complete in various measurements. These precisions completed level bars are accessible on finch conditions, including hard, half-hard and delicate alternatives, in this way giving best end utilization to electrical purposes. We can likewise convey compound and mechanical attributes of copper bars as per European gauges.

#Copper Flat Bars Manufacturers in Mumbai#Copper Flat Bars Suppliers in Mumbai#Copper Flat Bars Exporters in Mumbai#Copper Flat Bars Importers in Mumbai#Copper Flat Bars Manufacturers in India#Copper Flat Bars Suppliers in India#Copper Flat Bars Exporters in India#Copper Flat Bars Importers in India

2 notes

·

View notes

Text

Copper Bar: The Secret Weapon in Smart Design!

In a world increasingly defined by sleek lines, sustainable practices, and innovative materials, one timeless element is making a quiet but powerful comeback — the Copper Bar. Known for its durability, beauty, and versatility, copper is becoming a preferred choice in modern architecture and design. Whether in kitchens, commercial interiors, or high-tech installations, copper is no longer a background player — it's becoming the main attraction.

Why Designers Are Turning to Copper

Copper has always had an aesthetic appeal. Its warm, earthy tone and ability to develop a unique patina over time make it a natural fit for both rustic and contemporary design. But the Copper Bar offers more than just good looks.

From a functional standpoint, copper’s antimicrobial properties, thermal conductivity, and recyclability tick the boxes for both health-conscious and environmentally-aware clients. In fact, hospitals and wellness-focused commercial spaces are increasingly specifying Copper Bars and copper-based finishes to reduce surface-borne pathogens.

“I never realized how much of a difference material choice could make until we incorporated copper into our restaurant’s bar design,” says Amelia L., a commercial interior designer in Austin, TX. “The clients were amazed — it brought the whole space to life while serving a practical purpose.”

The Versatility of Copper Bars

The real secret behind copper’s rising popularity is its versatility. A Copper Bar can be cut, bent, or welded into just about any shape, making it ideal for custom applications. Whether you're working with minimalist lines or industrial chic, copper fits in effortlessly.

Here are just a few places you’ll find copper bars showing up in today’s smart designs:

Kitchen countertops and islands: For a luxe, yet earthy finish.

Architectural detailing: Window frames, stair railings, and door inlays.

Electrical and HVAC systems: Thanks to copper’s excellent conductivity.

Custom lighting: Where form meets function.

Even in smart homes, where efficiency meets elegance, copper is a key player — often hidden behind walls but essential for seamless functionality.

Understanding the Copper Sheet Price Connection

As copper demand rises, especially in design and tech-forward construction, many are keeping a close eye on the copper sheet price. It’s a topic that’s become particularly relevant as global supply chains continue to fluctuate.

The copper sheet price can vary based on thickness, finish, and purity — all critical factors when selecting the right material for a project. While pricing can be a concern, professionals argue that the long-term value of copper often offsets the initial investment. Unlike materials that wear or date quickly, copper ages gracefully and can last for generations.

“We chose copper for our office’s feature wall — not just for the look, but because it’s a one-time investment that requires little maintenance,” notes Martin G., an architect based in New York City. “It’s one of the few materials that actually gets better over time.”

Copper in Sustainable Design

Smart design today isn’t just about aesthetics or innovation — it's also about sustainability. Copper, being 100% recyclable without loss of quality, aligns perfectly with green building principles. Many LEED-certified buildings now include copper in their material lists, reinforcing its status as a responsible choice.

And with the increasing focus on circular design, materials like copper — which can be reused again and again — are becoming not just practical, but essential.

How to Source Copper Responsibly

When sourcing Copper Bars or sheets, transparency is key. Look for suppliers that provide detailed material specifications, including origin, composition, and compliance with environmental standards. Knowing how to read a material data sheet can be just as important as checking the copper sheet price.

Professionals also recommend comparing local vs. international pricing. While international suppliers may offer lower prices, domestic sources often provide better quality control and faster delivery — especially important for tight deadlines in construction and design.

The Bottom Line: Form Meets Function

There’s a reason why copper has been used for thousands of years — and why it's now gaining fresh attention in the world of smart design. A Copper Bar doesn’t just fulfill its role structurally or decoratively — it elevates the entire experience of a space. From touchpoints to tech integration, copper proves that good design isn’t just seen — it’s felt.

Whether you’re renovating a space, designing from scratch, or simply exploring new materials, copper offers a compelling mix of tradition and innovation. And with the right planning, understanding the Copper Sheet Price and selecting the appropriate type can ensure you get both aesthetic value and long-term performance.

In a design era where material matters more than ever, copper may just be the smartest choice of all.

#copper flat bar#copper flat bar suppliers melbourne#tinned copper flat bar#copper bar#copper bar suppliers

0 notes

Text

#LEADING COPPER ROUND ROD C101 SUPPLIER IN INDIA#ASTM B133 COPPER ROUND RODS#WEIGHT OF C12200 FLAT BAR#UNS C10300 HEX BAR STOCKIST#COPPER THREADED ROD MANUFACTURER#COPPER WELDING ROD#C110 BAR SUPPLIER#C10100 COPPER ROUND BAR WEIGHT CHART#ASTM B187 UNS C11000 ROD SUPPLIER IN INDIA.

0 notes

Text

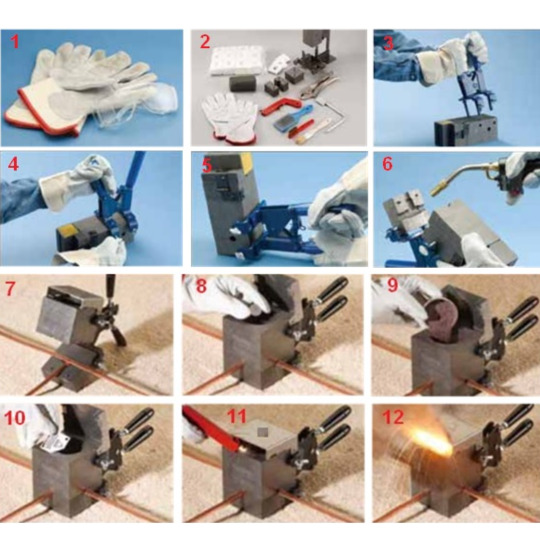

Exothermic Welding Mould: The Foundation of Reliable Grounding Joints

When it comes to permanent electrical connections in critical grounding systems, the role of the Exothermic Welding Mould cannot be overstated. It's the essential component that ensures precision, control, and safety during every weld.

At Amiable Impex, we specialize in high-quality Exothermic Welding Moulds that meet the highest industry standards. Whether you are working on electrical substations, solar plants, or railway grounding systems, using the right mould is key to successful exothermic bonding.

What is an Exothermic Welding Mould?

An Exothermic Welding Mould is typically made from high-grade graphite and designed to contain the exothermic reaction during a welding process. It holds the conductors (such as cable to cable, cable to rod, or cable to flat bar) in place and directs the molten metal precisely where it’s needed.

These moulds are reusable, durable, and manufactured in various shapes and sizes to suit different connection types. Every weld starts with a quality mould — and that’s why it’s such a crucial part of the process.

Why is the Mould So Important?

The mould is where the magic happens. It ensures:

Proper alignment of conductors

Controlled flow of molten metal

Consistent weld size and strength

Safety by containing the high-temperature reaction

With a poorly designed or low-quality mould, the risk of failed connections, leakage, or even fire hazards increases significantly. That’s why trusted suppliers like Amiable Impex provide precision-engineered Exothermic Welding Moulds to ensure flawless execution every time.

Applications of Exothermic Welding Mould

Exothermic Welding Moulds are used in a variety of industries where grounding and bonding are critical. These include:

Power generation and transmission

Oil & gas refineries

Petrochemical plants

Data centers

Telecom towers

Railway signaling systems

Lightning protection setups

Each application requires a different mould design, and Amiable Impex offers a full range of options to suit every configuration.

Why Choose Amiable Impex for Welding Moulds?

As a leader in the field, Amiable Impex provides:

High-quality graphite moulds with excellent heat resistance

Compatibility with a wide range of Exothermic Welding Powder

Long life span with up to 50–70 welds per mould

Custom moulds designed for specific project needs

Affordable Exothermic Welding Kit Price with complete accessories

We’re not just a Exothermic Welding Powder Manufacturer — we’re your one-stop solution for all things exothermic welding. Explore our products atexothermic-welding.com.

Types of Exothermic Welding Moulds

Here are some common types of Exothermic Welding Moulds offered by Amiable Impex:

Cable to cable (parallel or cross)

Cable to rod

Cable to ground rod

Cable to plate

Ground rod to structure

Each mould type is designed for a specific use case, ensuring optimal flow of molten copper and creating a strong, permanent bond.

Exothermic Welding Kit Price – What’s Included?

A typical Exothermic Welding Kit includes:

Exothermic Welding Mould

Exothermic Welding Powder

Cleaning brushes and tools

Ignition tools and flint igniter

Metal disks for reaction

The Exothermic Welding Kit Price varies depending on the number of connections and type of mould required. But when you choose Amiable Impex, you’re guaranteed value for money and the highest quality materials in the market.

What About Exothermic Welding Cost?

While the Exothermic Welding Cost may seem higher initially than mechanical connections, it's a one-time investment that brings lifelong value. No corrosion, no maintenance, and zero electrical resistance issues.

Think long-term — no recurring costs, no replacements, and no failures. That’s what makes exothermic welding a smart choice, especially for critical infrastructure.

Handling and Maintenance Tips

To extend the life of your Exothermic Welding Mould, follow these simple tips:

Clean thoroughly after every weld

Store in a dry place

Do not expose to moisture

Avoid rough handling to prevent surface cracks

Always use the correct amount of Exothermic Welding Powder

Taking good care of your mould not only ensures more welds but also guarantees better and safer performance.

FAQs

Q1. How many times can I reuse an Exothermic Welding Mould? A1. A well-maintained mould can last up to 50–70 welds, depending on the type and usage.

Q2. Can I use the same mould for different cable sizes? A2. No. Moulds are designed for specific conductor sizes and shapes. Always match the mould to your application.

Q3. What makes Amiable Impex a trusted supplier? A3. Our commitment to precision, quality materials, and full customer support has made us a preferred supplier across industries worldwide.

Conclusion

A high-quality Exothermic Welding Mould is the foundation of every successful weld. It ensures alignment, safety, and strength — three pillars of any reliable electrical connection. When paired with premium Exothermic Welding Powder and used properly, these moulds produce lifetime joints that can withstand even the harshest environments.

For all your exothermic welding needs — moulds, powders, kits, and accessories — trust Amiable Impex, your global partner in quality and performance.👉 Learn more atexothermic-welding.com and take the first step toward safer, stronger connections today.

0 notes

Text

Everything You Need to Know About Leading Copper Strip Manufacturers

Many industries put their trust in copper as a key material. The electrical and electronic industries heavily depend on copper which determines product effectiveness and casualty prevention. Industry professionals widely rely on copper strip for their applications. Despite its thinness it functions well as a material for power systems and motors as well as electrical transformer applications. All copper strip items do not share the same qualities. The quality difference comes from the selection of the producer. This content explains why top Copper Strip Manufacturers gain market trust across all industries in 2025.

Focus on High Purity Copper Material

Leading Copper Strip Manufacturers commence their production with superior copper as raw material. Copper purity determines how well copper conducts electricity as well as how flexible and resistant it remains. Top producers select copper bars that follow global standards and receive detailed chemical evaluation.The finished strip handles tough operating conditions effectively. Copper's performance improves no matter how you apply it either in electrical systems or special components. As top Copper Pipe and Copper Tube companies in India these suppliers recognize the fundamental role that base material plays in product performance.

Precision Manufacturing with Advanced Technology

The best copper strips come from rolled pieces of equal thickness and width. Mild thickness disparities between strips cause difficulties when installing or using them. Established producers rely on updated production machinery and exact measurements to manufacture their products. The machines produce accurate strip dimensions throughout production.These systems give products polished surfaces and flat ends. Using advanced equipment helps companies make more products and guarantees uniform product quality. These companies employ specialized equipment to produce perfect copper heat exchanger tubes and copper round bars as per customer requirements.

Custom Sizes and Fast Delivery

Each business sector demands unique product dimensions and forms. Leading Copper Strip Manufacturers offer custom solutions. Their service lets customers pick specific dimensions to match their specific application needs. The system saves both manufacturing sectors time and keeps unused resources from ending up as waste.Speedy shipment plays a major role in their services. Accredited suppliers maintain a ready supply of materials for quick shipment. As steel producers who have worked with busbars and fittings for many years they respect the need to deliver on schedule. Businesses from around the world trust them as their reliable supply partner.

Support for Various Industries and Applications

Power plants, switchgear, automobiles and renewable energy industries use copper strips. The leading producer knows all possible applications of copper strips. They supply valuable information and assist clients with selecting the ideal product grade and surface treatment.Some also deal in related materials like Copper Square Tube, Copper Capillary Tube, or even Brass Strip Manufacturers. When a manufacturer knows all product types it shows both their expertise and client reliability. Customers work with Copper Nickel Tubes Manufacturers but let the application choose which 90/10 Copper Nickel Tube they need.

Conclusion

In 2025, the top copper strip suppliers will lead due to their use of high-quality resources paired with state-of-the-art devices and dependable support. They offer unique product dimensions and quick shipping to several industries. Multimet Overseas delivers high-quality copper and brass products that exceed industry specifications. Our company delivers copper products with certainty alongside brass fitting support from Indian manufacturers. We will assist you in picking suitable materials for your upcoming project

0 notes

Text

How construction industry benefits from our Mild Steel Fittings

Mild steel is a ferrous metal made from iron and carbon. It is a low-priced material with properties that are suitable for most general engineering applications. Low carbon mild steel has good magnetic properties due to its high iron content, it is therefore defined as being ‘ferromagnetic’. MS plates are made from low-carbon steel, which offers excellent formability and weldability, making them suitable for numerous applications.

Mild Steel Fittings offer various benefits in construction, from its cost-effectiveness, tensile strength, versatility, and corrosion resistance to ease of installation. These advantages make mild steel pipes a perfect choice for contractors and builders looking for a reliable solution. Aesteiron Steel LLP is a top MS round, MS square, and MS pipe rectangular supplier in Maharashtra, India.

Steel quality inspections are an integral part of the quality control of steel. Its purpose is to check that the requirements of the specification are being complied with. Checking the processes, procedures and materials required for the manufacturing of steel structures is vital as durability can be significantly reduced if not fully complied with. A range of methods exists to test the strength and durability of steel.

Aesteiron Steel is an Indian based company active in the distribution and manufacturing of steel products worldwide. You can contact us for ready stock and sizes, for urgent deliveries please mail to [email protected]. We stock wide range of steel pipes, tubes, sheets, plates, round bars, billets, rods, flat products, pipe fittings -buttweld / forged, fasteners in all materials and shapes for industrial purpose. We supply all piping product globally along with mill and test certificates. We supply these piping material in stainless steel, carbon steel, alloy steel, aluminium, copper and copper nickel and special steel grades, visit our Alloys section for detailed information. We also deal in hard to find materials.

for more information about dimensions, weight chart, physical properties visit - Mild Steel Fittings

0 notes

Text

Flat Flange Mono, Blind Mono Flange, Butt Weld Adapter, Mumbai, India

Manufacturer and Supplier of Flat Flange Mono, Blind Mono Flange, Butt Weld Adapter, Integrated Threaded with O Ring, Mumbai, India.

Quick Release Coupling, Quick Release Couplings, Ball Valve, Ball Valves, Gemel Ball Valves, Industrial Ball Valves, Quick Coupling, Quick Couplings, Camlock Coupling, Camlock Couplings, Camlock Quick Coupling, Camlock Quick Couplings, Micro Hose, Micro Hose For High Pressure, Micro Hose For Pressure Fittings, Test Coupling, Test Couplings, Minipress Test Coupling, Minipress Test Couplings, Test Point Coupling, Test Point Couplings , Threaded Test Coupling, Threaded Test Couplings, Bulkhead Test Coupling, Bulkhead Test Couplings, Female Swivel Test Coupling, Female Swivel Test Couplings, Plug in Test Coupling, Plug in Test Couplings, Pressure Gauge Adaptors, Cartridge Valve, Cartridge Valves, Hydraulic Hoses, Hydraulics Hose, Hoses Crimped Hydraulic, Hydraulic Systems, Pneumatic Systems, Hydraulic Accessories, Hydraulic Couplings, Hydraulic Fitting, Hydraulic Fittings, SS304 Hydraulic Fittings, SS316 Hydraulic Fittings, CS Hydraulic Fittings, DIN 2353 Fittings, Pressure Gauge, Pressure Gauges, Industrial Valves, Coupling Valves, Hydraulic Components, Inline Valve, Inline Valves, Inline Flow Indicator, Inline Flow Indicators, Portable Hydraulic Crimping Machine, Portable Hydraulic Crimping Machines, Portable Hydraulic Instrument, Portable Hydraulic Instruments, Pressure Gauge Anti Shock Valve, Pressure Gauge Anti Shock Valves, Stainless Steel Hydraulic Components, High Pressure Check Valve, High Pressure Ball Valve, High Pressure Flow Control Valve, High Pressure Needle Valve, Non Return Valve, Gemels Italy Ball Valves, Holmbury Uk Couplings, Minipress Italy Couplings, Oleoweb Italy Valves, SS304 Csermeto Fittings, SS316 Csermeto Fittings, Flat Face Coupling, Quick Connect Disconnect Coupling, Screw Coupling 1000 Bar, Dust Cap, Test Point, Test Hose, Test Point Coupling, Test Point Hose, SAE Flange Ball Valve, Rotating Union, Hose Burst Check Valve, Compensated Load Control Valve, Compensated Flow Control Valve, Load Shuttle Ball Valve, End Stroke Valve, Single Acting Pilot Check Valve, Double Acting Pilot Check Valve, Double Cross Line Direct Acting Relief Valve, Single Cross Line Direct Acting Relief Valve, Sequence Valve, Single Counter Balance Valve, Dual Counter Balance Valve, Hand Pumps, Tube Clamp, Instrumentation Fittings, Lubrication Fittings, PP Pipe Clamp, Dowty Seal Copper Washer, Bonded Seal, Nut, Ferrule, asia, asian, india, indian, mumbai, maharashtra, industrial, industries, thane, navi mumbai, pune, nashik, aurangabad, ratnagiri, nagpur, ahmednagar, akola, amravati, chandrapur, dhule, jalgaon, raigad, sangli, satara, belgaum, kolhapur, belgaon

0 notes

Text

A Guide to Choosing the Right Aluminium Bronze Round Bar

Rajkrupa Metal Industries is one of the Superior Quality Aluminium Bronze Round Bar Manufacturer In India. We are now the industry leader in Aluminium Bronze Round Bar. Our exceptional corporate and technical people abilities have allowed us to consciously establish ourselves as a top-tier manufacturer and retailer in the global market for aluminum bronze round bars.

Aluminium Bronze Round Bar Manufacturer is a type of metal alloy that combines copper and aluminium. It is known for its excellent mechanical properties, high strength, and corrosion resistance. The main alloying elements in aluminium bronze are aluminium and copper, but small amounts of other elements like iron, nickel, manganese, and silicon might be present to enhance specific properties.

What is an Aluminium Bronze Round Bar?

An Aluminium Bronze Round Bar is a cylindrical metal bar made from aluminium, and it is often used in a variety of manufacturing processes. The round shape makes these bars perfect for machining, welding, and forming. Depending on the grade and alloy of aluminium used, these round bars can have different properties, making them suitable for different industrial applications. Aluminium Bronze Round Bars are a special type of round bar composed primarily of aluminium and copper, with added elements like iron, nickel, and manganese.

Types of Aluminium Round Bars

Aluminium Bronze CUAL10NI5FE4 Round Bar : Aluminium Bronze CUAL10NI5FE4 Round Bar market because of its substantial business and technical personnel experience. We provide areas with various kinds and sizes of Extruded Aluminium Bronze Round Bars in significant quantities.

Aluminium Bronze C63000 Round Bar: The Aluminium Bronze Round Bar comes with the promise of high quality and dimensional precision. Our manufactured Aluminium Bronze C63000 Centrifugal Casting Round Bar, Square Bar, Bush, Pipe, Flat Bar, Ring, and Circle are used worldwide.

Aluminium Bronze C63200 Round Bar : Aluminum Bronze C63200, also known as C632, is a specific grade of aluminium bronze alloy. When using Aluminum Bronze C63200 Round Bar or any other material, it's essential to consider the specific requirements of your application and consult with material experts or suppliers to ensure you choose the right alloy and form (like round bar) for your needs.

C90300 Tin Bronze Round Bar: Metal Industries has strategically positioned itself as a top manufacturer and supplier in the global C90300 Aluminium Bronze Round Bar market because of its substantial business and technical personnel experience. We provide areas with various kinds and sizes of Extruded Aluminium Bronze Round Bars in significant quantities.

Aluminium Bronze CA104 Round Bar: The Aluminium Bronze Forged Round Bar comes with the promise of high quality and dimensional precision. CA104 Aluminium Bronze Round Bar have made a name for themselves in a variety of industrial application fields, including offshore, marine, and aerospace, etc.

Advantages of Aluminium Bronze Round Bars

Strength and Durability

The strength of the aluminium round bar will depend on the alloy used. If your application requires high tensile strength, ensure you select an aluminium alloy with superior strength properties. Aluminium Round Bars Suppliers are known for their high strength and durability, especially in conditions that require resistance to wear and tear.

Corrosion Resistance

One of the key advantages of aluminium is its resistance to corrosion, but some alloys, like Aluminium Bronze Round Bars, offer even better corrosion resistance. This makes them ideal for applications exposed to harsh elements like seawater, chemicals, or extreme temperatures.

High Strength

This alloy has high tensile strength and toughness, making it ideal for applications that demand durability and resistance to wear. Aluminium Bronze Round Bars are commonly used in components like pumps, valves, and propellers, where strength is critical.

Wear Resistance

Aluminium bronze alloys are highly resistant to wear and tear, making them excellent for parts that experience heavy friction and mechanical stress. This makes them suitable for high-performance machinery parts.

Marine and Shipbuilding

Aluminium bronze is widely used in the marine industry for components like propellers, pumps, and valves. Its resistance to corrosion in seawater and ability to withstand mechanical stress make it the material of choice for these applications.

Industrial Applications

These round bars are also used in the manufacturing of industrial machinery parts, such as gears, shafts, and valve seats, where strength and wear resistance are important.

Conclusion

Choosing the right Aluminium Bronze Round Bar depends on your specific needs, including material strength, corrosion resistance, and machinability. Aluminium Bronze Round Bars offer outstanding properties for marine, aerospace, automotive, and industrial applications, ensuring superior performance in challenging environments. By understanding the properties and advantages of different alloys, you can select the perfect round bar for your project. Partnering with a reputable Aluminium Bronze Round Bar Manufacturer in India will ensure you receive high-quality products tailored to your exact requirements.

To Know more on details visit our website: rajkrupametal.com

Product Source: Aluminium Bronze Round Bar Suppliers in India

#Aluminium Bronze Round Bar Manufacturer In India#Aluminium Bronze Round Bar Manufacturer#Aluminium Bronze Round Bar#Aluminium Round Bars Suppliers#Aluminium Bronze Round Bar Suppliers in India#Aluminium Bronze CUAL10NI5FE4 Round Bar#Aluminium Bronze C63200 Round Bar#C90300 Tin Bronze Round Bar#CA104 Aluminium Bronze Round Bar

0 notes

Text

ASTM B221 Round Bars

The aluminum alloy used to make aluminum 6061 T6 Round Bar is well-known for its high heat capabilities and resistance to oxidation. One of the top producers and suppliers of aluminum 6061 T6 round bars, among other kinds, is Siddhgiri Tubes. Aluminum, chromium, titanium, magnesium, manganese, zinc, copper, iron, and silicon make up the substance. There are other trace elements.

Siddhgiri Tubes is a well-established supplier and exporter of Aluminium Alloy 6061T6 round bars in India. Renowned for offering top-quality products, they are a trusted name in the metal industry, catering to diverse sectors such as aerospace, automotive, and manufacturing with exceptional precision and reliability.

Product Overview:

Aluminium Alloy 6061T6 round bars are made from a heat-treated and artificially aged alloy, offering a combination of strength, light weight, and resistance to corrosion. These bars are used in a variety of applications, including structural and architectural components, marine equipment, and high-stress parts in machinery. Available in multiple sizes and grades, 6061T6 round bars are widely sought after for their versatility.

Specification Chart of Aluminium Alloy 6061 T6 Round Bars

Dimensions :- ASTM, ASME, AMS

Specifications:- ASTM B211, AMS 4115, 4116, 4117, 4128, AMS-QQ-A-225/8 & ASTM B221, AMS4150, 4160, 4161, AMS-QQ-A-200/8

Alloy:- 6061 – T6

Size:- 1/4” Dia – 16” Dia

Form:- Square , Round , Hex , Flat, Wire In Black & Bright Finish

Length:- Random, Fix & Cut Length

Finish:- Bright, Polish & Black

Advantages:

High Strength-to-Weight Ratio: Lightweight but with excellent strength, ideal for structural applications.

Corrosion Resistance: Resistant to oxidation, ideal for use in marine and industrial environments.

Machinability: Easily machined and formed to meet specific engineering requirements.

Versatility: Suitable for a wide range of applications due to its balanced properties.

Conclusion:

Siddhgiri Tubes stands out as a reliable exporter of Aluminium Alloy 6061T6 round bars, offering products that meet the highest standards of quality and performance. With exceptional durability, flexibility, and corrosion resistance, these bars are a top choice for industries needing robust, long-lasting solutions.

0 notes

Text

Supplier of Stainless Steel Pipe and Tubes in Andhra Pradesh

Arisa Impex is a leading Supplier of Stainless Steel Pipe and Tubes in Andhra Pradesh. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Arisa Impex is a Manufacturer, Exporter and Supplier of stainless steel products, including stainless steel round bars, wires, rods, sheets, coils, pipes, flat bars, square bars, hexagonal bars, angles, flanges, and alloy steel. We offer a diverse range of stainless steel (SS) pipes and tubes available in various forms, material grades, wall thicknesses, types, dimensions, and specifications. All of our pipes and seamless tubes are crafted in accordance with Indian and international standards, including ASME, ASTM, ANSI, and AISI. Stainless steel is one of the most widely used metal alloys across various industries. It primarily consists of nickel and chromium, with additional elements such as copper, carbon, molybdenum, titanium, and nitrogen. Features of SS Pipe and Tubes: High Strength: Stainless steel offers excellent tensile strength, making it suitable for high-pressure applications. Temperature Resistance: Stainless steel pipes and tubes withstand extreme temperatures, making them suitable for both high-heat and low-temperature environments. Versatile Finishes: Available in various finishes, including polished, matte, and brushed, enhancing their aesthetic appeal and suitability for different applications. Lightweight: Compared to other materials like carbon steel, stainless steel is lighter, making it easier to handle and install. Hygienic Properties: Non-porous and easy to clean, stainless steel is ideal for sanitary applications in food and pharmaceutical industries. Application: Construction Food and Beverage Industry Pharmaceutical Industry Oil and Gas Automotive Marine Applications Chemical Processing Arisa Impex is a Supplier of Stainless Steel Pipe and Tubes in Andhra Pradesh including locations like Visakhapatnam, Vijayawada, Guntur, Nellore, Kurnool, Rajahmundry, Tirupati, Kadapa, Kakinada, Anantapur, Vizianagaram, Eluru, Ongole, Nandyal, Machilipatnam, Adoni, Tenali, Proddatur, Chittoor, Hindupur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

Buy Brass Bar – Upgrade Your Metalworking with the Best!

Brass has long been a favorite among metalworkers, engineers, and DIY enthusiasts for its durability, versatility, and aesthetic appeal. Whether you're crafting intricate architectural designs, engineering components, or decorative fixtures, brass metal bars offer the perfect balance of strength and workability.

If you're looking to Buy Brass Bar for your next project, understanding its benefits, types, and best sourcing options is essential. Let’s explore why brass is the material of choice and where to find brass flat bars in Sydney and Brisbane.

Why Choose Brass Metal Bars for Your Project?

Brass, an alloy of copper and zinc, is renowned for its corrosion resistance, machinability, and conductivity. Its unique properties make it suitable for various industries, from construction to musical instruments.

1. Strength and Durability

A brass metal bar is highly resistant to wear and tear, making it ideal for applications that require a robust yet flexible material. It is commonly used in marine environments, plumbing, and industrial machinery, where exposure to moisture and chemicals is a concern.

“We switched to brass components for our industrial equipment, and the difference in longevity is remarkable. No rust, no degradation—just reliable performance.” – James L., Engineering Firm, Sydney

2. Easy to Work With

Brass is one of the most machinable metals, allowing for precise cutting, bending, and forming. Whether you're using a brass flat bar for structural or decorative applications, it can be drilled, soldered, or welded with ease.

3. Aesthetic Appeal

Brass is prized for its golden hue, which adds a sophisticated touch to any architectural or artistic project. Over time, it develops a rich patina, enhancing its vintage charm without compromising strength.

"We use brass flat bars in our interior designs, and clients love the elegant, timeless finish. It’s the perfect alternative to gold.” – Emily R., Interior Designer, Brisbane

Types of Brass Bars Available

Choosing the right brass metal bar depends on the intended application. Here are some common types:

1. Brass Round Bars

Ideal for machined components, plumbing fittings, and decorative elements, round brass bars are often used in manufacturing and engineering industries.

2. Brass Square & Rectangular Bars

Perfect for structural frameworks, railings, and furniture, these bars offer a sturdy foundation with a polished finish.

3. Brass Flat Bars

A popular choice for fabrication, construction, and decorative applications, brass flat bars provide a smooth, uniform surface that is easy to cut and shape.

If you’re in Sydney, finding a brass flat bar in Sydney is essential for local sourcing and fast delivery.

Similarly, businesses in Brisbane looking for brass flat bars should seek suppliers offering custom-cut sizes and quality finishes.

Where to Buy Brass Bars in Sydney & Brisbane?

With the rising demand for brass in industrial and creative sectors, it’s crucial to choose a supplier that offers high-quality, precision-cut bars.

1. Look for Certified Brass Suppliers

Not all brass bars are created equal. Ensure you buy brass bars from a supplier that provides certified, high-grade materials with clear specifications on alloy composition.

2. Choose Local for Faster Delivery

If you're in Sydney or Brisbane, sourcing brass flat bars locally ensures faster lead times and cost-effective shipping. Local suppliers often provide custom cutting services, saving time and reducing waste.

3. Compare Prices & Availability

Before purchasing, compare brass flat bar prices from different vendors to get the best deal without compromising quality. Some suppliers offer bulk discounts or customized solutions tailored to your needs.

"We always buy brass bars from local Sydney suppliers. The material quality is outstanding, and we never face delays.” – Alex T., Fabrication Specialist

Final Thoughts

If you’re planning a metalworking, construction, or decorative project, investing in high-quality brass metal bars is a smart choice. Their strength, flexibility, and corrosion resistance make them a superior alternative to other metals, ensuring your designs stand the test of time.

For those looking to buy brass bars, finding trusted suppliers in Sydney and Brisbane will guarantee high-quality materials, competitive pricing, and reliable service. Whether you need a brass flat bar in Sydney or Brisbane, choosing the right supplier will make all the difference in your project's success.

Have you worked with Brass Metal Bar before? Share your experience in the comments!

#brass flat bar suppliers#buy brass bar#brass metal bar#brass flat bar sydney#brass flat bar brisbane

0 notes

Text

Copper Hex Bars Suppliers in India

Copper Hex Bars highlight predominant constitution, including the nearness of 99.99% of copper substance that makes these hex bars ideal for use in an extensive variety of electrical applications. We are Manufacturers, Exporters & Stockist of Copper Hex Bars in India. Further, our skill additionally enables us to convey these according to International Standards including DIN, ASTM, JIS, BS, EN, and IS as requested by the clients. We additionally offer these with electroplated tin plating wrap up.

We are the pioneer fabricator, stockist, and distributor of unendingly copper alloy hex bars in and around world. It has great assurance from marine water disintegrating and is great for an application that needs certification from wet use. It has higher security from stress disintegrating and breaking and has impact strength. Acidic attacks and impingement separation are not issues for this copper alloy. The copper grade has a higher level of physical and mechanical strength when exposed to high temperatures.

It has extraordinary oxidation catch in different circumstances, especially in seawater applications. Molybdenum is one of the conflicting parts, and it ordinarily avoids what many would consider a conceivable precipitation zone. These capacities are extraordinarily important in conditions where splitting and pitting crumbling are an issue. Compound adjustment, vehicle applications, building applications, and other organizing locales are noticeable purposes for Copper Alloy Hex Bars. These hex bars have splendid processability and fabricability, allowing them to be obligingly shaped into various standards, tasks, requirements, and complex plans at particularly low costs. The width of these hex bars goes from 4 mm to 75 mm, with lengths up to 6 m. Copper hex bars are very simple to process, drill, and saw. They're also used in things like base plates, keepsakes, furtGeneral Properties:

Size - 3/16" up to 3 5/16

Thickness - 4 mm to 75mm

Weight - Weight per feet in kg

Standard & Material -BS, IS, AMS, DIN & All International Standards her making work, and kitchenware.

#copper flat bars suppliers in mumbai#copper round bars suppliers in india#copper round bars exporters in india

0 notes

Text

Tinned Copper Flat Bar – Protect Your Connections with High-Quality Metal!

In industries where electrical conductivity, corrosion resistance, and durability are non-negotiable, using the right materials is crucial. One such essential component is the Tinned Copper Flat Bar, a reliable solution for electrical grounding, power distribution, and various industrial applications.

But what makes this metal stand out? And why is it preferred over standard copper? Let’s explore the benefits, applications, and reasons why industries trust tinned copper for their critical connections.

Why Choose Tinned Copper Flat Bar?

Copper is already an excellent conductor, so why add a layer of tin? The answer lies in enhanced protection and longevity. Tinning copper helps combat oxidation, making it more resistant to corrosion, especially in high-moisture or high-temperature environments.

1. Superior Corrosion Resistance

Copper, while highly conductive, is susceptible to oxidation over time. This is particularly a concern in marine environments, power plants, and industrial settings. The tin coating acts as a protective barrier, ensuring long-term performance without degradation.

“We replaced our old copper busbars with tinned copper flat bars, and the difference in longevity is incredible. No more rapid oxidation or performance issues.” – Mark L., Electrical Engineer

2. Excellent Conductivity & Performance

Tinning does not reduce copper’s electrical conductivity—it enhances it by preventing surface oxidation. This ensures a stable, high-quality connection over time, making tinned copper flat bar ideal for switchboards, transformers, and grounding systems.

3. Easy Soldering & Low Maintenance

Tin-coated copper offers better solderability compared to bare copper. The smooth, non-reactive surface simplifies the soldering process, reducing labor costs and ensuring a secure electrical connection.

Key Applications of Tinned Copper Flat Bar

From electrical grids to renewable energy installations, tinned copper flat bars are used in diverse settings. Here’s where you’ll commonly find them:

1. Power Distribution & Electrical Grounding

Industries rely on copper grounding systems to maintain safe electrical connections. The tin-coated surface prevents corrosion, ensuring long-term reliability in grounding applications.

2. Marine & Outdoor Installations

Saltwater is highly corrosive to metals, making standard copper less ideal for marine applications. With its corrosion-resistant properties, tinned copper flat bar is widely used in shipbuilding, docks, and offshore electrical systems.

3. Renewable Energy & Solar Power Systems

Solar and wind energy systems require high-efficiency electrical components that can withstand environmental challenges. Tinned copper ensures efficient energy transfer and prevents oxidation-related failures in solar inverters and power storage units.

“Switching to tinned copper bars for our solar installation improved efficiency and reduced maintenance costs significantly.” – Emily J., Renewable Energy Technician

4. Busbars & Switchgear Manufacturing

Power control systems, industrial switchboards, and high-voltage panels use tinned copper for busbar connections, ensuring consistent power distribution without performance loss.

The Role of Copper Coils in Electrical Applications

In addition to tinned copper flat bars, copper coils play a crucial role in various industries, from power transmission to electromagnetism.

Why Are Copper Coils Important?

High Conductivity – Ensures efficient power transfer in electrical transformers and motors.

Flexibility & Durability – Ideal for wiring applications, electromagnetic coils, and induction heating systems.

Corrosion Resistance – Often used alongside tinned copper bars in high-exposure environments.

By combining tinned copper flat bar with copper coils, industries achieve superior electrical performance and system longevity.

Choosing the Right Tinned Copper Flat Bar for Your Needs

Selecting the right material is crucial to ensuring long-term efficiency and cost-effectiveness. Here’s what to consider:

1. Purity of Copper

Ensure the flat bar is made from high-purity copper to maintain optimal conductivity and prevent impurities from affecting performance.

2. Quality of Tin Coating

A uniform, high-quality tin layer enhances corrosion resistance and solderability. Look for electroplated or hot-dipped coatings for maximum durability.

3. Compliance with Industry Standards

For electrical and industrial applications, it’s important to choose a product that meets IEC, ASTM, or UL standards for safety and performance.

“Investing in high-grade tinned copper bars has saved us from costly repairs and replacements. Quality matters!” – Daniel S., Industrial Contractor

Final Thoughts

A tinned copper flat bar is more than just a metal component—it’s a reliable solution that enhances the efficiency, longevity, and safety of electrical systems. Whether used in power grids, marine applications, or renewable energy, its corrosion-resistant and conductive properties make it a superior choice.

Pairing tinned copper flat bars with Copper Coils ensures that electrical systems remain robust and high-performing even in harsh conditions.

Are you considering tinned copper for your next project? Understanding its advantages could be the key to better performance and long-term savings.

#copper flat bar#copper flat bar suppliers melbourne#tinned copper flat bar#copper bar#copper bar suppliers

0 notes

Text

COPPER ROD

Copper has been a cornerstone in human advancement for thousands of years, and today, its applications are more critical than ever. Among the many forms that copper takes, the copper rod stands out as a versatile and indispensable component in various industrial sectors. Nexus Copper Pvt. Ltd, a leader in the copper industry, exemplifies excellence in the production and supply of high-quality copper rods. This article delves into the importance of copper rods, their manufacturing process, applications, and how Nexus Copper Pvt. Ltd is setting new standards in the industry.

Understanding Copper Rods

Copper rods are long, cylindrical bars of copper that are used in a wide range of applications due to their superior electrical conductivity, thermal conductivity, corrosion resistance, and malleability. These rods are typically produced through a process known as continuous casting and rolling, which ensures uniformity and high-quality standards.

The Manufacturing Process

The production of copper rods involves several steps:

Melting: Copper scrap or raw copper is melted in a furnace at temperatures exceeding 1,000 degrees Celsius.

Casting: The molten copper is then poured into a casting machine to create billets or large ingots.

Rolling: These billets are heated again and rolled into long rods of specific diameters.

Drawing: The rods are then drawn through dies to achieve the precise dimensions required.

Finishing: Finally, the rods are cooled, cut to the desired lengths, and subjected to quality checks.

Nexus Copper Pvt. Ltd employs state-of-the-art technology in each of these stages, ensuring that every copper rod meets stringent quality standards.

Applications of Copper Rods

Copper rods play a vital role in numerous industries, including:

Electrical Industry: Copper rods are essential in the production of electrical cables and wires due to their excellent conductivity.

Construction: Used in plumbing, roofing, and industrial machinery, copper rods offer durability and resistance to corrosion.

Automotive Industry: Copper rods are used in the manufacturing of various electrical components and in cooling systems.

Telecommunications: The superior conductivity and durability of copper rods make them ideal for use in telecommunications cables.

Renewable Energy: Copper rods are pivotal in the construction of wind turbines and solar panel systems.

Nexus Copper Pvt. Ltd: A Leader in the Industry

Nexus Copper Pvt. Ltd stands at the forefront of the copper industry, renowned for its commitment to quality and innovation. The company's advanced manufacturing facilities and rigorous quality control processes ensure that their copper rods consistently meet the highest standards. Nexus Copper Pvt. Ltd has established a reputation for reliability, with products that are trusted by clients worldwide.

Commitment to Sustainability

In addition to producing top-quality copper rods, Nexus Copper Pvt. Ltd is dedicated to sustainable practices. The company invests in eco-friendly technologies and recycling processes to minimize its environmental impact. This commitment to sustainability not only benefits the planet but also enhances the company's reputation as a responsible and forward-thinking industry leader.

Conclusion

Copper rods are fundamental to modern industry, enabling advancements in technology, construction, and energy. Nexus Copper Pvt. Ltd has distinguished itself as a premier producer of these essential components, combining cutting-edge technology with a commitment to quality and sustainability. As the demand for copper continues to grow, Nexus Copper Pvt. Ltd is well-positioned to meet the needs of a rapidly evolving market, ensuring that copper remains a key driver of progress and innovation.

#LEADING COPPER ROUND ROD C101 SUPPLIER IN INDIA#ASTM B133 COPPER ROUND RODS#WEIGHT OF C12200 FLAT BAR#UNS C10300 HEX BAR STOCKIST#COPPER THREADED ROD MANUFACTURER#COPPER WELDING ROD#C110 BAR SUPPLIER#C10100 COPPER ROUND BAR WEIGHT CHART#ASTM B187 UNS C11000 ROD SUPPLIER IN INDIA.

0 notes

Text

Application of Monel Alloy in Electronic Components

Monel alloy, a flexible and sturdy nickel-copper alloy, is incredibly regarded in numerous industries for its notable corrosion resistance, excessive electricity, and outstanding mechanical residences. One of the less typically mentioned however similarly crucial programs of Monel alloy is inside the area of digital components. This weblog will discover the role of Monel alloy in digital additives, highlighting its advantages, specific uses, and why Jay Steel is your chosen Monel Alloy Product Supplier, Monel Alloy Round Bar Supplier, Monel Alloy Sheets Manufacture, and Monel Alloy Fittings Exporters.

Understanding Monel Alloy

Monel alloy often includes nickel and copper, with small amounts of iron, manganese, carbon, and silicon. The maximum not unusual grades of Monel alloy consist of Monel 400 and Monel K-500. These alloys are recognized for their great resistance to corrosion, mainly in marine and chemical environments, making them perfect for digital components uncovered to harsh conditions. Specification Grades : Monel 400 (UNS No. N04400) Standards : ASTM, ASME and API Specifications : ASTM B 127 / ASME SB 127 Size : 15NB to 150NB In Form : Coils, Foils, Rolls, Plain Sheet, Strip, Flats, Blank (Circle), Ring (Flange) etc. Type : Sheet, Plates, Coils, Flat, Strips, Profile, Blank ,Circle, Ring etc. Finish : Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) Chemical Properties Grade Ni Fe C Mn Si Cu Al S Monel 400 63.0 min 1.0 – 2.5 0.3 max 2.0 max 0.5 max 28.0 – 34.0 0.50 max 0.02 max Mechanical Properties Density Melting Point Tensile Strength Yield Strength (0.2%Offset) Elongation 8.8 g/cm3 1350 °C (2460 °F) Psi – 80,000 , MPa – 550 Psi – 35,000 , MPa – 240 40 % Key Properties of Monel Alloy

1. Corrosion Resistance Monel alloy is famous for superb resistance to a huge range of corrosive environments, together with seawater, acids, and alkalis. This asset is important for digital additives that have to operate reliably in difficult conditions.

2. High Strength and Toughness Monel alloy maintains its strength and toughness throughout a vast temperature range. This makes it suitable for digital additives that require sturdiness and reliability below mechanical pressure.

3.Thermal and Electrical Conductivity Monel alloy offers right thermal and electric conductivity, that’s useful for digital programs. Its potential to successfully behave with heat and electricity enhances the overall performance of digital additives.

4.. Magnetic Properties Certain grades of Monel alloy, including Monel K-500, have magnetic properties that can be fantastic in precise electronic programs, such as sensors and actuators. Applications of Monel Alloy in Electronic Components

1. Connectors and Terminals Monel alloy is used inside the manufacture of electrical connectors and terminals. Its awesome corrosion resistance guarantees dependable connections in marine and commercial environments in which publicity to moisture and chemical substances is commonplace. The alloy’s strength additionally offers durability for connectors subjected to mechanical pressure.

2. Springs and Actuators The high strength and longevity of Monel alloy make it best for springs and actuators in digital devices. These components require materials which can withstand repeated mechanical strain without deforming or losing their properties. Monel alloy’s potential to preserve its overall performance underneath such situations makes it a desired choice.

3. Sensor Components Monel alloy’s magnetic properties and corrosion resistance are nice for sensor additives utilized in numerous programs, along with car, aerospace, and commercial automation. The alloy’s stability and reliability ensure correct and constant sensor performance.

4. Four. Battery Components In battery manufacturing, Monel alloy is used for components along with terminals and connectors. Its incredible conductivity and resistance to corrosive electrolytes decorate the efficiency and lifespan of batteries, making it a precious fabric inside the strength storage zone.

5. Heat Sinks and Thermal Management Monel alloy’s exact thermal conductivity makes it suitable for heat sinks and thermal management components in digital devices. Effective heat dissipation is critical for maintaining the performance and sturdiness of digital components, and Monel alloy allows reap this with the aid of efficiently moving warmth away from vital areas.

Why Choose Jay Steel?

Monel Alloy Product Supplier At Jay Steel, we’re dedicated to offering extraordinary Monel alloy products that meet the stringent requirements of various industries. As a trusted Monel Alloy Product Supplier, we provide a extensive range of Monel alloy merchandise, consisting of sheets, bars, fittings, and greater. Our products are synthetic to the very best requirements, making sure reliability and performance.

Monel Alloy Round Bar Supplier

Jay Steel is a main Monel Alloy Round Bar Supplier, imparting spherical bars in diverse sizes and specifications. Our spherical bars are perfect for applications requiring high power and corrosion resistance, together with shafts, fasteners, and mechanical additives in digital devices.

Monel Alloy Sheets Manufacture

As an expert in Monel Alloy Sheets Manufacture, Jay Steel produces sheets that are appropriate for numerous electronic programs. Our Monel alloy sheets are regarded for his or her tremendous high-quality, sturdiness, and overall performance in disturbing environments. We utilize superior production techniques to make certain that our sheets meet the best enterprise requirements.

Monel Alloy Fittings Exporters

With a global presence, Jay Steel is likewise a depended on Monel Alloy Fittings Exporter. We deliver Monel alloy fittings to customers international, making sure well timed delivery and constant first-rate. Our fittings are designed to fulfill the specific needs of electronic applications, supplying reliable and durable connections in numerous gadgets.

Conclusion

Monel alloy performs a critical position inside the production of digital components, presenting excellent residences that beautify the performance and reliability of these devices. From connectors and terminals to sensors and warmth sinks, the versatility and sturdiness of Monel alloy make it a useful material within the electronics enterprise.

Jay Steel, a leading Monel Alloy Product Supplier, Monel Alloy Round Bar Supplier, Monel Alloy Sheets Manufacture, and Monel Alloy Fittings Exporters, is devoted to presenting pinnacle-fine Monel alloy products to satisfy the numerous needs of digital element manufacturers. Contact us today to learn extra approximately our products and how we will support your digital manufacturing needs.

Resourch Link: https://jaysteelcorporation.co.in/blog/application-of-monel-alloy-in-electronic-components/

0 notes