#construction grouting pumps india

Explore tagged Tumblr posts

Text

#grouting pumps x1 series#x1 series pump manufacturers india#grouting pump suppliers india#x1 series pump exporters india#grouting pump manufacturers india#x1 series grouting pump suppliers#industrial grouting pumps india#x1 series pump for construction#grouting pump exporters india#x1 series pump wholesale india#grouting pump applications#construction grouting pumps india#x1 series pump production india

0 notes

Text

Basement Construction in India: A Comprehensive Guide

Basement construction plays a pivotal role in modern construction practices across India, offering valuable space utilization solutions in both residential and commercial projects. As urban landscapes evolve and space becomes increasingly scarce, basements serve as indispensable assets, catering to diverse needs ranging from parking facilities to additional storage and recreational areas.

1. Planning and Design Considerations

Before embarking on basement construction, meticulous planning and design are crucial. Factors such as soil type, groundwater levels, structural integrity, and local building regulations must be carefully assessed. Wagad Infra Projects, renowned for its expertise in construction, emphasizes the importance of conducting thorough feasibility studies and obtaining necessary approvals from local authorities. Their comprehensive approach ensures that every project adheres to the highest standards of safety and efficiency.

2. Construction Techniques

In India, basement construction typically involves several techniques tailored to local conditions. Common methods include:

Excavation and Shoring

Excavation depth varies based on project requirements and soil stability. Shoring systems like soldier piles and lagging or diaphragm walls ensure structural support during excavation. Wagad Infra Projects utilizes advanced excavation techniques to achieve precision and safety in their projects.

Waterproofing Solutions

Given India's diverse climatic conditions, effective waterproofing is imperative to prevent water ingress and maintain structural integrity. Technologies such as membrane systems, crystalline waterproofing, and injection grouting are employed to safeguard basements against moisture penetration. Wagad Infra Projects integrates cutting-edge waterproofing technologies to enhance durability and longevity.

Foundation and Slab Construction

Robust foundation design and construction techniques, including reinforced concrete slabs and deep foundations, are essential for bearing the load of upper structures and supporting the basement's structural stability. Wagad Infra Projects' expertise in foundation engineering ensures that all basements are built to withstand significant loads and environmental stresses.

3. Utilization and Benefits

Basements offer multifaceted benefits in Indian construction:

Space Optimization

In metropolitan cities like Mumbai and Delhi, where land prices are exorbitant, basements provide cost-effective solutions for parking, storage, and utility spaces, thereby maximizing land utilization. Wagad Infra Projects excels in designing basements that optimize space and meet diverse client needs.

Environmental Benefits

Underground spaces contribute to energy efficiency by naturally insulating buildings, reducing heating and cooling demands, and minimizing environmental impact. Wagad Infra Projects is committed to sustainable construction practices, leveraging the environmental benefits of basement spaces.

Enhanced Property Value

Properties equipped with well-designed basements command higher market value due to added functionality and convenience. Wagad Infra Projects' innovative designs enhance property value and appeal, providing clients with a competitive edge in the market.

4. Challenges and Mitigation

Despite its advantages, basement construction in India presents challenges such as:

Groundwater Management

Controlling groundwater levels during excavation is critical to prevent flooding and structural instability. Techniques like wellpoint dewatering and sump pumping are employed to manage water ingress effectively. Wagad Infra Projects employs state-of-the-art groundwater management solutions to ensure project safety and stability.

Regulatory Compliance

Adhering to local building codes and regulations ensures safety and legality throughout the construction process. Wagad Infra Projects emphasizes strict compliance with statutory norms to uphold project integrity and stakeholder confidence. Their team is well-versed in navigating regulatory landscapes to ensure seamless project execution.

5. Future Trends and Innovations

Looking ahead, advancements in construction technology and sustainability practices are poised to revolutionize basement construction in India. Innovations such as modular construction, green roofs, and smart basement management systems promise enhanced efficiency and environmental stewardship. Wagad Infra Projects is at the forefront of adopting these innovations, continuously pushing the boundaries of what's possible in construction.

Conclusion

In conclusion, basement construction in India represents a cornerstone of modern urban development, offering versatile solutions to address space constraints and enhance property functionality. Wagad Infra Projects continues to lead the industry with its commitment to excellence, delivering innovative basement solutions that redefine urban living and commercial spaces across the nation. With a focus on quality, sustainability, and client satisfaction, Wagad Infra Projects is dedicated to shaping the future of construction in India. For more Visit Wagad Infra-projects.

#basement construction India#Wagad Infra Projects#construction planning#groundwater levels#waterproofing solutions#smart basement management#commercial space solutions#sustainable construction#InfrastructureDevelopment#ConcreteWalls#DiaphragmWalls#HighwayConstruction

0 notes

Text

Electric Grout Pumps - Cement Grouting Pump - Surface International

Surface International is one of the trustworthy organizations engaged in manufacturing a vast range of Electric Grout Pumps. Our Electric Grout Pumps are used in construction work like ultrafine cement, non-shrink grouts, self-leveling, fireproofing, metallic grouts, plaster, packed grout mixes, etc. We are the eminent Electric Grout Pumps Manufacturers in India.

Features:

-> Highly Durable

-> Resistant from quick breakdowns

-> Low Maintenance

-> Easy availability of spare parts

-> Steady pumping

#ElectricGroutPumps#ShotPeeningMachine#Shotblastingmachine#blastingroom#blastingcabinet#blastroomsystem#SurfacePreparation#Surfacetreatment#Surfacefinishing#Abrasiverecovery#Dustcollector#Shotblasting#Blasting#Sandblasting#surfaceinternational#manufacturers#suppliers#exporters#industrialproducts#heavymachinery#products#jodhpur#India

0 notes

Text

POLYMER CONCRETE MARKET ANALYSIS (2019-2027)

Polymer Concrete Market 2017–2027

Polymer concrete is categorized under composite materials that use thermoplastics polymers with an epoxy binder to harden materials in the construction industry. It has water, gravel, and sand as an important ingredient which makes it suitable for the repair of any concrete structure. Polymer concrete have higher compressive and impact strength as compared to other types of concretes used in the construction industry. They can be classified into a vinyl ester, polyester, epoxy-based & others. Some of the major end-user of the polymer concrete are industrial, residential & municipal, and commercial.

The global polymer concrete market is projected to reach US$ 691.8 million by the end of 2027, in terms of revenue, growing at CAGR of 7.9% during the forecast period (2019 to 2027).

Drivers

Rising demand for polymer concrete across emerging applications due to enhanced properties such as the ability to form complex shapes, brilliant vibration damping, and rapid curing properties is fueling the market growth of polymer concrete. Polymer concrete is now widely used across applications such as pump bases, waste containers, chemical containments, industrial flooring blocks, and trench drains. The aforementioned factors are projected to propel the market growth of polymer concrete over the forecast timeframe.

Increasing application of polymer concrete across the drainage application is expected to fuel the market growth of polymer concrete. Polymer concrete offers precision molding, precise finishing, which promote efficient hydraulic flow, to ensure superior discharge rates of water from the pipe. The aforementioned advantages are projected to fuel the demand for polymer concrete across municipal applications. Therefore, rising application of polymer concrete across the construction industry is expected to augment the market growth.

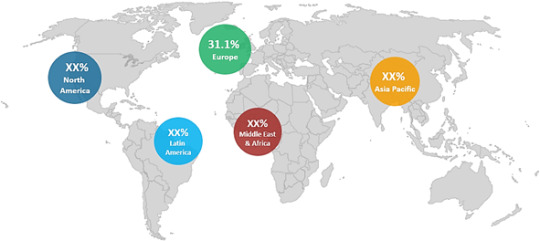

Regionally, Europe dominated the global polymer concrete market in 2018, reporting 31.1% market share in terms of revenue, followed by North America and Asia-Pacific, respectively.

Figure 1. Global Polymer Concrete Market, Revenue Share (%), By Region, 2018

Market Restraints

The high cost of polymer concrete compared to other materials is restricting its application across special needs. This factor is expected to hamper the market growth of concrete polymer over the forecast timeframe. Also, rising usage of a special type of plastics as a cheaper alternative to polymer concrete that offers the same properties as polymer concrete is further anticipated to hinder the market growth over the forecast timeframe.

Lack of awareness regarding the numerous advantages of polymer concrete is expected to impact the market growth of polymer concrete to some extent. Moreover, polymer concrete can be used across an application where there is less consumption of energy and less manpower. This factor is also projected to restrict the market growth of the polymer concrete over the forecast timeframe.

Market Opportunities

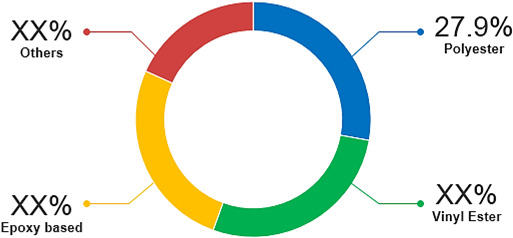

Rising usage of polyester & vinyl ester-based materials in the polymer concrete is projected to serve significant opportunity over the forecast timeframe. Since epoxy-based materials are comparatively more expensive than polyester & vinyl ester-based materials, for this reason, manufacturers mostly prefer polyester & vinyl ester-based materials for the production of polymer concrete. This factor is expected to propel the market growth of polymer concrete over the forecast timeframe.

Growing number of research and development initiatives by companies in order to enhance the technical properties of polymer concrete such as compressive and flexural strength, is projected to open a new door of opportunity to the market of polymer concrete. Moreover, some new research also suggests that polymer concrete with enhanced mechanical behavior could be produced by using polyesters. As polyester products are claimed to offer low volume shrinkage, and thus suitable for manufacturing of polymer concrete.

Figure 2. Global Polymer Concrete Market – Opportunity Analysis

Market Trends

A growing number of mergers and acquisitions among manufacturers to enhance the market presence is projected to propel the market growth of polymer concrete. For instance, in April 2017, integrated building materials vendor Chin Hin Group Bhd (Chin Hin) announced its acquisition of polymer concrete pipe manufacturer Mi Polymer Concrete Pipes Sdn Bhd (Mi Polymer) for around US$ 5.0 million to gain opportunities in the domestic and South-east Asia region.

Expanding the civil construction industry is raising demand for polymer concrete due to its high vibration resistance, high impact strength and excellent bonding properties with materials such as metals that are expected to propel the market growth of polymer concrete. Moreover, rising usage of polymer concrete in repair and maintenance applications instead of rebuilding infrastructure is further anticipated to foster the market growth of polymer concrete over the forecast period.

Figure 3. Global Polymer Concrete Market, Revenue Share (%), By Material Type, in 2018

On the basis of material type, in 2018, polyester accounted the largest market share of 27.9% in terms of revenue, followed by vinyl ester and epoxy based polymer, respectively.

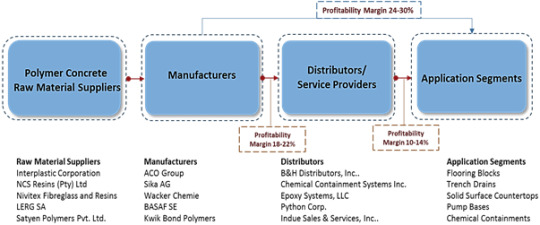

Figure 4. Global Polymer Concrete Market – Value Chain Analysis

Competitive Section

Key players active in the global polymer concrete market are BASF SE, Sika AG, Wacker Chemie AG, Dudick Inc., ACO Group, Kwik Bond Polymers LLC, Sauereisen Inc., Hubbell Power Systems Inc., Forte Composites, Inc., Ulma - Architectural Solutions, and Sandmix Sp. z o.o. S.K.

Few Recent Developments

BASF SE

In January 2017, the Construction Chemicals division of BASF Corporation announced the launch of MasterEmaco T 5000, a chemical resistant repair mortar and grout. The product is available in North America.

In August 2016, the company commissioned a new plant in Sri Lanka to produce concrete admixtures from global Master Builders Solutions brand

In May 2016, the company established a new concrete admixtures plant in Kharagpur, India. This is the 6th production site for BASF in India.

Get free sample report here: https://www.coherentmarketinsights.com/insight/request-sample/3386

Download PDF brochure: https://www.coherentmarketinsights.com/insight/request-pdf/3386

About Us:

Coherent Market Insights is a global market intelligence and consulting organization focused on assisting our plethora of clients achieve transformational growth by helping them make critical business decisions.

What we provide:

• Customized Market Research Services

• Industry Analysis Services

• Business Consulting Services

• Market Intelligence Services

• Long term Engagement Model

• Country Specific Analysis

Contact Us:

Mr. Shah

Coherent Market Insights Pvt. Ltd.

Address: 1001 4th ave, #3200 Seattle, WA 98154, U.S.

Phone: +1-206-701-6702

Email: [email protected]

Source: https://www.coherentmarketinsights.com/market-insight/polymer-concrete-market-3386

0 notes

Text

Cement Grouting Pump

Myto is one of the amazing grouting pumps manufacturers in India. It is known for its quality and performance, meeting challenging requirement of the client of different applications.

Pump is having arrangements of single mixing tank and twin mixing tank. Upper tank is mixing cement grout & lower mixing tank is for operating with an agitator to keep the grout as identical mixture. A pressure gauge is also provided at the passage of the pump to measure the required flow.

Application : – Pressure grouting, building construction, floor topping, floor restoration, slab under sealing, mud jacking, soil stabilization, anchors, roadways repair, dowel rod grouting, slab raising, waterproofing, cable, rock bolts, well casing, spraying top coats, plastering.

FEATURES & BENEFITS

Easy to install and works efficiently

Low maintenance hence Inexpensive to run

Quickly ready for operation

Wide range of viscosities and specific gravities

High tolerance of untrained air and gases High tolerance of contamination

Extremely rugged and reliable design

#cement grouting pump#cement grouting#pump manufacturer#cement grouting pumps#electrical cement grouting pump

0 notes

Text

Iris Publishers - Global Journal of Engineering Sciences (GJES)

Seepage Analysis for Soork Dam Foundation

Authored by Masoud Cheraghi Seifabad

Abstract

This paper presents a 3-D seepage analysis case study of the Soork Dam in Iran. For this study geotechnical information of the site was collected in two phases. Then the condition of the ground waters characteristics and the seepage through the foundation of the dam was modeled. In this way, numerical simulation was attempted by employing Seep/W, and Seep 3D software. This study shows the results of numerical simulations thus providing seepage measures.

Keywords: Joint Characteristics; Underground Flow; Seepage; 2D and 3D Modeling

Introduction

It is typical that the water reserved behind the dams cause the seepage and sometimes leakage. The rate of seepage should be specifically controlled so that it would not pass the permissible limits. Cedergreen [1] investigated the importance of seepage in all aspects and maintained that most damages to the water facilities can be from the seepage of underground water which are explained in two categories:

• That causes the soil particles move through an escape exit and cause piping or erosion failures;

• The damages caused by uncontrolled seepage patterns leading to saturation, excessive uplift or excessive seepage forces. The seepage control of the dam foundations was studied, and it was suggested that due to the discharge of the soil particles and weakening the foundations [2], the seepage of water occurred eventually leading to dam damage. The possibility of dam collapse due to erosion by the seepage was studied by Meyer [3].

The 3-dimensional seepage was analyzed by using a finite element method based on variable permeabilities [4]. The seepage of Kafrein dam and the ways to control it was studied by Malkavi [5]. The stress-strain, and seepage of a high rock-fill dam with clay core on the sand-gravel foundation was numerically simulated with FLAC 3D software [6]. A study [7] of seepage monitoring of RCC dam was conducted using entropy-based fuzzy matter-element analysis. Curtain grouting with minimum seepage pressure resultant [8] was studied. A regional numerical model was developed and used to evaluate the interaction between surface water bodies and the Quaternary aquifer system in the Nile Valley [9]. The seepage behavior of Gotvand Dam considering effects of dissolution of gypsum was evaluated with 2D and 3D models [10]. A mathematical model was established for coupled unsteady seepage and stress fields in the fractures network of the dam foundation [11]. The 3-D program was developed to analyze the coupling unsteady seepage and stress fields in the fracture rock mass (3D-coupled) used to analyze the influence of seepage field on the dam foundation due to water level fluctuation. The role of nuclear logging techniques and tracer tests were discussed to delineate the path of the seepage from a damaged portion of tailrace channel at the Bhama-Askhed Dam, Maharstra, India [12]. Penalty Function Element-Free Method was used to study the steady seepage field in main dam, that is, with a protective concrete slab and structure of hydro fracture grouting cutoff wall of Dashi Bu reservoir located in Donghai County (China), when it is normal water level for the reservoir, and then the errors between the measured value and computed values from piezometer tubes [13] were compared. An attempt was made to estimate the water seepage from the upper reservoir of Azad pumped storage power plant based on the combined geotechnical studies and geostatistical methods. In their study, using a geostatistical method (Kriging), Lugeon values were estimated for the walls of the reservoir [14]. Analytical methods and the results for assessing the variation in the concentration of sulfates (and other ions) over space and time in the ground water flowing through a soluble evaporate terrain beneath a dam [15] were presented. Remote sensing and geographic information system (GIS) techniques were applied to construct and integrate the hydrogeological data, inventory for potential sources of contamination and mapping the sensitive areas, in order to construct the protected buffer zone for the Ismailia Canal and to constrain the development activities in all the surrounding areas of surface water supply [16]. The aim of this present article is to analyze the seepage pattern within the Soork Dam.

Dam Site

Soork Dam is located southeast of Isfahan (Boroojen, central Iran). The average rainfall in this area is 323 mm/y. The Soork Dam is an earth dam with the clay core. The height of the dam measured from river bed is 39 m with a length of 590 m and a width of 11 m in crown.

Engineering geology and geotechnical characteristic of the Soork Dam

On the dam axis, the valley is an asymmetrical U shape with wide spans. The dips of the walls on the left and right abutments are about 25 and 6 degrees respectively. The rock outcrops of the area are generally of early Cretaceous limestone and shaly limestone. In the dam area, there is Quaternary alluvium with considerable thickness (about 100 m). At the deep areas of the valley, the coarse sediments are replaced by fine sediments of the surface area. Figures 1 and 2 illustrate the area geology of the dam site and the geological section respectively.

Geomechanical characteristics of Soork Dam

The rocks in the area consist of limestone with some abundant cracks, joints, and some small cavities on the surface which are possibly karstic cavities in depth. Two faults with the strikes N5E, N15W and the vertical dips cause the crush of the rock layers. According to the discontinuities, the joints of this area divide into two zones. Each zone is examined separately from another.

The Zone P

1

This zone consists of light grey limestone, full of white crystalline calcite veins. The abundance of calcific veins causes color change in rocks. The abundant joints in limestone create long blocks. The water flow and karst effects are observed on the joint surfaces and outcrops. This section is studied linear arrangement based on the spatial positions. The direction is vertical to main joint groups (S1, S2). However, in order to study the other groups (S3, S4), another scan line vertical to the first direction was chosen.

Joint Set S

1

This joint set is the most abundant and important. About 67% of the total data in this research is related to this joint. According to the information, the joint set is characterized as N23W/65NE and the average of vertical distance between the joints is 1.8 m. Most of the joints have openings which filled with clay, silt, and partly sand to gravel. There is no water leakage, or flow of water in any of the joints. Figure 3 illustrates all the joint sets of zones P1. Joint set S1 is more than 20 meters in 34 % of them has a length of 3-10 meters in 40 % of the cases. Joint set S1 is rough, and planar in 58% and 10mm opening and defined in 38 %, referred to as a very open one.

Joint Set S

2

This joint set is at a lower grade with reference to the abundance and persistence which includes 17 % of the total joints. The characteristic of the joint set S2 is N10E/35NW and the vertical distance between the joints is 4.5m. 35% of this joint set is 3-10m long and 29% has a length of over 20 m. Over 50% of the joints are rough, planar and 36% are rough and undulating.

Joint Sets S

3

, S

4

Compared with the first two sets, these joint sets are less important. They actually cross the others. Most joints are filled with transparent, white crystalline calcite and at the outcrop have openings filled with clay and silt. The representative plane characteristics of these two joint sets are as follows:

Joint Set S3: N90E/30SE

Joint set S4: N50E/80NW

The average spacing of the joint sets S3 and S4 are 1.5-2 m and 2-2.5 m respectively.

The Zone P

2

Lithologically this zone consists of a small outcrop of light grey limestone with brown to dark red chert nodules. The limestone is folded. The characteristics of the discontinuities in this zone are investigated linear arrangement in the direction of N38E. Figure 4 shows the counter of discontinuities. Accordingly, the joint sets S1 and S2 are defined from the discontinuity point-of-view. The characteristics of these planes are:

S5: N72W/52SW

S6: N12W/48NE

The average spacings of joint sets S5and S6 are 1-1.5m and 2m respectively.

Seepage Flow Analysis

Ten boreholes were drilled during the 1st stage of the studies. According to the technical exploration specifications and geotechnical studies, the water level of all boreholes was achieved fortnightly. The trend of the underground water level changes shows the alternative periods of dry and dump conditions of the underground water at dam axis. Such a water table at the dam site has been modeled. As shown in Figure 5, the direction of the underground water involves a mild deep slope towards the middle of the valley and the water level of the dam axis passes borehole 10.

Water flow monitoring

The movement of water in the cavities and different joints in the rock differed during water pressure tests. This depends on the type of joint or cavity. Thus, the water flow behaved differently. In most cases the turbulent type of the water flow was observed. Normally in these cases the permeabilities are high and there is need for grouting. In these areas, the joints are very open and there is lack of filling.

Seepage of alluvium materials

To achieve permeability of granular sediments in the field, the Laufran permeability test was conducted in all of the boreholes in the field. The permeability test was conducted using both methods ‘constant head’, and ‘falling head’. The results differed from 10-7 to 10-2cm/s. Because of the variation in permeability, it is important to note the following:

• The boreholes BH3 & BH9 were drilled and tested around the bed river in fine materials. The average permeability in borehole 3 was 10-4cm/s and the maximum permeability change from 10-4 to 10-3cm/s. The maximum permeability in borehole 9 changed from 10-3 to 10-2cm/s. Therefore, it is reasonable to choose 10- 3cm/s for the horizontal permeability of this section. Generally, the vertical permeability is less than this and should be taken into consideration in the calculations.

• In the middle section of the valley, the fine alluvium sediments mixed with the course were located to depth of 100m. The boreholes BH2, BH7 were drilled and tested in this area. Unfortunately, the drilling quality of BH2 was not satisfactory and therefore most of the materials were washed and destroyed. For this reason, BH7 borehole was drilled and Laufran permeability test was performed repeatedly to a depth of 70m. The permeability results in BH7 borehole changed from 10-5 to 10-3cm/s. There was no special arrangement for this dispersion. Hence, the upper limit, i.e. 10-3cm/ s was chosen for the horizontal permeability of this area.

• On the right-hand side, boreholes BH6, BH10 were drilled and tested. The permeability test of BH10 was approximately 10-3 cm/s. This situation was approved for the whole length of BH6. Figure 6 shows the permeability of different sections at the bed rock.

Two-Dimensional seepage analysis

To estimate the seepage water flow, based on the model of alluvium permeabilities with it, different values Ky/Kx (0.1,0.5,1), the amount of flow rate was calculated with Seep/W software [17]. Figure 7 shows the two-dimensional model of section A: the flow rate and flowlines for different Ky/Kx are also illustrated in Figures 8-10. The results of seepage in section A (alluvium foundation) are presented in Table 2. Tables 3 and 4 illustrate the results of seepage analysis for foundation in sections B and C. According to Tables 2,3 and 4 the total amount of flow rate in alluvium foundation can be achieved. In Table 5, the results of alluvium foundation of two-dimensional seepage are shown. Based on a 25-million cubic water reservoir volume, the water loss was shown to be 5.4% in this analysis.

Three-Dimensional seepage analysis

In this part, the report of seepage analysis for different Ky/ Kx is presented. For this purpose, the seep 3D software [17] was used. Figure 11 shows a three-dimensional model and Figures 12 to 14 show the counters for the seepage flow rate. The results of three-dimensional seepage analysis are shown in Table 6. As far as the 25-million cubic meter water reservoir volume is concerned, the water loss here is shown to be 5.4% in this analysis.

omparison of 2 and 3-Dimensional analysis

Analysis shows that most seepage occurs in section A and the least in section C. The results of 2D and 3D analyses are different. The reason for this is that since the flows are vertical to the transverse sections, they are calculated in 3D analysis. Therefore, the flow rates are calculated more accurately. The differences in the results of 2D, 3D analyses are presented in Table 7.

Conclusion

• The Soork Dam site is an asymmetrical U shape with relatively wide spans. The dips of the walls on the left and right abutments are about 25 and 6 respectively.

• The discontinuities of the left abutment dam site are divided into two zones: P1, P2. P1 include 4 joint sets and P2 two joint sets.

• The quality of rock in wide areas on the left abutment is relatively low. This affects the joint sets and cracks.

• The materials around the river bed on the left end of the valley are generally fine sand, silt, and clay.

• The direction of the underground water is from the abutment sides with a mild dip slope towards the middle of the valley.

• The water loss in 2D and 3D is 5.4% and 6.5% respectively.

• The 2D and 3D analyses of seepage are different. Because the flows are vertical to transverse sections in 3D, the flow rate is calculated more accurately.

For more about Iris Publishers please click on: http://irispublishersgroup.com/submit-manuscript.php.

To read more about this article - https://irispublishers.com/gjes/fulltext/seepage-analysis-for-soork-dam-foundation.ID.000637.php

Indexing List of Iris Publishers: https://medium.com/@irispublishers/what-is-the-indexing-list-of-iris-publishers-4ace353e4eee

Iris publishers google scholar citations :https://scholar.google.co.in/scholar?hl=en&as_sdt=0%2C5&q=irispublishers&btnG=

0 notes

Text

How Investments in Manufacturing Sector Propelling Asia-Pacific (APAC) Construction Chemicals Market?

From $120 billion in 2017, the real estate sector of India is expected to grow to $1 trillion by 2030, according to the India Brand Equity Foundation (IBEF). This would be a direct result of the increasing population, which already numbers at 1.35 billion. Similarly, China, the world’s most populous nation, is home to 1.39 billion people; the number of people in both the countries continues to increase. This is resulting in the rising demand for residential, industrial, and commercial infrastructure in the Asia-Pacific (APAC) region.

Thus, with population growth, the APAC construction chemicals market size is projected to increase to $29,686.2 million by 2023 from $19,754.8 million in 2017, at a 7.1% CAGR during 2018–2023 (forecast period). A wide range of chemicals is used in the construction of infrastructure, including adhesives, concrete admixtures, protective coatings, sealants, and asphalt modifiers. Among these, concrete admixtures witness the highest consumption, as concrete is one of the most essential materials used in the infrastructure sector, especially for tunnels, roads, water retention structures, and bridges.

Get a sample report of the market analysis: https://www.psmarketresearch.com/market-analysis/apac-construction-chemicals-market/report-sample

With the use of admixtures in concrete, the usage of water and time taken to complete the construction project are reduced a good deal, which automatically results in substantial cost savings for real estate firms. There are several types of admixtures available, such as water-reducing, retarding, accelerating, air-entraining, pozzolanic, damp-proofing, gas-forming, air-detraining, alkali-aggregate-expansion-inhibiting, anti-washout, grouting, corrosion-inhibiting, bonding, fungicidal, germicidal, insecticidal, and coloring admixtures, to fulfill a number of purposes within the construction sector.

With regional countries focusing on economic prosperity, they are increasing efforts to set up manufacturing plants. For instance, $405.88 billion was pumped into India’s manufacturing sector by government as well as private companies in 2019–20, as per the IBEF. Thus, with an increasing in the construction projects for production plants, the demand for the various chemicals associated with the process will also go up. Vietnam, Malaysia, China, and numerous other emerging economies in the region are undergoing a similar industrial transformation, which is further leading to an increasing requirement for construction chemicals.

Apart from the rising building activities, the awareness on the quality of the infrastructure is also increasing in the region. This is why construction firms are upping their usage of various chemicals to enhance the strength and durability of the built structures. Further, with the rise in the number of aesthetically pleasing skyscrapers, construction chemicals are being used more than ever. New York City is no more the world’s skyscraper capital, but cities like Shanghai, Tokyo, Kuala Lumpur, Seoul, and Hong Kong are.

Additionally, many of these cities are situated on or near the Pacific Ring of Fire. Being a high-seismic-activity region, it is prone to severe earthquakes, such as the 9.1-Richter earthquake of 2011, which resulted in the Tōhoku tsunami in Japan. With the population in the above-mentioned cities burgeoning, the construction activities are also picking up. And, with the land becoming increasingly scarce, skyscrapers are being erected to cater to as many people as possible, which is raising concerns over the quality of construction. Hence, strict regulations have been implemented in most APAC countries mandating the structures be durable and strong.

Up till now, China has been the most productive country in the APAC construction chemicals market, on account of its strong economy, in terms of purchasing power parity. Further, the infrastructure development projects are rising at a rapid pace in the nation, which is further driving the consumption of associated chemicals. Additionally, the majority of the leading manufacturers of construction chemicals have plants in China, which results in an easy availability of these materials here. In the coming years, the consumption of these materials would rise the fastest in India, owing to its high urbanization and industrialization rate.

Thus, with the increasing demand for residential, commercial, and industrial infrastructure and the surging awareness about its quality, the consumption of construction chemicals would continue to grow in the APAC region.

#Construction Chemicals Market#APAC Construction Chemicals Market#APAC Construction Chemicals Market Share#APAC Construction Chemicals Market Size#APAC Construction Chemicals Market Forecast#APAC Construction Chemicals Market Trends#APAC Construction Chemicals#APAC Construction Chemicals Market Overview#APAC Construction Chemicals Market Scope

0 notes

Photo

Surface International holds the enormous expertise in providing an extensive series of Electric Grout Pump that will be helpful in all kinds of commercial and residential construction works. We are the top Electric Grout Pump Manufacturers and Electric Grout Pump Exporters in India.

#Electric Grout Pump#Electric Grout Pump Manufacturer#Electric Grout Pump supplier#Electric Grout Pump exporter#surface finishing#surface treatment

0 notes

Text

𝐄𝐋𝐄𝐂𝐓𝐑𝐈𝐂 𝐆𝐑𝐎𝐔𝐓 𝐏𝐔𝐌𝐏𝐒 - Surface International

We hold enormous expertise in providing an extensive series of 𝐄𝐋𝐄𝐂𝐓𝐑𝐈𝐂 𝐆𝐑𝐎𝐔𝐓 𝐏𝐔𝐌𝐏𝐒 that will be helpful in all kinds of commercial and residential construction works. We are the top 𝐄𝐋𝐄𝐂𝐓𝐑𝐈𝐂 𝐆𝐑𝐎𝐔𝐓 𝐏𝐔𝐌𝐏𝐒 Manufacturers and 𝐄𝐋𝐄𝐂𝐓𝐑𝐈𝐂 𝐆𝐑𝐎𝐔𝐓 𝐏𝐔𝐌𝐏𝐒 Exporters in India.

👉𝐒𝐏𝐄𝐂𝐈𝐅𝐈𝐂𝐀𝐓𝐈𝐎𝐍𝐒:

⚈Sturdy construction

⚈Great self-priming rate

⚈Steady pumping

⚈Resistant from quick breakdowns

⚈Easy availability of spare parts

👉𝐀𝐏𝐏𝐋𝐈𝐂𝐀𝐓𝐈𝐎𝐍𝐒:

⚈Great solution to pump solid or abrasive laden material

⚈Pumps repair mortars and heavily sanded grouts

⚈Spray mortar by using air compression

⚈Widely used in mining shafts and construction sites where operation or access or transportation is not easy

#electricgroutpumps#electricgrout#groutpumps#pumps#BlastingMachine#heavyequipment#heavymachinery#equipment#machinery#surfaceinternational#Machines#Jodhpur#Rajasthan#India

0 notes

Text

PU Grouting Pump

Myto is one of the amazing grouting pumps manufacturers in India. It is known for its quality and performance, meeting challenging requirement of the client of different applications.

The electric high pressure injection pump is a professional machine used for high pressure chemical grouting, which works with both single and double component grouting material. It can produce high pressure itself. When there are leakage-stop constructions on engineering include architecture, underground, water conservancy, environment protection, civisms, subway, tunnel, culvert, crack reinforcement, it is the preferred equipment.

Applications : – Leak-stoppage, waterproof & reinforcement for concrete structure, such as Basement, floor, the second joints, subway, tunnel, Continuous wall, cracks, Water seepage, etc.

FEATURES & BENEFITS

Easy to install and works efficiently

Low maintenance hence Inexpensive to run

Quickly ready for operation

Wide range of viscosities and specific gravities

High tolerance of entrained air and gases High tolerance of contamination

Extremely rugged and reliable design

0 notes