#conveyor belt suppliers in Bangalore

Explore tagged Tumblr posts

Text

Miletech Conveyor Belts Ensure Consistent Performance and Longevity

In the dynamic world of industrial manufacturing, the reliability and efficiency of conveyor systems are critical for seamless operations. Miletech Conveyor Belt stands at the forefront of this industry, providing top-notch solutions tailored to meet diverse industrial needs across India. Known for their commitment to quality and innovation, Miletech specializes in designing and manufacturing a wide range of conveyor belts that ensure optimal performance and durability.

Miletech's expertise extends across various sectors, offering solutions that cater to specific operational requirements. Whether it's a need for heavy-duty belts in mining or precision belts in food processing, their products are crafted with precision to enhance productivity and reduce downtime. By integrating advanced technology and stringent quality control measures, Miletech ensures that each belt meets the highest standards of excellence.

High-Quality Conveyor Belts by Miletech for Diverse Industrial Needs

As one of the leading conveyor belt suppliers in Bangalore, Miletech is renowned for its extensive product range and exceptional service. Their operations in the region are complemented by their status as prominent conveyor belt manufacturers in Hyderabad, where they continue to provide tailored solutions that meet the unique challenges of various industries.

Beyond regional expertise, Miletech Conveyor Belt is recognized among the top belt manufacturers in India, showcasing a dedication to innovation and client satisfaction that sets them apart in the competitive landscape. Their comprehensive approach to manufacturing and customer service ensures that every client receives the most efficient and cost-effective solutions.

Choosing Miletech Conveyor Belt means partnering with a company that prioritizes your success. Their commitment to delivering high-quality, reliable products, coupled with their customer-focused service, makes them a preferred choice for businesses looking to optimize their operations. Trust Miletech as conveyor belt manufacturers to provide the conveyor solutions that drive your business forward, ensuring efficiency and excellence at every turn.

#conveyor belt suppliers in Bangalore#conveyor belt manufacturers in Hyderabad#belt manufacturers in India#conveyor belt manufacturers

0 notes

Text

#Industrial Conveyor manufacturers in Bangalore india#Belt conveyor manufacturers in india#Conveyor belt suppliers and manufacturers in bangalore#Over head conveyor manufacturers#Conveyor System manufacturers in bangalore#Roller conveyor manufacturers in india#Conveyor oven manufacturers in india#Gravity roller Conveyor manufacturers in bangalore#Conveyor rollers manufacturers in bangalore

0 notes

Text

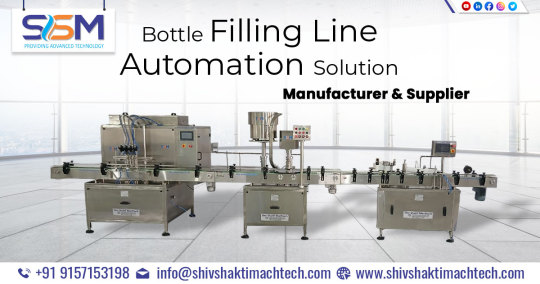

Bottle Filling Line Automation Solution

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Bottle Filling Line Automation Solution in Ahmedabad, Gujarat, India Our Manufacturer Unit is in Ahmedabad, Gujarat, India. The Bottle Filling Line Automation Solution offers a state-of-the-art, automated system for filling, capping, labeling, and packaging bottles across various industries. How Does Bottle Filling Line Automation Work? A typical bottle-filling line automation system consists of several key components that work in synergy: Bottle Feeding System: Bottles are automatically fed into the filling station from the conveyor belt. Filling Machine: This part of the system fills each bottle to the desired level based on preset parameters. Capping and Sealing: After filling, caps are automatically placed and sealed to ensure the bottle is ready for distribution. Labeling: A labeling machine attaches labels to each bottle, ensuring correct branding and product information. Packaging: Finally, we package the filled and labeled bottles for distribution, making them ready to reach consumers. Applications: Food and Beverage Pharmaceuticals Cosmetics and Personal Care Chemicals Agricultural Products What types of liquids can be filled using this automation system? Our automation solutions can fill a wide range of liquids, from thin solutions like water and beverages to thicker liquids such as oils, syrups, and pharmaceutical medicines. Can the filling line handle different bottle sizes? Yes, Shiv Shakti Machtech’s automated bottle-filling lines are highly customizable and can handle various bottle sizes and types, ensuring versatility in your production process. Shiv Shakti Machtech is a Supplier of Bottle Filling Line Automation Solution in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For more information or to request a quote, please reach out to us. Read the full article

1 note

·

View note

Text

Industrial Bearings Wholesale Dealers In Bangalore | Expo Groups

When it comes to sourcing high-quality industrial bearings, businesses in Bangalore have a trusted partner in Expo Groups. As one of the leading industrial bearings wholesale dealers in Bangalore, Expo Groups offers an extensive range of products that cater to various industries, from manufacturing to automotive and heavy machinery. With a strong reputation built on years of service and commitment, Expo Groups stands out as a reliable supplier of top-tier bearings that ensure the smooth functioning of machinery and equipment.

Why Choose Expo Groups for Industrial Bearings?

Expo Groups has established itself as a key player in the bearings market in Bangalore, providing an array of products from trusted global brands. Whether you need ball bearings, roller bearings, tapered bearings, or custom solutions for unique applications, Expo Groups can meet your needs efficiently. Here’s why businesses trust Expo Groups as their preferred industrial bearings dealer:

Wide Range of Bearings Expo Groups offers an extensive selection of industrial bearings that are suitable for different applications. From standard bearings to specialized solutions for high-speed, high-load, or temperature-sensitive operations, Expo Groups has the right product for every industry. The company's catalogue includes products from leading manufacturers, ensuring long-lasting performance.

Competitive Pricing As a wholesale dealer, Expo Groups is able to offer its products at competitive prices. Bulk buying options allow businesses to save significantly, making Expo Groups the go-to choice for cost-effective solutions without compromising on quality.

Quality Assurance With an emphasis on delivering only the highest quality bearings, Expo Groups ensures that every product meets international standards. The bearings are thoroughly tested for performance, durability, and reliability, so you can rest assured that your machinery will function smoothly for longer periods.

Customized Solutions Different industries have different needs when it comes to bearings. Expo Groups understands this and provides customized bearing solutions to meet specific requirements. Whether you need precision-engineered bearings or solutions for unusual applications, Expo Groups offers expert guidance and a wide range of products that can be tailored to your needs.

Timely Delivery Expo Groups values the importance of minimizing downtime. As one of the trusted industrial bearing suppliers in Bangalore, the company ensures prompt and reliable delivery of bearings. Whether you are ordering in bulk or need urgent replacements, Expo Groups is committed to delivering on time.

Types of Bearings Available at Expo Groups

Expo Groups stocks a comprehensive range of bearings, including:

Ball Bearings: Ideal for low-friction applications and ensuring smooth rotation, ball bearings are a popular choice in machines and motors.

Roller Bearings: These bearings can handle heavy radial loads, making them suitable for applications such as conveyor belts, crushers, and large machinery.

Tapered Roller Bearings: Known for their ability to handle both radial and axial loads, these bearings are widely used in automotive and industrial machinery.

Needle Bearings: These bearings are perfect for applications with limited radial space, offering a compact solution for heavy-load machinery.

Thrust Bearings: Designed to handle axial loads, thrust bearings are essential for machines like pumps, compressors, and gearboxes.

Self-Aligning Bearings: Used in equipment where alignment errors are common, these bearings adjust to the shaft misalignment automatically, ensuring smooth operation.

Industries Served by Expo Groups

Expo Groups serves a wide variety of industries, including:

Automotive Industry: Bearings are crucial components in engines, gearboxes, and other machinery that power vehicles. Expo Groups ensures that the bearings provided can withstand the intense conditions in the automotive sector.

Manufacturing Sector: From assembly lines to packaging machines, Expo Groups supplies bearings that ensure continuous operation and improved productivity.

Heavy Machinery and Construction: Bearings are critical in construction machinery such as cranes, excavators, and bulldozers. Expo Groups offers durable and high-performance bearings to meet the demands of heavy-duty equipment.

Renewable Energy: Bearings play a crucial role in wind turbines and solar power systems. Expo Groups supplies bearings that contribute to the efficient functioning of renewable energy projects.

Agricultural Machinery: Bearings are key in ensuring that agricultural equipment such as tractors, harvesters, and plows operate without issues. Expo Groups provides bearings designed for these heavy-duty applications.

The Expo Groups Advantage: Customer-Centric Approach

Expo Groups believes in building long-term relationships with clients by providing exceptional service, reliable products, and expert guidance. The company’s team of knowledgeable professionals is always ready to offer support and technical assistance, helping businesses make informed decisions when it comes to bearings.

As a wholesale bearings supplier in Bangalore, Expo Groups stands out not only for its broad product range but also for its commitment to customer satisfaction. Whether you’re a small business or a large corporation, Expo Groups offers personalized service that meets your specific needs.

Conclusion

For businesses in Bangalore looking for high-quality industrial bearings at competitive prices, Expo Groups is the name to trust. As leading industrial bearings wholesale dealers, they offer an unmatched variety of products and solutions that ensure the smooth and efficient running of your machinery. Whether you’re in manufacturing, automotive, or construction, Expo Groups has the perfect bearings solution for your business.

Contact Expo Groups today to learn more about their range of industrial bearings and how they can support your operations with reliable and cost-effective bearing solutions.

0 notes

Text

Conveyor Belt Manufacturers in Bangalore: Pioneering Excellence in Material Handling Solutions

Bangalore, often referred to as the Silicon Valley of India, is not only a hub for the IT industry but also a significant player in various manufacturing sectors. Among these, the conveyor belt manufacturing industry stands out for its crucial role in facilitating efficient material handling solutions across diverse industries. Conveyor belt manufacturers in Bangalore are renowned for their innovative designs, high-quality products, and exceptional service, making them leaders in the global market.

The Significance of Conveyor Belts

Conveyor belts are essential components in manufacturing and production lines, enabling the seamless movement of materials and products from one point to another. They enhance operational efficiency, reduce manual labor, and ensure the smooth flow of production processes. In industries such as mining, agriculture, automotive, food processing, and logistics, conveyor belts are indispensable.

Leading Conveyor Belt Manufacturers in Bangalore

Bangalore hosts some of the most prominent conveyor belt manufacturers in India. These companies are known for their state-of-the-art manufacturing facilities, adherence to international quality standards, and a strong focus on customer satisfaction. Here are some key features that distinguish conveyor belt manufacturers in Bangalore:

Innovative Design and Engineering: The conveyor belt manufacturers in Bangalore invest heavily in research and development to create innovative designs that cater to specific industry requirements. Their engineering teams are adept at developing customized solutions that enhance productivity and efficiency.

High-Quality Materials: Quality is a hallmark of the conveyor belt manufacturers in Bangalore. They use premium materials to ensure durability, reliability, and longevity of their products. This commitment to quality helps in minimizing downtime and maintenance costs for their clients.

Advanced Manufacturing Processes: These manufacturers employ cutting-edge technologies and advanced manufacturing processes to produce conveyor belts that meet stringent quality standards. From automated production lines to rigorous quality control measures, every step is meticulously monitored.

Wide Range of Products: Conveyor belt manufacturers in Bangalore offer a comprehensive range of products, including rubber conveyor belts, PVC conveyor belts, modular conveyor belts, and specialized belts for specific applications. This diverse portfolio allows them to cater to the unique needs of various industries.

Exceptional Customer Service: Customer satisfaction is a top priority for conveyor belt manufacturers in Bangalore. They provide excellent after-sales support, technical assistance, and maintenance services to ensure that their clients' operations run smoothly.

Why Choose Conveyor Belt Manufacturers in Bangalore?

Choosing conveyor belt manufacturers in Bangalore offers several advantages. Their expertise in the field, combined with a commitment to quality and innovation, ensures that clients receive top-notch products and services. Additionally, their strategic location in Bangalore provides easy access to a vast network of suppliers and logistics services, facilitating timely delivery and efficient distribution.

Conclusion

In the realm of material handling solutions, conveyor belt manufacturers in Bangalore have carved a niche for themselves with their unparalleled expertise, quality products, and exceptional service. Their continuous efforts in innovation and customer satisfaction make them the preferred choice for industries seeking reliable and efficient conveyor belt solutions. By choosing conveyor belt manufacturers in Bangalore, businesses can enhance their operational efficiency and achieve new heights of productivity.

1 note

·

View note

Text

Automatic Multi Head Aluminum Cap Sealing Machine in Karnataka

Automatic Multi Head Aluminum Cap Sealing Machine in Karnataka: Laxmi Pharma Equipment: Laxmi Pharma Equipment is a prominent manufacturer, exporter, and supplier based in India, specializing in pharmaceutical machinery. Its leading manufacturing capabilities and recognition as a key player in the pharmaceutical machinery sector are well-known. Product Range: Laxmi Pharma Equipment provides a comprehensive array of pharmaceutical machinery, including encompassing vial filling machines, bottle filling machines, liquid filling machines, powder filling machines, vial sealing machines, ampoule filling machines, ROPP capping machines, screw capping machines, aluminum cap sealing machines, sticker labeling machines, and more. Laxmi Pharma Equipment is one of the leading manufacturers and exporter and Supplier of Automatic Multi Head Aluminum Cap Sealing Machine. The company is a leading manufacturer and exporter of the Automatic Multi Head Aluminum Cap Sealing Machine, known as the "LACS Series."Constructed on a robust welded steel frame with convenient doors for easy maintenance, this compact device offers exceptional functionality. Appropriately halted vials from the filling machine's turntable are continuously fed onto the sealing machine's flat conveyor belt. An infeed worm ensures proper spacing as it transfers the vials to an infeed star wheel, ultimately guiding them into the delivery chute. The Automatic Multi Head Aluminum Cap Sealing Machine efficiently handles flip-off, aluminum, and tear-off caps. A vibrating bowl automatically orients and arranges these caps in the correct position. Applications Across Industries: The machine is suitable for a broad spectrum of industries, including Pharmaceuticals, Food, Cosmetics, Pesticides, and more. We Provide Automatic Multi Head Aluminum Cap Sealing Machine in Karnataka Including Bangalore, Hubli-Dharwad, Mysore, Kalaburagi, Mangalore, Belgaum, Davanagere, Bellar, Vijayapura, Shimoga, Tumkur, Raichur, Bidar, Udupi, Hospet, Gadag-Betageri, Robertsonpet, Hassa, Bhadravati, Chitradurga, Kolar, Mandya, Chikmagalur, Gangavati, Bagalkot, Ranebennuru. For a comprehensive view of our product catalog, feel free to connect with us using the provided contact information. Read the full article

#AutomaticMultiHeadAluminumCapSealingMachine#Bagalkot#Bangalore#Belgaum#Bellar#Bhadravati#Bidar#Chikmagalur#Chitradurga#Davanagere#Exporter#Gadag-Betageri#Gangavati#Hassa#Hospet#Hubli-Dharwad#India#Kalaburagi#Kolar#Mandya#Mangalore#Manufacturer#Mysore#Raichur#Ranebennuru#Robertsonpet#Shimoga#Supplier#Tumkur#Udupi

0 notes

Text

Chip Conveyor Styles and Applications

Effective, dependable chip collection and removal is a key ingredient in maximizing the performance of today’s machine tools. Depending on the volume and type of chip being produced, there are some results for Manufacturers of Chip Conveyors that are available in India, Pune, Mumbai, Bangalore, Chennai, Indore, Kolhapur, Nashik, Aurangabad, Coimbatore, and Delhi. Chip conveyors, when named duly, will increase productivity by reducing the time-out needed for homemade cleaning of the chip visage.

It's important to use the correct style in Chip Conveyor Manufacturers for the type of machining being performed. frequently, the client will order a standard conveyor with no consideration for the type of chips that the machine will be producing.

Guidelines

Chip conveyors are typically available in 4 different styles from various suppliers depending on belt, scraper, glamorous, and micro-fine. Then we will take a more in-depth look at each style and its operations. In some of these styles, a variable speed drive can also be added( as a special) to control the conveyor speed if needed by the client.

Hinge Belt Style:

This style carries chips on top of a dependable belt and is recommended for larger types of chips, similar to the sword, as well as long curled or fibrous types. The belt face is frequently perforated with holes to grease coolant drainage back into the tank. When used in operations with veritably fine chips, frequently the chips will fall through the perforations leading to chip figures on the bottom of the coolant tank. This can clog pollutants or pumps and jam the conveyor resulting in the need for a more constant drawing of the tank, pollutants, pumps, and conveyor system.

Scraper Style:

This style has large openings between the squabblers which allow coolant and chips to fall to the bottom of the tank where the chips are also scraped out of the system. This type of system is recommended for fine types of chips, similar to those produced when machining cast iron, brass, aluminum, and other non-ferrous types of accouterments. Long, stingy, or curled chips will frequently come entangled around the scrapers causing jamming or damage to the conveyor system.

Magnetic Style:

This type carries chips out of the system on top of a stationary pristine sword cover and the chips are conveyed out by important attractions moving under. The chips are also released from the attractions at the discharge end and fall down from the conveyor. This type of system is recommended for fine or veritably small ferrous accouterments, typically in operations using coolant. Long fibrous chips and non-ferrous material operations won't work well with this type of system.

Micro-Fine Style:

This style is a binary conveyor design. The upper conveyor is a hinge belt type that carries the larger, and long, fibrous types of chips, and the lower conveyor is a scraper type that removes the forfeitures and small chips trapped in the lower conveyor. Coolant may also be filtered through a filtration system to minimize coolant pump damage. Filtration can be specified down to the 50-micron position if needed.

Chip conveyors offer numerous advantages in maximizing the performance of moment’s machine tools chips are removed without interposing product, hot chips are removed from the machine terrain, therefore, reducing heat make-up, and chips are removed from the coolant automatically. It's important when considering Chip Conveyor selections to understand the strengths and sins of each style, as well as the type of chip that will be produced. Drasla Technologies Pvt. Ltd. may only offer limited styles as standard options on some outfits. Specials can be ordered through the Custom Results Team.

0 notes

Text

VISIT : https://irajrobotics.com/vibratory-feeder-bowl.html

I Raj Robotics & Automation is the leading Manufacturers of Vibratory Bowl Feeder in Pune, Mumbai, Jamshedpur, Angul, Jharsuguda, Bhubaneswar, Chennai, Bangalore, Hyderabad, Coimbatore, Gurgaon.

We Vibratory Bowl Feeder Manufacturers have been producing quality products for over more than 6 years

We are well known for the high-quality products that can be found at low prices. Our customers are well satisfied with our products and are able to offer great prices for the products. The Vibratory Bowl Feeder manufacturers, suppliers, dealers have a great reputation in the marketplace and we are able to produce components that are easy and affordable to use.

Features: Vibratory Bowl Feeder

The Vibratory Bowl Feeder manufacturers enable the production process to be controlled by an operator or human operator using a remote control unit or an automated system that controls the machine.

The feeder can be installed in the production line of an industrial plant or manufacturing facility.

The vibration generated by this device is converted into electrical signals that are sent through wires and are then converted back into mechanical vibrations that move objects around on a conveyor belt or other machinery.

Phone: +91 99750 45502

Email: [email protected]

Address: Gat No 1336, Near Vikas Anath Ashram, Behind Ralphs Polymer, Jyotiba Nagar Road, Sonwane Wasti, Chikhali, Pune, 411062, MH, India

0 notes

Text

How High End Baking Machines Can Help You Speed up The Baking Process?

Baking is an art and method of cooking where in continued supply of dry heat is supplied into raw mixture to obtain finished food product, We all have baked products almost every day namely, biscuits, buns, breads and cookies. It is an oldest form of cooking the human race has ever known. Almost all the food can be baked and also some need special care and attention.

It all starts with the dough. Most of them bakery products such as bread, bun are obtained from baking of dough. And it ends with tasty and crunchy biscuits and cookies. Today baking has become any essential part of food style which includes different methods like boiling and frying. And also question arises what’s between dough and cookies, the process involved and the equipment used. Use of Machineries and equipment help in maintaining quality consistency in finished products. Let us take a look into different equipment available to ease the baking process.

1. Dough kneader This kneaded mixes the required ingredients for dough to a fine tilth to prepare pizza, roti, samosa, breads, bun and biscuits.

2. Pulverized masala mix The mixer is used to grind and blend the grains and masala and ensure uniform distribution of ingredients in the mix and make the dough a perfect blend.

3. Gravy machine This is a specialized kind of machinery to extract flavours from spice blends, onion, chillies and wet mixes and masala.

4. Potato peeler machine Potato is highest selling vegetable in the industry and used widely. Potato peeling is a labour intensive work. To ease peeling, here’s a specialized peeling machine.

5. Vegetables cutting machine Another time consuming and labour intensive work is vegetable cutting and this sophisticated machine helps you with standard cuts and quality of vegetables. With wide range of blades, the vegetables can be cut into different shapes and sizes.

6. Dough sheets This machine helps increasing efficiency and consistency by flattening dough by repeated pressing into thin crusts. This machine repeatedly presses the dough sheets one above the other.

7. Rotary rack oven This commercial oven is where the baking process i.e from dough to bread by continuous supply of dry heat. They are used to prepare rusks, breads, buns, biscuits and cookies.

8. Farsen namkeen machine Namkeen is always a part of Indian food. This machine is designed to match the perfection of Indian namkeen preparation of varied sizes and cuts.

9. Bread slicer machine Slicing of bread in uniform slices is the tedious work. This machinery is designed to get perfect and equally sized slices of bread.

10. Meat Slicer Machine Meat slicer machine is designed to prepare the slices of meat which are used in burgers and pizzas. It is designed to be a more sophisticated machine ensures perfect cuts.

11. Meat Mincer Meat is consumed in minced form since traditional times and this machinery is designed and is being implemented to prepare minces of meat.

12. Conveyor pizza oven Pizza is a baked product. Specialized machinery designed to prepare pizza to bake the pizza dough base and toppings along with a conveyor belt.

13. Chapatti Making machine Chapatti or roti is an essential part of Indian food and preparing them is labor intensive and time-consuming. To ease the process of making chapattis, this machinery is designed to perfectly prepare chapattis.

Mahesh Hotelware is manufacturers and suppliers on High-End Bakery Equipment in Bangalore. They have a wide range of hotel kitchen equipment experience.

0 notes

Text

Air Compressor Supplier In Delhi, India | Syndicate Industry

Syndicate Industry successfully supplied air compressor around the india. We will to stay and confirm that we are a experienced an ISO certified air compressor supplier in India. our product range is Low pressure and high pressure reciprocating piston type air compressor 90KW-200KW and 9 Bar - 12 Bar pressure range, high pressure and low pressure air receiver tank 30 liters to 80,000 liters capacity, 100% salient oil free air compressor for food and pharmaceutical companies, Car washing pump for automobile service station, we have oil less Oxygen Compressor concentration for medical hospitals applications High pressure Compressors for Pet blow molding Oil Free air Compressor manufacturers and exporters for Power Plants we are India based world class air compressor manufacturing company.Air compressor manufacturers in India Ahmedabad reciprocating piston air compressor high pressure air compressor oil free air compressor, Syndicate Industry AIR COMPRESSOR is one of the best manufacturers and exporters of “Syndicate Industry COMPRESSOR” BRAND Industrial and Commercial reciprocating, air cooled and water cooled lubricated and non lubricated compressors in single stage, two stage, and multistage air compressor in piston compressor from 2 HP to 20HP up to Upto 65.5 CFM. We have wide range or pet blow high pressure compressor Upto 65.5 CFM, We have highly qualified professional team dedicated & committed to sales and service to iron and steel industry, conveyor belt manufacturers, precision forging manufacturers, air compressor supplier, bucket elevators manufacturers, conveyor chain manufacturers, fabrication services, Glass Industries, vertical conveyor horizontal conveyor, cnc turned components, ferrous and non ferrous metals .We have highly skilled engineers who is inspect each and every components strength and it’s reliability and accuracy before produce any compressor, We have most efficient team members who is regular working on creative ideas to provide high quality work to domestic , We are not selling our product but we are selling after sales technical support globally. We are looking dealer network in Mumbai, Delhi, Chennai, Coimbatore, Madurai, Karnataka Bangalore, Hyderabad, Pune, Surat, Kolkata, Lucknow, Kanpur, Indore, Bhopal, Vadodara, Faridabad, Rajkot, Srinagar, Aurangabad, Amritsar, Ranchi, Vijayawada, Raipur, Chandigarh, Bhubaneswar, Dehradun, Agartala .

Air Compressor Specifications

Motor Power 90KW-200KW Horse Power 2 HP to 20HP Discharge Pressure 9 Bar - 12 Bar Maximum Flow Rate Upto 65.5 CFM Number of Compression Stages Two Stage Compressor Mounting Configuration Tank Mounted

The cutting edge fabricating industry couldn't get by without one fundamental instrument: modern air blowers. This sheltered, strong bit of hardware permits makers in different fields to accomplish their work adequately. Here's the ticket...

Different Categories and Models of Industrial Air Compressors Make Manufacturing Possible

In the event that you've at any point expanded your vehicle's tires at a service station or utilized canned air to clean your console, you've utilized rearranged forms of compacted air. On a more fantastic scope, nonetheless, modern air blowers make probably the biggest assignments possible.There are a few unique sorts of air blowers, each with shifting sizes and force supplies – enough to fill an inflatable cushion or gracefully pressurized air to a huge assembling office.

For the most part, air blowers are assembled into three classes regarding capacity: purchaser grade, proficient evaluation and modern evaluation. To the extent configuration goes, there are two fundamental models makers depend on: the responding cylinder and the turning screw. Whatever the model, these strong, solid machines require considerably less upkeep than electric apparatuses .

These air blower have Developed Over Time as Industrial Needs Have Progressed

Prior to the improvement of air pressure innovation, people had just their lungs to feed the flames of assembling. Howls, imagined around 1500 BC, helped us along, yet making a solid wellspring of air was still work serious. To satisfy our requirements for produced metal, it was to a great extent human muscle that kept industry moving for a considerable length of time. It wasn't until 1776 that a blowing gadget, an early model for a mechanical air blower, was created by an industrialist named John Wilkinson. More industrialists paid heed and started to builds up this new innovation. Before long, air blowers were utilized in metal working and mining to make a more secure, more effective condition.

0 notes

Text

Honey Jar Labeling Machine with Tamper Evident Label

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Honey Jar Labeling Machine with Tamper Evident Label in Ahmedabad, Gujarat, India. In the food and beverage industry, product integrity and consumer safety are paramount. A Honey Jar Labeling Machine with a tamper-evident labeling feature securely packages and labels your honey products. This machine automates the labeling process, ensuring efficiency, precision, and compliance with industry standards. Other Name of the Machine: Automatic Honey Jar Sticker Labeling Machine, Precision Labeling on Honey Containers, Hot Sauce Jam Jar Round Bottle Tamper Evident labeling Machine, Honey Jar Tamper Evident Labeling Solutions, Tamper Evident Labeling machine for Container, Honey Jar Wrap Around Labeling Machine with Tamper Evident Label, Wrap Around Labeling Machine with 3 Roller, 3 Roller Labeling Machine, Sticker Labeler Machine With 3 roller Pneumatic Process of Honey Jar Labeling Machines Bottle Feeding: Empty jars are fed into the machine, often through a conveyor belt. Label Application: The machine applies the tamper-evident label to the jar, typically using a pressure-sensitive adhesive. Tamper-Evident Seal Activation: The tamper-evident seal is activated, creating a physical barrier that indicates if the jar has been opened. Inspection: The machine inspects the labels to ensure they are applied correctly and the tamper-evident seal is intact. Jar Discharge: The labeled jars are discharged from the machine, ready for packaging or distribution. Features: Offers options for fully automated or semi-automatic systems. Capable of labeling a large number of jars per minute. Boosts production efficiency. Suitable for various jar shapes and sizes. Allows for easy adjustments. Ensures accurate label placement. Maintains a professional appearance. Built with high-quality materials. Designed to endure industrial demands. Shiv Shakti Machtech is a Manufacturer of Honey Jar Labeling Machine with Tamper Evident Label in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For more information or to request a quote, please reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner#Brahmapur#Changodar#Chennai#Chhachhrauli

1 note

·

View note

Text

5 Liter Jerry Can Capping Machine

Company Overview: Shiv Shakti Machtech is Manufacturer, Exporter and Supplier of 5 Liter Jerry Can Capping Machine in Ahmedabad, Gujarat, India. A 5-liter jerry can capping machine is an essential piece of equipment used to securely seal 5-liter jerry cans after they have been filled with liquids. Why Choose Our 5 Liter Jerry Can Capping Machine? High Efficiency: Designed for rapid capping, this machine can process hundreds of jerry cans per hour, significantly increasing your output. Precision Capping: Ensures accurate sealing every time, preventing leaks and product contamination. Durable Construction: Built with high-quality materials to withstand industrial environments, ensuring long-lasting performance. Versatile Design: Suitable for various jerry can designs, making it adaptable to your product range. Low Maintenance: Engineered for easy maintenance, reducing downtime and operational costs. How It Works: Loading: Jerry cans are automatically fed onto the conveyor belt from the filling station. Capping: As the cans pass through the capping station, we apply and tighten the caps using adjustable torque settings. Output: The capped jerry cans are then transferred to the next stage of production or packaging. Shiv Shakti Machtech is a Manufacturer of 5 Liter Jerry Can Capping Machine in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For more information or to request a quote, please reach out to us. View Product: Click Here Read the full article

#5LiterJerryCanCappingMachine#5LiterJerryCanCappingMachineinAhmedabad#5LiterJerryCanCappingMachineinGujarat#5LiterJerryCanCappingMachineinIndia#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner

1 note

·

View note

Text

Oil Pet Bottle CTC CAP Pressing Machine Manufacturer

Shiv Shakti Machtech is an Oil Pet Bottle CTC CAP Pressing Machine Manufacturer in Ahmedabad. We are Based in Ahmedabad, Gujarat, India. Our machine features advanced technology for precise capping, ensuring that every cap is securely applied to the oil PET bottles. This reduces the risk of leaks and contamination. Designed for easy maintenance, the machine minimizes downtime and ensures consistent performance over time. Working Principles: Feeding System: Bottles are fed into the machine via a conveyor belt or feeding mechanism. Cap Placement: The machine automatically places the caps onto the bottles using a cap picker or feed mechanism to position them accurately. Capping Process: The machine uses a pressing mechanism to apply the caps firmly onto the bottles. The pressing force is adjustable to accommodate different cap types and sizes. Sealing and Inspection: After capping, the machine seals or inspects each cap to ensure it secures and the seal remains intact. Discharge: The machine discharges sealed bottles and directs them to the next stage of the packaging line. Shiv Shakti Machtech is Oil Pet Bottle CTC CAP Pressing Machine Manufacturer in Ahmedabad, Supplier in Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For further details or inquiries, feel free to reach out to us. View Product: Click here Read the full article

1 note

·

View note

Text

Packing Conveyor Unit

Laxmi Pharma Equipment is one of the leading manufacturers and exporter and Supplier of Packing Conveyor Unit. A packing conveyor unit is a piece of equipment used in various industries, including manufacturing, logistics, and packaging. It's designed to facilitate the packing process by providing a controlled and efficient platform for workers to prepare products for shipment. Types of packing conveyor units: Belt conveyors Roller conveyors Spiral conveyors Chain conveyors Modular conveyors Applications: Food and beverage industry Pharmaceutical industry Electronics industry Cosmetics and personal care industry Automotive industry: Packaging car parts, accessories, and other automotive components. Key features and benefits: Increased efficiency: Automates product movement, significantly reducing manual labor and accelerating the packaging process. Improved accuracy: Consistent product flow ensures proper positioning and alignment for labeling, sealing, and other packaging tasks. Reduced labor costs: Automation reduces reliance on manual labor, leading to lower labor costs and improved resource allocation. Enhanced product quality: Controlled movement minimizes the risk of product damage and ensures consistent packaging quality. Increased throughput: Higher processing speeds allow for handling larger volumes of products and fulfilling greater demand. Improved ergonomics: Reduces physical strain on workers by eliminating manual lifting and carrying of products. Versatility: Adaptable to various packaging lines and configurations with different product types and sizes. We Provide Packing Conveyor Unit in Karnataka Including Bangalore, Hubli-Dharwad, Mysore, Kalaburagi, Mangalore, Belgaum, Davanagere, Bellar, Vijayapura, Shimoga, Tumkur, Raichur, Bidar, Udupi, Hospet, Gadag-Betageri, Robertsonpet, Hassa, Bhadravati, Chitradurga, Kolar, Mandya, Chikmagalur, Gangavati, Bagalkot, Ranebennuru. Read the full article

#Bagalkot#Bangalore#Belgaum#Bellar#Bhadravati#Bidar#Chikmagalur#Chitradurga#Davanagere#Gadag-Betageri#Gangavati#Hassa#Hospet#Hubli-Dharwad#India#Kalaburagi#Karnataka#Kolar#Mandya#Mangalore#Manufacturer#Mysore#PackingConveyorUnit#Raichur#Ranebennuru#Robertsonpet#Shimoga#Supplier#Tumkur#Udupi

0 notes

Text

Drasla Technology - Chip Conveyors Manufacturers in India

Chip conveyors are sword conveyor belts that are designed for transporting chips from the end of the machining center or other feathers of machines to another place. Chip Conveyor Manufacturers give a wide variety of high-quality chip conveyors for chip and scrap removal operations for colorful machine tools. Chip removal outfit is fleetly getting popular moment. In nearly all fields, conveyor systems are extremely important to efficiently and precisely move products, accouterments, tools, and unwanted particulars from one point to another.

The machines the chip conveyors can match with include small lathes, machining centers, and gantry milling machines and accommodate colorful coolant systems, conveying different types of essence chips hundreds of bases from the machines to central collecting installations. Conveyors from Draslatech, a leading Chip Conveyors Suppliers in India Pune, Mumbai, Bangalore, Chennai, Indore, Kolhapur, Nashik, Aurangabad, Coimbatore, Delhi. Can be manufactured to extents from 4” to 80”, depending on the need.

Chip conveyors are machines used to convey material or transport effects from one end to another. They're getting more popular day by day. Conveyor systems are needed in all the fields you name or suppose, for moving effects from one point to another or transporting accouterments at a distance. The benefit of a similar system is the fact that they may be located, or set up, veritably nearly anywhere. Presently, they're getting a necessity in all walks of life, whether it's artificial, mining, marketable, medicinal, packaging, truck loading, etc. The unique Hennig belt hinge is designed as one nonstop piece, whereas numerous competitive brands don't have this point.

The manufacturing of these belts is done on Hennig’s in-house press outfit. End druggies from the general manufacturing, food manufacturing, parcel, and packaging diligence have snappily embraced the new product immolation. A variety of diligence can profit from the features that are considered add-ons to utmost other Chip Conveyor Manufacturers. Some can be bought and also successfully installed by the purchaser; still, those people with a demand for further sophisticated models can have the conveyors installed to suit. This just means that anyhow the space is, and where it's deposited, if there's acceptable space for your conveyor outfit needed, the system can fluently be installed. For this reason, you'll find conveyor units outdoors throughout diligence of all kinds.

1 note

·

View note

Text

Vibratory Bowl Feeder Manufacturers Suppliers Dealers

Manufacturers of Vibratory Bowl Feeder in Pune, Iraj Robotics & Automation is the leading Manufacturers of Vibratory Bowl Feeder in Pune, Mumbai, Jamshedpur, Angul, Jharsuguda, Bhubaneswar, Chennai, Bangalore, Hyderabad, Coimbatore, Gurgaon.

We Vibratory Bowl Feeder Manufacturers have been producing quality products for over more than 6 years

We are well known for the high-quality products that can be found at low prices. Our customers are well satisfied with our products and are able to offer great prices for the products. The Vibratory Bowl Feeder manufacturers, suppliers, dealers have a great reputation in the marketplace and we are able to produce components that are easy and affordable to use.

Features: Vibratory Bowl Feeder

The Vibratory Bowl Feeder manufacturers enable the production process to be controlled by an operator or human operator using a remote control unit or an automated system that controls the machine.

The feeder can be installed in the production line of an industrial plant or manufacturing facility.

The vibration generated by this device is converted into electrical signals that are sent through wires and are then converted back into mechanical vibrations that move objects around on a conveyor belt or other machinery.

Phone +91 99750 45502

Email [email protected]

Address: Gat No 1336, Near Vikas Anath Ashram, Behind Ralphs Polymer, Jyotiba Nagar Road, Sonwane Wasti, Chikhali, Pune, 411062, MH, India

0 notes